Abstract

Sel-roti is a delicious, deep-fat fried, puffed, ring shaped spongy doughnut like Nepalese indigenous food prepared from the batter of rice flour, ghee and sugar. A study was conducted to determine the effect of particle size of rice flour on bulk density, oil uptake and texture of Sel-roti. Rice was soaked in water and ground with the help of iron mortar and pestle and the flour was analyzed for particle size distribution by using standard sieves and separated into three particle size categories as coarse (> 890 u), medium (120–890 u) and fine (< 120 u). The rice flour of different particle sizes were mixed in different proportions and Sel-roti was prepared from these flours. Bulk density and oil uptake were determined and sensory test was carried out. The results showed significant good positive correlation between mean particle size and bulk density (r = 0.97, p ≤ 0.05) and a good negative correlation between mean particle size and oil-uptake (r = 0.90, p ≤ 0.05). Good positive correlation of mean particle size with texture attributes like hardness (r = 0.99, p ≤ 0.05) and fracturability (r = 0.96, p ≤ 0.05) and good negative correlation with smoothness (r = -0.97, p ≤ 0.05), cohesiveness (r = -0.92, p ≤ 0.05), stickiness (r = -0.76, p ≤ 0.05) and oily mouth feel (r = -0.85, p ≤ 0.05) and fair positive correlation with chewiness (r = 0.65, p > 0.05) were found.

Keywords: Sel-roti, Rice flour, Particle size, Bulk density, Oil uptake, Texture

Nepal is a country of ethnical, cultural, religious and linguistic diversity. So also, diverse kinds of traditional foods can be found in Nepal, which the people have inherited from their ancestors. Sel-roti is a local Nepali name given to the ring shaped spongy doughnut like Nepalese indigenous food usually prepared by deep-frying the batter made up of rice flour, cream or ghee (clarified milk fat), sugar and water in ghee or any other cooking oil. Mention of Sel-roti is found in ancient sacred and religious Hindu religious books like Puran and Swasthani Bratakatha (Anon. 2003). This food has ever since special ritual value and regarded essential or special to offer in worships and other holy occasions, marriage ceremony and many other Hindu rituals. Sel-roti is a popular delicious and energy rich food prepared both at home and restaurants.

There was no systematic study on Sel-roti until a survey study was conducted by Katawal and Subba (2008) and information regarding its origin, ingredients and their functions, recipe, method of preparation, equipments, quality characteristics and factors affecting the quality were collected and documented. Proper documentation is important not only to authenticate its origin and preserve its culture but also to improve its technology and standardize the technological parameters for eventual successful commercialization. The coarseness or fineness of rice flour has been found to tremendously affect the physical and sensory properties of Sel-roti such as appearance, integrity, texture and eating quality. Doughnut like ring-shape, puffed and spongy nature and sweet taste are its indispensable characteristics. Soft and crumbly texture is most acceptable. Its colour is normally light to reddish brown. As said before, the process of Sel-roti preparation is still traditional one. The rice flour used by the Sel-roti makers is coarse ground flour containing mixture of fine flour and grits of rice prepared by traditional pounding equipment such as Dhiki (A local word used for leg-pound made up of log of wood), Okhali (a local word meaning a large wooden mortar and pestle) and Silouto (stone grinder). Only a very small number of Sel-roti makers are using fine rice flour produced by modern rice flour mills. The Sel-roti makers estimate the particle size of the flour by perceiving its texture by rubbing it between thumb, index and middle finger. The objective of the present work was to study the effect of particle size of rice flour on bulk density, oil uptake and texture of Sel-roti.

