Abstract

Five blends of refined wheat flour (RWF) (63.2 – 96.8, %RWF) and millet were used to manufacture biscuits baked for varying time (3.3–6.7 min) and temperature (166.6 – 183.4 °C). The manufactured biscuits were evaluated in terms of textural attributes (crispness, hardness and cutting strength) and overall acceptability (OAA). Results showed that increasing the amount of RWF in biscuits decreased (p < 0.01) hardness. Prolonging the baking time led to a decrease (p < 0.01) in hardness and cutting strength and a significant increase (p < 0.05) in OAA. Increase in baking temperature was followed by an increase in crispness (p < 0.01) and OAA (p < 0.1), while hardness and cutting strength (p < 0.01) decreased. Optimum processing condition generated form the models was, — blend ratio, 90%RWF; baking time, 6 min and baking temperature, 170 °C. The predicted responses in terms of crispness, hardness, cutting strength and OAA were 45, 0.3N, 27.2N and 8.9, respectively. The desirability of the optimum conditions was 0.98.

Keywords: Biscuit, Millet, Texture, Overall acceptability, Optimization

Introduction

Biscuits may be regarded as relatively simple cereal based food products commonly consumed as a snack food to answer the occasional pangs of hunger. Snacks contribute an important part of many consumers in daily nutrient and calories intake (Detweiler 1991). The nutritional awareness amongst the consumers has warranted the production of low calorie food products with an increased fibre content that can be readily included in the balanced diet. Biscuits are predominantly based on refined wheat flour (RWF) and the blending of RWF with millet can upgrade the nutritional quality of such products. The use of composite flours in the production of baked products has been a subject for research in the past. The use of millet flour is becoming more and more common in baked products especially in bread, cookies, crackers that are targeted at consumers who are gluten sensitive or diabetic (Lovis 2003). Millets are rich source of dietary fibre, phytochemicals, micronutrients, nutraceuticals, and hence now a days they are rightly termed as nutricereals (Desikachar 1977). Foods that are high in total dietary fibre (TDF) and soluble dietary fibre (SDF) have been related to decrease the occurrence of a wide spectrum of diseases. The cholesterol lowering effect of SDF in specific foods has been established in animal (Ranhotra et al. 1987) and human clinical studies (Anderson and Tietyen-Clark 1986).

Industrial production of millet incorporated biscuits would require the understanding of the function of raw ingredients in order to manipulate the quality of the final product. One of the major problems involved in incorporating dietary fibres into a food system is the negative effect it has on the functional properties of the food (Brennan and Samyue 2004). Attempts to bolster the nutritional properties of cereal based snack foods by incorporating legumes, animal protein, fibre rich products, etc. have been made by several workers in the past (Rao and Shurpalekar 1996; Singh et al. 1996; Awasthi and Yadav 2000; Prasad et al. 2004; Gajera et al. 2008). In meeting the expectations of consumers in terms of texture and overall acceptability (OAA), fibre can only be added to food if the product being manufactured has good sensory characteristics, irrespective of the nutritional benefits (Ellis 1985). The present study was carried out to understand the influence of processing parameters, — blend ratio (RWF: millet), baking time, baking temperature upon the textural attributes (viz. crispness, cutting strength, hardness) and OAA of the biscuits. Further, second order polynomial models were developed to investigate the interrelationship between the processing parameters and for their optimization, thereof to obtain biscuits with acceptable textural properties and maximum OAA.

Materials and methods

Materials

Dehusked barnyard millet (Echinochloa frumantacea L.) was obtained from College of Agriculture, Sehore, Jawaharlal Nehru Agricultural University, Jabalpur, Madhya Pradesh, India seed store. The millet was cleaned of all the foreign materials and was ground into flour by a hammer mill. The millet flour was then passed through 200 mesh I.S. sieve, the underflow was collected for further research work. RWF of 60% extraction was purchased from the local market of Jhansi city of India.

