Abstract

Postharvest quality of Alphonso mangoes (Mangifera indica L) is vital to ensure proper ripening and good quality. 500 g mature green mangoes, were subjected to three pre- packaging hot water dips (20, 30 & 40°C) for 40 min, two packaging films (OPP unperforated and perforated), using three levels of gas concentrations of 25,50 and 75% v/v CO2 treatments (balance N2) and stored at 10°C for 21 days. During the storage period headspace gas composition, weight loss, ascorbic acid, pulp firmness, external fruit colour and overall quality score were measured to determine optimum storage conditions. The most effective postharvest condition was found to be dipping in water maintained at 40°C for 40 min, followed by packaging under 50% CO2 in bags made of unperforated film when compared to mangoes packed under 25 and 75% CO2 which showed deteriorated quality including spoilage and mould. Good keeping quality of at least 21 days was achieved under these conditions, which was much superior to the control samples that showed deterioration after 12 days of storage.

Keywords: Alphonso mango, Modified atmosphere packaging, Carbon dioxide, Quality, Postharvest, Hot water treatment

Introduction

Mango (Mangifera indica L.) is one of the most important fruits. India is the largest producer of mango, growing over an area of 1.6 million hectare of farm land (FAO 2005). It is a popular tropical fruit all over the world due to its bright colour, characteristic taste, and nutritional value. Mango imports to the United States (US) and Europe have grown steadily in response to increased demand and affordable prices (Sauco 2004). When consumed regularly, mango can be a valuable dietary source of many phytochemical, which also impart a characteristic capusine yellow or reddish colour and distinct sweet rich flavour to the fruit which is contributed by the volatile flavour compounds present in it (Johnson et al. 1997, Grundhofer et al. 2001; Haard and Chism 1996). It is also considered as a source of antioxidants including ascorbic acid (mango fruit provides about 50% of the recommended daily intake of vitamin C) and carotenoids, which are lipophilic radical scavengers found in many fruits and vegetables. Carotenoids are also responsible for the bright yellow colour of mango (Vinci et al. 1995; Berardini et al. 2005; Schieber et al. 2000).

Mangoes are climacteric and ripen rapidly after harvest. Disease susceptibility, sensitivity to low storage temperatures (below 13°C), and perishability due to ripening and softening, limit the storage, handling and transport potential of the fruit (Mitra and Baldwin 1997). Mangoes are harvested commercially over a range of maturities including: immature green (dark green, no shoulders, ripens with poor quality), mature green (lighter green, shoulders formed, ripens with acceptable quality) and tree ripe (fruit that show colour breaking to red or orange-yellow, ripen with optimum quality) (Bender et al. 1997). External and internal quality is critical to consumer acceptability, and flavour is an important marketing consideration (Gholap et al. 1986).

Much research has focused on the use of postharvest treatments to extend shelf-life, for example with the addition of antioxidants (ascorbic acid), firming agents (calcium derivatives) and modified atmosphere packaging with reduced oxygen levels. Although, some of these treatments were found to be effective, consumers are increasingly demanding a reduction in the overall use of chemicals on fresh products and alternative methodologies should be investigated (Sarzi de Souza et al. 2006; Jacobi et al. 2001)

The atmosphere generated by modified atmosphere packaging (MAP) delays ripening of certain subtropical-tropical fruits, including mango (Kader 1994). The main factors that maintain mango quality in various film packaging are increased CO2 and decreased O2 levels, which reduce respiration rate and prevent water loss (Chaplin et al. 1982; Miller et al. 1983; Rodov et al. 1997 and Yuen et al. 1997). However, despite its success at the laboratory level (Chaplin et al. 1982; Miller et al. 1983; Rodov et al. 1997 and Yuen et al. 1997), MAP is still not a commercial technique. Some extension of shelf life has been demonstrated using controlled atmosphere (CA) storage (relatively low O2 and high CO2) (Bender et al. 1997). However, CO2 injury, increased ethylene production and flavour problems due to anaerobic respiration have also been reported (Lakshminarayana 1980 and Bender et al. 1997).

In addition to modified atmosphere storage, the use of heat treatments may provide other advantages. For example, pre-storage of ‘Keitt’ mangos in air at 38°C for 24 or 48 h was found to increase the tolerance of the fruit to chilling (McCollum et al. 1993). Recently, the use of hot water dip, vapour heating or heating in air, has increased in order to control insect pests, prevent fungal rots and increase resistance to chilling injury (Lurie 1998). Such heat treatments are also known to inhibit ripening, softening and improved postharvest quality. This was observed in the case of whole fruits, with apples (Klein and Lurie 1990), strawberries (Civello et al. 1997), citrus fruit (Porat et al. 2000) and mangoes (Jacobi and Giles 1997 and Benitez et al. 2006). However, reports on the effect of heat treatment on the physiology and quality of fresh mangoes are limited, as noted by Tefera et al. (2007) who suggest that most researchers have used this treatment in combination with other preservation methods to enhance quality and shelf life.

Although, some earlier researchers have employed low/high CO2 treatments to increase shelf life and quality of mangoes, (Ali et al. 1995; Ali et al. 2005; Mitcham and McDonald 1993; Ortega-Zaleta and Yahia 2000; Pesis et al. 2000; Beaulieu and Lea 2003; Sarzi de Souza et al. 2006; Kim et al. 2007), all these studies utilise controlled atmosphere or low carbon dioxide in modified atmosphere or when used high carbon dioxide in modified atmosphere, it is used for very short time span before storage conditions are set, whereas our study aims to look at the net effect of high CO2 concentrations under modified atmosphere along with film properties and different hot water dipping temperatures to improve the shelf life of mangoes stored at 10°C.

