Abstract

Portable and manually operated chapati press cum vermicelli extruder device was designed and fabricated for the preparation of chapatis and vermicelli. Sensory evaluation overall quality scores of 50.15 and 48.4 for pressed chapatis and rolled chapatis respectively showed that quality of chapatis was not adversely affected as a result of mechanical pressing. The difference in chapati making time by manual rolling and machine pressing was 17 s per chapati and was statistically significant (p < 0.05). Combined machine produced more numbers of chapatis as machine press time per chapati was 12 s compared to 29 s of manual sheeting time. The observed variation in 1.5 mm thickness and 173.8 mm diameter from chapati to chapati was of the order of ± 0.1 mm and 1.93 mm respectively. Pressed chapati repeatability results indicated that there was no significant difference in diameters of the samples. Appearance quality characteristics scores of 8 and 7 for 2 mm and 3 mm diameter vermicelli respectively indicated smooth and uniform surface characteristics. Sensory evaluation of the cooked vermicelli indicated no significant difference (p > 0.05) between 2 mm and 3 mm diameter vermicelli. Cooked weight (72.8 g) and water absorption (191.2%) of 2 mm diameter vermicelli was more compared to 3 mm diameter vermicelli (51.75 g, 107%). This machine can also be used as a laboratory model as products of consistent thickness and diameter were obtained.

Keywords: Wheat, Chapati, Press, Extruder, Vermicelli

Introduction

Wheat is the basic raw material for the preparation of chapati, bread, biscuit and pasta etc., Chapati, a baked product prepared from whole wheat flour is the staple food of a majority of the population in many regions of the Indian subcontinent (Venkateswara Rao et al. 1986). It is prepared by mixing whole wheat flour and water as described by Shurpalekar and Prabhavathi (1976), followed by sheeting the dough to about 1.5 mm thickness and cutting it into 150 mm diameter discs. The discs are baked on a hot plate at 200–210°C for 1–2 min and puffed over a live flame or coal fire for few seconds. Chapatis are generally prepared manually and served hot (Sridhar and Manohar 2001). Increasing demand for ready to eat and easy to carry foods vested in mechanizing chapati for marketing in unit packs. Flattening and sheeting of the dough is one of the most crucial steps in flat bread production and small variations in thickness changes bread quality significantly (Rubenthaler and Faridi 1981). Flattening of dough is done by pressing / rolling or sheeting methods. In sheeting method, dough pieces or extruded dough is repeatedly passed under pressing rollers to form flat dough of required thickness (www.thebiscuitdoctor.com). Dough pieces are first rolled into flat oval shapes and then turned over for second rolling, which forms the oval shapes into round discs of desired thickness. In sheeting and die cut method, sheeted dough of desired thickness is passed under a rotary die and cut to get desired shapes. In pressing (stamping) method dough pieces are transferred to flat pans and hydraulic ram descends on the dough pieces and presses the dough (Qarooni 1996). Stickiness of the dough, non-uniformity in the thickness and quality are some of the drawbacks of few commercial machines, which can be avoided by mechanical extrusion (Sridhar 1991). Vermicelli, spaghetti and noodles, known as pasta products, have become major products of the cereal food industry. Pasta products are popular on account of their sensory appeal, low cost, ease of preparation, storage stability and increased consumer interest in ethnic foods (Prabhasankar et al. 2007). Vermicelli is made using refined wheat flour or semolina milled out of durum wheat varieties (Vetrimani et al. 2005). Changing lifestyles and greater awareness about health have made vermicelli very popular and considered as an item of mass consumption. Sourrav Kumar et al. 2009, Ghufran Saeed et al. 2009 have studied rheological properties of wheat flour and dough. Seema midha and Renu mogra 2007 have studied quality evaluation of vermicelli. Several studies have been reported on the technological aspects of chapati and vermicelli processing, but very little information is available on mechanization of processing. Commercially available machines produce either chapatis or vermicelli but none in combination. Considering the advantages of dough pressing and extrusion methods, an attempt was made to develop a combined machine. The objective of this work was to develop a portable, manually operated chapati press cum vermicelli extruder to produce both chapatis and vermicelli.

