Abstract

The different sizes (3, 4 and 5 cm) of hybrid variety of cauliflower (variety no. 71) were dehydrated in thin layer at three temperatures of 55, 60 and 65 °C with velocities of 40, 50 and 60 m/min. Dehydrated samples were analyzed for vitamin C, rehydration ratio and browning. Statistical analysis indicated that drying time was dependent on initial size of cauliflower, drying air temperature and velocity, but rehydration ratio was significantly affected by the combined effect of temperature and airflow velocity. Vitamin C content of the dried cauliflower samples were significantly affected by temperature only and non enzymatic browning was function of temperature, airflow velocity, and combined effect of temperature and airflow velocity. Optimization of the drying process parameters for the given constraints resulted in 60.100C, 59.28 m/min, 3.35 cm. The predicted responses for the optimized combination of process parameters were time, vitamin C content, rehydration ratio, and browning values of 491.22 min (time), 289.86 mg/100 g (Vitamin C), 6.91 ( rehydration ratio), and 0.14 (browning), respectively with the desirability factor of 0.787.

Keywords: Cauliflower, Drying, Optimization, Drying characteristics, RSM

Introduction

India produces a significant portion of fruits and vegetables production all over the world. Although the production of fruits and vegetables is high, post harvest losses in the segment are more than 25% (Rdhakrishanan 1999). The level of fruits and vegetables processing in India is hardly 2% of the total production, whereas countries such as Thailand, Brazil, Philippines and Malaysia process 30%, 70%, 78% and 83% of their produce, respectively.

Fruits and vegetables are important sources of essential vitamins and minerals for human consumption. Different fruits and vegetables have their own unique mix of nutrients to serve. High postharvest losses and huge availability during glut demands to preserve fruits and vegetables so that their useful characteristics can be reaped during unavailability.

Removal of water from foods is the essence to enhance the shelf life of vegetables and dehydration is one of the techniques, widely used to preserve agricultural produce. Dehydration simultaneously combines heat and mass transfer. The fundamental aspect of food dehydration is to reduce the availability of water in food to such an extent, which is not favourable for undesirable microorganism and favourable for minimized rates of chemical reactions. Dehydration is one of the oldest methods of food preservation and an important food processing stage (Lima et al. 2002). Dehydration not only facilitates reduction in the bulk of fresh material, easy transport because of reduced weight and volume but also increases availability of food throughout the year.

Fruits and vegetables are important source of vitamins and their drying demands special attention for their nutritional aspects of the end product. The drying operation in convective heating involves moisture transfer from the wet material to heated air, which may be illustrated as a transport of moisture from the material core to its surface, followed by evaporation from the surface of the material, and dissipation of water vapour into the bulk of the drying air. Drying causes irreversible structural damage to the cellular structure of foods, whereby rehydration of the dehydrated product affected. Pretreatment, subsequent drying and rehydration may induce changes in the structure and composition of plant tissues (Lewicki 1998) which affect the organoleptic properties upon rehydration. A number of studies for drying of fruits and vegetables have been reported by various authors (Maskan et al. 2002; Togrul and Pehlivan 2002; Doymaz 2006; Akpinar 2006; Eren and Kaymak-Ertekin 2007; Mudgal and Pandey 2009; Shalini et al. 2009). Rahman et al. (2005), Kadam et al. (2008), Singh et al. (2008), Lidho (2008), Pardeshi et al.(2009) have identified that the structure of dried foods depends on the drying methods and conditions such as temperature, relative humidity, air velocity and initial physico-chemical characteristics of the product. Also, the quality of end product in terms of sensory and other physico-chemical factors is significantly influenced by drying conditions (Carbonell et al. 1986 and Simal et al. 2005).

Cauliflower (Brassica oleracea) is an important cole crop of north India and belongs to crucefere family. Overall estimated per hectare cauliflower post-harvest losses were 49% in India (Sehgal 1999). Cauliflower prices become very low during main season and sometimes farmers have to pay to throw away their produces because of higher perishable nature of the produce. Fresh cauliflower has 92 to 94% water (w.b.) and it can be stored for 2 to 4 weeks at 0 °C (Mudgal and Pandey 2007). Processing of cauliflower can be an alternate for extending the shelf life. Dehydrated Cauliflower can be used to enhance the taste and nutritional value of various products such as rehydrated vegetable mix, soups, canned products, extruded products etc. The selection of proper drying condition is of prime importance for reduced thermal stress and to retain the key compounds in the rehydrated product. A number of scientists including Shukla and Sigh (2006), Jadhav et al. (2005), (Kadam and Samule 2006) have reported drying mechanism of cauliflower, but optimum conditions are required to be accessed as per desired characteristics in the dried product. The presented manuscript discusses not only about drying mechanism of cauliflower under hot air convective drying, but also about optimization of drying conditions and initial size of raw cauliflower depending upon drying time and quality attributes of the final product. The presented study investigate the effect of drying air temperature, air flow velocity, and initial size of cauliflower on drying time, vitamin C content, rehydration ratio and enzymatic browning and focuses on optimization of the process variables.

Material and methods

Experiments were conducted at Department of Processing and Agricultural Structures, Punjab Agricultural University, Ludhiana, Punjab for the mentioned study.

