Abstract

The present overview is intended to point the readers’ attention to the important subject of calcium orthophosphates. This type of materials is of special significance for human beings, because they represent the inorganic part of major normal (bones, teeth and antlers) and pathological (i.e., those appearing due to various diseases) calcified tissues of mammals. For example, atherosclerosis results in blood vessel blockage caused by a solid composite of cholesterol with calcium orthophosphates, while dental caries and osteoporosis mean a partial decalcification of teeth and bones, respectively, that results in replacement of a less soluble and harder biological apatite by more soluble and softer calcium hydrogenphosphates. Therefore, the processes of both normal and pathological calcifications are just an in vivo crystallization of calcium orthophosphates. Similarly, dental caries and osteoporosis might be considered an in vivo dissolution of calcium orthophosphates. Thus, calcium orthophosphates hold a great significance for humankind, and in this paper, an overview on the current knowledge on this subject is provided.

Keywords: calcium orthophosphates, hydroxyapatite, fluorapatite, bones, teeth, antlers, calcification, crystallization, biomimetics

Introduction

Due to their abundance in nature and presence in living organisms, calcium apatites[a] and other calcium orthophosphates remain the chemical compounds of a special interest in many fields of science, including geology, chemistry, biology and medicine. Due to big problems with access to the scientific literature published in the 19th century and before, a historical description of the subject appears to be very brief. Namely, according to the accessible literature,1 as early as the end of the 18th century, French chemist Joseph-Louis Proust (1754–1826) and German chemist Martin Klaproth (1743–1817) proposed that calcium apatite was the major inorganic component of bones. In the middle of the 19th century, attempts to establish the chemical composition of calcium apatites and other calcium orthophosphates were performed by J. Berzelius,2 R. Warington Jr.3 and R. Fresenius.4 The chemical formula of perfectly transparent crystals of natural fluorapatite (FA) as Ca5(PO4)3F was established in 1873,5 while the crystallographic faces of a natural calcium apatite were described in 1883.6 Furthermore, a paper on a behavior of an undisclosed calcium orthophosphate in organisms of carnivores was published in 1883.7 Further, the quantitative analysis of a calcium orthophosphate was performed in 1884,8 followed by remarks by C. Glaser in 1885.9 In the 1880s, occurrence of a calcium apatite10 and another calcium orthophosphate11-13 in a metallurgical slag was discovered. Chemical reactions between calcium orthophosphates and other chemicals were investigated in 1891.14 Research papers on bone repairing are known since at least 1892,15 while the earliest well-documented systematic studies of calcium orthophosphates were performed at the beginning of the 20th century by F.K. Cameron with coworkers16-20 and H. Bassett.21-24 The majority of the aforementioned researchers already operated with individual chemical compounds.

By definition, all calcium orthophosphates consist of three major chemical elements, calcium (oxidation state +2), phosphorus (oxidation state +5) and oxygen (reduction state -2), as a part of orthophosphate anions. These three chemical elements are present in abundance on the surface of our planet: oxygen is the most widespread chemical element of the Earth’s surface (~47 mass%), calcium occupies the fifth place (~3.3–3.4 mass%) and phosphorus (~0.08–0.12 mass%) is among the first 20 of the chemical elements most widespread on our planet.25 In addition, the chemical composition of many calcium orthophosphates includes hydrogen, as an acidic orthophosphate anion (for example, HPO42- or H2PO4-); hydroxide [for example, Ca10(PO4)6(OH)2] and/or incorporated water (for example, CaHPO4·2H2O). Diverse combinations of CaO and P2O5 (both in the presence of water and without it) provide a large variety of calcium phosphates, which are distinguished by the type of the phosphate anion: ortho-(PO43-), meta-(PO3-), pyro-(P2O74-) and poly-[(PO3)nn-]. In the case of multi-charged anions (orthophosphates and pyrophosphates), calcium phosphates are also differentiated by the number of hydrogen ions attached to the anion. Examples include mono-[Ca(H2PO4)2], di-(CaHPO4), tri-[Ca3(PO4)2] and tetra-(Ca2P2O7) calcium phosphates (here, prefixes “mono,” “di,” “tri” and “tetra” are related to the amount of hydrogen ions replaced by calcium).26-28 However, only calcium orthophosphates will be considered and discussed in this review. The names, standard abbreviations, chemical formulae and solubility values are listed in Table 1.29,30 Since all of them belong to calcium orthophosphates, strictly speaking, all abbreviations in Table 1 are incorrect; however, they are extensively used in the literature, and there is no need to modify them.

Table 1. Existing calcium orthophosphates and their major properties29,30.

| Ca/P molar ratio | Compound | Formula | Solubility at 25°C, -log(Ks) |

Solubility at 25°C, g/L |

pH stability range in aqueous solutions at 25°C |

|---|---|---|---|---|---|

| 0.5 |

Monocalcium phosphate monohydrate (MCPM) |

Ca(H2PO4)2·H2O |

1.14 |

~18 |

0.0–2.0 |

| 0.5 |

Monocalcium phosphate anhydrous (MCPA or MCP) |

Ca(H2PO4)2 |

1.14 |

~17 |

[c] |

| 1.0 |

Dicalcium phosphate dihydrate (DCPD), mineral brushite |

CaHPO4·2H2O |

6.59 |

~0.088 |

2.0–6.0 |

| 1.0 |

Dicalcium phosphate anhydrous (DCPA or DCP), mineral monetite |

CaHPO4 |

6.90 |

~0.048 |

[c] |

| 1.33 |

Octacalcium phosphate (OCP) |

Ca8(HPO4)2(PO4)4·5H2O |

96.6 |

~0.0081 |

5.5–7.0 |

| 1.5 |

α-Tricalcium phosphate (α-TCP) |

α-Ca3(PO4)2 |

25.5 |

~0.0025 |

[a] |

| 1.5 |

β-Tricalcium phosphate (β-TCP) |

β-Ca3(PO4)2 |

28.9 |

~0.0005 |

[a] |

| 1.2–2.2 |

Amorphous calcium phosphates (ACP) |

CaxHy(PO4)z·nH2O, n = 3–4.5; 15–20% H2O |

[b] |

[b] |

~5–12 [d] |

| 1.5–1.67 |

Calcium-deficient hydroxyapatite (CDHA or Ca-def HA)[e] |

Ca10-x(HPO4)x(PO4)6-x(OH)2-x (0 < x < 1) |

~85 |

~0.0094 |

6.5–9.5 |

| 1.67 |

Hydroxyapatite (HA, HAp or OHAp) |

Ca10(PO4)6(OH)2 |

116.8 |

~0.0003 |

9.5–12 |

| 1.67 |

Fluorapatite (FA or FAp) |

Ca10(PO4)6F2 |

120.0 |

~0.0002 |

7–12 |

| 1.67 |

Oxyapatite (OA, OAp or OXA)[f] |

Ca10(PO4)6O |

~69 |

~0.087 |

[a] |

| 2.0 | Tetracalcium phosphate (TTCP or TetCP), mineral hilgenstockite | Ca4(PO4)2O | 38–44 | ~0.0007 | [a] |

[a] These compounds cannot be precipitated from aqueous solutions. [b] Cannot be measured precisely. However, the following values were found: 25.7 ± 0.1 (pH = 7.40), 29.9 ± 0.1 (pH = 6.00), 32.7 ± 0.1 (pH = 5.28).31 The comparative extent of dissolution in acidic buffer is: ACP > > α-TCP > > β-TCP > CDHA > > HA > FA.32[c] Stable at temperatures above 100°C. [d] Always metastable. [e] Occasionally, it is called “precipitated HA (PHA).” [f] Existence of OA remains questionable.

The atomic arrangement of calcium orthophosphates is built up around a network of orthophosphate (PO4) groups, which gives stability to the entire structure. The majority of calcium orthophosphates are sparingly soluble in water; however, all of them are easily soluble in acids but insoluble in alkaline solutions. All chemically pure calcium orthophosphates are crystals of white color and moderate hardness. However, natural minerals of calcium orthophosphates are always colored due to impurities, the most widespread of which are ions of Fe, Mn and rare earth elements.33,34 Biologically formed calcium orthophosphates are the major component of all mammalian calcified tissues,35 while the natural ones are the major raw material to produce phosphorus-containing fertilizers.36-39

Geological and Biological Occurrences

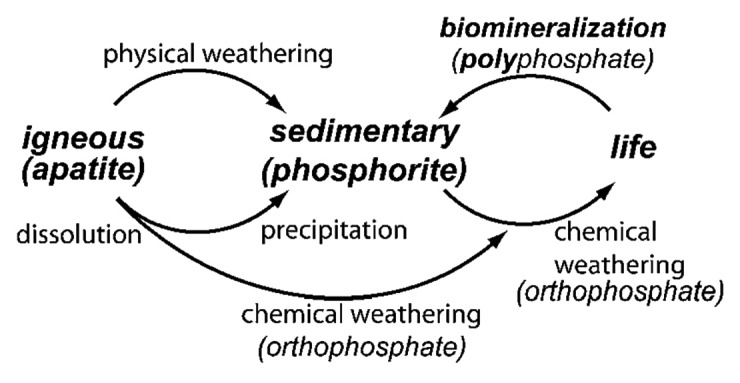

Geologically, natural calcium orthophosphates are found in different regions mostly as deposits of apatites (belong to igneous rocks), mainly as natural FA or phosphorites (a sedimentary rock).37-40 Some types of sedimentary rocks can be formed by weathering of igneous rocks into smaller particles.41 Other types of sedimentary rocks can be composed of minerals precipitated from the dissolution products of igneous rocks or minerals produced by biomineralization (Fig. 1).42 Thus, due to a sedimentary origin, both the general appearance and the chemical composition of natural phosphorites vary a great deal.43,44 It is common practice to consider francolite (or carbonate-hydroxyfluorapatite regarded as its synonym) as the basic phosphorite mineral.40,45-49 A cryptocrystalline (almost amorphous) variety of francolite (partly of a biological origin) is called collophane (synonyms: collophanit, collophanita, collophanite, grodnolite, kollophan).50-52 It occurs in natural phosphorites predominantly as fossil bones and phosphatized microbial pseudomorphs: phosphatic crusts of chasmolithic biofilms (or microstromatolites) and globular clusters with intra-particular porosities.53-56 Natural phosphorites (therefore, francolite and collophane as well) occur in various forms, such as nodules, crystals or masses. Occasionally, other types of natural calcium orthophosphates are found as minerals, for example, clinohydroxylapatite,57 staffelite (synonyms: staffelit, staffelita) belonging to carbonate-rich fluorapatites (chemical formula: Ca5[(F,O)(PO4,CO3)3])4,58 and DCPD.59 Furthermore, calcium orthophosphates were found in meteoric stones.60 The world deposits of natural calcium orthophosphates are estimated to exceed 150 billion tons, out of which approximately 85% belong to phosphorites and the remaining ~15% belong to apatites.40

Figure 1. Simplified schematic of the phosphorus cycle from apatitic igneous rock to phosphorite sedimentary rock through chemical or physical weathering. Life forms accumulate soluble phosphorus species and can produce apatite through biomineralization. Reprinted from reference 42 with permission.

