Abstract

Extrusion cooking of sorghum (Sorghum vulgaris), horse gram (Dolichos biflorus) and defatted soy (Glycine max) flour blends was done to prepare snacks by using a Brabender single—screw laboratory extruder. The combined effect of moisture content, blend ratio of feed, barrel temperature and screw speed of extruder on physical parameters of extrudate was studied. It was observed that 15% moisture content of feed, 80:10:10 (sorghum flour: horse gram flour: defatted soy flour) of blend ratio, 130 °C barrel temperature and 130 rpm of screw speed gave the highest sectional expansion index and longitudinal expansion index of extrudate, while 12% moisture content, 75:15:10 of blend ratio of feed, 135 °C of barrel temperature and 135 rpm of screw speed gave lowest bulk density of extrudate. A central composite rotable design (CCRD) of response surface methodology was used to develop prediction model. Second order quadratic regression model fitted adequately in the variation. The significance was established at p ≤ 0.05. It was also observed that increasing feed moisture content results in a higher density and lower expansion of extrudate. Increasing barrel temperature and screw speed reduced density but increased expansion of extrudate.

Keywords: Sorghum, Horse gram, Defatted soy flour, Extrusion cooking, Bulk density, Sectional expansion index, Longitudinal expansion index

Introduction

In recent years, there has been an increasing interest in the production of extruded foods such as snacks, pastas, breakfast cereals, baby foods and pet foods. Extrusion cooking has advantages, including versatility, high productivity, low operating costs, energy efficiency and shorter cooking times (Harper 1981). Several legumes have been treated by extrusion and good expansion has been reported (Balandran et al. 1998). In addition, and as a result of high temperatures, high pressures and several shear forces reaching inside the barrel, chemical reactions and molecular modifications like gelatinization of starch, denaturation of proteins, inactivation of many food enzymes and reduction of microbial counts can occur (Harper 1981). Inside the extruder the cereal mixture is heated above the starch gelatinization temperature leading to a cooked product that may be directly enrobed and flavored, or may need further processing such as frying or roasting. In the blend of flours made from starch and protein rich grains, the selection of machine and process parameters for extrusion becomes more important as the starch gets gelatinized and protein gets denatured at different process parameters. Sorghum, which contains adequate quantity of sulphur bearing amino acids, is deficient in lysine (Jambunathan et al. 1986). Incorporation of defatted soy flour to sorghum and horse gram will enhance its nutritional quality and will be useful as a means of adding value to the horse gram pulses which are currently used as animal feed.

Chemical and physical characteristics of products strongly depend upon process variables such as extrusion temperature, screw speed and moisture content (De Clindio et al. 2002). In cereal-based products, the degree or proper processing of starch is important for major quality aspects such as taste, digestibility, texture, appearance and puffing. Extrusion operational parameters such as barrel temperature, and screw speed affect the snack quality. In addition to these, processing parameters like feed moisture content, blending ratio also play important role on the quality of extrudate. Therefore, the effects of various operational and processing parameters and their interaction on quality of extrudate has to be studied and established.

In the present study, sorghum (Sorghum vulgaris), horse gram (Dolichos biflorus) and defatted soy (Glycine max) flour were used to develop an extruded snack which is protein rich, has good textural properties due to the incorporation of sorghum and also has some medicinal properties which are attributed to horse gram. The main objective of this study is to develop a nutritionally rich snack at an affordable price and was to examine the effect of extrusion conditions (temperature, feed moisture content, blending ratio and screw speed) on physical properties of extrudate.

Materials and methods

Sorghum and horse gram grains were procured from local market. After cleaning, these grains were milled in a laboratory scale Hammer Mill to obtain required quantity of flour. Defatted soy flour was procured from Ruchi Soy industry, Indore, India. The moisture content of flour of different blend ratios were measured by hot air oven method. After getting the moisture content of blends, water was added to maintain desired moisture content levels in the blends i.e. 9, 12, 15, 18 and 21%, kept for conditioning for for 24 h, calculated by using the formula:

|

where

- Ww

Wt of water to be added

- Wd

Bone dry wt. of raw flour

- M1

Initial moisture content of flour,% wb in decimal

- M2

Desired moisture content of flour,% wb in decimal

The laboratory—scale single—screw extruder (model Kompakt E 19/25 D Brabender Duisburg, Germaney) (length-to-dia 20:1; compression ratio 2:1 and die opening 5 mm) was used for extrusion cooking.