Materials and methods

Approximately one year old ‘Kanchhi Mansuli’ rice (a local coarse variety of rice) was purchased from a local rice mill of Dharan, Nepal soaked overnight in water, drained and ground to flour by using mortar and pestle made of iron locally called Khal-Bachcha . The flour was analyzed for particle size distribution by using ASTM standard set of sieves with clear openings of 2000, 1180, 600, 300, 150, 90 and 75 u (Pradeep Trading Co. Delhi) by placing the sieve of largest mesh size on top and the sieve of smallest mesh size at the bottom and shaking the screens while the flour sample was fed on the topmost sieve (Badger and Banchero 1955; Toledo 1997). The flour retained in each sieve was collected and weighed. The average particle size and weight percent retained were calculated. The mean particle diameter i.e. weighted mean diameter of particle was determined summing up the value obtained by multiplying the mass fraction by the mean particle size in each screen. Based on the mean particle size the rice flour was divided into three groups as coarse (>890 u), medium (120–890 u) and fine (<120 u). The rice flour having these three different particle sizes were mixed in various proportions as shown in Table 1. Analysis of particle size distribution was carried out and mean particle size determined.

Table 1.

Sel-roti flour formulations

| Sample | Mixing proportion of different particle size flour | |||

|---|---|---|---|---|

| Coarse (>890 μ) | Medium (120–890 μ) | Fine (<120 μ) | Mean Particle Size (μ) | |

| A | 10 | 60 | 30 | 359 ± 4 |

| B | 20 | 50 | 30 | 425 ± 6 |

| C | 30 | 30 | 40 | 465 ± 6 |

| D | 30 | 50 | 20 | 520 ± 6 |

| E | 40 | 50 | 10 | 614 ± 8 |

| F | 50 | 30 | 20 | 652 ± 8 |

| G | 60 | 30 | 10 | 746 ± 10 |

Figures in the parentheses are standard deviations

For the preparation of Sel-roti, rice flour of each of different mean particle sizes shown in Table 1 was taken. Sugar (21% by weight of rice flour) and ghee purchased from Dairy Development Corporation, Nepal (10.5% by weight of rice flour) were added to the rice flour and mixed. The mixture was rubbed moderately by hand for about 10 min. The mixture was kneaded with water (25 ± 0.8 ml per 100 g flour) to prepare batter. The recipe used in the experiments quite resembled the most common recipe used by Sel-roti makers in the market. The batter was allowed to stand for 1 h and hand poured in heated refined soybean oil (210°C) taken in a Tai and by forming ring shaped structures. The rings were cooked till the development of reddish brownish coloration on the lower side of Sel-roti. It was then turned upside down with the help of Jhir, which is a local word for a pointed iron stick and further cooked till whole of the Sel-roti turned reddish brown in color. It was removed from Tai and drained properly.

Bulk density of Sel-roti was determined by volumetric replacement method using mustard seeds of almost same size as the replacement medium (Nepal Standard 2036 B.S.). A wooden box suitable for the measurement was designed for this purpose. The bulk density of Sel-roti was calculated using the formula:

|

Where ρs = bulk density of Sel-roti (kg/m3); Ws = weight of Sel-roti; Wm = weight of mustard seeds with the same volume as that of the Sel-roti (g); and ρm = bulk density of mustard seeds (kg/m3). Three measurements were made. Moisture content of Sel-roti was determined following AOAC official method 920.36 (AOAC 2005). Fat content of Sel-roti was determined as per AOAC official method 920.39 (AOAC 2005). Oil-uptake was calculated as follows:

|

(Dry & fat free basis)

Texture of Sel-roti was evaluated by a sensory panel consisting of six trained panelists. Procedures, training of panelists and terminological description(i.e., definition of the terms) used were according to Cardello et al. (1982); Civille and Liska (1975); Mabesa (1986); Watts et al. (1989), Lee and Resurrection A.V.A (2002) and Sanchesa-Brambila et al. (2002). The description of texture attributes applied in this study is presented in Table 2. The test was conducted in panel booths with sufficient light (day light complement with tube light). Line scales with intensity value 0 (none) to 15 (high) were used to record panelist responses to each texture attribute (Sanchesa-Brambila et al. 2002; Chen et al. 2002). Sel-roti samples were presented to the panelists in paper plates coded with 3-digit random number. The order of samples by treatment was completely randomized. Warm water was provided to the panelists between the tests for mouth rinsing. Three replicate tests were performed.

