Abstract

This review paper included the recent progress made in heat pump assisted drying, its principle, mechanism and efficiency, type and its application for drying of agricultural produce. Heat pump assisted drying provides a controllable drying environment (temperature and humidity) for better products quality at low energy consumption. It has remarkable future prospects and revolutionaries ability. The heat pump system consists of an expansion valve, two heat exchangers (evaporator and condenser), and a compressor, which are connected by using copper tubes. In this paper we also provided a review discussion on different type of heat pump assisted drying system ready for remarkable and commercial use in different type of food industries. Here we also have given some major advantage and disadvantage of heat pump assisted drying.

Keywords: Heat pump, Assisted drying, Fruits and vegetables, Efficiency and control

Introduction

Drying is an indispensable process in many food industries and in many agricultural countries, the large quantities of food products are dried to improve shelf life, reduce packaging cost, lower shipping weights, enhance appearance, encapsulate original flavour and maintain nutritional value (Chou and Chua 2001). The primary objective of drying is to remove moisture from the food so that bacteria, yeast and mold cannot grow and spoil the food. The economic consideration, environmental concerns and product quality aspects are the main three fold goal of drying process research in food industry (Okos et al. 1992). The big market for dehydrated fruits and vegetables increases importance of drying for most of the countries worldwide (Funebo and Ohlsson 1998). For example, the dehydrated products and their market worth of some countries are given in the Table 1.

Table 1.

Dehydrated products and their worth

India’s export of dried and preserved vegetables has increased from Rs. 364.11 crores (USD Million 82.25) in 2005–06 to Rs.424.06 crores (USD Million 94.07) in 2006–07. The major importers of Indian dried and preserved vegetables are Russia, France, U.S.A, Germany and Spain. So, to obtain good economic return, the proper long term storage of fruits and vegetables required. For this, these products need to be dried to low moisture contents (Anon 2009).

However, drying slows down the action of enzymes (naturally occurring substances which cause foods to ripen), but does not inactivate them, and also these methods of drying allows some lowering in nutritional value of the products e.g. loss of vitamin C, and changes of colour (Arabhosseini et al. 2010) and appearance that might not be desirable. For example, air-drying is the most common method in the drying of foodstuffs but this method leads to serious injuries such as the worsening of the taste, colour and nutritional content of the product, decline in the density and water absorbance capacity and shifting of the solutes from the internal part of the drying material to the surface, due to the long drying period and high temperature (Yongsawatdigul and Gunasekaran 1996; Lin et al. 1998; Maskan 2001). To avoid all these discrepancies, drying should be in control manner.

Nevertheless, control is the word of well being for everyone and for everything i.e. experiment/or activity/or function, when we follow and apply it in our daily life. Often human being as well as all other living organism does feel very well when they found themselves in controlled atmosphere. In the same way, when we do any experiment/research in controlled atmosphere/process, the result do found excellent than the uncontrolled environment/process. Ultimately, if we talk about controlled technologies the result will be not only economical, efficient and time saving but also should have good quality. So, by adopting such technologies, we can save energy and time, which is today’s demand. Heat pump assisted drying is an example of one of such technologies in which temperature and humidity do control. The other conventional dryers found in the food industry are spray dryers, freeze dryers, vacuum dryers, tray dryers, rotary dryers, fixed bed dryers, fluidized bed dryers, etc. (Mujumdar and Law 2010).

Drying is an ancient, popular and well known unit operation or method for preservation of food materials. But due to more energy and time consumption it has limited application for drying of fruits and vegetables i.e. higher moisture content food material/more susceptible to perish. While in the case of heat pump assisted drying, it is an energy-efficient process because the heat is recoverable and has lowest operating cost. However, the economic feasibility of the heat pump dryer (HPD) is debatable so far, because of using high grade energy (electricity) and now a question is arising which drying system will be more feasible and efficient, and how it can be recognise etc. Although tray, rotary, flash, spray, fluidized bed, vacuum, freeze and batch dryers are classified as conventional, there is great number of areas suitable for further improvement. Mujumdar (2007b) has identified various areas and aspects that need further research and development efforts. Some of the areas (including limitations) and characteristics addressed by researchers in recent years have been given in the Table 2.

Table 2.

General characteristics of some conventional dryers and suggested areas for further improvement

| Dryer type | General characteristics | General characteristics |

|---|---|---|

| Tray | Materials are placed on trays and directly make contact with drying medium (typically hot air) | Uniformity of air flow distribution |

| Heat transfer mode is typically convective. | Uniformity of final product quality and moisture content | |

| Conductive is possible by heating tray | Hybrid mode by combining with the microwave heat input | |

| Rotary | A cylindrical drying chamber rotates while material tumble in the chamber | Precise prediction of particle motion, particle residence time distribution and uniformity of final moisture content |

| Drying medium (typically hot air) is charged into the chamber contacts the material in cross flow | Effect of polydispersity and cohesiveness of solids on drying kinetics | |

| Flights are used to lift the material | Design of flights, internal heat exchangers, delumpers | |

| Internal heat exchangers installed to allow conductive heat transfer | Effect of solid holdup and hot air injection on drying kinetics | |

| Model-based control | ||

| Flash | Flash dryer is used to remove surface moisture. Material is charged into a fast moving drying medium stream, drying occurs while the drying medium conveys the material pneumatically | Modeling of particle motion including effects of agglomeration attrition and geometry of dryer |

| Cyclone is normally used to separate the drying medium and the material | Use of pulse combustion exhaust, superheated steam, internal heat exchangers, variable cross-section ducts, hot air injection along length of dryer duct | |

| Spray | Atomizer mounted on top of a drying chamber sprays liquid/suspension and forms droplets | Effects atomizer design on droplet trajectories, product properties, agglomeration, size reduction |

| Drying medium (typically hot air) is supplied into the chamber concurrently or counter currently | Effect of chamber geometry | |

| Hot air exits the chamber at the chamber outlet and carries dried powder | Injection of supplementary air | |

| Separation of hot air and powder takes place in Cyclone | Use of superheated steam | |

| Uniformity of product quality and final moisture content | ||

| Fluidized Bed | Similar to fixed bed dryer but operating hot air velocity is higher to ensure the particles are suspended in the sir stream | Effect of particle moisture content/polydispersity on fluidization hydrodynamics, agglomeration, heat and mass transfer |

| Large contacting surface areas between the drying medium and the material if compare with fixed bed dryer | Effect of agitation, vibration, pulsation, acoustic, radiation on drying kinetics and characteristics | |

| Conventional fluidized bed is not suitable for drying fine powders (due to channeling and slugging) and coarse particles (due to formation of big bubbles) | Design of internal heat exchangers | |

| However, modified FBD such as vibrating FBD, agitating FBD, etc. can be used to dry difficult-to-fluidized particles | Classification of particle type based on fluidization quality at varying particle moisture content and stickiness | |

| If the materials are polydispersed, the hot air stream may carries over some fine particles | Mathematical modeling of fluidization hydrodynamics, heat and mass transfer by taking into account agitation, vibration, pulsation, internal heat exchanger, varying particle moisture content, etc. | |

| A cyclone is used to separate the fine particles from the gas stream | Over 30 variants possible | |

| Vacuum | Need to maintain high vacuum; expensive | Combined mode of heat transfer, e.g., MW vacuum drying |

| Drying chamber is operated at reduced pressure or vacuum | Hybrid drying, e.g., vacuum superheated steam drying, etc. | |

| Boiling point of water/solvent is reduced thus reducing the operating temperature | Use of internal heating media | |

| However, absence of drying medium in the vacuum drying chamber disables convective heat transfer but enhances mass transfer at low temperatures | Enhancement in drying kinetics by incorporating radiant heat input, internal heating media, etc. | |

| Freeze | Vacuum freeze drying is expensive in terms of capital costs and operating costs due to very low vacuum required at very low temperature | Use of magnetic/electric/acoustic fields to control nucleation and crystal size of ice during freezing; permits better quality product |

| Drying times are long; most operated batchwise | ||

| Suitable only for very high value products like pharmaceutical products | ||

| Batch dryer | Not all dryers can operate in batch mode | Effects of intermittent/cyclic/variable heat inputs and variable operating profiles on drying kinetics and characteristics as well as product quality |

| Good for low capacity needs | Use of heat pump including chemical heat pump | |

| Tray, rotary, drum, fixed bed, fluidized bed vacuum dryers etc. can be operated batchwise | Reduction in labor costs | |

| Model-based control | ||

| Intermittent drying |

Mujumdar and Law (2010)

Furthermore, far better results and to complete all, our today’s need, reasons of recommendation for selection of heat pump assisted drying, the most rapid emerging technology, for agricultural produce are given in this paper. In this paper we have provided a basis and reasons of advocating of heat pump assisted drying. Since the selection of drying equipment and method should be governed on the basis of low energy consumption. Prasertsan and Saen-saby (1998) have showed that heat pump drying (HPD) had the lowest operating cost when compared to electrically heat convective dryers and direct-fired dryers. Reay and MacMichael (1988), Mc Mullen and Morgan (1981) and Heap (1979) have dealt with the fundamentals of operation and applications of heat pump. Some recent work conducted on heat pump drying of selected food products has been given in Table 3.

Table 3.

