Abstract

Seaweed is a macroscopic marine algae which has been used as human food since ancient times. Food values of seaweed are mainly due to significant amounts of protein, vitamin, mineral, trace elements and dietary fibre apart from substances of antibiotic nature. In this study edible red seaweed Eucheuma (Kappaphycus alvarezzi), was used as an ingredient in the preparation of spice adjunct. Functional properties such as soluble solids, water-holding capacity, oil holding capacity and swelling capacity of Eucheuma were studied. Steamed Eucheuma powder was added at levels of 15, 20 and 25% in the preparation of spice adjunct. Sensory analysis and consumer acceptability study of spice adjunct showed that the incorporation of Eucheuma upto 20% had high acceptability. Spice adjunct containing 20% Eucheuma had 6.2% moisture, 22.2% ash, 29.2% fat, 10.0% protein, 9.4% crude fibre and 23% carbohydrates. Based on equilibrium relative humidity studies metallized polyester was selected as the packaging material. Storage studies indicated that metallized polyester provided a shelf life of 120 days at both the ambient and accelerated conditions.

Keywords: Seaweed, Eucheuma, Spice adjunct, Sensory, Sorption

Introduction

Marine algae have been consumed in Asia since ancient times (Chapman and Chapman 1980). Seaweeds are one of the important living marine resources. In India seaweeds are used to certain extent as food in coastal areas of Tamilnadu for making gruel (Chennubhotla et al. 1981, Krishnamurthy 2003.) Out of 844 species of marine algae enumerated along the Indian coast (Oza and Zaidi 2001) some of the species are utilized as raw material for manufacture of algae, algin and liquid seaweed fertilizer and some of the species have found their use in food, manure & pharmaceuticals. In India edible seaweed like ulva lactula (sea lettuce) and caulerpa peltala may be used in salads as curry leaves. Moreover, dried or fresh seaweed can be made into seaweed masala. These seaweeds (Red, brown or green) which are rich in trace elements, minerals and vitamins can be used in low calorie diet and as a source of gelling and thickening food additives (Agar, carrageenan and alginate) (Lahaye and Kaeffer 1997). Various bioactive materials of seaweed origin and their potential applications were studied by Bhaskar et al. (2008).

Eucheuma, red seaweed (Kappaphycus alvarezii) of the family Solieriaceae, also known in the trade as Eucheuma cottonii, accounts for the largest consumption worldwide, which is a good source of kappa-carrageenan, a major component of dietary fibre (De Ruiter and Rudolph 1997, Mc Hugh 1987). It serves as raw material, from which polysaccharide with gel forming properties of the carageenan type are extracted for use as stabilizers or the formation of emulsion in food industries (Mabeau and Fleurence 1993). Because of its high content of gum, it has restricted use in most of the food preparations. In India use of seaweed is very limited. In our earlier study incorporation of 7.5% of seaweed (Enteromorpha) in Indian traditional fried snack namely pakoda was carried out (Mamatha et al. 2007). The product was highly acceptable to the sensory panel. Eucheuma when incorporated to fish cutlet at 10% level did not cause any undesirable changes in the product characteristics (Senthil et al. 2005). Preliminary work on using Eucheuma in other traditional Indian foods was beset with the problem of textural changes particularly the mouthfeel. However, trials showed that the problem related to mouthfeel may be overcome by using Eucheuma in certain type of adjuncts that are mixed with cooked rice. In the present study effort has been made to formulate an adjunct in a concentrated form which can be readily mixed with cooked rice or that can be consumed with Indian traditional preparations like idli, chapathi, dosa etc. In this study, effect of using Eucheuma in the product its nutritional composition and sensory quality are assessed.

