Abstract

An investigation was undertaken to explore the possibility of utilizing defatted rice bran (DRB) for making chapati. DRB was ground in hammer mill, sieved for different particle size i.e. 0.336 mm (large), 0.234 mm (medium) and 0.157 mm (fine), blended with wheat flour in the proportion of 0, 5, 10, 15, 20, 25% and blends were evaluated for dough and chapati making quality. Extensibility of dough and chapati decreased (19.9 ± 0.08 to 14.3 ± 0.08 mm, 11.2 ± 0.05 to 6.3 ± 0.04 mm, respectively) while peak load to rupture of chapati increased (3.1 ± 0.04 to 3.6 ± 0.05 N) at 25% replacement of flour with fine DRB. Water absorption capacity of flour increased from 73 ± 0.4% to 74.6 ± 0.4% with 25% of large DRB, while the increase was up to 78.4 ± 0.3 and 80.6 ± 0.3% in case of medium and fine DRB. Overall acceptability score of chapati was also significantly (p ≤ 0.05) decreased (8.4 ± 0.2 to 6.8 ± 0.2) with 20% of large DRB, whereas it was 7.0 ± 0.1 and 7.6 ± 0.1 for medium and fine DRB at the same proportion. The chapati prepared from the wheat flour containing 20% fine DRB was rated acceptable and also had significantly (p ≤ 0.05) higher ash (2.1 ± 0.05) and total dietary fiber (4.3 ± 0.10%) content than control chapati.

Keywords: Defatted rice bran, Particle size, Pasting properties, Dough extensibility, Texture, Chapati

Introduction

Rice (Oryza sativa) is ranked first among cereal crops based on production in India. India produced 96.0 million tonnes of total rice and 6.53 million tonnes of defatted rice bran in 2008 (SEA 2008). Defatted rice bran is a by-product of rice bran oil extraction industry and comparatively contains more nutrients than full fat rice bran. In spite of being abundantly available and nutritionally rich, it is under utilized for human consumption and mostly utilized as animal/poultry feed. Consumption of bran is reported to have a number of health benefits like laxative and stool bulking ability (Tomlin and Read 1988), anti-carcinogenic effect (Aoe et al. 1993) and hypocholestrelomic effect for both full fat and defatted bran (Newman et al. 1992; Hegsted and Windhauser 1993; Kahlon et al. 1994). Due to its overall composition, nutritional profile, functional characteristics and apparent hypoallergenicity, rice bran has many applications in diet which is characterized by high in dietary fiber and low in saturated fat (Shariff and Butt 2006). Defatted rice bran increases dough yield, contributes to an attractive crumb and crust, does not alter fermentation or mixing tolerance of dough, causes baked products to remain fresher and more moist and add significant amino acids, minerals and vitamins to baked goods (Marshall and James 1994). A number of potential food uses of full fat and defatted rice bran for the preparation of bread, muffins, pancakes and cakes have also been reported (Barber and Barber 1980; James and Sloan 1984; Bera and Mukherjee 1989; Carroll 1990; Chavan and Kadam 1993; Shariff and Butt 2006). Incorporation of protein concentrate from full fat and defatted bran in bread, cookies and weaning foods has been reported by Saunders (1990) and Prakash and Ramanathan (1995). Bran with lesser coarseness and ash content, higher protein as well as other health beneficial components could be incorporated in human diet and used in the production of health foods. Since large quantity of defatted rice bran is available at cheaper prices, it was realized to utilize this untapped source of nutrients. Chapati, a flat unleavened, hot plate baked product prepared from whole wheat flour is the staple food of more than 60% of the Indian population. It is similar to tortilla which is prepared either from corn or wheat flour. On baking, chapati is slightly puffed that gives a golden brown colour with a few brown spots on the surface. On an average, 90% of wheat produced in India is consumed in the form of chapati and only 10% is used for making biscuits, bread, cakes and such other products (Bedekar 2001). Since, wheat flour is widely consumed in the form of chapati in India; it is selected as a base ingredient to explore the benefits of defatted rice bran. The present investigation was planned with the aim to explore the possibility for incorporation of defatted rice bran in wheat flour as well as to optimize its level and particle size for preparation of chapati with respect to acceptability.

Materials and methods

Branded whole wheat flour was procured from the local market. Edible grade defatted rice bran (DRB) was procured from a local extraction unit (AP Organics Pvt Ltd Dhuri, Punjab, India). It was stabilized by heating at 105 °C for 10 min (Yokochi 1974).

