Abstract

The marinated and battered chicken leg meat and breast meat were pressure fried and their physico-chemical qualities were compared to the conventional fried product (open pan deep fat frying). Shrinkage due to frying process was significantly lesser in case of pressure fried leg meat (PLM) and breast meat (PBM) as compared to products prepared by conventional frying leg meat (CLM) and breast meat (CBM). Also, juiciness of pressure fried chicken products was superior (p ≤ 0.05) than fried products obtained by the conventional method. PLM and PBM had lower fat content (p ≤ 0.05) compared to conventionally fried CLM and CBM. Lipid oxidation was higher (p ≤ 0.05) in conventional frying as compared to pressure frying. Irrespective of the type of chicken meat, conventionally fried meat required higher shear force as compared to pressure fried products. Salmonella, Staphylococcus aureus, Shigella and E. coli were not detected. The study indicates the usefulness and superiority of pressure frying in comparison to conventional deep fat frying.

Keywords: Battered fried chicken, Pressure frying, Conventional frying, Juiciness, Hunter colour, Texture

Introduction

Meat is an integral part of diet for the large majority of mankind, not only as a good source of protein but also because of its sensory properties, of which texture is one of the most important. Further, texture of meat is a function of moisture and method of cooking which affects on the oil absorption. The growing demand by consumers for healthier products is stimulating the development of meat products with reduced fat content. (Colmenero 1996). With the increased interest in reducing the ingestion of fat, low-fat products are being developed as they are perceived to be healthier. An understanding of fat transfer during frying of meat products has been of interest to processors as consumers become more concerned about the amount of fat they consume. Hence, oil uptake and means to reduce it have always been given priority due to its negative effect on health.

Deep-fat frying is one of the oldest and most popular thermal processing techniques used for the preparation of various food products including meat, fish and poultry. Fried foods constituted a primary choice in our diets and have remained popular among today’s consumers of all ages. Also frying of meat products has gained its popularity because it generates flavourful products having crispy exteriors and moist and juicy interiors, but on the contrary product absorbs more fat (Scott 1987). In addition pressure frying is one of a way to fry meat, fish and poultry because it speeds up the cooking time. Lesser the time the meat is exposed to high temperature, more the moisture is retained and results in a juicy meat. It is similar to conventional open frying in which meat is fried for longer period in a well filled with cooking oil, except that in a pressure fryer the food is cooked under controlled pressure in a sealed vessel.

Pressure frying is known to yield more tender and juicier products—a distinct difference can be felt in comparison to open-fried foods, which are often greasy on the outside and dry on the inside (Mallikarjunan et al. 1997; Rao and Delaney 1995). By appropriately selecting temperature and pressure in deep-fat frying, consumer desired characteristics can be obtained in the end product (Rao et al. 1995). Farkas et al. (1992) found out that increasing the frying temperature generally decreases oil uptake within a certain temperature range, if frying duration was short. Researchers have also studied the relationship between moisture content and frying time (Kozempel et al. 1991; Esturk et al. 2000). Many researchers have focused their attention to understand the relationship between oil uptake and moisture loss during frying (McDonough et al. 1993; Saguy and Pinthus 1995). Edible coatings prepared from ingredients such as polysaccharides, proteins, lipids or their combinations have been used as a part of batters and breading to improve coating performance and oil uptake during frying (Stark and Gross 1992; Feeney et al. 1993). Most of the researchers have reported the quality characteristics of conventionally fried potato chips. However, pressure frying of chicken meat products has been seldom reported. This affect on type of muscles has also never been reported in literature. The objective of this paper was to study the influence of pressure frying on quality characteristics and oil uptake by battered chicken meat in order to produce a low-fat fried meat product. Conventional frying was used for comparative studies because of its predominant use for frying of chicken meat products. The quality characteristics of pressure fried leg chicken meat (PLM) and pressure fried breast chicken meat (PBM) were compared with the conventional fried leg chicken meat (CLM) and conventional fried breast chicken meat (CBM).

Materials and methods

Ingredients

Eight fresh dressed deskinned broiler chickens weighing 1.2–1.4 kg, for each treatment (pressure frying and conventional frying) were procured from the local market, brought to the laboratory and washed with tap water. All subcutaneous fat, trimmable fat, external fascia and all adhering connective tissues were removed from the muscles and was deboned and separated into two batches, leg meat and breast meat. The meat was cut into chunks of 3–4 cm sizes. The wheat flour, corn flour and all the spices and condiments were procured from local market. The pre-gelatinized rice flour was prepared in the laboratory by cooking the coarse rice grains after thoroughly washing. The cooked rice was dried in cross flow drier at 90–95°C. The dried rice particles were finely ground (60 mesh size) in the mill, packed in air tight glass bottles and stored at room temperature (27 ± 2°C) till further use. Wheat flour, corn flour and modified starch (pre-gelatinized) were used in the batter formulation for their better functionality (Loewe 1990). Refined sun flower oil was used for frying the chicken meat.

