Abstract

Studies were carried out to replace bakery shortening with refined rice bran oil in bread preparation. Physico-chemical properties of bakery shortening and rice bran oil were studied. Rice bran oil was found to have a higher content of essential fatty acid linoleic acid (34.98%) as compared to that of bakery shortening (5.14%). Chemical composition of wheat flour used was also evaluation. Bread samples were prepared by replacing bakery shortening with rice bran oil at 0, 25, 50, 75 and 100% levels. Breads were examined for bread making quality i.e. loaf weight, loaf height, loaf volume and specific volume and organoleptic quality i.e. appearance, crust colour, crumb colour, aroma, texture, taste and overall acceptability on a 9 point hedonic scale. Statistical analysis regarding bread making quality and organoleptic quality of bread revealed that bread making and organoleptic quality of breads prepared after replacing bakery shortening with rice bran oil at 50% level varied significantly from that of control. Statistically significant variations were observed in the texture of breads prepared with shortening from that prepared after replacing bakery shortening with rice bran oil at 50% level.

Keywords: Shortening, Rice bran oil, Bread, Organoleptic quality, Texture

Of the ingredients used in bread preparation, shortening is one of the major raw material (40–50%). “Shortening” is a word used to describe fats, oils and various processed versions of fats and oils that are used as ingredients in dough and batters. Shortening may contain substances other than fats and oils e.g. flavour colours and emulsifiers (Matz 1996). It modifies the physical and chemical properties of doughs and batters so that these intermediate products can be processed more effectively. It lubricates the internal structure of intermediates to allow greater expansion during proofing and baking and make the texture of finished product more tender. It modifies the visual and tactile texture of crust in the desirable ways. In some cases, natural fats contribute highly desirable flavour notes to bread (Matz 1996). Shortening can be plastic, semisolid, in pourable fluid form, in encapsulated powder form or pellet or flake form. It is produced by formulating a blend, solidifying and plasticizing the blend and packaging and tempering. The large numbers of minute air bubbles, incorporated in the shortening improves the leavening of bread.

Shortening is mostly prepared from soybean or cottonseed oil. Soybean oil is rich in essential fatty acid, linoleic acid. Use of soybean oil as such in baking has not been studied. Rapeseed oil has faced some problems related to health particularly due to its erucic acid content, but its improved version called hyola oil falls in health food category, as it is low in erucic acid. The FDA (Food and Drug Administration) limits the erucic acid content of rapeseed intended for human consumption to 2% of the fatty acid content, whereas the figure for rapeseed oil for industrial use is 45%. Canola oil is currently marketed as salad oil. Its principle appeal to the health conscious consumer is that 94% of its fatty acid content is unsaturated (Anon 1989). Its use in bakery products needs to be explored.

Vegetable oils are generally excellent sources of polyunsaturated fatty acids. Although general consumption of fats and oils has increased, recent trends in the baking industry are to reduce total usage of fats and oils and to replace plastic fats with liquid vegetable oils (Chung and Pomeranz 1983, Kamran et al. 2005). Two of the changes recommended in a recent study by Salz (1982) were replacement of most high fat baked products by those lower in fat and replacement of some animal fat by polyunsaturated vegetable oil products.

India is the second largest producer of rice in the world and has the high potential to produce rice bran oil, a by-product of rice milling industry. Since rice bran oil is unconventional oil, its chemical composition, nutrient evaluation, and toxicological safety were assessed. Experimental studies have demonstrated the hypolipidaemic effect of rice bran oil. It was established that minor constituents present in the unsaponifiable fraction of rice bran oil were responsible for its hypolipidaemic effect. Nutritional and toxicological studies had shown that there were no abnormalities in animals fed with either rice bran oil or groundnut oil. In view of its safety and hypolipidaemic activity, rice bran oil could be considered as an alternative source of edible oil (Raghuram and Rukmani 1995).

