Abstract

The fruits of semi-soft pear (Pyrus communis) cv. Punjab Beauty harvested at physiologically mature stage in 3rd week of July were packed in corrugated fiberboard boxes (CFB) with low density polyethylene (LDPE) liners, CFB with high density polyethylene (HDPE) liners, crates with LDPE liners, crates with HDPE liners, CFB, crates and wooden boxes and stored in walk-in-cool chamber at 0–1 °C and 90–95% RH. The fruits were analyzed after 30, 45, 60 and 75 days for physiological loss in weight (PLW), fruit firmness, core browning, spoilage, total soluble solids (TSS), juice acidity and sensory quality. The PLW was maximum in crates while the spoilage was maximum in fruits packed in wooden boxes. Core browning was more in fruits packed in crates and CFB boxes with LDPE liners while minimum was in fruits packed in CFB boxes. However, core browning did not occur up to 45 days of storage in any of the package. Fruits packed in CFB boxes with HDPE liners effectively reduced the weight loss, spoilage and retained acceptable firmness up to 75 days of storage with maximum edible quality. TSS and sugars were maximum in fruits packed in wooden boxes while the acidity was maximum in CFB boxes with HDPE liners. The fruits in CFB boxes with HDPE liners maintained the perfect balance between sugars and acids up to 75 days of storage.

Keywords: Pear fruit, Pyrus communis, Cold storage, Packaging, Quality

Introduction

Pear (Pyrus communis) is next only to apple in importance, acreage, production and varietal diversity among the temperate fruits in India. It is grown under temperate and subtropical conditions because of its wider climatic and soil adaptability. The superior cultivars have high chilling requirements and are being grown in higher reaches of Kashmir, Himachal Pradesh and Uttarakhand; whereas some low chilling types are quite successful in northern plains of India. The pear germplasm has been found to be suitable under sub-tropical conditions (Sandhu et al. 2007). Semi-soft pear cultivar named ‘Punjab Beauty’ has gained popularity because of its superior organoleptic qualities. This cultivar matures in the third week of July, when the temperature and humidity are very high, which interferes with the shelf life of fruits in the market. The loss of great magnum at this time not only robs the labour and resources but also cuts short a profit. In order to prevent the glut in market, storage of fruits is necessary. Further, the storage of fruits in proper packaging materials helps in curtailing the post-harvest losses. Packaging of fresh fruits in polyethylene films can result in a commodity-generated modified atmosphere which diminishes dehydration and preserves freshness (Ben-Yehoshua et al. 1994). Several authors have studied the effect of packaging and storage environment on post-harvest storage life and quality of different fruits (Gonzalez et al. 1997; Ding et al. 2002; Yadav et al. 2005; Kudachikar et al. 2007). Hence, there is a need to study the combined effect of storage conditions and variety of packaging materials including liners in pears so that it can maintain its quality during storage till it reaches to consumer. Keeping these view points in forefront, this study was conducted.

Materials and methods

The present investigation was carried out during the years 2006 and 2007. Uniform sized and disease free fruits of pear (Pyrus communis) cv. ‘Punjab Beauty’ were randomly harvested in 3rd week of July from all the sides of the tree. The fruits were collected in crates, kept in shade and immediately shifted to laboratory for further studies. The fruits were thoroughly washed with tap water and air dried. These fruits were then packed in CFB with LDPE liners, CFB with HDPE liners, crates with LDPE liners, crates with HDPE liners, CFB, crates and wooden boxes and stored in walk-in-cool chamber at 0–1 °C and 90–95% RH. The observations for various biochemical and quality attributes were recorded at 30, 45, 60 and 75 days storage interval.

The physiological loss in weight (PLW) was calculated on initial weight basis. The firmness of the fruit was measured with hand held penetrometer (Model FT-327, Italy) made in Italy and supplied by Elixir Technologies, Bangalore having plunger diameter of 8 mm, and expressed in terms of kg/cm2. The spoilage percentage of fruits was calculated on number basis. The fruits were cut from the centre and the browning of the core was noted. It was done on fruit number basis and percentage was calculated. The total soluble solids (TSS) were recorded with hand refractometer (Erma, Japan) calibrated at 20 °C. The titratable acidity in juice as malic acid was determined by titrating a known volume of juice with 0.1 N NaOH using phenolphthalein as an indicator. Palatability rating of fruit was recorded by a panel of five judges on the basis of 9- point hedonic scale (9: extremely desirable to 1: extremely undesirable). The sugars were determined by the method of Lane and Eynon (AOAC 2000).

