Abstract

Freshly harvested mushrooms are highly perishable because of high moisture content metabolism and susceptible to enzymatic browning. Mushroom is a fungal fruiting body which is cultivated throughout the world. Effect on quality of dried mushrooms was studied for various chemical pretreatments viz. 1.0% potassium metabisulphite, 0.5% citric acid, 0.5% potassium metabisulphite + 0.2% citric acid, control and low cost drying methods viz. domestic solar dryer, medium size solar dryer and open sun drying. It was observed that application of 1% potassium metabisulphite treatment prior to drying using medium size solar dryer gave best quality dried mushrooms with results in accordance with statistical analysis. The drying time and final moisture content was also comparatively less than the mushrooms dried under shading plates and open sun drying.

Keywords: White button mushroom, Pretreatments, Solar drying, Sun drying, Quality

Introduction

Mushroom is a fungal fruiting body, which produces and disseminates spores. Many mushrooms have cap and a large number of mushroom species grow wild and are deadly poisonous (Parkash et al. 1986; Khader 1999). Mushrooms can be grown on substrate based on various agricultural wastes which in turn can be recycled. Mushroom farming is practiced in more than 100 countries. Production of mushroom has already crossed 5 million metric tones annually in the world and is expected to reach 7 million metric tones in the next 10 years. Large scale white button mushroom production is centered in Europe, North America, and South East Asia. Total mushroom production in India is 50,000 tonnes with 85% of this production being of white button mushrooms (Anon. 2010). Although, many species of mushrooms are edible, very few are being cultivated commercially and the most popular are white button mushroom (Agaricus bisporus), paddy straw mushroom (Volvariella spp.), Oyster mushroom (Pleurotus spp.) and Shiitake (Lentinus edodes). In India, white button mushroom, paddy straw mushroom and oyster mushroom are cultivated in different parts of the country, depending upon the suitability of region and season as these varieties need different temperature ranges for growing (Khader and Pandya 1981). White button mushroom is cultivated throughout the world and contributes about 35–45% of total world production of mushroom. The white button mushroom is more acceptable to the consumer and fetches higher prices. For its successful and profitable cultivation, careful attention must be paid to four aspects. i.e. good compost, pure and productive spawn, proper environmental conditions and good hygiene of the farm. Mushroom continues to grow even after removing from the beds. It is known for its high yield and quality. Harvesting for processing has to be done at proper stage only when it reaches its peak of perfection with regard to appearance, weight and quality just before the cap opens to expose gills.

Mushroom is the most priced commodity among vegetables not because of its nutritive value but because of its characteristic aroma and flavor. However, it is now a well established fact that mushrooms are excellent sources of vitamins and minerals (Khader 1999). Fresh mushrooms contain about 85–95% moisture content, 3% protein, 4% carbohydrate, 0.3–0.4% fat and 1% minerals and vitamins. They also contain appreciable amount of niacin, pantothenic acid and biotin. In addition mushroom also contain folic acid and vitamin B12 which are absent in most of the vegetables.

Mushroom may be baked, fried, boiled, creamed, roasted, pickled and stuffed. In India, it is mostly consumed fresh and a negligible amount is used for processing. However, where mushrooms can be grown at ambient temperature (i.e. hilly areas) but cannot be transported quickly to consumption places (i.e. big cities in plains) the only way to its utilization is its processing. They can be processed as canned, dried and frozen mushrooms. The vitamins in mushroom are well retained during cooking, canning and dehydration. The moisture content in dried mushrooms should be between 5 and 8%. The dried mushrooms are packed in hermetically sealed air tight tins for quality retention and stored at a cool dry place. Processed products can then be sent easily to all parts of the country for consumption. Mushroom ketchup and soup are other important products. Increased production at the least cost might include mushroom growers particularly those from remote hilly areas to adopt mushroom processing. For establishment of mushroom farm one must take into consideration the availability of adequate raw material in the area and good local market for fresh mushrooms as they are perishable and cannot withstand transportation over long distances, other-wise one should have canning or preservation facilities (Kapoor 1989).

