Abstract

Increasing population and high cost of fuels have created opportunities for using alternate energies for post-harvest processing of foods. Solar food processing is an emerging technology that provides good quality foods at low or no additional fuel costs. A number of solar dryers, collectors and concentrators are currently being used for various steps in food processing and value addition. Society for Energy, Environment and Development (SEED) developed Solar Cabinet Dryer with forced circulation which has been used for dehydration and development of value added products from locally grown fruits, vegetables, leafy greens and forest produce. Drying under simulated shade conditions using UV-reducing Blue filter helps retain nutrients better. Its simple design and ease of handling makes SEED Solar Dryer an ideal choice for application of food processing in rural settings, closer to where the harvest is produced, eliminating the need for expensive transportation or storage of fresh produce. It also creates employment opportunities among the rural population, especially women. Other gadgets based on solar collectors and concentrators currently being used at various steps of food processing are reviewed.

Keywords: Solar cabinet dryer, Solar food processing, Forced circulation drying, Fruit Bars

Introduction

Dehydration is one of the most important steps for preservation and value addition of food products through moisture control. Conduction, convection and radiation are the basic techniques by which water is forced to vapourise and the resulting vapour is removed either naturally or by force resulting in dehydration. Conventional convective drying is used for drying fruits and vegetables (Nijhuis et al. 1998). However, this process also brings in some important changes in physical and chemical properties such as loss of color (Chua et al. 2000), and change of texture, flavour and loss of nutrients (Mayor and Sereno 2004). While high temperature used during the processing are responsible for the alterations, lowering temperature increases the time of dehydration therefore increase in cost. Since fresh fruits and vegetables contain over 80 % moisture, the process of dehydration to a desirable lower moisture content such as 5–10 % (Eg. 75 kg of water from a 100 kg sample) is very energy-consuming. The process of dehydration alone contributes up to 30 % of the total cost of processing of most fresh produce. Thus, the cost of dehydration and energy consumption and quality of dried products play very important role in choosing an appropriate drying process.

The process of drying in the Solar Dryer is facilitated by circulation of hot air, the spreading density of the product, the nature of pretreatment as well as the nature of the product to be dried itself. The time taken for drying is also determined by the factors such as the initial moisture content and the desired final % moisture of the product. For example, it may take 4 h to bring moisture level from an initial 4 to 0 % final in a single 50 kg load of refined wheat flour that is used in Instant Gulabjamun Mixes where as 6 h are needed to reduce moisture level from an initial of 63 % to 4 % final level from a 4 kg load of curry leaves.

Solar food processing brings in two emerging technologies together to solve the two major problems the world facing in 21st century, namely: how to generate energy enough for an expanding global population? and how to feed the constantly expanding world population? This has a different connotation with respect to developing countries. Growing population and unequal wealth distribution in these countries has created a section of the society being left behind and chronically poor. Lack of reliable and affordable energy sources in these parts only complicates the matter. This situation also demands search for faster, cheaper and safer methods by which food can be conserved and distributed to the poorer, usually rural populations, especially women and children. In the face of such great demand for food to feed people, it is sad to note that 30–40 % of food goes waste in India every year for lack of a systematic post-harvest processing and preservation. The food processing industry in India accounts for only 2.2 % of the total.

The International Energy Agency in its 2011 Solar Energy Perspectives: Executive Summary (SEP 2011) states that “Solar energy offers a clean, climate-friendly, very abundant and inexhaustible energy resource to mankind, relatively well-spread over the globe. Its availability is greater in warm and sunny countries—those countries that will experience most of the world’s population and economic growth over the next decades. They will likely contain about 7 billion inhabitants by 2050 versus 2 billion in cold and temperate countries (including most of Europe, Russia, and parts of China and the United States of America)”. Thus there is an urgency in addressing the twin problems of energy and hunger facing world in this century.

The present review tries to summarize some of the solar technologies available for food processing where solar energy can and is playing a key role, possible strengths and drawbacks in the current practices and put-in some suggestions for moving forward.

Recent studies indicate that while post-consumer food waste accounts for the greatest overall losses among affluent economies, food wastes are much higher at the immediate post-harvest stages in developing countries and wastage of perishable foods is higher across industrialized and developing economies alike. Food losses at various processing steps are quantified and presented in Table 1 along a generic food supply chain (Parfitt et al. 2010).

Table 1.

Food waste within food supply chains: Quantification and potential for change to 2050

| S Nr | Stage | Food waste/loss characteristics |

|---|---|---|

| 1 | Harvesting—handling at harvest | Edible crops left in field, ploughed into soil, eaten by birds, rodents, timing of harvest not optimal: loss in food quality Crop damaged during harvesting/poor harvesting technique |

| 2 | Threshing | Loss through poor technique Out-grades at farm to improve quality of produce |

| 3 | Drying—transport and distribution | Poor transport infrastructure, loss owing to spoiling/bruising |

| 4 | Storage | Pests, disease, spillage, contamination, natural drying out of food |

| 5 | Primary processing—cleaning classification, de-hulling, pounding, grinding, packaging, soaking, winnowing, drying, sieving, milling | Process losses Contamination in process causing loss of quality |

| 6 | Secondary processing—mixing, cooking, frying moulding, cutting, extrusion | |

| 7 | Product evaluation—quality control: standard recipes | Product discarded/out-grades in supply chain |

| Packaging-weighing, labeling, sealing | Inappropriate packaging damages produce Grain spillage from sacks Attack by rodents | |

| 9 | Marketing-publicity, selling, distribution | Damage during transport: spoilage Poor handling in wet market |

| 10 | Post-consumer—recipes elaboration: traditional dishes, new dishes product evaluation, consumer education, discards | Losses caused by lack of cooling/cold storage Plate scrapings Poor storage/stock management in homes: discarded before serving Poor food preparation technique: edible food discarded with inedible Food discarded in packaging: confusion over ‘‗best before and ‗use by’ dates |

| 11 | End of life—disposal of food waste/loss at different stages of supply chain | Food waste discarded may be separately treated, fed to livestock/poultry, mixed with other wastes and land filled |

Source: Parfitt et al. (2010)

Open sun drying is one of the oldest methods and traditionally practiced for preserving many vegetables, fruits and marine products all over the world. Dehydrated foods have higher shelf life, making them available throughout the year, even in off season. Because of their relatively low weight and low volume, the dehydrated products are easy to store as well as transport across distances. The modern food processing technology in general benefited vastly from the advances made in preparing food for human space voyages as well as for military use. Therefore it is not surprising that the dehydrated foods can easily meet the needs of defense establishments as well as outdoor lovers such as campers, expeditioners and mountaineers. The dehydrated products can be used in various preparations as in cooking, baking and pickling. However, traditional open air sun drying of vegetables, fruits and fishes is time consuming and less hygienic. Mechanized drying has pretty much replaced the open air sun drying in most of the industrialized countries. Even though the modern mechanized drying is faster than open-air drying and uses much less land, the equipment cost as well as the continued recurring cost of fuel to operate these systems is very high. Table 2 summarizes various drying methods used in food processing and relative benefits of each. With oil supply ever volatile and uncertain because of constantly changing geo-political scenario and the supply and cost of electricity very undependable especially in rural areas of developing countries such as India, solar drying can be a good alternative option for food processing.

Table 2.

Comparison of various drying methods

| Open sun drying | Mechanized-fuel drying | Solar drying |

|---|---|---|

| • No equipment costs | • Drying is even and continuous | • Product is protected from rain, insects, animals and dust and fecal matter |

| • Labor-intensive | • Initial high cost of equipment | • Faster drying than open solar drying, therefore reduces mould growth |

| • But labor is cheap in developing countries | • Continuing fuel costs | • Higher drying temperatures lead to more complete drying and therefore longer shelf life |

| • Requires more land (Eg. 100 m2 per ton of rice) | • This may be offset by using cheaper fuels like burning rice husk (Eg. One ton of rice gives 200 kg of husks) or fire wood but these are not environmentally friendly alternatives | • Finally, control over drying rates is possible. But: |

| • But large space may not be an issue | • Higher initial cost | |

| • Unprotected from dust, animals, insects etc. unhygienic | • Drying only during the day i.e. discontinuous |

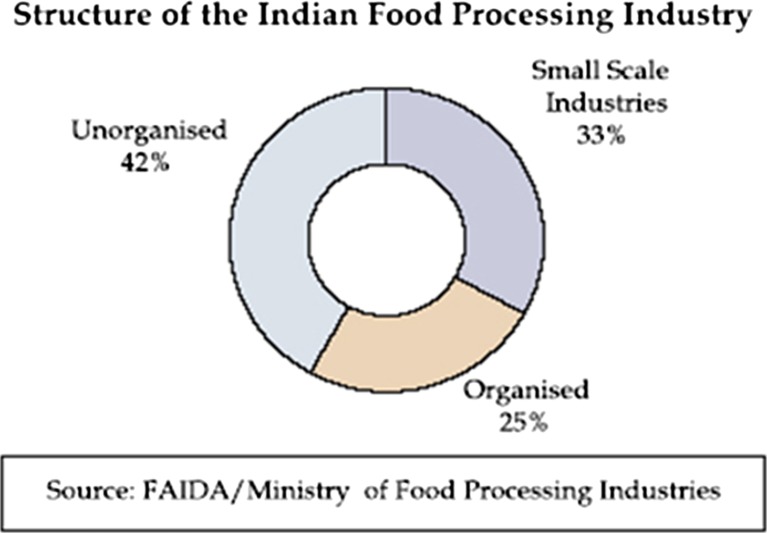

The post-harvest food processing industry is fragmented in most developing countries including India. The Indian Ministry of Food Processing Industry in its 2003–04 annual Report indicates over 40 % of the sector as unorganized (Fig. 1) with 33 % classified as small scale and only 25 % organized (MoFPI 2004).

Fig. 1.

