Abstract

To explore the potentiality of cereal brans for preparation of fiber enriched pasta, various cereal brans (Wheat, Rice, Barley and Oat) were added at 0, 5, 10, 15, 20 and 25 per cent to durum wheat semolina. The effect of cereal bran enrichment on the colour, cooking, sensory quality and shelf life of enriched pasta was assessed at ambient temperature. Pasta prepared with added fiber at 25 per cent level had the highest protein and dietary fiber content as compared to control. Enrichment with variable fiber sources improved the brightness of pasta, as colour of pasta enhanced significantly. Addition of cereal brans resulted an increase in the water absorption and cooking losses of pasta. This effect was dependent on the level and type of cereal brans. Significant correlation (r = 0.80) was obtained between water absorption and volume expansion in all types of bran enriched pasta. At 25 per cent level of supplementation, maximum solids were leached into cooking water. Bran enriched pasta required less cooking time for complete gelatinization of starch. Increasing level of cereal brans had significantly affected the overall acceptability of enriched pasta. Cooking quality of pasta remained constant during storage. Non significant effect of storage was found on water activity, free fatty acids. Enriched pasta (15 per cent level of wheat, rice and oat bran and 10 per cent barley bran) was highly acceptable upto 4 months of storage with respect to quality.

Keywords: Cereal bran, Durum wheat semolina, Pasta, Cooking quality, Sensory quality

Bran, a byproduct of milling industry, is yet to be efficiently utilized for human consumption. The poor functionality of bran and the deleterious effects that it may have on functional properties of the other food components are the two problems encountered when formulating high fiber products (Ellis 1985). Despite its excellent nutrition, hypoallergencity and nutraceutical properties, it is mainly utilized for animal feed. It is of interest to incorporate this healthy ingredient back into our diet (Isabel et al. 2001). Presence of bran particles physically interferes with dough development, which results in weak dough properties. Dough strength will affect the amount of mechanical energy required to extrude and the rate of extrusion (Levine 2001). Hence, fiber must be added to foods in an appealing manner to insure consumer acceptance in terms of its texture, taste and colour (Brockmole and Zabik 1976).

Bran is composed mainly of insoluble cellulose and hemicelluloses, with only 5% soluble fiber and has little hypercholesterolemia effect (Kay and Truswell 1980). Bran contributes a pleasing sweet, nutty flavour when added as a flour replacement in baked products and pasta. Bran improves the nutritional quality (fiber, proteins, vitamins and minerals} of the resultant product. Antinutritional effects of cereal bran have been reported, such as cation binding may result in decreased mineral availability and accelerated loss of certain body mineral. Phytic acid, considered as the major constituent in bran and whole wheat, responsible for di-trivalent deficiency disorders in monogastric animals. Bran is the identified source of dietary fiber added to baked goods and supplementation at 7.5% level of flour replacement in the dough formulation is about the maximum level if product quality is to be maintained (Sosulski and Wu 1988).

During the recent years there has been a special recognization of the role of fiber in the human diet and a great deal of interest was exhibited in cereal fiber. Dietary fiber is the edible parts of plants or analogous carbohydrates that are resistant to digestion and absorption in the human small intestine with complete or partial fermentation in the large intestine. Dietary fiber includes polysaccharides, oligosaccharides, lignin, and associated plants substances. Dietary fibers promote beneficial physiological effects including laxation, and/or blood cholesterol attenuation, and/or blood glucose attenuation (AACC 2000). Consumers are becoming increasingly health conscious and are demanding natural, wholesome, health-promoting foods. Public concerns about the health effects of dietary fiber have prompted a fast-growing market of high fiber and calorie-reduced products. Most common fiber sources include bran from wheat, barley, corn and oats, fruits and vegetables fiber (apple or sugarbeet fiber), legume fiber, powdered cellulose and gums (Sievert et al. 1990). Cereals are considered to be an important source of fiber, there is little information concerning the quantity and composition of fiber in manufactured cereal products.