Analysis of particle size distribution

DRB samples were first ground in a hammer mill. The particle size measurement of ground bran and wheat flour was carried out by shaking 200 g of sample for 5 min in a set of standard test sieve (Tyler Mentor, USA) (Sahay and Singh 2001). Sieve fractions were weighed and used for preparation of blends. The sieve fractions of DRB were categorized and termed as follows:

Passed through 0.336 mm openings: Large

Passed through 0.234 mm openings: Medium

Passed through 0.157 mm openings: Fine

Preparation of blends

DRB (14% wb) of different particle size (large, medium and fine) were blended with wheat flour in the proportion of 0%, 5%, 10%, 15%, 20% and 25%.

Proximate analysis

The proximate parameters like moisture, protein, crude fat, ash and crude fiber were determined using the standard methods of AACC (1990). The carbohydrate content of sample was estimated by subtracting the sum of moisture, protein, fat, ash and total dietary fiber from 100 (Merrill and Watt 1973). All the chemicals used were of analytical grade and procured from S D Fine chemicals, Mumbai, India.

Water absorption

The water was added in the blended flour using bowl of laboratory dough kneader (Spar Mixer, Spar Food Machinery Mfg Co Ltd Model 800-B, Taiwan,). The optimum water was subjectively determined till it gave a smooth non-sticky dough, easy to handle and suitable for sheeting without cracking (Gujral and Gaur 2002; Gujral and Pathak 2002).

Preparation of chapaties

Dough was prepared from the blended flour using laboratory dough kneader (Spar Mixer, Spar Food Machinery Mfg Co Ltd Model 800-B, Taiwan) for 10 min at optimum water. The dough was allowed to rest for 15 min and divided into 40 g pieces. Each dough piece was formed into spherical shape and manually rolled into circular form of about 150 mm diameter using rolling pin. The circular dough sheets were baked on a hot plate at 230 ± 5 °C for 1–2 min on either side (Yadav et al. 2008).

Measurement of puffing height

The height of chapati was measured immediately after puffing (Haridas Rao et al. 1986).

Colour values

The colour values in terms of L (lightness or darkness), a (redness or greenness) and b (yellowness or blueness) of flour blends, dough and chapatis were measured using a Hunter Lab Miniscan XE Plus colorimeter (45/O,10°/D65, Hunter Associates Laboratory Inc., Reston, Virginia, USA). For each sample, three measurements were taken and averaged. Total colour change was calculated as

|

where the subscript ‘0’ indicates initial colour value of the sample

Pasting properties

Pasting properties of different samples were measured using a Rapid Visco-Analyser 4D (Newport Scientific Pvt Ltd Warie Wood, Australia). Flour sample (3.5 g at 14% wb) was dispersed in 25 ml of distilled water. The rotating speed of paddle was 160 rev/min except for first 10 s (960 rev/min). The suspension was equilibrated at 50 °C for 1 min and heated to 95 °C at the rate of 12 °C/min and then held at 95 °C for 2.5 min. The sample was then cooled to 50 °C at the rate of 12 °C/min and then held at the temperature of 50 °C for 3 min. Parameters such as peak viscosity (PV), break down viscosity (BD), set back viscosity (SB), hot paste viscosity (HPV, minimum viscosity at 95 °C), cool paste viscosity (CPV, final viscosity at 50 °C), break down (BD) = PV- HPV and Set back (SB) = CPV-HPV were calculated. All measurements were carried out in triplicate.

Texture profile analysis

Textural profile analysis of dough and chapati was performed using texture analyzer (Stable Micro System Model-TA-HDi, UK). The dough extensibility was measured using SMS/Kieffer dough and gluten extensibility rig. The size of the dough strip was 60 × 5 × 5 mm and the test was carried out with pre and post test speed of 25 mm/min using 5 kg load cell. For the extensibility of chapati, rectangular strips of 90 mm × 18 mm were cut from the centre portion of chapati using a metal template. The chapati strip was held between two clamps. One clamp was attached to the moving arm of the instrument and other was attached to the platform. Both the clamps were properly aligned and set 50 mm apart. A load cell of 50 N was used at a cross head speed of 50 mm/min to pull the chapati strip apart until it tear. Peak load to rupture was obtained from extension displacement curve and extensibility was calculated as suggested by Sharma et al. (2000). Three replications were carried out and ten measurements were taken for each replication.

Sensory evaluation

The sensory attributes of chapati in each experimental block were evaluated in terms of colour, aroma, taste and texture by a semi-trained panel consisting of ten members from the scientific staff of the laboratory with knowledge of consumer’s preference using a nine point-Hedonic scale having a score of 9-extreme liking, 8- like very much, 7-like moderately, 6-like slightly, 5-neither like nor dislike, 4-dislike slightly, 3-dislike moderately, 2-dislike very much and 1 for extreme disliking (Larmond 1977). The overall acceptability score (OAA) was calculated as the average scores of all the four parameters.