Materials and methods

Whole wheat flour

Commercial whole wheat flour from Pillsbury with proximate composition of protein 12.6 g/100 g, fat 1.9 g/100 g, carbohydrate 74 g, dietryfibre 12 g, moisture 8.1% and ash 1.2% was procured from local market to produce chapatis and vermicelli

Design consideration

Formulae used for designing chapati press cum vermicelli extruder machine were taken from ‘Mechanical engineers design data hand book’ (Mahadevan and Balaveera Reddy 1996). Force analysis was carried out by considering applied load (P) of 10 kg (Shurpalekar and Prabhavathi 1976) acting at a distance (L) of 115 mm from the screw centerline. Applied torque was calculated using the Eq. (1)

|

1 |

Square threaded rod was designed by considering frictional torque at mean radius (Tn) and frictional torque of the collar (Tc). Assumed Tn as 80% of Ta and Tc as 20% of Ta. Normal series square single start thread with major diameter of 22 mm, minor diameter of 17 mm and pitch of 5 mm (Sq 22x5-IS:4694-1968) was considered. Thread helix angle (α) was determined by Eq. (2)

|

2 |

Maximum load (W) up to which the proposed machine can withstand was calculated by Eq. (3)

|

3 |

Major and minor principal stresses are direct stresses acting on mutually perpendicular planes. Major principal stress, minor principal stress and allowable stress for the mild steel material were 0.354 kg/mm2, 2.67 kg/mm2, 8.26 kg/mm2 respectively. Since major & minor principal stresses were less than allowable stress, design is safe.

Supporting rods diameter was calculated by Eq. (4)

|

4 |

For practical application supporting rod diameter was considered as 10 mm

Thickness of the plate was calculated by Eq. (5)

|

5 |

diameter of the handle was calculated by using Eq. (6)

|

6 |

10 mm diameter of the handle was obtained by solving Eq. (6)

Extrusion force required for designing of extruder socket was calculated by using Eq. (7) (Ugheoke 2006)

|

7 |

Equation (7) when evaluated for dough with yield stress σy = 0.001 kg/mm2 (Trevor et al. 2006), flow stress σf = σy/30.5 = 5.77(10−4) kg/mm2 with a dough diameter of 55 mm and product diameter of 3 mm, strength factor of f(α) of 1.0, an extrusion force of 151 kg was obtained. This capacity was well within the force used for pressing chapati.

Extruder socket was treated as thin cylinder and Eq. (8) (Ugheoke 2006) was used to determine the thickness of the cylinder.

|

8 |

Container thickness of 3 mm for an internal diameter of 55 mm and a maximum dough length of 95 mm was obtained by solving Eq. (8).

Land of the die was calculated by using Eq. (9) (Ugheoke 2006).

|

9 |

Calculated die land was 8 mm. However to maintain the L/D ratio, land of the dies were considered as 4 mm and 6 mm for 2 mm and 3 mm hole dia respectively.