Pasta products are becoming popular in current lifestyle because they are healthy, tasty and convenient for transportation and preparation (Cubadda 1994).Pastas, in general, are considered to have low glycemic indices and, correspondingly, produce low postprandial blood glucose and insulin responses (Jenkins et al. 1983; Granfeldt et al. 1991).Approximately 12.3 million tons of pasta is produced world wide with an estimate of 100,000 tons production of India (Anon 2008). Among cereals, only wheat is usually considered suitable for pasta manufacture. This is because their proteins have the properties required for interaction between themselves and with other components, mainly lipids, to form a very specific viscoelastic lipoprotein complex called gluten when flour (or semolina) and water are mixed together. Pasta, with legumes, vegetables and herbs, is considered a complete, delicious and healthy food. Pasta made from durum semolina maintains a desirable firm texture during cooking, and it has a natural amber colour that is associated with good quality pasta.

Pasta has a universal appeal and good carrier for supplying nutrition for such a section of people who are health conscious. The addition of increasing levels of fiber in a long way improves the health status of vast majority of health conscious population who are the main target of this study. The present investigation was, therefore undertaken to explore the functionality of fiber enriched pasta as dietetic pasta and its quality assessment.

Materials and methods

Raw materials

Commercial Durum wheat semolina and Oat bran (Baggry’s) were purchased from local market. Wheat bran was collected from Ludhiana Flour Mill, Ludhiana. Rice bran was purchased from A.P. Solvex Pvt. Ltd., Dhuri, Punjab, India. Barley bran was prepared by milling of barley in Barley pearler.

Dry heat treatment at 100 °C for 10 min. was given to cereal brans for inactivation of enzymes. Different cereal brans were processed and kept in pearl pet jars for further processing. The grinding of dried cereal brans was done to a uniform particle size using Cemotec mill (FOSS) having setting at No. 1.

Physico-chemical composition of raw materials

Approved methods (AACC 2000) were used to determine ash (method 08-01) and protein (N x 5.7) for durum wheat semolina and (N x 6.25) (method 46-10.01) for cereal brans. Fat content was determined using a 16-h soxhlet extraction with petroleum ether (AACC 2000). Dietary fiber {acid detergent fiber (ADF), neutral detergent fiber (NDF), Cellulose and Lignins} were estimated by extracting with neutral detergent solution as prescribed by Robertson and Van Soest (1981). Crude fiber of raw materials was estimated using Fibertec (FOSS). Per cent carbohydrates were determined as (100 - per cent estimated proximate components).

Pasta preparation

Durum wheat semolina was supplemented with wheat bran, rice bran, barley bran and oat bran at different levels ranged from 5 to 25% (0, 5, 10, 15, 20, and 25%). Semolina and brans were weighed in required amounts and mixed well by passing 3 times through 20 mesh sieve. Flour was mixed with optimum amount of water in the mixing chamber of pasta extruder (le monferrina Masoero Arturo and C.S.N.C., Italy) for 10 min. to distribute water uniformly throughout the flour particles. The moist flour aggregate was placed in a metal extruder attachment of the pasta machine fitted with an adjustable die.

Drying of pasta was carried out in a hot air oven at 45–50 °C for about 4–5 h to attain a moisture content to about 6.5 per cent. The resultant dried products of various blends were packed in high density polyethylene (HDPE) bags for subsequent analysis.

Pasta quality

Colour

Colour of dried pasta was measured using Hunter Lab colorimeter (MiniScan XE Plus). Colour readings were expressed by Hunter values for L, a and b. L values measure black to white (0-100); +a = red, -a = green; +b= yellow, -b = blue.

Cooking quality

Weighed samples (10 g) of pasta (fresh and stored) were cooked in 250 ml boiling distilled water. Optimum cooking time, firmness of pasta and solids lost to cooking water was assessed using standard method (AACC method 66–50).Per cent water absorption and volume expansion ratio was calculated from increase in weight and volume on cooking of pasta for optimum cooking time.