Statistical analysis

The experiments were performed using factorial design. The independent parameters were particle size of DRB (large, medium and fine) and its proportion with wheat flour (0, 5, 10, 15, 20 and 25%). Analysis of variance (Snedecor and Cochran 1994) was carried out using statistica software version-7 (State Soft Corporation, Tulsa, USA). The multiple response regression analysis for total colour change of flour, dough and chapati was carried out using Minitab statistical software.

Results and discussion

The wheat flour and DRB were analysed for its moisture, protein, fat, ash, total dietary fiber and carbohydrate. The corresponding values for wheat flour in percentage were 10.6 ± 0.15, 12.7 ± 0.10, 1.2 ± 0.03, 1.2 ± 0.06, 3.7 ± 0.05 and 70.6 and that for DRB were 12.7 ± 0.10, 14.9 ± 0.10, 2.7 ± 0.13, 8.2 ± 0.07, 12.7 ± 0.0.08 and 48.8, respectively. The analysis of particle size of wheat flour was also performed and found that 99% of the particles passed through 100 mesh sieve.

Effect of particle size and proportion of DRB on pasting properties of wheat flour

The results of pasting properties of wheat flour as affected by proportion of DRB and particle size are reported in Table 1. All the pasting properties of wheat flour significantly (p ≤ 0.05) decreased with increase in the proportion of DRB. The interactive effect of particle size of DRB and its proportion also had significant effect on all pasting properties at p ≤ 0.05. The magnitude of reduction in pasting properties decreased with decrease in particle size. Therefore, little change in pasting properties was observed in case of fine particle size of DRB. The reason for this trend may be due to availability of more surface area and better mixing, causing higher water absorption capacity. Yadav et al. (2010) also observed reduction in all pasting properties of wheat flour, while replacing with wheat bran and explained that it may be due to insoluble nature of the fiber as well as by the dilution of wheat starch. Similar reduction in peak and final viscosity of wheat flour was also observed by Sekhon et al. (1997) in replacement of the wheat flour with rice bran beyond 5% level.

Table 1.

Pasting properties of wheat flour as affected by the amount and particle size of DRB

| Pasting properties | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| % DRB | Peak viscosity, cP | Break down, cP | Set back, cP | Final viscosity, cP | ||||||||

| Particle size of DRB | ||||||||||||

| Large | Medium | Fine | Large | Medium | Fine | Large | Medium | Fine | Large | Medium | Fine | |

| 0 | 1,753 ± 12ax | 1,753 ± 12ax | 1,753 ± 12ax | 737 ± 6ax | 737 ± 6ax | 737 ± 6ax | 934 ± 6ax | 934 ± 6ax | 934 ± 6ax | 1,950 ± 12ax | 1,950 ± 12ax | 1,950 ± 12ax |

| 5 | 1,527 ± 14bx | 1,590 ± 8by | 1,648 ± 12bz | 617 ± 7bx | 649 ± 6by | 675 ± 7bz | 880 ± 5bx | 910 ± 9ay | 939 ± 8az | 1,790 ± 14bx | 1,851 ± 12by | 1,903 ± 10bz |

| 10 | 1,326 ± 10cx | 1,476 ± 10cy | 1,479 ± 8cz | 508 ± 6cx | 580 ± 8cy | 578 ± 6cz | 810 ± 9cx | 880 ± 6by | 894 ± 8by | 1,627 ± 14cx | 1,776 ± 10cy | 1,795 ± 14cy |

| 15 | 1,198 ± 12dx | 1,273 ± 11dy | 1,404 ± 9dz | 443 ± 6dx | 494 ± 9dy | 538 ± 8dz | 775 ± 6dx | 784 ± 7cx | 877 ± 7cy | 1,530 ± 12dx | 1,562 ± 11dx | 1,742 ± 12dy |

| 20 | 1,018 ± 12ex | 1,175 ± 12ey | 1,237 ± 11ez | 361 ± 5ex | 421 ± 7ey | 457 ± 6ez | 664 ± 8ex | 757 ± 6cy | 810 ± 6cz | 1,320 ± 12ex | 1,494 ± 13ey | 1,590 ± 13ez |

| 25 | 883 ± 13fx | 1,025 ± 13fy | 1,170 ± 12fz | 308 ± 8fx | 350 ± 6fy | 416 ± 9fz | 586 ± 6fx | 685 ± 6dy | 794 ± 6dz | 1,161 ± 10fx | 1,360 ± 12fy | 1,549 ± 12fz |