Experiment design and analysis

Response surface methodology (RSM) was used in designing the experiment (Cochran and Cox 1957). Independent variables such as moisture content, blend ratio of feed, barrel temperature and screw speed were coded as X1, X2, X3 and X4 respectively. Five levels of each of the four variables were chosen according to a central composite rotable design (CCRD). The coded and actual parameter values are presented in Table 1. The data obtained from the experiment was processed in trial Design Expert 7.0.1 (45 days). The observed data was analyzed, employing multiple regression technique. The best fitting model was chosen, based on lack of fit criteria (Cochran and Cox 1957).

Table 1.

Coded and decoded parameter levels

| Parameter | Code levels | ||||

|---|---|---|---|---|---|

| −2 | −1 | 0 | 1 | 2 | |

| Blend ratio of feed,(X2) Sorghum: Horse gram: DFS | 80:10:10 | 75:15:10 | 70:20:10 | 65:25:10 | 60:30:10 |

| Barrel Temperature (zone-III) (X3), °C | 120 | 125 | 130 | 135 | 140 |

| Screw Speed (X4), rpm | 120 | 125 | 130 | 135 | 140 |

Determination of physical properties

Bulk density, Sectional expansion index and longitudinal expansion index of extrudate was calculated by standard method (Anderson et al. 1969; Moreyra and Peleg 1981).

The data obtained from the experiments for different combinations (Table 2) were analyzed by using multiple regression and second order polynomial model and fitted to the experimental data with coded values of independent variables and inter- treated with the help of models and graphs. From the tabulated values, three-dimensional graphs were prepared treating two independent variables to be constant and showing the effect of other two variables on physical properties i.e. bulk density, sectional expansion index and longitudinal expansion index of extrudate.

Table 2.

Variation of observed data during the experimentation for extrusion cooking blends