Materials and method

Mangoes (Mangifera indica), of the cultivar Alphonso were imported from a farm in Tamil Nadu (Southern India). This variety was selected because it is considered to be the best in terms of sweetness and flavour. Mature green mangoes, with a uniform size of 250 g ± 25 g, were selected to reduce variations among treatments. Then mango fruits were packed in well ventilated cardboard boxes to prevent suffocations which could lead to spoilage during transportation from India to UK by air cargo within 24 h of harvesting. The mature green samples were packed in soft tissue and hay to prevent excessive stress in addition to cardboard boxes. Once arrived in the UK, the mangoes were taken to the laboratory and placed on open trays for 24 h at 20°C for reconditioning of the fruit. Mango fruits were dipped in three water baths maintained at 20, 30 & 40°C (± 1°C) for 40 min with the temperature controlled throughout. The immersion time of 40 min was chosen to enable disintegration of ethylene synthesis enzymes (Kader et al. 1989).The mangoes were then cooled (10°C), washed and wiped clean, before uniformly sized fruits weighing to the nearest 500 g were selected and packed in bags (thickness 40 μm) made of two films: OPP (Oriented Polypropylene)—unperforated (1,100 cm3/m-2/d-1 O2, 2,700 cm3/m-2/d-1 transmission rates and 10 gm-2d-1 moisture permeability rates) and perforated (5,000 cm3/m-2/d-1 O2, 6,700 cm3/m-2/d-1 CO2 transmission rates and 10 gm-2d-1 moisture permeability rates). Ten drops of water were added to each bag in order to maintain uniform relative humidity, and the headspace was actively modified to contain three initial CO2 partial pressures with the overall pressure being atmospheric (25% by volume, 50% and 75%, the remaining being N2). Three replicate bags were prepared to investigate each treatment condition(three initial atmospheres, three hot water dipping treatments and two films) giving 54 bags in total which were stored at 10°C for 21 days. At the end of the experiment, the total weight loss, ascorbic acid, pulp firmness, colour measurement and sensory evaluation of the mango were performed.

Weight loss

Fruits were removed from the bag and weighed at the beginning and end of the 21 days storage. The weight loss was calculated and all the results shown represent means of three replicates ± S.E.

Ascorbic acid

Ascorbic acid (AsA) concentration was measured according to Kampfenkel et al. (1995), only scaled down for micro-plates (Power Wave HT, Bio. Tek). Ten cubes (approx. 8 g) of mango, per sample condition were taken and immediately frozen in liquid N2 before storage at −80°C. Prior to analysis, the samples were also ground under liquid N2 and the frozen fruit powder (0.3 g) was homogenized in 1 ml of 6% (w/v) TCA (Trichloroacetic acid). The homogenate was centrifuged at 16,000 g at 4°C for 15 min. The supernatant was used for AsA determination of which,10 μl was added to 40 μl of phosphate buffer (0.2 mM, pH 7,4) and 150 μl of a specific reagent (50 μl 10% TCA, 40 μl 42% (v/v) H3 PO4, 40 μl 4% (w/v) 2.2-bipyridyl dissolved in 70% ethanol and 20 μl 3% (w/v) FeCl3). After maintaining for 40 min at 42°C, the absorbance was measured at 525 nm in a micro-plate reader (Power Wave HT, Bio. Tek). Commercial l-ascorbic acid was used for calibration. The ascorbic acid was calculated and all the results shown represent means of three replicates ± S.E.

Pulp firmness

The maximum force (N) to rupture the pulp tissue (after removal of skin) was determined on one cheek of the fruit (three measurements/fruit), with a stable micro systems TA-XT2 texture analyzer (Texture Technologies Corp, NY) equipped with a 8 mm diameter probe penetrating at a velocity of 5 mms-1 to a final depth of 8 mm. The pulp firmness was calculated and all the results shown represent means of three replicates ± S.E.

Colour measurement

CIELAB colour values were obtained on the external (exocarp) tissue, with three measurements per fruit(on two opposite faces of the fruit (at the equator of the face) and the central part and averaged for each fruit., using a Minolta CR-2002 chromameter (Minolta, Osaka, Japan) with illuminant A and 10° viewing angle and calibrated on a white tile. The colour was expressed in terms of hue angle values (Mc Guire 1992). As fixed measurement points were selected on the fruit, a, b and L values seemed inaccurate, hence hue angles were calculated to determine colour formation. The colour measurement was calculated and all the results shown represent means of three replicates ± S.E.

Quality analysis

Mangoes on day 21 were rated for visual quality on a ten point scale with 10 representing firm & sweet to taste and the quality score ratings decreasing to 0 in the case of poorly ripened, squishy and inedible. Ten trained panellists reported the scores using three samples per condition, and the mean was used for results depiction. The quality analysis was performed and all the results shown represent means of three replicates ± S.E.

Statistical analysis

A factorial experiment design with three modified atmosphere modifications (25, 50, 75% CO2, balance N2), three hot water dipping temperatures (20, 30, 40°C for 40 min), two packaging films (OPP perforated and unperforated) and three replications were used in this study. Analysis of variance (ANOVA) using MINITAB package programme (MINITAB statistical software Inc, USA) was applied to each treatment combination. Interaction plots were also plotted using weight loss, firmness, and ascorbic acid and colour measurements and quality values as responses to the four main factors: initial CO2%, hot water dipping temperature, film and time where applicable to determine the best combination for maximum shelf life and good quality mangoes. The ‘P’ values determining the level of significance were represented where appropriate.