Values expressed are means (n = 3) ± standard deviation; a-f, means in the same column with different superscripts were significantly (p ≤ 0.05) different; x-z for the same pasting properties, means in the same row with different superscripts were significantly (p ≤ 0.05) different

Effect of particle size and proportion of DRB on textural properties of dough and chapati

The textural parameters of dough and chapati had direct effect on quality and acceptability of chapati (Yadav et al. 2008). The proportion of DRB, particle size and their interaction had significant effect on dough extensibility, peak load to rupture and extensibility of chapati at p ≤ 0.05 (Table 2). Dough extensibility significantly (p ≤ 0.05) decreased with increase in the proportion of DRB, while at fine particle size, the reduction was less as compared to larger one. The dough extensibility decreased due to dilution of the gluten. At 20% replacement, the dough extensibility was 13.5 mm, 13.9 mm and 15.8 mm for large, medium and fine particle sizes, respectively. The extensibility of dough containing 20% fine DRB was significantly (p ≤ 0.05) higher (15.8 mm) than the dough containing large and medium DRB at the same proportion. On an average there was 34.6% reduction in dough extensibility at 25% proportion of DRB. The chapati prepared in control condition was soft and extensible as shown by low peak load (3.1 N) and longer distance of extension (11.2 mm) reached before the tear of the sample (Table 2). The peak load for chapati increased significantly (p ≤ 0.05) with addition of DRB. It was also observed that particle size of DRB had significant (p ≤ 0.05) effect on the peak load. The peak load of chapati having 25% large DRB was significantly (p ≤ 0.05) increased (161.3%) whereas, increase was 33.33% in case of medium and only 16.7% in case of fine DRB at the same proportion. The reason for this trend may be attributed to the fine particles of DRB that absorbed more water and made the chapati more pliable, thus caused comparatively less increase in the peak load. The extensibility of chapati decreased significantly (p ≤ 0.05) with an average value of 45.8% at 25% replacement of wheat flour with DRB. In this case also the chapati containing fine DRB showed less decrease in extensibility than the chapati containing large and medium size DRB.

Table 2.

Textural parameters of dough and chapati

| % DRB | Dough extensibility, mm | Peak load to rupture, N | Chapati extensibility, mm | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Particle size of DRB | |||||||||

| Large | Medium | Fine | Large | Medium | Fine | Large | Medium | Fine | |

| 0 | 19.9 ± 0.08ax | 19.9 ± 0.08ax | 19.9 ± 0.08ax | 3.1 ± 0.04ax | 3.1 ± 0.04ax | 3.1 ± 0.04ax | 11.2 ± 0.05ax | 11.2 ± 0.05ax | 11.2 ± 0.05ax |

| 5 | 18.3 ± 0.08bx | 18.5 ± 0.07bx | 18.9 ± 0.09by | 3.4 ± 0.03bx | 3.2 ± 0.05ay | 3.1 ± 0.04ay | 8.0 ± 0.04bx | 9.5 ± 0.06by | 11.1 ± 0.04az |

| 10 | 16.9 ± 0.06cx | 17.3 ± 0.08cx | 18.2 ± 0.08cy | 5.1 ± 0.05cx | 3.4 ± 0.06by | 3.3 ± 0.03bcy | 7.8 ± 0.05bcx | 7.8 ± 0.05cx | 8.4 ± 0.05bcy |

| 15 | 15.1 ± 0.06dx | 15.5 ± 0.06dx | 16.6 ± 0.06dy | 5.6 ± 0.06dx | 3.7 ± 0.04cy | 3.4 ± 0.03cdz | 7.6 ± 0.05cx | 7.3 ± 0.04dy | 8.2 ± 0.05cz |

| 20 | 13.5 ± 0.08ex | 13.9 ± 0.07ex | 15.8 ± 0.06ey | 7.6 ± 0.05ex | 3.9 ± 0.04dy | 3.5 ± 0.04dez | 6.1 ± 0.03dx | 6.8 ± 0.04ey | 7.5 ± 0.04dz |

| 25 | 12.1 ± 0.05fx | 12.6 ± 0.08fx | 14.3 ± 0.08fy | 8.1 ± 0.06fx | 4.1 ± 0.05ey | 3.6 ± 0.05ez | 5.9 ± 0.03ex | 6.1 ± 0.05fy | 6.3 ± 0.04ez |

Values expressed are means (n = 3) ± standard deviation; a-f, means in the same column with different superscripts were significantly (p ≤ 0.05) different; x-z for the same textural parameter, means in the same row with different superscripts were significantly (p ≤ 0.05) different

Effect of particle size and proportion of DRB on water absorption

The water absorption of the samples increased significantly (p ≤ 0.05) with increase in proportion of DRB and with decrease of particle size (Table 3). The water absorption of control sample was 73% in comparison to 80.6%, 78.4% and 74.6% for flour containing 25% DRB of fine, medium and large, respectively. It indicated that fine particles had greater water absorption probably due to more surface area availability. The hydrophilic nature of crude fiber might have contributed to the increase in water absorption. Similar results were also reported by Sekhon et al. (1997) in wheat flour samples, upon replacement with rice bran beyond 5% level.