Recent work conducted on heat pump drying of selected food products

| Researchers | Application(s) | Conclusions |

|---|---|---|

| Meyer and Greyvenstein (1992) (South Africa) | Grain | There is a minimum operating period that makes the HPD more economical than other dryers |

| Rossi et al. (1992) (Brazil) | Vegetable (onion) | Drying of sliced onions confirmed energy saving of the order of 30% and better product quality due to shorter processing time. |

| Mason and Blarcom (1993) (Australia) | Macadamia nuts | – |

| Strommen and Kramer (1994) (Norway) | Marine products (fish) | The high quality of the dried products was highlighted as the major advantage of HPD and introducing a temperature controllable program to HPD makes it possible to regulate the product properties such as porosity, rehydration rates, strength, texture and colour. |

| Prasertsan and Saen-saby (1998); Prasertsan et al. (1997) (Thailand) | Agricultural food drying (Bananas) | HPD is suitable for drying high moisture materials and the running cost of HPD is cheap making them economically feasible |

| Chou et al. (1998, 2001); Chua et al. (2000) (Singapore) | Agricultural and marine | The quality of the agricultural and marine products can be improved with scheduled drying conditions |

| Products (mushrooms, fruits, sea-cucumber and oyster) | ||

| O’Neill et al. (1998) (New Zealand) | Apple | Produces products with a high level of open pore structure and contributing to the unique physical properties |

| Strommen et al. (1999) | – | HPD with hydrocarbon and natural working fluids can save significant amounts of energy; ammonia was found most favorable refrigerant in the temperatures (30–80 °C). |

| Oktay et al. (2003) (Turkey) | Wool | The SMER was between 0.65 and 1.75 kg/kWh. COP was between 2.47 and 3.95. |

| Teeboonma et al. (2003) (Thailand) | Fruits (papaya and mango glace) | Developed and validated mathematical models; the effects of initial moisture content, cubic size and effective diffusion coefficient of products on the optimum conditions of HPD are also investigated. Exergy and energy analysis was made. |

| Kohayakawa et al. (2004) (Brasil) | Mango | The energy efficiency improved compared with an electrical resistance dryer |

| Hawlader et al. (2006) (Singapore) | Apple, guava and potato | Modified atmosphere heat pump dryer produced better physical properties. |

| Chegini et al. (2007) (Iran) | Plum | Optimum temperature of drying for plums is in vicinity of 70–80 °C; also SMER was notably more than conventional dryers. |

| Aktaş et al. (2009) (Turkey) | Apples | A system which is composed of the combination of both dryers is considered to be more efficient |

Daghigh et al. (2009)

Heat pump assisted drying

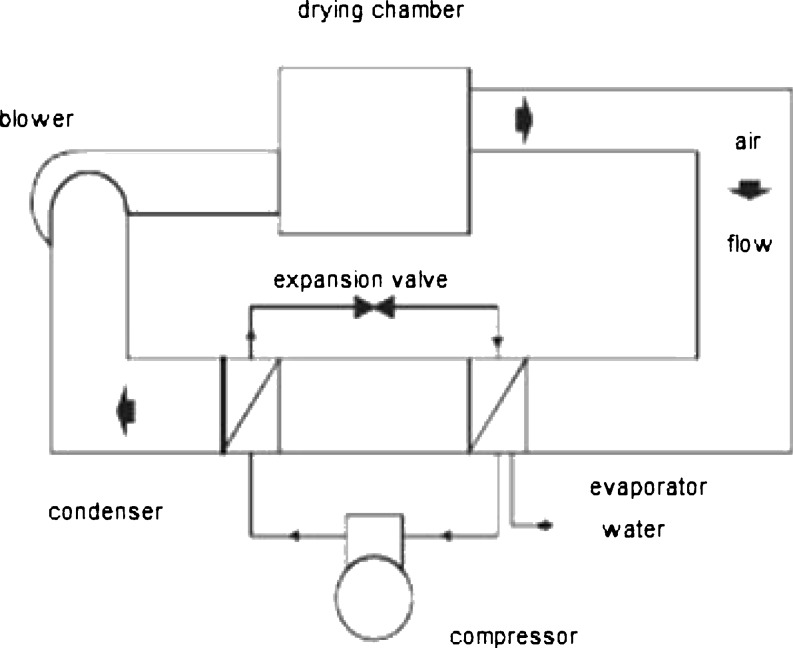

Heat pump-assisted drying is a type of hybrid or combined drying. Hybrid or combined drying technologies include implementation of different modes of heat transfer, two or more stages of the same or different type of dryer. The heat pump assisted drying get by addition of heat pump to the drying processes that can be made in several different ways and also there are some of the most promising methods, heat pump drying and heat pump assisted drying, being used in food industries so far. In these methods, the efficiency of drying concerning both energy, time of process, and dictates intensive research. Since, the amount of heat absorbed by a wet material in a dryer varies from 5 to 10% of the supplied energy (Lazzarin 1994, 1995). The 95–90% of this energy may be recovered by means of a heat pump assisted drying, leading to substantial energy savings. Vázquez et al. (1997) suggested that the use of driers with heat pump as an alternative method to dry fruits and vegetables with lower values in consumption of energy, relative humidity and temperatures. According to Best et al. (1996), the low temperature and better control in the heat pump assisted drier showed several advantages. So, heat pump assisted drying is an excellent alternative to traditional drying systems. The test of a R-114 heat pump dehumidification system was carried out by Tai et al. (1982a, b) and it has been proved that the heat pump assisted drying is more efficient and a lot of theoretical analysis of heat pump assisted dryers can also be found in literatures. Figure 1 shows, a typical arrangement for a heat pump assisted dehumidifier.

Fig. 1.

Schematics diagramme of a heat pump assisted dehumidifier (Reay 1979; Reay and Macmichael 1979)

For the better result, Cartwright (1987) described the modelling of the heat pump assisted dryer and Baines and Carrington (1988) conducted a simulation analysis where they were studied different configurations and the effects of modifications of basic design. In the heat pump assisted drying process two component viz., the heat pump and the actual drying material, treated separately (Alves-Felho et al. 1998). The basic design, principles and mechanism of heat pump assisted dehumidification can be found in literatures provided by Reay 1979, and Reay and MacMichael 1979. Furthermore, heat pump drying can also be incorporated with other drying methods such as spray drying (Alves-Filho et al. 2009), atmospheric freeze drying (Alves-Filho and Eikevik 2009; Bantle et al. 2009), and solar drying (Chen et al. 2008). Table 4 shows an overview of some heat pump assisted dryers, applications, conclusion of the systems and references used in the agricultural sector.

Table 4.

Summary of some heat pump assisted dryer (HPAD)/related work to HPAD in agricultural sector

| HP assisted dryer/related work to HPAD | Application | Conclusion | References |

|---|---|---|---|

| HP dehumidifier assisted dryer | Grain | Mechanically feasible but not attractive economically due to low fuel prices prevailing at the time. | Flikke et al. (1957) |

| HP assisted dryer | Grain | Marginal energy saving but has some economic drawback (high capital cost), over drying and risk of spoilage due to mold growth. | Brook (1986) |

| HP assisted Dryer | Seed | Accelerated drying process without elevating the temperature, less expensive to operate than traditional natural gas fired systems and produces high quality seed. | Fritz et al. (1990) |

| HP assisted microwave dryer | Sliced carrot and whole root ginger | Higher product through put with low SMER. | Jia et al. (1993) |

| HP assisted fluidized bed dryer | Pharmaceutical products, fruits and vegetables | Low energy consumption due to high SMER and COP, and high products quality | Alves-Filho and Strommen (1996a, b, c) |

| Close loop solar assisted HP dryer | Material sensitive to the direct sunlight | Control temperature and humidity in the drying chamber. Since system deal with environmental changes. | Zafri et al. (2007) |

| Simulation model of HP assisted dryer | Garlic and white mulberry leaves | Applicable to drying herb, adaptable to examine effects of humidity and temperature of dried air to calculate the yield of the dried products with low deviation | Phoungchandang (2009) |

Principle and mechanism

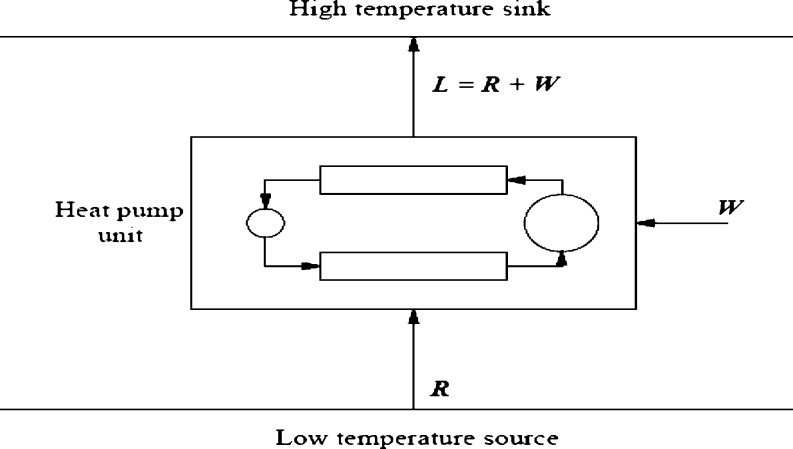

The basic principle of heat pump assisted drying (hybrid) is same as that of heat pump drying (pure) heat pump can be thought of as a heat engine operating in reverse (Lu 2007). The heat pump works on the principle of refrigeration that cools an air stream and condenses the water contained in it. This renders the air dry and recovers the latent heat of evaporation through water vapour removal which permits air recirculation. According to Gac et al. (1988), heat pump is a thermodynamic system whose function is to heat at the required temperature with the aid of heat extracted from a source at lower temperature. So, heat pump is such device which designed to utilise low temperature sources of energy which exist in atmospheric air, lake or river water and in the earth. These sources are referred to as “ambient energies”. Heat pump can also be operated using “waste heat” from commercial and industrial processes (Newbert 1985) and thereby upgrading this to the required temperature level for some thermal process operations (Mc Mullen and Morgan 1981) and since heat pump is an electric device with both heating and cooling capabilities. It extracts heat from one medium at a lower temperature (a low grade source) and transfers it to another at a higher temperature (high grade sink), thereby cooling the first and warming the second (Lu et al. 2005) (Fig. 2).

Fig. 2.

Energy flow from low temperature source to high temperature sink (Lu et al. 2005)

The heat pump dryer consists of a conventional drying chamber with an air circulation system and the usual components of an air-conditioning refrigeration system. The drying air is dehumidified by the evaporator (cooling section of the refrigeration cycle) and reheated by the condenser of the heat pump. The maximum drying temperature is determined by the condensing temperature of the refrigerant used. Heat pump drying is essentially a low-temperature process which can be controlled from −20 °C to 70 °C by selecting an appropriate refrigerant and regulating the compressor capacity and air flows within the system. In the preliminary studies, the dried products quality compared between the heat pump dried and hot air dried products, and proved that the color and aroma of the first ones are better (Prasertsan and Saen-saby 1998). Still many works have been done to increase the efficiency of the drying by convection, mainly using heat pumps and the succeeding research gave an idea of heat pump assisted-drying that provides a controllable drying environment (temperature and humidity) for better products quality at low energy consumption.

Further advancements have been made in heat pump drying which employ loop thermosyphons, which are a type of heat pipe (Phaphuangwittayakul et al. 2000). A loop thermosyphon consists of evaporator and condenser sections, with tubes connecting the two sections. When the working fluid is condensed, it is returned to the evaporator due to gravity (Phaphuangwittayakul et al. 2002). Phaphuangwittayakul et al. (2000) placed the loop thermosyphon around the evaporator of the heat pump dryer, to first pre-cool the air before entering the heat pump evaporator and then reheat the air after the evaporator. Phaphuangwittayakul et al. (2002) numerically studied the effects of by-pass air ratios and the fraction of recirculation air on the heat transfer characteristics of a heat pump dryer, with and without a loop thermosyphon. Phaphuangwittayakul et al. (2003) furthered their research by building a heat pump dryer with a loop thermosyphon to dry longan fruit. However, according to Baker (1997), heat pump drying is an extremely expensive drying process. To solve this problem Chua et al. (2002a) suggested that the break even period for initial capital cost can be significantly reduced through lower operating cost and higher output volume. Chua et al. (2002a) further stated that the performance of any dryer can be defined with respect to its capacity or energy effectiveness.