Coating mix preparation

Coating mix was prepared by mixing optimum quantities of binders and spices together in Hobert Mixer (N-50, Paddle Mixer, OH, USA). It contained a mixture of wheat flour (28%), corn flour (25%), and pre-gelatinized rice flour (9%) as binders and spice mix (38%). Spice mix was a mixture of red chilly powder (58%), garam masala powder (25%), and salt (17%), whereas, garam masala was a mixture of spices viz; clove, cinnamon, cardamom, coriander, cumin, pepper corn, nutmeg, and mace etc. (MDH brand).

Battering process

The chicken leg or breast meat was marinated under ambient condition (27 ± 2°C) using lime juice (7%) and salt (1.3%) and left undisturbed for 20 min. Coating paste was prepared by mixing coating mix (100 g), water (125 ml) and 50 gm paste each of ginger, garlic, coriander leaves and green chilly in a domestic blender (Sumeet Research & Holdings Ltd., Chennai, India) to obtain a final coating paste. The resultant paste was applied to 1 Kg marinated chicken pieces and called battered chicken.

Frying protocol

The marinated and battered chicken was deep fat fried. The conventional (open pan) frying and pressure frying was carried out for each batch of leg or breast meat separately. Pressure frying was carried out using Broaster pressure fryer: (The Broaster Company Model 1600, Beloit, USA).

Pressure frying

The pressure frying operations were conducted using the Broaster pressure fryer having a well capacity of 12 Lt of oil. The fryer was initially filled with fresh oil. In the first part of the study 1 Kg of leg or breast meat chunks representing one batch, were pressure fried. The marinated and battered meat was dropped in preheated oil (160°C) and oil well was closed immediately. The meat was fried at 12 lbs for 4 min, thereafter the pressure was released immediately and the lid was opened and fried meat was removed by draining excess fat. The fried meat was allowed to cool and analysed for quality parameters. The frying was repeated four times on different days.

Conventional frying

The conventional frying was carried out in an open pan heated with cooking gas as is done in domestic uses. The oil (3 Lt) was heated to 170 ± 3°C and the breast or leg meat (1 kg) was dropped in oil. The oil and meat ratio was kept 3:1 (w/w). The frying of a batch was continued for 7.5 min. The meat was stirred well and reversed every min. for uniform cooking. At the end of frying cycle the oil temperature was 145 ± 5°C. The fried meat was removed from oil by draining excess fat and placed in a vessel. The core temperature of the product was 85 ± 3°C in either case of frying. For replicates each time, fresh oil was used for frying.

Physical analysis

Shrinkage

The shrinkage (decrease in size) was determined by measuring the area of battered chicken meat before and after frying with planimeter. As the meat pieces were uneven in shape and relatively uniform in size, area of battered or fried chicken on all the surfaces (each piece was placed on different sides and area marked for the same pieces at each side) and area averaged. This was repeated for at least 6 pieces from each batch. Average surface area of battered and/or fried chicken was considered for calculation of shrinkage (%) as per the following equation.

|

1 |

Where, A1 is area of raw battered chicken and A2 is area of fried chicken.

Moisture retention

Moisture retention value represents the amount of moisture retained in the fried product per 100 g of sample and was determined as described by El-Magoli et al. 1996.

Cooking yield

The cooking yield, of the fried product was determined by weighing the battered chicken meat before and after frying as explained by Serdaroglu and Degirmencioglu (2004).

Oil usuage

Oil usage or uptake were calculated by taking the weight of the oil, before and after the frying process by using the following equation.

|

2 |

Where, W1 is weight of oil before frying, W2 is weight of oil after frying and W3 is weight of raw battered chicken.

Juiciness

Juiciness was measured using the filter paper press method described by Mallikarjunan and Mittal (1994).The fried samples (0.4–0.6 g) were placed on a weighed Whatman filter paper. After compression, the meat portion from the filter paper was removed and the filter paper was weighed again. The juiciness was calculated by using the following equation.

|

3 |

Where, WFPA is weight of filter paper after pressing, WFPB is weight of filter paper before pressing and WF is weight of fried sample.

Chemical analysis

Approximately 200 g of fried meat sample (deboned) was mixed in a domestic blender. Estimation of moisture, protein, fat and ash were determined according to AOAC (2007) procedures. Carbohydrate was calculated by difference. Ten grams of blended sample was stirred with 90 ml distilled water in a beaker and pH measured by immersing combined glass-calomel electrode directly in a mixture using pH meter (Control Dynamic, APX 175 E/C, Bangalore India). Free fatty acid (FFA) (Modi et al. 2006) and thiobarbituric acid (TBA) were determined by the method of Tarladgis et al. 1960.

Instrumental analysis

Colour measurements

Fried chicken coating colour measurement was performed at the surface of fried meat chunks using a Hunter Colour Measuring System (Labscan XE, Virginia, USA) 60 min after frying. The chromameter was standardized with a white tile (L = 90.43, a = −0.97 and b = 1.11). Colour was described as coordinates, e.g. L (lightness), a (redness) and b (yellowness). The visual impression of colour formed from hue-angle (h) and Chroma (C) was calculated by the following formulae:  ,

,  (Ulu 2004). The measurements hue-angle and Chroma were used to study the relative position of colour between redness and yellowness and to assess the colour intensity respectively.

