Abstracts

NaCl treatment was optimized for maximum reduction of cyanide content in raw bamboo (Dendrocalamus strictus) shoot using response surface methodology with 4 independent variables like concentration of NaCl, thickness of bamboo shoot, amount of NaCl solution and duration of treatment at 3 levels of each variable. Box-Behnken design was used to select the levels of variables in experimental runs. Cyanide content ranged between 12.8 and 29.6 mg/kg in bamboo shoot after NaCl treatment. The effect of concentration of NaCl was higher in reducing the cyanide content followed by thickness of bamboo shoot and treatment time in decreasing order. Amount of NaCl solution did not affect the reduction of cyanide content significantly. Optimum condition was 2.4% NaCl concentration, 1.25 cm thickness of bamboo shoot, 216 ml of NaCl solution and 23 min treatment. Corresponding cyanide content was 11.2 mg/kg. Experimental verification at optimum condition gave average cyanide content of 11.3 mg/kg on fresh weight basis, which was in good agreement with predicted and was well below permissible limit (500 mg/kg). The reduction of cyanide content was of 98.3% at optimum level.

Keywords: Bamboo shoot, Cyanide, Sodium chloride, Dendrocalamus strictus, Response surface methodology, Optimization

Introduction

In search for new sources of food for humans and animals, many wild plants are being investigated as food sources. Bamboo is one such uncommon food. It has now achieved the status of an economically most important plant, rightly considered as “Green Gold” (Dutt 2004). Bamboo shoots are traditionally consumed more often as fresh vegetable during their season of availability. Bamboo shoots are used extensively for preparation of pickles, snacks, papads and other stuff to curries, bhaajis and other preparations with rice (Kumbhare and Bhargava 2007). The common edible bamboo species in India are Dendrocalamus strictus and Bambosa bambos (Awasthi and Tewari 2008; Pandey and Jharia 2009).

Zhang and Liu (2001) reported that bamboo shoots contain vitamins C, B6 and B2, and amino acids essential for human nutrition. They also contain minerals (Zn, Co, K, Mn) and plenty of dietary fiber. Sucrose is the most abundant sugar in bamboo shoot. Bamboo shoots contain high proportion of linoleic acid. The major fatty acid in bamboo shoots is palmitic acid; glutamic acid and lysine are the most abundant amino acids in bamboo shoots (Soo-Jung and Sung-Ja 1993).

Bhargava et al. (1996) have reported that bamboo shoot contains appreciable quantities of vitamin C, carbohydrates and protein. Besides, bamboo shoots of many species also contain lethal concentration of cyanogenic glucosides, which on endogenic hydrolysis, yield hydrocyanic acid. Cooking destroys the enzymes responsible for the endogenic hydrolysis largely. Another constituent of bamboo shoot, known as homogentistic acid is responsible for the disagreeable, pungent taste, characteristics of bamboo shoots (Ferreira et al. 1991). Freshly harvested bamboo shoot has a necessity for a precooking processing, primarily to remove the toxic and bitter components, prior to the preparation of any dish. The level of cyanogenic glucosides up to 500 ppm in foods is considered to be of no health hazard (Anon 2005; FAO 2005). Soaking in water, sun drying, boiling and steaming are some popular traditional methods of reducing cyanide content (Coursey 1973).

The present study was carried out to optimize the sodium chloride (NaCl) treatment for reduction of cyanide content of raw bamboo shoot to the maximum level.

Materials and methods

Samples of bamboo (Dendrocalamus strictus) tender shoots were procured from Agro-forestry Research Centre of the university. Bamboo shoots were washed thoroughly with tap water for removal of dust and dirt. Then tip was cut and thick outer sheath was peeled off. Inedible portion of shoot was removed and finally edible portion of tender bamboo shoots were sliced (1, 1.5, 2 cm thick). Sample (25 g) was taken for the treatment in boiling solution as per the experimental conditions. Treatment time was noted after temperature of solution reached 100 °C.

Hydrocyanic acid was determined following the test described by Hogg and Ahlgren (1942).