Drying of mushrooms is done to remove free water to such a level such that the biochemical and microbial activity are checked due to reduced water activity. Freeze drying yields excellent quality mushrooms but, the cost of removal of water is 10 times higher than the conventional air-drying. Lidhoo and Agrawal (2006) dried white button mushroom in a hot air oven and observed that minimum browning index was recorded at 65 °C and rehydration ratio obtained at this temperature was 2.9. Shivhare et al. (2004) found the EMC values for Agaricus bisporus as 9.50, 8.19, 7.00, 5.89 and 4.50 (g/100 g dry matter) at temperatures 30, 40, 50, 60, 70 °C respectively. Sun drying is suitable for tropical and sub-tropical regions where plenty of sunshine is there. Farmers can used sun drying on farm without any sophisticated equipments, provided the climate is hot, relatively dry and free of rainfall. Solar energy is diffuse in nature and provides low-grade heat which is good for the drying at low temperature. Even the energy stored in the product itself will help in removing excess moisture during the period of no sunshine. The high capital cost of solar dryers can be compensated if the dryer is used for drying other products also. Suguna et al. (1995) conducted the studies on dehydration of mushroom by sun drying, thin layer drying, fluidized bed drying and solar bed drying. Trials with natural convection solar cabinet dryer showed a drying time of 7 h, when the ambient temperature varied between 29 and 32 °C. Kaur et al. (2006) studied the effect of different pretreatments and drying methods on the quality of dried coriander. The best pretreatment was found to be dipping for 15 min in solution of 0.1% Magnesium chloride, 0.1% Sodium bicarbonate and 2.0% KMS in water at room temperature and the best method was drying in mini multi rack solar dryer.

If a little technology and money is applied then solar energy can be a possible solution for the dehydration of food. Experiments conducted in many countries have clearly shown that solar dryers can be effectively used for drying food. Solar drying system must be properly designed in order to meet particular drying requirement of specific crop. Keeping in view all the aspects, a study was planned and this paper discusses the effect of various pretreatments on solar drying of mushrooms and to study the drying characteristics of mushrooms using different solar dryers and open sun drying method.

Materials and methods

The white button mushrooms (Agaricus bisporus) were procured from Mushroom Research Farm, Punjab Agricultural University, India. These mushrooms were washed, trimmed, and cut into slices of thickness about 1 cm. Initially mushrooms were pretreated using different chemical pretreatments (T1: 1.0% potassium metabisulphite, T2: 0.5% citric acid and T3: 0.5% potassium metabisulphite + 0.2% citric acid) for 15 min as well as control (samples without pretreatment) were dried using medium size dryer to select the suitable pretreatments. The selected pretreatments were then used in different solar dryers viz. domestic solar dryer and medium size solar dryer and open sun drying, to select the best drying method. The domestic solar dryer was of natural circulation, integral type. There were three trays with shading covers to cover the produce from direct sun light. The shading plates got heat from sun and transfer this heat to the produce and provides shade and it allows air to pass through it. It has been designed in such a way that air enters from the bottom and passes through all the trays. The material used for its construction was mainly window glass (4 mm thick), mild steel sheet and angle iron. The top layer of the dryer was designed in such a way that the rain water does not enter the dryer. The medium size dryer was of natural circulation, integral, open solar drying type. Main difference being that there was no covering of the produce from direct sunlight. It had five perforated trays arranged at five different levels. The trays were designed in such a way so that after loading the material, there was no heat loss in the form of air leakage and could easily put in or draw out from the dryer. The sun drying of mushrooms was done on different polythene sheets viz. black polythene sheet (0.12 mm thick), transparent polythene sheet (0.07 mm thick). The best combination of pretreatment and drying method was selected. The samples were prepared depending upon the type of drying and type of dryer. The samples taken for sun drying on black polythene sheet and transparent polythene sheet were 0.5 kg. The samples for solar dryers i.e. domestic solar dryer and medium size dryer were taken depending upon the size and the capacity of trays. The samples were fed into the dryers and kept out for solar drying. After every 1 h, the decrease in weight of each sample was recorded and at the same time the internal temperatures of solar dryers, ambient air temperatures, dry and wet bulb temperatures, and incident solar intensity readings were also recorded till the weights become constant. After the equilibrium moisture content of mushrooms, the final moisture content was determined with the help of oven method. Mercury thermometers were used to measure the inside temperature of the dryers and the ambient air temperature. To find the relative humidity of the air, the dry and wet bulb thermometers were used. These readings were taken after every 1 h to see the change in relative humidity. Surya mapi (Make: Central Electronic Cell, range 0–1 kW) was used to measure the intensity of solar radiation incident on the surface of the dryer. Colour was determined using colorimeter (Make: Hunter Lab Model: Miniscan XE Plus). ΔE is total colour difference derived from L, a and b values obtained from colorimeter using the formula