Results and discussion

Weight loss

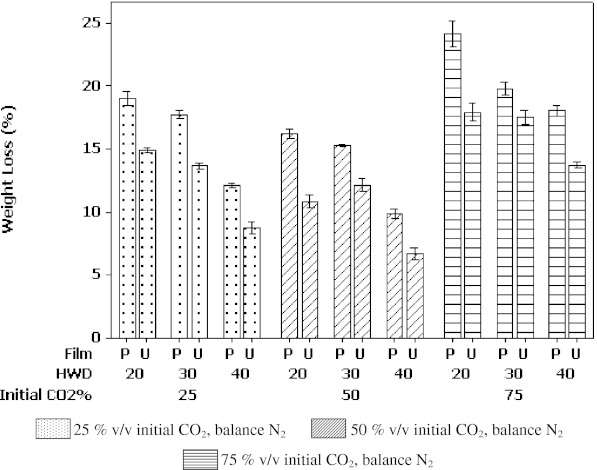

Maintaining the initial weight of the produce (before storage) is vital as an increase in weight loss shows deteriorated quality and poor quality of the produce. After 21 days of storage at 10°C, weight loss ranged between 9.9 to 25.9% (Fig. 1). Weight loss was slightly lower at 40°C than at other temperatures (20 and 30°C).

Fig. 1.

Effect of MAP (25, 50 & 75% v/v CO2) and HWD (20, 30 & 40°C) for 40 min on weight loss (%) of fresh mangoes packed in two different film packaging bags (Unperforated (U) & Perforated (P)) after 21 days of storage at 10°C. Each value calculated represents the mean of 3 replicates ± SE

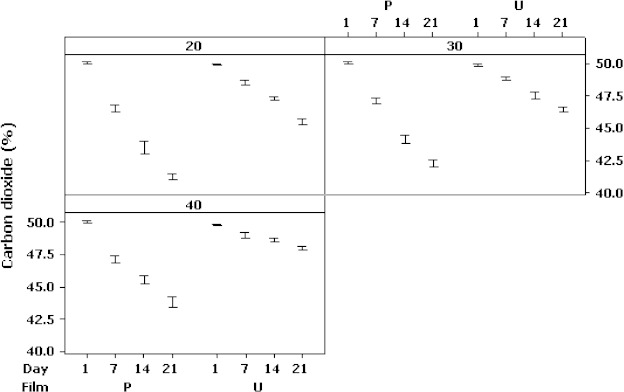

Headspace gas composition was monitored (Fig. 2) during the storage period. Figure 1, shows the initial headspace composition also influences weight loss (P < 0.001); mangoes packed in bags under 50% CO2 initially, seemed to show the least average weight loss (11.4%) followed by mangoes packed in bags with an initial 25% CO2 (14.9%) and 75% CO2 (18.7%); values stated within brackets are means taken across different film packages and hot water dipping treatments. The underlying reasons for why 50% CO2 was beneficial in extending shelf life of mangoes are still not fully understood. At this stage we can only provide a plausible explanation. On the one hand, we can expect carbon dioxide to be converted to carbonic acid upon contact with residual moisture within the package and lower the overall pH of the product (Maga 1995). This resulting decrease in the cytoplasmic pH plays an important role in regulating fermentative metabolism (Roberts et al. 1989). Also under these conditions, ethylene synthesizing enzymes get inactivated to prolong shelf life. On the other hand, very high CO2 levels can introduce physiological stress in the fruit and result in unfavourable values of ATP/ADP ratios (Nanos and Kader 1993). These factors strongly point to the existence of an optimum level of CO2 which, based on the present study, appears to be around 50%. Film packaging also played a significant role (P < 0.05), where mangoes packed in bags made of unperforated film material showed the least decrease in average weight loss (12.32%) when compared to mangoes packed in bags made with perforated film (17.2%) taken across different initial headspace compositions and hot water dipping treatments respectively. This can be attributed to the film characteristics which might have suited the overall respiration and metabolic activity of the mango packed in it.

Fig. 2.

Change in CO2% in the headspace in different film bags (U- unperforate & P –perforate) subjected to various HWD treatments (20, 30 & 40°C) for 40 min during storage of Alphonso mangoes over 21 days (Initial Gas Composition 50% v/v CO2). Each value calculated represents the mean of 3 replicates ± SE

It was also seen that the temperature of HWD (Hot Water Dipping) seemed to play a significant role (P < 0.005), where mangoes dipped in water maintained at 40°C seemed to show the least average weight loss (11.3%) followed by 30°C (16.1%) and 20°C (17.8%) taken across different initial headspace compositions and film packaging material respectively. This is consistent with literature reports which state that ethylene synthesising enzyme in fruits is inactivated at temperatures around 40°C (Gorny 1997; Kader et al. 1989).