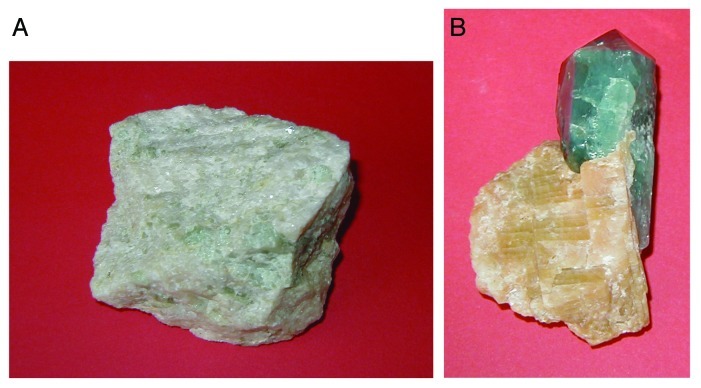

Natural calcium orthophosphates occur in most geological environments, usually as accessory minerals (< 5%). Concentrations sufficient for economic use (> 15%) are also available. The largest world deposits of natural apatites are located in Russia (the Khibiny and Kovdor massifs, Kola peninsula61,62), Brazil and Zambia, while the largest world deposits of natural phosphorites are located in Morocco, Russia, Kazakhstan, USA (Florida, Tennessee), China and Australia, as well as in the oceans.36-40 Most of natural calcium orthophosphates occur as small polycrystalline structures (spherulitic clusters). Larger crystals are rare.63 They usually have the crystal structure of apatites (hexagonal system, space group P63/m). Giant crystals, including “a solid but irregular mass of green crystalline apatite, 15 feet long and 9 feet wide”64 and a single euhedral crystal from the Aetna mine measuring 2.1 x 1.2 min with an estimated weight of 6 tons,65 were found. None of them are pure compounds; they always contain admixtures of other elements. For example, ions of calcium might be partially replaced by Sr, Ba, Mg, Mn, K, Na, Fe; ions of orthophosphate may be partly replaced by AsO43-, CO32- and VO4;2-30,33-66 ions of hydroxide, chloride, bromide, carbonate and oxide may, to a certain extent, substitute for fluoride in the crystal lattice of natural apatites.48 Furthermore, various organic radicals have been found in natural apatites.67,68 In principle, the crystal structure of apatites can incorporate half of the periodic table in its atomic arrangement. In medicine, this property might be used as an antidote for heavy metal intoxication.69 Ease of atomic substitution for apatite leaves this mineral open to a wide array of compositions. This might be related to the fact that the apatite structure type displays porous properties.70 The substitutions in apatites are usually in trace concentrations, but large concentrations and even complete solid solutions exist for certain substituents (e.g., F- and OH-). To make things even more complicated, some ions in the crystal structure may be missing, leaving crystallographic defects, which leads to formation of non-stoichiometric compounds. Figure 2 shows examples of polycrystalline and single-crystalline samples of natural FA.

Figure 2. Polycrystalline (A) and single-crystalline (B) FA of a geological origin. The single crystal has a gray-green color due to incorporated ions of transition metals.

Manufacturing of elementary phosphorus (white and red),71,72 phosphoric acids,37,73-76 various phosphorus-containing chemicals and, especially, agricultural fertilizers (namely, superphosphate,77-79 ammonium orthophosphates80) are the major industrial applications of natural calcium orthophosphates. The annual consumption of a phosphate rock has approached ~150 million tons, and about 95 percent of this production is utilized in the fertilizer industry.81,82

In biological systems, many organisms, ranging from bacteria and isolated cells to invertebrates and vertebrates, synthesize calcium orthophosphates.42 Formation of calcium orthophosphates in primitive organisms is believed to enable the storage and regulation of essential elements, such as calcium, phosphorus and, possibly, magnesium. The morphology of precipitates in these organisms (small intracellular nodules of ACP often located in mitochondria) complies with the necessity for rapid mobilization and intracellular control of the concentration of these elements.83 In vertebrates, calcium orthophosphates occur as the principal inorganic constituent of normal (bones, teeth, fish enameloid, deer antlers and some species of shells) and pathological (dental and urinary calculus and stones, atherosclerotic lesions, etc.) calcifications.26,84-89 Except for small portions of the inner ear, all hard tissue of the human body is formed of calcium orthophosphates. Structurally, they occur mainly in the form of poorly crystalline, non-stoichiometric, calcium-deficient, Na-, Mg- and carbonate-containing HA [often called “biological apatite”90-94 (which might be abbreviated as BAp95,96), bioapatite97-100 or dahllite.[b],101 The main constituents of human bones are calcium orthophosphates (~60–70 wt%), collagen[c] (~20–30 wt%) and water (up to 10 wt%).32,88,97-99,101,102 Detailed information on the chemical composition of the most important human normal calcified tissues can be found in Table 2. One should note that the values mentioned in Table 2 are approximate; the main constituents can vary by one percent or more.106

Table 2. Comparative composition and structural parameters of inorganic phases of adult human calcified tissues. Due to the considerable variation found in biological samples, typical values are given in these cases26,32.

| Composition, wt% | Enamel | Dentine | Cementum | Bone | HA |

|---|---|---|---|---|---|

| Calcium[a] |

36.5 |

35.1 |

~35 |

34.8 |

39.6 |

| Phosphorus (as P)[a] |

17.7 |

16.9 |

~16 |

15.2 |

18.5 |

| Ca/P (molar ratio)[a] |

1.63 |

1.61 |

~1.65 |

1.71 |

1.67 |

| Sodium[a] |

0.5 |

0.6 |

[c] |

0.9 |

– |

| Magnesium[a] |

0.44 |

1.23 |

0.5–0.9 |

0.72 |

– |

| Potassium[a] |

0.08 |

0.05 |

[c] |

0.03 |

– |

| Carbonate (as CO32-)[b] |

3.5 |

5.6 |

[c] |

7.4 |

– |

| Fluoride[a] |

0.01 |

0.06 |

up to 0.9 |

0.03 |

– |

| Chloride[a] |

0.30 |

0.01 |

[c] |

0.13 |

– |

| Pyrophosphate (as P2O74-)[b] |

0.022 |

0.10 |

[c] |

0.07 |

– |

| Total inorganic[b] |

97 |

70 |

60 |

65 |

100 |

| Total organic[b] |

1.5 |

20 |

25 |

25 |

– |

| Water[b] |

1.5 |

10 |

15 |

10 |

– |

|

Crystallographic properties: Lattice parameters (± 0.003 Å) |

|

|

|

|

|

|

a-axis, Å |

9.441 |

9.421 |

[c] |

9.41 |

9.430 |

|

c-axis, Å |

6.880 |

6.887 |

[c] |

6.89 |

6.891 |

| Crystallinity index (HA = 100) |

70–75 |

33–37 |

~30 |

33–37 |

100 |

| Typical crystal sizes (nm)103–105 |

100 µm × 50 × 50 |

35 × 25 × 4 |

[c] |

50 × 25 × 4 |

200–600 |

| Ignition products (800°C) |

β-TCP + HA |

β-TCP+ HA |

β-TCP+ HA |

HA + CaO |

HA |

| Elastic modulus (GPa) |

80 |

23.8 ± 3.7 |

15.0 ± 3.6 |

0.34–13.8 |

10 |

| Tensile strength (MPa) | 10 | 100 | [c] | 150 | 100 |

[a] Ashed samples. [b] Unashed samples. [c] Numerical values were not found in the literature but they should be similar to those for dentine.

The Members of the Calcium Orthophosphate Family

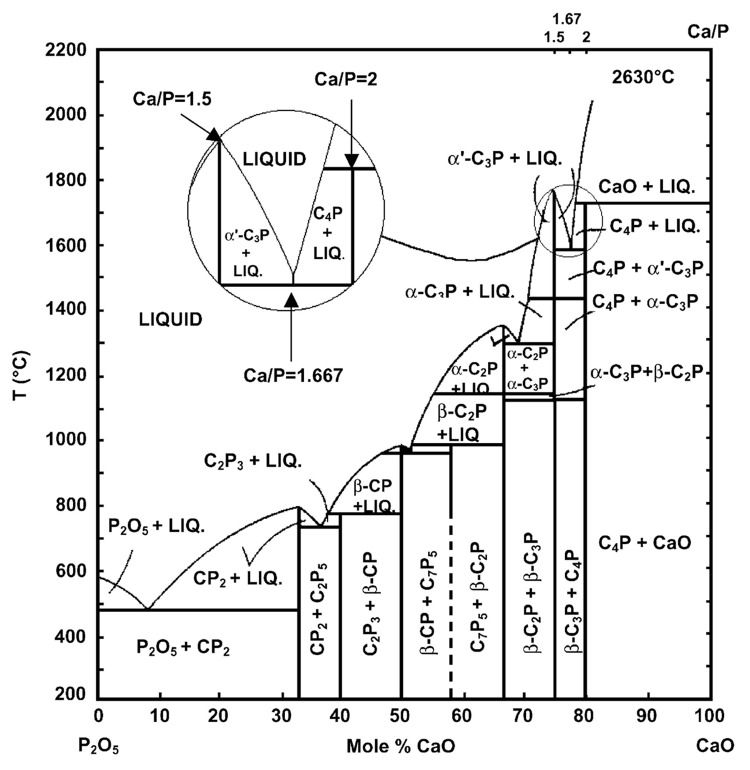

In the ternary aqueous system Ca(OH)2-H3PO4-H2O (or CaO-P2O5-H2O),107-109 there are 12 known non-ion-substituted calcium orthophosphates with the Ca/P molar ratio ranging between 0.5 and 2.0 (Table 1). An anhydrous phase diagram CaO-P2O5 at temperatures within 200–2,200°C is shown in Figure 3.110,111Table 3 comprises crystallographic data of the existing calcium orthophosphates.27,112-114 The most important parameters of calcium orthophosphates are the ionic Ca/P ratio, basicity/acidity and solubility. All these parameters strongly correlate with the solution pH. The lower the Ca/P molar ratio is, the more acidic and water-soluble the calcium orthophosphate is.26-28 One can see that the solubility ranges from high values for acidic compounds, such as MCPM, to very low values for basic compounds, such as apatites, which allows calcium orthophosphates to be dissolved, transported from one place to another and precipitated when necessary. Crystallization, dissolution and phase transformation processes of different calcium orthophosphates under various experimental conditions have been reviewed recently in reference 115.

Figure 3. Phase diagram of the system CaO-P2O5 (C = CaO, p = P2O5) at elevated temperatures. Here: C7P5 means 7CaO·5P2O5; other abbreviations should be written out in the same manner. Reprinted from references 110 and 111 with permission.

Table 3. Crystallographic data of calcium orthophosphates27,112,113.

| Compound | Space group | Unit cell parameters | Z[a] | Density, g cm−3 |

|---|---|---|---|---|

| MCPM |

triclinic P |

a = 5.6261(5), b = 11.889(2), c = 6.4731(8) Å, α = 98.633(6)°, β = 118.262(6)°, γ = 83.344(6)° |

2 |

2.23 |

| MCPA |

triclinic P |

a = 7.5577(5), b = 8.2531(6), c = 5.5504(3) Å, α = 109.87(1)°, β = 93.68(1)°, γ = 109.15(1)° |

2 |

2.58 |

| DCPD |

monoclinic Ia |

a = 5.812(2), b = 15.180(3), c = 6.239(2) Å, β = 116.42(3)° |

4 |

2.32 |

| DCPA |

triclinic P |

a = 6.910(1), b = 6.627(2), c = 6.998(2) Å, α = 96.34(2)°, β = 103.82(2)°, γ = 88.33(2)° |

4 |

2.89 |

| OCP |

triclinic P |

a = 19.692(4), b = 9.523(2), c = 6.835(2) Å, α = 90.15(2)°, β = 92.54(2)°, γ = 108.65(1)° |

1 |

2.61 |

| α-TCP |

monoclinic P21/a |

a = 12.887(2), b = 27.280(4), c = 15.219(2) Å, β = 126.20(1)° |

24 |

2.86 |

| β-TCP |

rhombohedral R3cH |

a = b = 10.4183(5), c = 37.3464(23) Å, γ = 120° |

21[b] |

3.08 |

| HA |

monoclinic P21/b or hexagonal P63/m |

a = 9.84214(8), b = 2a, c = 6.8814(7) Å, γ = 120° (monoclinic) a = b = 9.4302(5), c = 6.8911(2) Å, γ = 120° (hexagonal) |

4 2 |

3.16 |

| FA |

hexagonal P63/m |

a = b = 9.367, c = 6.884 Å, γ = 120° |

2 |

3.20 |

| OA |

hexagonal P |

a = b = 9.432, c = 6.881 Å, α = 90.3°, β = 90.0°, γ = 119.9° |

1 |

~3.2 |

| TTCP | monoclinic P21 | a = 7.023(1), b = 11.986(4), c = 9.473(2) Å, β = 90.90(1)° | 4 | 3.05 |

[a] Number of formula units per unit cell. [b] Per the hexagonal unit cell.