|

The data collected from the solar drying and sun drying was used to calculate final moisture content (FMC) [% db], drying time (DT) [h], drying rate (DR) [% db/h], rehydration ratio (RR) and coefficient of rehydration (COR). The moisture content before or after the drying was calculated by standard oven method (AOAC 2000). The rehydration characteristics were calculated as per Ranganna (1986). The data observed from various experiments was analyzed in terms of effect of different methods and pretreatments on the quality of dried mushrooms. The statistical analysis of the data was done by employing univariate analysis of variance (UNI-ANOVA) in general linear model using SPSS- 7.5.

Results and discussion

Selection of pretreatments

For selecting the treatments, drying experiments were performed using chemical pretreatments T1, T2, T3 and control (no chemical treatment). The average values of properties of mushrooms dried in medium size dryer using different pretreatments are shown in Table 1. Initial moisture content of fresh mushroom samples was 900% (d.b) and initial colorimeter readings were: L = 57.41; a = 3.68; b = 15.54. The perusal of Table 1 showed that the final moisture content in T3 was maximum and the L-value of T3, which represents the whiteness was less than even the L-value of samples without pretreatment. The values of rehydration ratio and coefficient of rehydration in T3 were also minimum as compared to the other pretreatments.

Table 1.

Effect of different chemical pretreatments on the properties of dried mushrooms in medium size dryer

| Parameters | T1 | T2 | T3 | Control |

|---|---|---|---|---|

| Drying time (h) | 13 | 14 | 14 | 13.5 |

| Final moisture content (% db) | 5.45 | 5.83 | 6.67 | 6.54 |

| Colorimeter readings | L = 43.5 | L = 40.1 | L = 37.7 | L = 41.4 |

| a = 4.2 | a = 4.6 | a = 4.4 | a = 4.3 | |

| b = 11.3 | b = 11.7 | b = 11.2 | b = 11.2 | |

| Rehydration ratio | 2.92 | 2.38 | 2.27 | 2.58 |

| Coefficient of rehydration | 0.29 | 0.24 | 0.22 | 0.26 |

T1: 1.0% potassium metabisulphite, T2: 0.5% citric acid and T3: 0.5% potassium metabisulphite + 0.2% citric acid) for 15 min and control (samples without pretreatment)

Pairwise comparison of pretreatment Table 2 showed that the difference with respect to COR, RR, ΔE and Final moisture content was non significant at 5% level between pretreatments Control-T1, Control-T2, Control-T3 and T2–T3. But pretreatments T1–T2 differ significant at 5% level with respect to COR, which suggested that pretreatment T1 is better than pretreatment T2. Now, the difference between pretreatments T1–T3 was significant at 5% level with respect to COR, RR and ΔE. The mean difference values suggested that pretreatment T1 was better than T3 with respect to COR, RR and ΔE.

Table 2.