Statistical analysis

The study was conducted for two seasons (2006 and 2007) and data were pooled and analyzed statistically as per completely randomized block design with factorial arrangement having three replications, each replication comprising of 2 kg fruits.

Results and discussion

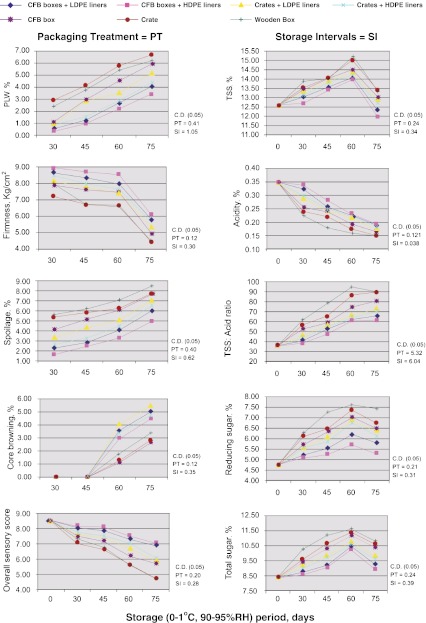

Results are presented in Fig. 1.

Fig. 1.

Changes in quality of pear (cv. Punjab Beauty) fruits packed in different packaging materials during storage (n = 3)

The increase in storage days from 30 to 75 days resulted in linear increase in PLW. The maximum PLW (5.1%) was observed after 75 days of storage, whereas minimum (1.2%) was recorded after 30 days of storage. The maximum PLW (4.8%) was in fruits packed in crates. Minimum PLW (1.6%) was in fruits packed in CFB boxes with HDPE liners. An increase in PLW during storage was as expected due to transpiration and respiration, continued in fruits even after harvest. In the present study, among different packaging materials, HDPE lined CFB boxes were the most efficacious treatment in reducing weight loss. Gonzalez et al. (1997) reported that plastic covering plays an important role in preventing dehydration by creating a saturated micro-atmosphere around the fruit. Reduction in PLW of polythene packed fruits could be attributed to retention of fruits in green fresh and firm form. Moreover, the polyethylene films have the characteristic feature of reducing the rate of transpiration by restricting the diffusion of gases and feedback mechanism.

The spoilage increased significantly with the prolongation of storage period. The mean minimum spoilage (3.6%) was recorded after 30 days of storage. However, after 75 days, the spoilage reached to 7.0%. The spoilage in fruits packed in different packaging materials was maximum (6.91%) in wooden boxes, followed by (6.3%) crates and (5.8%) CFB boxes, which were significantly higher than other packaging treatments. Minimum spoilage was (3.1%) recorded in fruits packed in CFB boxes with HDPE liners. The continuous processes of transpiration and respiration results in cellular disintegration due to reduced synthesis of protein and nucleic acids which enhances the senescence and spoilage of fruits. The lower spoilage percentage in polyethylene films lined CFB boxes and crates might be due to retardation of enzymatic activity of post harvest pathogens (Kader et al. 1989). The higher degree of degradation in crates and wooden boxes was due to shriveling of skin surface by high rate of dehydration. However, the present results found more spoilage in LDPE than HDPE lined crates and CFB boxes which might be due to the difference in permeability of polyethylene films. Geason et al. (1991) reported that Conference pears packed in low density polyethylene (LDPE) films retarded the rate of flesh softening. Whereas, an increase in spoilage of pear fruits with the advancement of storage period was noted by Sandhu and Singh (2000).

The firmness showed a linear decline with the increase in storage intervals. The fruits were quite firm after 30 days of storage. A significant decrease in fruit firmness was noted after 75 days of storage. Fruits packed in CFB boxes with HDPE liners recorded slow and gradual decline in firmness during storage and maintained highest final firmness (8.0 kg/cm2) after 75 days of storage. The minimum fruit firmness (6.2 kg/cm2) was recorded in fruits packed in crates. The softening of flesh during storage could be due to the degradation of soluble pectin by high activity of endopolygalacturonase enzyme in fruits (Martin-Cabrejas et al. 1994). The results are in agreement with Mann et al. (1990) who also reported a decrease in fruit firmness with the advancement in storage period. Roy and Pal (1993) observed that polyethylene films create modified atmosphere conditions around the fresh fruits. Further, the high humidity maintained inside these films, helps in reducing the transpiration loss and respiration activity and thus retained turgidity of the cells. The higher loss of firmness in fruits packed in crates and wooden boxes might be due to the increased metabolic activities of fruits in these containers resulting in breakdown of insoluble protopectin to soluble pectin and pectic acid.