Materials and methods

Preparation of Eucheuma powder

Dried samples of Eucheuma (Kappaphycus alverezii) were supplied by Central Salt and Marine Chemicals Research Institute (CSMCRI), Bhavnagar, India. The samples were washed with water, dried in a cross flow drier at 60–65°C and ground in a plate mill to obtain the powdered material passing through 60 mesh (BS). Other minor ingredients such as rice, refined vegetable oil, red chilly, coriander seeds, cumin, fenugreek, asafoetida, gingelly etc. were procured from the local market of Mysore, India.

Functional properties of Eucheuma powder

Functional properties like water holding capacity, oil holding capacity, swelling capacity and soluble solids of Eucheuma powder were assessed in triplicates according to the procedures developed by Ruperez and Saura-Calixto (2001).

Proximate composition of Eucheuma powder and spice adjunct

Eucheuma powder and spice adjunct were analysed for moisture, fat and ash according to the AOAC (1984) methods. Micro-kjeldhal method was used to determine nitrogen contents of both Eucheuma powder and spice adjunct (AACC 2000) and the percentage of protein was calculated by using the 6.25 conversion factor. Crude fibre was determined as per BIS method (IS: 2639: 1984) and the carbohydrate content was calculated by difference. All the values were reported on dry weight basis.

Preparation of spice adjunct

Eucheuma powder and refined vegetable oil were used as major ingredients in the preparation of spice adjunct (15:30, 20:40, 25:45). All other spice ingredients namely cumin, fenugreek, asafoetida, gingelly seeds, jaggery, salt, dehydrated garlic, ginger, tamarind, curry leaves etc., were kept constant except some minor adjustment for red chilly and coriander seeds.

Eucheuma powder was steamed before using for preparation. Other processed spices were powdered and added to the mix and finally seasoned with refined oil to obtain spice adjunct.

Vitamin analysis

The fat and water soluble vitamin content of spice adjunct containing highest (25%) level of Eucheuma were estimated according to AOAC method (2000).

Product evaluation and product profile of spice adjunct

Eucheuma powder was added at 3 different levels of 15, 20 and 25% in the formulation of spice adjunct. The prepared adjunct was mixed with cooked rice at 12.5% level and served immediately for sensory analysis. Sensory evaluation of spice adjunct was done by ranking test and quantitative descriptive analysis method.

Ranking test

Preference ranking test (Meilgaard et al. 1999) was conducted to evaluate the spice adjunct by panelists who were familiarized with quality attributes of the product. The panelists were asked to rank the samples according to intensity (Low- High) rank I to the lowest intensity and rank II to the next higher and so on for texture and aroma. Preference ranking for overall quality was also done. The most preferred sample gets rank I and next best as rank II and so on.

Quantitative descriptive analysis (QDA)

Profiling of spice adjunct was conducted with the help of 20 trained sensory panelists using the method of QDA (Stone et al. 1974) to get the detailed description of various attributes that influence the product acceptability. Descriptors were developed during initial sessions. Panelists were asked to describe the samples with as many spontaneous descriptive terms as they found applicable. The common descriptors chosen by atleast one third of the panel were compiled along with some impact making descriptors for the preparation of scorecard. Descriptors chosen for sensory evaluation were brown, moistness, rice intactness, oilyness, gumminess, spicy, fish/algae like, pungent, bitter and overall quality. The panel consisted of judges who regularly participate in sensory analysis and having experience in profiling of food products. Evaluation was done by the method of intensity scaling using a score card consisting of 15 cm scale wherein 1.25 cm was anchored as low and 13.75 cm as high. The panel was asked to mark the intensity of the attribute by drawing a vertical line on the scale and writing the code. The panelists were also asked to indicate the overall quality of the product, on an intensity scale which was anchored at very poor, fair and very good to assess the liking or preference of spice adjunct.