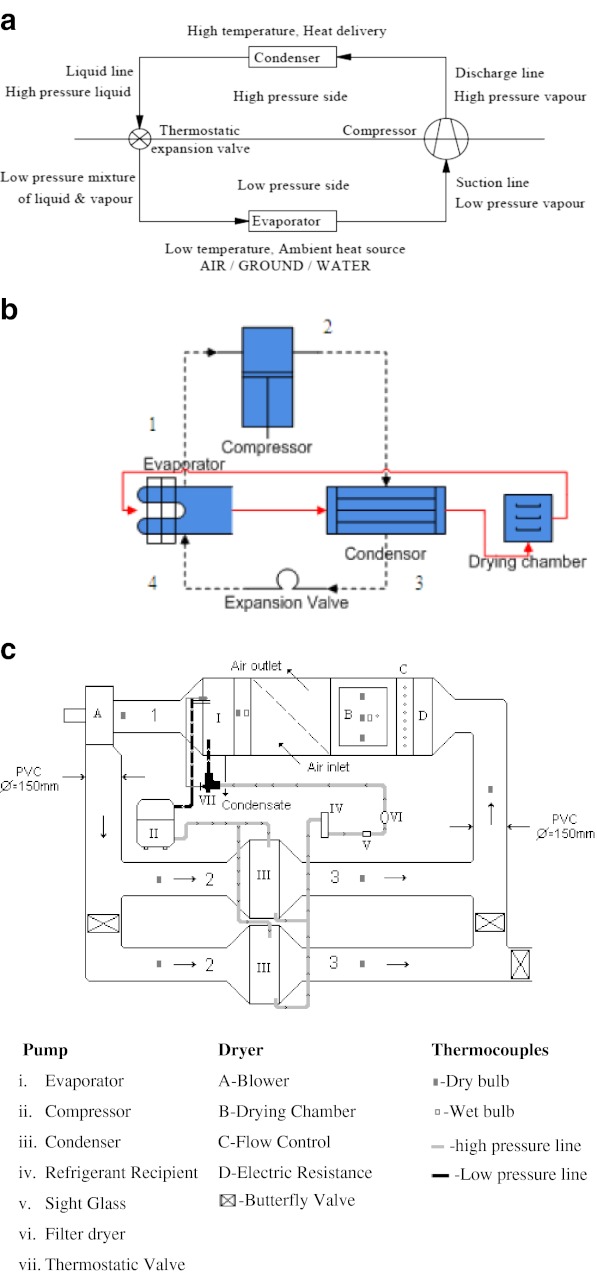

The thermal characteristics of HPD and system performance can be evaluated in terms of the amount of heat recovered at the evaporators, MER (moisture extraction rate i.e. kilogram of moisture removed per hour) that indicates the dryer capacity, SMER (specific moisture extraction rate i.e. Kilogram of moisture removed per kilowatt-hour) which defines the effectiveness of energy used in drying process and the energy efficiency of heat pump which gives by the COP (coefficient of performance i.e. the ratio of heat rejected at the condenser to the work used by compressor). In their review on HPD, Perera and Rahman (1997) stated that HPD has higher drying efficiency, offers better product quality, and it is environmentally friendly. SMER values ranged from 1.0 to 4.0, 0.72 to 1.2 and 0.12 to 1.28 kg·kW-1·h-1 for HPD, vacuum drying, and hot air drying, respectively. Drying efficiencies were 95% for HPD, less than 70% for vacuum drying, and between 35 and 40% for hot-air drying. A schematic diagram of heat pump dryer has been given in Fig. 3b.

Fig. 3.

a Schematic diagramme of heat pump circuit (Lu and Charters 2003). b Schematic diagram of main components of heat pump dryer (Daghigh et al. 2009). c Schematic diagram of the complete heat pump dryer (Kohayakawa et al. 2004)

Rossi et al. (1992) compared the performance of an electrical heating drying with and without heat pump assisted drying for onion and they reported that the drying time can be saved by 40.7% and electrical energy by 40% in heat pump assisted drying. Pendyala et al. (1986) enunciated that the sensitivity of the economics of heat pump assisted dryers to various factors such as design, economic and operational variables can be assessed for Indian conditions when payback period adopted as a criterion. For the specific, typical conditions and the current costs of electricity and steam in India, a heat pump assisted dryer has a payback period in the range of two to 3 years.

So it can be conclude that the performance of other drying methods can be assessed during commercial scale operation by adding heat pump. Sosle et al. (2001) investigated its economical role for agricultural food materials and they confirmed that HPD is useful for materials with high initial moisture content and in regions with high humidity of ambient air. There are some heat pump assisted drying came into their existence in food industries so far. For example, heat pump assisted solar drying, micro-wave drying, infrared drying, fluidized bed drying, atmospheric freeze drying, radio frequency drying and chemical heat pump assisted drying etc.

Performance evaluation

The overall performance of a HPD may be characterized by several criteria. Among them, the COP, the SMER (Hawlader et al. 2003; Clements et al. 1993; Mason et al. 1994) and the individual losses: can be determined by performing an exergy analysis of the whole system, have been used by many researchers (Schmidt et al. 1998). So, in order to obtain the performance of the conventional heat pump, knowledge of the thermodynamic properties is required (Abou-Ziyan et al. 1997). Daghigh et al. (2009) carried out a regression analysis to correlate thermodynamic properties of refrigerant (R134a) from −50 °C to near critical point of each refrigerant and modeled heat pump drying system mathematically. However, the computer simulation model can be regarded as a combination of a dryer model and a heatpump model. The dryer model used in the simulation was originally developed by Chen and Pei (1989), Jolly et al. (1990) and Chou et al. (1997), while the heat pump model was developed by Jolly et al. (1990). Recently, Phoungchandang (2009) simulated model for heat pump-assisted dehumidified air drying system to calculate the yield of dried products.

Mathematical modeling

Figure 3(a) represents the schematic diagram of heat pump dryer system. The system consists of two heat exchangers as condenser and evaporator, a thermostatic expansion valve a compressor, drying chamber, supporting structure and casing. The heat pump system and the chamber are attached together so that it becomes one unit. The heat from the condenser will produced hot and will use to heat the material in chambers and the cold heat from the evaporator will be use in dehumanization process. However, in general, simulation can be used to study variations in system or component configurations in order to identify critical parameters (Pendyala et al. 1990).The starting point of a heat pump model is the description of the operation of a heat pump in terms of mathematical relationships. The main parameters of the compressor are volumetric efficiency (ηvol), refrigerant mass flow rates (mr) and compression power (W) (Pendyala et al. 1990) (Fig. 3b).

|

1 |

|

2 |

|

3 |

Applying the energy equation for a mass m of refrigerant in the evaporator yields:

|

4 |

The heat rejection in the condenser is given by:

|

5 |

Where C is the clearance percentage, CR is the compression ratio and n is air constant, V is the displacement volume (m3), m is mass flow rate (Kg/s), ν is the specific volume (m3/kg), Q is rate of heat transfer (kW) and h is the specific enthalpy (KJ/Kg).

The heating coefficient of performance for the heat pump (COPh)

For an ideal refrigeration system operating between a condenser temperature of TC and an evaporator temperature of TE, the maximum heating coefficient of performance, COPc;h was obtained from the Carnot cycle (Cengel and Boles 1998) as:

|

6 |

For normal application/a mechanical vapor compression system, the net energy supplied is usually in the form of work, mechanical or electrical, and may include work to the compressor and heat pumps. The contribution of other sources, such as the circulating fan, is comparatively small. Therefore, the heating COP for the whole system was not taken into account (Hawlader et al. 1998). We here used the compressor power consumption Wc to represent W. Thus, the coefficient of performance (COP) is:

|

7 |

The specific moisture extraction rate

This can be defined as the energy required to remove 1 kg of water and may be related to the power input to the compressor (SMERhp) or to the total power to the dryer including the fan power and the efficiencies of the electrical devices (SMERoverall), as given by (Jia et al. 1990; Hawlader et al. 1998; Schmidt et al. 1998).

|

8 |

and

|

9 |

where md is the drying rate in kg water per hour, Wf is the power input to the fan and gel is the electrical efficiency. A schematic diagram of the complete heat pump dryer has been given in Fig. 3c.

The individual losses

The individual losses can be determined by performing an exergy analysis of the whole system, which will be a subject of future work.

Performance evaluation of heat pump assisted drying systems

The heat pump itself received all the attention, either as a dehumidifier or as a heater, and its effectiveness was often described with disregard of the drying process downstream. However, early research related to heat pump assisted drying had a narrow focus regarding the assessment of performance. Strommen (1986) suggested the term thermal efficiency, which was an indicator of the dehumidification of air. Since, a comparison of various processes can be made by considering the overall performance expressed by rating figures or the individual losses during the course of the state changes (Schmidt et al. 1998).

|

10 |

|

11 |

|

12 |

Where ἡ is the thermal efficiency, r is the latent heat of evaporation of water (kJ/kg), X is the absolute water content in air (kg water/kg dry air), h is the enthalpy of air (kJ/kg dry air), B is dryer inlet, C is dryer outlet, F is the point between the evaporator and the condenser, SMER is specific moisture extraction rate (kg/kW.h), COP is coefficient of performance of the heat pump (the ratio of cooling capacity to the power), SEC is the specific energy consumption, T is total energy consumed (MJ), W is the total moisture removed (kg) and E is the total energy input (kW.h).

Prasertsan et al. (1996a) introduce a term called dryer efficiency, which is defined as a percentage of the difference of absolute humidity of the air passing through the dryer with respect to the difference between the process air and saturated air. The dryer efficiency indirectly meant to represent the drying rate of the product. Based on this concept, the drying process divided into different zones described as high, medium and low dryer efficiency.

Exergy analysis

Exergy is the work that is available in a gas, fluid or mass of material, as a result of its nonequilibrium condition relative to some reference condition. The exergy concept is a child of the second law of thermodynamics and its implications are discussed by Haywood (1974a, b), McCauley (1983) and Soma (1983). Jorgensen (2001), Dincer and Cengel (2001), Brodyansky et al. (1994), Moran and Sciubba (1994), McGovern (1990) and O’Toole and McGovern (1990) provide good discussion of the fundamental concepts of exergy as well as some reviews.