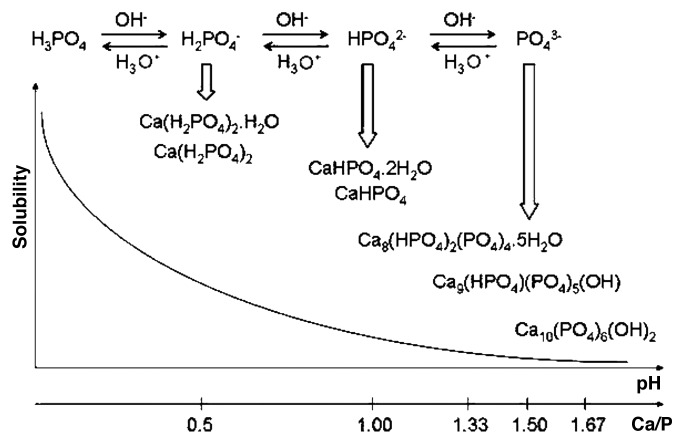

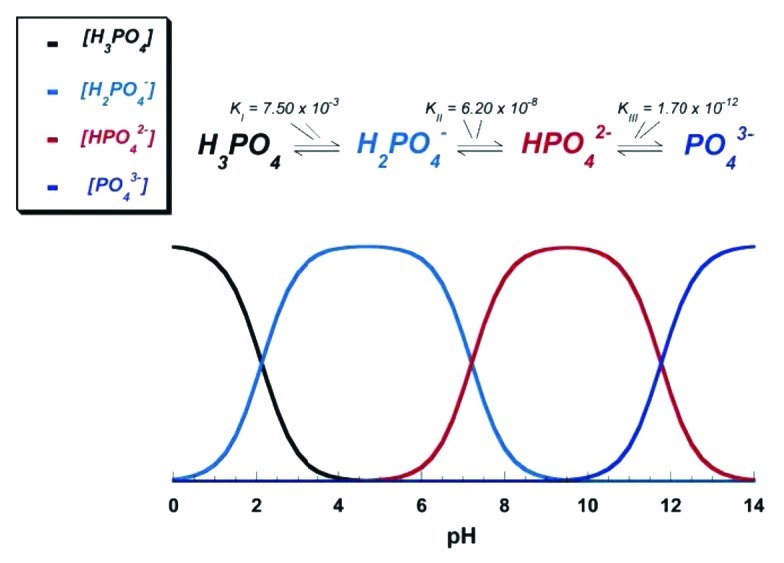

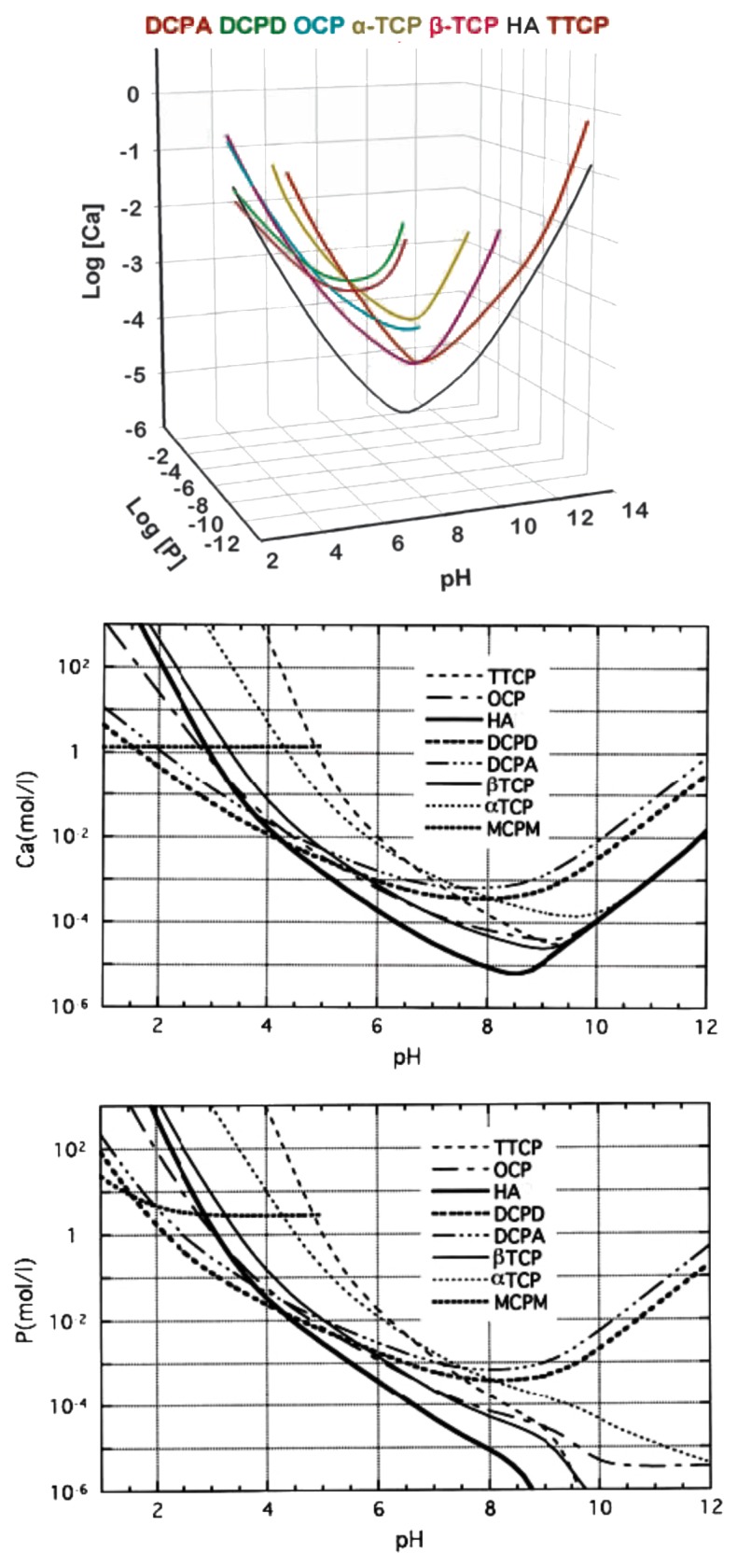

Due to the triprotic equilibrium that exists within orthophosphate-containing solutions, variations in pH alter the relative concentrations of the four polymorphs of orthophosphoric acid (Fig. 4)116 and, thus, both the chemical composition (Figure 5)117 and the amount of the calcium orthophosphates that are formed by a direct precipitation. The solubility isotherms of different calcium orthophosphates are shown in Figure 6.27,28,108,109,118-121 However, recently, the classic solubility data of calcium orthophosphates27,28,108,109,118-121 were mentioned to be inappropriate.122 According to the authors of the latter study, all previous solubility calculations were based on simplifications that are only crudely approximate. The problem lies in incongruent dissolution, leading to phase transformations and lack of the detailed solution equilibria. Using an absolute solid-titration approach, the true solubility isotherm of HA was found to lie substantially lower than previously reported. In addition, contrary to wide belief, DCPD appeared not to be the most stable phase below pH ~4.2, where CDHA is less soluble.122

Figure 4. pH variation of ionic concentrations in triprotic equilibrium for phosphoric acid solutions. Reprinted from reference 116 with permission.

Figure 5. Various calcium orthophosphates obtained by neutralizing of orthophosphoric acid. Ca/P are reported in the figure. The solubility of calcium orthophosphates in water decreases drastically from left to right, HA being the most insoluble and stable phase. Reprinted from reference 117 with permission.

Figure 6. Top: a 3D version of the classical solubility phase diagrams for the ternary system Ca(OH)2-H3PO4-H2O. Reprinted from reference 118 with permission. Middle and bottom: solubility phase diagrams in two-dimensional graphs, showing two logarithms of the concentrations of (a) calcium and (b) orthophosphate ions as a function of the pH in solutions saturated with various salts. Reprinted from reference 119 with permission.

A brief description of all known calcium orthophosphates (Table 1) is given below.

MCPM

Monocalcium phosphate monohydrate [Ca(H2PO4)2·H2O; the IUPAC name is calcium dihydrogen orthophosphate monohydrate] is both the most acidic and the most water-soluble compound. It precipitates from highly acidic solutions that are normally used in the industry of phosphorus-containing fertilizer production (“triple superphosphate”).37 Besides, MCPM might be fabricated by a simple precipitation method using CaCO3 and H3PO4 in aqueous and acetone media at ambient temperature.123 At temperatures above ~100°C it releases a molecule of water and transforms into MCPA. Due to high acidity and solubility, MCPM is never found in biological calcifications. Moreover, pure MCPM is not biocompatible[d] with bones.124 However, in medicine, MCPM is used as a component of several self-hardening calcium orthophosphate cements.125-128 In addition, MCPM is used as a nutrient, acidulant and mineral supplement for dry baking powders, food, feed and some beverages.129,130 Coupled with NaHCO3, MCPM is used as a leavening agent for both dry baking powders and bakery dough. MCPM might be added to salt-curing preserves, pickled and marinated foods. According to the European classification of food additives, MCPM is marked as E341 additive. Occasionally, MCPM is added to toothpastes. MCPM might also be added to ceramics and glasses, while agriculture is the main consumer of a technical-grade MCPM, where it is used as a fertilizer.37,129

MCPA (or MCP)

Monocalcium phosphate anhydrous [Ca(H2PO4)2; the IUPAC name is calcium dihydrogen orthophosphate anhydrous] is the anhydrous form of MCPM. It crystallizes under the same conditions as MCPM but at temperatures above ~100°C (e.g., from highly concentrated mother liquors during fertilizer production). Like MCPM, MCPA never appears in calcified tissues, and it is not biocompatible due to its acidity. There is no current application of MCPA in medicine. Due to its similarity with MCPM, in many cases, MCPA might be used instead of MCPM;37,129 however, highly hydroscopic properties of MCPA reduce its commercial application.

DCPD

Dicalcium phosphate dihydrate (CaHPO4·2H2O; the IUPAC name is calcium hydrogen orthophosphate dihydrate; the mineral brushite131) can be easily crystallized from aqueous solutions at ~2.0 < pH < ~6.5. Interestingly, precipitation of DCPD by mixing a Ca(OH)2 suspension and a H3PO4 solution in the equimolar quantities was found to occur in five stages; HA being the first precipitated phase.132,133 Alternatively, DCPD might be prepared in gels.134,135 DCPD transforms into DCPA at temperatures above ~80°C, and this transformation is accompanied by ~11% decrease in volume136 and structural changes.137 The value for ⊗rG0 for DCPD → DCPA transformation is -1.032 kJ/mol.137 Briefly, DCPD crystals consist of CaPO4 chains arranged parallel to each other, while lattice water molecules are interlayered between them. Using surface X-ray diffraction, Arsic et al. determined the atomic structure of the {010} interface of DCPD with water.138,139 Since DCPD contains water layers as part of its crystal structure, special ordering properties at the interface are expected. This interface consists of two water bilayers with different ordering properties. The first is highly ordered and can be considered as part of the DCPD crystal structure. Surprisingly, the second water bilayer exhibits no in-plane order, but shows only layering in the perpendicular direction. It has been proposed that the low level of water ordering at the interface is correlated with the low solubility of DCPD in water.139 Recently, data on DCPD solubility have been updated by solid titration technique.140 The optical properties of DCPD are well described in reference 141, while many additional data on DCPD as well as a good picture of DCPD atomic structure are available in the literature.142

DCPD is of biological importance, because it is often found in pathological calcifications (dental calculi, crystalluria, chondrocalcinosis and urinary stones) and some carious lesions.26,84-86 It has been proposed as an intermediate in both bone mineralization and dissolution of enamel in acids (dental erosion).26,84,85 In medicine, DCPD is used in calcium orthophosphate cements126,143-146 and as an intermediate for tooth remineralization. DCPD is added to toothpaste both for caries protection (in this case, it is coupled with F-containing compounds such as NaF and/or Na2PO3F) and as a gentle polishing agent.147-151 Other applications include a flame retardant,152 a slow-release fertilizer, use in glass production as well as a calcium supplement in food, feed and cereals.129 The importance of DCPD as a constituent of infant’s food was discovered as early as in 1917.153 In the food industry, it serves as a texturizer, bakery improver and water retention additive. In the dairy industry, DCPD is used as a mineral supplement. If added to food products, DCPD should be marked as E341 according to the European classification of food additives. In addition, plate-like crystals of DCPD might be used as a non-toxic, anticorrosive and passivating pigment for some ground coat paints.