(Ulu 2004). The measurements hue-angle and Chroma were used to study the relative position of colour between redness and yellowness and to assess the colour intensity respectively.

Texture profile analysis

After frying and cooling to room temperature, the battered fried chicken meat were subjected to texture profile analysis using a texture analyzer (LLOYD Instruments, LR5K, UK) as described by Bourne (1978). A cylinder plunger of 35 mm diameter was attached to a 100 kg load cell (1 KN) and sample of 30 × 30 × 12 mm (L X B X H) was compressed to 50% of its original height at a cross head speed of 100 mm/min twice in two cycles. For measurement of shear values, the fried meat chunks were cut into 15 × 10 × 10 cm (L X B X H) pieces and the shear values measured in a Lloyds Texturometer using 100-kg load cell (1 KN), at a speed of 50 mm/min with a 1 mm thick blade.

Microbiological analysis

A 10 g sample of ground fried chicken was placed in sterile Stomacher bag containing 90 ml of sterile saline (0.85% NaCl) solution and blended in Stomacher (Model SEWARD Stomacher 400, England) for 60 s. The blended samples were tested for standard plate counts (SPC), Total Staphylococcus, Staphylococcus aureus, E. coli, Salmonella, Shigella and yeast and molds, by spread plate and pour plate method as per APHA (2001) procedures.

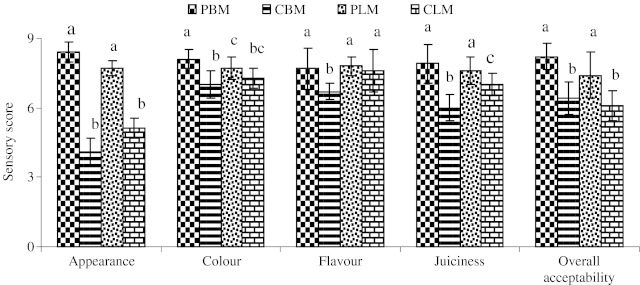

Sensory evaluation

A fresh batch of fried chicken was used for sensory studies. The leg or breast fried samples were subjected to sensory evaluation for appearance (oiliness), colour, flavour, juiciness, and overall acceptability. The sensory evaluation was carried out by 20 in-house trained panelists using 9 point Hedonic scale (Andres et al. 2006). Samples for evaluation were served separately (leg and breast) in a well lit room on coded white enamel plates. Water was provided to rinse their mouths after consumption of each sample. The mean score for each attribute is reported. The samples were served to panelists at 55 ± 5°C for evaluation.

Statistical analysis

The experiment was carried out in 4 batches (n = 4). The mean of all parameters were examined for significance (P ≤ 0.05) by analysis of variance (ANOVA) and mean separation and the significant effect was tested by Duncan’s Multiple Range Test using software STATISTICA (Statsoft 1999).

Results and discussion

Quality characteristics

Shrinkage

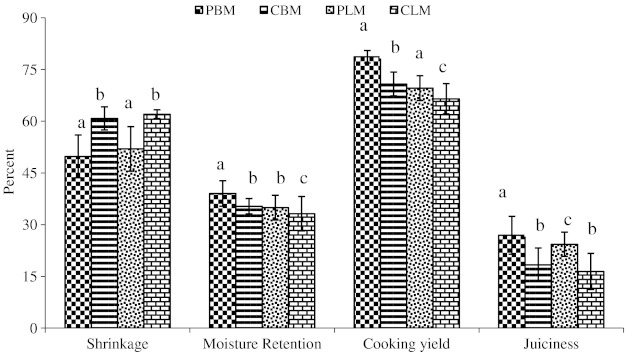

It was observed that chicken meat shrank irrespective of the type of method used for frying. This was due to moisture loss and protein denaturation. The shrinkage in the leg meat was more than the breast meat. Also, shrinkage was lesser (p ≤ 0.05) (51.9 ± 6.44%) in PLM compared to the CLM (62.01 ± 1.26%) (Fig. 1). A similar trend was observed in the PBM and CBM samples (Fig. 1). More shrinkage in leg meat could be explained that leg meat had more moisture loss than the breast meat (Fig. 1). Kilpatrick et al. (1955) proposed a linear relationship of bulk shrinkage over a full range of moisture levels. A non linear-behavior was found at lower moisture ranges for fish muscles by Rahman and Potluri (1990).

Fig. 1.

Changes in the physical characteristics of fried chicken under different test conditions. n = 4; Treatment with different superscript differ (p ≤ 0.05). PBM Pressure Fried Breast Meat; CBM Conventional Fried Breast Meat; PLM Pressure Fried Leg Meat; CLM Conventional Fried Leg Meat

Moisture retention

Moisture retention was more (p ≤ 0.05) in case of breast meat than in the leg meat, this could be due to the difference in the structural arrangement of muscle and degree of protein denature in chicken meat under frying conditions. Further high moisture retention (p ≤ 0.05) in pressure fried meat sample than conventional fried meat samples was recorded. Moisture retention was of 39.01 ± 3.69% in PBM and 35.31 ± 2.21% in CBM samples, whereas, it was 34.92 ± 3.59% in PFM and 33.13 ± 5.01% in CLM samples (Fig. 1). Both the above results favoured pressure frying. Innawong et al. (2005) reported from their findings that an increase in applied pressure during the frying process increased the moisture retention in products.