Core browning started appearing after 60 days of storage to the level of only 2.6%, followed by 4.1% after 75 days. It was significantly influenced by different types of packaging materials. Among the various types of packaging materials, maximum core browning occurred in fruits packed in CFB boxes and crates with LDPE and HDPE liners. Among these liners, LDPE recorded more core browning. The maximum mean core browning (2.4%) was observed in fruits packed in crates with LDPE liners, followed by CFB boxes with LDPE liners (2.1%) which was significantly higher than the other packaging treatments. However, minimum core browning (1.0%) was noted in fruits packed in CFB and crates. The probable reason for this disorder could be due to the activation of hydrolytic enzymes such as polyphenoloxidase and peroxidase (Dhillon et al. 2005). Further it might be due to ascorbic acid degradation which is related to oxidative damage. The increase in core browning with the progress in storage period might be due to the increase in internal CO2 in these packages which leads to anaerobic respiration and accumulation of ethanol and acetaldehyde. The higher core browning was observed in fruits packed in CFB boxes and crates with LDPE and HDPE liners with the prolongation of storage period which might be due to high CO2 and low O2 build up within these packages.

The mean sensory rating decreased gradually from 7.7 to 5.9 during storage from 30 to 75 days. The fruits packed in CFB boxes with HDPE liners maintained higher (7.8) mean sensory score, followed by (7.6) in fruits packed in CFB boxes with LDPE liners. The minimum score (6.0) was in fruits packed in crates. Higher sensory rating in crates and CFB boxes with HDPE and LDPE liners as compared to crates, wooden boxes and CFB might be due to better retention of quality parameters and high permeability of polyethylene to CO2 than O2 diffusion. The fruits in crates and wooden boxes showed unacceptable appearance coupled with abrupt increase in TSS and acidity which disturbed the TSS/acid ratio and poor sensory rating due to development of slight bitterness and shriveled texture. Ladaniya (2007) reported that modified atmosphere packaging reduced fruit weight loss and resulted in significantly higher flavour and appearance score in “Nagpur” mandarin fruits.

The total soluble solids (TSS) increased during storage up to 60 days and declined thereafter. The TSS content (14.5%) after 60 days of storage was significantly higher as compared to all other storage intervals. However, minimum TSS content (12.8%) was noted after 75 days of storage. Among the various packaging materials, wooden boxes showed significantly higher (14.1%) TSS content. The minimum mean TSS (13.0%) was in CFB with HDPE liners. The increase in TSS content during storage might be due to the moisture loss, hydrolysis of polysaccharides and concentration of juice as a result of degradation. The TSS increased up to 60 days of storage and declined thereafter which can be attributed to the fact that on complete hydrolysis of starch, no further increase in TSS occur and consequently a decline in TSS is predictable as they are the primary substrates for respiration (Wills et al. 1980). Low TSS was observed in fruits packed in CFB boxes and crates with LDPE and HDPE liners. This was probably due to maintenance of humid micro-climate inside these films, which delayed ripening and resulted in slow hydrolysis of starch, pectic acid, proteins and fats and thus low TSS. The highest TSS was recorded in fruits packed in crates, wooden boxes and CFB boxes might be due to the loss of water in these fruits. However, utilization of sugars in respiration and degradation of total soluble substances because of prolonged storage are possible reasons for the decrease in TSS after 60 days.

The level of acidity of fruits decreased during storage. The minimum acid content was recorded in fruits packed in wooden boxes (0.18%), followed by crates (0.20%). However, a significantly higher (0.26%) acidity was in fruits packed in CFB with HDPE liners. The decrease in acidity during storage could be attributed to the use of organic acids as respiratory substrate during storage (Echeverria and Valich 1989) and by conversion of acids into sugars. The higher content of acidity in polythene packed fruits might be due to lesser availability of oxygen to fruit. The organic acids, which participate in respiratory processes, are not oxidized and hence the acidity remains high. The fruits packed in CFB and crates exhibited higher acidity than the wooden boxes packed fruits. Relativity low decrease in acid content of fruits under better packaging in CFB and crates might have affected slower rate of ethylene production. Similarly Thakur and Lal (1989) reported that the apple fruits packed in CFB boxes maintained higher acidity as compared to wooden boxes and crates.