In the absence of a universal framework for efficiency analysis in drying, exergy analysis seems to be a suitable technique. Exergy analysis compares real performance to the ideal one in which there is no or little external of supplementary driving force required. When there is an external contribution to the driving force, the process occurs faster, but with greater exergy loss (Feng et al. 1996).

Little application of the exergy principles has been seen in food industry. Carrington and Baines (1988) pointed out that theoretically, the only unavoidable loss in a heat pump system was due to the humidification of air in the drying chamber. The unavoidable losses are closely related to the actual thermodynamic losses in heat pump dryer, and it is remarked that careful design can limit the total losses. Ying and Canren (1993) break up the exergy change into the physical and chemical components in an analysis related to the heat pump assisted drying and Topic (1995) presented the exergy analysis of a high-temperature forage drying process.

Type of heat pump assisted drying

Heat pump assisted solar drying

Solar heat pump systems provide a real capability of upgrading low-grade energy sources from the surroundings as well as using solar energy (Charters et al. 1980; Lu and Charters 2003). Sporn and Ambrose (1955) described an attempt at harnessing solar energy to improve the overall performance of a heat pump system and the use of a combined solar-heat pump rice drying system is being developed by Best et al. 1994, as an alternative to conventional mechanical dryers. They modified 7 kW R-22 air conditioning units and combined with a solar collector in their equipment, for a more precise control of temperature and humidity. Fatouh et al. (2006) designed and constructed a heat pump assisted dryer to investigate the drying characteristics of various herbs.

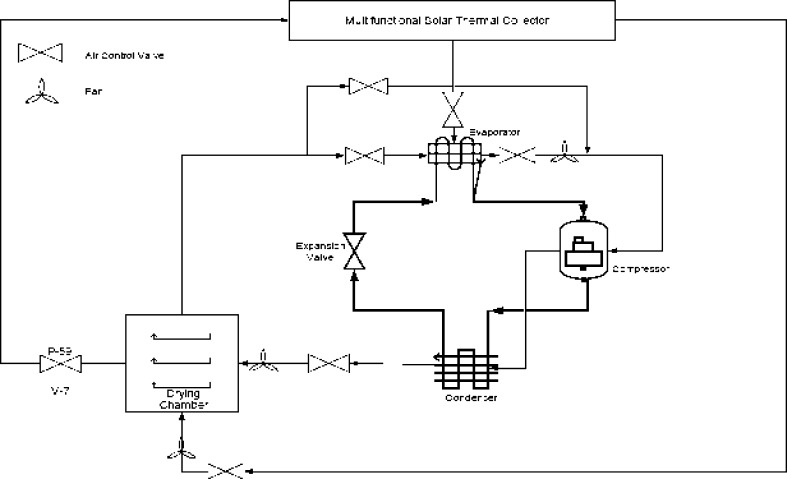

A solar-assisted heat-pump dryer and water heater has been designed, fabricated and tested by Hawlader et al. (2003) and they investigated the performance of the system under different meteorological conditions of Singapore. Latter, Hawlader et al. (2006) evaluated the performance of solar-assisted heat-pump dryer and water heater again in the tropics, and a simulation programme was developed by them. After comparing between both results, they reported that the total drying time of the product decreases with the increase in drying potential. Drying potential is directly proportional to the air flow rate, drying air temperature and inversely proportional to the air relative humidity. Three important parameters that affect the system performance are solar radiation, compressor speed and the total load placed in the drying chamber. Zafri et al. (2007) has development a solar assisted heat pump dryer using the multifunctional solar collector and they reported that this one is extension to this technology, which partially powered by solar radiation to sustain the power.

Abou-Ziyan et al. (1997) has presented two serial solar-assisted heat pump (SAHP) systems: solar assisted R22 and R134a for low temperature applications. A schematic diagram of the solar assisted heat pump drying system using multifunctional solar collector by Othman et al. (2008) shown in Fig. 4.

Fig. 4.

The schematic diagram of the solar assisted heat pump drying system using multifunctional solar collector (Othman et al. 2008)

Heat pump assisted infrared drying

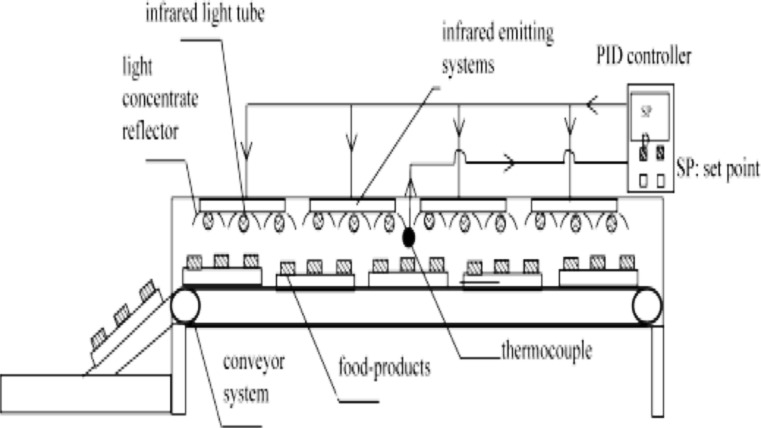

Infrared drying has been found more important, as the subject of investigation, by recent researchers and Paakkonen et al. (1999) infrared drying improve the quality of herbs and Zbicinski et al. (1992) suggested for intermittent irradiation drying mode coupled with convective air for heat sensitive food products. Since this mode of operation (convective followed by intermittent irradiation) ensure faster initial drying rate due to the direct transfer of energy from heating element to the product surface without heating the surrounding air (Jones 1992). There are much evidence that infrared (IR) drying helps to reduce the drying time by providing additional sensible heating to expedite the drying process. Schematic diagram of IR assisted heat pump dryer has been given in Fig. 5.

Fig. 5.

Schematic diagram of IR assisted heat pump dryer (Chou and Chua 2001)

Oktay and Hepbasil (2003) evaluated the performance of a heat pump assisted mechanical opener drying system. They reported that the dryer is capable of extracting specific moisture with extraction rates ranging from 0.65 to 1.75 kg/kW h and the heating coefficient of performance of the dryer was found between 2.47 and 3.95, depending upon condenser and evaporator temperatures.

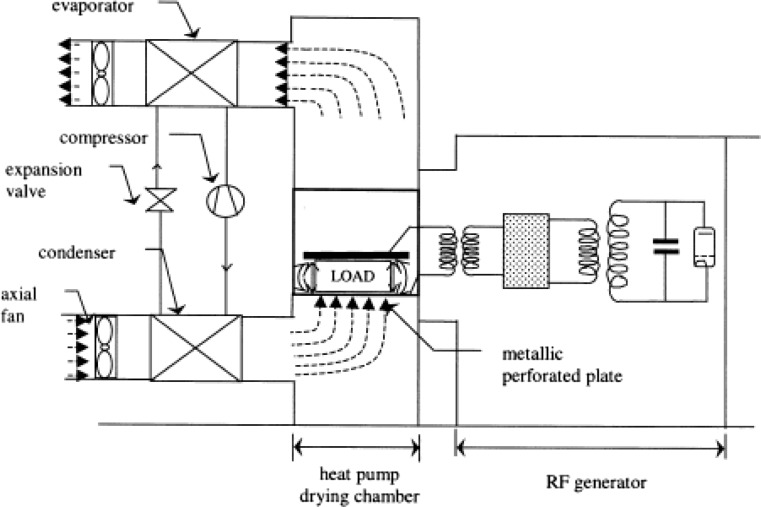

Radio frequency assisted heat pump drying

Radio Frequency (RF) energy generates heat volumetrically within the wet material by the combined mechanisms of dipole rotation and conduction affects which speeds up the drying process (Marshall and Metaxas 1998). Latter on Marshall and Metaxas 1999 described radio frequency assisted heat pump drying of crushed brick and they combined radio frequency energy with heat pump batch drier, and showed several improvements resulting from the combination drying process. They also developed a simplified mathematical model of the dryer, using mass and energy conservation. According to Thomas (1996) radio frequency heat all parts of the product mass and evaporate the water in situ at relatively low temperature. They suggested that the limitation of heat transfer in convectional drying with hot air alone can be overcome by combining radio frequency heat with conventional convective drying. The schematic diagram of RF assisted heat pump dryer has been given in Fig. 6.

Fig. 6.

Schematic diagram of RF assisted heat pump dryer (Chua et al. 2002a, b)

Despite of the clear advantages of heat pumps and high (radio) frequency heating that offer for drying, the combination of these two techniques until recently has not been studied. A series of experiments carried out comprising a motor driven heat pump which was retro-fitted with the ability of imparting RF energy into a material at various stages of the drying cycle are described and compared with a mathematical model. A schematic diagram of RF assisted heat pump dryer is given in Fig. 7. Since RF-assisted heat pump drying is a relatively new technology there is not much published data concerning energy, performance, and quality issues. Marshall and Metaxas (1998) proved that the combined use of pulsed radio frequency heating with heat pump drying improves the specific moisture extraction rate (SMER) of the system due to reduce electrical energy because of RF heating. The pulsed drying configuration shows a slight reduction in COP for R12 radio frequency assisted heat pump drying and with respect of product quality. The RF-assisted heat pump drying reduces discolouring of dried products, especially those that are highly susceptible to surface colour change. Also, cracking caused by stress due to uneven shrinkage during drying, can be eliminated by RF assisted drying (Kudra and Mujumdar 2002)

Fig. 7.