Overall acceptability

Overall acceptability of stored pasta was evaluated on the basis of sensory attributes (appearance, colour, texture, stickiness, flavor and taste) by a panel of semi-trained judges (Larmond 1970).

Storage studies

Best levels of enrichment (Wheat, rice and oat bran at 15 per cent and barley bran at 10 per cent level) were selected on the basis of sensory and product quality and subjected for assessing the storage stability. Prepared products were packed in high density polyethylene packs (200 gauge) and stored at ambient temperature for shelf life study. Subsequent quality analysis was as follows:

Free Fatty Acids

Standard AOAC procedure (Anon 2001) was followed. 10 gm ground sample was taken in flask. 50 ml benzene was added and kept for 30 min. for extraction of free fatty acids. 5 ml extract was taken in flask to which 5 ml. benzene, 10 ml alcohol and phenolphthalein as indicator was added and titrated against 0.02 N KOH till light pink colour disappeared.

Water activity

Water activity of enriched pasta was estimated using water activity meter having HygroLab 3 bench-top indicator (Rotronic company).

Statistical analysis

Experiments were carried out in triplicate and data was analysed with the help of factorial designs (Singh et al. 1998).

Results and discussion

Analysis of raw materials

Results of proximate analysis of the raw materials used in the production of dietetic pasta is shown in Table 1. Durum wheat semolina had 11.7% protein whereas the protein content of cereal brans ranged from 9.6 to 15.0%. Rice and barley brans had protein values at par. The fat content ranged from 1.81 to 19.3% and was highest for rice bran. Dietary fiber was highest for rice bran (38.9%). Barley bran had maximum value for crude fiber (14.9%). Maximum ash content (6.72%) was observed in rice bran samples.

Table 1.

Proximate composition* of raw materials

| Raw materials | Crude protein (%) | Ash (%) | Fat (%) | Dietary fiber (%) | Crude fiber (%) | Carbohydrates (%) |

|---|---|---|---|---|---|---|

| Semolina | 11.7 | 0.54 | 1.81 | 0.2 | 1.41 | 70.6 |

| Wheat bran | 9.6 | 4.06 | 4.07 | 33.4 | 7.75 | 60.5 |

| Rice bran | 11.8 | 6.72 | 19.3 | 38.9 | 11.5 | 36.6 |

| Barley bran | 11.9 | 3.07 | 4.24 | 22.6 | 14.9 | 51.9 |

| Oat bran | 15.0 | 1.45 | 10.6 | 14.0 | 3.31 | 55.6 |

| LSD (p < 0.05) | 0.07 | 0.24 | 0.12 | 0.18 | 0.05 | 0.06 |

*Expressed at 14% moisture basis

Values are mean of 3 replications

Pasta quality

Colour

Table 2 depicts the colour values for dietetic pasta as analyzed by Hunter Lab Colorimeter. Increase in bran level from 5 to 25 per cent led to a significant increase in the darkness of the product. Pasta made from cereal bran enrichment was significantly darker than those made from durum wheat semolina. Increase in redness and decrease in yellowness were observed as bran level increased from 0 to 25 per cent. Overall results indicated that the red colour intensity significantly increased with increasing bran level in flour. Our results are in accordance with Gajula et al. 2008. They reported that the barley bran had a reddish brown colour, thus higher levels of barley bran substitution led to darker products followed by products prepared with wheat, rice and oat bran.

Table 2.