Sample preparation

The cauliflower (variety 71) samples for this study were procured from a local farmer (Samrala, Ludhiana). Fresh cauliflower was procured for each trial during the experiment. Procured cauliflower was destalked and trimmed manually and edible part, curd, was sized down to desirable florets’ sizes. The curd, with the help of stainless steel knife and vernier calipers, was roughly sized into 3, 4, and 5, cm diameter florets (kadam et al. 2008), where the dimension is approximate diameter of a floret. Sized cauliflower florets were washed in tap water and then the sample was drained to remove the excess water. Washed cauliflower samples were blanched by tying them in muslin cloth and dipping the samples in boiling water for 5 min (Kaur and Singh 1981). The blanched samples were cooled immediately by keeping them under flowing water at ambient conditions to prevent overcooking of the samples. The blanched samples then were dipped in 1% solution of potassium meta bisulphate, KMS (Srivastava and Kumar 1993) for 20 min by tying them in the muslin cloth. The treated samples were then spread on a screen to drain the excess water.

Dryer set up and drying conditions

The experimental convective drier with an automatic weighing system and an electrically heated hot air system to supply hot air was used to dry the cauliflower samples. The centrifugal blower was capable to deliver 28.32 m3/min flow rate of hot air. The blower had a 19 cm diameter suction duct for the inlet of the air. To control the air velocity, this duct is provided with two (46.5 × 28 cm) sliding vents in the suction side of the blower. The air velocity was varied according to plan of work. Drying chamber for thin layer drying consisted of a plywood box, which was placed on the plenum chamber. The box was open from the top and the bottom side. On the bottom side, iron mesh was fixed to stream line the airflow. One 2.00 cm × 10.00 cm slit was cut on one side of the box to measure continuous weighing of sample being dried. The area of false floor was 0.08 m2. Cauliflower samples were dried in a pan. The 32 cm diameter 100 mesh pan suspended from the lever at the balance, placed on the wedge of the horizontal level arm. The hot air was force upward through the sieve and the sample. There was no control mechanism attached with the drying set-up to control relative humidity of the drying air and to re-circulate of drying air. The automatic weighing (Pardeshi et al. 1999) had a mechanical balance, linear variable differential transformer (LVDT), precision full wave rectifier, summing amplifier and a multi-meter to note down millivolt readings corresponding to the weight of drying sample at any time. The balance was able to determine up to 0.1 g. For measurement of sample weight, the automatic weighing system was calibrated for multi-meter readings and weight of the samples. The multi-meter readings were converted into weight (W, g) by using the following equation

|

1 |

Where,

MRt is the multi-meter reading at any time t.

Three different sizes (3, 4, and 5 cm), three different temperatures (55, 60, 65 0C), and three different airflow velocities (40, 50, and 60 m/min) were considered the process parameters for cauliflower drying. Experimental plan (Table 1) in triplicate was employed to generate data on drying kinetics of cauliflower to ascertain the effect of thee process parameters on drying kinetics and quality analysis of cauliflower samples.

Table 1.

Experimental values of response variables for Box—Behnken design

| Run | DT (°C) | AV (m/min) | S(cm) | Drying time (min) | Vitamin C (mg/100 g) | Rehydration Ratio | Browning |

|---|---|---|---|---|---|---|---|

| 1 | 65 | 50 | 3 | 436 | 255.00 | 5.69 | 0.14 |

| 2 | 60 | 60 | 3 | 425 | 290.24 | 6.54 | 0.14 |

| 3 | 60 | 50 | 4 | 602 | 286.00 | 7.35 | 0.12 |

| 4 | 60 | 50 | 4 | 585 | 280.00 | 7.28 | 0.13 |

| 5 | 60 | 50 | 3 | 600 | 290.00 | 6.93 | 0.11 |

| 6 | 55 | 40 | 4 | 735 | 270.00 | 5.99 | 0.14 |

| 7 | 65 | 40 | 4 | 525 | 260.20 | 5.45 | 0.14 |

| 8 | 60 | 40 | 3 | 558 | 285.40 | 6.35 | 0.11 |

| 9 | 60 | 40 | 5 | 615 | 285.33 | 6.28 | 0.12 |

| 10 | 65 | 60 | 3 | 472 | 252.00 | 6.48 | 0.18 |

| 11 | 60 | 60 | 5 | 535 | 278.00 | 6.31 | 0.12 |

| 12 | 60 | 50 | 4 | 653 | 285.00 | 7.00 | 0.12 |

| 13 | 55 | 60 | 3 | 681 | 274.38 | 5.78 | 0.13 |

| 14 | 55 | 50 | 5 | 727 | 260.00 | 5.47 | 0.12 |

| 15 | 55 | 50 | 3 | 643 | 260.00 | 5.39 | 0.13 |

| 16 | 65 | 50 | 5 | 529 | 246.20 | 5.43 | 0.16 |

| 17 | 60 | 50 | 4 | 625 | 290.00 | 6.85 | 0.12 |

Before each drying runs, dryer was started 2 h in advance to attain steady state conditions. Automatic weighing system was started 5 min before the trials for stabilization. The glass vent of drying chamber was taken off from the front side and the sample was uniformly distributed in a single layer on the drying pan. About 2.5 to 3 kg of fresh cauliflower florets were dehydrated for each experiment. Dehydrated cauliflower samples were packed in high density polyethylene bags of 500 gauge (Kaur and Singh 1981) and the samples were kept at room temperature for further quality analysis.