Table 3.

Water absorption and height of puffed chapaties

| % DRB | Water absorption,% | Height of puffing, mm | ||||

|---|---|---|---|---|---|---|

| Particle size of DRB | ||||||

| Large | Medium | Fine | Large | Medium | Fine | |

| 0 | 73 ± 0.4ax | 73 ± 0.4ax | 73 ± 0.4ax | 6.7 ± 0.3ax | 6.7 ± 0.3ax | 6.7 ± 0.3ax |

| 5 | 73.2 ± 0.4abx | 73.4 ± 0.2bx | 74.6 ± 0.4by | 5.3 ± 0.2bx | 5.6 ± 0.3by | 6.3 ± 0.3bz |

| 10 | 73.4 ± 0.4bcx | 75.0 ± 0.3cy | 76.5 ± 0.3cz | 5.1 ± 0.4bx | 5.4 ± 0.4bcy | 6.4 ± 0.4bz |

| 15 | 73.6 ± 0.5cx | 75.2 ± 0.3cy | 78.2 ± 0.4dz | 4.8 ± 0.4cx | 5.2 ± 0.3cy | 6.3 ± 0.3bz |

| 20 | 74 ± 0.3dx | 77.8 ± 0.2dy | 79.2 ± 0.2ez | 4.6 ± 0.5cx | 4.9 ± 0.2dy | 5.6 ± 0.4cz |

| 25 | 74.6 ± 0.4ex | 78.4 ± 0.3ey | 80.6 ± 0.3fz | 3.9 ± 0.4dx | 4.1 ± 0.4ex | 4.7 ± 0.3dy |

Values expressed are means (n = 3) ± standard deviation; a-f, means in the same column with different superscripts were significantly (p ≤ 0.05) different; x-z for the same parameter, means in the same row with different superscripts were significantly (p ≤ 0.05) different

Effect of particle size and proportion of DRB on height of puffed chapaties

The height of chapati puffing is a critical parameter in determination of its quality. The low height of chapati puffing is basically attributed to its poor gluten quality, slower rate of steam formation and low moisture content of the dough (Haridas Rao et al. 1986). The chapati prepared from high moisture dough, puffed more than that of low moisture. The height of puffing reduced significantly (p ≤ 0.05) by the addition of DRB, however, fine particle size indicated improvement in puffing height in comparison to that of large and medium size. The sample with fine DRB showed higher puffing over their counterparts i.e. medium and large at all the levels of replacement.

Effect of particle size and proportion of DRB on total colour change

The following mathematical models were developed for total colour change of flour, dough and chapati.

|

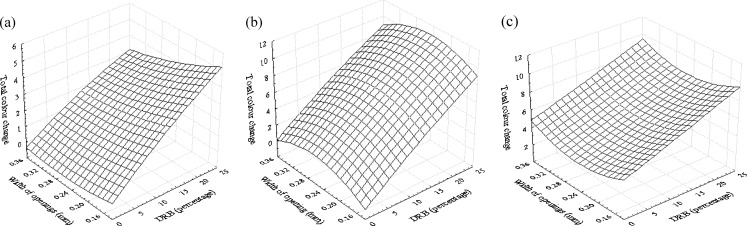

The linear, quadratic and interaction effects were calculated for each of the above models. The adequacy of the models was tested using F-ratio and correlation coefficient (R2). The models were considered adequate when the calculated F-ratio was more than the table F-value (2.35) and R2 was more than 0.80 (Henika 1982). The correlation coefficients for total colour change of wheat flour, dough and chapati were 0.98, 0.99 and 0.89, indicating that all the values were more than 0.80. The proportion of DRB had shown significant (p ≤ 0.05) positive effect on the total colour change of wheat flour, dough and chapati at linear level. The particle size had also positive effect (p ≤ 0.05) on colour change of dough but negative effect (p ≤ 0.05) on flour and chapati at linear level. The positive effect on total colour change of dough may be attributed to uniform distribution during kneading of flour as well as due to more water absorption during mixing. It might be also due to that, the flour particles adhered uniformly on the fine particles of DRB and masked its colour. However, negative effect on total colour change of flour and chapati might be due to more surface area availability of fine DRB. Overall the interaction had negative effect (p ≤ 0.05) on total colour change. The response surface for total colour change of flour, dough and chapati are presented in Fig 1.