Experimental design

Response surface methodology (RSM) was used to investigate the influence of treatment variables, namely, concentration of NaCl, thickness of tender bamboo shoot, amount of NaCl and duration of treatment on cyanide content of bamboo shoots. A Box and Behnken factorial design with 4 factors each varied at 3 levels and with 3 centre point replications, was used for experimental design and a second order response surface. Tables 1 and 2 show the factors and their levels at which the experiments were carried out. Independent variables were coded using the following:

|

1 |

|

2 |

|

3 |

|

4 |

Table 1.

Variables and their levels used in the experiments

| Variables | Code | level | ||

|---|---|---|---|---|

| −1 | 0 | +1 | ||

| NaCl concentration,% | X1 | 1 | 2 | 3 |

| Thickness, cm | X2 | 1 | 1.5 | 2 |

| Amount of NaCl solution, ml | X3 | 100 | 200 | 300 |

| Time, min | X4 | 15 | 20 | 25 |

Table 2.

Experimental design and observed response

| Expt. No. | Coded (real values) | Cyanidea content mg/kg | |||

|---|---|---|---|---|---|

| X1 (NaCl conc,%) | X2 (Thickness, cm) | X3 (Amount of NaCl, ml) | X4 (Time, min) | ||

| 1 | −1(1) | −1 (1) | 0(200) | 0 (20) | 23.81 |

| 2 | +1 (3) | −1 (1) | 0 (200) | 0 (20) | 17.50 |

| 3 | −1 (1) | +1 (2) | 0(200) | 0 (20) | 25.03 |

| 4 | +1 (3) | +1 (2) | 0(200) | 0 (20) | 26.72 |

| 5 | 0 (2) | 0 (1.5) | −1(100) | −1 (15) | 20.02 |

| 6 | 0 (2) | 0 (1.5) | +1(300) | −1 (15) | 15.31 |

| 7 | 0 (2) | 0 (1.5) | −1(100) | +1 (25) | 15.84 |

| 8 | 0 (2) | 0 (1.5) | +1(300) | +1 (25) | 14.82 |

| 9 | 0 (2) | 0 (1.5) | 0(200) | 0 (20) | 15.43 |

| 10 | −1 (1) | 0 (1.5) | 0(200) | −1 (15) | 28.41 |

| 11 | +1 (3) | 0 (1.5) | 0(200) | −1 (15) | 18.22 |

| 12 | −1 (1) | 0 (1.5) | 0(200) | +1 (25) | 23.21 |

| 13 | +1 (3) | 0 (1.5) | 0(200) | +1 (25) | 14.91 |

| 14 | 0 (2) | −1 (1) | −1 (100) | 0 (20) | 15.73 |

| 15 | 0 (2) | +1 (2) | −1 (100) | 0 (20) | 19.46 |

| 16 | 0 (2) | −1 (1) | +1 (300) | 0 (20) | 13.53 |

| 17 | 0 (2) | +1 (2) | +1 (300) | 0 (20) | 22.52 |

| 18 | 0 (2) | 0 (1.5) | 0 (200) | 0 (20) | 12.50 |

| 19 | 0 (2) | −1 (1) | 0 (200) | −1(15) | 21.0 |

| 20 | 0 (2) | +1 (2) | 0 (200) | −1(15) | 22.50 |

| 21 | 0 (2) | −1 (1) | 0 (200) | +1(25) | 13.42 |

| 22 | 0 (2) | +1 (2) | 0 (200) | +1(25) | 19.81 |

| 23 | −1 (1) | 0 (1.5) | −1 (100) | 0 (20) | 30.03 |

| 24 | +1 (3) | 0 (1.5) | −1 (100) | 0 (20) | 15.61 |

| 25 | −1 (1) | 0 (1.5) | +1 (300) | 0 (20) | 25.03 |

| 26 | +1 (3) | 0 (1.5) | +1 (300) | 0 (20) | 12.81 |

| 27 | 0 (2) | 0 (1.5) | 0 (200) | 0 (20) | 13.06 |

aValue on fresh weight basis

where, X1,X2, X3, X4 are coded values for concentration of NaCl (%), thickness of bamboo shoot (cm), amount of NaCl (ml) and duration of treatment (min), respectively. Coding of variables helps in computational simplicity and brings the independent variables in the same range irrespective of the actual magnitude of the variables. Therefore, the effect of the variables at linear, quadratic and interactive level can be deduced using the magnitude of the regression coefficients. Higher the magnitude of the coefficient, higher is the effect of that variable.