Dehydration characteristics

Initial moisture content: The moisture content of dehydrated cauliflower was determined by standard hot air oven method (AOAC 2000) and initial moisture content was presented on dry basis in percentage.

Equilibrium Moisture Content: The sample was allowed to dry under actual drying conditions till the weight of sample became constant and the moisture content of that dried sample was assumed to be the equilibrium moisture content at the condition during the trial (Brooker et al. 1974)

Drying Rate: Drying rate was calculated by the following formula:

|

2 |

Where,

- Dm/Dt

Drying rate, % moisture loss per minute

- Mi

Moisture content, (% d b) of sample at time ti

- Mi+1

Moisture content, (%d b) of sample at time ti+1

Quality parameters of the dried cauliflower samples

Vitamin C determination: Vitamin C of dried cauliflower samples was determined by 2,4-die chloro phenol indophenol dye method (Srivastava and Kumar 1993).

Rehydration Ratio: Five gram of dehydrated sample was put into a small container and 55 ml of cold water was added. Container was covered with a watch glass and the water was boiled gently for 20 min. After boiling, the excess water was removed using filter paper and then the weight of sample was recorded. The rehydration ratio was calculated by using the following formula (Srivastava and Kumar 1993):

|

3 |

Where,

- B

weight of sample (g) after rehydration

- A

weight of sample (g) before rehydration

Non Enzymatic Browning: The increase in the absorbance of the sample extract at 420-nm wavelengths was taken as a measure of non enzymatic browning (Negi and Roy 2001). Five gram of dehydrated cauliflower sample was soaked in 100 ml of 60% alcohol for 12 h and filtered. Absorbance of the filtrate was recorded at 440 nm using 60% alcohol as blank and expressed in terms of optical density (Ranganna 1986).

Statistical analysis

Response Surface Methodology (RSM) was used to investigate the main effects of process variables on the drying time, vitamin C retention, rehydration ratio and browning of the dried samples. Drying temperature (DT), drying air velocity (AV) and cauliflower florets’ size (S) were selected as independent variables. Box—Behnken design was used for the experimental data and data were fitted to a second order polynomial model and regression coefficients obtained. Mathematical models were evaluated for each response by means of multiple regression analysis. The modeling was started with a quadratic model including linear, squared and interaction terms. Significant terms in the model for each response were found by analysis of variance (ANOVA) and significance was judged by the F-statistic calculated from the data (Eren and Kaymak-Ertekin 2007). Design Expert Ver. 7.1.0 (Stat-Ease 2009) was used to fit response surfaces and optimize the drying process.

Result and discussion

Initial moisture content of cauliflower samples were 1738.38 ± 0.15, % (d.b) and samples were dried up to moisture content to 5.25 ± 0.5, % (d.b). The Results of the study are discussed as follows:

Equilibrium Moisture Content (EMC)

Results indicated that equilibrium moisture content decreases as the drying air temperature increased for prevailing relative humidity because heat transfer at higher air temperature is more due to higher temperature difference between the product and the drying air. But, at lower relative humidity temperature has less impact on EMC, similar finding has been reported by (Mulet et al. 1999). The equilibrium moisture content represents the limiting moisture content for given condition of temperatures and humidity. The EMC values for different drying conditions are tabulated in Table 2. Statistical analysis of the data revealed that EMC was significantly affected by drying air temperature and relative humidity at 1% level of significance. Several Authors (Rao et al. 1992; Hong et al. 2002; Gazor and Chaji 2010) have reported the similar relationship among EMC, temperature, and relative humidity of the prevailing environment.

Table 2.