Schematic diagram of the prototype HPAMW dryer (Jia et al. 1993)

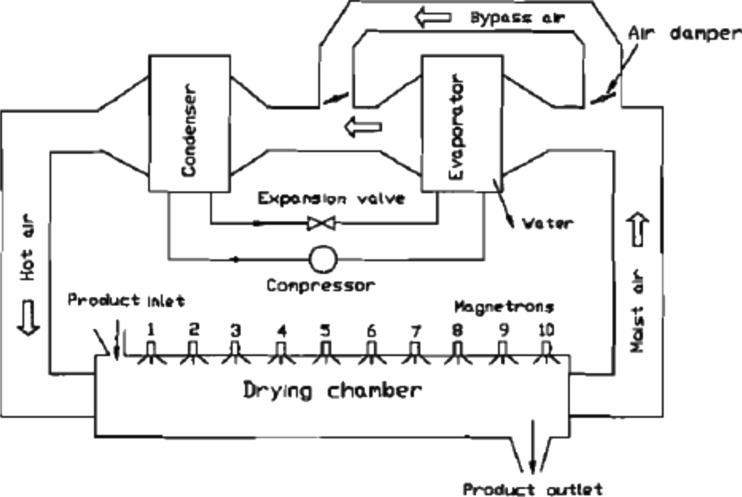

Heat pump assisted microwave drying

MW drying offers opportunities to shorten the drying time and improves the final quality of the dried products but MW drying alone has some major drawbacks that includes uneven heating, off flavour (Clark 1996; Nijhuis et al. 1998), possible textural damage due to puffing (Nijhuis et al. 1998) and limited penetration depth of the MW field into the products (Wang et al. 2003). According to Wang et al. (2003), MW power at 915 MHz penetrates to a greater depth than does at 2,450 MHz, in large-scale drying applications; the penetration depth is still much smaller compared to that attained in radio frequency (RF) heating at 10–300 MHz. Other drying methods can be combined to overcome some of these drawbacks of single MW drying. The MW drying can also be combined with heat pump drying (Jia et al. 1993). Jia et al. (1993) worked on HPD assisted MW drying and reported that heat pump assisted MW drying competed well with conventional hot-air drying, having lower SMER and higher product throughput. Further, Jia et al. (2003) carried out a simulation study on combined convection and MW heating using potato and carrot as model materials and it was found possible to predict the bulk drying rate of the product and the overall performance of a heat pump assisted microwave dryer, combining a simplified microwave power distribution model with the heat pump dryer model (Jolly et al. 1990). Jia et al. (1993) constructed a prototype heat pump assisted microwave dryer and developed a corresponding mathematical model to investigate the feasibility and the performance of heat pump assisted microwave drying of agricultural produce. In their study they reported that the experimental and numerical results were in good agreement and the validation of the heat pump model, drying chamber model and the combined heat pump assisted microwave drying model was detailed in research papers published by researchers.

In the design of combined microwave and convective drying systems, there have always been uncertainties relating to when the microwave power should be applied during the drying process. According to their preliminary experimental results, Bhartia et al. (1973) suggested that for highly hygroscopic materials, it was more beneficial to apply the microwave energy in the latter stages of the drying process. Turner and Jolly (1990) studied this problem using a mathematical drying model and their conclusion was that it was more beneficial to apply microwave power in the initial stages of the drying if the dielectric properties of the material to be dried were highly dependent on moisture content and the converse was observed for the case that the material dielectric properties were highly temperature dependent.

Furthermore, to determine the performance of the combined heat pump microwave dryer for drying products having a commercial value, the sliced carrots and whole root ginger were tested by Jia et al. (1993). In their study they reported that the sliced carrots had an initial moisture content of approximately 83% (wet basis) and was dried to a finial moisture content of 42% (wet basis). The experimental results of this test were showed throughput 18 kg/hr and SMER 1.6 kg/kWh when input power was 3.3 kW. However, in the case of ginger, had an initial moisture content of approximately 87% (wet basis) and was dried in the prototype dryer to a moisture content of 55% (wet basis) with two magnetrons in operation, the throughput and bypass air ratio were found 8 kg/hr and 66% when input MW power was 3.2 kW. Comparing these results with the drying of sliced carrots, it is apparent that both SMER and product throughput have dropped significantly. This low drying efficiency was attributed to the high hygroscopicity of the ginger. As well, the tough outer skin of the ginger made moisture diffusion to the ginger’s surface more difficult (Jia et al. 1993). However, the outward flux of vapour and generated vapour pressure during MW-assisted drying, can help to prevent the shrinkage of tissue structure (Feng et al. 2001).

Funebo and Ohlsson (1998) described MW-assisted air dehydration of apple and mushroom and they concluded that the drying time for apple and mushroom was reduced with the use of MW-assisted drying in whole air drying process (MDWAD). So, in general, the MW-related drying can meet the four major requirements in drying of foods: speed of operation, energy efficiency, cost of operation and quality of dried products (Gunasekaran 1999). A schematic diagram of the prototype heat pump assisted microwave (HPAMW) dryer has been given in Fig. 7.

Andres et al. (2004) studied the drying kinetics of apple cylinders under combined hot air MW dehydration. Ruiz et al. (2003) modelled dehydration and hydration of orange slices in combined MW/air drying. Despite the low levels of MW power used in their study, a sharp reduction in drying time of orange slices was obtained. Maskan (2001) investigated MDWAD drying of banana, a very difficult product to dry with traditional hot air drying method. In order to prevent significant quality degradation, MW-assisted vacuum drying is introduced to replace the conventional hot airflow drying. To overcome the drawback of vacuum drying, MW-assisted combination drying with vacuum has been investigated to speed up the process. Most microwave assisted vacuum drying (MWVD) studies have been focused on the fruits and vegetables so for that needs the ‘puffing’ quality in the final product. But the same method can also be applied to other food products, such as parboiled rice and shrimp (Lin et al. 1998).

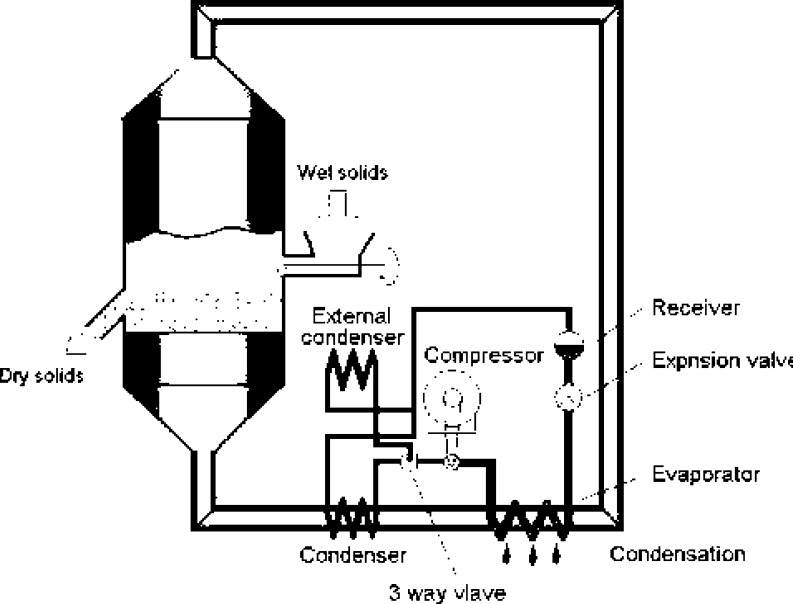

Heat pump assisted fluidized bed and atmospheric freeze drying

Experiments performed on various heat sensitive materials such as pharmaceutical products, fruits and vegetables have shown that fluidized bed drying offers a better product quality but higher cost. Since this technique produces a premium quality product, the incremental increase in drying cost may be offset by the higher market value fetched by these better quality products (Chou and Chua 2001). The use of fluidised bed dryers for drying many types of food materials is limited because of the irregular particle sizes and sticky nature of the products. As heat pumps are very efficient for removing 70–80% of initial moisture and most semi-dried products are not sticky, the fluidised bed principle could be applied in combination with a more common configuration of heat pump dryer to enhance performance considerably. If a properly sized fluidised bed (or bin dryer) is used in series with a heat pump dryer, in such a way dehumidified hot air first enters the fluidised bed and then passes through a drying cabinet (main section of conventional heat pump dryers currently used in industry), the performance of the system can be increased by two- or threefold, depending on the drying characteristics of the product being dried. This can be achieved without increasing the compressor power of the heat pump itself. A schematic diagram of a heat pump fluidized bed dryer has been in Fig. 8.

Fig. 8.

Schematic diagram of a heat pump fluidized bed dryer (Law and Mujumdar 2007)

Fluidized bed dryers incorporating heat pump drying mechanism have been developed at the Norwegian Institute of Technology (Alves-Filho and Strommen 1996a, b, c; Strommen and Jonassen 1996). According to Alves-Filho and Strommen (1996a, b, c), this set-up can produce drying temperatures from 20 to 60 °C and air humidity ranging from 20 to 90%. The advantages offered by heat pump fluidized bed dryer are: low energy consumption due to high specific moisture extraction rate (SMER), high coefficient of performance (COP), drying temperature can be regulated within the range of −20 °C to 110 °C, environmental friendly and high product quality (Lawand and Mjumdar 2007). Islam and Mujumdar (2004) have classified many types of heat pump dryers. Much research works have been done on various types of heat pump dryer, viz, fluidized bed heat pump dryer (Alves-Filho and Strommen 1996a, b, c; Strommen et al. 2002). Klocker et al. (2002) presented the design of a batch cabinet heat pump dryer using CO2 as the working fluid. Alves-Filho (2002) proposed a new type of fluidized bed heat pump dryer that uses CO2 as the refrigerant. Chua et al. (2002a, b) studied the effect of different temperature profile on the quality of the dried product and developed a dual purpose heat pump dehumidifier dryer.

Combining atmospheric freeze-drying (AFD) with a properly designed heat pump system (HP) results in an energy-efficient drying process. This combination makes HP-AFD competitive with vacuum freeze-drying (VFD). The advantages of AFD compared to VFD are lower production costs and the ability to manufacture a similar porous product (Bantle et al. 2009). An atmospheric freeze-drying (AFD) process as described by Claussen et al. (2007a) is more economical and gives product qualities similar to VFD (Donsi et al. 2001). A schematic diagram of heat pump assisted atmospheric freeze drying system has been given in Fig. 9.

Fig. 9.

Schematic diagram of heat pump assisted atmospheric freeze drying (Bantle et al. 2009)

Chemical heat pump assisted drier

The chemical heat-pump is a cost-effective: using waste heat to provide industrial process heat, using waste heat to provide space-heating and cooling, and as an off-peak heat-pump (re-concentration by electricity). Chemical heat pumps (CHPs) provide high storage capacity and high heat of reaction as compared to sensible heat generated by absorption (Ogura et al. 2004).

Ogura et al. (2002) put forward the study on a chemical heat pump (CHP) assisted convective dryer and they used CaO/H2O/Ca(OH)2 gas-solid reversible hydration/dehydration reaction to store and recover heat from the dryer exhaust air to enhance the thermal efficiency of the dryer. In their study, they reported that the CHP unit can be operated to increase the temperature level and also to dehumidify the air, which is a particularly attractive feature for drying. Ogura et al. (2005) again worked on heat pump dehumidified dryers for control strategy of chemical heat pump dryer and reported that the hot air temperature can be controlled by adjusting the reactor temperature and pressure. However, in another study, Ogura et al. (2003) had documented on enhancement of energy/efficiency of a chemical heat pump-assisted convective dryer. They reported that the chemical heat pump (CHP) unit can be used to recover waste heat from dryers and reuse it by storing and releasing heat with upgrading the temperature or by dehumidification. However, the final thermal energy production efficiency of the CHP for drying was found to be low but the CHP-assisted convective dryer system is found to be energy-efficient over a wide temperature range of industrial interest. A schematic diagram of CHPD system using CaO/H2O/Ca(OH)2 reaction operating in heat enhancement mode has been given in Fig. 10.