DCPA (or DCP)

Dicalcium phosphate anhydrous (CaHPO4; the IUPAC name is calcium hydrogen orthophosphate anhydrate, the mineral monetite154) is the anhydrous form of DCPD. It is less soluble than DCPD due to the absence of water inclusions. Like DCPD, DCPA can be crystallized from aqueous solutions but at temperatures ~100°C. Furthermore, it might be prepared at room temperature in gels,134 ethanol155 as well as in oil-in-water and water-in-oil systems.156 DCPA is physically stable and resisted hydration even when dispersed in water for over 7 mo in the temperature range of 4–50°C.157 A calcium-deficient DCPA was prepared recently. It might be sintered at ~300°C.158 Unlike DCPD, DCPA occurs in neither normal nor pathological calcifications. It is used in calcium orthophosphate cements.145,159-166 Besides, DCPA might be implanted.167 Other applications include use as a polishing agent, a source of calcium and phosphate in nutritional supplements (e.g., in prepared breakfast cereals, enriched flour and noodle products), a tabletting aid168 and a toothpaste component.129 In addition, it is used as a dough conditioner in the food industry.

OCP

Octacalcium phosphate [Ca8(HPO4)2(PO4)4·5H2O; the IUPAC name is tetracalcium hydrogen orthophosphate diorthophosphate pentahydrate; another name is octacalcium bis(hydrogenphosphate) tetrakis(phosphate) pentahydrate] is often found as an unstable transient intermediate during the precipitation of the thermodynamically more stable calcium orthophosphates (e.g., CDHA) in aqueous solutions. Its preparation technique might be found in references 169–174. A partially hydrolyzed form of OCP with Ca/P molar ratio of 1.37 might be prepared as well.174,175 The full hydrolysis of OCP into CDHA occurs within ~6 h.173 Furthermore, OCP might be non-stoichiometric and be either Ca-deficient (Ca/p = 1.26) or include excessive calcium (up to Ca/p = 1.48) in the structure.174 Ion-substituted OCP might be prepared as well.176 Crystals of OCP are typically small, extremely platy and almost invariably twinned.

The triclinic structure of OCP displays apatitic layers (with atomic arrangements of calcium and orthophosphate ions similar to those of HA) separated by hydrated layers (with atomic arrangements of calcium and orthophosphate ions similar to those in DCPD).26-28,177,178 A similarity in crystal structure between OCP and HA179,180 is one reason that the epitaxial growth of these phases is observed. Morphologically, OCP crystallizes as {100} blades of triclinic pinacoidal symmetry elongated along the a-axis and bordered by the forms {010}, {001} and {011}. It is generally assumed that in solutions, the hydrated layer of the (100) face is the layer most likely exposed to solution. The water content of OCP crystals is about 20% that of DCPD, and this is partly responsible for its lower solubility. New data on OCP solubility have been published recently in reference 181.

OCP is of a great biological importance, because it is one of the stable components of human dental and urinary calculi.182-185 OCP was first proposed by W.E. Brown to participate as the initial phase in enamel mineral formation and bone formation through subsequent precipitation and stepwise hydrolysis of OCP.179,180,186 It plays an important role in in vivo formation of apatitic biominerals. A “central OCP inclusion” (also known as “central dark line”) is seen by transmission electron microscopy in many biological apatites and in some synthetically precipitated HA.187-191 Although OCP has not been observed in vascular calcifications, it has been strongly suggested as a precursor phase to biological apatite found in natural and prosthetic heart valves.192,193 In surgery, OCP is used for implantation into bone defects.194-200 For comprehensive information on OCP, the readers are referred to other reviews in references 174 and 184.

β-TCP

β-tricalcium phosphate [β-Ca3(PO4)2; the IUPAC name is tricalcium diorthophosphate β; other names are calcium orthophosphate tribasic β or tricalcium bis(orthophosphate) β] cannot be precipitated from aqueous solutions. It is a high temperature phase, which can be prepared at temperatures above 800°C by thermal decomposition of CDHA or by solid-state interaction of acidic calcium orthophosphates, e.g., DCPA, with a base, e.g., CaO. However, β-TCP can be obtained at a relatively low temperature (150°C) by precipitation in organic medium, such as ethylene glycol.201,202 Apart from the chemical preparation routes, ion-substituted β-TCP can be prepared by calcining of bones;203 such a type of β-TCP is occasionally called “bone ash.” In β-TCP, there are three types of crystallographically nonequivalent PO43- groups located at general points of the crystal, each type with different intratetrahedral bond lengths and angles. At temperatures above ~1,125°C, β-TCP is transformed into a high-temperature phase α-TCP. Being the stable phase at room temperature, β-TCP is less soluble in water than α-TCP (Table 1). Furthermore, the ideal β-TCP structure contains calcium ion vacancies that are too small to accommodate calcium ions but allow for the inclusion of magnesium ions, which thereby stabilize the structures.204,205 Both ion-substituted206-209 and organically modified210-212 forms of β-TCP can be synthesized as well. The maximum substitution of Mg2+ in β-TCP was found to correspond to the Ca2.61[Mg(1)0.28,Mg(2)0.11](PO4)2 stoichiometric equation.209 The modern structural data on β-TCP are available in references 213–215; those on Vicker’s and Knoop microhardness studies might be found if reference 216, while solubility data can be found in reference 217. Furthermore, the ability of β-TCP to store an electrical charge by electrical polarization was studied, and this material was found to have a suitable composition and structure for both ion conduction and charge storage.218

Pure β-TCP never occurs in biological calcifications. Only the Mg-substituted form, called whitlockite[e] [β-TCMP-β-tricalcium magnesium phosphate, β-(Ca,Mg)3(PO4)2], is found in dental calculi and urinary stones, dentineal caries, salivary stones, arthritic cartilage as well as in some soft tissue deposits.26,84-86,219-222 However, it has not been observed in enamel, dentine or bone. In biomedicine, β-TCP is used in calcium orthophosphate bone cements31,223-227 and other types of bone substitution bioceramics.203,228-235 Dental applications of β-TCP are also known.236 Pure β-TCP is added to some brands of toothpaste as a gentle polishing agent. Multivitamin complexes with calcium orthophosphate are widely available in the market, and β-TCP is used as the calcium phosphate there. In addition, β-TCP serves as a texturizer, bakery improver and anti-clumping agent for dry powdered food (flour, milk powder, dried cream, cocoa powder). Besides, β-TCP is added as a dietary or mineral supplement to food and feed, where it is marked as E341 according to the European classification of food additives. A prenatal development of rats during gestation was found to be sensitive to E341 (TCP) exposure.237 There is a good review on the toxicological properties of inorganic phosphates, where the interested readers are referred.238 Occasionally, β-TCP might be used as inert filler in pelleted drugs. Other applications comprise porcelains, pottery, enamel, use as a component for mordants and ackey as well as a polymer stabilizer.129 β-TCP of a technical grade (as either calcined natural phosphorites or bone dust) is used as a slow-release fertilizer for acidic soils.37

α-TCP

α-tricalcium phosphate [α-Ca3(PO4)2; the IUPAC name is tricalcium diorthophosphate α; other names are calcium orthophosphate tribasic α or tricalcium bis(orthophosphate) α] is usually prepared from β-TCP at heating above ~1,125°C,239 and it might be considered a high temperature phase of β-TCP. However, at the turn of the millennium, the previously forgotten data indicating that the presence of silicates stabilized α-TCP at lower temperatures of 800–1,000°C240 has been rediscovered again. Such type of α-TCP is called “silicon-stabilized α-TCP.”241-246

Although α-TCP and β-TCP have exactly the same chemical composition, they differ in their crystal structure (Table 3) and solubility (Table 1). In the absence of humidity, both polymorphs of TCP are stable at room temperatures; however, according to a density functional study, stability of β-TCP crystal lattice exceeds that of α-TCP.214 Therefore, of the two, α-TCP is more reactive in aqueous systems, has a higher specific energy, and in aqueous solutions, it can be hydrolyzed to CDHA.247-249 Milling was found to increase the α-TCP reactivity even more.250 Although, α-TCP never occurs in biological calcifications, in medicine, it is used as a component of calcium orthophosphate cements.126,143-146,161-163,251-254 On the other hand, the chemically pure α-TCP has received not much interest in the biomedical field.233 The disadvantage for using α-TCP is its quick resorption rate (faster than formation of a new bone), which limits its application in this area. However, the silicon-stabilized α-TCP (more precisely, a biphasic composite with HA) has been commercialized as a starting material to produce bioresorbable porous ceramic scaffolds to be used as artificial bone grafts.228,241-245 Upon implantation, α-TCP tends to convert to CDHA, which drastically reduces further degradation rate. Theoretical insights into bone grafting properties of the silicon-stabilized α-TCP might be found in reference 255. The structure of α-TCP is well-described in the literature,214,215,256 while the surface and adsorption properties are available in reference 257. Similar to β-TCP, α-TCP of a technical grade might be used in slow-release fertilizer for acidic soils.129

To conclude, one should briefly mention the existence of α'-TCP phase. However, it lacks a practical interest, because it only exists at temperatures above ~1,465 ± 5°C and reverts to α-TCP by cooling below the transition temperature.

ACP

Amorphous calcium phosphates (ACPs) represent a special class of calcium orthophosphate salts, having variable chemical but more or less identical glass-like physical properties, in which there are neither translational nor orientational long-range orders (LRO) of the atomic positions. Until recently,258 ACP has been considered as an individual chemical compound; however, this is just an amorphous state of other calcium orthophosphates. Therefore, in principle, all compounds mentioned in Table 1 might be somehow fabricated in an amorphous state, but, currently, only a few of them (e.g., an amorphous TCP) are known.258 Thus, strictly speaking, ACP should be excluded from Table 1.