Equilibrium moisture content, %(d.b), for different drying conditions

| Air Velocity (m/min) | Temperaturea and relative humiditya | |||

|---|---|---|---|---|

| 55 °C, 48.8% | 60 °C, 43.2% | 65 °C, 40% | ||

| 40 | 3.18 | 3.01 | 2.95 | |

| 50 | 3.15 | 3.07 | 2.97 | |

| 60 | 3.17 | 3.03 | 2.99 | |

aSignificant terms at 1% level of significance

Relation between Moisture Content, Drying Rate and Drying Time

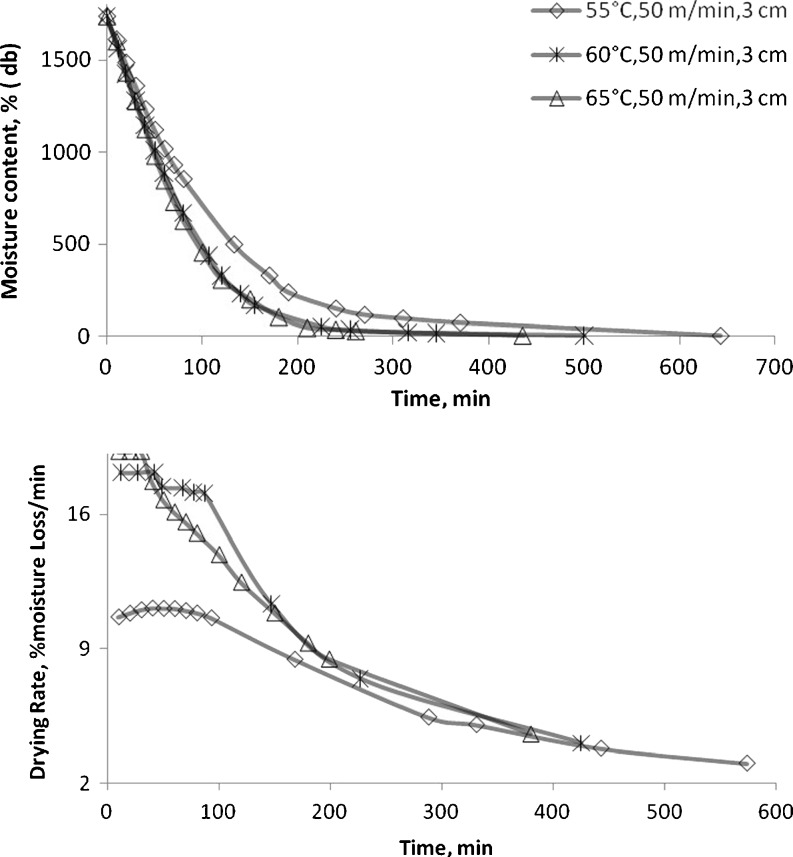

Drying time was plotted for all the samples. A representative plot between drying time and moisture content is shown in Fig. 1. The relationship between moisture content and drying time was non-linear and moisture decreased with respect to drying time. Initially moisture content decreased rapidly at constant rate and then slowed down in falling rate period region. The total drying time varied with drying conditions. The 3 cm size samples dried at higher temperature (65 °C) and higher velocity (60 m/min) took relatively less time to attain the final moisture content of the product. Figure 1 represents a set of drying rate and time plot for three drying conditions: 55 °C, 60 m/min, 3 cm; 60 °C, 60 m/min, 3 cm and 65 °C, 60 m/min, 3 cm. It was observed that moisture depletion per minute was higher initially then it started to decrease with time. Higher drying rates were observed at higher temperatures and higher air flow velocities. The drying rate was found maximum for 3 cm size of samples dried at 65 °C and 60 m/min air velocity. In some cases drying rate was less initially then it started to increase and later on remained constant for some time. The period for which drying rate increased initially is known as heating period. A constant rate period and a falling rate period were observed (Fig. 1). Similar findings were reported by Saravacos and Charm (1962), Mudgal and Pandey (2007). The extent of these constant and falling rate periods depended on Drying air temperature, relative humidity, velocity and product.

Fig. 1.

Variation in moisture and draying rate of cauliflower with time

Effect of Drying Parameters on Responses

The response parameters drying time, vitamin C, rehydration ratio, and browning were analyzed with the help of RSM to ascertain the behavaiour on the basis of initial size of cauliflower (S), drying air temperature (DT) and flow velocity (AV). Multiple linear regression analysis of the experimental data yielded second order polynomial models for predicting drying time, vitamin C, rehydration ratio, and browning. ANOVA was employed to identify the significant effects of the process variables on each response and to fit appropriate models to the experimental data. Regression equation coefficients of the proposed models with statistical significance of the main responses were calculated for each response and their significance (p ≤ 0.05) were judged as shown in Table 3. R2, Adj- R2, Pre- R2, PRESS Value, Adeq. precision and coefficient of variation (C.V.) were evaluated to check the suitability of the model. Lack of fit for all the responses was not significant and CV was less than 10 (Table 3). The combined effects of two factors on any response were visualized with the response three dimensional surface plots for the fitted model as the function of two independent variables. Three different response surface plots (Figs. 2 and 3) are presented by taking two independent variables for each response.

Table 3.

ANOVA evaluation of linear, quadratic and interaction terms for responses, and coefficient of prediction models

| Drying time | Vitamin C | Rehydration ratio | Non enzymatic browning | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Source | df | Coefficient | Sum of Squares | df | Coefficient | Sum of Squares | df | Coefficient | Sum of Squares | df | Coefficient | Sum of Squares |

| Model | 9 | 129157.44 | 9 | 3468.37 | 9 | 6.821 | 9 | 0.0049 | ||||

| DT | 1 | −103a | 84872.00 | 1 | −6.3725a | 324.87 | 1 | 0.0525a | 0.022 | 1 | 0.0125a | 0.0013 |

| AV | 1 | −40a | 12800.00 | 1 | −0.78875 | 4.98 | 1 | 0.13a | 0.135 | 1 | 0.0075a | 0.0005 |

| S | 1 | 43a | 14792.00 | 1 | −2.63875 | 55.7 | 1 | −0.06 | 0.029 | 1 | 0 | 0.0001 |

| DTAV | 1 | 0.25 | 0.25 | 1 | −3.145 | 39.56 | 1 | 0.31 | 0.384 | 1 | 0.0125a | 0.0006 |

| DTS | 1 | 2.25 | 20.25 | 1 | −2.2 | 19.36 | 1 | −0.085 | 0.029 | 1 | 0.0075a | 0.0002 |

| AVS | 1 | 13.25 | 702.25 | 1 | −3.0425 | 37.03 | 1 | −0.04 | 0.006 | 1 | −0.0075a | 0.0002 |