Structure of Indian food processing industry (FAIDA: Food and Agriculture Integrated Development Action) Source: MoFPI (2004)

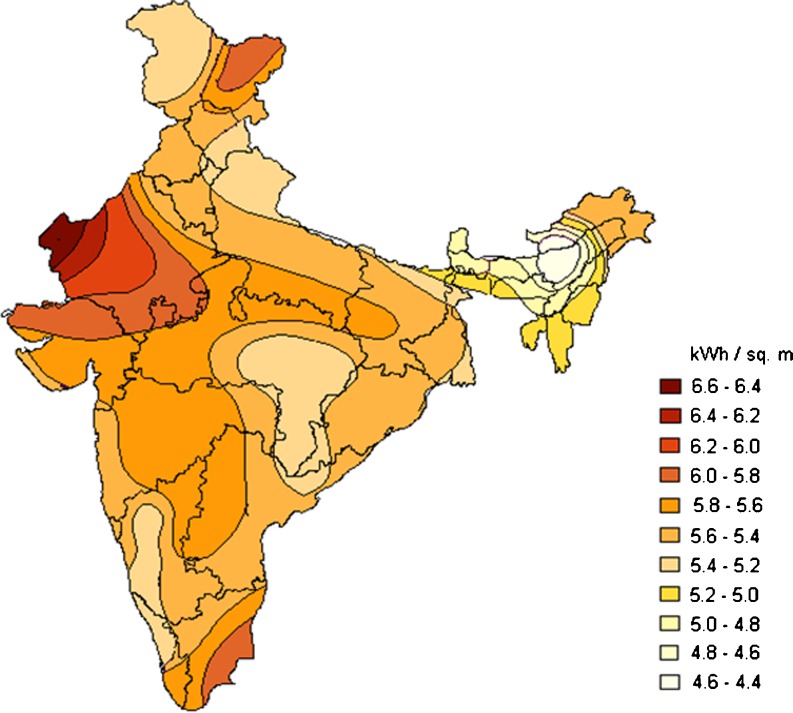

India is blessed with climatic conditions ranging from high alpine to subtropical and tropical. A whole range of crops can therefore be and are grown across the country, fully capable of feeding its population, provided there is proper infrastructure in place for the harvest so produced to be transported and conserved from spoilage. It also means that India is ideally suited for harnessing solar energy to meet its energy needs. The daily average solar energy incidence across the country varies from 4 to 7 kWh/m2, and in general there are 250 to 300 days of sunshine per year in most parts of the country. Solar dryers can be utilized for 250–300 days a year in most southern parts of the country.

Even though there is a gradient in the radiation received through various parts of the country, India is divided broadly into five zones for practical purposes: Eastern Zone (3.5–4.0 kwh/m2); Himalayan Zone(4.0–4.6 kwh/m2); Northern Zone (4.6–5.2 kwh/m2); Southern-Middle Zone(5.2–5.8 kwh/m2); and Western Zone (5.8–8.3 kwh/m2) (Fig. 2).

Fig. 2.

Solar radiation map of India

While solar energy is an obvious choice because it is pristine, abundant, (Eg. 1 h of sunshine, if harnessed properly, can sustain the whole globe for a year) renewable and no carbon foot print but it is diffuse as it reaches the Earth, to put in a very simplistic way, and therefore needs a concentrating step. With the current technologies available, it is possible to have small units that can concentrate solar energy for immediate and localized use. Solar gadgets including Solar Dryers are based on this idea.

Historical perspective

From the historical perspective, Indian Solar Energy sector owes much to the initiatives taken in the 1970s by Dr Arcot Ramachandran, the then Secretary of Department of Science and Technology, Government of India and Dr Mahesh Dayal, the then Secretary, Ministry of Non-Conventional Energy Sources, MNES (later The Ministry of New and Renewable Energy, MNRE). After an initial turbulent start, the technology has reached a mature state and is now on a better footing (Ramakrishna Rao 2011). In recent years many solar gadgets have been developed for a variety of applications in food processing. Different solar concentrators and box ovens provide boiling, steaming, blanching and roasting capabilities while solar air dryers/heaters do the work of moisture removal. According to some estimates, India has the second highest number of Solar Cookers in the world. It is highly creditable for an emerging economy to embrace a totally new and cutting-edge technology. Therefore, the time has come to revisit the role of solar energy in economies at large and rural economy through food processing in particular for improving the standard of living of the hither-to neglected sections of the society.

Effort will be made in the following pages to discuss briefly the various solar gadgets that are currently being used in food processing. Finally, this article will emphasize on SEED developed Solar Cabinet Dryer and its application in Post-Harvest food processing.

Solar collectors, concentrators and dryers in food processing

Solar energy is harnessed for thermal energy through a process of collection. The solar thermal collectors are classified as low, medium or high as per the US Energy Information Administration. Low-temperature and medium-temperature collectors are usually flat plates. The medium-temperature collectors are used for heating water or air for residential and commercial use while the low-temperature collectors are used for space heaters or swimming pools etc. High-temperature collectors concentrate sunlight using mirrors and lenses and are generally used for electric power production as well as for providing industrial process heating. The four most common forms of Concentrated (or concentrating) Solar Power (CSP) technologies are parabolic trough, dish stirling which is a variation of parabolic trough where the dish is coupled with a Stirling engine, Fresnel reflectors and solar power towers. Different types of concentrators produce different peak temperatures and correspondingly varying thermodynamic efficiencies, due to differences in the way they track the sun and focus light. New innovations in CSP technologies are making systems to become more and more cost-effective and are being applied effectively in food processing as well.

The most common non-concentrating collectors such as flat plate collectors consist of (1) a dark flat-plate solar energy absorber, (2) a transparent cover that allows solar energy to pass through but reduces heat losses, (3) a heat-transport fluid (air, antifreeze or water) to remove heat from the absorber, and (4) a heat insulating backing. The concentrating Solar Collectors include Parabolic troughs, dishes and towers. The solar concentrators have been noted to perform far below their theoretical maximum concentration. For example, the parabolic trough concentration is about 1/3 of the theoretical maximum for the same accepting angle (Winston et al. 2005, Chaves 2008).

Much research is going on in improving these systems which is beyond the scope of this article except to mention cases where the collector/concentrator systems have been used in post-harvest food processing with success. The list is by no means complete. Most of the systems described below are indirect solar processing methods where in the product is not directly exposed to solar radiation but is processed through hot air/other fluid that has been heated in a separate chamber by Sun radiation. The hot air/fluid is forced into the product chamber using blowers which usually run on conventional energy sources such as electricity or other fossil fuels.

-

Roof Top and other Collectors

Planters Energy Network (PEN), based in Theni, Tamilnadu, a leader in this technology uses flat plate solar collectors having a blackened solar heat absorber that has a 4 mm thick tempered glass as transparent cover with insulation on its lower side with mineral wool. Air is heated in the space between the cover and the absorber, where it has been forced in. PEN solar collector is installed on existing buildings, on the south-facing roofs of factories, keeping the roof as a base for the collector. Collectors are also installed on the ground where the roof is not ideally oriented. An appropriate capacity blower draws hot air from the panel into an insulated duct, from which it is distributed to the points of use (Palaniappan 2009). Success has been reported with above described solar collectors for more than 45 projects covering drying of a wide spectrum of products both in agro industry and also in other processing industries including tea, spices, herbal and fish drying. Improved efficiency up to 50 % has been reported in more recent trials.

-

Double Pass Solar Collector backed Solar Drying System for Seaweed drying

A solar dryer system has been constructed which consists of double-pass solar collector with finned absorber, the blower, the auxiliary heater and the drying chamber suitable for agricultural and marine products. The collector, drying system and pick-up efficiencies are found to be 35, 27 and 95 %, respectively. This system was developed specially for the drying of seaweed. Open sun drying of seaweed takes 10–14 days to obtain 10 % of final moisture level from 90 % original moisture content. With the solar dryer it is reduced to 15 h. (Fudholi et al. 2011).

-

Collectors and Concentrators for Cooking and Baking

Scheffler concentrator of 10 m2 was successfully tested for bakery application. One concentrator could bake 180 loaves of 200 g each in a day in the month of March. Quality of bread was excellent with uniform puffiness and color (Chandak et al. 2006).

-

Solar Concentrator Application In Dairy—Milk Pasteurization

ARUN™ is a Solar Concentrator System—Fresnel Paraboloid Concentrating Solar Collector System (Fig. 3), providing medium range temperatures for industrial thermal applications. The dish and support structure are made up of mild steel fitted with flat mirror reflectors that are at pre-calculated inclined angle. They reflect and concentrate the solar beam radiation at its focus having about 500 mm diameter area and generate high temperature heat energy. It is absorbed by hat-shaped downward facing cavity receiver designed for minimum thermal loss. An insulated pipeline (Fluids used are Water-steam or thermic fluid or air) delivers this heat-energy to ‘user’. A temperature of 200 °C can be attained by the system fluid outlet. The dish always faces the sun automatically which is made possible by a microprocessor based electronic control circuit (Kedare 2006). The current capacity for this solar system is about 20,000 to 30,000 l of milk daily resulting in savings of 80 to 100 l of furnace oil (Kedare et al. 2010).

-

Solar Concentrators for Medicinal/herbal Plant Processing

Parabolic dish concentrators are used for boiling herbs and preparation of syrups (kadhas) used in Indian Traditional “Ayurvedic” medicines. The product prepared by solar concentrator was found to be more potent than the one prepared on cooking gas (Chandak et al. 2006).

Solar Concentrator of 2.3 m size was also used for (a) boiling Amla (Indian Gooseberry) for different applications like Amla candy, Amla pickles etc.; (b) For preparing hair oil from Amla and Aloe Vera and (c) Roasting cashew nuts was carried on small scale for viability studies. Boiling, blanching, frying and roasting applications were successfully tried which require temperatures less than 200 °C. Scheffler concentrators of 12 and 16 m2 size are more suitable for higher, commercial scale preparations with higher temperature requirements (Chandak et al. 2006).