Quality attributes of dietetic pasta

| Type of cereal bran and level of supplementation (%) | Acceptability score | L* | a* | b* |

|---|---|---|---|---|

| Wheat bran | ||||

| 0 | 7.6 | 59.7 | 3.52 | 17.6 |

| 5 | 7.4 | 54.2 | 5.25 | 16.2 |

| 10 | 7.3 | 52.8 | 5.42 | 15.5 |

| 15 | 7.1 | 51.2 | 5.74 | 14.9 |

| 20 | 6.4 | 46.1 | 6.69 | 15.5 |

| 25 | 4.6 | 43.8 | 6.84 | 13.2 |

| LSD (p < 0.05) | 0.19 | 0.08 | 0.20 | 0.06 |

| Rice bran | ||||

| 0 | 8.1 | 59.7 | 3.52 | 17.6 |

| 5 | 7.5 | 55.2 | 4.02 | 13.9 |

| 10 | 7.6 | 45.9 | 4.86 | 13.5 |

| 15 | 7.7 | 47.6 | 5.61 | 14.5 |

| 20 | 6.3 | 51.8 | 5.80 | 13.4 |

| 25 | 6.0 | 46.9 | 6.56 | 12.8 |

| LSD (p < 0.05) | 0.15 | 0.05 | 0.02 | 0.05 |

| Barley bran | ||||

| 0 | 8.1 | 59.7 | 3.52 | 17.6 |

| 5 | 7.6 | 49.2 | 5.24 | 14.7 |

| 10 | 7.0 | 45.4 | 5.30 | 12.9 |

| 15 | 5.4 | 40.6 | 5.85 | 11.4 |

| 20 | 4.1 | 38.7 | 6.53 | 11.9 |

| 25 | 3.9 | 32.4 | 6.96 | 12.1 |

| LSD (p < 0.05) | 0.15 | 0.16 | 0.03 | 0.05 |

| Oat bran | ||||

| 0 | 8.0 | 59.7 | 3.52 | 17.6 |

| 5 | 7.7 | 60.5 | 3.48 | 15.6 |

| 10 | 7.6 | 57.2 | 3.26 | 15.5 |

| 15 | 7.6 | 55.8 | 3.91 | 16.5 |

| 20 | 7.4 | 65.0 | 4.37 | 15.5 |

| 25 | 7.1 | 59.3 | 4.58 | 15.1 |

| LSD (p < 0.05) | 0.13 | 0.38 | 0.03 | 0.05 |

Values are mean of 3 replications

Cooking quality

Optimum cooking time was less for pasta that contained cereal bran as compared to durum wheat semolina pasta. Optimum cooking time was 5:38 min. for control pasta, which reduced to 5:24 min., 5:22 min., 5:17 min. and 5:22 min. for wheat, rice, barley and oat bran enriched pasta at 25 per cent level of supplementation. This may be due to the physical disruption of the gluten matrix by the bran and germ particles which provided a path of water absorption into the whole wheat spaghetti strand that also reduced cooking time. Similar observations were reported by Manthey and Schorno 2002.

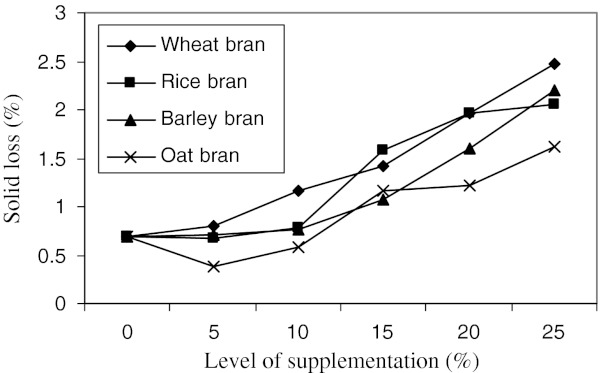

Significant variation was reflected in pasta with respect to water absorption (%) (Fig. 1). Control pasta absorbed 117.7% water on cooking. However, beyond 5% level, there was a significant increase in water absorption by pasta on cooking. Maximum increase in per cent water absorption (11.8%) was observed in 25% rice bran enriched pasta as compared to control. This substantial increase in water absorption is due to increase in fiber content of resultant pasta. Chen et al. (1988) stated that the increasing water absorption may be caused by the strong water binding ability of fibers.

Fig. 1.