Experimental plan

Response surface methodology which involves design of experiments, selection of levels of variables in experimental runs, fitting mathematical models and finally selecting variables’ levels by optimizing the response (Khuri and Cornell 1987) was employed in the study. A central composite rotatable design (CCRD) was used to design the experiments comprising three independent processing parameters (Table 1). Twenty experiments were conducted for the present research work. There were six experiments at centre point to calculate the repeatability of the method (Montgomery 2001). The experimental design and the codes for the processing variables have been reported in Table 1. The coding was carried out with the help of Eqs. 1, 2, and 3.The present study was carried out to understand the effect of processing parameters on textural characteristics of the biscuits, viz. crispness, hardness, cutting strength, and upon its’ overall acceptability. Response surface analysis required coding of the values of the processing parameters. The codes of the processing parameters, blend ratio (X1), baking time (X2), and baking temperature (X3) were generated with help of the following equations:

|

1 |

|

2 |

|

3 |

All the coded processing parameter had five levels. There were two primary levels or factorial points ( +1 and − 1), a coded centre point (0), and two augmented points (−am and +am).

|

4 |

Table 1.

Experimental design for the manufacture of biscuits from RWF and millet

| Code for the values | Processing parameters and values | ||

|---|---|---|---|

| Blend ratio,% RWF | Baking time, min | Baking temperature, °C | |

| −1.68 | 63.2 | 3.3 | 166.6 |

| −1 | 70 | 4 | 170 |

| 0 | 80 | 5 | 175 |

| +1 | 90 | 6 | 180 |

| +1.68 | 96.8 | 6.7 | 183.4 |

| No. of experiments | Coded processing parameters | ||

| X1 | X2 | X3 | |

| 8 | ±1 | ±1 | ±1 |

| 2 | ±1.68 | 0 | 0 |

| 2 | 0 | ±1.68 | 0 |

| 2 | 0 | 0 | ±1.68 |

| 6 | 0 | 0 | 0 |

| 20 = Total number of experiments | |||

Code ‘0’ is for centre point of the parameter range investigated, ‘±1’ for factorial points and ‘±1.682’ for augmented points; X1, blend ratio; X2, baking time; X3, baking temperature.

Manufacture of biscuits

The RWF and millet flour were mixed in the required proportions (i.e. 63.2, 70, 80, 90, and 96.8%, RWF). The various blends were sieved thrice to ascertain through mixing. The levels of the other processing parameters, baking time and baking temperature, are reported in Table 1. The process adopted for biscuit manufacture was as per the method elaborated by the AACC 1994. The biscuits were cooled for 30 min and stored in air-tight containers for 24 h, before further analysis.

Texture analysis

The textural properties of the biscuits were judged on the basis of crispness, hardness and cutting strength. The texture analysis was done with the help of a Texture Analyzer TA-XT2i (Stable Micro Systems, Surrey, England). The tests were conducted by using different kinds of probes i.e. cylindrical, needle and cutting. The studies were conducted at pre-test speed of 5.0 mm/sec, test speed of 2.0 mm/sec, post test speed of 10 mm/sec, distance 10 mm, trigger force of 25 g, and load cell of 5 kg. Crispness was measured in terms of major positive peaks (Nath and Chattopadhyaya 2007). A macro was developed which counts number of major peaks obtained in the product during compression. The first peak of the force-distance plot of the texture analyzer was interpreted as hardness of the product, expressed in Newtons (N) (Chakraborty et al. 2009). The peak of the force-distance plot of the texture analyzer was recorded as cutting strength, expressed in Newtons (N) (Chakraborty et al. 2009). The peak is followed by a steep fall over the force axis, which shows that the resistance ceases to exist; or the product has been cut.

Sensory evaluation

Sensory evaluation was done on freshly made biscuits. Seventy frequent consumers of biscuits comprised the panel for evaluating sensory attributes of freshly baked biscuits. The attributes evaluated were flavour, mouth feel and overall acceptability. For each sample, panelists scored their liking of these characteristics using the nine-point hedonic scale (1 = dislike extremely, 2 = dislike very much, 3 = dislike moderately, 4 = dislike slightly, 5 = neither like nor dislike, 6 = like slightly, 7 = like moderately, 8 = like very much and 9 = like extremely).