| DT2 | 1 | 20.375 | 1747.96 | 1 | −25.7488 | 2791.57 | 1 | −1.016a | 4.346 | 1 | 0.02125a | 0.0019 |

| AV2 | 1 | −30.13 | 3821.12 | 1 | 3.69375 | 57.45 | 1 | −0.141 | 0.084 | 1 | 0.00625 | 0.0002 |

| S2 | 1 | −49.63 | 10369.01 | 1 | −5.15125 | 111.73 | 1 | −0.571a | 1.373 | 1 | −0.00375 | 0.0001 |

| Residual | 7 | 4259.50 | 7 | 92.94 | 7 | 0.243 | 7 | 0.0003 | ||||

| Lack of Fit | 3 | 1441.50 | 3 | 24.14 | 3 | 0.048 | 3 | 0.0001 | ||||

| Pure Error | 4 | 2818.00 | 4 | 68.8 | 4 | 0.195 | 4 | 0.0002 | ||||

| Std. Dev. | 24.67 | 3.64 | 0.186 | 0.006 | ||||||||

| Mean | 585.06 | 273.4 | 6.269 | 0.1312 | ||||||||

| R2 | 0.968 | 0.974 | 0.966 | 0.952 | ||||||||

| Adj R2 | 0.927 | 0.94 | 0.921 | 0.89 | ||||||||

| PredR2 | 0.794 | 0.861 | 0.848 | 0.785 | ||||||||

| Adeq Precision | 16.438 | 16.298 | 11.76 | 15.818 | ||||||||

| C.V. % | 4.216 | 1.333 | 2.97 | 4.556 | ||||||||

| PRESS | 27467.125 | 493.727 | 1.073 | 0.001 | ||||||||

aSignificant terms of the model

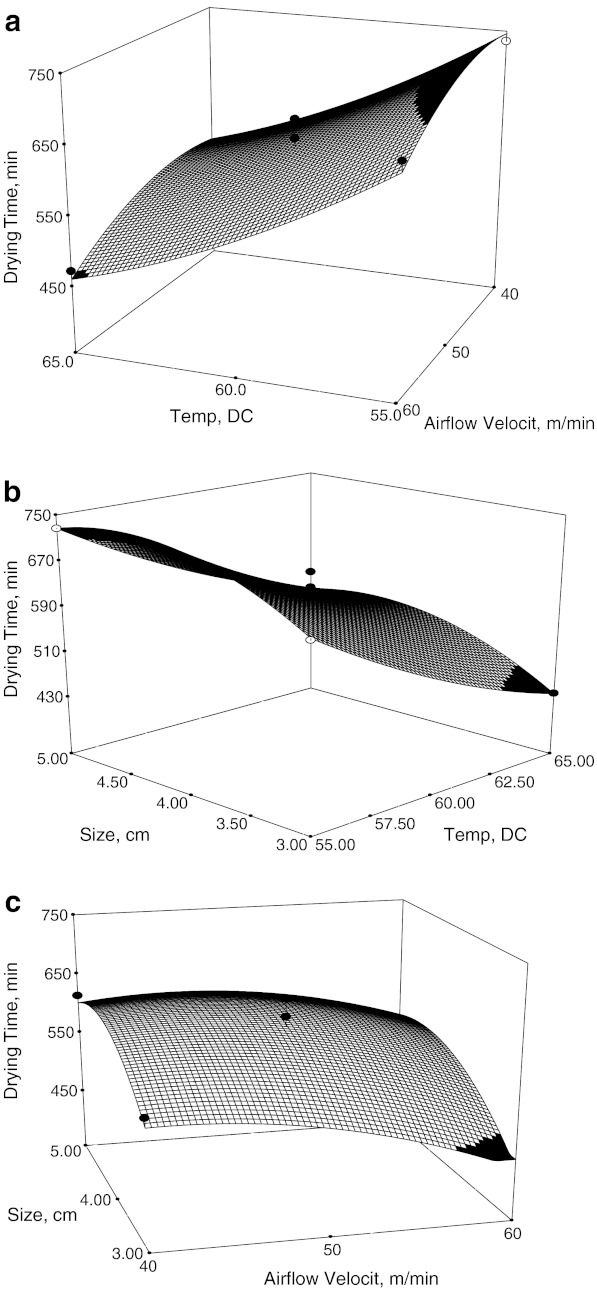

Fig. 2.

Response surface and contour plots for total drying time (min) with respect to significant process parameters