Ascorbic acid

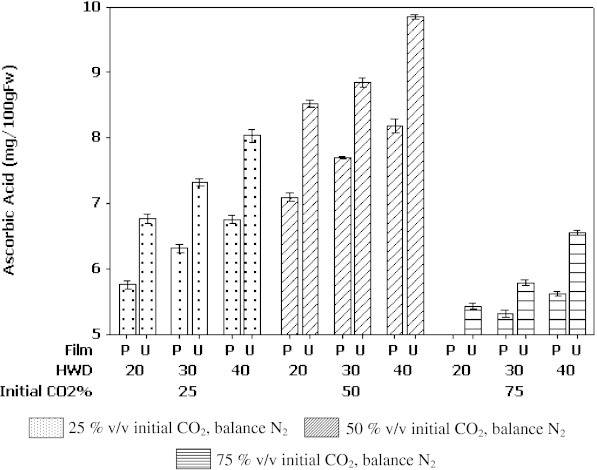

Fruits are natural source of ascorbic acid (AsA) (vitamin C) and it is known that its level decreases during processing and ripening (Kader 1994). Moreover, as the oxidative processes occur more rapidly in produce under stress, they are expected to show greater losses (Kader 1994). In the present study the AsA values ranged from 4.78 to 11.70 mg/100gFw.

Figure 3 shows AsA content of fruits stored under various conditions for 21 days of storage. The initial CO2% clearly influences AsA content (P < 0.03), with mangoes packed under 50% CO2 showed the average least decrease (2.15 mg/100gFw) followed by 25% CO2 (3.6 mg/100gFw) and 75% CO2 (4.8 mg/100gFw); the values are means taken across different film packaging and hot water dipping treatments.

Fig. 3.

Effect of MAP (25, 50 & 75% v/v CO2) and HWD (20, 30 & 40°C) for 40 min on the change in Ascorbic acid (AsA) content present in fresh mangoes packed in 2 film packaging bags (Unperforated (U) and Perforated (P)) after 21 days of the storage period at 10°C. Each value calculated represents the mean of 3 replicates ± SE. The initial ascorbic acid content of the mangoes had a value of 10.55 ± 0.56 in the present study

It was also seen that the film packaging played a role (P < 0.01), where mangoes packed in unperforated film showed the least average decrease (3.1 mg/100gFw) when compared to the mangoes packed in perforated film (4.3 mg/100gFw); the values are means taken across different initial headspace compositions and hot water dipping treatments.

Hot water dipping treatments also played a vital role (P < 0.05), with mangoes dipped in hot water maintained at 40°C showing the least average decrease (1.85 mg/100gFw) followed by 30°C (3.6 mg/100gFw) and 20°C (4.08 mg/100gFw); the values being means taken across various initial headspace compositions and film packaging material respectively. Djioua et al. (2009) have reported that ascorbic acid levels were higher in mangoes dipped in hot water (50°C/30 min) at the end of 9 days. However, with a proper time–temperature combination, like HWD 40°C/40 min, this decrease can be reduced and fresh-cut products can still contain significant amounts of vitamin C after storage for 21 days.

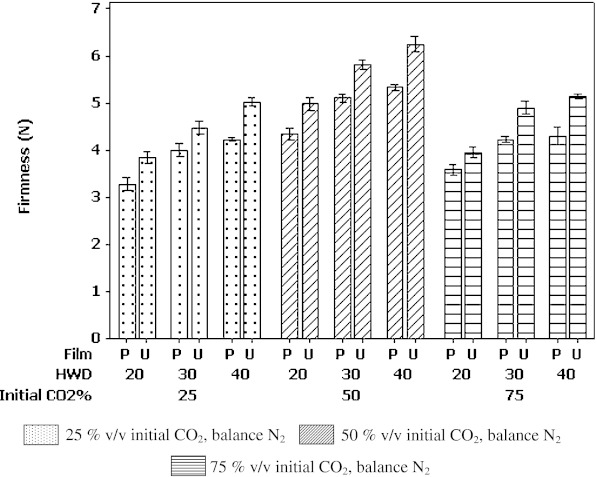

Pulp firmness

Firmness changes during the storage of mangoes are shown in Fig. 4. Although researchers have proposed that firmness loss during storage is due to the release of water within the fruit (Chatanawarangoon 2000; Shellie et al. 1997), the present experiment showed no significant water accumulation (estimated by drying samples at 80°C) during storage (data not shown). Firmness in mangoes ranged from 3.72 to 8.86 N (Fig. 3). As reported by many authors, the firmness loss could also be linked to the action of the softening promoting enzymes, such as polygalacturonase (Lazan et al. 1986), galactosidases (Ali et al. 1995), pectin methylesterase and β-1,4-glucanases (Ali et al. 2005).

Fig. 4.

Effect of MAP (25, 50 & 75% v/v CO2) and HWD (20, 30 & 40°C) for 40 min on the pulp firmness (N) of fresh mangoes packed in 2 different film packaging bags (Unperforated (U) & Perforated (P)) at the end of 21 days of storage at 10°C. Each value calculated represents the mean of 3 replicates ± SE. The initial value of firmness (N) of the raw mango fruit was 8.45 ± 0.43

It was seen that initial headspace CO2% played a significant role (P < 0.05), in determining the pulp firmness. Mangoes stored under 50% CO2 seemed to maintain flesh firmness (av. 5.5 N), followed by 25% CO2 (4.3 N) and 75% CO2 (3.9 N); the values being means taken across different film packaging and HWD treatments respectively.

Film packaging did not influence fruit firmness significantly with values of mangoes in unperforated film packaging (4.9 N) being marginally higher than mangoes packed in perforated film (4.4 N); the values being means taken across various initial headspace CO2 compositions and HWD treatments respectively.