Effect of supplementation of cereal brans on cooking quality of dietetic pasta. * Values are mean of 3 replications

Disruptions in the protein matrix by bran particles would promote water absorption and facilitate starch granule swelling and rupture (Manthey et al. 2004). Sosulski and Wu (1988) reported that the incorporation of fiber ingredients into wheat flour increased water hydration values in proportional to the level of replacement. Composite flours containing 20 per cent of fiber sources had water hydration capacities that were 8 per cent greater than that of the control flour.

Parallel trend of significant rise in volume expansion of cereal bran supplemented pasta from control is delineated in Fig. 1. Maximum volume expansion ratio (1.26) was observed in 25 per cent barley bran enriched pasta as compared to control pasta (0.94). A positive correlation of (r = 0.82) was observed between per cent water absorption and volume expansion for wheat bran enriched pasta (Fig. 1a) and similarly for rice, barley and oat bran enriched pasta (r = 0.94), (r = 0.79) and (r = 0.66) respectively.

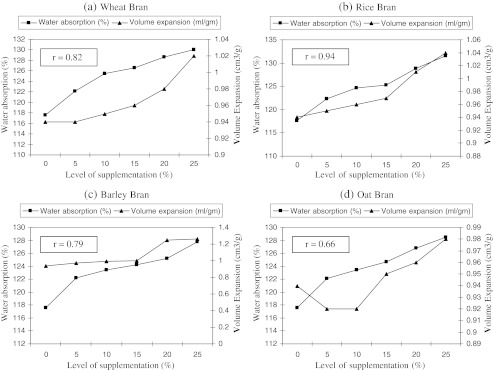

There was an increase in the leaching of solids in cooked water by addition of cereal brans, mainly in case of 25 per cent durum wheat bran enriched pasta (Fig. 2), however the increase was significant for all blended samples. Kunerth and Youngs (1984) reported that greater cooking losses from spaghetti made with ground whole wheat than with semolina is due to disruptions in the gluten matrix by bran particles, along with the presence of water-soluble components within the bran and aleurone layers. The disruption in gluten matrix, along with space between bran particle and matrix in dried spaghetti could promote water absorption and expose starch granules to swelling and rupture. This led to greater cooking losses as bran particles sloughed off the spaghetti into the cooking water. Inspection of the cooking water revealed that bran particles were suspended in the water used to cook the whole wheat spaghetti.

Fig. 2.

Effect of supplentation of cereal brans on gruel solid loss of dietetic pasta. * Values are mean of 3 replications

Acceptability

Overall acceptability scores of different cereal brans enriched pastas differed significantly (Table 2). These were calculated on the basis of various sensory attributes (appearance, colour, texture, stickiness, flavour and taste) through a panel of semi—trained judges. Maximum acceptability score was observed for pastas enriched with cereal brans upto 15 per cent level. Beyond that, acceptability scores was affected because of colour of enriched pasta. According to Gajula et al. (2008), increase in bran level from 0 to 25 per cent in uncooked flour significantly reduced the overall acceptability and all other attributes to tortillas except for chewiness. Vijayakumar et al. (2010) reported that 20% level of millet flour blend incorporation was found to be acceptable for development of noodles.

Storage studies

Cooking quality

Storage period had no significant effect on the minimum cooking time of stored enriched pasta as the storage period progressed,the time required to cook pasta increased, however, the increase was very less.

The cooking time ranged from 5:25 to 5:38 min for bran enriched pasta and for storage it ranged from 5:23 to 5:47 min. The physical disruption of the gluten matrix by the bran and germ particles provided a path of water absorption into the whole wheat spaghetti strand that reduced cooking time (Manthey and Schorno 2002). Amount of water absorbed by pasta during cooking increased with the progressive storage (Table 3). Variation among pasta with respect to storage was non significant. Maximum increase in per cent water absorption during entire storage period was observed in wheat bran enriched pasta followed by rice bran enriched pasta, while as minimum water absorption (%) was observed in oat bran enriched pasta.

Table 3.