Statistical analysis Cyanide content data were analyzed by multiple regressions through the least square method to fit the following equation:

|

5 |

where, β0, βi, βii, βij are the coefficients of the regression equation; i and j, the integers; and Y, the response and X i, Xj independent variables.

Adequacy of the model was determined using coefficient of determination (R2), F value, and lack of fit. Effect of variables was deduced from the magnitude and sign of the regression coefficients. The best-fitted equation was obtained by eliminating the insignificant terms from full second order equation in order to get simple predictive equation. The coefficients of the response function, their statistical significance and process conditions for minimum cyanide content were determined using statistical package “Design Expert Trial version 7.1.3”(Statease Inc., Minneapolis, USA) were repeated at optimum condition to asses the reproducibility and its validity. Surface plots and contour plots were developed to study the effect of variables on cyanide content.

Results and discussion

The results of cyanide content under various conditions are given in Table 2. It shows that cyanide content ranged between 12.5 and 30.0 mg/kg. The lowest cyanide content was at 3% NaCl concentration, 1.5 cm thickness of tender bamboo shoot, 300 ml of NaCl solution and 20 min duration, while the highest cyanide content was at 1% NaCl concentration, 1.5 cm thickness of bamboo shoot, 100 ml of NaCl solution and 20 min duration. The cyanide content of the fresh tender bamboo shoot was 649 mg/kg, which indicated that reduction in cyanide content varied between 95.4 and 98.1%.

Equation 5 was fitted into the response variable cyanide content using least square regression analysis and the results of analysis are given in Table 3. F value suggests that the model was significant at p < 0.0001. Coefficient of determination, R2 was 0.8758 suggesting that 87.6% variability in the data was explained by the model. Moreover, there was insignificant lack of fit. Therefore, the model was adequate to predict the response and interpret the effect of variables on the response. The standard of estimate of the coefficients for the variables at linear, quadratic and interactive level was 0.79, 1.154 and 1.332, respectively. The model obtained for cyanide content (Y) was as follows:

|

6 |

Table 3.

Analysis of variance (ANOVA) for NaCl treatment

| Source | df | SS | MS | F value |

|---|---|---|---|---|

| Regression | ||||

| Model | 14 | 601.13 | 42.94 | 6.05 |

| Linear | 4 | 345.17 | 86.29 | 12.15** |

| Quadratic | 4 | 282.07 | 70.51 | 9.93** |

| Cross product | 6 | 34.56 | 5.76 | 0.81ns |

| Residual | 12 | 85.21 | 7.10 | 3.35ns |

| Lack of fit | 10 | 80.41 | 8.04 | |

| Pure error | 2 | 4.81 | 2.40 | |

| Total effect of factors | ||||

| Concentration | 5 | 418.36 | 83.67 | 11.78** |

| Thickness | 5 | 174.44 | 34.88 | 4.91* |

| Amount of NaCl solution | 5 | 29.69 | 5.93 | 0.83ns |

| Time | 5 | 73.86 | 14.77 | 2.08ns |

F Fisher’s ratio; df Degrees of freedom; SS Sum of squares; MS Mean sum of squares; ns not significant; significant at **p ≤ 0.01, *p ≤ 0.05

Regression results indicated that the concentration of NaCl and thickness of bamboo shoot had significant effect (p < 0.01) on cyanide content while time had significant effect (p < 0.05) at linear level. Amount of NaCl solution did not affect cyanide content significantly. Concentration of NaCl, amount of NaCl solution and treatment time had negative effect i.e. increase in the level of these variables decreased the cyanide content while the thickness of bamboo shoot showed positive effect i.e. increase in level of thickness of bamboo shoot decreased reduction in cyanide content. As the concentration of NaCl increases in the solution, the osmotic pressure of the solution decreases. This facilitates the increased removal of water from bamboo shoots and thereby decreases the cyanide content. Moreover, treatment time affects the diffusion of solution. Longer the treatment time, higher is the diffusion and hence lower is the cyanide content. Thickness of bamboo shoot of the material increases the resistance to diffusion and therefore, cyanide content increases. Concentration of NaCl and thickness of bamboo shoot affected the cyanide content at p < 0.01 and p < 0.05, respectively at quadratic level. Amount of NaCl solution and treatment time did not affect cyanide content quadratically. Interactions among the variables were not present in the experimental range investigated.