-

Solar food processing on the International Arena

Under the initiative of International Solar Energy Society, many countries from Africa, South America and Asia have been selected for implementing solar food processing at local levels, involving local organizations (Behringer 2006). Space prohibits discussing each of the projects in detail here. Suffice to say that the Solar Food Processing is as much an International issue as Energy and Food are. The following is the list of projects undertaken by the initiatives:- Burkina Faso, solar roasting of peanuts, production of shea butter, solar drying, production of solar stoves, Scheffler cookers and SF 14 (since 1998 ongoing)

- Namibia, baking and selling bread, roasting peanuts, solar catering, production of solar stoves, cooking demonstrations (since 2000 ongoing)

- Tanzania, production of solar stoves, cooking demonstrations, roasting peanuts (since January 2006 ongoing)

- Gambia, selling solar bread and cake, traditional food, solar stove production in preparation (since November 2005 ongoing)

- Paraguay, production of solar stoves, Scheffler cookers, solar-hybrid dryers, production of marmalade, pasteurizing fruit juice, bread and drying plants and fruits (since 1998 ongoing)

- Afghanistan, production of scheffler cookers and dryers. Development of solar tandur stoves for traditional bread (since April 2005 ongoing)

- India, production of scheffler community kitchen, SK 14 Solar Cookers

-

Solar Power for Institutional cooking—India Example:

The International Solar Energy Society (Anon 2011) showcases a number of stories as discussed in section (vi) where solar energy was used with some success for a variety of food and forest produce processing. Similarly, day-to-day cooking meals for large population are reported both in India and elsewhere using solar collectors. One of the impressive examples is the kitchen of the Brahma Kumaris Ashram (Fig. 4). Through the installation of 84 Scheffler Reflectors of 10 m2 each, steam is provided to cook a maximum of 38, 000 meals a day at the centre of Brahma Kumaris in Abu Road, Rajasthan. Similar large scale solar energy cooking operations have been installed and currently operated at other pilgrimage centers in India such as at Tirumala-Tirupathi Devasthanam, Tirupathi, Andhra Pradesh and Shirdi Sai Baba Temple in Shirdi town, Maharashtra, where large scale free meal distribution is a common daily practice. On a different continent, Müller et al. (2009) from Argentina reported Solar Baking ovens for community baking thus reducing possible massive deforestation happening in the Andes region.

Fig. 3.

‘ARUN™160’: Fresnel Paraboloid concentrator with cavity receiver with 2-axes tracking having 160 m2 aperture area installed under IIT-Bombay Clique R and D Project sponsored by MNRE for milk pasteurization at Mahanand Dairy, Latur, Maharashtra, India

Fig. 4.

An array of 84 Scheffler Reflectors of 10 m2 each, Abu Road, Rajasthan for the kitchen at the centre of Brahma Kumaris

Frito Lay and “sun” chips

Commercial viability of the role of solar energy in food processing is exemplified by the recent solar concentrator installation by Frito Lay for making its “sun chips” (Salerno 2008). At its Modesto, Calif. manufacturing facility, Frito-Lay in collaboration with the California Energy Commission in 2008 inaugurated the five-acre solar concentrator field which includes 54,000 square feet of concave mirrors designed to absorb sunlight (Fig. 5). The solar energy captured by the 384 solar collectors will generate steam that helps heat the cooking oil used in the Sun Chips manufacturing process. By utilizing steam in the manufacturing process, the facility is able to significantly reduce its use of natural gas, air pollution and greenhouse gas emissions and produce 145,000 bags of SunChips® snacks every day. By using the Solar Energy technology for the manufacturing of Potato chips, they could reduce 1.7 million pounds of CO2 emissions every year. Modesto region recorded 306 days in the past year that were not cloudy or partly cloudy (Salerno 2008). According to their web site (Frito Lay 2012) they reduced the electricity consumption by 22 % per bag, which was enough energy to power over 15,000 homes for a year and the goal is to run their Casa Grande, Arizona, USA plant which is located in a desert climate, eventually depending entirely on solar energy.

Fig. 5.

Frito Lay “sun Chips” manufacturing unit at Modesto, CA (USA)

Solar dryers

The process of drying is based on the fact that when air is heated, it’s relative humidity decreases therefore is capable of picking up moisture from products of greater moisture when it passes through them. The Solar Dryers may be divided broadly into two classes based on the way the solar energy reaches the product from which the moisture is to be removed. Table 3 describes the classification of drying based on the source of energy used.

Table 3.

Classification of solar food dryers

| Category | Description |

|---|---|

| Open air | Food is exposed to Sun in open containers or on the ground. No protection from extraneous contamination |

| Direct solar dryer | Food is placed in a closed container. Solar radiation is allowed to fall on food directly through a clear cover. Vents provide air flow |

| Indirect solar dryer | Fresh air is heated in a solar heat collector and passed through the food placed in a drying chamber. Thus the food is not directly exposed to solar radiation |

| Mixed dryers | Food is dried through direct sun as well as by hot air heated through a separate solar heat collector |

| Hybrid dryer | Drying is done using Solar heat as well as conventional electricity, fossil fuel/biomass |

| Fuel dryer | Non-Solar; 100 % on conventional electric or fossil fuel |

Tunnel and Chimney type solar dryers

Tunnel and Chimney type dryers can be used for drying various spices, fruits and vegetables such as turmeric, long melon, tapioca radish, banana, papaya, pineapple, maize, cooked rice, green leafy vegetables, cabbage, paddy and even meat apart from ginger and chillies. In a study reported by Sharma (2009), the drying was successful and time required to bring down moisture level varied for each product However, the author reported hindrance like hail storm which damaged the solar dryer’s polythene material and fans.

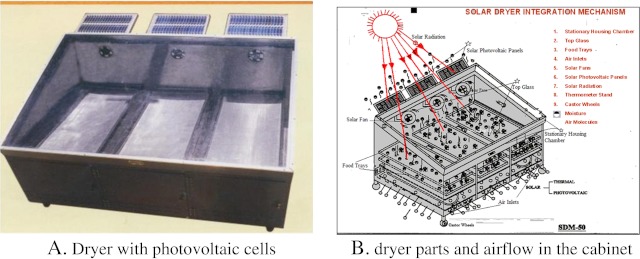

Solar cabinet dryer developed by SEED

A Solar cabinet dryer was originally designed in 1996 specifically for the benefit of 10,000 Tribal families who make a living by collecting Gum Karaya from the forests of Andhra Pradesh. At the time, The Tribal Development Corporation of Andhra Pradesh was very much interested in the development of a Dryer that would help dry Gum Karaya efficiently and add value. The newly developed solar dryer could reduce the drying time of gum karya to 2–3 days when open sun drying was taking 10–15 days and this new technology blended Solar Thermal with Solar Photovoltaic technologies (Ramakrishna Rao 2004). The project was initially supported by UNDP through a small grant.

The development of the commercial version of prototype and its use in making Mango Bars was subsequently funded by United Nations Development Programme (UNDP), Department of Science and Technology (DST), Government of India and Renewable Energy Project Support Office—United States Agency for International Development (REPSO-USAID) The dryer has been patented since (Mallavarupu Ramakrishna Rao 2007).

Parts and construction of Solar Cabinet Dryer

The Solar Cabinet Dryer developed by SEED consists of a Stationary Chamber built of Stainless Steel with a top glass cover at a 20° slant for proper radiation impact. The product is placed in stainless steel trays which are loaded into the chamber from a front opening. The air inlets are placed at the bottom while the exhaust fans which are powered by the Photovoltaic cell panels, are placed slightly above the food trays, at the back of the chamber. Castor wheels are provided for easy mobility of the Dryer. Figure 6a (Ramakrishna Rao 2004) gives the details of the dryer parts and Fig. 6b depicts the process of drying through solar radiation and forced air circulation. The working principles of this dryer are:

The incident solar radiation enters the closed chamber through the top glass window and heats the inside air that has entered from bottom inlets (Ramakrishna Rao 2004).

The hot air thus created is trapped inside the chamber, shifting the wave length from visible to Infrared (IR). Since the glass cover is not permeable to IR radiation, the heat is not allowed to dissipate through the top window, thus causing a “Green House” effect within the Chamber.

The heated air thus created inside the chamber, being lighter, travels up passing through the wet products placed in trays and carrying the moisture along from the product to the top space between the tray and the glass cover.

The hot air with moisture is continuously exhausted out from the chamber by the Solar Fans which are powered by the solar photovoltaic panels fitted above.

Thus the Solar Cabinet Dryer operates on dual power generated by single solar radiation i.e. solar thermal power inside the cabinet chamber and solar electric power outside through the solar photovoltaic cells, by way of exhaust fans.

Because of the forced air circulation created by the exhaust fans, moisture removal in SEED solar dryers is highly efficient. This results in shorter drying time, which is a highly desirable property in a dryer.

The chamber temperature reaches 15–30 °C above the ambient temperature at the peak of radiation intensity.

The temperature inside the chamber can be read through a thermometer housed in the chamber and/or can also be monitored from outside through a digital display.

The more recent models of SEED Dryers have been fitted with a Thermostat for regulating the chamber temperature.

It is thus considered a “Direct” Solar Dryer since the product is dehydrated by direct exposure to the solar radiation and it is accelerated by forced circulation.

The electric energy generated is radiation dependent and therefore varies throughout the day, proportional to the intensity of the solar radiation at the given time.

Fig. 6.

SEED developed Solar Cabinet Dryer. 1. Stationary stainless steel housing chamber; 2. Top glass cover at a 20° slant for proper radiation impact. This also helps drain rain water; 3. Stainless steel food trays for loading the product from the front of the chamber; 4. Air inlets are placed at the bottom of the cabinet; 5. Exhaust fans that are powered by Photovoltaic cell panel are at the back of the chamber; 6. Solar photovoltaic panels sit on top of the chamber directly above the fans to which they are connected. 7. A pictorial depiction of solar radiation on the cover glass and the solar photovoltaic cells; 8. Thermometer stand; 9. Castor wheels for movability; 10. Air molecules carrying moisture

Some distinguishing features of SEED developed solar cabinet dryer are:

Because of the superior quality of the materials used for the construction of the cabinet, the dryer can be left outside throughout the year under all weather conditions, without the fear of rusting.

The chamber is fitted with coasters for easy movability.

It can easily be assembled and disassembled for transportation purposes.

It is modular and thus scalable. The current models range from 8 to 100 kg loading capacity. A 200 kg capacity dryer is being designed and under way.

Like all the solar powered dryers, SEED Cabinet Dryer is functional only during the day time therefore the drying is ‘discontinuous.’ or “intermittent”.

The dryer needs no other auxiliary power source for its full functioning and therefore adds zero cost to the total drying process.

However, it is provided with electrical backup for continuous use if so desired or for any other emergency contingencies.

Because of the dual function-design which provides forced air circulation along with direct thermal drying, the dehydration process in SEED Dryers is highly efficient, capable of removing for example, 15 kg of water from a 50 kg sample.

This is accomplished through clean, green energy at no additional cost and without depending on conventional electric and/or fossil fuels, thus making the dryer environmentally friendly.