| Coded levels | Dependent parameters | |||||

|---|---|---|---|---|---|---|

| X1 | X2 | X3 | X4 | Bulk density, g/cm3 | SEI | LEI |

| −1 | −1 | −1 | −1 | 0.156 | 16.78 | 0.282 |

| 1 | −1 | −1 | −1 | 0.187 | 14.72 | 0.250 |

| −1 | 1 | −1 | −1 | 0.168 | 16.72 | 0.279 |

| 1 | 1 | −1 | −1 | 0.248 | 14.68 | 0.250 |

| −1 | −1 | 1 | −1 | 0.197 | 16.81 | 0.288 |

| 1 | −1 | 1 | −1 | 0.266 | 14.75 | 0.248 |

| −1 | 1 | 1 | −1 | 0.168 | 16.75 | 0.274 |

| 1 | 1 | 1 | −1 | 0.249 | 14.69 | 0.247 |

| −1 | −1 | −1 | 1 | 0.159 | 16.79 | 0.286 |

| 1 | −1 | −1 | 1 | 0.248 | 14.74 | 0.249 |

| −1 | 1 | −1 | 1 | 0.220 | 16.69 | 0.275 |

| 1 | 1 | −1 | 1 | 0.267 | 14.68 | 0.244 |

| −1 | −1 | 1 | 1 | 0.118 | 16.81 | 0.280 |

| 1 | −1 | 1 | 1 | 0.258 | 14.78 | 0.248 |

| −1 | 1 | 1 | 1 | 0.161 | 16.79 | 0.273 |

| 1 | 1 | 1 | 1 | 0.276 | 14.73 | 0.245 |

| −2 | 0 | 0 | 0 | 0.195 | 16.70 | 0.290 |

| 2 | 0 | 0 | 0 | 0.287 | 14.78 | 0.235 |

| 0 | −2 | 0 | 0 | 0.127 | 16.88 | 0.292 |

| 0 | 2 | 0 | 0 | 0.178 | 16.71 | 0.259 |

| 0 | 0 | −2 | 0 | 0.181 | 16.74 | 0.265 |

| 0 | 0 | 2 | 0 | 0.162 | 16.76 | 0.266 |

| 0 | 0 | 0 | −2 | 0.165 | 16.71 | 0.264 |

| 0 | 0 | 0 | 2 | 0.201 | 16.73 | 0.267 |

| 0 | 0 | 0 | 0 | 0.162 | 16.69 | 0.266 |

| 0 | 0 | 0 | 0 | 0.150 | 16.67 | 0.271 |

| 0 | 0 | 0 | 0 | 0.191 | 16.70 | 0.274 |

| 0 | 0 | 0 | 0 | 0.189 | 16.72 | 0.272 |

| 0 | 0 | 0 | 0 | 0.205 | 16.69 | 0.269 |

| 0 | 0 | 0 | 0 | 0.198 | 16.73 | 0.267 |

Results and discussion

Bulk density of extrudate (BDE)

The BDE varied from 0.127 to 0.287 g/cm3 (Table 2). The BDE increased with increase in moisture content, blend ratio of feed (increasing protein content and decreasing starch) and screw speed. It may be because the increase in moisture content brings about increase in the bulk density whereas reduction in protein decreases the density. Further, it was observed that when barrel temperature increased gradually, the bulk density of extrudate decreased. This may be because the high barrel temperature evaporates more moisture and hence reduce moisture and then reduced BDE. This could be due to the effect of high temperatures on viscosity and starch degradation resulting in less expansion (Balandran et al. 1998). Similar results were reported by Köksel et al. (2004) and Ding et al. (2006).

The analysis of variance for Eq. 1 indicated non- significant lack of fit (Table 3), indicating adequate fit of data (Cochran and Cox 1957) and it is revealed that observed and predicted values are nearly the same, hence a second order model seems to be adequate to describe the effect of variables in the experimental zone. The test of significance of individual regression coefficients show that linear term of moisture content and blend ratio of feed and square term of moisture content have significantly contributed towards the BDE.

Table 3.

Analysis of variance for Eq. 2 (R2 = 0.8447)

| Source | Sum of square | df | Mean square | F-value | p-value prob>F | Remark |

|---|---|---|---|---|---|---|

| Model | 0.051 | 14 | 3.618 × 10−3 | 5.83 | 0.0008 | S |

| Lack of Fit | 6.975 × 110−3 | 10 | 6.975 × 110−4 | 1.49 | 0.3448 | NS |

| Error | 9.313 × 110−3 | 15 | 6.208 × 110−4 | |||

| Pure error | 0.002338 | 5 | 0.0004675 | |||

| Total | 0.60 | 29 |

S Significant; NS non-significant at 5% level

The following model was developed:

|

1 |

where

- Y

Bulk density of extrudate,g/cm3

- X1

Moisture content of feed (%,wb)