Rice bran oil is generally considered to be one of the highest quality vegetable oil in terms of its cooking quality, shelf life and fatty acid composition (Sayre and Saunders 1990). Rice bran oil is miracle product obtained from the outer brown layer of rice. Generally rice bran contains 15% to 20% oil (Marshall and Wadsworth 1994). It is extensively used in Japan, Korea, China, Taiwan and Thailand as “Premium Edible Oil”. In Japan, Rice Bran Oil is more popularly known as a “Heart Oil”. In Western countries Rice Bran Oil has acquired the status of a “Health Food”. The oryzanol present in rice bran is reported to have functions similar to vitamin E in promoting growth, facilitating capillary growth in the skin, and improving blood circulation along with stimulating hormonal secretion (Luh et al. 1991). Rice bran oil is an excellent source of PUFA (Poly Unsaturated Fatty Acids), which are helpful in lowering cardiovascular risks. Rice bran oil lowered human blood cholesterol more effectively than did sunflower, corn and safflower oils (Suzuki and Oshima 1962). RBO is superior cooking oil and is used in the manufacture of mayonnaise and salad dressings (Swern 1972). Rice bran oil is an excellent cooking medium because it is nutritionally superior, contains more micronutrients, longer shelf life, more stable at higher temperature, gives better taste & flavor to food items, frying takes less time so saves energy and economical due to 15% less absorption of oil during frying (Sharma 2002).

Materials and methods

Procurement of raw material

Commercial wheat flour,.fresh compressed baker’s yeast (Prestige Yeast) manufactured by SAF Yeast Co., Mumbai, hydrogenated fat (Gagan brand, manufactured by Gagan Vanaspathi Ltd.) which had a melting point of 37 °C,crystal cane sugar, ground sugar and salt were purchased from the local market .Refined Rice bran oil (Ricela) was procured from A.P. Solvex Ltd, Dhuri. Potassium bromate (BDH.AR) was used as an improver in bread making.

Chemical analysis of rice bran oil and bakery shortening

Rice bran oil and bakery shortening were subjected to chemical analysis for the determination of colour, iodine value, saponification value, moisture, refractive index, peroxide value, free fatty acid value, specific gravity, smoke point and flash point according to methods given by AOAC (Anon, 2000). Fatty acid profile of rice bran oil and bakery shortening was also studied using Gas liquid chromatography.

Bread making

Various ingredients and their quantity used in the preparation of bread were flour -100 g, compressed yeast -3 g, sugar-2.5 g, bakery shortening-4.0,salt-1.0,potassium bromate 10 ppm and water-optimum. Bread was prepared by using the standard Straight Dough method given by AACC (Anon, 1990) with remixing procedure. In the preparation of bread, shortening was used as following treatments i.e., T1 = 100% Normal Shortening (NS), T2 = 75% NS + 25% Rice Bran Oil (RBO), T3 = 50% NS + 50% RBO, T4 = 25% NS + 75% RBO, T5 = 100% RBO.

Evaluation of bread making quality

The loaves prepared were analyzed for height, weight, volume and specific volume.

Sensory evaluation

The bread samples were evaluated for appearance, crust colour, crumb colour, aroma, taste, texture and overall acceptability by a panel of six semi trained judges.

Texture studies

Firmness of bread samples was analyzed by Stable Microsystem Texture Analyzer.

Statistical analysis

The data obtained for each parameter was subjected to statistical analysis to determine the level of significance according to the methods described by Steel et al. (1997).

Results and discussion

Chemical analysis of rice bran oil and bakery shortening

Data with regard to physico-chemical properties of bakery shortening and rice bran oil used in the study are presented in Table 1. Bakery shortening had colour 2R ± 0.10, 1.7Y ± 0.10, iodine value of 91.7 ± 0.70, saponification value 187.2 ± 10.4, refractive index 1.5 ± 0.2, peroxide value 0.9 ± 0.1 meq/kg, free fatty acid value 0.09 ± 0.01%, moisture 0.05 ± 0.02%, specific gravity 0.91 ± 0.02, smoke point of 202.0 ± 5.8 °C and flash point of 271 ± 6.1 °C. Rice bran oil had colour 2.2R ± 0.10, 2Y ± 0.10, iodine value of 103.7 ± 0.46, saponification value 184.6 ± 4.4, refractive index 1.5, ±0.1,peroxide value 0.9 ± 0.20 meq/kg, free fatty acid value 0.05 ± 0.02%, moisture 0.03 ± 0.02%, specific gravity 0.91 ± 0.01, smoke point of 213 ±4.2 °C and flash point of 280 ± 7.4 °C. Earlier Perzybylski and Mag (2002) studied the composition, properties and uses of vegetable oils used in food technology and reported similar results. Rice bran oil was found to be having a much higher content of linoleic acid (35 ± 0.04) when compared to that of bakery shortening (5.1 ± 0.07) as shown in Table 2.