Fig. 10.

Schematic diagram of CHPD system using CaO/H2O/Ca(OH)2 reaction operating in heat enhancement mode (Ogura et al. 2004)

Ogura et al. (2007) examined characteristics of chemical heat pump (CHP) for heat storage and heat release in repetitive operation and they found input/output heat of the CHP in repetitive operation that can be controlled by the special pressure adjustment procedure such as instant vacuuming or additional vacuuming for pressure-temperature control of the CHP reactor. In the case of CaO/H2O/Ca(OH)2 hydration/dehydration system, the CHP was found to produce controlled-temperature, hot/cold heat, in a repetitive operation using chemically stored energy during both heat-storing and heat-releasing steps.

Assessments of agricultural produce

Dried products are gaining popularity, despite considered to having the lowest quality among processed foods. Increasing demands and higher trading in the market are predicted for dried foods (Strumillo and Adamiec 1996). Over the last four decades, research has been carried out on the use of multiple drying methods to obtain with superior quality along with reduced energy consumption due enhanced heat and mass transfer. Since the heat pumps were traditionally considered to be supplementary devices in drying equipments, the heat pump assisted drying has great worth for agricultural produce. In Norway, low temperature drying studies have been carried out using a heat pump dryer, and biomaterials were dried at temperatures as low as −25 °C (Alves-Filho and Strommen 1996a, b). Perera and Rahman (1997) and Hesse (1995) provided a general view of heat pump dehumidifier assisted drying. The paper by Flikke et al. (1957) is perhaps the earliest of published works in the area of heat pump assisted grain drying. In general, they found the concept to be mechanically feasible but not attractive economically due to low fuel prices prevailing at the time. The detailed analysis of HPD assisted grain drying by Brook (1986) revealed marginal energy savings, but according to him the system has economic drawbacks over drying of large portion of grain, risk of spoilage due to mould growth during the slow drying process and high capital cost of the equipment were cited as some of the reason. However, the simultaneous heating and cooling capacities of heat pumps was always considered desirable (Flikke et al. 1957). Based on this assumption, Oliver (1982) discussed the use of heat pump dehumidifiers in process drying and Hogan et al. (1983) developed a heat pump system for low temperature grain drying and their system was found to be economically desirable. Simultaneously, they reported that the energy consumption was about 2.1 MJ per kg water remove compared to 6.44 MJ per kg water, required in electrically heated bin dryer.

Recently works on heat pump dehumidified dryers were Ogura et al. (2005) for a control strategy for chemical heat pump dryer; Saensabai and Prasertsan (2007) for condense coil optimization and component matching and Pal and Khan (2008) for calculation steps for the design of different components. Moreover, various types of product have been dried in experimental heat pump dehumidified dryers. Dried product included biomaterials (Alves-Filho and Strommen 1996a) sawn rubber, wood and banana (Prasertsan and Saen-saby 1998), banana (Chua et al. 2001), holy basil (Phoungchandang et al. 2003), garlic (Boonnattakorn et al. 2004) mangoes (Chottanom and Phoungchandang 2005), ginger (Hawlader et al. 2006) composite food products (Rahman et al. 2007), and red pepper (Alves-Filho et al. 2007), protein (Alves-Filho et al. 2008). Simulation model of the heat pump dehumidified dryer were developed by Alves-filho et al. (1997) for fruit and root drying and Achariyaviriya et al. (2000) for fruit drying. Phoungchandang (2009) developed a computer simulation model of the heat pump assisted drying for some herbs (garlic and white mulberry leaves) and reported that model was in good agreement with experimental results, applicable to air drying of herb in single layer and sufficiently adaptable to examine the effects of relative humidity and temperature of the drying air.

Advantages and disadvantages heat pump assisted drying

The main objective of any drying process is to produce a dried product of desired quality at minimum cost and maximum throughput and to optimize these factors consistently (Chua et al. 2001). Much effort has therefore been directed towards examining potential energy saving technologies (Keeye 1978; Strumillo and Adamiec 1996). Utilizing energy efficient heat pump in drying system can achieve this goal and recover both latent and sensible heat which would otherwise be wasted. Since the greatest source of heat losses in conventional dryers is due to the venting of the moist air (Lawton 1978; Kato 1985), attention has been focused on waste heat recovery. As a preliminary energy conservation measure, a part of the exhaust air can be recycled and mixed with that of the intake (Sokhansanj 1984). Chou et al. (1993) and Prasertsan et al. (1997) studied the applications of heat pump dryer for agricultural produce and they reported that the heat pump dryer is economically feasible. According to Soponronnarit et al. (1998), the heat pump fruit dryer offered better product quality. Besides yielding better food quality, Rossi et al. (1992) has reported that onion slices dried by HPD used less energy in comparison to a conventional hot air system. Since the optimum temperature for drying of agricultural produce by which the good quality can be obtained is 60 °C. The heat pump/heat pump assisted drying is such type of low temperature drying.

Chua et al. (2000) have demonstrated that HPD can produce pre-selected cyclic temperature schedules to improve the quality of various agricultural products they dried in their two-stage HPD. They have shown that with appropriate choice of temperature-time variation, it is possible to reduce the overall colour change and ascorbic acid degradation by up to 87 and 20%, respectively.

Heat pump drying of sapota pulp to produce sapota powder was reported to be faster than hot air drying (Jangam et al. 2008). Drying of Australian nectarine slices in a heat pump dryer was found to produce the dried product that was better than that from cabinet and tunnel dryers in terms of lactone and terpenoid retention (Sunthonvit et al. 2007).

The fluidized bed dryers incorporating heat pump drying mechanism set-up can produce drying temperatures from −20 to 60 °C and air humidities ranging from 20 to 90%. With these features, heat-sensitive food materials can be dried under convective air or freeze drying conditions (Alves-Filho and Strommen 1996a, b, c).

Mujumdar (1991) has identified and proposed for the first time the use of multiple modes of variable levels of heat input, simultaneous or consecutive, as well as cyclical variations in velocity or operating pressure as technologies of the future for batch and continuous heat pump drying processes. Using multiple modes of heat input, it is possible to speed up drying kinetics without adversely affecting the quality of dried products.

Like all other mechanical systems, the heat pump assisted dryer has it’s a set of advantages and disadvantages that should be consider before adopting the technology for drying applications (Chua et al. 2002a, b). In Table 5 some advantages and disadvantages have been summarised.

Table 5.

Benefits and drawbacks of heat pump/heat pump assisted dryers

| References | |

|---|---|

| Advantages | |

| Recoverable energy from exhaust | Mujumdar et al. (2002) |

| Have more SMER (specific moisture extraction rate) | Islam and Mujumdar (2004) |

| Have more or improved efficiency/High COP | Islam and Mujumdar (2004) |

| Ability to produced well controlled drying condition | Kudra and Mujumdar (2001) Mujumdar et al. (2002); Daghigh et al. (2009): |

| Wide range of drying conditions | Chua et al. (2002a, b) |

| Better product quality | Daghigh et al. (2009) |

| Increased throughput and reduced operation cost | Jia et al. (1993) |

| Save drying time and energy | Rossi et al. (1992) |

| Low energy consumption | Islam and Mujumdar (2004) |

| Disadvantages | |

| Environmental issue | |

| Regular maintenance required | |

| Possibility of refrigeration leak | |

| Higher capital cost | |

Conclusions

The need for drying biological materials is very important in the argil-food industry, producing high quality and shelf-stable products. However, there is a downside to the process, as it is a high energy consuming process. This has two drawbacks, the first is the cost of energy, and the second is the environmental degradation that is associated with some types of energy production. In response to these concerns, there has been much work on novel drying techniques to improve energy and drying efficiencies. This article has covered heat pump assisted drying techniques, with hope that this techniques, along with future research, will produce dryers and drying process that are more economical and less harmful to the environment.

References

- Abou-Ziyan HZ, Ahmed MF, Metwally MN, Abd El-Hameed HM. Solar-assisted R22 and R134a heat pump systems for low-temperature applications. Appl Therm Eng. 1997;17(5):455–469. doi: 10.1016/S1359-4311(96)00045-2. [DOI] [Google Scholar]

- Achariyaviriya S, Soponronnarit S, Terdyothin A. Mathematical model development and simulation of heat pump fruit dryer. Drying Technol. 2000;18:479–491. doi: 10.1080/07373930008917718. [DOI] [Google Scholar]

- Alves-Filho O. Combined innovation heat pump drying technologies and new cold extrusion techniques for production of instant foods. Drying Technol, HPD special issue. 2002;20(8):1541–1557. [Google Scholar]

- Alves-Filho O, Eikevik TM (2009) Acceleration of heat pump atmospheric freeze drying of green peas by controlled fluidization and infrared radiation. Proceedings of the 4th Nordic Drying Conference, 17–19 Jun, Reykjavik, Iceland (CD-ROM)

- Alves-Filho O, Strommen I. Application of heat pump in drying of biomaterials. Drying Technol. 1996;14:2061–2090. doi: 10.1080/07373939608917196. [DOI] [Google Scholar]

- Alves-Filho O, Strommen I (1996b) Performance and improvements in heat pump dryers. In: Strumillo C, Pakowski Z (eds) Drying technol 96. Poland: Krakow, pp 405–415

- Alves-Filho O, Strommen I (1996c) Performance and improvements in heat pump dryers. Drying 96—Proceedings of the 10th International Drying Symposium, Krakow, Poland, 30 July-2Aug, vol. A, pp 405–416

- Alves-Filho O, Strommen I, Thorbergsen E. Simulation model for heat pump dryer plants for fruits and roots. Drying Technol. 1997;15:1369–1398. doi: 10.1080/07373939708917299. [DOI] [Google Scholar]

- Alves-Filho O, Thorbergsen, Strommen I (1998) A component model for simulation of multiple fluduzed bed heat pump dryers. Drying 98-Proceedings of the 11th International Drying Symposium (IDS 98), Halkidiki, Greece, August 19–22: 94–10

- Alves-Filho O, Eikevik TM, Mulet A. Kinetics and mass transfer during atmospheric freeze drying of red pepper. Drying Technol. 2007;25(7–8):1155–1161. doi: 10.1080/07373930701438469. [DOI] [Google Scholar]