- X2

Blend ratio of feed

- X3

Barrel temperature °C, and

- X4

Screw speed,rpm

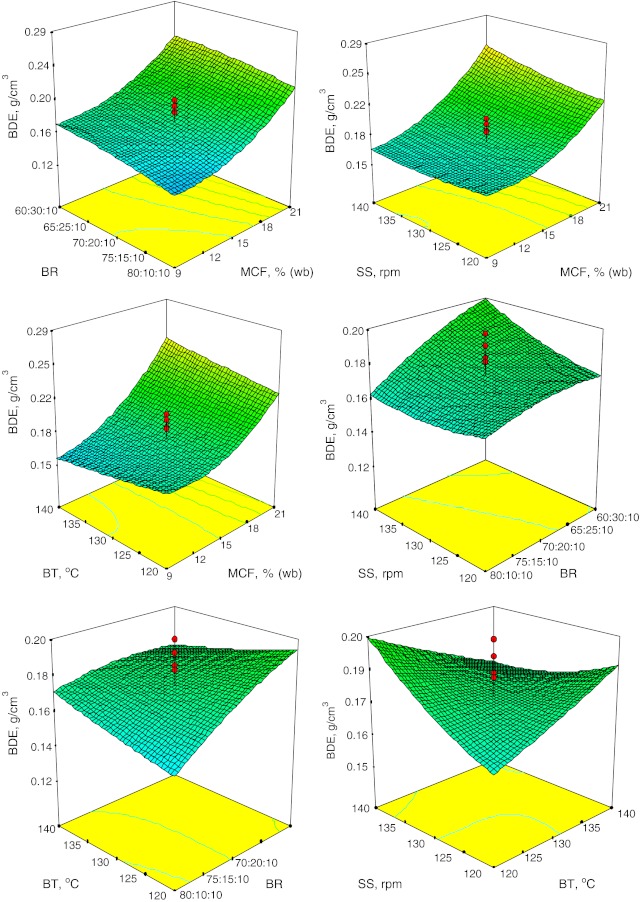

Effect of different parameters on BDE

Effect of different parameters on BDE is presented in Fig. 1. The variation of BDE with respect to blend ratio is curvilinear along the axis of moisture content of feed. It was noted that the BDE increased with increasing in moisture content and blend ratio of feed (increasing protein content and decreasing starch). It may be because the increase in moisture content brings about increase in the bulk density whereas reduction in protein decreases the density. The variation of BDE with respect to screw speed is also curvilinear along the axis of moisture content of feed. It was noted that BDE increased with increase in moisture content of feed and screw speed. This variation along the axis of screw speed is constant. The variation of BDE with respect to barrel temperature is curvilinear along the axis of moisture content of feed. It may be because the change in barrel temperature brings about decrease in moisture content of extrudate. The variation of BDE with respect to screw speed was not significant. The variation of BDE with respect to barrel temperature is curvilinear along the axis as that of blend ratio. It may be because the change in barrel temperature brings about more change in the hardness there by increasing its bulk density. The variation of BDE with respect to screw speed is linear but increased barrel temperature decreased bulk density. It may be because the increase barrel temperature and screw speed increases hardness and decreases the residence time therefore increasing the BDE.

Fig. 1.

Effect of differenct parameters on bulk density of extrudate (BDE). MCF: Moisture Content, BT: Barrel Temperature, SS: Screw Speed, BR: Blend Ratio

Sectional expansion index of extrudate (SEI)

As moisture content and blend ratio of feed increased (increasing protein content and decreasing starch), the SEI decreased (Table 2). Further, it was observed that when barrel temperature and screw speed increased, then SEI increased. This may be due to a reduction in viscosity, which resulted in less mechanical damage to starch, thus enabling dough to expand more and faster. As temperature increased, starch became more fully cooked and thus better able to expand (Balandran et al. 1998). This confirmed similar results reported by Köksel et al. (2004) and Ding et al. (2006).

The analysis of variance for Eq. 1 indicated non- significant lack of fit (Table 4), indicating adequate fit of data (Cochran and Cox 1957).

Table 4.

Analysis of variance for Eq. 3 (R2 = 0.8190)

| Source | Sum of square | df | Mean square | F-value | p-value prob>F | Remark |

|---|---|---|---|---|---|---|

| Model | 20.98 | 14 | 1.50 | 4.85 | 0.0022 | S |

| Lack of Fit | 4.63 | 10 | 0.46 | 965.03 | 0.2301 | NS |

| Error | 4.63 | 15 | 0.31 | |||

| Pure error | 0.0024 | 5 | 0.00048 | |||

| Total | 25.61 | 29 |

S Significant; NS non-significant at 5% level

The following model was developed:

|

2 |

where

- Y

is the sectional expansion index of extrudate.

Table 4 revealed that observed and predicted values are nearly the same, hence a second order model seems to be adequate to describe the effect of variables in the experimental zone. The test of significance of individual regression coefficients shows that only linear and square term of moisture content of feed have significantly contributed towards the SEI.