Cooking yield

Cooking yield is a direct measure of commercial equation. It was observed that cooking yield was more (p ≤ 0.05) in pressure frying than in open frying, irrespective of the type of chicken meat (Fig. 1). An average of 8.0% yield was more in pressure fried product than conventional fried product. Variation in the yield in leg and breast meat was due to difference in their moisture retention characteristics.

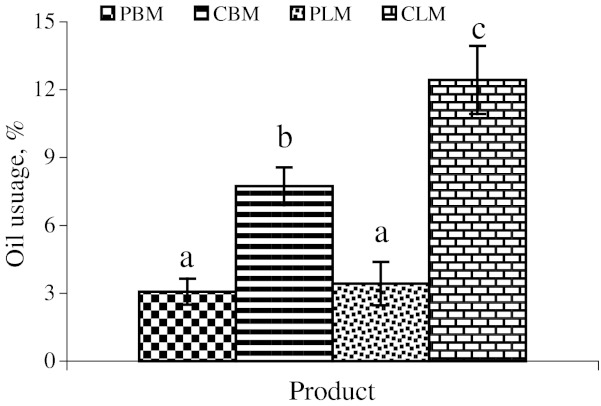

Oil usuage

Oil usage showed a significant difference between pressure frying and conventional frying. More oil (p ≤ 0.05) was used in leg meat frying than breast meat (Fig. 2). PBM had an oil usage value of 3.07 ± 0.58%, whereas, CBM showed 7.73 ± 0.84%. PLM had oil usage value of 3.43 ± 0.96% and CLM showed 12.43 ± 6.64% (Fig. 2). A similar result was found by Innawong et al. (2005), who concluded that pressure application during the frying process reduced oil uptake.

Fig. 2.

Changes in the oil usage of fried chicken fried under different test conditions. n = 4; Treatment with different superscript differ (p ≤ 0.05). PBM Pressure Fried Breast Meat; CBM Conventional Fried Breast Meat; PLM Pressure Fried Leg Meat; CLM Conventional Fried Leg Meat

Juiciness

Juiciness was another physical characteristic which was considered as a quality parameter. Juiciness measures the amount of liquid which is retained in the product. Consumers usually accept a juicier product due to better mouth-feel. It was observed that pressure fried chicken meat were juicier (p ≤ 0.05) than the conventional fried meat. PBM had a juiciness of 26.91 ± 5.49%, CBM of 18.33 ± 4.86%, PLM of 24.30 ± 3.54% and CLM of 16.39 ± 5.23% (Fig. 1). The lower moisture retention property and more shrinkage in leg meat explained the lower juiciness percentage as compared to breast meat. Innawong et al. (2005) observed that a pressure frying resulted in a significant increase in juiciness in the core more than atmospheric pressure or conventional frying.

Proximate composition

Moisture content was more (p ≤ 0.05) in pressure fried (53.0%) product than conventional fried (50.0%) product, irrespective of the type of chicken meat (Table 1). Also, moisture content of the breast meat was more than leg meat. A higher moisture content in pressure fried product could be due to the less cooking time (4 min.) provided for frying. This, in turn, is affected by the temperature of oil and pressure conditions maintained during frying, whereas, the more moisture in breast meat could be the reason of structural changes in muscles.

Table 1.

Changes in the proximate composition and pH of fried chicken under different test conditions

| Parameters | PBM | CBM | PLM | CLM |

|---|---|---|---|---|

| Moisture (%) | 53.9 ± 1.94a | 51.3 ± 3.69b | 52.5 ± 4.62b | 48.5 ± 3.11c |

| Protein (%) | 18.5 ± 1.51a | 18.4 ± 1.95a | 17.0 ± 2.38 b | 17.2 ± 2.49 b |

| Total fat (%) | 15.3 ± 3.06a | 19.7 ± 2.97b | 14.4 ±1.23 a | 18.5 ± 1.37 b |

| Ash (%) | 3.5 ± 0.43a | 3.2 ± 0.44a | 3.4 ± 0.25a | 3.7 ± 0.21b |

| Carbohydrate (%) | 8.8 ± 0.32a | 7.4 ± 0.27b | 12.7 ± 0.11c | 12.0 ± 0.15c |

| pH | 5.7 ± 0.12a | 5.7 ± 0.20a | 5.8 ± 0.19b | 5.9 ± 0.12b |

All the values indicate mean ± SD, (n = 4).