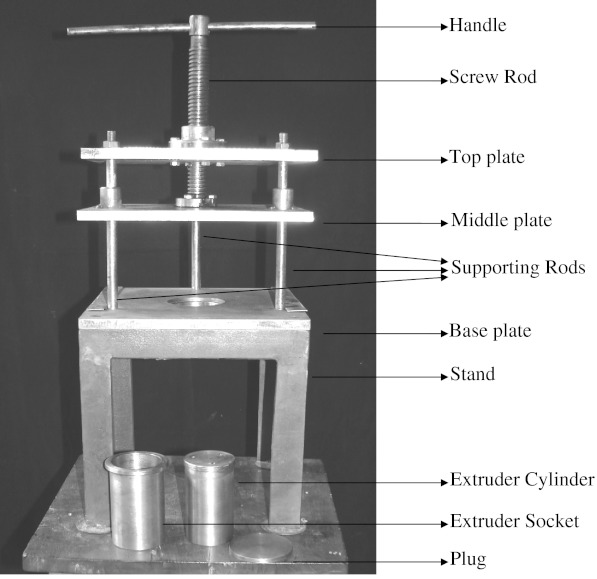

Manually operated system consisted of handle to rotate a single flighted screw, for movement of middle plate on a vertical axis. Supporting rods were used to support and guide the middle plate to apply uniform pressure and maintain parallality with fixed plate. Metal strips were placed on fixed plate to maintain uniform thickness of dough. Plug was inserted in fixed plate during chapati preparation and removed during extrusion process. Extruder socket, cylinder and two different die plates with hole diameters of 2 mm and 3 mm with hole length of 4 mm and 6 mm (L/D ratio of 2) respectively were used during extrusion process. Individual parts / subassemblies were fabricated and fitted on a supporting stand. Overall length, width and height of the machine was 250, 250 and 470 mm respectively. Figure 1 shows the system developed at the Central Food Technological Research Institure, (Mysore, India) for making chapatis and vermicelli.

Fig. 1.

Chapati press cum vermicelli extruder

Chemical characteristics

A commercial sample of whole wheat flour was analyzed for moisture, ash and protein content according to the AACC methods (2000).

Chapati preparation

Test baking of chapati was done as per the standard procedure of Haridas Rao et al. 1986.

Preparation of dough

Dough for chapatis and vermicelli was prepared by mixing 500 g of whole wheat flour with the predetermined amount of water (325 ml) for 3 min in a hobart mixer (model N-50, Ontario, Canada) at 59 rpm and rested for 10 min.

Rolling the dough

About 40 g of the dough was rolled (sheeted) manually to a thickness of 1.5 mm using a specially designed platform (Shurpalekar and Prabhavathi 1976) and cut into a circle, 150 mm diameter, using a steel cutter.

Pressing the dough

About 40 g of the dough was placed between two polythene sheets (0.3 mm thickness, greased with vegetable oil to prevent dough sheet stickiness) and kept in between middle and bottom plates of the machine. Dough was pressed to a thickness of 1.5 mm and cut into a circle, 15 cm diameter, using a steel cutter.

Baking of chapati

Chapatis produced from rolling and pressing were baked on one side for 30 s, and on the other side for 45 s, on a thermostatically controlled hot plate (Sumuki Enterprises, Mysore, India) maintained at 185 ± 2°C. Finally they were puffed for 3 to 5 s in a gas tandoor oven (approximately 320°C).

Chapati firmness

The firmness of baked chapati samples was measured as described by Walsh et al. 1970 and Prabhasankar et al. 2007 by using a Texture Analyzer model Ta-Hdi (Stable Microsystems, Surrey, UK). Baked chapati strips were sheared at 90° to length of strips. The shear was performed at a crosshead speed of 50 mm/min and load cell of 5 kg. The force required to shear the chapati was measured. The results reported are average of four readings.

Preparation of vermicelli

Bottom plate plug of the machine was removed and extruder socket was inserted. The dough was extruded using dies having perforations of 2 mm and 3 mm. The extruded vermicelli was dried at 75°C for 3 h in a hot air drier (Shrisat Electronics, Mumbai, India) to get vermicelli moisture content of 9%.

Cooking quality of vermicelli

To evaluate cooking quality 25 g (on as is basis, immediately after extrusion) of vermicelli was cooked in 250 ml of boiling water for 10 min and drained using a wire mesh to separate cooked vermicelli and the gruel. The cooked weight of vermicelli sample was noted. The gruel was tested for solid content by evaporating 20 ml of drained liquid on a boiling water bath, and then transferred to a hot air oven maintained at 105 ± 2°C and dried to constant mass (ISI 1993).