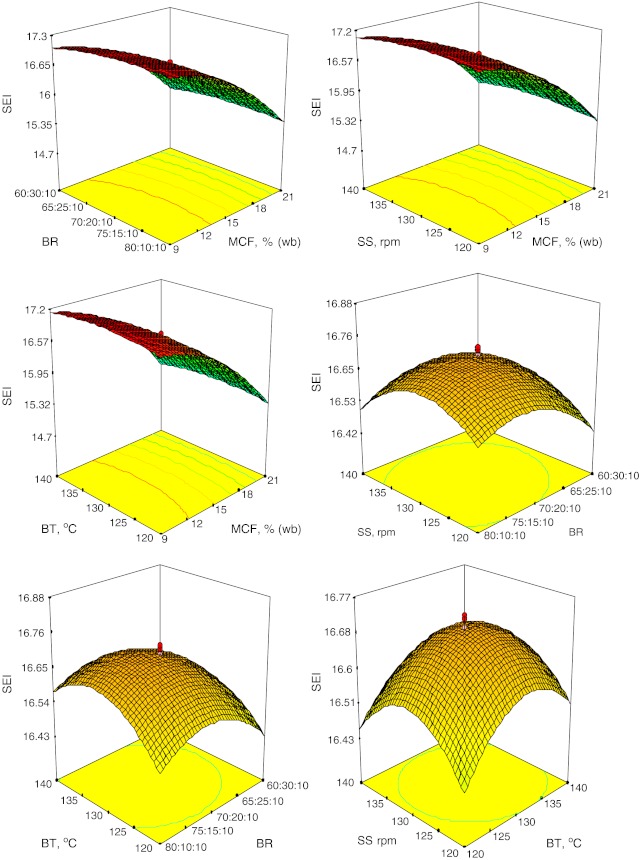

Effect of different parameters on SEI

Effect of different parameters on SEI is presented in Fig. 2. The variation of SEI with respect to blend ratio is curvilinear along the axis of moisture content of feed. It may be because the feed materials change their expansion behavior. The variation of SEI with respect to screw speed is also curvilinear along the axis of moisture content of feed. This may be because high moisture present in the feed. The variation of SEI with respect to barrel temperature is curvilinear as it is along the axis of moisture content of feed. It may be because the feed materials became hard due to higher moisture content of feed resulting in low puffing. The variation of SEI with respect to screw speed is curvilinear as along the axis of blend ratio. This may be due to change in molecular structure brought in by various blend ratios. The variation of SEI with respect to barrel temperature is curvilinear along the axis of blend ratio. It may be because the feed materials became hard due to denaturation of protein with increasing blending ratio (increasing protein content and decreasing starch). Heat and shear induce denaturation of proteins, which unravel and are subjected to cross-linking reactions. The result is the formation of a new molecular aggregate structure (De Clindio et al. 2002).

Fig. 2.

Effect of different parameters on sectional expansion index of extrudate (SEI). MCF: Moisture Content, BT: Barrel Temperature, SS: Screw Speed, BR: Blend Ratio

The variation of SEI with respect to screw speed is curvilinear along the axis of barrel temperature. It may be because the feed materials became hard due to denaturation of increasing protein and decreasing starch d due to gelatinization of starch at higher barrel temperature. Heat and shear induce denaturation of proteins, which unravel and are subjected to cross-linking reactions. The result is the formation of a new molecular aggregate structure (De Clindio et al. 2002).

Longitudinal expansion index (LEI)

As moisture content and blend ratio of feed increased the LEI decreased (Table 2). Further it was observed that when barrel temperature and screw speed increased then LEI increased. This may be due to a reduction in viscosity, which resulted in less mechanical damage to starch, thus enabling dough to expand more and faster. As temperature increased, starch became more fully cooked and thus better able to expand (Balandran et al. 1998). This confirmed similar results reported by Christofides et al. (2004), Köksel et al. (2004) and Ding et al. (2006).