Effect of storage period on the cooking quality of enriched pasta

| Storage period (months) | Water absorption (%) | Volume expansion ratio | Gruel solid loss (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wheat Bran | Rice Bran | Barley Bran | Oat Bran | Wheat Bran | Rice Bran | Barley Bran | Oat Bran | Wheat Bran | Rice Bran | Barley Bran | Oat Bran | |

| 0 | 126.1 | 125.1 | 123.5 | 124.7 | 0.94 | 0.97 | 0.99 | 0.95 | 1.41 | 1.59 | 0.76 | 1.16 |

| 1 | 126.5 | 125.1 | 123.7 | 125.1 | 0.94 | 0.98 | 0.99 | 0.95 | 1.45 | 1.61 | 0.77 | 1.17 |

| 2 | 126.7 | 126.3 | 124.4 | 125.3 | 0.94 | 0.98 | 1.00 | 0.95 | 1.45 | 1.61 | 0.77 | 1.18 |

| 3 | 126.9 | 126.5 | 124.9 | 125.4 | 0.95 | 0.99 | 1.01 | 0.96 | 1.45 | 1.61 | 0.78 | 1.18 |

| 4 | 127.3 | 126.6 | 125.0 | 125.7 | 0.96 | 1.00 | 1.01 | 0.96 | 1.46 | 1.62 | 0.79 | 1.19 |

| LSD (p < 0.05) | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS |

Values are mean of 3 replications

Water absorbed by fresh pasta during cooking was found to increase with refrigerated storage (Manthey et al.2008). Some loss of gluten strength during storage was reflected by the loss of cooked firmness. Weakening of the gluten network would allow easier water penetration and hence increased water absorption.

Volume expansion ratio

Volume expansion of bran enriched pasta increased with the storage period but with very little difference (Table 3). Throught the storage period, maximum value for volume expansion expansion was observed in barley enriched pastas, whereas, wheat bran enriched pastas showed minimum volume expansion ratio.

The variation was statistically non significant. Similar results were observed by Pinarch et al.2004, who stated that volume increase was significantly affected by type of macaroni, but storage period had no significant affect on swellings.

Gruel solid loss

As storage progressed, not much increase in the leaching of solids in cooked water was observed (Table 3). Dietetic pasta prepared from incorporation of different cereal brans exhibited better and stable cooking quality during storage upto 4 months with respect of volume expansion and solid loss on cooking. Cooking quality is an important assessing parameter for pasta quality. Storing macaroni samples upto 1 year did not significantly affect cooking loss (Pinarch et al. 2004).

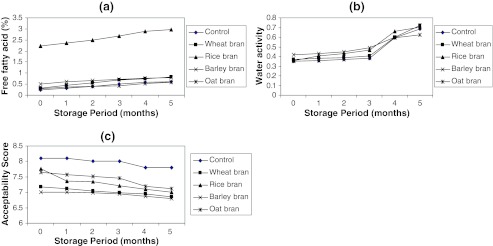

Free fatty acids

Storage period tangibly affected free fatty acid content of pasta containing cereal brans (Fig. 3a). Free fatty acids (%) for enriched pasta increased with storage period, but the values remained in the acceptable range because of which, the taste, flavour and acceptability of pasta was not much affected. Rice bran enriched pasta supplemented at 15 per cent level had maximum values of free fatty acids (%).This may be contributed to the fact that rice bran contained maximum amount of fat per centage than other cereal brans. Manthey et al. (2008) reported that the FFA content increased from 1.90 to 2.36% during refrigerated storage.

Fig. 3.

Effect of storage period on (a) free fatty acid(%), (b) water activity and (c) acceptability score of dietetic pasta. * Values are mean of 3 replications

Water activity

Water activity content of bran enriched pasta as influenced by storage period is shown in Fig. 3b. Significant variations were noticed in water activity content with progressing storage time. In the first 3 months, not much variation was observed in water activity of dietetic pasta, but beyond third month, a significant increase was observed. This may be due to the change in temperature conditions of the surroundings. Water activity values were acceptable upto 4th month of storage (Fig. 3b). Manthey et al. (2008) reported that during storage, water activity was similar for both traditional pasta and pasta containing Flaxseed flour.