Depending on the production temperatures, ACPs are divided into two major groups: low-temperature ACPs (prepared in aqueous solutions) and high-temperature ACPs. Low-temperature ACPs [described by the chemical formula CaxHy(PO4)z·nH2O, n = 3–4.5; 15–20% H2O] are often encountered as a transient precursor phase during precipitation of other calcium orthophosphates in aqueous systems. Usually, an ACP is the first phase precipitated from a supersaturated solution prepared by rapid mixing of solutions containing ions of calcium and orthophosphate;27,259-264 however, other production techniques are known. ACPs are thought to be formed at the beginning of the precipitation due to a lower surface energy than that of OCP and apatites.260 The amorphization degree of ACPs increases with the concentration increasing of Ca- and PO4-containing solutions as well as at a high solution pH and a low crystallization temperature. A continuous gentle agitation of as precipitated ACPs in the mother solution, especially at elevated temperatures, results in a slow recrystallization and formation of better crystalline calcium orthophosphates, such as CDHA.26,27 The lifetime of ACPs in aqueous solution was reported to be a function of the presence of additive molecules and ions, pH, ionic strength and temperature. Thus, ACPs may persist for appreciable periods and retain the amporphous state under some specific experimental conditions.265 The chemical composition of ACPs strongly depends on the solution pH and the concentrations of mixing solutions. For example, ACPs with Ca/P ratios in the range of 1.18 (precipitated at solution pH = 6.6) to 1.53 (precipitated at solution pH = 11.7)27,266 and even to 2.526,84,85 have been described. The presence of poly(ethylene glycol),267 ions of pyrophosphate, carbonate and/or magnesium in solution during the crystallization promotes formation of ACPs and slows down their further transformation into more crystalline calcium orthophosphates, while the presence of fluoride has the opposite effect.26-28,32,268 The solution-mediated transformation of an ACP to CDHA, which can be described by a “first-order” rate law, is a function only of the solution pH and depends upon the experimental conditions that regulate both the dissolution of ACP and the formation of early HA nuclei.269

High-temperature ACPs might be prepared using high-energy processing at elevated temperatures. This method is based on a rapid quenching of melted calcium orthophosphates occurring, e.g., during plasma spraying of HA.270-272 A plasma jet, possessing very high temperatures (5,000–20,000°C), partly decomposes HA. That results in formation of a complicated mixture of products, some of which would be ACPs. Obviously, all types of high-temperature ACPs are definitively anhydrous contrary to the precipitated ACPs. Unfortunately, no adequate chemical formula is available to describe the high-temperature ACPs.

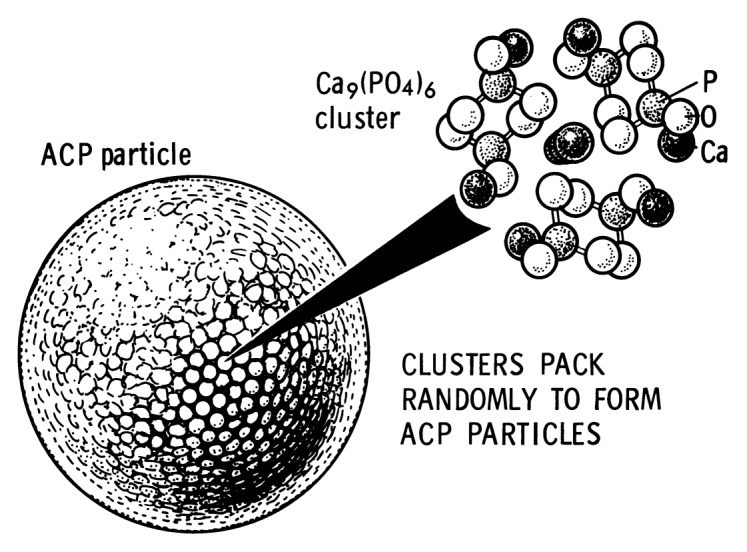

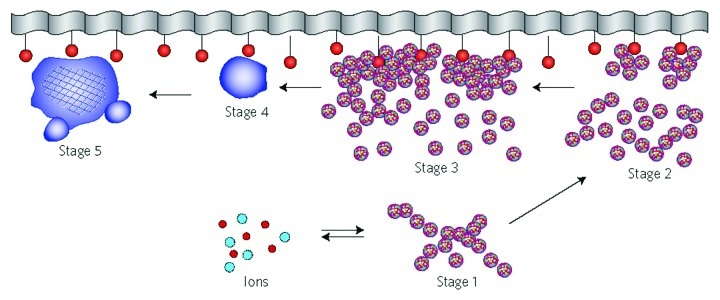

In general, as all amorphous compounds are characterized by a lack of LRO, it is problematic to discuss the structure of ACPs (they are X-ray amorphous). Concerning a short-range order (SRO) in ACPs, it exists, just due to the nature of chemical bonds. Unfortunately, in many cases, the SRO in ACPs is uncertain, because it depends on many variables, such as Ca/P ratio, preparation conditions, storage, admixtures, etc. It is well known that freshly precipitated ACPs contain 10–20% by weight of tightly bound water, which is removed by vacuum drying at elevated temperature.273 Infrared spectra of ACPs show broad featureless phosphate absorption bands. Electron microscopy of freshly precipitated ACPs usually shows featureless nearly spherical particles with diameters in the range of 20 to 200 nm. However, there is a questionable opinion that ACPs might have an apatitic structure but with a crystal size so small that they are X-ray amorphous. This is supported by X-ray absorption spectroscopic data (EXAFS) on biogenic and synthetic samples.274-277 On the other hand, it was proposed that the basic structural unit of the precipitated ACPs is a 9.5 Å diameter, roughly spherical cluster of ions with the composition of Ca9(PO4)6 (Fig. 7).27,266,278,279 These clusters were found experimentally, first as nuclei during the crystallization of CDHA, and a model was developed to describe the crystallization of HA as a step-wise assembly of these units280 [see section 3.10. HA (or HAp or OHAp) below]. Biologically, ion-substituted ACPs (always containing ions of Na, Mg, carbonate and pyrophosphate) are found in soft-tissue pathological calcifications (e.g., heart valve calcifications of uremic patients).26,84-86

Figure 7. A model of ACP structure. Reprinted from reference 278 with permission.

In medicine, pure ACPs are used in calcium orthophosphate cements143-145 and as a filling material in dentistry.258 Bioactive composites of ACPs with polymers have properties suitable for use in dentistry281-284 and surgery.285-288 Due to a reasonable solubility and physiological pH of aqueous solutions, ACP appeared to be consumable by some microorganisms, and for this reason, it might be added as a mineral supplement to culture media. Non-biomedical applications of ACPs comprise their use as a component for mordants and ackey. In the food industry, ACPs are used for syrup clearing. Occasionally, they might be used as inert filler in pelleted drugs. In addition, ACPs are used in glass and pottery production and as a raw material for production of some organic phosphates. To get further details on ACPs, the readers are referred to special reviews in references 258, 279, 289 and 290.

CDHA (or Ca-def HA)

Calcium-deficient hydroxyapatite [Ca10-x(HPO4)x(PO4)6-x(OH)2-x (0 < x < 1)] can be easily prepared by simultaneous addition of calcium- and orthophosphate-containing solutions into boiling water followed by boiling the suspension for several hours (an aging stage). That is why, in literature, it might be called as “precipitated HA (PHA).”291,292 Besides, it might be prepared by hydrolysis of α-TCP.247-249 Other preparation techniques of CDHA are known as well.293-295 During aging, initially precipitated ACPa are restructured and transformed into CDHA.[f] Therefore, there are many similarities in the structure, properties and application between the precipitated in alkaline solutions (pH > 8) ACPs and CDHA. Recent data indicated on presence of intermediate phases during further hydrolysis of CDHA to a more stable HA-like phase.296 CDHA crystals are poorly crystalline and of submicron dimensions. They have a very large specific surface area, typically 25–100 m2/g. On heating above ~700°C, dry CDHA with Ca/p = 1.5 will convert to β-TCP, and that with 1.5 < Ca/p < 1.67 will convert into a biphasic composite of HA and β-TCP (see the Biphasic, Triphasic and Multiphasic Calcium Orthophosphate Formulations section below).297-308 A reasonable solid-state mechanism of a high-temperature transformation of CDHA into BCP has been proposed.309,310

The variability in Ca/P molar ratio of CDHA has been explained through different models: surface adsorption, lattice substitution and intercrystalline mixtures of HA and OCP.311 Due to a lack of stoichiometry, CDHA usually contains other ions.83 The extent depends on the counter-ions of the chemicals used for preparation (e.g., Na+, Cl-). Direct determinations of the CDHA structures are still missing, and the unit cell parameters remain uncertain. However, unlike that in ACPs (see section 3.8. ACP above), a LRO exists in CDHA. The following lattice parameters were reported for formate (HCO2-) containing CDHA with Ca/p = 1.596 (ionic): a = 9.4729(20) and c = 6.8855(9) Å. A loss of Ca2+ ions happened exclusively from Ca(2) sites, while the PO4 tetrahedron volume and P-O bonds were ~4.4% and ~1.4% smaller, respectively, than those in HA.312

A systematic study of defect constellations in CDHA is available in literature.313 As a first approximation, CDHA may be considered as HA with some ions missing.314 The more calcium is deficient, the more disorder and imperfections are in CDHA structure.315 Furthermore, a direct correlation between Ca deficiency and the mechanical properties of the crystals was found: calcium deficiency lead to an 80% reduction in the hardness and elastic modulus and at least a 75% reduction in toughness in plate-shaped HA crystals.316 According to the chemical formula of CDHA (Table 1), there are vacancies of Ca2+ [mainly on Ca(2) sites] and OH- ions in crystal structure of this compound.312,314-319 However, due to Ca2+ vacancies in CDHA, the resulting negative charge might be compensated by protonation of both an OH- ion within the deficient calcium-triangle and a PO43- ion in the nearest neighborhood of the vacant calcium site. This results in the presence of some water in the CDHA structure: Ca10-x(HPO4)x(PO4)6-x(OH)2-x(H2O)x (0 < x < 1).313 According to this approach, there are no hydroxide vacancies in CDHA, just a portion of OH- ions are substituted by water molecules. Concerning possible vacancies of orthophosphate ions, nothing is known about their presence in CDHA. It is considered that a portion of PO43- ions is either protonated (as HPO42-) or substituted by other ions (e.g., CO32-).320 Theoretical investigations of the defect formation mechanism relevant to non-stoichiometry in CDHA are available in reference 321.

Unsubstituted CDHA (i.e., that containing ions of Ca2+, PO43-, HPO42- and OH- only) does not exist in biological systems. However, the ion substituted CDHA, Na+, K+, Mg2+, Sr2+ for Ca2+; CO32- for PO43- or HPO42-; F-, Cl-, CO32- for OH-, plus some water forms biological apatite, the main inorganic part of animal and human normal and pathological calcifications.26,83,84 Therefore, CDHA is a very promising compound for industrial manufacturing of artificial bone substitutes,322 including drug delivery applications.323 Non-biomedical applications of CDHA are similar to those of ACP and HA. Interestingly, CDHA was found to possess a catalytic activity to produce biogasoline.324

HA (or HAp, or OHAp)

Hydroxyapatite[g] [Ca5(PO4)3(OH), but is usually written as Ca10(PO4)6(OH)2 to denote that the crystal unit cell comprises two molecules; the IUPAC name is pentacalcium hydroxide tris(orthophosphate)] is the second most stable and least soluble calcium orthophosphate after FA. Chemically pure HA crystallizes in the monoclinic space group P21/b.325 However, at temperatures above ~250°C, there is a monoclinic to hexagonal phase transition in HA (space group P63/m).27,113,266,326,327 The detailed description of the HA structure was first reported in 1964,328 and its interpretation in terms of aggregation of Ca9(PO4)6 clusters, the so-called Posner’s clusters, has been widely used since the publication of the article by Posner and Betts.273 The Ca9(PO4)6 clusters appeared to be energetically favored in comparison to alternative candidates, including Ca3(PO4)2 and Ca6(PO4)4 clusters.329 In hexagonal HA, the hydroxide ions are more disordered within each row when compared with the monoclinic form, pointing either upward or downward in the structure. This induces strains that are compensated for by substitutions or ion vacancies. Some impurities, like partial substitution of hydroxide by fluoride or chloride, stabilize the hexagonal structure of HA at ambient temperature. For this reason, hexagonal HA is seldom the stoichiometric phase, and it is very rare that single crystals of natural HA exhibit the hexagonal space group. The crystal structure of HA is well-described in references 27 and 112–114 the detailed analysis of the electronic structure, bonding, charge transfer, optical and elastic properties are also available,330-334 while the readers interested in Posner’s clusters are referred to other papers.329,335-337 A shell model was developed to study the lattice dynamics of HA,338 while a cluster growth model was created to illustrate its growth.280 Polarization characteristics339,340 and pyroelectrical properties341 of HA bioceramics have been investigated. First-principles calculations for the elastic properties of doped HA342 and vacancy formation in HA343 were performed. Computer simulations of the structures and properties of HA are well-described in recent feature articles.344,345