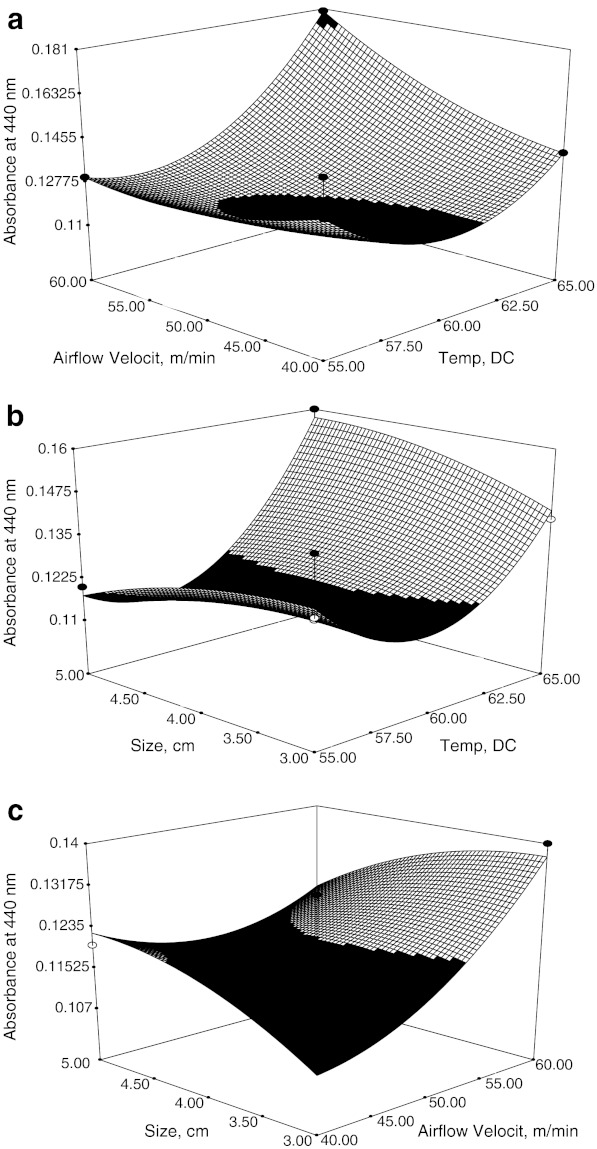

Fig. 3.

Response surface and contour plots for browning with respect to significant process parameters

Drying Time

ANOVA analysis clearly depicted that drying time was significantly affected by drying air temperature and velocity and initial size of cauliflower. The similar finding were reported (Hawlader et al. 1991) by showing the significant effect of drying air temperature and velocity on drying time for drying of tomatoes.

Figure 2 (a, b, and c) shows that drying time was reduced with increasing DT, AV, and decreasing S; however the combined effect of DT and AV, AV and S, and S and DT did not significantly (Table 3) affected the drying time to achieve the mentioned final moisture content of the product. The sample of 3 cm initial size took minimum time at 650C and 60 m/min air flow velocity of the drying air because of higher temperature of drying air and less thickness of the florets. Jadhav et al. (2005) reported that small pieces of cauliflower took less time for dehydration with minimum drying constant. Similar findings, reduction in drying time with the increase in drying air temperature, have been reported by Pardeshi et al. (2009) for green peas, and Hii et al for cocoa. (2009).

Vitamin C

Statistical analysis (Table 3) revealed that vitamin C was significantly affected by only drying air temperature. The maximum vitamin C content was observed at 60 °C and it decreased at 55 °C and 65 °C, however higher values of vitamin C were observed at 65 °C than those at 55 °C. Though S did not affect the vitamin C retention significantly, maximum amount of vitamin C retention was observed in case of 4.5 cm size of cauliflower, 60 °C and 60-m/min air velocity. Vitamin C is heat sensitive and prolonged exposure at higher temperature destroys it. Optimum temperature for maximum vitamin C retention was observed to be 60 °C. Kaur and Singh (1981) also reported the similar findings. Vega-Galvez et al. (2008) reported loss of vitamin C during drying of red pepper.

Rehydration Ratio

Rehydration ratio was significantly affected by the combined effect of DT and AV, DT2, and S2 terms (Table 3). Maximum rehydration ratio was observed at 60 °C, 50 m/min air velocity for initial size of 4 cm. This behaviour might be due the fact that more heating coagulates the protoplasmic protein and destroys the osmotic properties of cell membrane, resulting less swelling of dehydrated material (Vega-Galvez et al. 2008).

Non Enzymatic Browning of Dried Cauliflower

Browning of dried cauliflower was significantly affected by DT, AV, DT and AV, DT and S, AV and S, and DT2 model terms (Table 3 and Fig. 3). It was observed that more the temperature, the more was the browning. Browning of dried cauliflower samples was minimum when the samples were dehydrated at 60 °C and maximum browning was observed at 65 °C. The more was the temperature of drying air, the more was the browning. High temperature and higher exposure of cauliflower to the exalted level of temperature increased the browning of dried samples of cauliflower. The combined effect of DT & AV, AV& S, and DT & S are shown in Fig. 3 (a, b, & c).

Optimization of Process Parameters

Optimum conditions for drying of cauliflower were determined on the basis of following criteria; minimum drying time and browning, and maximum vitamin C retention and rehydration ratio. The process described by Erbay and Icier (2009) was followed for the optimization. Second order polynomial models obtained in this study were utilized to obtain the optimized drying parameters to meet out the above stated criteria. Process Parameters were optimized to minimize non enzymatic browning and to maximize vitamin C content and rehydration ratio within the range of temperature, air flow velocity and sample size studied. RSM desirability function was applied and three optimized combinations of drying process parameters were obtained (Table 4). Although all the three combinations were similar, the best optimized conditions obtained for the given criteria were 60.100C (DT), 59.28 m/min (AV), and 3.35 cm (S) on the basis of maximum desirability (0.787). For the optimized combination of drying parameters, the predicted time, the vitamin C content, the rehydration ratio, and the browning were 491.22, 289.86 mg/100 g, 6.91, and 0.14 respectively.