The total effect of concentration of NaCl and thickness of bamboo shoot was significant at p < 0.01 and p < 0.05, respectively while the effect of amount of NaCl solution and time was nonsignificant. The total effect of variables was significant at p < 0.01 at linear and quadratic level (Table 3).

The insignificant terms were eliminated from the full second order model to get simplified predictive equation. The result of regression analysis was as follows:

|

7 |

Coefficient of determination, R2, was 0.7989 and F value was 13.24 with probability of p = 0.000 suggesting predictive model was adequate.

Optimization of the process variables

Design Expert (v 7.1.3) software was employed to minimize cyanide content by NaCl treatment using numerical method of optimization. The optimum obtained was at 2.4% NaCl concentration, 1.25 cm thickness of bamboo shoot; 216 ml NaCl solution and treatment time 23 min at 100 °C. The cyanide content predicted was 11.2 mg/kg at optimum point. This was verified by conducting 3 replications at optimum point and it was observed that cyanide content ranged between 11.28 and 11.33 mg/kg. Two experiments were also conducted at variable concentrations of NaCl (2.4 and 2.5%), thickness of bamboo shoot (1.25 and 1.05 cm), amount of NaCl (260 and 250 ml), and time (20 and 21 min). The resultant cyanide contents were 11.8 and 11.5 mg/kg, respectively. This validates the optimum condition.