Means in a row with a different superscript letter differ (p ≤ 0.05)

PBM Pressure Fried Breast Meat; CBM Conventional Fried Breast Meat; PLM Pressure Fried Leg Meat; CLM Conventional Fried Leg Meat

Total fat content showed a significant difference between pressure and conventional frying. PBM and PLM had a lower fat (p ≤ 0.05) content of 15.32 ± 3.06% and 14.44 ± 1.23%, whereas, CBM and CLM had 19.74 ± 2.97% and 18.51 ± 1.37% respectively (Table 1). More (p ≥ 0.05) fat content was seen in breast meat than in leg meat. The difference in fat contents could be because pressure frying seals the food’s moisture and natural juices within the product, preventing the penetration of cooking oil which in term less oil in product. Mallikarjunan et al. (1997) and Balasubramaniam et al. (1995, 1997) found a significant differences in fat in fried product preceded by different treatments. The ash content and protein content in the chicken meat showed no significant difference based on the different frying methods.

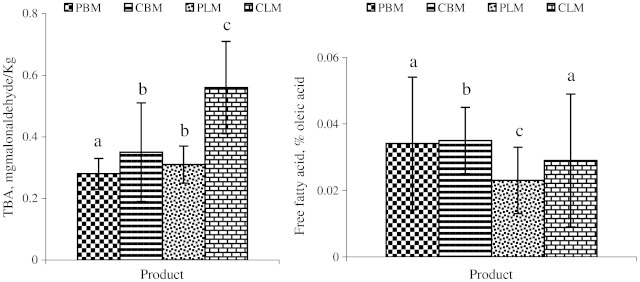

Chemical characteristics

The pH content in the chicken meat was unaffected due to frying conditions. A similar trend was observed in free fatty acid values, where no significant difference between pressure fried and conventional fried chicken meat was observed. The FFA values in all the samples were in the range of 0.02–0.04%. TBA values are essential in determining the quality of the products, especially fried products. The results showed that the conventional fried chicken meat had higher (p ≤ 0.05) TBA values (0.35 ± 0.16 for CBM and 0.56 ± 0.15 for CLM) than that of pressure fried chicken meat (0.28 ± 0.05 for PBM and 0.31 ± 0.06 for PLM) (Fig. 3). This result also justified the pressure frying is a better option over conventional frying.

Fig. 3.

Changes in the thiobarbituric acid (TBA) values and free fatty acid (FFA) values of fried chicken under different test conditions. n = 4; Treatment with different superscript differ (p ≤ 0.05). PBM Pressure Fried Breast Meat; CBM Conventional Fried Breast Meat; PLM Pressure Fried Leg Meat; CLM Conventional Fried Leg Meat

Colour traits

Several chemical reactions occur during frying, including denaturation of protein, gelatinization of starch and browning reaction of batter and breading system. All these reactions affect crust color changes. The results obtained showed that the pressure fried meat appeared darker (L values) (p ≤ 0.05) as compared to conventional frying of meat (Table 2). The pressure fried products were found to be redder (a values) (p ≤ 0.05) than the conventional fried products. This result was similar as those of Innawong et al. (2005) who found that frying under pressure resulted in redder core color than atmospheric pressure. Further they found that based on L, product fried with nitrogen gas under pressure was significantly darker in appearance than product fried with steam. The b values were unaffected due to frying conditions. Landes and Blackshear (1971) reported that cooking time and temperature affect the color of the coating.

Table 2.

Changes in colour characteristics of fried chicken under different test conditions

| Parameters | PBM | CBM | PLM | CLM |

|---|---|---|---|---|

| Lightness (L) | 30.7 ± 2.14a | 29.9 ± 2.83a | 27.9 ± 0.79b | 31.7 ± 4.11a |

| Redness (a) | 14.6 ± 2.03a | 14.6 ± 0.91a | 12.4 ± 1.33b | 11.0 ± 1.14c |

| Yellowness (b) | 15.2 ± 1.57a | 14.3 ± 1.27a | 13.2 ± 0.82b | 12.6 ± 1.39b |

| Overall average (ΔE) | 63.7 ± 1.42a | 64.3 ± 2.43a | 65.5 ± 0.95c | 64.8 ± 3.48ac |

| Hue angle (h) | 46.1 ± 1.85a | 44.5 ± 2.93b | 49.0 ± 2.36c | 46.8 ± 5.97a |

| Chroma (C) | 21.2 ± 2.45a | 20.5 ± 1.23a | 18.2 ± 1.36b | 16.9 ± 0.71b |

All the values indicate mean ± SD, (n = 4).