Several techniques might be utilized for HA preparation; they can be divided into solid-state reactions and wet methods,346 which include precipitation, hydrothermal synthesis and hydrolysis of other calcium orthophosphates. Even under the ideal stoichiometric conditions, the precipitates are generally non-stoichiometric, suggesting intermediate formation of precursor phases, such as ACP and CDHA. HA can be prepared in aqueous solutions by mixing exactly stoichiometric quantities of Ca- and PO4-containing solutions at pH > 9, followed by boiling for several days in CO2-free atmosphere (the aging or maturation stage), filtration, drying and, usually, sintering at about 1,000°C.347 As the first precipitates are rich in non-apatitic environments (see ACP and CDHA), the aging stage appears to be very important: the Ca/P molar ratio of 1.67 was attained in as little as 5 h after the completion of the reaction at 90°C.348 The surface of freshly precipitated HA is composed of a structured hydrated layer containing easily exchangeable mobile ionic species.349 Usually unsintered HA is poorly crystalline and often non-stoichiometric, resembling the aforementioned CDHA. However, well crystalline HA can be prepared from an aqueous solution.350 Microcrystalline samples of HA can also be prepared by solid-state reaction of other calcium phosphates (e.g., MCPM, DCPA, DCPD, OCP) with CaO, Ca(OH)2 or CaCO3 at temperatures above ~1,200°C in an atmosphere of equal volumes of water and nitrogen. HA can be prepared by hydrothermal synthesis.27,266,351,352 A water-free synthesis can be performed in ethanol from Ca(OEt)2 (Et = ethyl) and H3PO4.353,354 In addition, HA might be prepared by mechanochemical synthesis of a dry mixture of CaO and DCPD346,355 or from coral skeletal carbonate by hydrothermal exchange.356-358 Relatively large single crystals of HA might be prepared from those of chlorapatite359 or by a recently developed controlled homogeneous precipitation method.360 Smaller sized particles of HA might be prepared by a pyrosol technique, where an aerosol containing calcium and orthophosphate ions in the adequate ratio is transported to a furnace where the pyrolisis takes place.361 Synthesis of nano-sized HA has also been described in references 362 and 363, while the chronological development of nano-sized HA synthesis might be found in another paper.364 Two-dimensional nanocrystalline HA might be also synthesized.365 Space-grown and terrestrial HA crystals were found to differ in size: the former appeared to be at least 1–1.5 orders of magnitude bigger in length.366,367 Transparent HA ceramics is also known.368-371 The detailed information on HA synthesis is available in references 372–380. In addition, there are good reviews on HA solubility, crystal growth and intermediate phases of HA crystallization381 as well as on HA dissolution.382

Pure HA never occurs in biological systems. However, due to the chemical similarities to bone and teeth mineral (Table 2), HA is widely used as a coating on orthopedic (e.g., hip joint prosthesis) and dental implants.383-390 HA particles might be implanted as well.391 Due to a great similarity to biological apatite, HA has been used in liquid chromatography of nucleic acids, proteins and other biological compounds392-401 and for drug delivery purposes402-405 for a long time. Also, HA is added to some brands of toothpaste as a gentle polishing agent instead of calcium carbonate.406,407 Non-biomedical applications of HA include its use as an environmentally friendly filler for elastomers,408 a sorbent of poisonous chemical elements409,410 and a carrier for various catalysts.411-413 Furthermore, HA by itself might act as a catalyst for formaldehyde combustion at room temperature.414 To conclude this topic, one should mention other reviews devoted to HA and its biomedical applications.415-419

FA (or FAp)

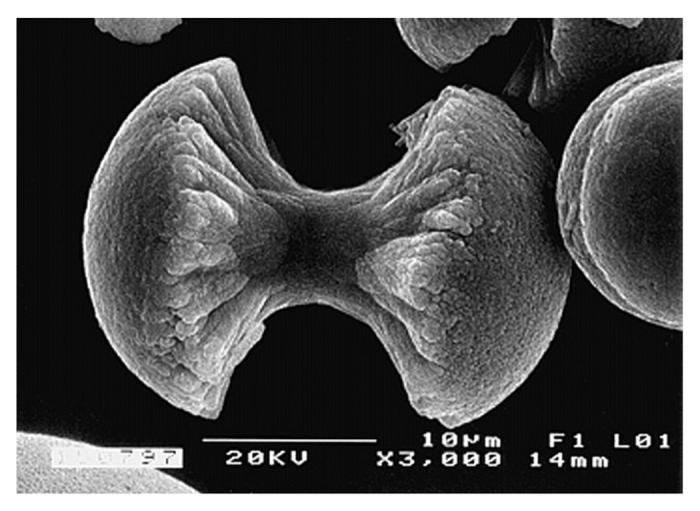

Fluorapatite [Ca5(PO4)3F, usually written as Ca10(PO4)6F2 to denote that the crystal unit cell comprises two molecules; the IUPAC name is pentacalcium fluoride tris(orthophosphate) is the only ion-substituted calcium orthophosphate considered in this review. It is the hardest (5 according to the Mohs’ scale of mineral hardness), most stable and least soluble compound among all calcium orthophosphates (Table 1). Perhaps, such “extreme” properties of FA are related to the specific position of F- ions in the center of Ca(2) triangles of the crystal structure.113 Due to its properties, FA is the only calcium orthophosphate that naturally forms large deposits suitable for the commercial use36-39 (see also Fig. 2). Preparation techniques of the chemically pure FA are similar to the aforementioned ones for HA, but the synthesis must be performed in presence of the necessary amount of F- ions (usually, NaF or NH4F is added). Unlike that for HA (see CDHA), no data are available on existence of calcium-deficient FA. Under some special crystallization conditions (e.g., in presence of gelatin or citric acid), FA might form an unusual dumbbell-like fractal morphology that, finally, close into spheres (Fig. 8).420-426 A hierarchical structure for FA was proposed.427 The crystal structure of FA was studied for the first time in 1930428,429 and is well-described in references 27, 112–114 and 430. The detailed analysis of the electronic structure, bonding, charge transfer and optical properties is available as well.332 In addition, there are reviews on FA solubility381 and the dissolution mechanism.382

Figure 8. A biomimetically grown aggregate of FA that was crystallized in a gelatin matrix. Its shape can be explained and simulated by a fractal growth mechanism. Scale bar: 10 µm. Reprinted from reference 420 with permission.

FA easily forms solid solutions with HA with any desired F/OH molar ratio. Such compounds are called fluorhydroxyapatites (FHA) or hydroxyfluorapatites (HFA) and described with a chemical formula Ca10(PO4)6(OH)2-xFx, where 0 < x < 2. If the F/OH ratio is either uncertain or not important, the chemical formula of FHA and HFA is often written as Ca10(PO4)6(F,OH)2. The lattice parameters, crystal structure, solubility and other properties of FHA and HFA lay in between those for the chemically pure FA and HA.431-435

Similar to pure HA, pure FA never occurs in biological systems. Obviously, a lack of the necessary amount of toxic fluorides (the acute toxic dose of fluoride is ~5 mg/kg of body weight) in living organisms is the main reason of this fact (pure FA contains 3.7% mass F). Enameloid of shark teeth32,103,436-440 and some exoskeletons of mollusks441 seem to be the only exclusions, because they contain substantial amounts of FA. Among all normal calcified tissues of humans, the highest concentration of fluorides is found in bones and the lowest in dental enamel.[h] However, even in bones, the total amount of fluorides is not enough to form FA; it is generally considered that the inorganic part of bones consists of ion-substituted CDHA. Due to its low solubility, good chemical stability and the toxicity of high amounts of fluorides, chemically pure FA is rarely used as a bone substituting material.442 However, various FA-containing composites,443-445 FHA446,447 and porous FA bioceramics448 seem to be better candidates for biomedical applications. Furthermore, due to the ability to form FHA and/or HFA, minor amounts of fluorides might be intentionally added to calcium orthophosphate biomaterials.449-455 The effect of fluoride contents in FHA on both osteoblast behavior456,457 and leukemia cells proliferation458 has been described. Non-biomedical applications of FA include its application as a catalyst.459

OA (or OAp, or OXA)

Oxyapatite [Ca10(PO4)6O; the IUPAC name is decacalcium oxide hexakis(phosphate)] is the least studied calcium orthophosphate. To the best of my knowledge, pure OA has never been prepared; therefore, its properties are not well-established. Furthermore, still there are doubts that pure OA exists. However, a mixture of OA and HA (oxy-HA) might be prepared by dehydration of HA at temperatures exceeding ~900°C (e.g., during plasma-spray of HA) only in the absence of water vapor.27,28,460,461 It also might be crystallized in glass-ceramics.462 Computer modeling techniques have been employed to qualitatively and quantitatively investigate the dehydration of HA to OA.463 OA has the hexagonal space group symmetry P (174) of cesanite type,112 while the space group symmetry for partially dehydrated HA was found to change from hexagonal P63/m to triclinic P when more than ca. 35% of the structurally bound water had been removed.461 OA has no stability field in aqueous conditions;464 it is very reactive and transforms to HA in contact with water vapor.460 Due to the aforementioned problems with OA preparation, no information on biomedical applications of pure OA is available. Plasma-sprayed coatings of HA, in which OA might be present as an admixture phase, seem to be the only application.

TTCP (or TetCP)

Tetracalcium phosphate or tetracalcium orthophosphate monoxide [Ca4(PO4)2O; the IUPAC name is tetracalcium oxide bis(orthophosphate); the mineral hilgenstockite465] is the most basic calcium orthophosphate. However, its solubility in water is higher than that of HA (Table 1). TTCP cannot be precipitated from aqueous solutions. It can be prepared only by a solid-state reaction at temperatures above 1300°C, e.g., by heating homogenized equimolar quantities of DCPA and CaCO3 in dry air or in a flow of dry nitrogen.27,266,466,467 These reactions should be performed in a dry atmosphere in a vacuum or with rapid cooling (to prevent uptake of water and formation of HA). DCPA might easily be replaced by ammonium orthophosphates,468,469 while calcium carbonate might be replaced by calcium acetate.469 Furthermore, TTCP often appears as an unwanted byproduct in plasma-sprayed HA coatings, where it is formed as a result of the thermal decomposition of HA to a mixture of high-temperature phases of α-TCP, TTCP and CaO.470 TTCP is metastable: in both wet environment and aqueous solutions, it slowly hydrolyzes to HA and calcium hydroxide.27,266,471 Consequently, TTCP is never found in biological calcifications. In medicine, TTCP is widely used for preparation of various self-setting calcium orthophosphate cements;120,127,143,159,165,166,252,470,472 however, to the best of my knowledge, there is no commercial bone-substituting product consisting solely of TTCP. For the comprehensive information on TTCP, the readers are referred to a recent review in reference 470, while the structure,473 spectra474 and solubility217 of TTCP are well-described elsewhere.

There is an opinion,113,184 that all calcium orthophosphates listed in Table 1 might be classified into three major structural types: (1) the apatite type, Ca10(PO4)6X2, which includes HA, FA, OA, CDHA, OCP and TTCP; (2) the glaserite type, named after the mineral glaserite, K3Na(SO4)2, which includes all polymorphs of TCP and, perhaps, ACP and (3) the Ca-PO4 sheet-containing compounds, which include DCPD, DCPA, MCPM and MCPA. According to the authors, a closer examination of the structures revealed that all available calcium orthophosphates could be included into distorted glaserite type structures, but with varying degrees of distortion.113,184

Biphasic, triphasic and multiphasic calcium orthophosphate formulations

Calcium orthophosphates might form biphasic, triphasic and multiphasic (polyphasic) compositions, in which the individual components cannot be separated from each other.475 Presumably, the individual phases of such compositions are homogeneously “mixed” at well below submicron level (< 0.1 µm) and strongly integrated with each other. Nevertheless, the presence of all individual phases is easily seen by X-ray diffraction technique.