Interactive effects of variables on reduction of cyanide content

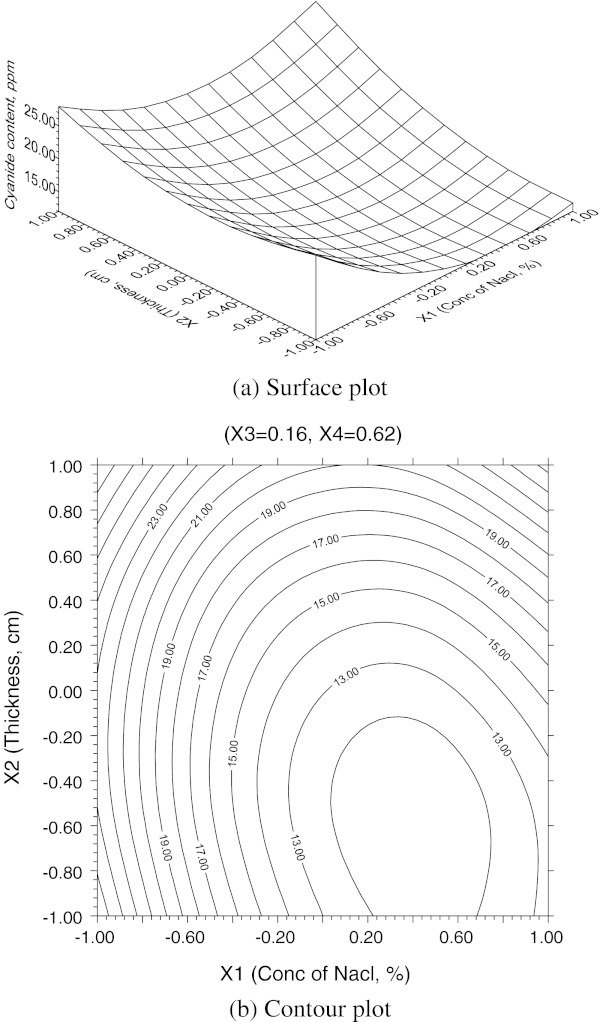

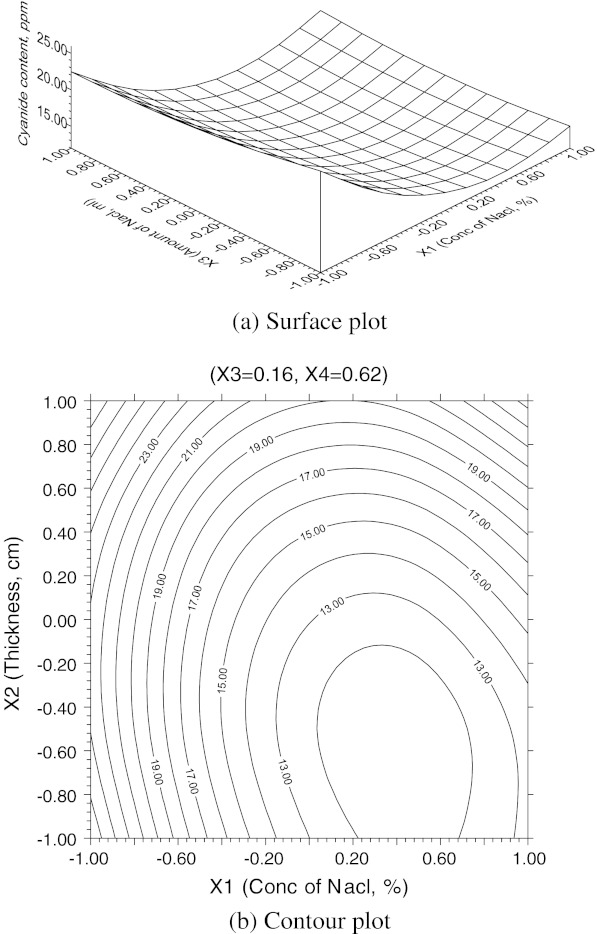

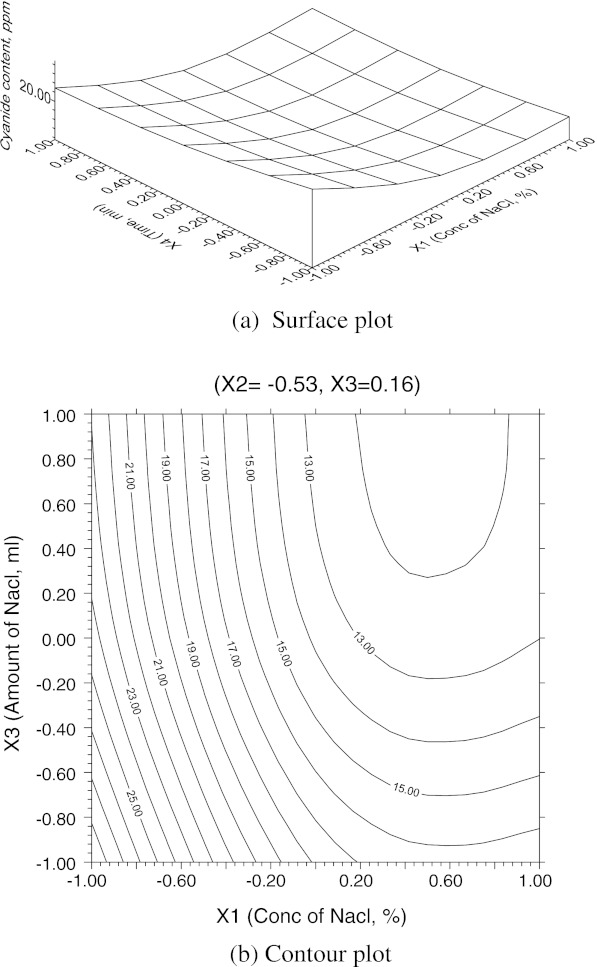

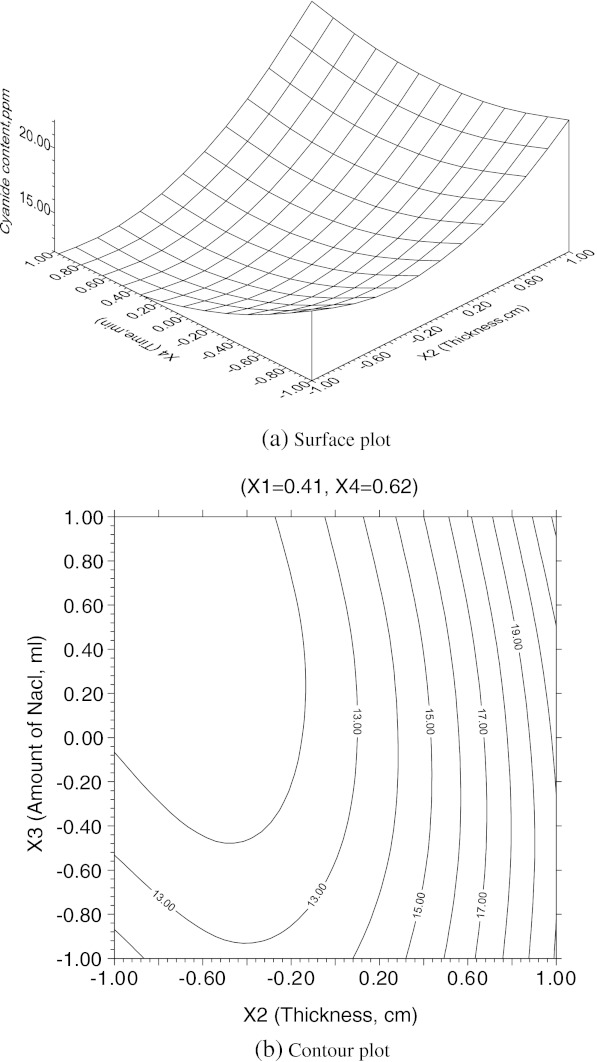

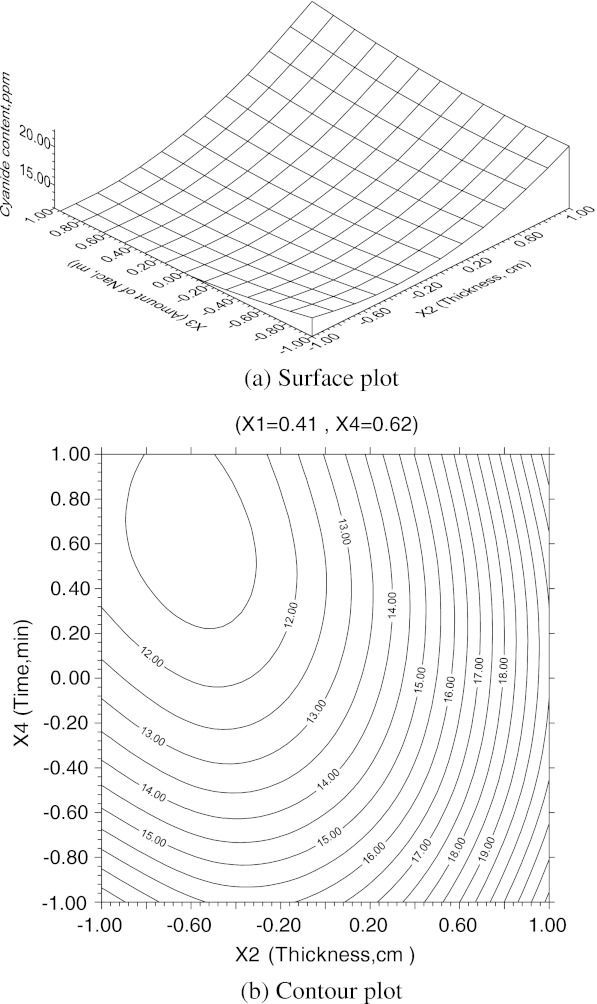

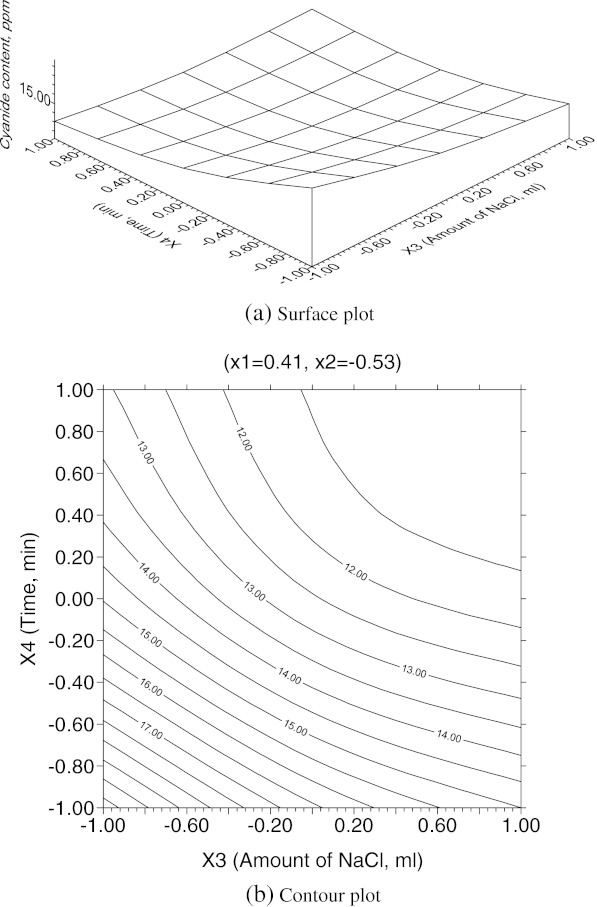

Three dimensional surface plots and contour plots were developed between two variables using full second order model and keeping other variables at optimum to show the effects of variables on cyanide content.

Effect of concentration of NaCl and thickness of bamboo shoot on cyanide content showed (Fig. 1) that the cyanide content decreased as concentration of NaCl increased up to 2.4% and then decreased. However, thickness of bamboo shoot had slight effect on the cyanide content up to 2% concentration of NaCl. It can be also seen that cyanide content was higher at higher and lower levels of both concentration of NaCl and thickness of bamboo shoot as well as at low level