Means in a row with a different superscript letter differ (p ≤ 0.05)

PBM Pressure Fried Breast Meat; CBM Conventional Fried Breast Meat; PLM Pressure Fried Leg Meat; CLM Conventional Fried Leg Meat

Textural profile analysis

Texture of battered meat products involves many characteristics, foremost of which are hardness, which describes the textural attributes of the substrate, and crunchiness, which describes the crust (Luyten et al. 2004). The other textural attributes which were under study were cohesiveness, springiness, gumminess, chewiness, adhesiveness and shear force (Table 3). The pressure fried chicken meat were harder (p ≤ 0.05) than the conventional fried meat. The hardness values were 89.65 ± 4.27 N for PBM and 80.27 ± 4.08 N for CBM. Similarly, for PLM and CLM the values were 64.47 ± 5.44 N and 55.56 ± 2.92 N respectively (Table 3). Also it was observed the breast fried meat was harder (p ≤ 0.05) than leg fried meat. This could be because of the difference in histological arrangements of meat fiber in leg meat with breast meat. The hardness could also be explained, as the frying temperature increases, the rate of heat transfer also increases and subsequently the surface hardens because of crust formation. The pressure fried breast meat had higher (p ≤ 0.05) values in terms of gumminess and chewiness. The trend was similar (p ≤ 0.05) in case of leg meat. The same trend was reflected in sensory acceptability evaluation. Commonly, frying under pressure is known to produce fried products that are juicier and tenderer (Mallikarjunan et al. 1997; Rao et al. 1995). In addition, the author reported pressure fried chicken meat was also found to be crispier than the open fried meat. Lower pressures during frying produced a more open starch–protein network, more porosity in crust and more increase in continuity of the starch granules, resulting in less moisture in crust portion, brittle texture and porous appearance (Rao and Delaney 1995). It was also found that irrespective of the types of chicken meat i.e. leg and breast, a lower force (p ≤ 0.05) was required to shear the pressure fried meat compared to conventional fried meat. Innawong et al. (2005) stated that the applied force to shear the fried products was higher for lower pressure used during frying.

Table 3.

Changes in textural profile analysis of fried chicken under different test conditions

| Parameters | PBM | CBM | PLM | CLM |

|---|---|---|---|---|

| Hardness (N) | 89.6 ± 4.27a | 80.3 ± 4.08b | 64.5 ± 5.44c | 55.6 ± 2.92d |

| Cohesiveness | 0.3 ± 0.03a | 0.3 ± 0.04a | 0.2 ± 0.06b | 0.2 ± 0.01c |

| Springiness (mm) | 2.5 ± 0.01a | 2.7 ± 0.07a | 2.4 ± 0.03b | 2.4 ± 0.06b |

| Gumminess (N) | 26.2 ± 2.75a | 24.3 ± 2.65a | 15.0 ± 3.65b | 6.3 ± 0.64c |

| Chewiness (Nmm) | 0.1 ± 0.01a | 0.1 ± 0.01a | 0.03 ± 0.01b | 0.01 ± 0.02c |

| Adhesive force (N) | 0.2 ± 0.01a | 0.1 ± 0.01b | 0.1 ± 0.02b | 0.1 ± 0.02b |

| Shear force (N) | 11.3 ± 2.28a | 12.4 ± 2.78b | 10.9 ± 1.03a | 12.3 ± 1.92b |

All the values indicate mean ± SD, (n = 4).

Means in a row with a different superscript letter differ (p ≤ 0.05)

PBM Pressure Fried Breast Meat; CBM Conventional Fried Breast Meat; PLM Pressure Fried Leg Meat; CLM Conventional Fried Leg Meat

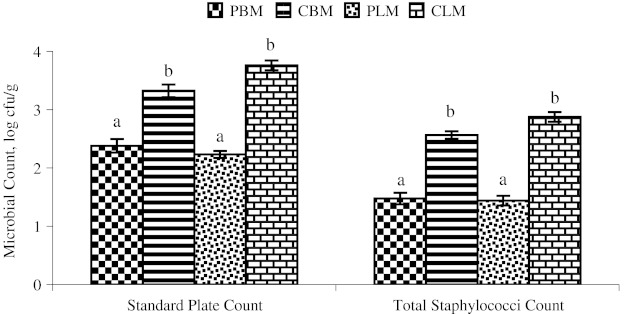

Microbiological analysis

It was found that Salmonella, Staphylococcus aureus, Shigella, E. coli and yeast and moulds were not detected in all the fried samples. Total plate counts were 2.38 cfu/g, 2.23 cfu/g, 3.32 cfu/g and 3.76 cfu/g in PBM, PLM, CBM and CLM respectively (Fig. 4). The low counts in pressure fried product could be because of high temperature maintained during frying compared to conventional frying where the frying temperature significantly dropped immediately after adding the product in oil. However, Total Staphylococcus colonies were detected in pressure fried as well as conventional fried samples. All the fried chicken samples were found to be free from pathogens.

Fig. 4.

Changes in the standard plate count and total staphylococci count of fried chicken under different test conditions. n = 4; Treatment with different superscript differ (p ≤ 0.05). PBM Pressure Fried Breast Meat; CBM Conventional Fried Breast Meat; PLM Pressure Fried Leg Meat; CLM Conventional Fried Leg Meat

Sensory evaluation

The sensory scores of pressure fried chicken for all the attributes were in the range of 4.1–8.2, whereas, the scores for conventional fried chicken ranged from 6 to 8.4 (Fig. 5). Scores of all sensory attributes for pressure chicken were higher (p ≤ 0.05) compared to conventional fried control. Appearance scores of the pressure fried were higher (p ≤ 0.05) compared to conventional fried product. This was mainly because of more shrinkage, oil uptake (oily appearance) and crust colour in conventional fried samples observed than pressure fried samples. In pressure fried chicken, the moisture retention was more (Fig. 1) hence appearance was better retained.