Table 4.

Results of optimization by desirability function of RSM

| S.No. | Temperature, 0C | Airflow velocity, m/min | Size, cm | Drying Time, min | Vitamin C,mg/100 g | Rehydration ratio | Browning | Desirability |

|---|---|---|---|---|---|---|---|---|

| 1 | 60.10 | 59.28 | 3.35 | 491.22 | 289.85 | 6.91 | 0.136 | 0.787 |

| 2 | 60.11 | 59.18 | 3.35 | 491.71 | 289.75 | 6.91 | 0.135 | 0.787 |

| 3 | 60.10 | 59.45 | 3.36 | 490.35 | 290.01 | 6.91 | 0.136 | 0.787 |

Conclusion

Different drying parameters for cauliflower were evaluated to find out the effect of these parameters on responses: Drying time, vitamin C content, rehydration ratio, and browning of the dehydrated cauliflower. Drying time reduced with increasing temperature and air flow velocity with reducing size, while vitamin C content was maximum for the samples dried at 60 0C. Higher rehydration ration and minimum browning were observed at 60 0C.

Optimization process was employed to find out the best combination of process parameters. Temperature- 60.100C, Air flow velocity- 59.28 m/min, and initial size of cauliflower- 3.35 cm were the optimized conditions for cauliflower drying in convective hot air and for the combination predicted time, vitamin C content, rehydration ratio, and browning were 491.22, 289.86 mg/100 g, 6.91, and 0.14 respectively. The desirability factor for the combination was 0.787.

Nomenclature

- W

Weight of sample g

- MRt

Multi-meter reading at any time t mv

- Dm/Dt

Drying rate % moisture loss per minute

- Mi

Moisture content (% d b) of sample at time ti

- Mi+1

Moisture content (%d b) of sample at time ti+1

- A

Weight of sample before rehydration g

- B

Weight of sample after rehydration g

- DT

Drying air temperature °C

- AV

Drying air velocity m/min

- S

Cauliflower Size cm

References

- Akpinar EK. Mathematical modelling of thin layer drying process under open sun of some aromatic plants. J Food Eng. 2006;77:864–870. doi: 10.1016/j.jfoodeng.2005.08.014. [DOI] [Google Scholar]

- AOAC (2000) Official Methods of Analysis. Association of Official Analytical Chemists, Washington DC

- Brooker DB, Baker AFW, Hall CW. Drying cereal Grains. Westport: The AVI publishing Company Inc; 1974. [Google Scholar]

- Carbonell JV, Pin˜aga F, Yusa´ V, JL Pen˜ a. The dehydration of paprika with ambient and heated air and the kinetics of colour degradation during storage. J Food Eng. 1986;5(3):179–193. doi: 10.1016/0260-8774(86)90024-5. [DOI] [Google Scholar]

- Doymaz I. Thin layer drying behaviour of mint leaves. J Food Eng. 2006;74:370–375. doi: 10.1016/j.jfoodeng.2005.03.009. [DOI] [Google Scholar]

- Erbay Z, Icier F. Optimization of hot air drying of olive leaves using response surface methodology. J Food Eng. 2009;91:533–541. doi: 10.1016/j.jfoodeng.2008.10.004. [DOI] [Google Scholar]

- Eren I, Kaymak-Ertekin F. Optimization of osmotic dehydration of potato using response surface methodology. J Food Eng. 2007;79:344–352. doi: 10.1016/j.jfoodeng.2006.01.069. [DOI] [Google Scholar]

- Gazor HR, Chaji H. Equilibrium moisture content and heat of desorption of saffron. Int J Food Sci & Technol. 2010;45(8):1703–1709. doi: 10.1111/j.1365-2621.2010.02321.x. [DOI] [Google Scholar]

- Hawlader MNA, Uddin MS, Ho IC, Ten ABW. Drying characteristics of tomatoes. J Food Eng. 1991;14(4):259–268. doi: 10.1016/0260-8774(91)90017-M. [DOI] [Google Scholar]

- Hii CL, Law CL, Cloke M. Modeling using a new thin layer drying model and product quality of cocoa. J Food Eng. 2009;90:191–198. doi: 10.1016/j.jfoodeng.2008.06.022. [DOI] [Google Scholar]

- Hong TD, Ellis RH, Gunn J, Moore D. Relative humidity, temperature, and the equilibrium moisture content of conidia of Beauveria bassiana (Balsamo) Vuillemin: a quantitative approach. J Stored Products Res. 2002;38(1):33–41. doi: 10.1016/S0022-474X(00)00043-6. [DOI] [Google Scholar]

- Jadhav MS, Gawade BJ, Nimbalkar CA. Dehydration kinetics of cauliflower cv. snowball-16. Journal of Maharashtra Agricultural Universities. 2005;30(2):198–201. [Google Scholar]

- Kadam DM, Samule DVK. Convective Flat-plate Solar Heat Collector for Cauliflower Drying. Biosystems Eng. 2006;93(2):189–198. doi: 10.1016/j.biosystemseng.2005.11.012. [DOI] [Google Scholar]

- Kadam DM, Samule DVK, Chandra P, Sikarwar HS. Impact of processing treatments and packaging material on some properties of stored dehydrated cauliflower. Int J Food Sci Technol. 2008;43:1–14. doi: 10.1111/j.1365-2621.2006.01372.x. [DOI] [Google Scholar]