of concentration of NaCl and higher thickness of bamboo shoot. Effect of concentration of NaCl and amount of NaCl was also depicted (Fig. 2) that the least cyanide content was obtained at 2.4% NaCl and 216 ml of NaCl solution. The cyanide content of about 13 mg/kg can be obtained over wide range of NaCl concentration. The amount of solution had a little effect on the cyanide content.

Fig. 1.

Interactive effect of NaCl concentration and thickness on cyanide content (amount of NaCl solution 216 ml, boiling time 23 min)

Fig. 2.

Interactive effect of NaCl concentration and amount of NaCl solution on cyanide content (thickness l.25 cm, boiling time 23 min)

In Fig. 3, the minimum cyanide content was observed at 2.4% NaCl concentration and 23 min of treatment time. The effect of NaCl concentration and treatment time was more pronounced at higher levels. The interactive effect of thickness of bamboo shoot and amount of NaCl showed (Fig. 4) that the cyanide content increased with increase in thickness of bamboo shoot. The minimum cyanide content was obtained at 1.25 cm thickness of bamboo shoot and 216 ml of NaCl. However, there was no significant effect of amount of NaCl content. The effect of thickness of bamboo shoot was more pronounced at their higher values.

Fig. 3.

Interactive effect of NaCl concentration and time on cyanide content (amount of NaCl solution 216 ml, thickness l.25 cm)

Fig. 4.

Interactive effect of thickness and amount of NaCl solution on cyanide content (NaCl concentration 2.4%, time 23 min)

The interactive effect of treatment time and thickness of bamboo shoot showed (Fig. 5) that the minimum cyanide content (11.2 mg/kg) was obtained at 23 min treatment and 1.25 cm thickness of bamboo shoot. The cyanide content decreased with increase in thickness of bamboo shoot and increased with increase in time. The effect of time was more pronounced at lower level while the effect of thickness of bamboo shoot was uniform at all levels.

Fig. 5.