Pairwise comparison of different pretreatments using statistical analysis

| Pretreatments | C.O.R. (C.D. = 0.0520) | R.R. (C.D. = 0.5414) | ΔE (C.D. = 3.9280) | Final moisture content (C.D. = 2.0949) | |

|---|---|---|---|---|---|

| I | J | Mean difference (I-J) | Mean difference (I-J) | Mean difference (I-J) | Mean difference (I-J) |

| Control^ | T1^ | −0.0314 | −0.3250 | 1.9540 | 0.8900 |

| Control^ | T2^ | 0.0248 | 0.2020 | −1.1815 | 1.5200 |

| Control^ | T3^ | 0.0321 | 0.3170 | −3.5335 | 0.8700 |

| T1^ | T2^ | 0.0562* | 0.5270 | −3.1355 | 0.6300 |

| T1^ | T3^ | 0.0634* | 0.6420* | −5.4875* | −0.0200 |

| T2^ | T3^ | 0.0072 | 0.1150 | −2.3520 | −0.6500 |

^Refer Table 1

* Indicates significant at 5% level of significance

It is clear from the experimental data and statistical analysis that the quality of the samples treated with T3 was even poor than the samples without pretreatment, so the pretreatment T3 was rejected. The samples with pretreatment T1, T2 yielded similar results, so these pretreatments were used for further study.

Properties of mushrooms using selected pretreatments in different dryers

The selected pretreatments were used to dry the mushrooms in domestic dryer, medium size dryer and open sun drying with black polythene sheet and transparent polythene sheet. The results of the drying of mushrooms using selected pretreatments in different dryers are discussed in Table 3.

Table 3.

Properties of dried mushrooms using selected pretreatments and different drying methods

| Parameters | Domestic solar dryer | Medium size solar dryer | Open sun drying | ||||||

|---|---|---|---|---|---|---|---|---|---|

| T1^ | T2^ | Control^ | T1^ | T2^ | Control^ | T1^ | T2^ | Control^ | |

| DT (h) | 13 | 13 | 12 | 13 | 14 | 14 | 19 | 19 | 20 |

| FMC (% d.b) | 7.72 | 9.34 | 8.23 | 6.86 | 8.30 | 8.25 | 10.27 | 11.35 | 11.14 |

| Colour readings | L = 31.1 | L = 29.0 | L = 29.3 | L = 52.8 | L = 45.4 | L = 48.7 | L = 27.9 | L = 25.3 | L = 25.6 |

| a = 4.0 | a = 3.9 | a = 3.71 | a = 4.9 | a = 4.0 | a = 4.4 | a = 3.3 | a = 3.0 | a = 3.6 | |

| b = 7.9 | b = 7.6 | b = 7.51 | b = 15.1 | b = 11.2 | b = 11.6 | b = 4.0 | b = 3.8 | b = 3.4 | |

| RR | 2.39 | 2.11 | 2.20 | 2.98 | 2.02 | 2.56 | 2.43 | 2.23 | 2.26 |

| COR | 0.25 | 0.22 | 0.23 | 0.31 | 0.21 | 0.27 | 0.25 | 0.24 | 0.24 |

^Refer Table 1

A perusal of Table 3 indicates that in case of domestic solar dryer the samples treated with T1 gave the least final moisture content as compared to the samples treated with T2 and control. As the L-value of T1 was more than the T2 and control, the dried samples with T1 showed more whiteness. The RR and COR values were also maximum for T1 samples. The experimental data suggests that the sample treated with T1 gave best results in domestic dryer.

In case of medium size solar dryer the drying time of samples treated with T1 was least in case of T1, which indicates that the moisture was removed at a faster rate as compared to T2 and control. The values of RR, COR and L-values were also maximum in samples treated with T1. The experimental data suggests that the sample treated with T1 gave best results in medium size dryer.

The open sun drying was done on the black polythene sheet and transparent polythene sheet. The results were similar in both the cases, so the average values were taken and are shown in Table 3. The samples with pretreatment T1 gave more whiteness and lower final moisture content as compared to the others pretreatments. The RR and COR values for samples dried with pretreatment T1 was maximum. The experimental data suggests that the sample treated with T1 gave best results in medium size dryer.