Table 1.

Physico-chemical properties of bakery shortening and rice bran oil

| Property | Bakery shortening | Rice bran oil |

|---|---|---|

| Colour (1.25″ Lovibond red) | 2R ± 0.10 | 2.2R ± 0.10 |

| 1.7Y ± 0.10 | 2Y ± 0.10 | |

| Iodine value | 91.7 ± 0.70 | 103.7 ± 0.46 |

| Saponification value | 187.2 ± 10.4 | 184.6 ± 4.4 |

| Refractive Index | 1.5 ± 0.2 | 1.5 ± 0.1 |

| Peroxide value (meq/kg) | 0.9 ± 0.1 | 0.9 ± 0.2 |

| Free fatty acid (as% Oleic acid) | 0.09±.01 | 0.05 ± 0.02 |

| Moisture (%) | 0.05 ± 0.02 | 0.03 ± 0.02 |

| Specific gravity | 0.91 ± 0.02 | 0.91 ± 0.01 |

| Smoke point (°C) | 202 ± 5.8 | 213 ± 4.2 |

| Flash point (°C) | 271 ± 6.1 | 280 ± 7.4 |

#Each value is a mean of three observations

Table 2.

Fatty acid composition of bakery shortening and rice bran oil (g/100 g)

| Sample | Palmitic acid | Stearic acid | Oleic acid | Linoleic acid | Linolenic acid | Arachidonic acid | Erucic acid |

|---|---|---|---|---|---|---|---|

| Bakery shortening | 38.1 ± 0.03 | 4.5 ± 0.05 | 51.6 ± 2.3 | 5.1 ± 0.07 | – | 1.0 ± 0.01 | – |

| Rice bran oil | 18.8 ± 0.07 | 1.8 ± 0.02 | 42.9 ± 2.7 | 35.0 ± 0.04 | 1.3 ± 0.03 | 0.50 ± 0.02 | – |

# Each value is a mean of three observations

Effect of different treatments on bread making quality

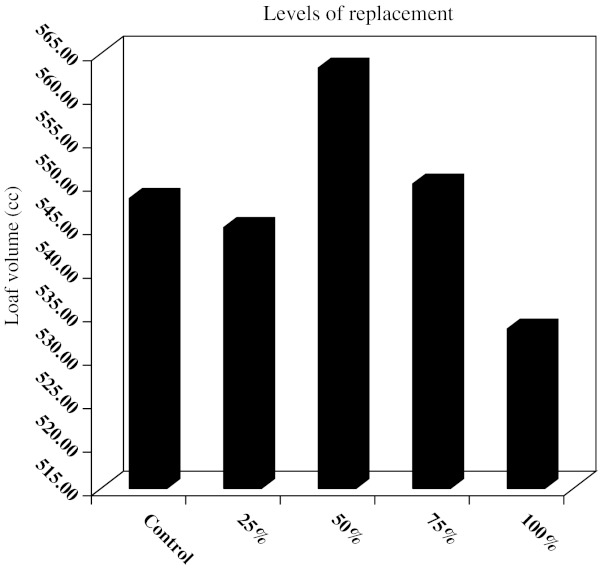

Handling of dough was smooth at various levels of incorporation of rice bran oil. Non-significant variations were observed in loaf weight at different levels of rice bran oil replacement. Loaf volume of breads increased with increase in the level of incorporation of rice bran oil upto 50% level of replacement (Fig. 1). At 50% level of replacement higher loaf volume (558.30 cc/g) was observed as compared to control (545.00 cc/g) as shown in Fig. 2. A decrease in loaf volume was observed in 75 per cent (541.70 cc/g) and 100 (531.70 cc/g) per cent levels of replacement as shown in Fig. 2. Values for loaf height were found to be more for breads prepared after replacing bakery shortening with rice bran oil at 25 and 50% levels, in comparison to control(Table 3). Maximum value for loaf height was observed in breads prepared with 50% replacement of bakery shortening (9.1 ± 1.2 cm) whereas minimum value for the same was observed in 100% replacement level (7.9 ± 1.02 cm).