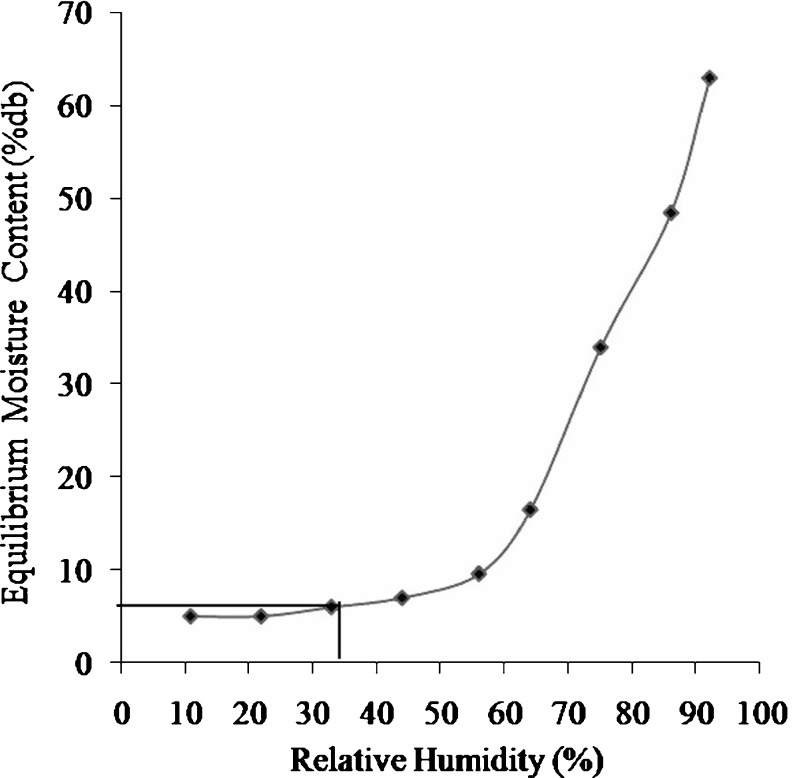

Sorption study

In order to ascertain the packaging material of spice adjunct mix, Equilibrium Relative Humidity studies (ERH) were carried out for the mix containing 20% Eucheuma at room temperature (25–27°C). The moisture content (MC) and RH relationship were studied by exposing known weights of samples to different Relative Humidities (RHs) ranging from 11 to 92% in built-in desiccators using appropriate saturated salt solutions at 27 ± 1°C (Lopez et al. 1995). Samples were weighed at regular intervals till the constant weight was attained or showed the signs of visible mold growth, whichever is earlier. The MC (%) of equilibrated samples was calculated from the weight loss/gain in the samples exposed. The initial moisture content (IMC) of the product was determined by drying a known weight of the sample in duplicate by Air oven method (AOAC 1995) until achieving constant weight.

Shelf life studies

Seventy five grams of the instant spice adjunct mix (20% level) was packed in metallized polyester pouches and stored under ambient (27°C, 65% RH) and accelerated conditions (92% RH and 38°C). In order to trace the changes in quality of the products during storage, samples were withdrawn periodically after 30, 90 and 120 days and seasoned with refined oil along with mustard, dhal and curry leaves. The prepared mix was mixed with cooked rice at 12.5% level and the product was subjected to sensory analysis by the method of Quantitative Descriptive Analysis (15 cm scale).

Free fatty acid and peroxide value

Chemical analysis was also carried out for the same instant mix packaged in Met/Polyester, stored under 2 different conditions. The initial and final FFA and PV were analysed according to the AOCS Method (1973).

Consumer acceptance study of spice adjunct

Consumer acceptance study was carried out among 50 trained and non trained panelists as target groups for the selected spice adjunct mix containing Eucheuma at 20% level by using 7 point hedonic scale to assess the degree of liking that ranged from ‘Like very much’ to ‘Dislike very much’ with Neither like Nor Dislike (NLND) as midpoint. The prepared adjunct was mixed with cooked rice at 10% (S1) and 12.5% (S2) level on the basis of weight of cooked rice and analysed sensorily. The data were analysed and expressed the number of responses as percentage.