Fig. 1.

Effect of level of DRB and its particle size on total colour change of flour (a), dough (b) and chapati (c)

Effect of particle size and proportion of DRB on sensory properties

Sensory scores of chapati having different proportions of DRB and particle size are reported in Table 4. The sensory parameters except aroma were found to be affected significantly (p ≤ 0.05) by the proportion of DRB and its particle size. Because of subjective nature of parameters, a sensory score of more than 7.5 was considered acceptable and based on this assumption, the chapati samples with 20% fine DRB was found most acceptable having the scores for colour 7.5, aroma 8.0, taste 7.5, texture 7.6 and overall acceptability as 7.6. It was observed that fine particle size of DRB had better sensory scores as compared to large and medium. It might be due to fact that the fine particles absorbed more water and cooked uniformly. Hence, addition of fine DRB to the wheat flour at 20% level is recommended for the preparation of an acceptable chapati. The chapati samples with 20% fine DRB along with control (without DRB) were prepared and analyzed for proximate composition that exhibited the corresponding values in percentage for moisture 30.3 ± 0.22, protein 10.2 ± 0.10, fat 1.1 ± 0.10, ash 2.1 ± 0.05, total dietary fiber 4.3 ± 0.10 and carbohydrate 52.0 ± 0.12, and 28.5 ± 0.15, 10.1 ± 0.08, 0.9 ± 0.10, 1.0 ± 0.04, 2.9 ± 0.10 and 56.6 ± 0.08, respectively. The values for ash and total dietary fiber increased significantly (p ≤ 0.05) in chapati containing 20% DRB.

Table 4.

Sensory scores of chapaties containing different proportion of DRB with varied particle size

| Sensory parameters | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| % DRB | Colour | Aroma | Taste | Texture | OAA | ||||||||||

| Particle size of DRB | |||||||||||||||

| Large | Medium | Fine | Large | Medium | Fine | Large | Medium | Fine | Large | Medium | Fine | Large | Medium | Fine | |

| 0 | 8.4 ± 0.2ax | 8.4 ± 0.2ax | 8.4 ± 0.2ax | 8.5 ± 0.2ax | 8.5 ± 0.2ax | 8.5 ± 0.2ax | 8.5 ± 0.2ax | 8.5 ± 0.2ax | 8.5 ± 0.2ax | 8.4 ± 0.2ax | 8.4 ± 0.2ax | 8.4 ± 0.2ax | 8.4 ± 0.2ax | 8.4 ± 0.2ax | 8.4 ± 0.2ax |

| 5 | 7.5 ± 0.1bx | 7.8 ± 0.2by | 8.0 ± 0.2by | 8.2 ± 0.2bx | 8.2 ± 0.2bx | 8.2 ± 0.1bx | 7.6 ± 0.2bx | 7.8 ± 0.1bx | 8.2 ± 0.2by | 7.6 ± 0.1bx | 8.2 ± 0.2by | 8.2 ± 0.1by | 7.7 ± 0.1bx | 8.0 ± 0.1by | 8.2 ± 0.1abz |

| 10 | 7.1 ± 0.2cx | 7.4 ± 0.1cy | 7.8 ± 0.1bz | 8.2 ± 0.1bx | 8.2 ± 0.1bx | 82 ± 0.2bx | 7.5 ± 0.1bx | 7.6 ± 0.1bcx | 8.0 ± 0.1bcy | 7.4 ± 0.1cx | 7.6 ± 0.1cx | 8.0 ± 0.1cy | 7.5 ± 0.2bx | 7.6 ± 0.1cx | 8.0 ± 0.2bcy |

| 15 | 6.8 ± 0.1dx | 7.2 ± 0.2cy | 7.8 ± 0.2bz | 8.0 ± 0.1bx | 8.0 ± 0.2bx | 8.0 ± 0.1bx | 6.8 ± 0.2cx | 7.4 ± 0.2cdy | 7.8 ± 0.2cz | 7.1 ± 0.1dx | 7.0 ± 0.1dx | 8.0 ± 0.2cy | 7.0 ± 0.1cx | 7.2 ± 0.2dx | 7.8 ± 0.1cdy |