Data analysis

The data obtained from the experiment were analyzed for optimization of processing parameters with respect to the responses, viz. crispness, hardness, cutting strength, and overall acceptability of the biscuits. Regression analysis and analysis of variance (ANOVA) were conducted for fitting the model (Eq. 5) and to examine the statistical significance of the model terms.

|

5 |

where, Yk = responses, Xi, Xj = coded processing parameters, βk = regression coefficients

The adequacy of the models were determined using model analysis, lack-of-fit test and R2 (coefficient of determination) analysis as outlined by (Weng et al. 2001). The lack-of- fit is a measure of the failure of a model to represent data in the experimental domain, especially for those points which were not included in the regression or variations in the models and thus cannot be accounted for by random error (Montgomery 2001). A model is adequate in describing the response if the lack-of-fit is insignificant. The R2 is defined as the ratio of the explained variation to the total variation and is a measure of the degree of fit (Haber and Runyon 1977). If the R2 value for a model is more than 80 per cent then the can be considered for further analysis (Filmore et al. 1976). Coefficient of variation (c.v.) indicates the relative dispersion of the experimental points from the prediction of the model. It is desirable to have a c.v. of less than 10 per cent (Nath and Chattopadhyaya 2007). The effect of variables at linear, quadratic and interactive level on the response was described using significance at 1 (p < 0.01), 5 (p < 0.05) and 10% (p < 0.1).

Optimization

Numerical optimization technique of the Design-Expert (7.1.6) software was used for simultaneous optimization of the multiple responses. The desired goal for each processing parameter and response was chosen. All the processing parameters were kept within range while the responses, crispness and overall acceptability were maximized, whereas cutting strength and hardness were minimized. In order to search a solution, the goals are combined into an overall composite function, D(x), called the desirability function (Myers and Montgomery 2002), which is defined as:

|

6 |

where, d1, d2,…,dn are the responses and ‘n’ is the total number of responses in the measure.

The numerical optimization finds a point that maximizes the desirability function. In the desirability function D(x) each response can be assigned an importance in relation to the other response. The importance varies from least important (a value of 1), to the most important (a value of 5). In the present study all the responses were assigned an importance of 3, as per the default settings of the software. The characteristics of a goal may be altered by adjusting the weight or importance of specific parameters (Design Expert version 7.1.6 2009). The response surfaces help to understand the effect of varying the processing parameters up on the response, i.e. in which direction the response is increasing or decreasing. Response surfaces were generated with the help of commercial statistical package, Design Expert version 7.1.6.

Results and discussion

Response surface analysis was applied to the experimental data and the second order response surface model (Eq. 4) was fitted to all the textural characteristics (viz. crispness, hardness and cutting strength) and OAA. The statistical significance of the model terms were examined with the help of regression analysis and analysis of variance (ANOVA). It was observed that the lack-of-fit test (F-values) for all the models were insignificant (Fcal < Ftab), implying that the models were accurate enough to predict the responses. The variability explained by all the models was more than 80 per cent (R2 > 0.80). The coefficient of variation (c.v.) was 11.5% in case of hardness, other wise it was less than 10 per cent in case of other responses. Thus, indicative of the fact that the experiments were carried out with adequate precision. Ergo, all the models exhibited statistically adequacy and were hence used to study the effect of processing parameters on the various responses. The result of the regression analysis and analysis of variance (ANOVA) for all the models is reported in Table 2.

Table 2.

Regression analyses of the second order polynomial models for the various responses

| Predictor | β (coded factors) | |||

|---|---|---|---|---|

| Crispness | Hardness | Cutting strength | OAA | |

| Intercept | 23.779*** | 0.439*** | 36.883*** | 6.38*** |

| X1 | 4.849*** | −0.019*** | 3.209*** | 0.59*** |

| X2 | −0.067 | −0.084*** | −6.511*** | 0.33** |

| X3 | 2.084*** | −0.083 | −3.890*** | 0.23* |

| X1* X2 | 2.875*** | 0.008 | 1.686* | 0.19 |

| X1* X3 | −1.875* | −0.013 | −0.073 | −0.38** |

| X2* X3 | −0.875 | 0.077*** | 2.598** | −0.31* |

| X21 | 6.244*** | −0.039** | −6.559*** | 0.60*** |

| X22 | 3.239*** | 0.006 | −3.356*** | 0.42*** |

| X23 | 3.946*** | 0.015 | 0.521 | −0.11 |

| ANOVA | ||||

| Model (F-value) | 24.5*** | 12.5*** | 32.6*** | 9.0*** |

| Coefficient of determination (R2),% | 95.6 | 91.8 | 96.7 | 89.2 |

| Coefficient of variation (c.v.),% | 7.3 | 11.5 | 8.0 | 6.50 |

*significant at p < 0.1, ** significant at p < 0.05, *** significant at p < 0.01; X1, blend ratio; X2, baking time; X3, baking temperature.