Drying behavior of mushrooms in different dryers

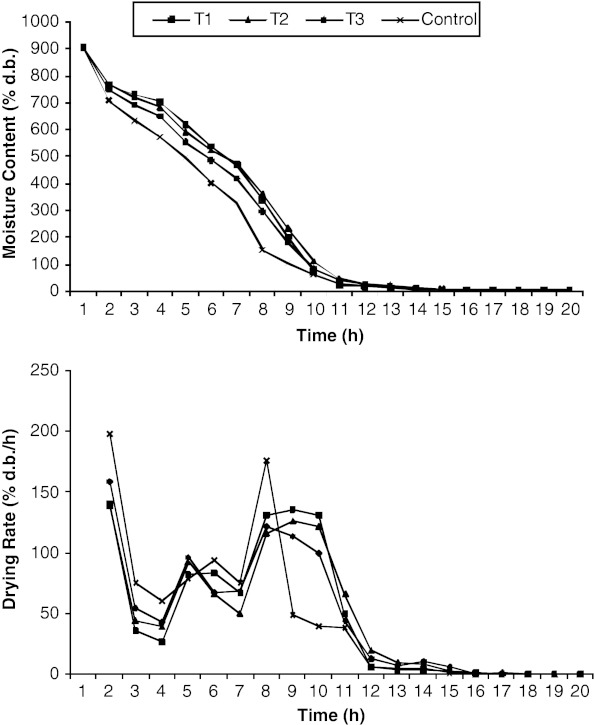

The observations taken during the drying of mushrooms were used to plot the drying curves. The drying curves for moisture content (% db) versus drying time (h) and drying rate (% db/h) versus drying time (h) for all drying techniques were plotted.

Relation between moisture content and drying time

The change in the moisture content of mushrooms with drying time for all drying techniques was studied. The moisture time relationship is non linear, the decrease in moisture is being larger initially as compared to the later part of the drying. Solar drying required 13 to 14 h drying time, whereas open sun drying required 19–20 h drying time. Lesser time for drying in solar dryers is due to the higher air temperature and less relative humidity inside the dryer. The drying curve for medium size dryer which was found to be best on the basis of quality of dried product produced is shown in Fig. 1.

Fig. 1.

Drying curves for medium size solar dryer

Relation between drying rate and drying time

The plots between drying rate vs drying time were made for different type of drying techniques. The drying occurred in falling rate period and constant rate period could not be observed for different drying methods. In open sun drying, there were more fluctuations because when the cloudy condition prevails, the surrounding atmosphere became cooler and the drying rate slows down rapidly. All the three pretreatments witnessed nearly same drying rate trend. Initailly the drying rate was in the range of 140–160 (% d.b./h) which came down to about 10–15 (% d.b./h) after 13 h for all the pretreated samples. In case of solar dryers the heat remain entrapped inside the dryer during the cloudy conditions which helps in removing the moisture at a subsequent rate and the drying rate does not slow down at high rate. The drying curve for medium size dryer is shown in Fig. 1.

Selection of drying method

Pairwise comparison of different drying methods and pretreatments was done statistically; data for mean differences for different quality parameters is shown in Table 4. Pairwise comparison of different drying methods shows that methods A–B differs significantly at 5% level with respect to ΔE and difference with respect to ΔE and final moisture content was significant at 5% level between the methods A–C and B–C. the values of mean difference at 5% level for methods A–B and B–C with respect to ΔE was much higher, which suggest that method B is significantly better than method A and method C. Pairwise comparison of different selected pretreatments shows that the difference was non significant at 5% level between pretreatment Control-T2. But, pretreatment Control-T1 differs significantly with respect to COR and pretreatment T1–T2 differs significantly with respect to COR, RR and ΔE. The values of mean difference at 5% level suggested that pretreatment T1 was significantly better than the Control and T2. So, it is clear from the above discussion that pretreating the produce with 1.0% potassium metabisulphite and drying using medium size solar dryer produced best quality dried mushrooms.

Table 4.