The analysis of variance for Eq. 1 indicated non- significant lack of fit (Table 5), indicating adequate fit of data (Cochran and Cox 1957).

Table 5.

Analysis of variance for Eq. 4 (R2 = 0.9448)

| Source | Sum of square | df | Mean square | F-value | p-value prob>F | Remark |

|---|---|---|---|---|---|---|

| Model | 6.459 × 10−3 | 14 | 4.614 × 10−4 | 18.35 | 0.0001 | S |

| Lack of Fit | 3.302 × 10−4 | 10 | 3.302 × 10−5 | 3.53 | 0.0884 | NS |

| Error | 3.771 × 10−4 | 15 | 2.514 × 10−5 | |||

| Pure error | 0.006836 | 5 | 0.000009367 | |||

| Total | 0.006836 | 29 |

S Significant; NS non-significant at 5% level

The following model was developed:

|

3 |

where

- Y

is the longitudinal expansion index.

Table 5 reveals that observed and predicted values are nearly the same; hence a second order model seems to be adequate to describe the effect of variables in the experimental zone. The test of significance of individual regression coefficients shows that linear terms of moisture content and blend ratio of feed and square term of feed have significantly contributed towards the moisture content of extrudate.

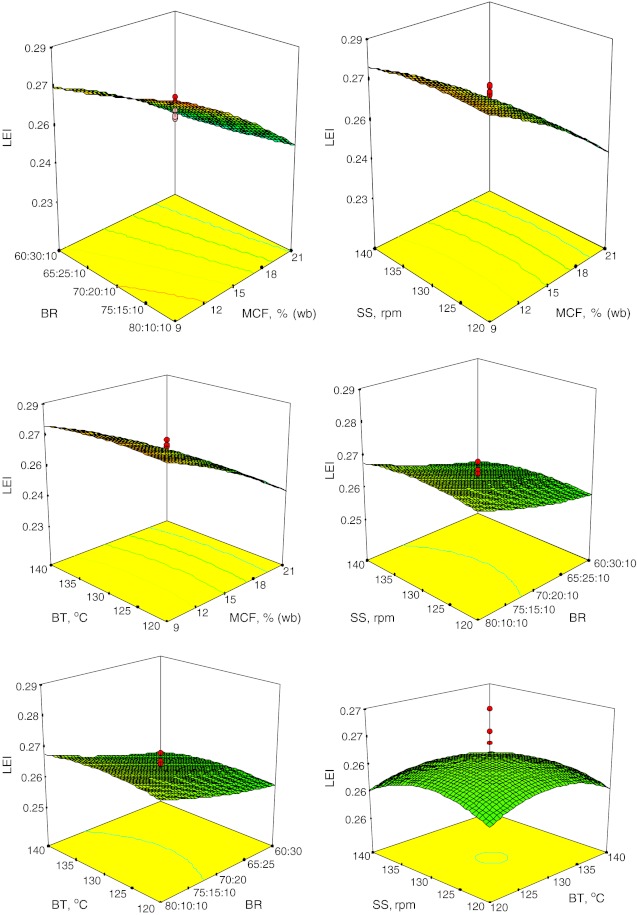

Effect of different parameters on LEI

Effect of different parameters on LEI is presented in Fig. 3. The variation of LEI with respect to blend ratio is curvilinear along the axis of moisture content of feed. It may be because the feed materials became hard due to higher moisture content of feed resulting in low puffing. The variation of LEI with respect to screw speed is also curvilinear along the axis of moisture content of feed. The variation of LEI with respect to barrel temperature is also curvilinear along the axis of moisture content of feed. It may be because the fed material became hard due to higher change in moisture content resulting in poor puffing due to poor gelatinization of starch. The variation of LEI with respect to screw speed is straight line along the axis of blend ratio. The variation of LEI with respect to barrel temperature and blend ratio is a straight line. It may be because the feed materials became hard due to denaturation of protein with increasing blending ratio (increasing protein content and decreasing starch) and temperature resulting in poor puffing. Heat and shear induce denaturation of proteins, which unravel and are subjected to cross –linking reactions. The result is the formation of a new molecular aggregate structure (De Clindio et al. 2002). The variation of LEI with respect to screw speed is curvilinear along the axis of barrel temperature. It may be because the feed materials became hard due to denaturation of increasing protein and decreased due to gelatinization of starch at higher barrel temperature. Heat and shear induce denaturation of proteins, which unravel and are subjected to cross-linking reactions. The result is the formation of a new molecular aggregate structure (De Clindio et al. 2002)

Fig. 3.