| 20 | 6.6 ± 0.2dx | 6.9 ± 0.1dy | 7.5 ± 0.1cz | 8.0 ± 0.2bx | 8.0 ± 0.1bx | 8.0 ± 0.2bx | 6.6 ± 0.1cdx | 7.2 ± 0.1dy | 7.5 ± 0.1dz | 6.5 ± 0.2ex | 6.4 ± 0.2ex | 7.6 ± 0.1dy | 6.8 ± 0.2cdx | 7.0 ± 0.1ex | 7.6 ± 0.1dy |

| 25 | 6.3 ± 0.1ex | 6.4 ± 0.2ey | 7.0 ± 0.2dz | 8.0 ± 0.2bx | 8.0 ± 0.2bx | 8.0 ± 0.2bx | 6.4 ± 0.1dx | 6.5 ± 0.2ex | 6.8 ± 0.2ey | 6.2 ± 0.2fx | 6.1 ± 0.1fx | 7.0 ± 0.2ey | 6.6 ± 0.1dx | 6.7 ± 0.1fx | 7.0 ± 0.1ey |

Values expressed are means (n = 3) ± standard deviation; a-f, means in the same column with different superscripts were significantly (p ≤ 0.05) different; x-z for the same sensory parameter0, means in the same row with different superscripts were significantly (p ≤ 0.05) different

Correlation of rheological characteristics with sensory qualities

The sensory attributes of chapati particularly taste, texture and OAA were significantly (p ≤ 0.05) correlated with the pasting behavior of flour and textural characteristics of chapati as well as with height of puffing (Table 5). Peak load of chapati sample was negatively correlated with above sensory parameters, whereas the relation between height of puffing and above sensory parameters was found positive. All the pasting properties showed a significant (p ≤ 0.05) positive correlation with sensory attributes.

Table 5.

Correlation coefficients between rheological characteristics of wheat flour, chapati and sensory properties of chapati

| Colour | Aroma | Taste | Texture | OAA | |

|---|---|---|---|---|---|

| Peak viscosity | 0.95* | 0.07 | 0.95* | 0.92* | 0.95* |

| Break down viscosity | 0.95* | 0.05 | 0.95* | 0.92* | 0.95* |

| Set back | 0.92* | 0.16 | 0.94* | 0.93* | 0.94* |

| Final viscosity | 0.94* | 0.13 | 0.95* | 0.94* | 0.95* |

| Dough extensibility | 0.96* | 0.23 | 0.98* | 0.94* | 0.98* |

| Peak load to rupture | −0.92* | −0.10 | −0.94* | −0.93* | −0.94* |

| Extensibility | 0.92* | −0.09 | 0.92* | 0.90* | 0.93* |

| Height of puffing | 0.95* | 0.27 | 0.97* | 0.98* | 0.96* |

*OAA, Overall acceptability, *significant (p ≤ 0.05)

Conclusion

The pasting properties of wheat flour decreased and water absorption of the samples increased with addition of defatted rice bran to wheat flour. Texture of chapati was negatively affected by the addition of DRB due to the dilution of gluten. The change in quality parameters of the flour and chapati was significantly (p ≤ 0.05) affected by the particle size of DRB and finer particle size showed better acceptability. Hence, it was recommended to substitute the wheat flour with fine (0.157 mm particle size) DRB at 20% proportion for the preparation of optimally acceptable chapati. These findings may create an opportunity for the use of an underutilized nutritional source in the formulation of wheat flour based food products.

References

- AACC (1990) American association of cereal chemists: approved methods. St Paul, MN USA

- Aoe S, Oda T, Tojima T, Tanak M, Tatsumi K, Mizutani T. Effect of rice bran hemicelluloses on 1, 2-dimethylhydrazine induced intestinal carcinogenesis in Fischer 344 rat. Nutr Cancer. 1993;20:41–49. doi: 10.1080/01635589309514269. [DOI] [PubMed] [Google Scholar]

- Barber S, Barber CB. Rice bran: chemistry and technology. In: Luh BS, editor. Production and utilization. Westport: AVI; 1980. pp. 790–862. [Google Scholar]

- Bedekar BR. Chapati- Indian bakery product of the 21st century. Indian Food Ind. 2001;20(1):21–24. [Google Scholar]

- Bera MB, Mukherjee RK. Preparation of rice bran protein concentrate and its use in bread. Indian J Nutr Diet. 1989;26:48–55. [Google Scholar]

- Carroll LE. Functional properties and applications of stabilized rice bran in bakery products. Food Technol. 1990;44:74–79. [Google Scholar]

- Chavan JK, Kadam SS. Nutritional enrichment of bakery products by supplementation with non wheat flours. CRC Crit Rev Food Sci Nutr. 1993;33:189–226. doi: 10.1080/10408399309527620. [DOI] [PubMed] [Google Scholar]