Sensory evaluations

Chapati

A panel comprising of 10 trained panelists carried out sensory evaluation of baked chapatis by assigning scores for appearance (10), tearing strength (10), pliability (10), aroma (10) and mouth feel (20). The overall quality (60) was taken as the combined score of all the five previous attributes.

Vermicelli

Sensory evaluation of cooked vermicelli was carried out by a panel of 10 trained panelists by assigning scores for appearance (10), strand quality (10) and mouth feel (10). The overall quality (30) was taken as the combined score of all the three previous attributes.

Statistical analysis

One way analysis of variance (ANOVA) was carried out to test for any significant differences in the mean values of all the groups by using Microsoft Excel software.

Results and discussion

Quality of chapati

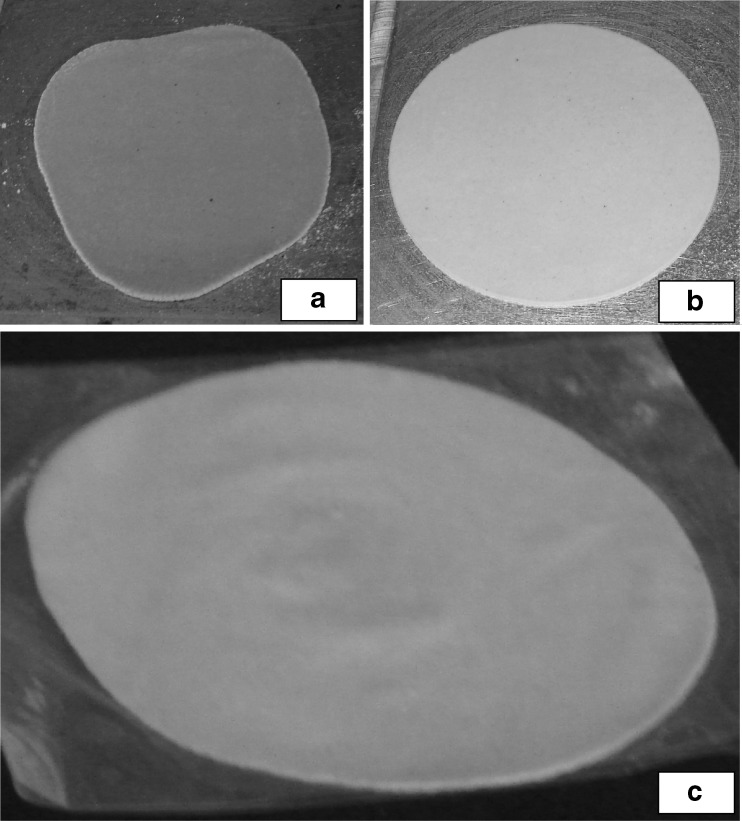

Chapati press cum vermicelli extruder is portable and manually operated machine. Figure 2 shows formed shapes by hand / rolling pin and pressing methods. Multiple rolling actions are required to produce desired circular shape in rolling method. Only compressive action is required to produce circular shape in press method. Table 1 shows quality characteristics of rolled and pressed chapatis. The shear force value which is a measure of firmness indicates that there was no significant difference between pressed and rolled chapati (p > 0.05, Fcrit > Fstat). Softer texture of pressed chapatis compared to rolled chapatis was supported by sensory evaluation tearing strength score (8.15). Sensory evaluation quality parameters of chapatis indicate that there was no significant difference between rolled chapatis and pressed chapatis except for mouth feel (p < 0.05, Fcrit < Fobs). Sensory data overall quality scores of 50.15 and 48.4 for pressed chapatis and rolled chapatis respectively indicated that the quality of chapatis was not adversely affected as a result of mechanical pressing.

Fig. 2.

Formed shapes by rolling and pressing methods, a: Hand rolled chapati b: Hand rolled and die cut chapati c: Machine pressed chapati

Table 1.