Overall acceptability

The colour, aroma, texture and taste are the important characteristics for acceptability and also these are good indicators for the physicochemical changes during storage (Rao et al. 1995). Significant effect on the liking of pasta was noticed upto 4 months of storage. Maximum overall acceptability scores were observed at 0, 1, 2 months of storage (Fig. 3c). Beyond this, the score was affected but with a non-significant variation. During the entire 4 months of storage, overall acceptability of dietetic pasta was within acceptable range. Payumo et al. (1969) studied the organoleptic test for the coco noodles prepared from wheat, coco and mung bean flour in ratio of 50:30:10. The noodles were acceptable over a storage period of 6 months. Duszkiewicz et al. (1988) reported no significant differences between spaghetti containing concentrates and flour for mouth feel at zero time and after 6 months of storage and for external appearance and general acceptability after 3 months.

Conclusion

The results illustrate the potentiality and functionality of cereal brans (wheat, rice, barley and oat bran) to enrich durum wheat semolina for the production of dietetic pastas that had high dietary fiber and protein contents with nutritional benefits. These cereal brans can be added upto 15 per cent levels (wheat, rice and oat brans) and 10 per cent levels (barley bran) without adversely affecting the physicochemical, cooking and sensory quality of pasta. These types of dietetic pasta products can go a long way in supplying the required quantities of dietary fiber and protein to various segments of our populations and also results in profitable utilization of byproducts of milling industry.

Acknowledgement

The financial support from the Council of Scientific and Industrial Research (CSIR) New Delhi is gratefully acknowledged.

Abbreviations

- AACC

(American Association of cereal chemists)

- AOAC

(Association of Official Analytical Chemists)

- ADF

(Acid detergent fiber)

- FFA

(free fatty acid)

- HDPE

(High density polyethylene)

- Ml

(milliliter)

- NDF

(Neutral detergent fiber)

Contributor Information

Gurkirat Kaur, Email: keerat.pau@gmail.com.

Savita Sharma, Email: savitasharmans@yahoo.co.in.

Basharat N. Dar, Email: darnabi@gmail.com

References

- AACC (2000) Approved methods of american association of cereal chemists, 10th edn. The Association St. Paul, MN

- Anon (2001) Official methods of analysis, 16th edn. The Association of official analytical chemists. Washington, DC,USA

- Anon (2008) Estimate of world pasta production. Union of Organizations of Manufacturers of Pasta Products of the European Union

- Brockmole CL, Zabik ME. Durum wheat bran and middlings in white layer cakes. J Food Sci. 1976;41:357–60. doi: 10.1111/j.1365-2621.1976.tb00618.x. [DOI] [Google Scholar]

- Chen H, Rubenthaler L, Leung HK, Baranowski JD. Chemical, physical and baking properties of apple fiber compared with wheat and oat bran. Cereal Chem. 1988;65(3):244–47. [Google Scholar]

- Cubadda R. Nutritional value of pasta. Effects of processing conditions. Ital Food Beverage Technol. 1994;3:27–33. [Google Scholar]

- Duszkiewicz R, Khan K, Dick JW, Holm Y. Shelf life stability of spaghetti fortified with legume flours and protein concentrates. Cereal Chem. 1988;65:278–81. [Google Scholar]

- Ellis P. Fiber and food products. In: Leeds AR, Avenell A, editors. Dietary fiber perspectives reviews and bibliography. London: John Libbey and Company Limited; 1985. [Google Scholar]

- Gajula H, Alavi S, Adhikari K, Herald T. Precooked bran – enriched wheat flour using extrusion: dietary fiber profile and sensory characteristics. J Food Sci. 2008;73(4):5173–79. doi: 10.1111/j.1750-3841.2008.00715.x. [DOI] [PubMed] [Google Scholar]