The main idea of the multiphasic concept is determined by a balance of more stable calcium orthophosphate phases (e.g., HA) and more soluble calcium orthophosphate phases (e.g., any type of TCP). The usual way to prepare biphasic, triphasic and multiphasic calcium orthophosphates consists of sintering non-stoichiometric calcium orthophosphates, such as ACP and CDHA, at temperatures above ~700°C. Furthermore, a thermal decomposition of the stoichiometric calcium orthophosphates at temperatures above ~1300°C might be used as well;476,477 however, this approach often results in the formation of complicated mixtures of various products including admixtures of CaO, calcium pyrophosphates, etc. Namely, transformation of HA into polyphasic calcium orthophosphates by annealing in a vacuum occurs as this: the outer part of HA is transformed into α-TCP and TTCP, while the α-TCP phase of the surface further transforms into CaO. Besides, in the boundary phase, HA is transformed into TTCP.476

Historically, Nery, Lynch and coworkers first used the term biphasic calcium phosphate (BCP) in 1986 to describe a bioceramic that consisted of a mixture of HA and β-TCP.226 Based on the results of X-ray diffraction analysis, these authors found that the “tricalcium phosphate” preparation material used in their early publication227 was in fact a mixture of ~20% HA and ~80% β-TCP. Currently, only biphasic and triphasic calcium orthophosphate formulations are known; perhaps more complicated formulations will be manufactured in the future. Furthermore, nowadays, only multiphasic and/or polyphasic compositions consisting of high-temperature phases of calcium orthophosphates, such as α-TCP, β-TCP, HA and, perhaps, high-temperature ACP, OA and TTCP, are known. No precise information on multiphasic compositions containing MCPM, MCPA, DCPD, DCPA, low-temperature ACP, OCP and CDHA has been found in the literature.475 Perhaps, such formulations will be produced in future.

All BCP formulations might be subdivided into two major groups: those consisting of calcium orthophosphates having either the same (e.g., α-TCP and β-TCP) or different (e.g., β-TCP and HA) molar Ca/P ratios. Among all known BCP formulations, BCP consisting of HA and β-TCP is both the most known and the best investigated.297-308 In 1986, LeGeros in the USA and Daculsi in France initiated the basic studies on preparation of this type of BCP and its in vitro properties. This material is soluble and gradually dissolves in the body, seeding new bone formation as it releases calcium and orthophosphate ions into the biological medium. Presently, commercial BCP products of different or similar HA/β-TCP ratios are manufactured in many parts of the world as bone-graft or bone substitute materials for orthopedic and dental applications under various trade marks and several manufacturers.307 A similar combination of α-TCP with HA forms BCP as well.241,242,244,478-481

Recently the concept of BCP has been extended by preparation and characterization of biphasic TCP (BTCP), consisting of α-TCP and β-TCP phases.482-486 The biphasic TCP is usually prepared by heating ACP precursors484-486 in which the α-TCP/β-TCP ratio can be controlled by aging time and pH value during synthesis of the amorphous precursor.485 Furthermore, triphasic formulations, consisting of HA, α-TCP and β-TCP487 or HA, α-TCP and TTCP476,477 have been prepared.

It is important to recognize that the major biomedical properties (such as bioactivity, bioresorbability, osteoconductivity and osteoinductivity) of the multiphasic and/or polyphasic compositions might be adjusted by changing the ratio among the calcium orthophosphate phases. When compared with both α- and β-TCP, HA is a more stable phase under the physiological conditions, as it has a lower solubility (Table 1) and, thus, slower resorption kinetics. Therefore, due to a higher biodegradability of the α- or β-TCP component, the reactivity of BCP increases with the TCP/HA ratio increasing. Thus, in vivo bioresorbability of BCP can be adjusted through the phase composition. Similar conclusions are also valid for both the biphasic TCP (in which α-TCP is a more soluble phase) and the triphasic (HA, α-TCP and β-TCP) formulation.

A phase transition from α-TCP into β-TCP in three types of BCPs (HA + TCP) was investigated, and the experimental results indicated that a sintering temperature for the complete phase transition from α-TCP into β-TCP increased with increasing HA content in BCP.488 Further details on biphasic, triphasic and multiphasic calcium orthophosphate formulations might be found in a very recent review in reference 475.

Ion-substituted calcium orthophosphates

Finally, one should very briefly mention the existence of carbonated apatite,489-495 chlorapatite496-498 as well as a great number of various ion-substituted calcium orthophosphates.83,499,500 Usually, they are of a non-stoichiometric nature, and there are too many of them to be mentioned in one review. Currently, this is a hot investigation topic; therefore, the readers are referred to other books and reviews in references 26–28, 32, 36, 38, 48, 266 and 416. In addition, there is a very good review, in which the structures of more than 75 chemically different apatites have been discussed in reference 112.

To conclude this topic, it is interesting to note that chemical elements not found in natural bones can be intentionally incorporated into calcium orthophosphate biomaterials to get special properties. For example, addition of Ag+,501-503 Zn2+,503,972 and Cu2+,503,972,973 has been used for imparting antimicrobial effect, while radioactive isotopes of 90Y,504,153Sm181,505-507Re505 have been incorporated into HA bioceramics and injected into knee joints to treat rheumatoid joint synovitis.504,505,507 More to the point, apatites were found to incorporate individual molecules, such as water, oxygen and carbon dioxide.83

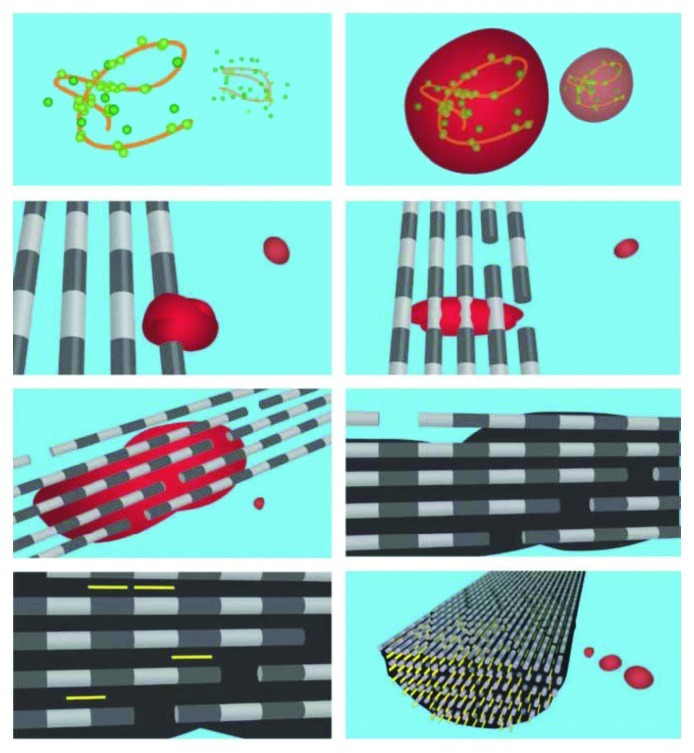

Biological Hard Tissues of Calcium Orthophosphates

Biological mineralization (or biomineralization) is the process of in vivo formation of inorganic minerals (so-called, biominerals). One should stress, that the term “biomineral” refers not only to a mineral produced by organisms, but also to the fact that almost all of these mineralized products are composite materials comprised of both inorganic and bioorganic components. Furthermore, having formed in vivo under well-controlled conditions, the biomineral phases often have properties, such as shape, size, crystallinity, isotopic and trace element compositions, quite unlike their inorganically formed counterparts (please, compare Figs. 2, 8, 10 and 14). Thus, the term “biomineral” reflects all this complexity.103,438

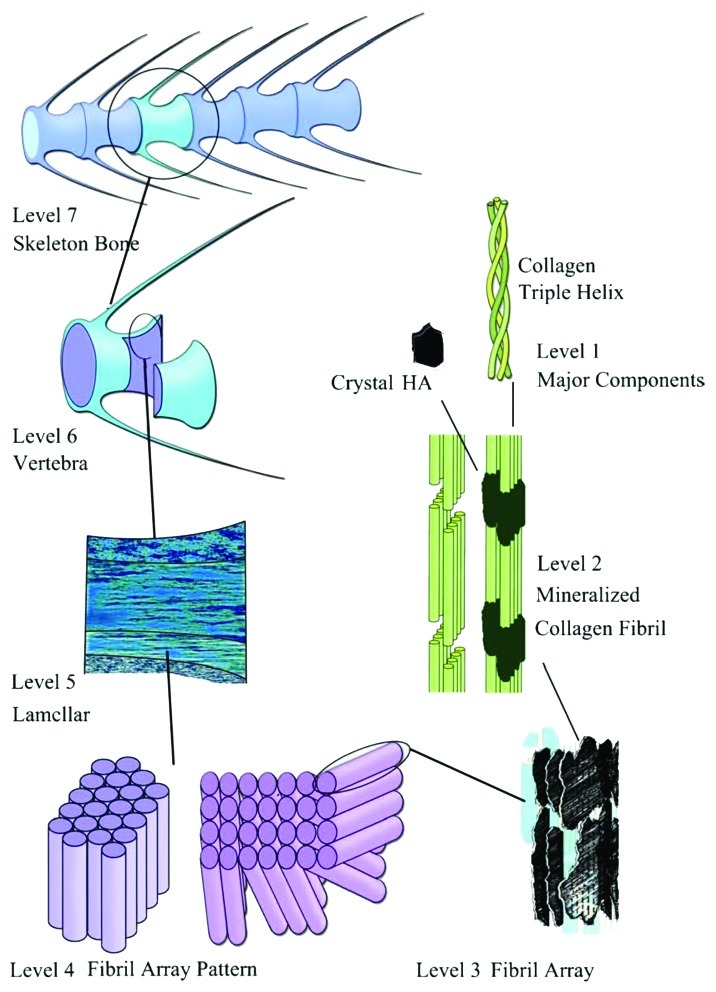

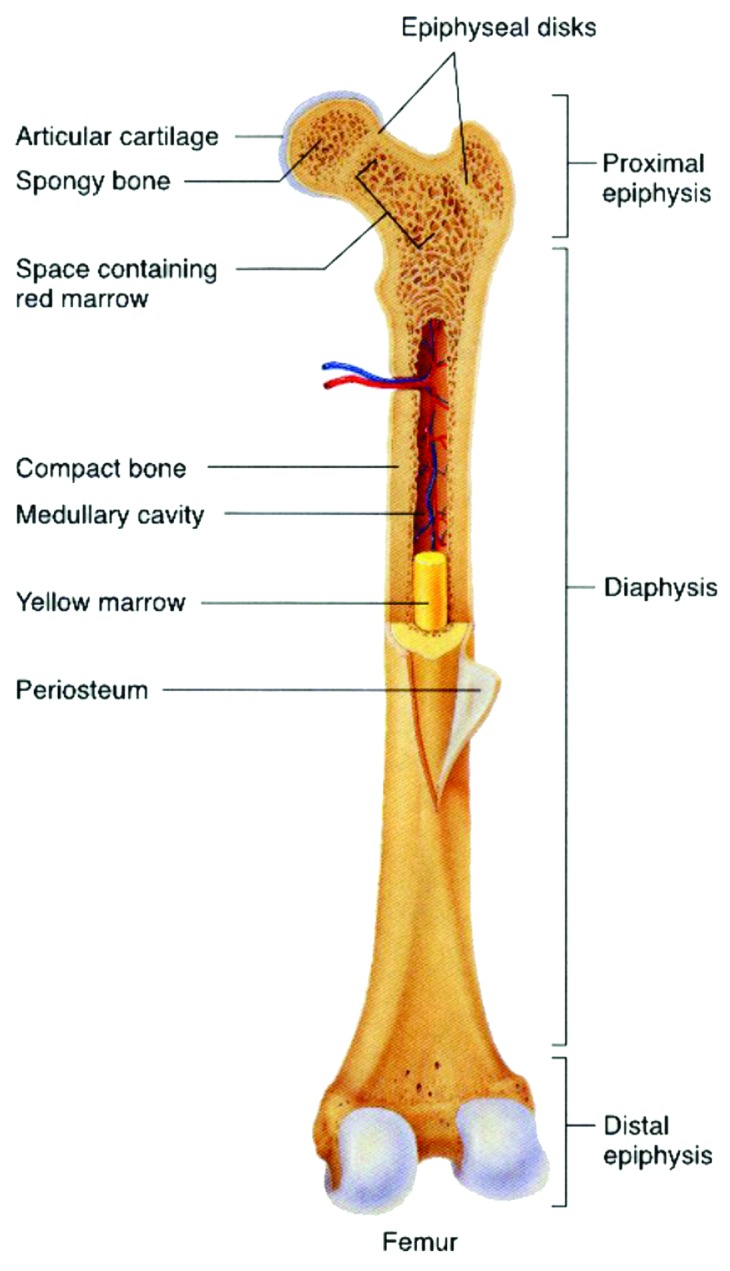

Figure 10. General structure of a mammalian bone. Other very good graphical sketches of the mammalian bone structure are available in references 88 and 508.