This last property alone makes it very attractive as a dryer of choice for rural, small scale food processing.

Because of its portability, it is also a choice tool for using the dryer in remote and/or rural areas where conventional energy supply is meager to nonexistent in most developing countries, including India.

The average efficiency of the dryer is around 90 %. The approximate 10 % loss accounts for the loss of heat through the top glass cover surface inside and out (4–5 % × 2).

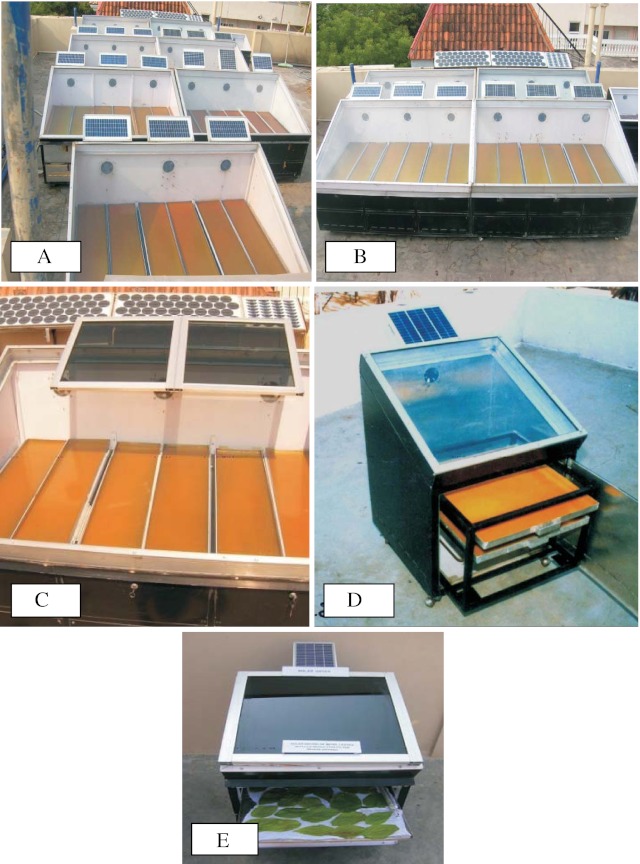

SEED Solar cabinet dryer models and their technical features

Figure 7a–e shows various models of SEED Solar cabinet dryers. Model-SDM-8 (Fig. 7d) has a load capacity of 8 kg with two trays in two rows. The next is SDM-50 (Fig. 7c.) with a load capacity of 50 kg and has six trays in two rows. SDM-100 (Fig. 7b) has 12 trays for handling 100 kg load at a time and Fig. 7a shows an array of solar dryers with a total capacity of 350 kg per load. Figure 7e shows an SDM-8 with blue filter, a simulated shade drying condition, for drying leafy vegetables. The modular design of the dryer makes scalability easy. The most important requirement for installing the dryers is a south facing location with no shade.

Fig. 7.

Different sizes of SEED Solar Cabinet Dryer models with photovoltaic panels

Table 4 lists the technical features of each of the models developed so far. Thus the SDM-8 (Fig. 7d) consists of two trays for loading the product with a single exhaust fan where as SDM-50 (Fig. 8c) is fitted with three exhaust fans and 12 trays in two rows. SDM-100 (Fig. 7B) which has 100 kg loading capacity is created by joining two SDM-50 models. Figure 7a presents an array of SDM-50 and SDM-100 to provide a drying load of 350 kg at a time. Figure 7e depicts the dehydration of leafy vegetables under simulated shade drying conditions in a SDM-8 model.

Table 4.

Technical specifications of SEED Solar cabinet dryer models

| Model | Loading capacity (kg) | Solar window | Drying area, (m2) | Solar photo-voltaic panel | Electrical backup, 220 V.A.C. |

|---|---|---|---|---|---|

| SDM-8 | 8 | 0.37 | 0.56 | 3.5 W | 600 W |

| SDM-50 | 50 | 2.23 | 3.6 | 21 W | 3.6 KW |

| SDM-100 | 100 | 4.46 | 7.2 | 42 W | 7.2 KW |

Fig. 8.

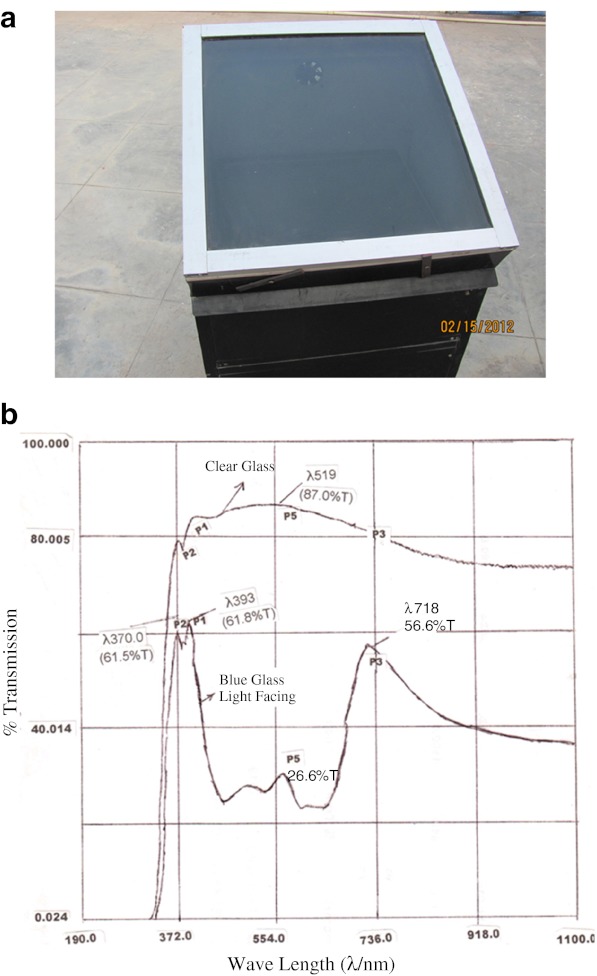

a UV Reduction glass blue filter (simulated shade drying)fitted on a SDM-8 Dryer. b Spectrum of U.V. Reduction Filter (Blue Filter)

Shade drying and UV reduction glass blue filter

A number of vegetables, especially leafy greens, spices, herbs and medicinal plants need shade drying to retain their nutrient value and other active components. Normal solar drying requires 65–70 °C which is damaging to many sensitive nutrients. It has been possible to devise a blue glass filter (Fig. 8a) which could reduce total radiation by 40 % and UV radiation by 20 % thereby simulating shade drying (Fig. 8b). This has been shown to improve the retention of nutrients like β-carotene (Bamji 2008). The drying time required, however is longer under the blue filter conditions.

Applications of SEED Solar Cabinet Dryer for post-harvest food drying

Food and Agriculture Organization (FAO) recently (May 2011) released a study on ‘Global Food Losses and Food Waste’ which states that “in developing countries 40 % of losses occur at post-harvest and processing levels while in industrialized countries more than 40 % of losses happen at retail and consumer levels. Thus there is an immediate need to improve post-harvest processing of food products. The various steps involved in post-harvest processing may be divided into primary, secondary and tertiary. The primary post-harvest food processing such as washing, cleaning, grading, sorting are mechanized in large enterprises but are simple and can also be performed manually by small farmers for immediate sale or for further processing. Secondary food processing involves such processes as drying, de-hulling, malting, roasting, and grinding of food grains, oil extraction, extrusion, preservation through pickling, jams, jellies, murabbas, sauces, purees, and beverages like juices, squashes, as well as fermentation and even baking. These involve steps such as pre-treatment with chemicals and addition of preservatives in order to achieve good organoleptic properties, retention of nutrients as well as greater shelf life and therefore value addition. Proper equipment and appropriate packing are also a part of this step. Some skill development and training is needed to achieve proper secondary processing.

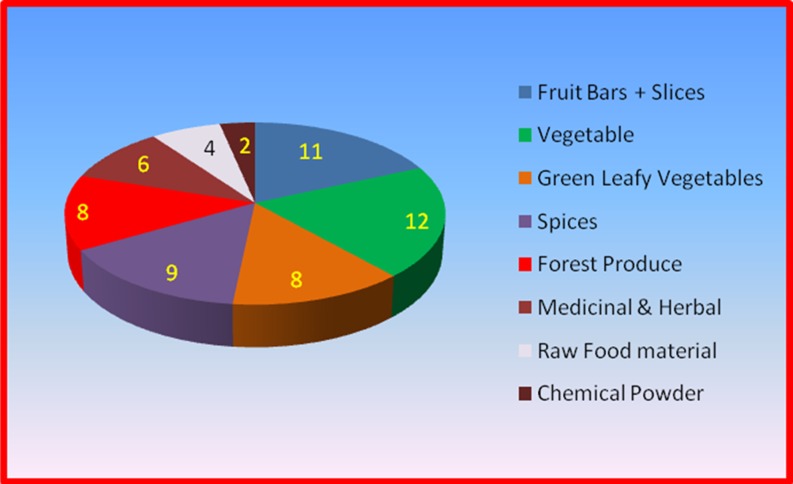

To date, SEED has developed over 60 products from various food groups using Solar Cabinet Dryer. Figure 9 summarizes the number of products developed in each category using SEED Solar Dryer. For example, 11 and 12 products were developed from fruit and vegetable groups respectively, 8 products from green leafy vegetables, 9 from spices class, 8 and 6 products respectively from forest and medicinal plant class, 4 from raw materials like refined wheat flour and the last 2 include non-edibles like silicon carbide and cellulose.

Fig. 9.

Number of products from various categories processed through SEED Solar Dryers

It is important to note that the pre-processing prior to dehydration for each group of the products listed is different. For example, the preparation of a Fruit Bar involves starting with the selection of the raw material, followed by preparation of the pulp, development of proper formulations and finally dehydration in the dryer. This will further be tested for proper shelf life after a desired packaging has been selected. The formulations are developed based on the initial and total and reducing sugar content as well as the acidity of the raw material. The product is also tested for the initial and final nutrient contents such as chlorophyll, vitamin-C and β-carotene and total protein so that optimal conditions can be set for minimal loss of nutrients during processing. Knowledge of initial and final moisture content of the product helps to determine the time needed for drying, the yield as well as the organoleptic properties of the product which are important in consumer acceptance of a product. Moisture is also the most important parameter which impacts the final shelf life of the product.