- Alves-Filho O, Eikevik TM, Goncharova-Alves SV. Single-and multistage heat pump drying of protein. Drying Technol. 2008;26(4):470–475. doi: 10.1080/07373930801929474. [DOI] [Google Scholar]

- Alves-Filho O, Eikevik TM, Walberg M, Fridberg C (2009) Energy and thermal efficiency analysis for combined spray drying and heat pump systems. Proceedings of the 4th Nordic Drying Conference, 17–19 Jun, Reykjavik, Iceland (CD-ROM)

- Andres A, Bilbao C, Fito P. Drying kinetics of apple cylinders under combined hot air microwave dehydration. J Food Eng. 2004;63:71–78. doi: 10.1016/S0260-8774(03)00284-X. [DOI] [Google Scholar]

- Anonymous (2009) Fruits and vegetables (accessed November 27). http://www.pfndai.com/Processed

- Arabhosseini A, Padhye S, Huisman W, Van-Boxtel A, Müller J. Effect of drying on the color of tarragon (Artemisia dracunculus L.) leaves. Food Bioprocess Technol. 2010 [Google Scholar]

- Baines PG, Carrington CG. Analysis of rankine cycle heat pump driers. Int J Energy Res. 1988;12(3):495–510. doi: 10.1002/er.4440120313. [DOI] [Google Scholar]

- Baker GJ. Industrial drying of foods, chap 4. London: Chapman and Hall; 1997. pp. 65–89. [Google Scholar]

- Bantle M, Eikevik TM, Rustad T (2009) Atmospheric freeze-drying of calanus finmarchicus and its effects on proteolytic and lipolytic activities 4th Nordic Drying Conf, June 17–19, Reykjavik, Iceland

- Best R, Soto W, Pilatowsky I, Gutierrez LJ. Evaluation of a rice drying system using a solar assisted heat pump. Renewable Energy. 1994;5(1–4):465–468. doi: 10.1016/0960-1481(94)90415-4. [DOI] [Google Scholar]

- Best R, Cruz JM, Gutierrez J, Soto W. Experimental results of a solar assisted heat pump rice drying system. Renewable Energy. 1996;9(1–4):690–694. doi: 10.1016/0960-1481(96)88379-0. [DOI] [Google Scholar]

- Bhartia P, Stuchly SS, Hamid MAK. Experimental results for combinational microwave and hot air drying. J Microwave Power. 1973;8(3):245–252. [Google Scholar]

- Boonnattakorn R, Phoungchandang S, Leenanon B, Khajarern S, Khajarern J. The comparative study of garlic powder processing by heated air and dehumidifier heat pump dryer. Food Constant J. 2004;34(3):248–260. [Google Scholar]

- Brodyansky VM, Sorin MV, Le Goff P. The efficiency of industrial processes: exergy analysis and optimization. Amsterdam: Elsier; 1994. [Google Scholar]

- Brook RC. Heat pumps for near-ambient grain drying: a performance and economics feasibility study. Agric Eng. 1986;41(2):52–57. [Google Scholar]

- Carrington CG, Baines PG. Second law limits in convective heat pump driers. Int J Energy Res. 1988;12:481–494. doi: 10.1002/er.4440120312. [DOI] [Google Scholar]

- Cartwright WG (1987) Computer modelling of an energy-efficient drying plant. 4th Asean Energy Conference - Energy Technology, pp. 268–279

- Cengel YA, Boles MA (1998) Thermodynamics: an engineering approach, 3rd edn. McGraw-Hill, p 1056

- Charters WWS, de Forest L, Dixon CWS, Taylor LE (1980) Design and performance of solar boosted heat pumps. In: Australian and New Zealand solar energy society annual conference, Melbourne

- Chegini G, Khayaei J, Rostami HA, Sanjari AR. Designing of a heat pump dryer for drying of plum. J Res Appli Agric Eng. 2007;52(2):63–65. [Google Scholar]

- Chen P, Pei DCT. A mathematical model of drying processes. Int J Heat Mass Transfer. 1989;32(2):297–310. doi: 10.1016/0017-9310(89)90177-4. [DOI] [Google Scholar]

- Chen HH, Huang TC, Tsai CH, Mujumdar AS. Development and performance analysis of a new solar energy assisted photo catalytic dryer. Drying Technol. 2008;26:503–507. doi: 10.1080/07373930801929557. [DOI] [Google Scholar]

- Chottanom P, Phoungchandang S. The development of osmotically dehydrated mangoes using conventional drying and dehumidified drying. Chem Engi Trans. 2005;6:897–902. [Google Scholar]

- Chou SK, Chua KJ. New hybrid drying technologies for heat sensitive foodstuffs. Trends Food Sci Technol. 2001;12:359–369. doi: 10.1016/S0924-2244(01)00102-9. [DOI] [Google Scholar]

- Chou SK, Hawlader MNA, Ho JC, Wijeysundera NE, Rajasekar S. Heat pump in the drying of food products. Int J Energy Res. 1993;14:397–406. [Google Scholar]

- Chou SK, Hawlader MNA, Chua KJ, Teo CC. A methodology for tunnel dryer chamber design. Int J Energy Res. 1997;21:395–410. doi: 10.1002/(SICI)1099-114X(199704)21:5<395::AID-ER260>3.0.CO;2-R. [DOI] [Google Scholar]

- Chou SK, Chua KJ, Hawlader MNA, Ho JC. A two-stage heat pump dryer for better heat recovery and product quality. J Institute of Engineers, Singapore. 1998;38:8–14. [Google Scholar]

- Chou SK, Chua KJ, Mujumdar AS, Tan M, Tan SL. Study on the osmotic pretreatment and infrared radiation on drying kinetics and colour changes during drying of agricultural products. ASEAN J Sci Technol Dev. 2001;18(1):11–23. [Google Scholar]

- Chua KJ, Mujumdar AS, Chou SK, Hawlader MNA, Ho JC. Convective drying of banana, guava and potato pieces: effect of cyclical variations of air temperature on convective drying kinetics and colour change. Drying Technol. 2000;18(5):907–936. doi: 10.1080/07373930008917744. [DOI] [Google Scholar]

- Chua KJ, Mujumdar AS, Hawlader MNA, Chou SK, Ho JC (2001) Batch Drying of Bannana Pieces-Effect of Stepwise Change in Drying Air Temperature on Drying Kinetics and Product Colour. Food Res Int 34:721–731

- Chua KJ, Chou SK, Hawlader MNA, Ho JC, Mujumdar AS. On the study of time-varying temperature drying—effect on drying kinetics and product quality. Drying Technol. 2002;20(8):1579–1610. doi: 10.1081/DRT-120014053. [DOI] [Google Scholar]

- Chua KJ, Chou SK, Ho JC, Hawlader MNA (2002b) Heat pump drying: recent developments and future trends. Drying Technol-An Int J 1532–2300, 20(8): 1579–1610

- Clark DE. Microwave processing of materials. Annu Rev Mater Sci. 1996;26:299–331. doi: 10.1146/annurev.ms.26.080196.001503. [DOI] [Google Scholar]

- Claussen IC, Andresen T, Eikevik TM, Strommen I. Atmospheric freeze drying—modeling and simulation of a tunnel dryer. Drying Technol. 2007;25(12):1959–1965. doi: 10.1080/07373930701727275. [DOI] [Google Scholar]

- Clements S, Ha X, Jolly P. Experimental verification of a heat pump assisted continuous dryer simulation model. Int J Energy Res. 1993;17:19–28. doi: 10.1002/er.4440170104. [DOI] [Google Scholar]

- Daghigh R, Ruslan MH, Alghoul1 MA, Zaharim A, Sopian K (2009) Design of nomogram to predict performance of heat pump dryer. Proceedings of the 3rd WSEAS Int. Conf. on Renewable Energy Sources, La Laguna, Tenerife, Canary Islands, Spain, July 1–3, pp 277–282

- Dincer I, Cengel Energy, entropy and exergy concepts and their roles in thermal engineering. Entropy. 2001;3:116–149. doi: 10.3390/e3030116. [DOI] [Google Scholar]

- Donsi G, Ferrari G, Di MP. Utilization of combined processes in freeze-drying of shrimps. Food Bioprod Process: Transactions of the Institution of Chemical Engineers, Part C. 2001;79(3):152–159. doi: 10.1205/096030801750425244. [DOI] [Google Scholar]

- FAS Online (2009) World raisin situation and outlook. http://gain.fas.usda.gov//Raisin%20Annual_BuenosArgentina_7-16-2010.pdf

- Fatouh M, Metwally MN, Helali AB, Shedid MH. Herbs drying using a heat pump dryer. Energy Convers Manage. 2006;47(15–16):2629–2643. doi: 10.1016/j.enconman.2005.10.022. [DOI] [Google Scholar]

- Feng X, Zhu XX, Zheng JP (1996) A practical exergy method for system analysis. Proceeding of the 31st Intersociety Energy Conversion Engineering Conference, IECEC 96, 11–16 Aug, Washington DC, pp 2068–2071

- Feng H, Tang J, Cavalieri RP, Lumb OA. Heat and mass transport in microwave drying of hygroscopic porous materials in a spouted bed. AIChE J. 2001;74(7):1499–1511. doi: 10.1002/aic.690470704. [DOI] [Google Scholar]

- Flikke AM, Cloud HA, Hustrulid Grain drying by heat pump. Agric Eng. 1957;38(8):592–597. [Google Scholar]

- Fritz VA, Cloud HA, Deef RF, Borowski AM. A versatile heat pump seed dryer. Hortic Sci. 1990;25(8):977–978. [Google Scholar]

- Funebo T, Ohlsson T. Microwave-assisted air dehydration of apple and mushroom. J Food Eng. 1998;38:353–367. doi: 10.1016/S0260-8774(98)00131-9. [DOI] [Google Scholar]

- Gac A, Vrinat G, Blaise JC, Camous JP, Fleury M (1988) Guide for the design and operation of average and large capacity electric heat pumps. Int Inst Refrig, Paris, p 152

- Gunasekaran S. Pulsed microwave-vacuum drying of food materials. Drying Technol. 1999;17(3):395–412. doi: 10.1080/07373939908917542. [DOI] [Google Scholar]

- Hawlader MNA, Bong TY, Yang Y (1998) A simulation and performance analysis of a heat pump batch dryer. In: Mujumdar AS, Series editor. Proc of the 11th Int Drying Symp, Halkidiki, Greece, August 19–22, pp 208–215

- Hawlader MNA, Chou SK, Jahangeer KA, Rahman SMA, Lau KWE (2003) Solar-assisted heat-pump dryer and water heater. Appli Energy 7(1): 185–193(9)