Statistical analysis

Significant differences among the samples for ranking test were tested using Friedman’s test (O’Mahony 1986). The sensory scores obtained for all the attributes were analyzed using Duncan’s Multiple Range Test (Duncan 1955).

Microbiological examination

Microbiological examinations of the stored samples were carried out as per standard methods (American Public Health Association) (APHA 2001). Food homogenate of well-mixed samples were prepared using 0.1% peptone water. Serial dilutions were prepared and plating for total viable plate count, coliforms, yeast and molds was carried out. Presence/Absence of Salmonella was determined in 25 g sample by preliminary enrichment, followed by streaking on selective agar plates.

Results & discussion

Functional properties of Eucheuma powder

The functional properties of Eucheuma powder shows rather high values when compared to the similar studies made on different seaweeds (Wong and Cheung 2000, Ruperez and Saura- Calixto 2001). The high swelling capacity (27.80 ml/g) and water holding capacity (17.70 g/g) enable the Eucheuma powder to be used as a functional ingredient to reduce calories, avoid syneresis and modify the viscosity and texture of formulated food. Oil absorption capacity is another important property of food ingredients used is formulated food. In this study, the considerably high oil absorption capacity (2.14 ± 0.07 g/g) of Eucheuma powder suggested its ability to stabilize food emulsion. The soluble solids were found to be 27.50 + 0.02% which is reported to contain soluble dietary fibre (Darcy-Vrillon 1993).

Proximate composition of Eucheuma powder and spice adjunct

The proximate composition of Eucheuma powder and spice adjunct is presented in Table 1. As shown in the table, the ash and crude fibre contents of Eucheuma powder and spice adjunct were higher. In general several seaweed species are rich in ash and fibre (Lahaye et al. 1991). The moisture content of three different levels of spice adjunct (15, 20 and 25%) was in the range of 5.9–6.2%. However, in case of fat content the samples showed increasing trend for the three levels which could be due to the addition of fat in the preparation of products. It is also observed that as the level of incorporation of Eucheuma increased there is a relative increase in ash, protein and crude fibre content of spice adjunct. The high values obtained for these three parameters was attributed to the high ash (18.90%), protein (9.5%) and fibre (4.44%) content of Eucheuma powder which are the characteristics for the seaweed. The carbohydrate contents for all the three samples varied from 2.39 to 38.62%.

Table 1.

Proximate composition of Eucheuma powder and spice adjunct

| Eucheuma Powder (%) | Moisture (%) | Fat* (%) | Ash* (%) | Protein* (%) | Crude fibre* (%) | Carbohydrates (by difference) (%) |

|---|---|---|---|---|---|---|

| 100 | 10.0 ± 0.04 | 0.5 ± 0.08 | 18.9 ± 0.19 | 9.5 ± 0.14 | 4.4 ± 0.46 | 58.5 |

| Spice adjunct | ||||||

| 15 | 6.1 ± 0.18 | 21.9 ± 0.16 | 16.7 ± 0.03 | 8.5 ± 0.01 | 8.1 ± 0.24 | 38.6 |

| 20 | 6.2 ± 0.21 | 29.2 ± 0.21 | 22.2 ± 0.08 | 10.0 ± 0.03 | 9.4 ± 0.47 | 23.0 |

| 25 | 5.9 ± 0.12 | 37.1 ± 0.24 | 28.2 ± 0.05 | 13.2 ± 0.05 | 13.2 ± 0.51 | 2.4 |

*Values are on dry basis for fat, ash, protein and crude fibre

Results are mean ± SD for three determination

Carbohydrate content was calculated by difference (100—fat-ash-protein-crude fibre)

Vitamin content

The fat and water soluble vitamin content of spice adjunct containing highest level of Eucheuma. The product had high amount of vitamin E (72.96 mg/100 g) and small amounts of niacin, vitamin B2 (3.36, 0.68 mg/100 g) and lower amount of vitamin B1 and vitamin A (0.04 and 0.03 mg/100 g).