Temperature of HWD treatments played a significant role (P < 0.001) in maintaining firmness of the flesh. According to Shalom et al. (1996), inhibition of solubilisation of the carbonate-soluble pectin fraction is one of the main factors contributing to firmness retention due to heat treatment. Several authors have reported this effect; Kim et al. (1993) have observed on several apple cultivars a significant maintenance of firmness depending on variety and heat treatment conditions. Abreu et al. (2003) have also shown that HWD 40°C/105 min maintained the firmness of fresh-cut ‘Rocha’ pears during 4 days storage at 2°C. Heat-treated kiwifruit at 45°C for 25 and 75 min also showed an increase in firmness (Beirão-da-Costa et al. 2006). Here it was seen that mangoes dipped in hot water at 40°C for 40 min showed greater firmness (5.32 N) followed by fruits dipped at 30°C (4.4 N) and 20°C (3.9 N); the values being means taken across different initial headspace compositions and film packaging respectively.

There it can be stated that cell wall integrity was maintained along with pulp firmness while employing higher temperature water dip, and this is due to the fact that under these conditions, along with ripening of fruit being inactivated, shrivelling and spoilage of fruit is in inhibited too (Kader 2003).

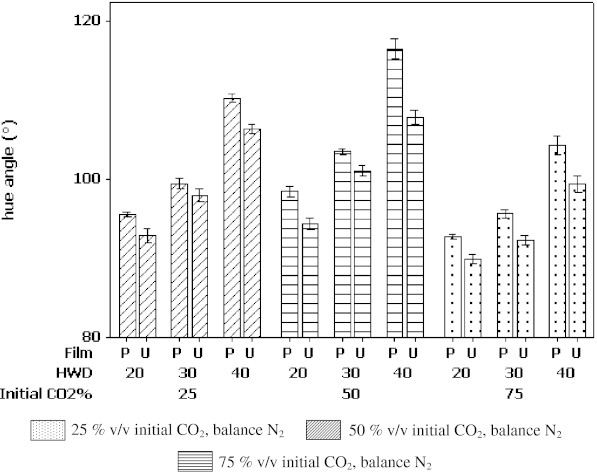

Colour

Although, fruit colour develops evenly, due to the fixed location of measurements, a and b measurement taken were not reported. The Hue angle was calculated and used for graphical depiction. ‘hue’ angle values (Fig. 5) increased during the 21 days storage compared to the initial value (av. 78.4°). The values increased as the hot water dipping temperature increased. Hue angle value, which is the angle from the + a axis to the ray from the origin to the a* and b* point, is a good estimate of the green to yellow colour turn (Mc Guire 1992). Generally, increasing the temperature increased the yellowness of the fruit (as indicated by the hue angle values). At the end of the 21 days storage period, the hue angle values ranged from 88.9 to 118.7 (Fig. 4). Initial CO2% played a significant role (P < 0.05), where in mangoes packed under initial 50% CO2 (av. 105.4°) turned to yellowish ripe fruit colour faster, followed by 25% CO2 (99.1°) and 75% (94.6°); the values being means taken across different film packaging and hot water dipping treatments.

Fig. 5.

Effect of MAP (25, 50 & 75% v/v CO2) and HWD (20, 30 & 40°C) for 40 min on the hue angle value (h) of fresh mangoes packed in 2 different film packaging bags (Unperforated (U) & Perforated (P)) at the end of 21 day storage at 10°C. Each value calculated represents the mean of 3 replicates ± SE. The initial hue angle value was 7.84° ± 0.62

Film packaging did not influence the colour change in mangoes vastly; the hue angle values of mangoes packed in perforated film packaging showed a marginal increase from (av. 101.9°) mangoes packed in unperforated film packaging (av. 98.04°); values being means taken across different initial headspace compositions and hot water dipping treatments.

Hot water dipping treatments although played a significant role (P < 0.01), where in mangoes initially dipped in water maintained at 40°C showed maximum colour change (av.108.2°), followed by 30°C (av. 96.4°) and 20°C (av. 91°); values being means taken across different initial headspace compositions and film packaging materials. This is coherent to various previous data which reports that high temperature hot water dipping (40°C±) is beneficial is maintaining uniform good ripening colour as similar of the mango compared to the mangoes at the start of the experiment (Ortega-Zaleta and Yahia 2000; Djioua et al. 2009; Jacobi et al. 2001).

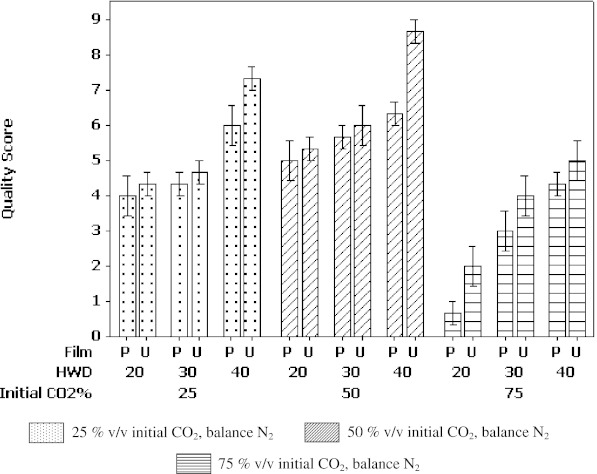

Subjective quality

Appearance is a major criterion for determining the acceptability of products. It is currently used as an indicator of freshness and quality in fresh-cut research and industry (Cantwell and Suslow 2002). In this study (Fig. 6), quality scores began to decrease after 15 days (data not shown) and further decreased at the end of the storage period of 21 days to score 0 (poorly ripened, squishy & inedible) respectively.