The amount of RWF in the dough had significant (p < 0.01) effect upon all the responses. Increasing the percentage of RWF resulted in an increase in crispness, cutting strength and OAA, while the hardness of the biscuits decreased. Dietary fibre enriched biscuits have been observed to have reduced resistance for snapping during texture analysis (Brennan and Samyue 2004). The fall of OAA of the biscuits have been reported to be influenced by the level of incorporation of the millet (Anu et al. 2007). The effect baking time was significant at p < 0.01 on hardness and cutting strength, while for OAA the significance was at p < 0.05. The hardness and cutting strength decreased, where as OAA increased with the increase in baking time. Variation in baking temperature had significant affect upon the all the responses except hardness. There was increase in the crispness (p < 0.01) and OAA (p < 0.1), while the cutting strength registered a significant fall (p < 0.01) as the baking temperature was increased.

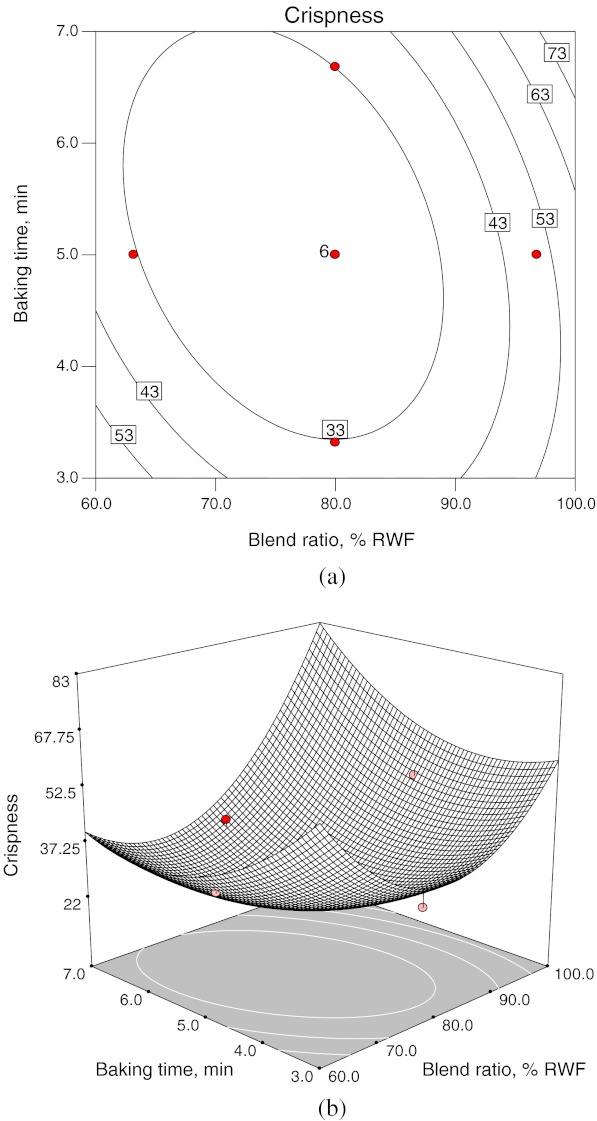

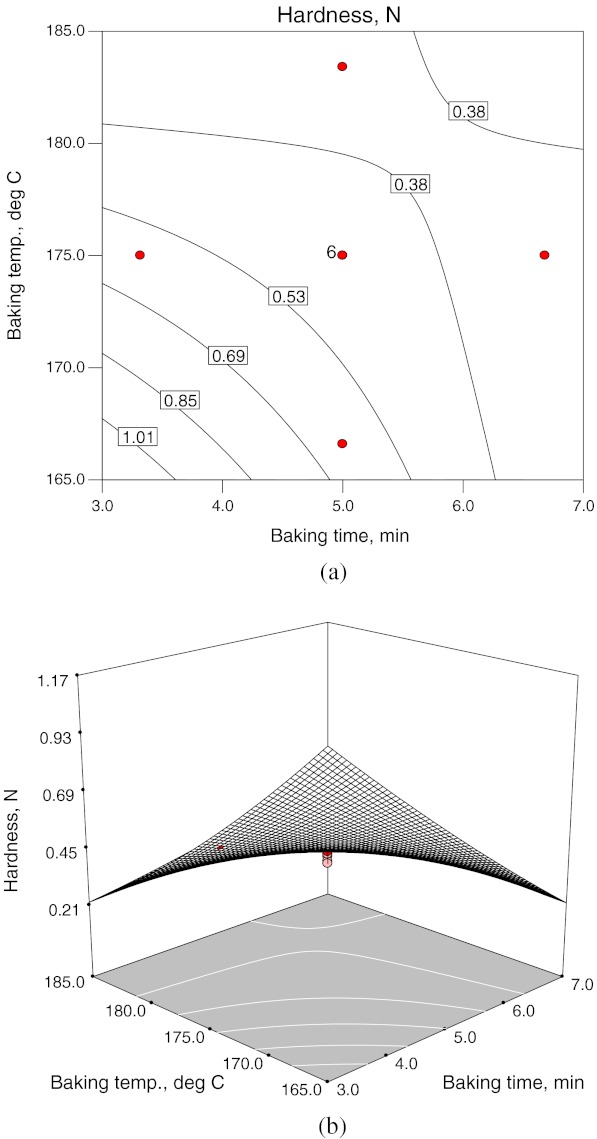

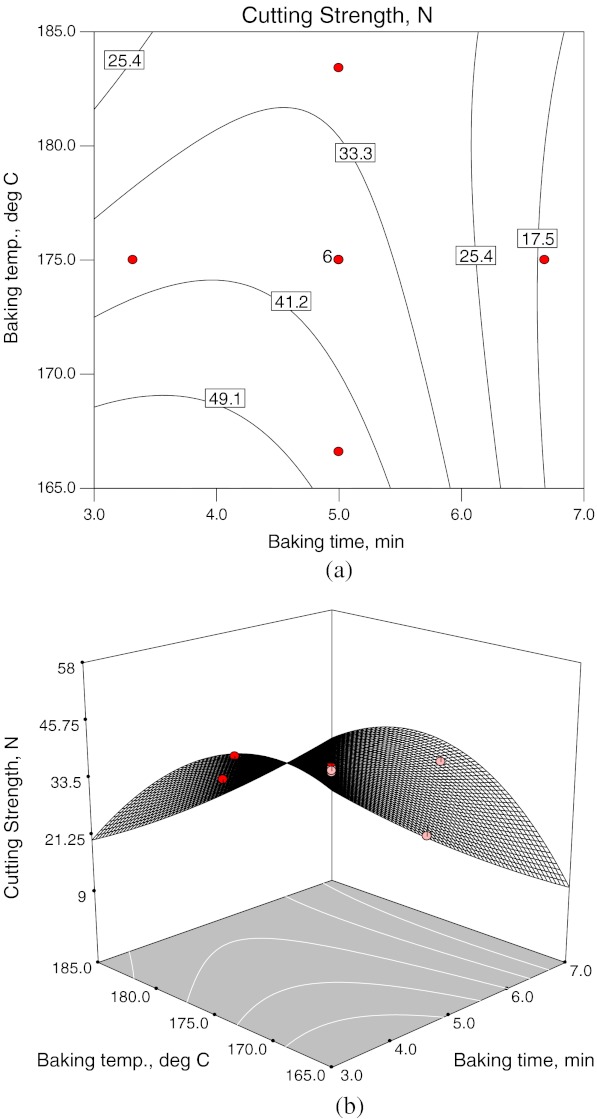

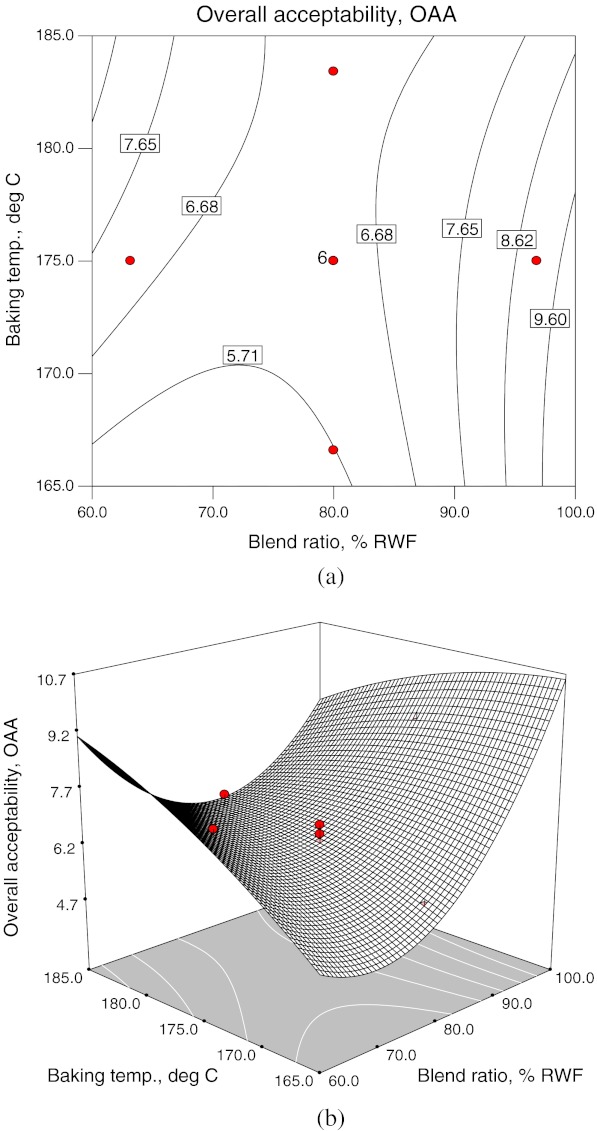

Crispness was significantly affected by the interactions of blend ratio with baking time (p < 0.01) and with baking temperature (p < 0.1). The interactive effect of ‘blend ratio-baking time’ was more pronounced (β = 2.875) and pursued. It can be inferred from Fig. 1(a) that the crispness would increase as the blend ratio and baking time increases. The interaction of baking time and baking temperature was found to have significant (p < 0.01) effect