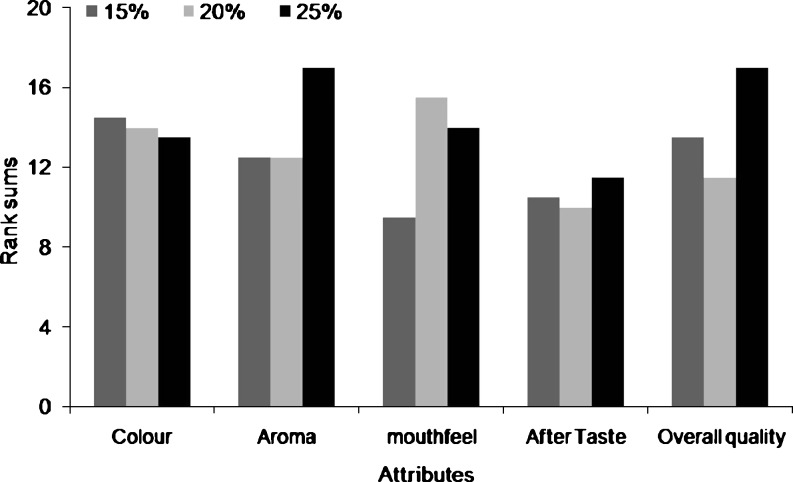

Ranking test

The results of total rank sums obtained for all the attributes were subjected to Friedman’s test showed that there was no significant difference between the samples for all the attributes viz colour, aroma, mouthfeel, after taste. Statistical analysis of data for overall quality (Fig. 1) (Preference ranking) revealed that the sample containing Eucheuma even at highest level (25%) was found to be acceptable. Results also showed that use of Eucheuma in spice adjunct up to 20% level did not contribute any undesirable flavour.

Fig. 1.

Ranksum scores for spice adjunct

Quantitative descriptive analysis (QDA)

The results of the QDA analysis (Table 2) showed that addition of Eucheuma powder did not cause any significant difference for most of the sensory attributes such as brown, moistness, gumminess, spicy, pungent, salt, sour etc. However, there was a slight increase in oiliness, and fish like aroma was perceptible particularly at higher level (25%) of addition. Overall quality for the two levels (15 and 20%) was high as shown by the mean scores. The studies revealed that in the preparation of spice adjunct, incorporation of Eucheuma upto 20% did not affect its sensory quality.

Table 2.

Mean scores for sensory attributes of spice adjunct

| Attributes | Eucheuma (%) | ||

|---|---|---|---|

| 15 | 20 | 25 | |

| Moistness | 6.5 ± 1.31a | 7.5 ± 1.32a | 6.3 ± 1.31a |

| Oilyness | 8.2 ± 2.40a | 8.3 ± 1.84a | 8.7 ± 1.33a |

| Gumminess | 5.0 ± 1.33a | 5.0 ± 1.36a | 5.9 ± 1.44a |

| Spicy | 8.3 ± 2.39a | 8.3 ± 1.22a | 8.4 ± 2.11a |

| Fish/Algae | 2.4 ± 1.19a | 2.8 ± 0.83ab | 4.9 ± 1.34a |

| Pungent | 5.7 ± 1.17a | 5.7 ± 1.43a | 6.0 ± 1.24a |

| Bitter | 1.3 ± 0.46a | 1.3 ± 0.47a | 1.7 ± 0.22a |

| Overall Quality | 9.8 ± 2.30a | 9.8 ± 1.23a | 8.0 ± 1.63a |

Mean values in the same row with different letters differ significantly at p ≤ 0.05 by DMRT