Fig. 6.

Effect of MAP (25, 50 & 75% v/v CO2) and HWD (20, 30 & 40°C) for min on the quality score of fresh mangoes packed in 2 different film packaging bags (Unperforated (U) & Perforated (P)) at the end of 21 day storage at 10°C. Each value calculated represents the mean of 3 replicates ± SE

Initial headspace CO2% played a significant role (P < 0.01), where in mangoes stored under initial 50% CO2 maintained good keeping quality (av. 7.1) followed by 25% CO2 (av. 5.1) and 75% (av. 3.1); the values being means taken across different film packaging and hot water dipping treatments respectively. Ortega-Zaleta and Yahia (2000) reported utilisation of 50% CO2 in controlled atmosphere but couldn't achieve the aim of their experiment.

Film packaging also played significant role (P < 0.05), where in mangoes packed in unperforated film (av. 6.8) showed better quality when compared to mangoes packed in perforated film (4.3); the values being means taken across various initial headspace compositions and HWD treatments respectively. Hot water dipping temperature treatments played a significant role (P < 0.03), wherein high temperature (40°C) showed significantly higher scores (av. 7.2) when compared to, dipping at 30°C (av. 4.6) and 20°C (av. 3.4) respectively. This result focused on the importance of a precise selection of time and temperature for a treatment to increase the keeping quality of fresh mangoes. Koukounaras et al. (2007) found that HWD 50°C/10 min applied 4 h before cutting improved the visual quality of fresh-cut peach. The present study selected 40°C/40 min HWD as an optimal combination to improve the visual quality of ‘Alphonso’ mangoes which kept the product visually acceptable for at least 21 days at 10°C. It was also noticed that that there was no water accumulating under these conditions, and off flavour development, mould formation and other forms of spoilage were minimum.

Conclusions

This study investigated the effects of different combinations of hot water dipping treatment (at 20, 30 & 40°C (±1°C) for 40 min), modified atmosphere (25, 50 & 75% v/v CO2) and film packaging material (Unperforated and Perforated) on the keeping quality of fresh mangoes stored over 21 days at 10°C. ‘Alphonso’ mango fruit did not suffer any injury when exposed to modified atmosphere (50% v/v CO2, balance 50% v/v N2) at 40°C for 40 min and then stored at 10°C for up to 21 days. However, fruits exposed to the other conditions investigated in this study showed signs of injury from day 12 onwards (including the control). A hot water dip (HWD) of 40°C/40 min enabled the mangoes to maintain the appearance and color over 21 days of storage at 10°C. Compared to the other hot water temperature/time combinations, HWD at 40°C for 40 min maintained firmness, weight loss, vitamin C content and improved the colour of the mangoes. It was also found that an initial headspace composition of 50% v/v CO2 was most effective in maintaining good keeping quality of mangoes over 21 days storage. Mangoes stored in unperforated bags appeared to be better than mangoes stored in perforated film bags under otherwise identical conditions. These results suggest that HWD of 40°C for 40 min combined with packing in unperforated film bags under 50% v/v CO2 atmosphere is highly effective method for achieving good keeping quality of fresh Alphonso mangoes.

References

- Abreu M, Beirão-da-Costa S, Concalves E, Beirão-da-Costa ML, Moldao-Marins M. Use of mild heat pre-treatments for quality retention of fresh-cut ‘Rocha’ pear. Postharvest Biol Technol. 2003;30:135–160. doi: 10.1016/S0925-5214(03)00105-4. [DOI] [Google Scholar]

- Ali ZM, Armugam H, Lazan H. β-Galactosidase and its significance in ripening mango fruit. Phytochem. 1995;38:1109–1114. doi: 10.1016/0031-9422(94)00804-3. [DOI] [PubMed] [Google Scholar]

- Ali ZM, Chin LH, Lazan L. A comparative study on wall degrading enzymes pectin modifications and softening during ripening of selected tropical fruits. Plant Sci. 2005;167:317–327. doi: 10.1016/j.plantsci.2004.03.030. [DOI] [Google Scholar]

- Beaulieu JC, Lea JM. Volatile and quality changes in fresh-cut mangos prepared from firm-ripe and soft-ripe fruit, stored in clamshell containers and passive MAP. Postharvest Biol Technol. 2003;30:15–28. doi: 10.1016/S0925-5214(03)00081-4. [DOI] [Google Scholar]

- Beirão-da-Costa S, Steiner A, Correia L, Empis J, Moldão-Martins M. Effects of maturity stage and mild heat treatments on quality of minimally processed kiwifruit. J Food Eng. 2006;76:616–625. doi: 10.1016/j.jfoodeng.2005.06.012. [DOI] [Google Scholar]

- Bender RJ, Brecht JK, Baldwin EA, Malundo, T (1997) Effects of controlled atmosphere storage on aroma volatiles of ‘Tommy Atkins’ mangoes; In: Kader AA (Eds.), Proceedings of the Seventh International Controlled Atm. Research Conference, vol. 3, Davis, CA, 13–18 July, p 82

- Benitez MM, Acedo AL Jr., Jitareerat P, Kanlavanarat P (2006) Mango fruit softening response to postharvest heat treatment. Acta Hort 712:811–816