TSS: acid ratio increased during storage. The maximum mean TSS: acid ratio was 75.8 after 75 days of storage, whereas a significantly lower TSS: acid ratio of 48.7 was observed in fruits after 30 days. Significantly higher mean TSS: acid ratio of 81.5 was in fruits packed in wooden boxes while it was minimum (51.9) in fruits packed in CFB with HDPE liners. The balance between TSS and acidity decides the overall acceptability of fruits. During storage many biochemical changes take place which disturbs the TSS: acid ratio ultimately rendering the fruit unacceptable. The present study recorded an increase in TSS: acid ratio during storage, which was due to the increase in TSS and decrease in acidity of fruits during storage. Thus, the continuous decrease in acidity and concomitant increase in TSS content resulted in increase in TSS: acid ratio. This was more pronounced in wooden boxes and crates due to higher TSS in these packages as compared with HDPE and LDPE lined CFB and plastic crates. The excessive increase in TSS: acid ratio in wooden boxes and crates caused imbalance in TSS and acid content which reduced the overall acceptability of fruits.

The reducing sugars increased with the storage intervals up to 60 days of storage and declined thereafter with subsequent storage. The maximum mean reducing sugars were 6.8% after 60 days of storage, which declined thereafter to 6.3% after 75 days. The fruits packed in CFB with HDPE liners recorded significantly lower (5.3%) reducing sugars content. However, maximum mean reducing sugars content was observed in fruits packed in wooden boxes (7.2%) which was closely followed by (6.7%) in crates and (6.4%) in CFB. The progressive increase in sugars during storage period up to 60 days and a gradual decline thereafter might be due to hydrolysis of polysaccharides and concentrations of juice as a result of dehydration. However, on complete hydrolysis of starch, no further increase in sugars occurred and consequently a decline in TSS is predictable as they are the primary substrates for respiration and are used by fruits in various metabolic activities (Wills et al. 1980).

Total sugars showed a progressive increase up till 60 days of storage but declined during the later period. The maximum total sugar content was 10.9% after 60 days of storage which was significantly higher than the other storage intervals. The maximum total sugars (11.0%) was in fruits packed in wooden boxes which were significantly higher than other packaging treatments. Significantly lower total sugars content (9.2%) was in fruits packed in CFB with HDPE liners. The initial increase in total sugars of fruits under different packages might be due to loss of water from the fruits and conversion of polysaccharides and pectic substances into sugars. The increase in total sugars with the storage interval up to 60 days might be due to the hydrolysis of starch, yielding mono-and-disaccharides. Thereafter, decline can be attributed to metabolic breakdown and senescence of fruit as a result of moisture and firmness loss during storage (Ryall and Pentzer 1982). The higher sugars content of fruits in crates and wooden boxes might be the result of rapid loss of moisture and fast hydrolysis of starch and other polysaccharides to soluble forms of sugars. During the storage of Patharnakh pear and Red Delicious apples, an increase in total sugars was reported by Mahajan (1994). However, Keditsu et al. (2003) observed that total sugar content in ‘Khasi’ mandarin showed a marginal increase during storage and declined slightly towards later date of observation under various treatments of modified packaging and low temperature. Lower sugar content in fruits from polythene packaging treatment was due to lower rate of metabolic processes.

Thus, it can be concluded that pear fruits cv. ‘Punjab Beauty’ harvested in 3rd week of July can be successfully stored for 60 days at 0–1 °C and 90–95% RH. Further, packaging of these fruits in CFB with HDPE liners increased their shelf life up to 75 days of cold storage.