Results are mean values of duplicates

Sorption study

The product had an Initial Moisture Content (IMC) of 6.18% (dry wt) equilibrated to 33% RH. The results showed (Fig. 2) that the product equilibrating to RHs between 11 and 56% with a Moisture Content (MC) ranging from 4.9 to 9.6 were free flowing, good and comparable to the fresh sample. The product equilibrating to 64% RH with a MC of 16.5% was not free flowing, slightly lumpy. Hence, for the end use of the product, a MC of 9.6% equilibrating to 56% RH was considered to be critical with respect to the acceptability of the product. Semwal et al. (2001) has reported that the instant vegetable pulav mix equilibrated to 2.6, 5.9, 8.2 and 12.2% moisture at 0.0, 0.33, 0.53 and 0.73 aw, respectively. No microbial spoilage was observed and the product was most stable at 0.33 aw. Rapid increase in moisture content was observed at 75 to 92% RH and the corresponding MC were 34.0 to 63.0%. There was a visible mould growth in the product at 92% RH at the end of 35 days. From the moisture sorption studies it is evident that, at above 56% RH, the spice adjunct needs good moisture barrier packages. Hence, metallized polyester pouch (a good barrier to moisture and flavour) was selected for storage studies.

Fig. 2.

Sorption isotherm of spice adjunct

Shelf life study

The results indicated (Table 3) that moistness, rice intactness, oilyness and spicy and pungent aroma which exhibited greater impact on Overall Quality, did not show any significant change up to a storage period of 120 days under ambient and accelerated conditions, indicating that it has good shelf life stability. It was also observed that there was a colour change in the mix stored at accelerated condition after 30 days. But this change did not affect the sensory quality. The studies indicate that Met/Polyester package provides a shelf life of 120 days at both the conditions.

Table 3.

Sensory mean scores of stored spice adjunct added with 20% Eucheuma powder

| Attributes | Sensory mean scores | ||||||

|---|---|---|---|---|---|---|---|

| Initial | 30 days | 90 days | 120 days | ||||

| Amb | Acc | Amb | Acc | Amb | Acc | ||

| Moistness | 7.7 ± 1.22a | 7.6 ± 1.31a | 7.8 ± 1.32b | 6.4 ± 2.21 a | 6.5 ± 1.23a | 7.4 ± 2.14a | 7.0 ± 1.48a |

| Oiliness | 7.8 ± 2.11a | 6.7 ± 1.39b | 7.0 ± 1.14a | 6.8 ± 1.33b | 6.2 ± 2.49a | 7.8 ± 3.14a | 7.2 ± 2.42a |

| Gumminess | 5.3 ± 1.24a | 5.5 ± 1.22a | 5.4 ± 1.33b | 4.9 ± 2.46a | 4.8 ± 1.22a | 5.5 ± 1.36a | 6.0 ± 2.81b |

| Spicy | 7.5 ± 2.23a | 8.3 ± 1.51b | 7.9 ± 1.29a | 7.5 ± 1.10a | 7.1 ± 2.38a | 7.6 ± 2.58a | 7.6 ± 1.72a |

| Fish/algae | 5.2 ± 2.31b | 4.5 ± 1.92b | 4.9 ± 1.26b | 3.1 ± 1.41a | 3.3 ± 1.34a | 4.2 ± 1.24b | 4.0 ± 1.63b |

| Pungent | 5.9 ± 1.34b | 4.7 ± 2.41a | 4.8 ± 1.11a | 5.0 ± 2.55ab | 5.1 ± 2.21a | 4.2 ± 1.17a | 4.2 ± 1.23a |

| Bitter | 1.9 ± 1.21a | 2.0 ± 2.34a | 2.1 ± 2.29a | 1.8 ± 2.21a | 2.4 ± 1.21a | 2.0 ± 3.35a | 2.6 ± 1.73a |

| Overall quality | 9.3 ± 2.34a | 9.3 ± 1.42a | 8.2 ± 2.02a | 9.0 ± 2.12a | 8.6 ± 2.32a | 8.9 ± 3.06a | 8.2 ± 2.21a |