Quality characteristics of chapati

| Shear force (g) | Appearance (10) | Tearing strength (10) | Pliability (10) | Aroma (10) | Mouth feel (20) | Overall quality score(60) | |

|---|---|---|---|---|---|---|---|

| Rolled chapati | 1151.5 ± 105.32 | 8.1 ± 0.53 | 7.9 ± 0.70 | 7.8 ± 0.88 | 8.3 ± 0.42 | 16.2 ± 1.34 | 48.4 ± 2.89 |

| Pressed chapati | 1131 ± 84.9 | 8.1 ± 0.53 | 8.1 ± 0.75 | 8.2 ± 0.79 | 8.2 ± 0.43 | 17.4 ± 1.07 | 50.1 ± 2.24 |

| p-value | 0.77** | 1** | 0.45** | 0.36** | 0.79** | 0.04* | 0.15** |

| Fcrit | 5.98 | 4.41 | 4.41 | 4.41 | 4.41 | 4.41 | 4.41 |

| Fstat | 0.09 | 0 | 0.59 | 0.87 | 0.07 | 4.89 | 2.29 |

| df | 7 | 19 | 19 | 19 | 19 | 19 | 19 |

Fcrit Fcritical, Fstat Fstatistical, df Degree of freedom

Significant at *p < 0.05 and not significant at **p > 0.05 along column, Sensory evaluation values reported are Mean±SD, n = 10, Shear force values reported are Mean±SD, n = 4

Combined machine produced chapatis with 1.5 ± 0.1 mm thickness and 173.8 ± 1.93 mm diameter. The difference in chapati making time between manual rolling and machine pressing (Table 2) was found to be statistically significant as p < 0.01and Fstat (202.82) > Fcrit (4.75). Pressed chapati reproducibility results indicated that there was no significant difference in diameters among samples (p = 0.06, Fcrit = 3.24, Fstat = 3.07). Combined machine produced chapatis with consistent thickness and diameter repeatability, which can also be used as a laboratory moulder.

Table 2.

Manual chapati rolling time versus machine pressing time & Pressed chapati repeatability

| Manual sheeting time per chapati (sec) | Machine press time per chapati (sec) | p-value | Fcrit | Fstat | df |

|---|---|---|---|---|---|

| 29 ± 2.73 | 12 ± 1.63 | 0.001* | 4.7 | 202.8 | 13 |

| Pressed chapati repeatability | |||||

| Machine pressed chapati diameter (mm) | 173.8 ± 1.93 | 0.06** | 3.2 | 3.1 | 19 |

| Chapati thickness (mm) | 1.5 ± 0.5 | ||||

Fcrit Fcritical, Fstat Fstatistical, df Degree of freedom

Significant at *p < 0.05 along row and not significant at **p > 0.05 among samples, Values reported are Mean±SD, n = 5