Table 2.

Sensory score for texture attributes of Sel-roti

| Texture attributes | Formulations1 | ||||||

|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | |

| Smoothness | 10.1 ± 1.88a | 9.4 ± 1.81ab | 10.1 ± 2.31a | 8.3 ± 2.17b | 7.4 ± 2.35c | 6.5 ± 1.63c | 4.7 ± 1.74 |

| Hardness | 5.4 ± 1.41a | 5.6 ± 1.30a | 6.2 ± 1.37b | 6.6 ± 1.76b | 8.0 ± 2.33c | 8.3 ± 2.26c | 9.7 ± 2.68 |

| Fracturability | 5.3 ± 1.80 a | 6.0 ± 2.07ab | 5.3 ± 2.00a | 6.6 ± 2.09b | 8.2 ± 2.24c | 8.6 ± 2.56cd | 9.2 ± 2.68d |

| Cohesiveness | 6.6 ± 2.92a | 7.1 ± 2.66a | 6.0 ± 2.80b | 6.1 ± 2.22b | 5.8 ± 2.24b | 5.1 ± (2.05c | 4.6 ± 1.72c |

| Stickiness | 5.8 ± 2.34ad | 6.6 ± 2.77 | 5.9 ± 3.21ab | 5.2 ± 2.05ad | 5.2 ± 1.78ad | 5.6 ± 2.06ab | 4.6 ± 1.64c |

| Oily mouth | |||||||

| Feel | 9.6 ± 1.96a | 8.9 ± 2.05ab | 8.6 ± 1.64ab | 9.0 ± 1.39ab | 8.0 ± 1.41 | 8.8 ± 0.83b | 6.8 ± 1.21 |

| Chewiness | 13.8 ± 2.32a | 14.9 ± 3.00b | 14.0 ± 2.68abc | 15.1 ± 3.15b | 14.0 ± 3.57bc | 14.8 ± 3.07abc | 14.9 ± 2.55bc |

N = 18(6 panelists x 3 replicates). n = 3. The values were recorded in 15 cm intensity scale except chewiness which is the number of chew per second

a,b,c,dsame alphabet in row indicates no significant difference (p > 0.05) as determined by LSD

1Refer the formulations to Table 1

The sensory test data were processed by GenStat statistical software and Excel 2003. Analysis of variance (ANOVA) was performed to determine the effect of particle size of rice flour on texture attributes of Sel-roti, while the least significant difference (LSD) test was used to detect significant differences (P ≤ 0.05) among the means. The data of bulk density, oil-uptake and texture attributes were subjected to Pearson’s product moment correlation coefficient tests. The ANOVA analysis of regression was carried out for significance. The regression coefficient, prediction equation and trend line were found out. The significance level of p < 0.05 was used.

Results and discussion

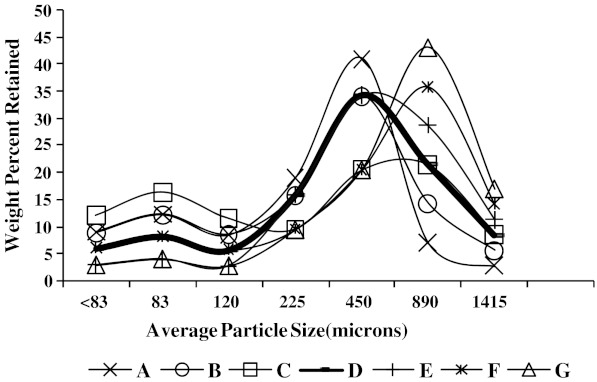

Figure 1 shows the particle size and frequency distribution of the rice flour. This frequency particle distribution curve shows that Curve G, E and F have high peak shifted to the right, curve A, B and C to the left and curve D (bold one) in between. The curve of the frequency size distribution can show the mean particle size of the flour having what type of size distribution would be good for the good quality of Sel-roti. The Sel-roti prepared from the rice flour having particle size distribution as curve D (Fig. 1) was preferred by panelists.

Fig. 1.