- Gujral HS, Gaur S. Effect of barley flour, wet gluten and liquid shortening on the texture and storage characteristics of chapati. J Texture Stud. 2002;33:461–469. doi: 10.1111/j.1745-4603.2002.tb01360.x. [DOI] [Google Scholar]

- Gujral HS, Pathak A. Effect of composite flours and additives on the texture of chapati. J Food Engg. 2002;55:173–179. doi: 10.1016/S0260-8774(02)00061-4. [DOI] [Google Scholar]

- Haridas Rao P, Leelavathi K, Shurpalekar R. Test Baking of chapati-Development of a method. Cereal Chem. 1986;63(4):297–303. [Google Scholar]

- Hegsted M, Windhauser MM. Reducing human heart disease risk with rice bran. Lousiana-Agric. 1993;36:22–24. [Google Scholar]

- Henika RG. Use of response surface methodology in sensory evaluation. Food Technol. 1982;36(11):96–101. [Google Scholar]

- James C, Sloan S. Functional properties of edible rice bran in model system. J Food Sci. 1984;49:310–311. doi: 10.1111/j.1365-2621.1984.tb13741.x. [DOI] [Google Scholar]

- Kahlon TS, Chow FI, Sayre RN. Cholesterol lowering properties of rice bran. Cereal Food World. 1994;39:99–103. [Google Scholar]

- Larmond E. Laboratory methods for sensory evaluation of foods. Ottawa: Canada Dept of Agric; 1977. p. 1637. [Google Scholar]

- Marshall WE, James IW. Rice: science and technology. New York: Marcel Dekker Inc; 1994. pp. 1–15. [Google Scholar]

- Merrill AL, Watt BK (1973) Energy value of foods: basis and derivation, Agriculture Handbook nr 74, USDA, p 2–4

- Newman RK, Betschart AA, Newman CW, Hoefer PJ. Effect of full fat or defatted rice bran on serum cholesterol. Plant Foods Hum Nutr. 1992;42:37–43. doi: 10.1007/BF02196071. [DOI] [PubMed] [Google Scholar]

- Prakash J, Ramanathan G. Physico-chemical and nutritional traits of rice bran protein concentrate-based weaning foods. J Food Sci Technol. 1995;32:395–399. [Google Scholar]

- Sahay KM, Singh KK. Unit operations of agricultural processing. 2. New Delhi: Vikash Publishing House Pvt Ltd; 2001. p. 219. [Google Scholar]

- Saunders RM. The properties of rice bran as a food stuff. Cereal Food World. 1990;35:632–636. [Google Scholar]

- SEA (2008) Rice bran oil consumer awareness program. The solvent extractors association of India, Mumbai, India, available at: www.seaofindia.com

- Sekhon KS, Dhillon SS, Singh N, Singh B. Functional suitability of commercially milled rice bran in India for use in different food products. Plant Foods Hum Nutr. 1997;50:127–140. doi: 10.1007/BF02436032. [DOI] [PubMed] [Google Scholar]

- Shariff K, Butt MS. Preparation of fiber and mineral enriched pan bread by using defatted rice bran. Int J Food Prop. 2006;9(4):623–636. doi: 10.1080/10942910600580625. [DOI] [Google Scholar]

- Sharma SK, Mulvaney SJ, Rizvi SSH (2000) Material testing and rheology of solid foods. In: Food Process Engineering, Wiley Interscience, New York, p 35

- Snedecor GW, Cochran WG. Statistical method. 8. Iowa: Iowa State Univ Press; 1994. [Google Scholar]

- Tomlin J, Read NW. Comparison of the effects on colonic function caused by feeding rice bran and wheat bran. Eur J Clin Nutr. 1988;42:857–861. [PubMed] [Google Scholar]

- Yadav DN, Patki PE, Mahesh C, Sharma GK, Bawa AS. Optimization of baking parameters of chapati with respect to vitamin B1 and B2 retention and quality. Int J Food Sci Technol. 2008;43:1474–1483. doi: 10.1111/j.1365-2621.2008.01712.x. [DOI] [Google Scholar]

- Yadav DN, Rajan A, Sharma GK, Bawa AS. Effect of fiber incorporation on rheological and chapati making quality of wheat flour. J Food Sci Technol. 2010;47:166–173. doi: 10.1007/s13197-010-0036-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yokochi K (1974) Rice bran processing for production of rice bran oil and uses of oil and defatted bran. In: Proceedings of rice by-products utilization. International conference, Vol III, Rice bran utilization: oil, Valencia, Spain, (Barber and Tortosa eds) Inst. Agroquim Technology, Ailments, Valencia, Spain