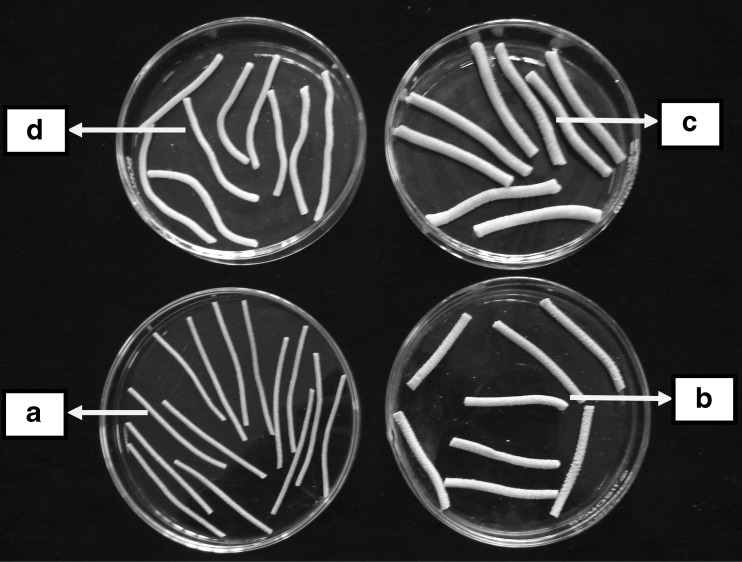

Quality of vermicelli

Figure 3 shows Photographs of extruded and cooked vermicelli. Quality characteristics of combined machine extruded vermicelli are shown in Table 3. Sensory evaluation of the cooked vermicelli indicates that there was no significant difference (p = 0.06) between 2 mm and 3 mm diameter vermicelli. Cooking weight (72.8 g) and water absorption (191.2%) of 2 mm diameter vermicelli was more compared to 3 mm diameter vermicelli (51.75 g, 107%). Decrease in cooking weight of 3 mm diameter vermicelli may be due to less water absorption during stipulated cooking time.

Fig. 3.

Extruded and cooked vermicelli, a,b: 2 mm and 3 mm diameters extruded and dried vermicelli c,d: 3 mm and 2 mm diameters cooked vermicelli

Table 3.

Quality characteristics of vermicelli

| Cooked weight (g/25 g) | Cooking loss (%) | % water absorption | Appearance (10) | Strand quality (10) | Mouth feel (10) | Overall quality score(30) | |

|---|---|---|---|---|---|---|---|

| 2 mm dia vermicelli | 72.8 ± 0.25 | 3.0 ± 0.05 | 191.2 ± 0.08 | 8.0 ± 0.88 | 7.0 ± 0.32 | 8.0 ± 0.75 | 26.0 ± 1.09 |

| 3 mm dia vermicelli | 51.7 ± 0.35 | 3.3 ± 0.05 | 107.0 ± 0.06 | 7.0 ± 0.79 | 8.0 ± 0.33 | 7.0 ± 0.87 | 25.0 ± 1.24 |

| df | 19 | 19 | 19 | 19 | 19 | 19 | 19 |

df degree of freedom, Values reported are Mean±SD, n = 3

Conclusion

The results of studies carried out for the design and development of multipurpose machine indicated that the press cum extruder machine could be used for preparation of chapatis and extruded products. Sensory evaluation quality parameters of chapatis indicated that there was no significant difference between rolled chapatis and pressed chapatis except for mouth feel. Sensory data overall quality scores of 50.15 and 48.4 for pressed chapatis and rolled chapatis respectively indicated that the quality of chapatis was not adversely affected as a result of mechanical pressing. Extruded vermicelli made from whole wheat flour had good texture and mouth feel. The extension of this work to other types of dough made of jowar, rice, ragi and other millets to explore flat dough and extruded products quality characteristics.

Acknowledgements

The authors are greatly indebted to Dr. G. Venkateswara Rao, Head, Flour Milling, Baking and Confectionery Technology Department for valuable suggestions.

Nomenclature

- Ad

Area of dough (mm2)

- Ae

Area of extruded product (mm2)

- B

Breadth of plate (mm)

- d1

Screw rod major diameter (mm)

- d2

Screw rod mean diameter (mm)

- d3

Screw rod minor diameter (mm)

- dd

Dough diameter (mm)

- Dd

Die diameter (mm)

- de

Diameter of extruded product (mm)

- dh

Diameter of handle rod (mm)

- ds

Supporting rod diameter (mm)

- f(α)

Strength factor

- L

Load acting distance (mm)

- l

Lead (mm)

- Lc

Die perimeter (mm)

- Ld

Land of die (mm)

- Ls

Socket length (mm)

- M

Bending moment of plate (kg-mm)

- P

Load on handle rod (kg)

- Pe

Extrusion force design load (kg)

- r1

Extruder socket internal diameter (mm)

- r2

Extruder socket external diameter (mm)

- t

Plate thickness (mm)

- Ta

Applied torque (kg-mm)