Mean values in the same row with different letters differ significantly at p ≤ 0.05 by DMRT

Amb- Ambient (27°C) Acc- Accelerated (38°C)

Free fatty acid and peroxide value analysis

Initial value of FFA and PV before storage was 0.30% oleic acid and 0.68 meq O2/Kg oil. A slight increase in FFA and PV was observed in both ambient (0.56% oleic acid and 0.75 meq O2/Kg oil) and accelerated samples (0.73 and 1.45 meq O2/Kg oil) stored for 120 days, but are within the permissible level. Hence, these findings indicate that the quality of spice adjunct stored upto 120 days was not significantly altered.

Consumer acceptance study

Consumer acceptance analysis indicated that majority of the population (100 and 94%) rated S1 and S2 under “Like” category” which showed that products were highly acceptable. The samples S1 and S2 represent spice adjunct levels of 10 and 12.5%, respectively mixed with 100 g of cooked rice each. These spice adjunct contained 20% of Eucheuma powder.

Microbiological examination

The aerobic mesophilic bacterial count (Log 10 cfu/g) at 30, 90 and 120 days was 5.94, 5.90 and 5.84, respectively at 38–40 °C (92% RH) and the count was 6.00, 5.90 and 5.90 Log 10 cfu/g, respectively at 25–27°C (65% RH). The count determined after 90 and 120 days of storage was also in that range, thus suggesting that the surviving microflora did not multiply in the sample. This could be attributed to the low water activity and the presence of anti-microbial substances in the spice mix. Coliforms, E.coli, yeasts and molds were not detected in any of the samples, suggesting that good manufacturing procedure were followed during the processing of the products.

Conclusion

Eucheuma powder can be used as an ingredient in the preparation of spice adjunct to enhance its nutritional quality. Addition of Eucheuma powder to spice adjunct showed marked increase in the ash, protein and crude fibre content. It also had high amount of Vitamin E and small amount of niacin and Vitamin B2. Sensory analysis of spice adjunct revealed that the incorporation of Eucheuma upto 20% did not affect its acceptability. Shelf life studies of instant mix showed greater impact on overall quality throughout the storage period at both the conditions.

Acknowledgements

The authors express heartfelt gratitude to Dr. V. Prakash, Director, Central Food Technological Research Institute (CFTRI) Mysore for providing necessary facilities to carry out the above work. Also authors gratefully acknowledge the department of Biotechnology, Govt of India for providing funds for the project.

References

- AACC (2000) American Association of Cereal Chemists. Approved method of AACC 2, method. 10th ed. St. Paul, Minnesota, USA, pp 46–13

- Official method of analysis. 14. Washington DC: Association of Official Analytical Chemists; 1984. [Google Scholar]

- Official method of analysis. 16. Washington: Association of official Analytical chemists; 1995. [Google Scholar]

- Official method of Analysis. 17. Maryland: Association of official Analytical chemists; 2000. [Google Scholar]

- Official and tentative methods of analysis, Vol.1. Ca- 5a-40, Cd-8-53. 3. Illinois: American oil chemists society; 1973. [Google Scholar]

- APHA (2001) American Public Health Association. Compendium of methods for the microbiological examination of foods. In Downes FP, Ito K (eds), 4th edn. Washington DC

- Bhaskar N, Kumar CS, Ganesan P, Suresh PV. Seaweeds as a source of nutritionally beneficial compounds—a review. J Food Sci Tech. 2008;45:1–13. [Google Scholar]

- Bureau of Indian standards IS: 2639, specification for papads. New Delhi: Appendix H; 1984. p. 11. [Google Scholar]

- Chapman VJ, Chapman DJ (1980) Sea veg (Algae as food for man), In: Seaweeds and their uses p (62–97), Chapman & Hall, London