on the hardness. Figure 2(a) shows that hardness increases as the baking time and baking temperature decrease. The cutting strength was affected more significantly (p < 0.05) by the interaction of baking time and baking temperature than by the ‘blend ratio-baking time’ interaction (p < 0.1). It can be concluded from the Fig. 3(a) that the cutting strength would maximize as the baking time and baking temperature reached their minimum values. The OAA was found to be significantly affected by the interaction of baking temperature with blend ratio (p < 0.05) and with baking time (p < 0.l). As seen in Fig. 4(a) the OAA increased progressively as the blend ratio increased and baking temperature was at values around the centre point (175 °C). It can also be inferred that the biscuits baked at high baking temperature had high OAA even at low blend ratio.

Fig. 1.

Contour plot (a) and response surface (b) representing the effect of blend ratio and baking time on crispness of the biscuits while baking temperature is at centre point

Fig. 2.

Contour plot (a) and response surface (b) representing the effect of baking temperature and baking time on hardness of the biscuits while the blend ratio is at centre point

Fig. 3.

Contour plot (a) and response surface (b) representing the effect of baking temperature and baking time on cutting strength of the biscuits while the blend ratio is at centre point

Fig. 4.

Contour plot (a) and response surface (b) representing the effect of blend ratio and baking temperature on OAA of the biscuits while the baking temperature is at centre point