- Kaur B, Singh S. Effect of dehydration on storage of cauliflower on the physical characteristics. Indian Food Packer. 1981;35(1):23–26. [Google Scholar]

- Lewicki P. Effect of pre-drying treatment, drying and rehydration on plant tissue properties: A review. Int J Food Prop. 1998;1(1):1–22. doi: 10.1080/10942919809524561. [DOI] [Google Scholar]

- Lidho CK. Thin layer drying characteristics of brinjal slices. J food Sci Technol. 2008;45(5):423–425. [Google Scholar]

- Lima AGB, Queiroz MR, Nebra SA. Simultaneous moisture transport and shrinkage during drying of solids with ellipsoidal configuration. Chem Eng J. 2002;86:85–93. doi: 10.1016/S1385-8947(01)00276-5. [DOI] [Google Scholar]

- Maskan A, Kaya S, Maskan M. Hot air and sun drying of grape leather (pestil) J Food Eng. 2002;54:81–88. doi: 10.1016/S0260-8774(01)00188-1. [DOI] [Google Scholar]

- Mudgal VD, Pandey VK (2007) Dehydration Characteristics of cauliflower. Int J Food Eng: 3(6): Article 6. doi:10.2202/1556-3758.1278

- Mudgal VD, Pandey VK. Thin layer drying kinetics of bittergourd. J Food Sci Technol. 2009;46(3):236–239. [Google Scholar]

- Mulet A, Garcia RJ, Sanjuan R, Bon J. Sorption isosteric heat determination by thermal analysis and sorption isotherms. J Food Sci. 1999;64(1):64–68. doi: 10.1111/j.1365-2621.1999.tb09862.x. [DOI] [Google Scholar]

- Negi PS, Roy SK. Effect of drying conditions on quality of green leaves during long term storage. Food Res Int. 2001;34:283–287. doi: 10.1016/S0963-9969(00)00165-4. [DOI] [Google Scholar]

- Pardeshi IL, Arora S, Bhatti MS. An automatic weighing system for thin layer drying. J of Agri Eng. 1999;36(3):41–48. [Google Scholar]

- Pardeshi IL, Arora S, Borker PA. Thin-layer drying of green peas and selection of a suitable thin-layer drying model. Drying Technol. 2009;27:288–295. doi: 10.1080/07373930802606451. [DOI] [Google Scholar]

- Rahman MS, Guizani N, Al-Zakwani I. Pore formation in apple during air-drying as a function of temperature: porosity and pore-size distribution. J Sci Food Agri. 2005;85:979–989. doi: 10.1002/jsfa.2056. [DOI] [Google Scholar]

- Ranganna S. Handbook of analysis and quality control for fruits and vegetable products. 2. New Delhi: McGraw Hill; 1986. pp. 497–528. [Google Scholar]

- Rao DG, Sridhar BS, Nanjundaiah G. Drying of toria (Brassica campistris var. toria) seeds: Part 1—Diffusivity characteristics. J Food Eng. 1992;17(1):49–58. doi: 10.1016/0260-8774(92)90064-D. [DOI] [Google Scholar]

- Rdhakrishanan KL. Editorial. Indian Food Packer. 1999;53(3):4–5. [Google Scholar]

- Saravacos GD, Charm SE. A study of mechanism of fruit and vegetable dehydration. Food Technol. 1962;16(1):78–81. [Google Scholar]

- Sehgal S. Indian economic data. Naraina: Shivam Offset Press; 1999. [Google Scholar]

- Shalini R, Gupta DK, Singh A. Drying kinetics of apple pomace cake. JFST. 2009;46(5):477–479. [Google Scholar]

- Shukla BD, Sigh SP. Osmo-convective drying of cauliflower, mushroom and greenpea. J Food Eng. 2006;80(2):741–747. doi: 10.1016/j.jfoodeng.2006.06.025. [DOI] [Google Scholar]

- Simal S, Garau C, Femenia A, Rossello C. Drying of red pepper (Capsicum annuum): Water desorption and quality. Int J Food Eng. 2005;1(4):10–22. [Google Scholar]

- Singh S, Rai RR, Rai M. Osmo-air drying of bitter gourd (Momordica charantia) Slices. J food Sci Technol. 2008;45(6):501–505. [Google Scholar]

- Srivastava RP, Kumar S. Fruits and Vegetable preservation Methods and practices. Lucknow: International Book Distribution Co.; 1993. [Google Scholar]

- Stat-Ease (2009) Stat-Ease Design Expert Package, Version 7.1.0. Minneapolis, USA

- Togrul IT, Pehlivan D. Mathematical modelling of solar drying of apricots in thin layers. J Food Eng. 2002;55:209–216. doi: 10.1016/S0260-8774(02)00065-1. [DOI] [Google Scholar]

- Vega-Galvez A, Lemus-Mondaca R, Bilbao-Sa´inz C, Fito P, Andre´s A. Effect of air drying temperature on the quality of rehydrated dried red bell pepper (var. Lamuyo) J Food Eng. 2008;85:42–50. doi: 10.1016/j.jfoodeng.2007.06.032. [DOI] [Google Scholar]