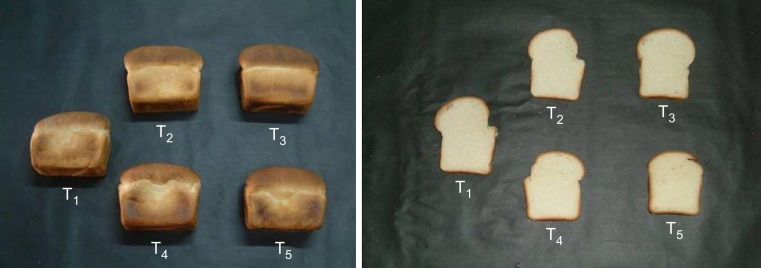

Fig. 1.

Effect of different levels of rice bran oil on bread quality. T1 = 100% Normal Shortening (NS), T2 = 75% NS + 25% Rice Bran Oil (RBO), T3 = 50% NS + 50% RBO, T4 = 25% NS + 75% RBO, T5 = 100% RBO

Fig. 2.

Effect of different levels of rice bran oil on the loaf volume of bread

Table 3.

Effect of different levels of rice bran oil on bread making quality and texture of bread

| Treatment | Dough handling | Loaf height (cm) | Specific volume (cc/g) | Force (g) |

|---|---|---|---|---|

| T1 | Smooth | 8.4 ± 1.43 | 3.7 ± 0.56 | 26.5 ± 0.92 |

| T2 | Smooth | 8.8 ± 0.95 | 3.7 ± 0.39 | 26.1 ± 1.03 |

| T3 | Smooth | 9.1 ± 1.20 | 3.8 ± 0.45 | 25.0 ± 0.78 |

| T4 | Smooth | 8.4 ± 0.84 | 3.7 ± 0.63 | 25.1 ± 0.82 |

| T5 | Smooth | 7.9 ± 1.02 | 3.7 ± 0.32 | 28.6 ± 0.57 |

| aCD (0.05) | – | 0.65 | NS | 0.020 |

aCD stands for critical difference. T1 = 100% Normal Shortening (NS), T2 = 75% NS + 25% Rice Bran Oil (RBO), T3 = 50% NS + 50% RBO, T4 = 25% NS + 75% RBO, T5 = 100% RBO

Effect of different treatments on the sensory quality of bread

Breads prepared after replacing bakery shortening with rice bran oil at 50 and 75% levels were awarded higher scores for appearance in comparison to control, while breads prepared after replacing bakery shortening with rice bran oil at 50% levels were awarded higher scores for overall acceptability in comparison to control (Table 4). Maximum scores for appearance were awarded to breads prepared with 50% replacement of bakery shortening (8.1 ± 0.57) as compared to control (7.8 ± 0.11) whereas minimum scores were awarded to breads prepared with 100% replacement of bakery shortening (7.0 ± 0.88) Maximum scores for texture were awarded to control breads (7.5 ± 0.35) whereas minimum score was awarded to breads prepared with 100% replacement of bakery shortening (6.3 ± 0.40). Overall acceptability at 50% level was best (8.1 ± 1.13) in comparison to control (8.0 ± 0.96) and other levels of replacement.

Table 4.

Effect of different levels of rice bran oil on sensory quality of bread

| Treatment | Appearance | Crust colour | Crumb colour | Aroma | Texture | Taste | Overall acceptability |