Over the last decade SEED R and D has been involved in developing a variety of products based on solar drying using locally available fruits, vegetables and other products for value addition. Tables 5, 6, 7, 8, 9 and 10 lists the products developed at SEED R and D data on the initial and final moisture content of each product, cabinet temperature during drying, time taken to achieve the desired final moisture content and the final yield for each product based on the initial weight. The following section gives a brief description of preparation of a few sample products from the list using solar dehydration process.

-

Preparation of Fruit Bars and Fruit Slices:

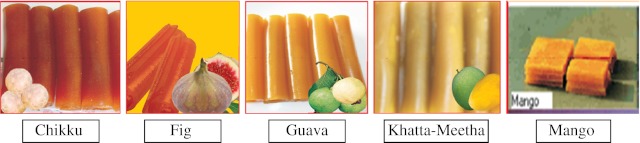

- Fruit bars/fruit jellies are traditionally prepared during the peak of the season when fruits are in plenty and cheap. Traditionally fruit pulps, mango being the most common, are spread on mats and dried in open sun for several days, where contamination from dust and bird, pet and fly-infestation is the most common. But with the cabinet type Solar Dryer, SEED has been able to produce a variety of Fruit Bars under hygienic conditions which are clean and nutritious and have a long shelf life. The general procedure for preparing a Fruit bar involves preparation of fruit pulp which is mixed with appropriate amount of sugar and glucose (to avoid sugar crystallization), pectin, citric acid and a preservative such as sodium or potassium metabisulphite. The formulated fruit pulp is spread in dryer trays at 7 kg/m2 and dried at 55–60 °C cabinet temperature. Often, additional layers of the same fruit are added after the first layer is dried to obtain either thicker product as in mango fruit bar or a different fruit pulp such as guava is added on top of mango for better texture and taste. The average drying time to attain a 12 % final moisture content for a two layer Fruit bar is 16 Sunny hours (Ramakrishna Rao et al. 2005).

- The resulting fruit bars have very good organoleptic properties such as appearance, color, flavor, taste and texture. When properly packaged, these fruit bars can have at least 10 months shelf life without losing any of their original properties.

- A variety of fruit bars and toffees have been produced using this basic solar drying technique. Examples include fruit bars from mango, from guava, chikku (Sapota), Khatta-Meetha (sweet and sour mango bars), fig bars, mixed fruit bars, fortified fruit bars (Eg. Ca, protein, vitamin C etc.) and no sugar added fruit bars, all with improved sensory properties and shelf-life. Figure 10 presents some of these products (Ramakrishna Rao 2011).

- In addition to the fruit bars, several Fruit slices such as Mango, Pineapple, and Papaya etc. were developed through solar dehydration.

A typical fruit bar preparation contains information on formulation details (Table 11), Drying time and the yield (Table 12) and finally analysis for a variety of parameters such as moisture, acidity, pH, total soluble solids, total sugars, reducing sugars, and browning index (Table 13). A moisture content of 12–15 %, with an average pH of 3.5 and total soluble solids 75–90 % provide the final product with improved sensory properties like appearance, texture, taste, flavor and shelf life of up to 10 months.

-

Processing of vegetable products

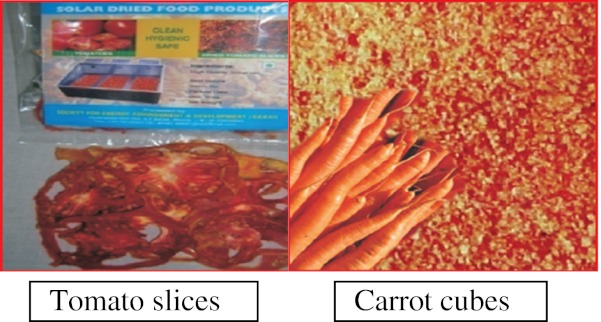

Hybrid Bangalore variety tomatoes, fresh carrots high in solids but low in woody fiber are used for dehydration. The vegetables were washed thoroughly, blanched at 93 °C in plain or in 2 % NaCl water for 3–4 min and sliced. Carrots were cubed before blanching. The sliced products were loaded at 5 kg/m2 and dried in Solar Cabinet Dryers. The time taken for achieving 4 % final moisture was 10–12 h. Dried tomatoes (Fig. 11a) and dried carrots (Fig. 11b) by this process retained their bright color. It is important to mention here the importance of these foods in wellness as well as in disease prevention. In a study conducted in the USA over a period of 4–5 years, researchers found an inverse association between total fruit and vegetable intake and head and neck cancer risk (Freedman et al. 2008). The association was stronger for vegetables than for fruits. Among the foods with strong inverse association for risk of head and neck cancer included tomatoes, carrots, dried beans, string beans, peas, apples, peaches, nectarines, plums, pears, strawberries and peppers. Fruits and vegetables, rich in potentially anticarcinogenic compounds, including carotenoids, fiber, folate, flavonoids, plant sterols, phenolic acids and vitamin C, have been considered to protect against head and neck cancer incidence.

-

Processing of green leafy vegetables

Curry leaves, gogu (roselle), drumstick and mint are most commonly available and consumed green leafy vegetables (GLVs) in most parts of India. They are also rich in micronutrients such as minerals especially Ca, Fe, β-Carotene and vitamin C (Table 14) (Kuhnlein 2003, Gopalan et al. 2004). Recent studies indicate that consumption of individual vegetable and fruit groups such as dark green leafy vegetables, cruciferous vegetables, carrots and tomatoes, banana, watermelon/papaya/cantaloupe were all inversely and significantly related with breast cancer risk. Further, an inverse association was also observed for vitamin A, carotene, vitamin C, vitamin E, and fiber intake (Zhang et al. 2009). Thus processing of the GLVs for longer shelf life without losing the nutrient content will be of importance in providing valuable nutrients at low cost. Mature leaves such as curry leaves, gogu (roselle), drumstick and mint were removed from the stem and washed thoroughly in water and drained. The washed leaves were blanched for 60 s in a solution containing 0.1–0.2 % magnesium oxide at 90 °C to retain the green color. The blanched leaves were spread in dryer trays at 5–6 kg/m2. The drying time is dependent on the initial moisture content of the leaves as well as the texture. Thus curry leaves dried in 8 h while gogu leaves took 15 h of drying at 55 °C chamber temperature (30 °C ambient temperature) to achieve a final moisture level of 4 %. GLVs such as drumstick leaves when dried under Blue Filter (simulated shade drying) retain higher β-carotene level (Bamji 2008). Thus, powdered leafy vegetables when used as food additives and/or sprinkles during cooking, are a ready source of fresh flavors as well as rich source of micronutrients. With appropriate packaging, they can have a long shelf life.

-

Solar processing of spices and condiments

Fresh ginger is one of the most commonly used spice in Indian and many other cusines around the world. The dry powder of ginger is also used as a flavoring agent in curries, soups, as well as in baking and confectionaries. The process of making ginger powder does not involve any pre-treatment nor the addition of a preservative. Fresh raw ginger was soaked overnight in water to remove dirt. Outer skin was scraped with bamboo knife, cut into small pieces and coarse grounded and spread in Solar Dryer tray at 5 kg/m2. A drying time of 16 h was required to achieve 4 % final moisture. Dried ginger was ground to fine powder for packing. Dry ginger powder, apart from being a flavoring agent in cooking and drinks, is a very important component in many Ayurvedic medicinal formulations. More recent systematic studies are helping us understand the active ingredients and the biochemical mechanisms involved in the emetic (Abdel-Aziz et al. 2006, Sang et al. 2009) as well as anti-inflammatory and anti-cancer properties in fresh as well dehydrated ginger. Studies reported by Nievergelt et al. (2010) indicated that at least some of the properties exhibited by ginger may have something to do with the binding of its active ingredients to serotonin-receptors.

-

Solar processing of forest produce for value addition

Indian Goosberry (Emblica officinalis) and Phyllanthus emblica more popularly known as Amla are grown in abundance in many parts of India. Amla fruits are edible and are widely consumed as pickles and murabbas. The fruits are a rich source of vitamin C (Gopalan et al. 2004). All parts of the plant are used Ayurvedic and Unani medicines. Amla is used for making hair oils and as well as in many Ayurvedic Formulations. Its high tannin content function as mordent for fixing dyes in textile industry. For preparing Amla powder, the fresh fruits were blanched at 90 °C for 1 min and cooled quickly, pitted, crushed, solar dried and powdered. The powder retained over 50 % of the original vitamin C content when dried under shade drying conditions Formulations for making Amla Supari or mouth freshner with solar dehydrated Amla has been developed in SEED R and D. Tables 5, 6, 7, 8, 9 and 10 lists the drying conditions of products processed in solar dryers.

Table 5.

Fruit bars and fruit slices processed in solar drying for value addition

| S Nr | Product | Drying conditions | ||||

|---|---|---|---|---|---|---|

| Spreading Density—kg/m2 | Time (Sunny Hours) | Yield (%) of Product | Cabinet/(Ambient) Temp. °C | Permissible limits of retention % of moisture on wet weight basis | ||

| 1 | Mango bar (2 Layers) | 7 | 16 | 55 | 60 (25) | 12.0 |

| 2 | Guava bar (2 Layers) | 7 | 16 | 55 | 60 (25) | 12.0 |

| 3 | Mixed bar (2 Layers) | 7 | 16 | 55 | 60 (25) | 12.0 |

| 4 | Sapota bar (3 Layers) | 7 | 16 | 55 | 60 (25) | 12.0 |

| 5 | Khatta-Meetha bar (2 Layers) | 7 | 16 | 55 | 60 (25) | 12.0 |

| 6 | Fig bar (2 Layers) | 7 | 16 | 40 | 60 (25) | 12.0 |

| 7 | No sugar added Mango bar (2 layers) | 7 | 16 | 40 | 60 (25) | 12.0 |

| 8 | Apple slices | 9 | 8 | 16 | 50 (25) | 8.0 |

| 9 | Mango slices | 9 | 10 | 26 | 59 (29) | 8.0 |

| 10 | Sapota slices | 4 | 8 | 27 | 50 (25) | 8.0 |

| 11 | Pineapple slices | 5 | 20 | 18 | 45 (27) | 8.0 |

| 12 | Papaya slices | 9 | 18 | 37 | 42 (27) | 8.0 |

| 13 | Grapes slices | 14 | 25 | 20 | 53 (31) | 4.0 |

Table 6.