- Berardini N, Fezer R, Conrad J, Beifuss U, Carle R, Schieber A. Screening of mango (Mangifera indica L.) cultivars for their contents of flavonol O- and xanthone C-glycosides, anthocyanins, and pectin. J Agric Food Chem. 2005;53:1563–1570. doi: 10.1021/jf0484069. [DOI] [PubMed] [Google Scholar]

- Cantwell MI, Suslow TV. Postharvest handling systems: fresh-cut fruits and vegetables. In: Kader AA, editor. Postharvest technology of horticultural crops. Davis: University of California; 2002. pp. 445–463. [Google Scholar]

- Chaplin GR, Scott KJ, Brown BI. Effects of storing mangoes in polyethylene bags at ambient temperature. Singapore J Pr. Ind. 1982;10:84–88. [Google Scholar]

- Chatanawarangoon S (2000) Quality maintenance of fresh-cut mango slices, Master Thesis, Davis University of California, CA

- Civello PM, Martinez GA, Chaves AR, Anon MC (1997) Heat treatment delay ripening and postharvest decay of strawberry fruit. J Agric Food Chem 45(12):4589–4594

- Djioua T, Charles F, Lopez-Lauri F, Filgueiras H, Coudret A, Freire M, Jr, Ducamp-Collin MN, Sallanon H. Improving the storage of minimally processed mangoes (Mangifera indica L.) by hot water treatments. Postharvest Biol Technol. 2009;52:221–226. doi: 10.1016/j.postharvbio.2008.10.006. [DOI] [Google Scholar]

- Food and Agriculture Organization (2005) FAOSTAT database collections, agricultural data, food and agriculture organization of the United Nation

- Gholap AS, Bandyopadhyay C, Nadkarni GB. Aroma development in mango fruit. J Food Biochem. 1986;10:217–229. doi: 10.1111/j.1745-4514.1986.tb00101.x. [DOI] [Google Scholar]

- Gorny JR (1997) A summary of CA and MA requirements and recommendations for the storage of fresh-cut (minimally processed) fruits and vegetables. Proc. Seventh International Controlled Atmosphere Research Conference; Davis, CA, July 13–18, 1997 Vol. 5: Fresh-Cut Fruits and Vegetables and MAP. Postharvest Horticulture Series No. 19, University of California at Davis, pp: 30–66

- Grundhofer P, Niemetz R, Schilling G, Gross GG. Biosynthesis and sub cellular distribution of hydrolysable tannins. Phytochem. 2001;57:915–927. doi: 10.1016/S0031-9422(01)00099-1. [DOI] [PubMed] [Google Scholar]

- Haard NF, Chism GW. Characteristics of edible plant tissues. In: Fennema OR, editor. Food Chemistry. 3. New York: Marcel Dekker; 1996. pp. 943–1011. [Google Scholar]

- Jacobi KK, Giles JE (1997) Quality of ‘Kensington’ mango (Mangifera indica Linn.) fruit following combined vapour heat disinfestation and hot water disease control treatments. Postharvest Biol Technol 12:285–292

- Jacobi KK, MacRae EA, Hetherington SE. Postharvest heat disinfestation treatments of mango fruit. Scientia Hort. 2001;89:171–19. doi: 10.1016/S0304-4238(00)00240-5. [DOI] [Google Scholar]

- Johnson GI, Sharp JL, Mine DL, Oostluyse SA (1997) Postharvest technology and quarantine treatments. In: Litz RE (Ed), The Mango: Botany, Production and Uses, Tropical Research and Education Center, USA

- Kader AA (1994) Modified and controlled atmosphere storage of tropical fruits. In: Champ BR, Highley E, Johnson GI (Eds.), ACIAR Proceedings, vol. 50: Postharvest Handling of Tropical Fruits, Thailand, p 239–249

- Kader AA. Physiology of CA treated produce. Acta Hort. 2003;600:349–354. [Google Scholar]

- Kader AA, Zagory D, Kerbel EL. Modified atmosphere packaging of fruits and vegetables. Crit. Rev. Food Sci. Nut. 1989;28:1–27. doi: 10.1080/10408398909527490. [DOI] [PubMed] [Google Scholar]

- Kampfenkel K, Van Montagu M, Inze D. Extraction and determination of ascorbate and dehydroascorbate from plant tissue. Anal Biochem. 1995;225:165–167. doi: 10.1006/abio.1995.1127. [DOI] [PubMed] [Google Scholar]

- Kim DM, Smith NL, Lee CY. Apple cultivar variations in response to heat treatment and minimal processing. J Food Sci. 1993;58:1111–1124. doi: 10.1111/j.1365-2621.1993.tb06126.x. [DOI] [Google Scholar]

- Kim Y, Brecht JK, Talcott ST. Antioxidant phytochemical and fruit quality changes in mango (Mangifera indica L.) following hot water immersion and controlled atmosphere storage. Food Chem. 2007;105:1327–1334. doi: 10.1016/j.foodchem.2007.03.050. [DOI] [Google Scholar]

- Klein JD, Lurie S (1990) Prestorage heat treatment as a means of improving post storage quality of apples. J Am Soc Hortic Sci 115:265–269

- Koukounaras A, Diamantidis G, Sfakiotakis E. The effect of heat treatment on quality retention of fresh-cut peach. Postharvest Biol Technol. 2007;48:30–36. doi: 10.1016/j.postharvbio.2007.09.011. [DOI] [Google Scholar]