Frequency particle size distribution of flour formulation. A, B, C, D, E, F, & G are sample codes depicted in Table 1

Effect of particle size of rice flour on bulk density of Sel-roti

The preparation of Sel-roti was not technically feasible from the rice flour having mean particle size smaller than 120 μ and greater than 890 μ. Sel-roti made from the flour of mean particle size smaller than 120 μ puffed excessively during frying but collapsed instantaneously upon cooling and also turned leathery in texture. Likewise, the batter made from the flour of particle size greater than 890 μ did not show satisfactory flow characteristics during pouring into the oil for frying. Even more it showed poor puffing characteristic, did not retain the desired ring shape, and it was excessively grainy and hard in texture.

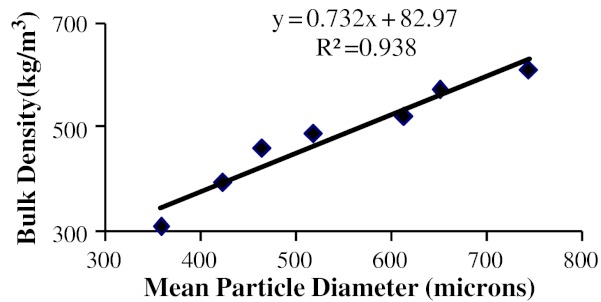

As expected a good positive correlation could be found between the particle size of rice flour and the bulk density of Sel-roti, the bulk density being increased with increase in the particle size and vice versa (Fig. 2). The results showed significant good positive correlation between mean particle size and bulk density (r = 0.97, p ≤ 0.05) .With the increase in flour particle size the puffiness of Sel-roti decreased and the product was dense. A hollow and puffy product with low bulk density was obtained from the flour having finer particle size. The flour comprised of coarse particles produced dense product with very less or no puffiness. Satisfactorily puffy and spongy product was obtained from the flour of intermediate particle size.

Fig. 2.

Relation between mean particle size and bulk density

Effect of mean particle size on oil-uptake

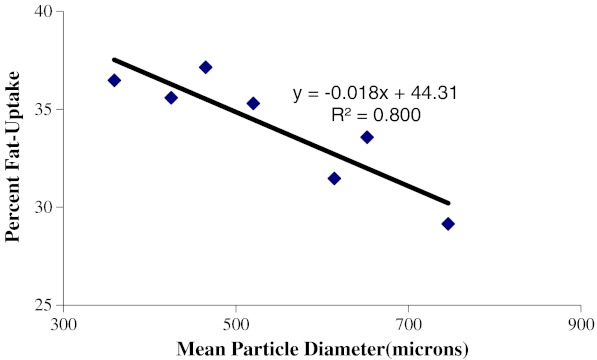

The relation between mean particle size of rice flour and oil uptake by Sel-roti is shown in Fig. 3. A good negative correlation of mean particle size with the oil-uptake, (r = -0.90, p ≤ 0.05) was found. Increase in the oil uptake with decrease in particle size could be attributed to increased surface area in smaller particle size absorbing more oil compared to rice flour containing large size rice particles. This even shows that the oil or fat content of the product can be adjusted by changing the pattern of particle size distribution of the rice flour.

Fig. 3.

Relation between mean particle size and oil uptake

Effect of particle size of rice flour on texture of Sel-roti

The mean score for various texture attributes by test panelists is shown in Table 2. The results showed good positive correlation of mean particle size with hardness (r = 0.99, p ≤ 0.05), fracturability (r = 0.96, p ≤ 0.05) and good negative correlation with smoothness (r = -0.97, p ≤ 0.05), cohesiveness (r = -92, p ≤ 0.05), stickiness (r = -0.76, p ≤ 0.05), and oily mouth feel (r = -0.85, p ≤ 0.05). Fair positive correlation was found with chewiness (r = 0.65, p > 0.05). It was determined from the analysis of Pearson moment correlation coefficients that hardness and fracturability were positively (r = 0.99, p ≤ 0.05) and hardness and smoothness were negatively correlated. The larger and coarser particles absorbs less oil/fat and dries up faster during frying and contains less moisture. This is an explanation why the Sel-roti made from rice flour of coarse particles is comparatively hard and fractures more. On the other hand, Sel-roti made from rice flour containing smaller or finer particles absorbs more oil or fat and it is soft. Such product tends to stick to gums and palate during mastication and gives oily mouth-feel. This means that a Sel-roti made from the rice flour of coarser particles is hard in texture, the flour should be of finer particles for making soft Sel-roti.