The interactive effects of baking time and baking temperature were found to have similar affect upon hardness and cutting strength. A low time-temperature combination of baking would lead to formation of biscuits which were high on hardness and cutting strength. Baking biscuits for a shorter time and at a lower temperature would result in less gas formation and an incomplete leavening action. The release of the gases during baking provides the final modifying action on the texture of the biscuits (Lindsay 1985).

The blend ratio, in quadratic term, was more significant in affecting crispness, cutting strength and OAA (p < 0.01) and affected hardness at p < 0.05. The quadratic term of baking time was insignificant for hardness but was significant (p < 0.01) for rest of the responses. However, the quadratic term of baking temperature would have a significant affect upon crispness only.

Perusal of Table 3 shows that there was significant (p < 0.01) overall effect of all the processing parameters upon the responses. However, there were some exceptions, the overall effect of blend ratio upon hardness was at p < 0.1; the OAA was significantly affected at p < 0.05 and at p < 0.1 by the baking time and baking temperature, respectively. All the models demonstrated significance at p < 0.01 at linear level. At interactive level the models of crispness, hardness and cutting strength were significant at p < 0.05, whereas the model of OAA was significant at p < 0.1. The overall effect of the quadratic terms upon the models of crispness, cutting strength and OAA was significant at p < 0.01, while, for the model of hardness the significance was at p < 0.1.