- Hawlader MNA, Perera CO, Tian M. Properties of modified atmosphere heat pump dried foods. Food Eng. 2006;74:392–401. doi: 10.1016/j.jfoodeng.2005.03.028. [DOI] [Google Scholar]

- Haywood RW. A critical review of theorems of thermodynamic availability with concise formulations Part 1: availability. I Mech Eng Sci. 1974;16(2):160–173. doi: 10.1243/JMES_JOUR_1974_016_030_02. [DOI] [Google Scholar]

- Haywood RW. A critical review of theorems of thermodynamic availability with concise formulations Part 2: irreversibility. I Mech Eng Sci. 1974;16(2):160–173. doi: 10.1243/JMES_JOUR_1974_016_030_02. [DOI] [Google Scholar]

- Heap RD. Heat pumps. In: E and F. N. Spon, London; 1979. pp. p1–2. [Google Scholar]

- Hesse B. Energy efficient electric drying systems for industry. Drying Technol. 1995;13(1):1543–1562. doi: 10.1080/07373939508917038. [DOI] [Google Scholar]

- Hogan MR, Ayers DL, Muller RE, Jr, Foster GH, Rall EC, Doering OC. Heat pump for low-temperature grain drying. Trans ASAE. 1983;26(4):1234–1238. [Google Scholar]

- Islam MR, Mujumdar AS. In: Heat pump assisted drying- in guide to industrial drying. Mujumdar AS, editor. Mumbai: Colour; 2004. pp. 187–210. [Google Scholar]

- Jangam SV, Joshi VS, Mujumdar AS, Thorat BN. Studies on dehydration of sapota (Achras zapota) Drying Technol. 2008;26:369–377. doi: 10.1080/07373930801898190. [DOI] [Google Scholar]

- Japan Statistics Bureau (2000) Japan statistical year book. Government of Japan: Management and Coordination Agency

- Jia X, Jolly P, Clemets S. Heat pump assisted continuous drying part 2: simulation results. Int J Energy Res. 1990;14:771–782. doi: 10.1002/er.4440140708. [DOI] [Google Scholar]

- Jia X, Clements S, Jolly P. Study of heat pump assisted microwave drying. Drying Technol. 1993;11(7):1583–1616. doi: 10.1080/07373939308916920. [DOI] [Google Scholar]

- Jia LW, Islam MR, Mujumdar AS. A simulation study on convection and microwave drying of different food products. Drying Technol. 2003;21(8):1549–1574. doi: 10.1081/DRT-120024679. [DOI] [Google Scholar]

- Jolly P, Jia X, Clements S. Heat pump assisted continuous drying part I: a simulation model. Int J Energy Res. 1990;14(7):757–770. doi: 10.1002/er.4440140707. [DOI] [Google Scholar]

- Jones P (1992) Electromagnetic wave energy in drying processes. In: Mujumdar AS (ed) Drying 92. Elsevier Science Publisher BV, pp 114–136

- Jorgensen SE. The thermodynamic concept: exergy. In: Jorgensen SE, editor. Thermodynamics and ecological modelling. Boca Raton: Lewis; 2001. pp. 153–163. [Google Scholar]

- Kato K (1985) Exergy evaluation in grain drying. In: Mujumdar AS (ed) Drying 85. Hemisphere Publishing Co., p 420–427

- Keeye RB. Introduction to industrial drying operations. New York: Pergamon; 1978. [Google Scholar]

- Klocker K, Schmidt EL, Steimle F. A drying heat pump using carbon dioxide as working fluid. Drying Technol, HPD special issue. 2002;20(8):1659–1671. [Google Scholar]

- Kohayakawa MN, Silveria-Junior V, Telis-Romero J, (2004) Drying of mango slices using heat pump dryer. Paper presented at the Proceedings of the 14th Int Drying Symp, Sao Paulo, Brazil, 22–25 August

- Kudra T, Mujumdar AS. Advanced drying technologies. New York: Marcel Dekker; 2001. p. 457. [Google Scholar]

- Kudra T, Mujumdar AS (2002) Advanced drying technologies- book, Radio frequency assisted heat pump drying-chapter 31: 407–408

- Law C, Mujumdar AS (2007) Fluidized bed dryers. Handbook of industrial drying, 3rd edn, chapter 8, pp 174–193

- Lawand CL, Mjumdar AS (2007) Hand book of industrial drying, 3rd edn. CRC Press, p 192

- Lawton J. Drying: the role of heat pumps and electromagnetic fields. Phys Technol. 1978;9:p214–p220. doi: 10.1088/0305-4624/9/5/I03. [DOI] [Google Scholar]

- Lazzarin R. Heat pumps in industry—I. Equipment. Heat Recovery Syst CHP. 1994;14(6):581–597. doi: 10.1016/0890-4332(94)90029-9. [DOI] [Google Scholar]

- Lazzarin R. Heat pumps in industry—II. Applications. Heat Recovery Syst CHP. 1995;15(3):305–317. doi: 10.1016/0890-4332(95)90014-4. [DOI] [Google Scholar]

- Lin TM, Durance TD, Scaman CH. Characterization of vacuum microwave, air and freeze-dried carrot slices. Food Res Int. 1998;31:111–117. doi: 10.1016/S0963-9969(98)00070-2. [DOI] [Google Scholar]

- Liu L. Entry into supermarket of agricultural products after entering WTO. Agric Prod Process. 2003;6(5):4–5. [Google Scholar]

- Lu A (2007) Heat pumps. Encyclopedia of energy engineering and technology - 3 volume set (print version). In: Barney L, Capehart (eds) CRC Press, p 814

- Lu A, Charters WWS. Electrical and engine driven heat pumps for effective utilisation of renewable energy resources. Appli Therm Eng. 2003;23(10):1295–1300. doi: 10.1016/S1359-4311(03)00056-5. [DOI] [Google Scholar]

- Lu A, Fuller RJ, Charters WWS (2005) Ambient energy fraction of a heat pump. renewable energy for a sustainable future—a challenge for a post carbon world ANZSES 2005, Reviewed as full paper, pp 1–7

- Marshall MG, Metaxas AC. Modeling the radio frequency electric field strength developed during the RF assisted heat pump drying of particulates. Int Microwave Power Inst. 1998;33:167–177. [Google Scholar]

- Marshall MG, Metaxas AC. Radio frequency assisted heat pump drying of crushed brick. Appli Therm Eng. 1999;19(4):375–388. doi: 10.1016/S1359-4311(98)00058-1. [DOI] [Google Scholar]

- Maskan M. Kinetics of colour change of kiwifruits during hot air and microwave drying. J Food Eng. 2001;48:169–175. doi: 10.1016/S0260-8774(00)00154-0. [DOI] [Google Scholar]

- Mason RL, Blarcom AV (1993) Drying macadamia nuts using a heat pump dehumidifier. In: Development and application of heat pump dryer, at Brisbane, Australia, pp 1–7

- Mason RL, Britnell PM, Young GS, Birchall S, Fitzpayne S, Hesse BJ. Development and application of heat-pump dryers to the Australian food industry. Food Aust. 1994;46(7):319–322. [Google Scholar]

- McCauley JF. A simplification of the second law of thermodynamics. Energy Eng. 1983;80(3):51–65. [Google Scholar]

- McGovern JA. Exergy analysis-a different perspective on energy Part 1: the concept of exergy. Proc Inst Mech Engineerrs Part A: J Power and Energy. 1990;204:253–268. doi: 10.1243/PIME_PROC_1990_204_034_02. [DOI] [Google Scholar]

- Mc Mullen JT, Morgan R. Heat pumps. Bristol: Adam Hilger Ltd; 1981. [Google Scholar]

- Meyer JP, Greyvenstein GP. The drying of grain with heat pumps in South Africa: a techno-economic analysis. Int J Energy Res. 1992;16:13–20. doi: 10.1002/er.4440160103. [DOI] [Google Scholar]

- Moran MJ, Sciubba E. Exergy analysis: principles and practice. Trans ASME—J Eng Gas Turbine Power. 1994;116:285–290. doi: 10.1115/1.2906818. [DOI] [Google Scholar]

- Mujumdar AS. Drying technologies of the future. Drying Technol. 1991;9:325–347. doi: 10.1080/07373939108916669. [DOI] [Google Scholar]

- Mujumdar AS. An overview of innovation in industrial drying: current status and R&D needs. Transp Porous Media. 2007;66:3–18. doi: 10.1007/s11242-006-9018-y. [DOI] [Google Scholar]

- Mujumdar AS, Law CL. Drying technology: trends and applications in postharvest processing. Food Bioprocess Technol. 2010;3:843–852. doi: 10.1007/s11947-010-0353-1. [DOI] [Google Scholar]

- Mujumdar AS, Devahastin S, Ernest CKJ (2002) Mini-workshop on industrial drying. King Monkut’s University Technol Thonburi, Bangkok, p 217, April 22

- Newbert GJ. Energy efficient drying, evaporation and similar processes. J Heat Recovery Syst. 1985;5:551–559. doi: 10.1016/0198-7593(85)90223-1. [DOI] [Google Scholar]

- Nijhuis HH, Torringa HM, Muresan S, Yuksel D, Leguijt C, Kloek W. Approaches to improving the quality of dried fruit and vegetables. Trends Food Sci Technol. 1998;9:13–20. doi: 10.1016/S0924-2244(97)00007-1. [DOI] [Google Scholar]

- Ogura H, Ymamoto T, Kage H, Matsuno Y, Mujumdar AS. Effects of heat exchange condition on hot air production by a chemical heat pump dryer using CaO/H2O/Ca(OH)2 reaction. Chem Eng J. 2002;86:3–10. doi: 10.1016/S1385-8947(01)00265-0. [DOI] [Google Scholar]

- Ogura H, Ishida H, Kage H, Mujumdar AS. Enhancement of energy efficiency of a chemical heat pump-assisted convective dryer. Drying Technol. 2003;21:279–292. doi: 10.1081/DRT-120017749. [DOI] [Google Scholar]

- Ogura H, Yamamoto T, OtsuboY, Hiroki Ishida H, Kage H, Mujumdar AS (2004) Controllability of a chemical heat pump dryer. Drying 2004—Proc 14th Int Drying Sym, São Paulo, Brazil, 22–25 Aug vol B, pp 998–1004

- Ogura H, Yamamoto T, Otsubo Y. A control strategy for a chemical heat pump dryer. Drying Technol. 2005;23(6):1189–1203. doi: 10.1081/DRT-200059337. [DOI] [Google Scholar]