Notwithstanding, very fine particle size (<120 u) should be rejected as the Sel-roti made from such flour puffs excessively on frying and instantaneously collapses on subsequent cooling and moreover becomes leathery in texture.

Conclusions

The particle size of rice flour was found to be positively correlated with bulk density but negatively correlated with oil uptake of Sel-roti. The mean particle size of flour was positively correlated with hardness, fracturability and chewiness but negatively correlated with smoothness, cohesiveness, stickiness and oily mouth feel. The particle size, particularly size distribution of rice flour has pronounced effect on the quality of Sel-roti.

Contributor Information

Dilip Subba, Phone: +977-1-4358917, Email: dilipsubba2009@yahoo.com.

Surendra Bahadur Katawal, Phone: +977-25-525144, Email: skatawal@yahoo.co.nz.

References

- Swosthani Bratakatha. Banarasi: Durga Sahitya Bhandar; 2003. [Google Scholar]

- Official methods of analysis. 18. Washington DC: Association of Official Analytical Chemists; 2005. [Google Scholar]

- Badger WL, Banchero JT. Introduction to chemical engineering. Tokyo: McGraw-Hill, Kogakusha LTD; 1955. [Google Scholar]

- Cardello AV, Maller O, Kapsalis JG, Segars RA, Sawyer FM, Murphy C, Moskowitz HR. Perception of texture by trained and consumr panelists. In: Linda BM, editor. Sensory evaluation of foods, principles and methods. Laguna: College of Agriculture; 1982. p. 54. [Google Scholar]

- Chen Z, Sagis L, Legger A, Linssen JPH, Schols HA, Voragen AGI. Evaluation of potato noodles made from three typical Chinese sweet-potato starches. J Food Sci. 2002;67:3342–3347. doi: 10.1111/j.1365-2621.2002.tb09589.x. [DOI] [Google Scholar]

- Civille GV, Liska IH. Modification and applications to food of the general food’s sensory texture profile technique. In: Linda BM, editor. Sensory evaluation of foods, principles and methods. Laguna: College of Agriculture; 1975. pp. 53–61. [Google Scholar]

- Katawal SB, Subba D. A survey study on technology of Sel-roti—a traditional food of Nepal. J Food Sc Technol Nepal. 2008;4:23–30. [Google Scholar]

- Lee CM, Resurrection AVA. Improved correlation between sensory and instrumental measurement of peanut butter texture. J Food Sci. 2002;67:1939–1949. doi: 10.1111/j.1365-2621.2002.tb08750.x. [DOI] [Google Scholar]

- Mabesa LB. Sensory evaluation of foods: principles and methods. Laguna: College of Agriculture; 1986. [Google Scholar]

- Nepal Standard (2036 B.S.). Standard of white bread. Office of the Nepal Standards, Ministry of Industry, Nepal.

- Sanchesa-Brambila GY, Lyon BG, Huang YW, Franco Santiago JR, Lyon CE, Gates KW. Sensory and texture quality of canned whelk (Astraea undosa) subjected to tenderizing treatments. J Food Sci. 2002;67:1559–1563. doi: 10.1111/j.1365-2621.2002.tb10322.x. [DOI] [Google Scholar]

- Toledo RT (1997). Sieving, physical separation process. In: Fundamentals of food process engineering. CBS Publishers and Distributors, New Delhi, pp 538-540

- Watts BM, Yumaki SL, Jeffery LE, Elias LG. Basic sensory methods for food evaluation. Ottawa: IDRC; 1989. [Google Scholar]