Table 3.

ANOVA for the overall effect of processing parameters on the responses

| Reponses | F-value | |||

|---|---|---|---|---|

| Crispness | Hardness | Cutting strength | OAA | |

| Total individual effect of processing parameters | ||||

| Blend ratio | 41.9*** | 3.0* | 32.7*** | 13.71*** |

| Baking time | 9.6*** | 14.9*** | 34.2*** | 6.11** |

| Baking temperature | 13.6*** | 15.0*** | 11.0*** | 3.35* |

| Combined effect of all processing parameters at | ||||

| Linear level | 21.7*** | 27.08*** | 51.59*** | 11.17*** |

| Interactive level | 5.74** | 6.94** | 4.28** | 3.52* |

| Quadratic level | 53.69*** | 3.47* | 43.79*** | 12.69*** |

*significant at p < 0.1, ** significant at p < 0.05, *** significant at p < 0.01

Design Expert (version 7.1.6) of the STAT-EASE software was used for simultaneous numerical optimization of the processing parameters. The optimum processing conditions were achieved after assigning certain constraints upon the processing parameters and the responses (Table 4). The optimum values of the processing parameters and their corresponding responses are reported in Table 4. It is noteworthy that the predicted OAA under the optimum conditions is 8.9, which is outside the range of the values obtained during the experiments. The experiments were also conducted under the predicted optimum conditions to verify the efficacy of the models. Perusal of Table 5 shows that the predicted values had non-significant (p < 0.01) difference from experimental values.

Table 4.

Constraints applied to the processing parameters and responses for numerical optimization

| Parameters | Goal | Lower Limit | Upper Limit | Importancea | Optimum valueb |

|---|---|---|---|---|---|

| Blend ratio, %RWF | in range | 70 | 90 | 3 | 90 |

| Baking time, min | in range | 4 | 6 | 3 | 6 |

| Baking temperature, °C | in range | 170 | 180 | 3 | 170 |

| Responses | |||||

| Crispness | maximize | 22 | 48.0 | 3 | 45 |

| Hardness, N | minimize | 0.28 | 0.7 | 3 | 0.3 |

| Cutting strength, N | minimize | 13.88 | 43.7 | 3 | 27.2 |

| OAA | maximize | 5.5 | 8.8 | 3 | 8.9 |

athe value of importance is as per the default setting of the software.

bthe desirability for this result was 0.98.

Table 5.

Verification of the models by comparing the experimental values with the predicted values

| Response | Predicted value(μo) | Actual valuea (μ1) ± SD | Standard error | Mean difference | % Variation | tcal |

|---|---|---|---|---|---|---|

| Crispness | 45 | 44.6 ± 2.07 | 0.93 | 0.4 | 0.90 | 0.43 |

| Hardness, N | 0.3 | 0.33 ± 0.02 | 0.01 | 0.03 | 7.90 | 2.53 |

| Cutting strength, N | 27.2 | 28.1 ± 0.92 | 0.41 | 0.86 | 3.06 | 2.09 |

| OAA | 8.9 | 8.4 ± 0.34 | 0.15 | 0.52 | 6.21 | 3.40 |

Ho: μo = μ1, tcal < ttable at p < 0.1, ‘Ho’ was accepted.

amean of five replications.

Conclusion

Response surface methodology was effective in optimizing processing parameters for the manufacture of biscuits form different blends of RWF and millet, baked at varying time and temperature. The regression analysis yielded models that were used for obtaining optimum conditions for desired responses within the range of conditions applied in this study. Model analysis, which included checking the validity of the model with the help of various relevant statistical aids, such as—F-value, coefficient of determination (R2), and coefficient of variation (c.v.) revealed that all the models were statistically adequate. The blend ratio was found to have a significant effect upon all the responses, however the baking time and baking temperature had significant effect on all the responses except crispness and hardness, respectively. Optimum values for the processing parameters were obtained via numerical optimization, which also satisfied the criterion of constraints of the responses.