Vegetables processed in solar drying for value addition

| S Nr | Product | Drying conditions | ||||

|---|---|---|---|---|---|---|

| Spreading density—kg/m2 | Time (Sunny hours) | Yield (%) of product | Cabinet (Ambient) temp. °C | Permissible limits of retention % of moisture on wet weight basis | ||

| 1 | Potatoes | 5.0 | 4 | 16 | 50 (31) | 5.0 |

| 2 | Donda (Coccinia indica) | 5.0 | 19 | 30 | 50 (30) | 5.0 |

| 3 | Carrot crush or minces | 5.0 | 10 | 15 | 50 (31) | 5.0 |

| 4 | Carrot slices | 4.0 | 14 | 15 | 50 (31) | 5.0 |

| 5 | Tomato | 5.0 | 10 | 10 | 60 (30) | 5.0 |

| 6 | Mushrooms | 4.0 | 12 | 15 | 50 (33) | 5.0 |

| 7 | Bitterguard crush or mince | 4.0 | 6 | 10 | 50 (26) | 4.0 |

| 8 | Bitterguard slices | 4.0 | 8 | 10 | 42 (26) | 4.0 |

| 9 | Onion | 5.0 | 18 | 17 | 50 (24) | 4.0 |

| 10 | Ragi malt | 3.5 | 4 | 75 | 50 (33) | 4.0 |

| 11 | Raw mango (Amchur) | 9.0 | 16 | 22 | 50 (28) | 4.0 |

| 12 | Desiccated coconut | 3.0 | 5 | 30 | 50 (29) | 4.0 |

| 13 | Cashew nuts | 3.0 | 8 | 97 | 49 (30) | 4.0 |

| 14 | Curry leaves | 6.0 | 8 | 35 | 55 (30) | 4.0 |

| 15 | Spinach leaves | 5.0 | 15 | 8 | 55 (30) | 4.0 |

| 16 | Fenugreek leaves | 5.0 | 6 | 13 | 55 (30) | 4.0 |

| 17 | Tamarind leaves Tender | 5.0 | 12 | 11 | 55 (30) | 4.0 |

| 18 | Gogu leaves | 5.0 | 15 | 16 | 55 (30) | 4.0 |

| 19 | Mint leaves | 5.0 | 5 | 17 | 55 (28) | 4.0 |

| 20 | Drumstick leaves | 5.0 | 6 | 15 | 55 (29) | 4.0 |

| 2221 | Coriander leaves | 5.0 | 6 | 12 | 50 (28) | 4.0 |

| 23 | Wheat grass powder Powder | 5.0 | 5 | 12 | 55 (29) | 4.0 |

Table 7.

Spice and condiments processed in solar drying for value addition

| S Nr | Product | Drying conditions | ||||

|---|---|---|---|---|---|---|

| Spreading density—kg/m2 | Time (Sunny hours) | Yield (%) of product | Cabinet (Ambient) temp. °C | Permissible limits of retention % of moisture on wet weight basis | ||

| 1 | Mango ginger | 5.0 | 12 | 16 | 50 (31) | 4.0 |

| 2 | Garlic powder | 3.0 | 4 | 33 | 55 (29) | 4.0 |

| 3 | Red chillies (Big variety) | 5.0 | 48 | 17 | 50 (30) | 4 |

| 4 | Red chillies (Small variety) | 4.0 | 30 | 26 | 59 (25) | 4 |

| 5 | Pickle red chillies | 4.0 | 24 | 25 | 55 (28) | 4 |

| 6 | Green chillies | 8.0 | 6 | 12 | 55 (27) | 4.0 |

| 7 | Green chillies (Bajji variety) | 2.0 | 34 | 10 | 49 (31) | 4 |

| 8 | Pepper | – | 8 | 34 | 55 (27) | 4 |

Table 8.

Forest produce processed in solar drying for value addition

| S Nr | Product | Drying conditions | ||||

|---|---|---|---|---|---|---|

| Spreading density—kg/m2 | Time (Sunny hours) | Yield (%) of product | Cabinet (Ambient) temp. °C | Permissible limits of retention % of moisture on wet weight basis | ||

| 1 | Karaya gum | 2.0 | 19 | 35 | 55 (30) | 2.0 |

| 2 | Karakkaya (Myrobalan; Terminalia chebula) | 2.0 | 44 | 52 | 55 (28) | 2.0 |

| 3 | Sugandhapala (Budipalagadda) Indian Sarsaparilla (Hemidesmus indicus) | 3.0 | 26 | 26 | 55 (27) | 4.0 |

| 4 | Aloevera (Green) | 2.0 | 9 | 3 | 50 (30) | 4.0 |

| 5 | Aloevera(White) | – | 9 | 1 | 52 (34) | – |

| 6 | Amla powder (Hybrid) | 5.0 | 6.5 | 32 | 50 (28) | 4.0 |

| 7 | Amla slices, | 5.0 | 10 | 30 | 49 (27) | 8.0 |

| 8 | Honey | 2.0 | 5.5 | 91 | 55 (28) | – |

| 9 | Amla supari | 4.0 | 12 | 35 | 50 (28) | 4.0 |

Table 9.

Medicinal and herbal products processed in solar drying for value addition

| S Nr | Product | Drying conditions | ||||

|---|---|---|---|---|---|---|

| Spreading density—kg/m2 | Time (Sunny hours) | Yield (%) of product | Cabinet (Ambient) temp. °C | Permissible limits of retention % of moisture on wet weight basis | ||

| 1 | Rosemary | 4.0 | 15 | 30 | 55 (27) | – |

| 2 | Spirulina Powder | 4.0 | 6 | 18 | 60 (28) | 4.0 |

| 3 | Tender Bamboo Shoots | 2.0 | 8 | 10 | 57 (29) | 4.0 |

| 4 | Tulasi (Oscimum) Leaves | 2.0 | 6 | 12 | 50 (30) | 4.0 |

| 5 | Turmeric | – | 8 | 14 | 62 (31) | 4.0 |

| 6 | Rose Petals | 50 (30) | 4.0 | |||

Table 10.

Other food items and a chemical powder processed in solar drying for value addition

| S Nr | Product | Drying conditions | ||||

|---|---|---|---|---|---|---|

| Spreading density—kg/m2 | Time (Sunny hours) | Yield (%) of product | Cabinet (Ambient) temp. °C | Permissible limits of retention % of moisture on wet weight basis | ||

| 1 | Maida | 4.0 | 4 | 96 | 56 (27) | 4.0 |

| 2 | Vermicelli | 6.0 | 4 | 35 | 55 (28) | 4.0 |

| 3 | Noodles | 8.0 | 4 | 77 | 55 (29) | 5.0 |

| 4 | Fish | 7.0 | 8 | 40 | 55 (27) | 11.0 |

| 5 | Silicon Carbide—Chemical powder | 2.0 | 3 | 80 | 60 (29) | 4.0 |

Fig. 10.

Fruit bars and fruit rolls produced using solar cabinet dryers

Table 11.

Formulations of apple (A), banana (B), plum (P) and strawberry (S) mixed fruit bars prepared using solar cabinet dryers

| Fruit bar | Apple pulp, kg | Banana pulp, kg | Plum pulp, kg | Straw berry Pulp, kg |

|---|---|---|---|---|

| A:P | 8.37 | – | 0.93 | – |

| A:B:P | 4.65 | 2.79 | 1.86 | – |

| A:B:S | 3.72 | 2.79 | – | 2.79 |

Each formulation in this example also contained 2.325 kg sugar (25 %), 0.93 kg liquid glucose (10 %), 9.3 g potassium metabisuaphite (0.1 %), 9.3 g pectin ((0.1 %) and 18.6 g citric acid (0.2 %)

Table 12.

Drying time and yield of apple (A), banana (B), plum (P) and Strawberry (S) mixed fruit bars prepared using solar cabinet dryers

| Fruit Bar | Final wt.(kg) | Yield (%) |

|---|---|---|

| A:P | 4.97 | 39.5 |

| A:B:P | 3.88 | 30.9 |

| A:B:S | 4.32 | 34.3 |

In each case initial weight was 12.592 kg, drying time 20 h, ambient temperature 33–37 °C and cabinet temperature 42–53 °C

Table 13.

Physico-chemical quality characteristics of fruit bars from apple (A), banana (B), plum (P) and strawberry (S) mixed fruit bars prepared using solar cabinet dryers

| Parameters | Fresh Pulp | Blended Pulp | Bars | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Apple (A) | Strawberry (S) | Plum (P) | A:P | P:A:B | S:A:B | A:P | P:B:A | S:B:A | |

| Moisture, % | 89.93 | 93.31 | 86.95 | 70.46 | 67.09 | 68.42 | 11.83 | 12.67 | 14.10 |

| Acidity, % | 0.21 | 0.49 | 0.90 | 0.39 | 0.44 | 0.44 | 0.50 | 0.90 | 1.007 |

| pH | 3.80 | 3.70 | 3.47 | 3.62 | 2.82 | 2.73 | 3.15 | 3.24 | 3.31 |

| Total soluble solids, % | 8.00 | 5.30 | 13.50 | 25.0 | 31.00 | 30.00 | 88.10 | 76.10 | 74.11 |

| Browning index (OD 420 nm) | 0.033 | 0.691 | 0.268 | 0.082 | 0.227 | 0.134 | 0.297 | 0.157 | 0.135 |

| Reducing sugars. % | 7.43 | 5.85 | 6.25 | 14.51 | 18.88 | 19.65 | 42.58 | 65.78 | 61.7 |

| Total sugars, % | 8.20 | 7.90 | 8.20 | 34.0 | 40.9 | 30.20 | 87.00 | 78.90 | 83.1 |

Fig. 11.

Solar dried tomato slices and carrot cubes

Table 14.