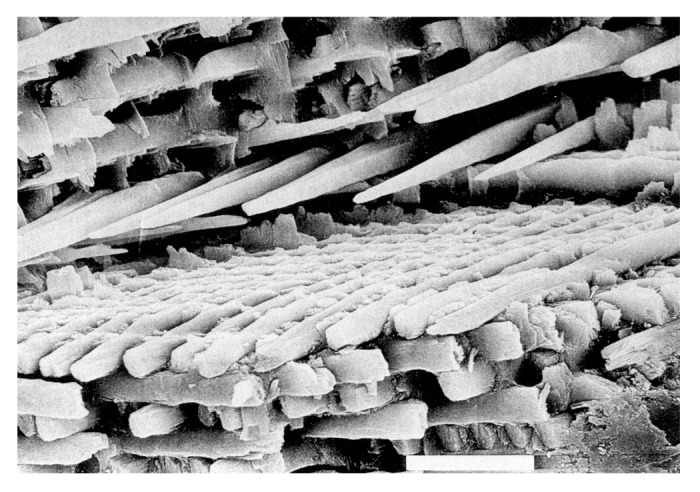

Figure 14. Scanning electron micrograph of the forming enamel of a continuously growing rat incisor showing ordered rods of calcium orthophosphates. Scale bar: 10 µm. Reprinted from reference 103 with permission.

As shown in Table 2 and discussed above, in the body of mammals, the vast majority of both normal and pathological calcifications consist of non-stoichiometric and ion-substituted calcium orthophosphates, mainly of apatitic structure.88,509 At the atomic scale, nano-sized crystals bone apatite exhibit a variety of substitutions and vacancies that make the Ca/P molar ratio distinct from the stoichiometric HA ratio of 1.67. Their chemical composition is complicated and varies in relatively wide ranges. This depends on what the animal has ingested.510 Occasionally, attempts are performed to compose chemical formulas of biological apatites. For example, the following formula Ca8.856Mg0.088Na0.292K0.010(PO4)5.312(HPO4)0.280(CO3)0.407(OH)0.702Cl0.078(CO3)0.050 was proposed to describe the chemical composition of the inorganic part of dental enamel.511

The impurities in biological apatite of bones and teeth introduce significant stresses into the crystal structure, which make it less stable and more reactive. Among all substituting ions, the presence of 4–8% of carbonates instead of orthophosphate anions (so called, B-type substitution26-28,493) and 0.5–1.5% of Mg is of special importance, because it leads to large lattice strain and significantly increases the solubility.509,511,512 Higher concentrations of magnesium and carbonates in bone or dentine compared with those in enamel (Table 2) may explain a higher solubility and a lower crystallinity (smaller crystal size) of bone or dentine compared with enamel.

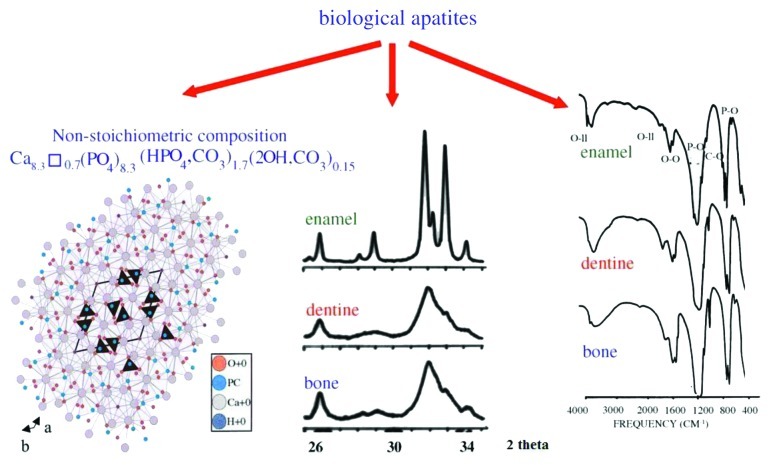

In addition, the crystals of biological apatite are always very small, which also increases its solubility when compared with that for the chemically pure HA and even CDHA.83 However, biologic apatites of enamel have considerably larger crystal size (about 2,000 nm) compared with that of either bone or dentine apatite, as indicated by the well-defined diffraction peaks in the X-ray diffraction profile of enamel apatite and much broader diffraction peaks of either bone or dentine apatites (Fig. 9, center). Small dimensions and a low crystallinity are two distinct features of biological apatites, which, combined with their non-stoichiometric composition, inner crystalline disorder and presence of other ions in the crystal lattice, allow explaining their special behavior. For example, the small crystal size means that a large percentage of the atoms are on the surface of the crystals, providing a large specific surface area for sorption of ions, proteins and drugs.508,512 The major physical properties of biological apatite are summarized in Figure 9. It is interesting to note, that the solubility and equilibrium phenomena of calcium orthophosphates related to the calcification process have been studied at least since 1925.513,514

Figure 9. Left: crystal structure of a biological apatite. Powder X-ray diffraction patterns (center) and infrared spectra (right) of human enamel, dentine and bone. Reprinted from reference 508 with permission.

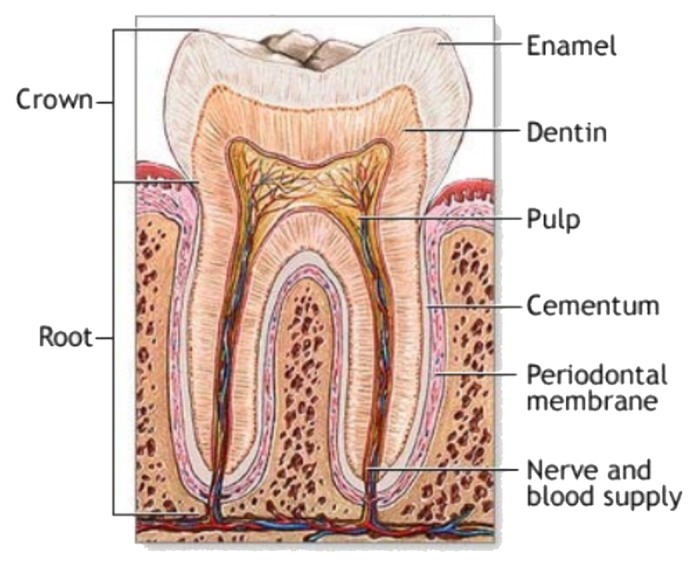

Attempts to mimic the calcium orthophosphate nature of bones were first performed in 1913.515 This discovery was clarified afterwards, suggesting that the bone mineral could be carbonated apatite.516,517 Further optical and X-ray analysis of bones and other mineralized tissues matched analyses of two apatites: FA and dahllite.518 Additional historical data on this point are available in literature.42 Nowadays, according to Weiner and Wagner, “the term bone refers to a family of materials, all of which are built up of mineralized collagen fibrils.”104,519 For mammals, this family of materials includes dentine, the material that constitutes the inner layers of teeth, cementum, the thin layer that binds the roots of teeth to the jaw, deer antlers and some other materials.104,105 It is worth noting, that bones and teeth contain almost 99% of the total body calcium and about 85% of the total body phosphorus, which amounts to a combined mass of approximately 2 kg in an average person.520,521 In addition, it is important to recognize that calcium orthophosphates of bones are by no means inert; they play an important role in the metabolic functions of the body. The recent data on the physico-chemical and crystallographic study of biological apatite have been reviewed in reference 511. Besides, there is a comprehensive review on the application of surface science methods to study the properties of dental materials and related biomaterials.522

Bone

Bone, also called osseous tissue (Latin: os), is a type of hard endoskeletal connective tissue found in many vertebrate animals. All the bones of a single animal are, collectively, known as the skeleton. True bones are present in bony fish (osteichthyes) and all tetrapods. Bones support body structures, protect internal organs and, in conjunction with muscles, facilitate movement.523 In addition, bones are also involved in blood cell formation, calcium metabolism and act for mineral storage. From the material point of view, bone is a dynamic, highly vascularized tissue that is formed from a complicated biocomposite containing both inorganic (Table 2) and bioorganic (chiefly, collagen) compounds.509,524-530 Furthermore, there is a cellular phase that consists of three different types of cells: osteoblasts, osteoclasts and osteocytes. The inorganic to bioorganic ratio is approximately 75% to 25% by dry weight and about 65% to 35% by volume. This ratio not only differs among animals, among bones in the same animal and over time in the same animal, but also it exerts a major control on the material properties of bone, such as its toughness, ultimate strength and stiffness. In general, load-bearing ability of bones depends on not only architectural properties, such as cortical thickness and bone diameter, but also intrinsic, size-independent material properties, such as porosity, level of mineralization, crystal size and properties derived from the organic phase of bone.531 A higher mineral to collagen ratio typically yields stronger but more brittle, bones.532-534 For example, bone from the leg of a cow has a relatively high concentration of calcium orthophosphates (for support), whereas bone from the antler of a deer has a relatively high concentration of collagen (for flexibility).122 It is interesting to note, that bone exhibits several physical properties such as piezoelectricity535 and pyroelectricity.536

Stability of the mineral composition of bones has a very long history: calcium orthophosphates were found in dinosaur fossils.53,100,537-540 Therefore, organisms have had a great deal of time to exploit the feedback between composition and structure in apatite, on the one hand, and benefit from its biological functionality, on the other. Bone in modern animals is a relatively hard and lightweight porous composite material, formed mostly of biological apatite (i.e., poorly crystalline CDHA with ionic substitutions). It has relatively high compressive strength but poor tensile strength.541 While bone is essentially brittle, it has a degree of significant plasticity contributed by its organic components.

The distribution of the inorganic and bioorganic phases depends on a highly complex process that takes place during bone formation. Each of these components may be assembled in different proportions, creating two different architectural structures depending on the bone type and function. They are characterized by different structural features that strongly correlate with the mechanical performance of the tissue. These two types of bones are (1) the cortical bone (or compact bone), which is a dense structure and (2) the cancellous bone (also known as trabecular or spongious bone), which is less dense and less stiff than compact bone. Usually, bone is composed of a relatively dense outer layer of cortical bone covering an internal mesh-like structure (average porosity of 75–95%) of cancellous bone, the density of which is about 0.2 g/cm3, but it may vary at different points (Fig. 10). Cortical bone makes up a large portion of the skeletal mass; it has a high density (~1.80 g/cm3) and a low surface area. Cancellous bone has an open meshwork or honeycomb-like structure. It has a relatively high surface area but forms a smaller portion of the skeleton. Bone is a porous material, with the pore sizes range from 1 to 100 ∝m in normal cortical bones and 200 to 400 µm in trabecular bones. 55 to 70% of the pores in trabecular bones are interconnected. The porosity reduces the strength of bones but also reduces their weight.26,32,84,85,101-104,525-529,542-546