- Lakshminarayana S, Subramanyam H. Carbon dioxide injury and fermentative decarboxylation in mango fruit at low temperature. J Food Sci Technol. 1970;7:148–152. [Google Scholar]

- Lazan H, Ali Z, Lee K, Voon J, Chaplin G. The potential role of polygalacturonase in pectin degradation and softening of mango fruit. ASEAN Food J. 1986;2:93–95. [Google Scholar]

- Lurie S (1998) Postharvest heat treatments. Postharvest Biol Technol 14:257–269

- Maga JA (1995) Influence of dips, modified atmospheric packaging, and storage time on the enzymatic discoloration of processed raw potatoes. Food Flavours, Ingredients and Composition 37A: 491–495

- McCollum TG, Daquino S, McDonald RE (1993) Heat treatment inhibits mango chilling injury. HortScience 28:197–198

- Mc Guire RG. Reporting of objective color measurements. HortScience. 1992;27:1254–1255. [Google Scholar]

- Miller WR, Hale PW, Spaldling DH, Davis P. Quality and decay of mango fruit wrapped in heat-shrinkable film. HortScience. 1983;18:957–958. [Google Scholar]

- Mitcham EJ, McDonald RE. Respiration rate, internal atmosphere, and ethanol and acetaldehyde accumulation in heat-treated mango fruit. Postharvest Biol Technol. 1993;3:77–86. doi: 10.1016/0925-5214(93)90029-3. [DOI] [Google Scholar]

- Mitra SK, Baldwin EA. Mango. In: Mitra SK, editor. Postharvest physiology and storage of tropical and subtropical fruits. New York: CAB; 1997. pp. 85–122. [Google Scholar]

- Nanos GD, Kader AA. Low O2 induced changes in pH and energy change in pear fruit tissue. Post Harvest Biol Technol. 1993;3:285–291. doi: 10.1016/0925-5214(93)90063-9. [DOI] [Google Scholar]

- Ortega-Zaleta D, Yahia EM. Tolerance and quality of mango fruit exposed to controlled atmospheres at high temperatures. Postharvest Biol Technol. 2000;20:195–201. doi: 10.1016/S0925-5214(00)00137-X. [DOI] [Google Scholar]

- Pesis E, Aharoni D, Aharon Z, Ben-Arie R, Aharoni N, Fuchs Y. Modified atmosphere and modified humidity packaging alleviates chilling injury symptoms in mango fruit. Postharvest Biol Technol. 2000;19:93–101. doi: 10.1016/S0925-5214(00)00080-6. [DOI] [Google Scholar]

- Porat R, Pavoncello D, Peretz, J Ben-Yehoshua S, Lurie S (2000) Effects of various heat treatments on the induction of cold tolerance and on the postharvest qualities of “Star Ruby” grapefruit. Postharvest Biol Technol 18:159–165

- Roberts JKM, Chang K, Webster C, Callis J, Walbot V. Dependence of ethanolic fermentation, cytoplasmic pH regulation and viability on the activity of alchohol dehydrogenase in hypoxic maize roots. Plant Physiol. 1989;89:1275–1278. doi: 10.1104/pp.89.4.1275. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rodov V, Fishman S, De la Asuncion R, Peretz J, Ben Yehoshua S. Modified atmosphere packaging (MAP) of ‘Tommy Atkins’ mango in perforated films. Acta Hort. 1997;455:654–661. [Google Scholar]

- Sauco VG. Mango production and world market: current situation and future prospects. Acta Hort. 2004;45:107–116. [Google Scholar]

- Schieber A, Ullrich W, Carle R. Characterization of polyphenols in mango puree concentrate by HPLC with diode array and mass spectrometric detection. Innovative Food Sci Emerg Technol. 2000;1:161–166. doi: 10.1016/S1466-8564(00)00015-1. [DOI] [Google Scholar]

- Shalom NR, Hanzon J, Pinto R, Lurie S. Cell wall changes and partial prevention of fruit softening in prestorage heat treated ‘Anna’ apples. J Sci Food Agric. 1996;72:231–234. doi: 10.1002/(SICI)1097-0010(199610)72:2<231::AID-JSFA644>3.0.CO;2-A. [DOI] [Google Scholar]

- Shellie C, Mangan RL, Ingle SJ. Tolerance of grapefruit and Mexican fruit fly larvae to heated controlled atmospheres. Postharvest Bio Technol. 1997;10:179–186. doi: 10.1016/S0925-5214(96)01306-3. [DOI] [Google Scholar]

- Tefera A, Seyoum T, Woldetsadik K. Effect of disinfection packaging, and storage environment on the shelf life of mango. Biosystems Eng. 2007;96:201–212. doi: 10.1016/j.biosystemseng.2006.10.006. [DOI] [Google Scholar]

- Vinci G, Botre F, Mele G, Ruggieri G. Ascorbic acid in exotic fruits: a liquid chromatographic investigation. Food Chem. 1995;53:211–214. doi: 10.1016/0308-8146(95)90791-5. [DOI] [Google Scholar]

- Youngmok Kim, Jeffrey K Brecht, Stephen T Talcott (2007) Antioxidant phytochemical and fruit quality changes in mango (Mangifera indica L.) following hot water immersion and controlled atmosphere storage. Food Chemistry 105:1327–1334

- Yuen CMC, Tan SC, Joyce D, Chettri P. Effect of postharvest calcium and polymeric films on ripening and peel injury in ‘Kensington Pride’ mango. ASEAN Food J. 1997;8:110–113. [Google Scholar]