|---|---|---|---|---|---|---|---|

| T1 | 7.8 ± 0.11 | 8.1 ± 0.88 | 8.0 ± 0.68 | 8.2 ± 0.55 | 7.5 ± 0.35 | 8.2 ± 0.49 | 8.0 ± 0.96 |

| T2 | 7.7 ± 0.08 | 8.1 ± 0.71 | 8.0 ± 0.82 | 8.6 ± 0.41 | 7.0 ± 0.21 | 8.1 ± 0.35 | 7.9 ± 0.44 |

| T3 | 8.1 ± 0.57 | 8.3 ± 0.92 | 8.3 ± 0.49 | 8.8 ± 0.96 | 6.8 ± 0.16 | 8.4 ± 0.83 | 8.1 ± 1.13 |

| T4 | 7.9 ± 0.71 | 8.1 ± 0.78 | 8.1 ± 1.16 | 8.5 ± 0.61 | 6.7 ± 0.82 | 8.2 ± 0.79 | 7.9 ± 0.64 |

| T5 | 7.0 ± 0.88 | 8.0 ± 0.64 | 8.0 ± 0.89 | 8.6 ± 0.64 | 6.3 ± 0.40 | 8.1 ± 0.44 | 7.7 ± 0.82 |

| CD (0.05) | 0.41 | NS | NS | NS | 0.36 | NS | 0.19 |

# Each value is a mean of six observations

Texture analysis of bread

Control (breads prepared with bakery shortening alone) and breads prepared after replacing bakery shortening with rice bran oil at 25, 50, 75 and 100% replacement levels were evaluated for firmness by texture analyzer. Force required to compress (g) was measured. Significant variations were observed in firmness of breads as shown in Table 3.

Breads prepared by replacing bakery shortening with rice bran oil at 100% replacement level were tougher when compared to control. Force required to compress the breads was minimum (25.0 ± 0.78 g)in case of breads prepared by replacing bakery shortening with rice bran oil at 50% replacement level.

Conclusion

It is concluded that bakery shortening can be successfully replaced with refined rice bran oil upto 50% level of replacement in the preparation of bread with improvement in baking quality of the product. At 50% level of replacement, rice bran oil proved to be superior than normal bakery shortening in the preparation of bread as far as quality (baking and organoleptic) of the product was concerned.

References

- Anon (1989) Fatty acid content is critical. Agricultural Outlook. p 11–13

- Anon . Approved laboratory methods. 8. Minnesota: American Association of Cereal Chemists St Paul; 1990. [Google Scholar]

- Anon . Official methods of analysis. 16. Washington DC: The Association of Official Analytical Chemists; 2000. [Google Scholar]

- Chung OK, Pomeranz Y. Recent trends in usage of fats and oils as functional ingredients in the baking industry. J Am Oil Chem Soc. 1983;60:1848–1851. doi: 10.1007/BF02901536. [DOI] [Google Scholar]

- Kamran S, Masood S B, Faqir MA, Muhammad N (2005) Improved quality of baked products by rice bran oil. Internet J Food Safety 5:1-8

- Luh BS, Barber S, Benedito de Barber C. Rice bran: chemistry and technology. In: Luh BS, editor. Rice production and utilization. New York: Van Nostrand Reinhold; 1991. p. 313. [Google Scholar]

- Marshall WE, Wadsworth JI. Rice science and technology. New York: Marcel Dekker, Inc; 1994. [Google Scholar]

- Matz SA. Bakery technology and engineering. 3. Westport CT: AVI Publishing Co. Inc; 1996. pp. 77–89. [Google Scholar]

- Perzybylski R, Mag T (2002) Canola/rapeseed oil. In: Gunstone DF (ed). Vegetable oils in food technology: composition, properties and uses. Blackwell Publishing Ltd USA. pp 98–127

- Raghuram TC, Rukmani C. Nutritional significance of rice bran oil. Indian J Med Res. 1995;10:593–601. [PubMed] [Google Scholar]

- Salz KM. Fat and cholesterol intakes of white adults in Columbia, Maryland. J Amer Diet Assoc. 1982;81:541. [PubMed] [Google Scholar]

- Sayre RN, Saunders RM. Rice bran and rice bran oil. Lipid Technol. 1990;2:72. [Google Scholar]

- Sharma AR (2002) Edible rice bran oil - Consumer awareness programme. Rice bran oil promotion committee. Solvent Extractors Association of India, Mumbai

- Steel RGD, Torrie JH, Dickey D. Principles and procedures of statistics. A biometrical approach. 3. New York: McGraw Hill Book Co. Inc; 1997. [Google Scholar]

- Suzuki S, Oshima S. Influence of blending oils on human serum cholesterol-rice bran oil, safflower and sunflower oil. J Nutr. 1962;28:194. [Google Scholar]

- Swern O (1972) Bailey’s industrial oil and fat products. 3rd ed. Inter. Sci Pub Technology p 196–225