Fig. 5.

Changes in the sensory score of fried chicken under different test conditions. n = 4; Treatment with different superscript differ (p ≤ 0.05). PBM Pressure Fried Breast Meat; CBM Conventional Fried Breast Meat; PLM Pressure Fried Leg Meat; CLM Conventional Fried Leg Meat

The panelists rated colour of pressure fried chicken with scores higher (p ≤ 0.05) than that of conventional fried product. This could be because of optimum caramelizing effect during pressure frying due to controlled frying conditions, specifically temperature, through out than conventional frying. Similarly, higher scores for flavour and juiciness in case of pressure fried chicken (p ≤ 0.05) as compared to conventional fried chicken is probably due to higher moisture retention in turn increasing the natural juice retention there by helping better release of flavour compounds. The difference in flavour due to cooking is probably a direct function of temperature and degree of moisture retention in the meat Heath (1970).

PLM or PBM had better (p ≤ 0.05) texture than CLM or CBM despite lower fat content in PLM or PBM. Since fat makes an important contribution to the texture of meat products, it was anticipated that pressure frying would decrease texture and overall acceptability scores compared to conventional frying with higher fat contents. But it was not found so in present investigation. The improvement in texture scores could be due to high moisture retention in PLM or PBM. Ahmed et al. (1990) reported that low fat meat products tend to be tougher than higher fat products. The overall acceptability scores were also higher (p ≤ 0.05) in pressure fried products compared to conventional fried samples. The PBM was rated highest in the overall acceptability.

Conclusion

Pressure frying at 160°C, (12 lbs) for 4 min. was found to be optimum for frying battered chicken meat. Frying conditions showed marked difference in the shrinkage of meat. Better moisture retention was observed in pressure frying which resulted better yield and juiciness in the product. The oil usage, total fat content was lesser in pressure fried products compared to conventional fried products. Hue angle and Chroma values were higher in pressure frying, which indicated redness or yellowness colour units, are higher in pressure fried products. This improved the sensory appeal. A marginal difference in shear force was also observed in either case of frying. Microbiological analysis revealed that the frying conditions in either case were sufficient to make the product safe for consumption. Overall, the degree of consumer acceptance level was much higher for pressure fried products. Pressure frying technique proved much better than conventional frying based on the product quality, time of processing, hygiene in processing and energy saving in whole process.

Acknowledgment

This work was supported by the Net Work Project (NWP) under the 11th five year plan funded by CSIR, New Delhi. Thanks to Dr KSMS Raghavarao, Head, Food Engineering, for his valuable suggestions during research work.

References

- Ahmed PO, Miller MF, Lyon CE, Vaughters HM, Reagan JO. Physical and sensory characteristics of low fat fresh pork sausage processed with various levels of added water. J Food Sci. 1990;55:625–628. doi: 10.1111/j.1365-2621.1990.tb05192.x. [DOI] [Google Scholar]

- Andres DK, Inz H, Szmanko T. Sensory quality of selected physicochemical properties of processed meat products produced in different plants. Acta Sci Pol Technol Aliment. 2006;52:93–105. [Google Scholar]

- Official methods of analysis. 18. Washington DC: Association of Official Analytical Chemists; 2007. [Google Scholar]

- Speck ML, editor. Compendium of methods for the microbiological examination of foods. 4. Washington DC: American Public Health Association; 2001. The effect of edible film on oil uptake and moisture retention of a deep-fat fried poultry product; p. 914. [Google Scholar]

- Balasubramaniam VM, Chinnan MS, Mallikarjunan P (1995) Deep-fat frying of edible film coated products: Experimentation and modeling. In: Food Processing Automation IV, Proceedings of the FPAC IV Conference, November 3–5, Chicago, Ill. St. Joseph, MI: American Society of Agricultural Engineers, pp 486–493

- Balasubramaniam VM, Chinnan MS, Mallikarjunan P, Phillips RD. The effect of edible film on oil uptake and moisture retention of a deep-fat fried poultry product. J Food Process Eng. 1997;20:17–29. doi: 10.1111/j.1745-4530.1997.tb00408.x. [DOI] [Google Scholar]

- Bourne MC. Texture profile analysis. Food Technol. 1978;32:62–66. [Google Scholar]

- Colmenero FJ. Technologies for developing low-fat meat products. Trends Food Sci Technol. 1996;7:41–48. doi: 10.1016/0924-2244(96)81327-6. [DOI] [Google Scholar]

- El-Magoli S, Laroia S, Hansen PMT. Flavor and texture characteristics of low fat ground beef patties formulated with whey protein concentrate. Meat Sci. 1996;42(2):179–193. doi: 10.1016/0309-1740(95)00032-1. [DOI] [PubMed] [Google Scholar]