Micronutrient-rich sources in the traditional cultural foods of indigenous population

| English name/Part used | Scientific name | Culture/Location | Nutrient content per 100 g |

|---|---|---|---|

| Wild betel/leaves | Piper sarmentosum Roxb | Karen/Thailand | 3095 μg β-carotene, 17 mg vitamin C |

| Sweet potato/leaves | Ipomea batats | Aetas/Philppines | 5176 μg β-carotene |

| Kupta/leaves | Moringa oleifera | Hausas/Niger | 5880 μg β-carotene |

| Roselle/leaves | Hibiscus sabdariffa Linn. | Karen/Thailand | 44 mg vitamin C |

| Ivy gourd/leaves | Coccinia grandis Voigt. | Karen/Thailand | 13 mg vitamin C, 3640 μg β-carotene |

| Gac/seed pulp | Momordica cochin chinensis Spreng | Vietnam | 45.8 mg β-carotene |

| Ooligan fish/oil | Thaleichthys pacifious | Nuxalk/Canada | 2500 μg retinol, 19 mg omega-3 fatty acids, 14 mg alpha-tocopherol |

| Nanwahl/meat Blubber mattak | Monodon monoceros | Inuit/Canada | 8.9 mg vitamin E, 3.6 g omega-3 fatty acids, 36 mg vitamin C |

Source: Kuhnlein (2003)

Over 150 SEED Solar Cabinet Dryers of various capacities have been installed in 13 States in India including Andaman and Nicobar since the development of the dryers. These are being used for processing of fruits and vegetables, dehydration of medicinal plants, drying of fish and other marine products. Through collaborations with educational institutions and other NGOs, it has been possible to expand and disseminate the concepts of clean and green energy utilization, income generation through safe, solar food processing, all with an eye on protecting the environment and reducing pollution.

Quality assessment of solar dried food products

The quality of solar dried products is assessed for physical, chemical/nutritional and microbial properties. The extent of changes in each of these parameters during drying depends on processes and steps taken during the preparation of the product for dehydration.

Physical parameters

Structure, case hardening, collapse, pore formation, cracking, rehydration properties, caking and stickiness are some of the physical parameters that are studied. These have influence on the quality of final dried products. A number of factors influence these parameters during drying process. For example hot air drying destroys cell structure causing more time for rehydration of the product where as freeze drying keeps the cell architecture almost intact (Saguy et al. 2004). Pretreatments such as immersion into alkaline or acidic solutions of oleate esters (Salunke et al. 1991) or osmo-dehydration before drying create more porous structure therefore better rehydration property with only a minor effect on product quality (Sunjka and Raghavan 2004).

SEED developed methods for making solar dehydrated figs using pretreatments such as immersion into alkaline or acidic solutions of oleate esters with good success.

Similarly, apple, banana, potato and carrots dried under air, vacuum and microwave had extensive browning whereas freeze drying seemed to result in products with better color characteristics (Krokida et al. 2001). Textural changes occur due to chemical changes of cellular components of fruits and vegetables such as degradation of pectin, gelatinization of starch and/or structural alterations in cellulose like crystallization (Krokida et al. 2001). Similar systematic studies for solar dehydrated products should be conducted for design improvements and better quality product output. Currently, experience in the conventional processing techniques has been providing guidelines for solar dehydration process development and product quality.

Chemical/nutritional parameters

Color loss, change of flavor, browning and rancidity (lipid oxidation) are some of the changes that occur in processed foods during drying and storage. Browning reactions can be categorised as enzymatic and non-enzymatic (Salunke et al. 1991). Enzymatic browning of foods is undesirable because it develops undesirable color and produces off flavor. Heating, sulphur dioxide or sulphites and acids are used to control enzymatic browning, though they are known to destroy vitamin B (thiamine). Dipping in citric acid/phosphoric acid/ascorbic acid solutions can inhibit enzymatic browning in fruits during osmosis.

Solar dried products developed at SEED R &D currently incorporate metabisulphite, ascorbic acid or citric acid in the formulation to prevent browning as well as improve shelf life.

Lipid oxidation is responsible for rancidity, development of unacceptable flavors, and loss of fat-soluble vitamins and pigments in many foods, especially in dehydrated foods. Factors that influence the oxidation rate include moisture content, type of substrate (fatty acid), extent of reaction and oxygen content. Most fruit and vegetable products developed by solar dehydration/drying are pretreated with proper antioxidants such as ascorbic acid in their formulations and improved packaging (under reduced oxygen) have been found to be helpful in minimizing rancidity.

Fruits, vegetables and their products in the dried form are good sources of energy, minerals and vitamins. However, during the process of dehydration, there are changes in nutritional quality (Sablani 2006). A more number of vitamins such as A, C and thiamine are heat sensitive and sensitive to oxidative degradation. Sulphuring can destroy thiamine and riboflavin while pre-treatments such as blanching and dipping in sulphite solutions reduce the loss of vitamins during drying. As much as 80 % decrease in the carotene content of some vegetables may occur if they are dried without enzyme inactivation. However, if the product is adequately blanched then carotene loss can be reduced to 5 %. Steam blanching retains higher amounts of vitamin C in spinach compared with hot-water blanching (Ramesh et al. 2001). Blanching in sulphite solution can retain more ascorbic acid in okra (Inyang and Ike 1998). Sodium metabisulphite treatment was able to reduce oxidation of carotenoid in carrots and L-cysteine-HCl help in retaining highest amount of ascorbic acid (Mohamed and Hussein 1994).

SEED is currently conducting a systematic investigation on the rate of nutrient loss/retention under various solar drying conditions including simulated shade conditions for a variety of produce such as fruits, vegetables, green leafy vegetables and forest produce. Continued investigation will eventually replace the sulfites with safer additives for better preserving color, prevent rancidity and minimize microbial contamination.

Microbial parameters

By controlling moisture level (water activity, aw) and the pH, microbial growth can be controlled but does not result in a sterile product. Similarly blanching can reduce the microbial load but cannot eliminate spore forming organisms. The heat of the drying process reduces total microbial count if not eliminate completely. The type of microflora present in dried products depends on the characteristics of the products, such as pH, composition, pre-treatments, types of endogenous and contaminated microflora and method of drying. (Pathogenic bacteria cannot grow below aw of 0.85–0.86 but yeast and mould can. Solar dried fruit and vegetable products are routinely tested for microbial load and are found to be within the allowed safe limits. This is further supported by the ability to obtain long shelf life for these products.

Solar drying and rural employment

Pilot projects conducted at Chennai, Thiruvananthapuram and New Delhi for self help groups concluded that an investment in a solar dryer provides an ideal source of income generation for poor women by producing value added products (Balakrishnan and Banerjee 2006). The SEED solar cabinet dryers are being used by women in Haryana for making fruit bars from fruits grown in their farms.

Conclusion

Solar energy based technologies are currently playing an important role in food processing. However, at present their use is limited to micro- to small-scale processing. The feasibility of using them on large scale can and should be studied and is the goal of future studies. Solar dehydration/drying is as effective as the mechanized equipments and offers an alternative at low or no cost. Evidence exists for improved nutritional and medicinal quality through Infra Red (IR) drying of fresh produce such as herbs. Paakkonen et al. (1999) have shown that IR drying improves the quality of herbs. Zbicinski et al. (1992) investigating convective air drying and IR drying, have suggested the use of an intermittent irradiation drying mode coupled with convective air drying is best for heat sensitive materials. Similar findings have also been reported by Carroll and Churchill (1986), Dostie et al. (1989) and Kian and Siaw (2005).

With changing life styles in India and elsewhere, there is a great demand for ready-to-eat (RET) foods that are also healthy and solar food processing can be a major contributor to meet such demand. Initial high cost of investment in solar gadgets, lack of confidence in the technology and scalability to large scale processing are some of the hurdles facing the wider use of solar energy in food processing. A limited number of governmental incentives that are currently in place through various ministries (Eg. Ministry of New and Renewable Energy, India) help fray the initial high cost of the solar gadgets and help reduce the pay-back time for small and micro-entrepreneurs nominally. In spite of such incentives and many technical developments, application of solar energy in food-processing industry has not progressed as fast. It has been recognized for a while that a big communication gap exists between solar researchers and food technologists. Food technologists are not aware of capabilities of new breed of solar gadgets like solar concentrators, ovens and dryers, while solar technologists are unaware of technical requirements of different processes followed in food processing. Apart from huge energy savings, reported big improvements in the quality of product should be substantiated with hard data. There is an urgent need to integrate the food processing industry with solar equipment developers (vice versa) through governmental, international agencies, as well as the expert bodies in these fields. Food processing is not only important in conserving the surplus harvest, but it is also a job creator. Studies show that food processing industry creates more jobs per every rupee invested compared to other industries like textiles. Food processing through micro-enterprises alone is not sufficient in bringing rural employment or to alleviate poverty. The construction of a stable and viable process-to-consumer chain tailored to fit the structure and needs of microenterprises is key to the success of small-and micro-enterprises which in turn help improve rural employment and standard of living down the line.

A combination of solar gadgets rather than any single one will ultimately take care of major energy needs in food processing industry. This is already happening with considerable success. As India advances in these fields, it can offer simple affordable technologies round the world and share its experience. As the promise of reduced cost of photovoltaic and collectors is realized and as newer technologies become reliable and affordable, solar power generators may produce most of the world’s electricity in the next 50 years, photovoltaic technologies and concentrated solar power together can become the major source of electricity dramatically reducing the emissions of greenhouse gases that harm the environment. Solar food processing will certainly be a beneficiary as well as a contributor in future.

Acknowledgement

The authors wish to thank Prof PN Murthy, President, SEED for his constant encouragement, for going through the manuscript and for his valuable suggestions.