References

- Approved laboratory methods. 9. Minnesota: American Association of Cereal Chemists; 1994. [Google Scholar]

- Anderson JW, Tietyen-Clark J. Dietary fibre: hyperlipidemia, hypertension, and coronary heart disease. Am J of Gastroenterol. 1986;81(10):907–919. [PubMed] [Google Scholar]

- Anu, Sehgal S, Kawatra A. Use of pearl millet and green gram flours in biscuits and their sensory and nutritional quality. J Food Sci Tech. 2007;44(5):536–538. [Google Scholar]

- Awasthi P, Yadav MC. Effect of incorporation of liquid dairy products on chemical characteristics of soy-fortified biscuits. J Food Sci Technol. 2000;37(2):158–161. [Google Scholar]

- Brennan CS, Samyue E. Evaluation of starch degradation and textural characteristics of dietary fiber enriched biscuits. Int J of Food Prop. 2004;7(3):647–657. doi: 10.1081/JFP-200033070. [DOI] [Google Scholar]

- Chakraborty SK, Singh DS, Kumbhar BK, Singh D. Process parameter optimization for textural properties of ready-to-eat extruded snack food form millet and pulse-brokens blends. J Texture Stud. 2009;40(6):710–726. doi: 10.1111/j.1745-4603.2009.00207.x. [DOI] [Google Scholar]

- Design Expert version 7.1.6, 2009. Stat-Ease, Inc., MN, USA

- Desikachar HSR. Processing of sorghum and millets for versatile food uses in India. In: Dendy DAV, editor. Proceedings of symposium on sorghum and millets for human food. London: Tropical Products Institute; 1977. pp. 41–46. [Google Scholar]

- Detweiler P. Snack food world wide. Food Technol. 1991;45(2):58–61. [Google Scholar]

- Ellis PR. Fiber and food products. In: Leeds AR, Avenell A, editors. Dietary fiber perspectives: reviews and bibliography. London: John Libbey Company Limited; 1985. pp. 83–105. [Google Scholar]

- Filmore EB, Kramer A, Gerald K. Response surface techniques. In: Filmore FE, Kramer A, Gerald K, editors. Systems analysis for food industry. Westport: AVI; 1976. p. 127. [Google Scholar]

- Gajera HP, Kapopara MB, Patel VH, Patel MM. Influence of peanut butter on quality characteristics of biscuits. J Food Sci Technol. 2008;45(4):373–375. [Google Scholar]

- Haber A, Runyon R. General statistics. 3. Reading: Addison-Wesley Publishing Company; 1977. [Google Scholar]

- Khuri AI, Cornell JA. Response surfaces, designs and analysis. New York: Marcel Dekker Inc; 1987. [Google Scholar]

- Lindsay RC. Food additives. In: Fennema OR, editor. Food chemistry. 2. New York: Marcel Dekker, Inc; 1985. p. 634. [Google Scholar]

- Lovis LJ. Alternatives to wheat flour in baked goods. Cereal Food World. 2003;48(2):61–63. [Google Scholar]

- Montgomery DC. Design and analysis of experiments. 5. New York: Wiley; 2001. pp. 455–492. [Google Scholar]

- Myers R, Montgomery DC. Response surface methodology. New York: Wiley; 2002. [Google Scholar]

- Nath A, Chattopadhyaya PK. Optimization of oven toasting for improving crispness and other quality attributes of ready to eat potato-soy snack using response surface methodology. J Food Engg. 2007;80(4):1282–1292. doi: 10.1016/j.jfoodeng.2006.09.023. [DOI] [Google Scholar]

- Prasad NN, Swamy MSL, Viswanathan KR, Santhanam K. Nutritional quality of egg fortified biscuits. J Food Sci Technol. 2004;41(5):534–536. [Google Scholar]

- Ranhotra G, Gelroth J, Bright P. Effect of source of fibre in bread-based diets on blood and liver lipids in rats. J Food Sci. 1987;52(5):1420–1422. doi: 10.1111/j.1365-2621.1987.tb14097.x. [DOI] [Google Scholar]

- Rao PH, Shurpalekar SR. Utilisation of mint in bakery products. J Food Sci Technol. 1996;13(3):293–299. [Google Scholar]

- Singh R, Singh G, Chauhan GS. Effects of incorporation of defatted soy flour on the quality of biscuits. J Food Sci Technol. 1996;33(4):355–357. [Google Scholar]

- Weng W, Liu W, Lin W. Studies on the optimum models of the dairy product Kou Woan Lao using response surface methodology. Asian Austral J Anim. 2001;14(10):1470–1476. [Google Scholar]