- Esturk O, Kayacier A, Singh RK. Reduction of oil uptake in deep fried tortilla chips Reducción de la absorción de aceite en la fritura de tiras de maíz. Food Sci Technol Int. 2000;6(5):425–431. doi: 10.1177/108201320000600509. [DOI] [Google Scholar]

- Farkas BE, Singh RP, McCarthy MJ (1992) Determination of oil/water distribution within fried foods. Presented at the Annual Meeting of the Inst. of Food Technologists, New Orleans, LA

- Feeney RD, Gross AT, Haralampu SG (1993) Potato and other food products coated with edible oil barrier films. U.S. Patent 5,217,736

- Heath H (1970) Flavour: a brief consideration of the chemistry and technology. Flavour Industry 586–590

- Innawong B, Mallikarjunan P, Marcy J, Cundiff J. Pressure conditions and quality of chicken nuggets fried under gaseous nitrogen. J Food Process Preservation. 2005;30:231–45. doi: 10.1111/j.1745-4549.2006.00061.x. [DOI] [Google Scholar]

- Kilpatrick PW, Lowe E, Van Andel WB. Tunnel dehydrators for fruit and vegetables. Adv Food Res. 1955;6:313–372. doi: 10.1016/S0065-2628(08)60126-3. [DOI] [Google Scholar]

- Kozempel MF, Tomasula PM, Craig JC. Correlation of moisture and oil concentration in French fries. Lebensm Wiss Technol. 1991;24:445–448. [Google Scholar]

- Landes DR, Blackshear CD. The effects of different cooking oils on flavor and color of fried chicken breading material. Poult Sci. 1971;50:894–897. doi: 10.3382/ps.0500894. [DOI] [Google Scholar]

- Loewe R. Ingredient selection for batter systems. In: Kulp K, Loewe R, editors. Batters and breadings in food processing. Minnesota: American Association of Cereal Chemists, Inc; 1990. pp. 11–28. [Google Scholar]

- Luyten H, Plijter JJ, Van vliet T. Crispy/crunchy crusts of cellular solid foods. A literature review with discussion. J Texture Stud. 2004;35:445–492. doi: 10.1111/j.1745-4603.2004.35501.x. [DOI] [Google Scholar]

- Mallikarjunan P, Mittal GS. Meat quality kinetics during beef carcass chilling. J Food Sci. 1994;59(291–294):302. [Google Scholar]

- Mallikarjunan P, Chinnan MS, Balasubramaniam VM. Mass transfer in edible film coated chicken nuggets: Influence of frying temperature and pressure. In: Narsimhan G, Okos MR, Lombardo S, editors. Food engineering. West Lafeyette: Purdue University; 1997. pp. 107–111. [Google Scholar]

- McDonough C, Gomez MH, Lee JK, Waniska RD, Rooney LW. Environmental scanning electron microscopy evaluation of tortilla chip microstructure during deep-fat frying. J Food Sci. 1993;58:199–203. doi: 10.1111/j.1365-2621.1993.tb03244.x. [DOI] [Google Scholar]

- Modi VK, Sidde Gowda GS, Sakhare PZ, Mahendrakar NS, Narasimha Rao D. Pre-processed spice mix formulation and changes in its quality during storage. LWT Food Sci Technol. 2006;39:613–620. doi: 10.1016/j.lwt.2005.05.004. [DOI] [Google Scholar]

- Rahman MS, Potluri PL. Shrinkage and density of squid flesh during air drying. J Food Engr. 1990;2:133–143. doi: 10.1016/0260-8774(90)90024-3. [DOI] [Google Scholar]

- Rao VNM, Delaney AM. An engineering perspective on deep-fat frying of breaded chicken pieces. Food Technol. 1995;49(4):138–141. [Google Scholar]

- Saguy IS, Pinthus EJ. Oil uptake during deep-fat frying: factors and mechanism. Food Technol. 1995;49(4):142–145. [Google Scholar]

- Scott R. A review of crumb coatings. In: Fuller DB, Parry RT, editors. Suvoury coatings. New York: Elsevier Applied Science; 1987. pp. 7–11. [Google Scholar]

- Serdaroglu M, Degirmencioglu O. Effects of fat level (5%, 10%, 20%) and corn flour (0%, 2%, 4%) on some properties of Turkish type meatballs (Koefte) Meat Sci. 2004;68:291–296. doi: 10.1016/j.meatsci.2004.03.010. [DOI] [PubMed] [Google Scholar]

- Stark LE, Gross AT (1992) Hydrophobic protein micro particles and preparation thereof. U.S. Patent 5,145,702

- Statistica for windows. Tulsa: Stasoft Inc; 1999. [Google Scholar]

- Tarladgis BG, Walts BM, Younatahtan MT, Durgan JR. A distillation method for quantitative determination of malonaldehyde in foods. J Am Oil Chem Soc. 1960;37:44–48. doi: 10.1007/BF02630824. [DOI] [Google Scholar]

- Ulu H. Effect of wheat flour, whey protein concentrate and soya protein on oxidative processes and textural properties of cooked meatballs. Food Chem. 2004;87:523–529. doi: 10.1016/j.foodchem.2004.01.002. [DOI] [Google Scholar]