References

- Official methods of analysis. 15. Benjamin Franklin Station, Washington DC: Association of Official Analytical Chemists; 2000. [Google Scholar]

- Ben-Yehoshua S, Fishman S, Fang D, Rodov V (1994) New developments in modified atmosphere packaging and surface coatings for fruits. Proc Int Conf Post-harvest handling of tropical fruits, Chiang Mai, Thailand, 19–23 July 1993, p 250–60

- Dhillon WS, Mahajan BVC, Dhatt AS, Sandhu AS. Waxing and storage studies in soft pear cv. Punjab Beauty. Acta Hortic. 2005;696:485–492. [Google Scholar]

- Ding CK, Chachin K, Ueda Y, Imahori Y, Wang CY. Modified atmosphere packaging maintains post harvest quality of loquat fruit. Postharvest Biol Technol. 2002;24:341–348. doi: 10.1016/S0925-5214(01)00148-X. [DOI] [Google Scholar]

- Echeverria E, Valich J. Enzymes of sugars and acid metabolism in stored ‘Valencia Oranges’. J Am Soc Hortic Sci. 1989;114:445–449. [Google Scholar]

- Geason JO, Genge PM, Smith SM, Sharbes RO. The response of unripe Conference pear to modified retail packaging. J Food Sci Technol. 1991;26:215–233. [Google Scholar]

- Gonzalez AG, Vasquez C, Felix L, Baez R. Low oxygen treatment before storage in normal or modified atmosphere packaging of mango. J Food Sci Technol. 1997;34:399–404. [Google Scholar]

- Kader AA, Zagory D, Kerber EL. Modified atmosphere packaging of fruits and vegetables. Crit Rev Food Sci Nutri. 1989;28:1–30. doi: 10.1080/10408398909527490. [DOI] [PubMed] [Google Scholar]

- Keditsu R, Sema A, Maiti CS. Effect of modified packaging and low temperature on post harvest life of ‘Khasi’ mandarin. J Food Sci Technol. 2003;40:646–651. [Google Scholar]

- Kudachikar VB, Kulkarni SG, Vasantha MS, Aravinda Prasad B, Aradhya SM. Effect of modified atmosphere packaging on shelf- life and fruit quality of banana stored at low temperature. J Food Sci Technol. 2007;44:74–78. [Google Scholar]

- Ladaniya MS. Quality and carbendazim residues of ‘Nagpur’ mandarin fruit in modified atmosphere. J Food Sci Technol. 2007;44:85–89. [Google Scholar]

- Mahajan BVC. Biochemical and enzymatic changes in apple during cold storage. J Food Sci Technol. 1994;31:142–144. [Google Scholar]

- Mann SS, Grewal GPS, Dhillon DS, Sandhu AS, Singh R, Sharma KK, Minhas PPS. Studies on storage of Baggugosha pear. Punjab Hortic J. 1990;30:57–60. [Google Scholar]

- Martin-Cabrejas MA, Waldron KW, Selvandran RR, Parker ML, Moates GK. Ripening related changes in cell wall of ‘Spanish’ pear. Physiol Plant. 1994;91:671–679. doi: 10.1111/j.1399-3054.1994.tb03004.x. [DOI] [Google Scholar]

- Roy SK, Pal RK. Use of plastics in post-harvest technology of fruits and vegetables- A Review. Indian Food Pack. 1993;47:27–45. [Google Scholar]

- Ryall AL, Pentzer WT. Handling, transportation and storage of fruits and vegetables. Westport: AVI Pub. Co. Inc; 1982. [Google Scholar]

- Sandhu SS, Singh AP. Effects of harvesting dates and individual seal packaging on the pear fruit cv. Le Conte during cold storage. Haryana J Hortic Sci. 2000;29:48–52. [Google Scholar]

- Sandhu AS, Singh T, Singh R, Dhillon WS. Evaluation of oriental pear germplasm under subtropical conditions. Indian J Hortic. 2007;64(2):127–130. [Google Scholar]

- Thakur NS, Lal BB. Evaluation of plastic carton and corrugated fiber board carton vis -a- vis conventional wooden box for packaging and transportation of apple. J Food Sci Technol. 1989;26:239–241. [Google Scholar]

- Wills RBH, Cambridge PA, Scott KJ. Use of flesh firmness and other objective tests to determine consumer acceptability of Delicious apples. Aust J Exp Agric Anim Husb. 1980;20:252–256. doi: 10.1071/EA9800252. [DOI] [Google Scholar]

- Yadav S, Kumar A, Saini RS. Biochemical and organoleptic quality changes during storage of ber fruit transported with different packaging materials. Haryana J Hortic Sci. 2005;34:25–28. [Google Scholar]