- Chennubhotla VSK, Kaliaperumal N, Kalimuthu S. Seaweed recipes and other practical uses of seaweed.Seafood. Exp J. 1981;13:9–16. [Google Scholar]

- Darcy-Vrillon B. Nutritional aspects of the developing use of marine marcroalgae for the human food industry. Int J Food Sci Nutr. 1993;44:S23–S35. [Google Scholar]

- De Ruiter GA, Rudolph B. Carrageenan biotechnology. Trends Food Sci Technol. 1997;8:389–395. doi: 10.1016/S0924-2244(97)01091-1. [DOI] [Google Scholar]

- Duncan DB. Multiple range test and multiple F-tests. Biometrics. 1955;11:1–42. doi: 10.2307/3001478. [DOI] [Google Scholar]

- Krishnamurthy V (2003) Phycology-principles, process and applications. Amrik Sing Aluwalia (ed), Daya Publishing House, New Delhi, India

- Lahaye M, Kaeffer B. Seaweed dietary fibres: Structures, physico chemical and biological properties relevent to intestinal physiology. Sci des Aliments. 1997;17:563–584. [Google Scholar]

- Lahaye M, Fleury N, Barry JL, Michel C, Mabeau S (1991) Seaweed and dietary fibres. COST 48 subgroup III Workshop, 9–14, March 1991, Paimpol- St Malo

- Lopez A, Pique MT, Tasins J. The hygroscopic behavior of the hazelnut. J Food Eng. 1995;25:197–203. doi: 10.1016/0260-8774(94)00021-Z. [DOI] [Google Scholar]

- Mabeau S, Fleurence J. Seaweed in food products: boichemical and nutritional aspects. Trends Food Sci Technol. 1993;4:103–107. doi: 10.1016/0924-2244(93)90091-N. [DOI] [Google Scholar]

- Mamatha BS, Namitha KK, Senthil A, Smitha J, Ravishankar GA. Studies on use of Enteromorpha in snack food. Food chem. 2007;101:1701–1713. doi: 10.1016/j.foodchem.2006.04.032. [DOI] [Google Scholar]

- Mc Hugh DJ. Production and utilization of products from commercial seaweeds (FAO Fisheries Technical paper 288) Rome: Food and Agricultural organization of the United Nations; 1987. pp. 1–189. [Google Scholar]

- Meilgaard M, Civille GV, Carr BT. Sensory evaluation techniques. 3. Boca Raton: CRC; 1999. [Google Scholar]

- O’Mahony M. Sensory evaluation of food, statistical method of procedures. New York: Marcel Dekker; 1986. [Google Scholar]

- Oza RM, Zaidi SH. A revised checklist of Indian Marine Algae. Bhavnagar: CSMCRI; 2001. p. 296. [Google Scholar]

- Ruperez P, Saura-Calixto F. Dietary fibre and physicochemical properties of edible Spanish seaweeds. Eur Food Res Tech. 2001;212:349–354. doi: 10.1007/s002170000264. [DOI] [Google Scholar]

- Semwal AD, Sharma GK, Patki PE, Padmashree A, Arya SS. J Food Sci Technol. 2001;3:231–234. [Google Scholar]

- Senthil A, Mamatha BS, Mahadevaswamy M. Effect of using seaweed (Eucheuma) powder on the quality of fish cutlet. Int J Food Sci Nut. 2005;56(5):327–335. doi: 10.1080/09637480500224205. [DOI] [PubMed] [Google Scholar]

- Stone H, Sidle J, Oliver S, Woolsey A, Singleton RC. Sensory evaluation by quantitative descriptive analysis. Food Technol. 1974;28(11):24–34. [Google Scholar]

- Wong KH, Cheung PCK. Nutritional evaluation of some subtropical red and green seaweeds Part 1- Proximate composition, amino acid profiles and some physico chemical properties. Food Chem. 2000;71:475–478. doi: 10.1016/S0308-8146(00)00175-8. [DOI] [Google Scholar]