Pairwise comparison of different drying methods and selected pretreatments using statistical analysis

| Methods | C.O.R. (C.D. = 0.0406) | R.R. (C.D. = 0.3514) | ΔE (C.D. = 3.3400) | Final moisture content (C.D. = 1.5150) | |

|---|---|---|---|---|---|

| I | J | Mean difference (I-J) | Mean difference (I-J) | Mean difference (I-J) | Mean difference (I-J) |

| A | B | −0.0098 | −0.2487 | 19.6210* | 0.3620 |

| A | C | −0.0050 | −0.0887 | −5.1600* | −2.8200* |

| B | C | 0.0148 | 0.1600 | −24.7820* | −3.1820* |

| Treatments | |||||

| Control^ | T1^ | −0.04614* | −0.2628 | 2.4250 | 0.8700 |

| Control^ | T2^ | 0.02133 | 0.2072 | −1.1940 | −0.4080 |

| T1^ | T2^ | 0.06748* | 0.4692* | −3.6180* | −1.2780 |

A drying using domestic solar dryer; B drying using medium size solar dryer; C open sun drying

* Indicates significant at 5% level of significance

^Refer Table 1

Conclusions

From the study it may be concluded that solar drying took minimum effective time for drying followed by sun drying. The samples deteriorated by the insects and rodents in open sun drying. The drying rate was also very slow and final moisture content was above the recommended limit, so the open sun drying method was not suitable. The mushrooms sample dried in domestic dryer under shading plates gave poor quality parameters as compared to those which are dried under direct sunlight in medium size dryer. This implies that the shade drying of mushrooms is not recommended. It was statistically proved that the pretreatment with 0.5% potassium metabisulphite + 0.2% citric acid gave the poor results. The mushrooms dried in medium size dryer using pretreatment of 1.0% potassium metabisulphite gave the maximum values of L i.e. whiteness, rehydration ratio and coefficient of rehydration. The drying time and final moisture content was also comparatively less than the mushrooms dried under shading plates and open sun drying. Based on the results of the study and statistical analysis, it can be concluded that solar dryer particularly medium size dryer with samples treated with 1.0% potassium metabisulphite gave the best results and the shelf life of the mushrooms could be extended by the farmers’ at the farm without using any sophisticated equipments. In future a study can be formulated to see the effect of produce size (whole) and sliced crop in combination with various pretreatments for comparison of different economical dryers.

References

- Anonymous (2010) Button mushroom. www.nhb.gov.in accessed on 10.06.2010

- AOAC (2000) Official methods of analysis. Association of official analytical chemists. Washington D.C., USA.

- Kapoor JN (1989) Mushroom cultivation. Indian council of agricultural research, New Delhi. pp 5–11.

- Kaur P, Kumar A, Arora S, Ghuman BS. Quality of dried coriander leaves as affected by pretreatments and method of drying. Eur Fd Res Technol. 2006;223(2):189–194. doi: 10.1007/s00217-005-0164-1. [DOI] [Google Scholar]

- Khader V. Mushroom processing. Preservation of fruits and vegetables. New Delhi: Kalyani Publishers; 1999. pp. 124–129. [Google Scholar]

- Khader V, Pandya BN. Acceptability studies on weaning foods and a pickle prepared out of paddy straw mushroom (Volvariella volvacea) and the keeping quality of the same. Ind J Mush. 1981;7(1&2):31–36. [Google Scholar]

- Lidhoo CK, Agrawal YC. Hot-air over drying characteristics of button mushroom-safe drying temperature. Mush Res. 2006;15(1):59–62. [Google Scholar]

- Prakash TN, Tejaswini and Ramana R (1986) Mushroom a promising crop for future. SBM Farm News. pp 5–7.

- Ranganna S. Handbook analysis and quality control for fruits and vegetable products. New Delhi: Tata Mc.Graw Hill Publishing Co. Ltd; 1986. pp. 27–36. [Google Scholar]

- Shivhare US, Arora S, Ahmed J, Raghavan GSV. Moisture adsorption isotherms for mushroom. Lebensm Wiss U Technol. 2004;37:133–137. doi: 10.1016/S0023-6438(03)00135-X. [DOI] [Google Scholar]

- Suguna S, Usha M, Narayanan VV, Raghupathy R, Gothandapani L. Dehydration of mushroom by sun drying, thin layer drying, fluidized bed drying and solar cabinet drying. J Fd Sci Technol. 1995;34:284–288. [Google Scholar]