- Granfeldt Y, Bjorck I, Hagander B. On the importance of processing conditions, product thickness and egg addition for the glyceamic and hormonal responses to pasta: A comparison with bread made from pasta ingredients. Eur J Clin Nutr. 1991;45:489–99. [PubMed] [Google Scholar]

- Isabel L, Guraya H, Champange E. The functional effectiveness of reprocessed rice bran as an ingredient in bakery products. Wiley Inter Sci. 2001;46:112–17. doi: 10.1002/1521-3803(20020301)46:2<112::AID-FOOD112>3.0.CO;2-N. [DOI] [PubMed] [Google Scholar]

- Jenkins DJ, Wolever TM, Jenkins AL, Lee R, Wong GS, Josse R (1983) Glycemic response to wheat products: reduced response to pasta but no effect of fiber. Diabetes Care 6:155–159 [DOI] [PubMed]

- Kay RM, Truswell AS. Dietary fiber: Effects on plasma and biliary lipids in man. In: Spiller GA, Kay RM, editors. Medical aspects of dietary fiber. New York: Plenum press; 1980. p. 183. [Google Scholar]

- Kunerth WH, Youngs VL. Effect of variety and growing year on the constituents of durum bran fiber. Cereal Chem. 1984;61:350–52. [Google Scholar]

- Larmond E (1970) Methods for sensory evaluation of food. Canada Department of Agriculture Pubn 1284

- Levine L. Extruder screw performance V. Cereal Foods World. 2001;46:169. [Google Scholar]

- Manthey FA, Schorno AL. Physical and cooking quality of spaghetti made from whole wheat durum. Cereal Chem. 2002;79:504–10. doi: 10.1094/CCHEM.2002.79.4.504. [DOI] [Google Scholar]

- Manthey FA, Yalla SR, Dick TJ, Badaruddin M. Extrusion properties and cooking quality of Spaghetti containing buckdurum wheat bran flour. Cereal Chem. 2004;81:232–36. doi: 10.1094/CCHEM.2004.81.2.232. [DOI] [Google Scholar]

- Manthey FA, Sinha S, Wolf Hall CE, Hall CA. Effect of flaxseed flour and packaging on shelf life of refrigerated pasta. J Food Proc Preser. 2008;32:75–87. doi: 10.1111/j.1745-4549.2007.00166.x. [DOI] [Google Scholar]

- Payumo EH, Briones PP, Banzon EA, Torres ML. The preparation of coco noodles. J Nutr. 1969;22:216–24. [Google Scholar]

- Pinarch L, Lu EB, Oner MD. Effect of storage on the selected properties of macaroni enriched with wheat germ. J Food Eng. 2004;64:249–56. doi: 10.1016/j.jfoodeng.2003.10.005. [DOI] [Google Scholar]

- Rao STS, Ramayana MN, Ashok N, Vibhakar HS. Storage properties of wheat egg powder incorporated biscuits. J Food Sci Technol. 1995;32:470–76. [Google Scholar]

- Robertson JB, Van Soest PJ. The detergent system of analysis and its application to human foods. In: James WPT, Thrander O, editors. The analysis of dietary fiber. New York: Marcell Dekker; 1981. pp. 123–58. [Google Scholar]

- Sievert D, Pomeranz Y, Abdelrahman A. Functional properties of Soy polysaccharides and durum wheat bran in Soft wheat products. Cereal Chem. 1990;67:10–13. [Google Scholar]

- Singh S, Bansal ML, Singh TP, Kumar R. Statistical methods for research workers. New Delhi: Kalyani Publishers; 1998. [Google Scholar]

- Sosulski FW, Wu KK. High fiber breads containing field pea hulls, wheat, corn and Oat brans. Cereal Chem. 1988;65:186–91. [Google Scholar]

- Vijayakumar TP, Mohankumar JB, Srinivasan T. Quality evaluation of noodles from millet flour blend incorporated composite flour. J Sci Ind Res. 2010;69:48–54. [Google Scholar]