Effect of different parameters on longitudinal expansion index of extrudate (LEI). MCF: Moisture Content, BT: Barrel Temperature, SS: Screw Speed, BR: Blend Ratio

Conclusion

The BDE varied from 0.127 to 0.287 g/cm3. It increased with increasing in moisture content, blend ratio of feed and screw speed, while when barrel temperature increased gradually, the BDE decreased. Minimum value of BDE was observed at 12% (wb) moisture content of feed, 75:15:10 of blend ratio, 135 rpm of screw speed and 135 °C barrel temperature. The SEI and LEI varied from 14.78 to 16.88 and 0.235 to 0.292, respectively. As moisture content and blend ratio of feed increased, the SEI and LEI decreased, while when barrel temperature and screw speed increased the SEI and LEI increased. Maximum values of SEI and LEI were observed at 15%(wb) moisture content, 80:10:10 blend ratio, 130 rpm of screw speed and barrel temperature of 130 °C.

References

- Anderson RA, Conway HF, Pfeifer VF, Griffin EL., Jr Gelatinization of corn grits by roll and extrusion cooking. Cereal Sci Today. 1969;14(4–7):11–12. [Google Scholar]

- Balandran RR, Barbosa JJ, Zazueta JJ, Anzaldua A, Quinterro A. Fuctional and nutritional properties of extruded of whole pinto bean meal (Phaseolus Vulgaris L.) J Food Sci. 1998;63(1):113–116. doi: 10.1111/j.1365-2621.1998.tb15688.x. [DOI] [Google Scholar]

- Christofides V, Ainsworth P, Ibanoglu S, Gomes F. Physical evaluation of a maize-based extrude snack with cury powder. Nahrung/Food. 2004;48(1):61–64. doi: 10.1002/food.200300388. [DOI] [PubMed] [Google Scholar]

- Cochran WG, Cox GM (1957) A text book of experimental designs. John Wiley & Sons. Inc, pp 335–375

- De Clindio B, Gabriele D, Pollini CM, Peressini D, Sensidoni A. Filled snack production by extrusion-cooking: rheological modelling of the process. J Food Eng. 2002;52:67–74. doi: 10.1016/S0260-8774(01)00087-5. [DOI] [Google Scholar]

- Ding Q-B, Ainsworth P, Plunkett A, Tucker G, Marson H. The effect of extrusion conditions on the functional and physical properties of wheat-based expanded snacks. J Food Eng. 2006;73(2):142–148. doi: 10.1016/j.jfoodeng.2005.01.013. [DOI] [Google Scholar]

- Harper JM. Extrusion of foods. Boca Raton: CRC Press Inc; 1981. p. 212. [Google Scholar]

- Jambunathan R, Singh U, Subramanian V. Grain quality of sorghum, pearl mollet, pigeon pea, and chick pea. J Food Sci Technol. 1986;38:231–238. [Google Scholar]

- Köksel H, Ryu GH, Basman A, Demiralp H, Ng PKW. Effects of extrusion variables on the properties of waxy hulless barley extrudates. Nahrung/Food. 2004;48(1):19–24. doi: 10.1002/food.200300324. [DOI] [PubMed] [Google Scholar]

- Moreyra R, Peleg M. Effect of equilibrium water activity on the bulk properties of selected food powders. J Food Sci. 1981;46(6):1918–1922. doi: 10.1111/j.1365-2621.1981.tb04519.x. [DOI] [Google Scholar]