Interactive effect of thickness and time on cyanide content (concentration of NaCl 2.4%, amount of NaCl solution 216 ml)

From Fig. 6 it is clear that the minimum cyanide content was occurred at higher levels of time and amount of NaCl. The cyanide content decreased with increase in time. However, amount of NaCl had slight effect on cyanide content. The effect of time had more pronounced effect at lower than at higher values.

Fig. 6.

Interactive effect of amount of NaCl solution and time on cyanide content (concentration of NaCl 2.4%, thickness 1.25 cm)

Conclusion

RSM was successfully used for optimization of NaCl concentration, thickness of bamboo shoot, amount of NaCl and duration of NaCl treatment for getting minimum cyanide content. Concentration of NaCl, thickness of bamboo shoot and time affected cyanide content significantly. Increase in concentration of NaCl, amount of NaCl solution and time of treatment decreased cyanide content while thickness of bamboo shoot increased cyanide content. It was also found that boiling of bamboo shoot at optimum conditions (2.4% NaCl concentration, 1.25 cm thickness of bamboo shoot, 216 ml of NaCl solution and 23 min of treatment time at 100 °C) reduced HCN content to 11.3 mg/kg, which was well below permissible limit (500 mg/kg). The reduction of cyanide content was of 98.3% at optimum level. Therefore, boiling of shoots under optimum conditions may be very effective to make tender bamboo shoots suitable for human consumption.

Contributor Information

Bindu Rana, Email: brana_09@rediffmail.com.

Pratima Awasthi, Email: pratimawasthi@yahoo.co.in.

B. K. Kumbhar, Email: bkkumbhar@rediffmail.com

References

- Anon (2005) Cyanogenic glycosides in cassava and bamboo shoots: A human health assessment. Food Standards, Australia New Zealand. Technical report, Series no. 28, July 2004. Canberra, FSANZ, Australia, p 22

- Awasthi P, Tewari L 2008. Utilizing bamboo as a viable food option. In: Souvenir, Int Conf Improvement of bamboo productivity and marketing for sustainable livelihood, New Delhi, 15–17 April, p 16–18

- Bhargava A, Kumbhare V, Srivastava A, Sahai A. Bamboo parts and seeds for additional source of nutrition. J Food Sci Technol. 1996;32:145–146. [Google Scholar]

- Coursey DG (1973) Cassava as food: toxicity and technology, In: Nestel B, MacIntyre R, (eds), Chronic cassava toxicity. IDRC-01Oe, Int. Develop. Res. Centre, Ottawa. p. 27–36

- Dutt S. Exploring successful journey of bamboo. Indian Hort. 2004;49:1–24. [Google Scholar]

- FAO (2005) National Mission on Bamboo Applications. FAO Recommended Nutritional Composition, 3 Aug. Food and Agricultural Organization, Rome, Italy

- Ferreira VLP, Marsaiolo AJ, Iaderoza M. Simplified methods for identification and detection of taxiphyllin in bamboo shoots. Coletanea INST Technol Aliment. 1991;21(1):57–63. [Google Scholar]

- Hogg PG, Ahlgren HL. A rapid method for determining hydrocyanic acid content of single plant of sudan grass. J Am Soc Agron. 1942;34:199–200. doi: 10.2134/agronj1942.00021962003400020011x. [DOI] [Google Scholar]

- Kumbhare V, Bhargava A. Effect of processing and nutritional value of Central Indian Bamboo shoots. Part I. J Food Sci Technol. 2007;44:29–31. [Google Scholar]

- Pandey AK, Jharia P (2009) Influence of processing methods on nutritional value of bamboo shoots. In: Souvenir, National seminar on Bamboo plantation, management and its utilization, Arid Zone Forest Research Institute, Jodhpur, 17–19 Mar, p 74

- Soo-Jung H, Sung-Ja K. Study on the chemical composition in bamboo shoot, lotus root and burdock: free sugar, fatty acid, amino acid and dietary fibre contents. J Korean Soc Food Sci. 1993;9(2):82–87. [Google Scholar]

- Zhang Y, Liu H (2001) Food, nutrition and health. Vol. 12. Beijing China Materials Publisher (Chinese), p 230, 234