- Tc

Frictional torque of the collar (kg-mm)

- Tn

Frictional torque at mean radius (kg-mm)

- W

Maximum load (kg)

- αd

Half die angle (degree)

- αt

Thread helix angle (degree)

- σ

Working stress (kg/mm2)

- σ all

Allowable stress (kg/mm2)

- σC

Compressive stress (kg/mm2)

- σf

Flow Stress (kg/mm2)

- Ф

Friction angle (degree)

References

- American association of cereal chemists. Approved methods. St. Paul: AACC; 2000. [Google Scholar]

- Ghufran Saeed SM, Arif S, Ahmed M, Ali R, Shih F. Influence of rice bran on rheological properties of dough and in the new product development. J Food Sci Technol. 2009;46(1):62–65. [Google Scholar]

- Haridas Rao P, Leelavathi K, Shurpalekar SR (1986) Test baking of chapati. Cereal Chem 63(4):297–303

- http://www.thebiscuitdoctor.com/manufacturing-processes/biscuit-making-processes. Accessed on 08 June 2009

- Indian Standards Institution (ISI) (1993) Vermicelli making IS 1485-1993

- Qarooni J. Flat bread technology. New York: Internatiional Thomson publishing; 1996. [Google Scholar]

- Mahadevan K, Balaveera Reddy K. Design data hand book for mechanical engineers. New Delhi: CBS publishers; 1996. [Google Scholar]

- Prabhasankar P, Rajiv J, Indrani D, Venkateswara Rao G. Influence of whey protein concentrate, additives, their combinations on the quality and microstructure of vermicelli made from Indian T. Durum wheat variety. J Food Eng. 2007;80:1239–1245. doi: 10.1016/j.jfoodeng.2006.09.013. [DOI] [Google Scholar]

- Rubenthaler GL, Faridi HA. Laboratory dough molder for flat breads. Cereal Chem. 1981;59(1):72–73. [Google Scholar]

- Midha S, Mogra R. Quality evaluation of value added vermicell. J Food Sci Technol. 2007;44(2):220–223. [Google Scholar]

- Shurpalekar SR, Prabhavathi C. Brabender farinograph, research extensometer and hilliff chapati press as tools for standardization and objective assessment of chapati dough. Cereal Chem. 1976;53(4):457–469. [Google Scholar]

- Kumar S, Srivastava AK, Prasad Rao US, Haridas Rao P. Studies on gluten proteins and farinograph characteristics of wheat flour mill streams. J Food Sci Technol. 2009;46(1):21–25. [Google Scholar]

- Sridhar BS (1991) An improved continuous chapati making machine. Indian patent No.177722

- Sridhar BS, Manohar B. Optimization of the continuously extruded flat bread (chapati) process. Eur Food Res Technol. 2001;212:477–486. doi: 10.1007/s002170000280. [DOI] [Google Scholar]

- Trevor SK Ng, McKinley GH, Padmanabhan M (2006) Linear to non linear rheology of wheat flour dough. Internationl Symposium on Food Rheology and Structure (ISFRS2006), ETH, Zurich

- Ugheoke BI. Design, construction and performance evaluation of a laboratory extrusion rig. Au J Technol. 2006;9(3):175–180. [Google Scholar]

- Venkateswara Rao G, Leelavathi K, Haridasa Rao P, Shurpalekar SR. Changes in the quality characteristics of chapati during storage. Cereal Chem. 1986;63(2):131–135. [Google Scholar]

- Vetrimani R, Sudha ML, Haridas Rao P. Effect of extraction rate of wheat flour on the quality of vermicelli. Food Res Int. 2005;38:411–416. doi: 10.1016/j.foodres.2004.10.013. [DOI] [Google Scholar]

- Walsh DE, Youngs VL, Gilles KA. Inhibition of durum wheat lipoxidase with L-ascorbic acid. Cereal Chem. 1970;47:119–125. [Google Scholar]