Contributor Information

Amruta R. Eswara, Email: areswara@gmail.com

M. Ramakrishnarao, Email: seed@seedngo.com

References

- Abdel-Aziz H, Windeck T, Ploch M, Verspohl EJ. Mode of action of gingerols and shogaols on 5-HT3 receptors: binding studies, cation uptake by the receptor channel and contraction of isolated guinea-pig ileum. Eur J Pharmacol. 2006;530(1–2):136–143. doi: 10.1016/j.ejphar.2005.10.049. [DOI] [PubMed] [Google Scholar]

- Anon (2011) Project information sheet—Solar food processing and conservation (SOLAR-FOOD). https://www.ises.org/ises.nsf/f3e5b699aa79d0cfc12568b3002334da/0eadf836d17a7e88c125702e0037369e/PageContent/M2/Solar-Food-Project_Projects%20site.pdf?OpenElement-Accessed on 09 December 2011

- Balakrishnan L, Banerjee M. Solar dryers—an income generation option for poor women. ENERGIA News. 2006;9(2):16–17. [Google Scholar]

- Bamji MS. Food technology for rural settings. Compr Rev Food Sci Food Saf. 2008;7:353–357. [Google Scholar]

- Behringer R (2006) Solar food processing—network and support. http://www.solare-bruecke.org/infoartikel/Papers_%20from_SCI_Conference_2006/paper_granada_2006_BehringerR_ISEScorrection-1.pdf Accessed on 08 December 2011

- Carroll MB, Churchill SW. A numerical study of periodic on-off versus continuous heating by conduction. Numer Heat Transfer. 1986;10:297–310. [Google Scholar]

- Chandak A, Sham P, Vilas S (2006) Solar energy for quality improvement in food processing industry—Paper presented at “Solar Cookers and Food Processing International Conference”, Co sponsors: Solar Cookers International, Terra Foundation, The Good Works Institute, Junta de Andalucía, Parque de las Ciencias, Granada, Spain, 12–16th July, 2006 http://www.princeindia.org/Food%20processing%20article.pdf./ Accessed on 18 January 2012

- Chaves J (2008) Introduction to nonimaging optics. Series: optical science and engineering. CRC Press (ISBN 978-1420054293)

- Chua KJ, Mujumdar AS, Chou SK, Hawlader MNA, Ho JC. Convective drying of banana, guava and potato pieces: effect of cyclical variations of air temperature on drying kinetics and color change. Drying Technol. 2000;18:907–936. doi: 10.1080/07373930008917744. [DOI] [Google Scholar]

- Dostie M, Seguin JN, Maure D, Ton-That QA, Chatingy R. Preliminary measurements on the drying of thick porous materials by combinations of intermittent IR and continuous convection heating. In: Mujumdar AS, Roques MA, editors. Drying 89. New York: Hemisphere; 1989. pp. 513–520. [Google Scholar]

- Freedman ND, Park Y, Subar AF, Hollenbeck AR, Leitzmann MF, Schatzkin A, Abnet CC. Fruit and vegetable intake and head and neck cancer risk in a large United States prospective cohort study. Int J Cancer. 2008;122(10):2330–2336. doi: 10.1002/ijc.23319. [DOI] [PubMed] [Google Scholar]

- Frito Lay (2012) Snacks made with the help of the Sun (http://www.fritolay.com/our-planet/snacks-made-with-the-help-of-the-sun.html Accessed on 11 February 2012

- Fudholi A, Otman MY, Ruslan MH, Yahya M, Azamizarim, Sopian K (2011) Techno-economic analysis of solar drying system for seaweed in Malaysia. World Scientific and Engineering Academy and Society Conf, Angers, France, November 16–19

- Gopalan C, RamaSastri BV, Balasubramanian SC (2004) Nutritive value of Indian foods (Revised and updated, Narasinga Rao BS, Deosthale YG and Pant KC), ICAR-National Institute of Nutrition, Hyderabad

- Inyang UE, Ike CI. Effect of blanching, dehydration method, temperature on the ascorbic acid, color, sliminess and other constituents of okra fruit. Int J Food Sci Nutr. 1998;49:125–130. doi: 10.3109/09637489809089392. [DOI] [PubMed] [Google Scholar]

- Kedare SB (2006) Solar concentrator for industrial process heat. Proc Int Congress on Renwable Energy (ICORE) 2006, 08–11 February 2006, Hyderabad, pp 135–141 (http://www.ircc.iitb.ac.in/∼webadm/update/archives/Issue1_2006/solar-concentrator.html, Accessed on 18 January 2012

- Kedare SB, Ashok D, Paranjape AD, Porwal R (2010) ARUN Solar concentrator for industrial process heat applications. (http://mnre.gov.in/mnre-2010/file-manager/UserFiles/arun_article_kedare.pdf) Accessed on 18 January 2012

- Kian JC, Siaw KC. A comparative study between intermittent microwave and infrared drying of bioproducts have reported shorter drying time with improved product quality for intermittent IR heating. Int J Food Sci Technol. 2005;40:23–39. doi: 10.1111/j.1365-2621.2004.00903.x. [DOI] [Google Scholar]

- Krokida MK, Maroulis ZB, Saravacos GD. The effect of method of drying on colour of dehydrated product. Int J Food Sci Technol. 2001;36:53–59. doi: 10.1046/j.1365-2621.2001.00426.x. [DOI] [Google Scholar]

- Kuhnlein HV (2003) Micronutrient nutrition and traditional food systems of indigenous peoples. ftp://ftp.fao.org/docrep/fao/005/y8346m/y8346m04.pdf. Accessed on 08 January2012

- Mayor L, Sereno AM. Modelling shrinkage during convective drying of food materials. J Food Eng. 2004;61:373–386. doi: 10.1016/S0260-8774(03)00144-4. [DOI] [Google Scholar]

- MoFPI (2004) Present status and future prospects of Indian food processing industries. Annual Report of Ministry of Food Processing Industries 2003–04 http://mofpi.nic.in/ContentPage.aspx?CategoryId=122, Accessed in January 2012

- Mohamed S, Hussein R. Effect of low temperature blanching, cysteine-HCl, N-acetyl-L-cysteine, Na metabisulphite and drying temperatures on the firmness and nutrient content of dried carrots. J Food Process Preserv. 1994;18:343–348. doi: 10.1111/j.1745-4549.1994.tb00257.x. [DOI] [Google Scholar]

- Müller C, EcoAndina F, Arias C (2009) Solar community bakeries on the Argentinean Altiplano. International Solar Food Processing Conference; 14–16 January, Indore, India

- Nievergelt A, Huonker P, Schoop R, Altmann KH, Gertsch J. Identification of serotonin 5-HT1A receptor partial agonists in ginger. Bioorg Med Chem. 2010;18:3345–3351. doi: 10.1016/j.bmc.2010.02.062. [DOI] [PubMed] [Google Scholar]

- Nijhuis HH, Torringa HM, Muresan S, Yukel D, Leguijt C, Kloek W. Approaches to improving the quality of dried fruits and vegetables. Trends Food Sci Technol. 1998;9:13–20. doi: 10.1016/S0924-2244(97)00007-1. [DOI] [Google Scholar]

- Paakkonen K, Havento J, Galambosi B, Pykkonen M. Infrared drying of herb. Agric Food Sci Finl. 1999;8:19–27. [Google Scholar]

- Palaniappan C (2009) Perspectives of solar food processing in India. Int Solar Food Processing Conf. 14–16 January Indore, India

- Parfitt J, Barthel M, Macnaughton S. Food waste within food supply chains: quantification and potential for change to 2050. Philos Trans R Soc B. 2010;365:3065–3081. doi: 10.1098/rstb.2010.0126. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ramakrishna Rao M (2004) New solar powered solar air dryer for food processing. Proc Nat Workshop on Solar Drying Technologies and their Applications in India resulting in high efficiency drying, May 7, Hyderabad, India

- Ramakrishna Rao M (2007) Solar powered closed cabinet food dryer with electric stand-by facility. Indian Patent Nr 211911

- Ramakrishna Rao M (2011) Innovative solar food processing technology—New Technology for Food Safety and Conservation—Published by SEED, Hyderabad, India

- Ramakrishna Rao M, Sarojini G, Veena V (2005) Solar drying for safe and quality mango bar—National seminar on Food Safety and Quality Control in India, Acharya N.G. Ranga Agricultural University(ANGRAU), May 12, Hyderabad, India

- Ramesh MN, Wolf Tevini D, Jung G. Influence of processing parameters on the drying of spice paprika. J Food Eng. 2001;49:63–72. doi: 10.1016/S0260-8774(00)00185-0. [DOI] [Google Scholar]

- Sablani SS. Drying of fruits and vegetables: retention of nutritional/functional quality. Dry Technol. 2006;24:428–432. [Google Scholar]

- Saguy IS, Marabi A, Wallach R (2004) Water imbibition in dry porous foods. Proc 9th Int Conf on Engineering and Food Montpellier, France, 7–11 April, p 147–152

- Salerno C (2008) Frito Lay solar system puts the sun in SunChips, takes advantage of renewable energy: Manufacturer to use Central Valley’s biggest asset—The Modesto Bee, Friday, April.04, 2008/http://www.modbee.com/2008/04/04/259206/frito-lay-solar-system-puts-the.html#storylink=cpy/ Accessed on 12 February 2012

- Salunke DK, Bolin HR, Reddy NR (1991) Dehydration. In: Storage, processing and nutritional quality of fruits and vegetables, 2nd edn, Vol II, Processed fruits and vegetables. CRC Press, Boca Raton, pp 49–98

- Sang S, Hong J, Wu H, Liu J, Yang CS, Pan MH, Badmaev V, Ho CT. Increased growth inhibitory effects on human cancer cells and anti-inflammatory potency of shogaols from Zingiber officinale relative to gingerols. J Agric Food Chem. 2009;57:10645–10650. doi: 10.1021/jf9027443. [DOI] [PMC free article] [PubMed] [Google Scholar]

- SEP (2011) Solar Energy Perspectives: The International Energy Agency-Executive Summary (http://www.iea.org/Textbase/npsum/solar2011SUM.pdf). Accessed on 08 December 2011

- Sharma RB (2009) Thematic studies for processing and preservation of food supplement, chilies and ginger by drying through solar energy. Intl Solar Food Processing Conf. January 14–16, Indore, India

- Sunjka PS, Raghavan GSV. Assessment of pretreatment methods and osmotic dehydration of cranberries. Can Biosyst Eng. 2004;4:35–40. [Google Scholar]

- Winston R, Minano JC, Benitez PG (2005) Nonimaging optics. Academic Press (ISBN: 978-0-12-759751-5)

- Zbicinski I, Jakobsen A, Driscoll JL. Application of infra-red radiation for drying of particulate material. In: Mujumdar AS, editor. Drying 92. Amsterdam: Elsevier Science; 1992. pp. p704–p711. [Google Scholar]

- Zhang CX, Ho SC, Chen YM, Fu JH, Cheng SZ, Lin FY. Greater vegetable and fruit intake is associated with a lower risk of breast cancer among Chinese women. Int J Cancer. 2009;125(1):181–188. doi: 10.1002/ijc.24358. [DOI] [PubMed] [Google Scholar]