Abstract

Paneer was prepared by application of hurdle technology (HT) and its shelf stability studied by modified atmospheric packaging (MAP). The hurdles adopted comprised of water activity (aw), pH, preservative and MAP. The aw was reduced by using NaCl (1–3%), citric acid (CA, 0.01–0.1%) and potassium sorbate (0.1%). NaCl and CA at 3 and 0.1% reduced aw from 0.994 to 0.970 and pH from 5.6 to 5.1, respectively. Sensory scores of all samples decreased (p ≤ 0.05) from control during storage at different temperatures, but these scores at the end of 20 days were still under acceptable limit of 6 and above (liked moderately). MAP was carried out by using a mixture of CO2 to N2 in the ratio of 50:50. The HT adopted paneer with MAP had extended the shelf-life from 1 to 12 days at room temperature (30 ± 1°C) and 6 to 20 days at refrigeration (7 ± 1°C) temperatures.

Keywords: Paneer, Hurdle technology, Citric acid, Modified atmospheric packaging, Potassium sorbate

Introduction

Dairy industry in India has witnessed rapid growth in the last 3 decades. The milk production during 2009 was estimated to be 104.8 million tonnes (NSI 2009) of which 45–50% were converted into variety of traditional milk products (Venkateshaiah 2003). Paneer is one of the important Indian traditional heat and acid coagulated dairy product, which is being widely used in varieties of culinary dishes. The annual paneer production is about 150,000 tonnes (Aneja et al. 2002). The higher moisture content of this product (50–60%) makes it more prone to faster spoilage resulting in limited shelf life. The shelf-life of paneer is only 1 day at room temperature (30 ± 1°C) and the spoilage is mainly attributed to the growth of surface tainting and off-flavour producing microbes. In order to enhance the shelf life of paneer several attempts have been made in the past, which included addition of preservatives (Kaur et al. 2003), vacuum packaging, low temperature storage, dehydration and heat sterilization (Rao and Patil 2001), treatment with brine, chlorinated water, H2O2, delvocid, sorbic acid, potassium sorbate and antioxidants (Rao 2000). However, these methods could not improve the shelf-life and fully also led to jeopardize the flavour and texture of the product. Hurdle technology (HT) concept may enhance the shelf stability of paneer. Each hurdle like aw, pH, redox-potential (Eh) and modified atmospheric packaging (MAP), which are either bacterio-static or bactericidal in nature, may help to extend shelf life. When used in combination at an optimum level without affecting the product quality, HT enhances shelf-life of the product (Leistner 1994). MAP is known to bring about changes in respiration rate, microbial growth, oxidation reactions and by changing the levels of gases that surround the product and thus increase the keeping quality (Mangarj and Goswami 2009). Present study was undertaken to study the effect of HT and MAP on shelf-life enhancement of paneer.

Materials and methods

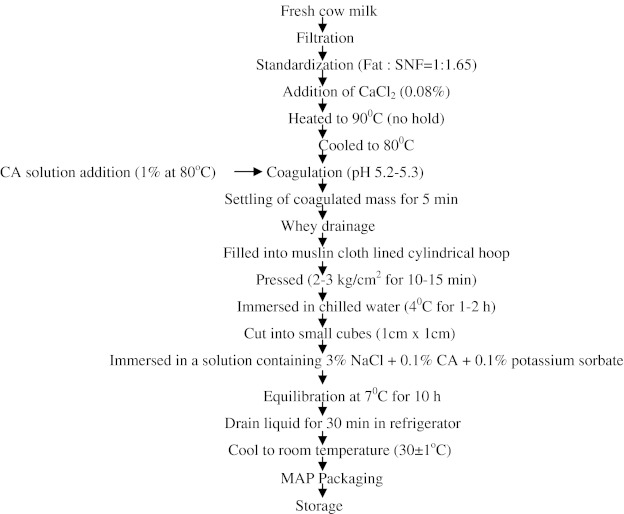

Preparation of paneer

Fresh cow’s milk, cream and skim milk were procured from Students Experimental Dairy Plant of the University. Cow milk was filtered and standardized to fat: solids not fat ratio of 1:1.65 using cream and skim milk. The standardized milk was transferred into a double jacketed insulated stainless steel vat. CaCl2 (@ 0.08% of milk) was added to milk. The milk was heated to 90 C (no hold) and cooled to 80 C. Coagulation of milk was done by adding 1% citric acid (CA) solution at 80 C (2 g CA/l) and the coagulated mass was allowed to settle for 5 min. After the drainage of whey, curd was collected and filled in muslin cloth lined circular stainless steel hoops (10 cm diameter and 25 cm height) with holes on its side to facilitate the expulsion of whey. The hooped curd was pressed at 2-3 kg/cm2 for 10–15 min. The pressed curd was immersed in chilled water (4 C/1-2 h) followed by cutting into pieces of 1 cm cubes for further studies.

Water activity and pH

aw and pH of paneer were reduced by dipping paneer cubes of 1 cm (100 g) each in stainless steel vessels containing 1 l of 1, 2 and 3% NaCl and 0.01, 0.05 and 0.1% CA solutions for diffusion at refrigeration (7 ± 1°C) temperature for 12 h, respectively. After diffusion, paneer cubes were taken out and kept on wire gauze in refrigerator for approximately 30 min to facilitate drainage. Paneer was then subjected to sensory evaluation by a panel of 5 judges. Potassium sorbate (01%) was used as a preservative (Thakral et al. 1990).

MAP

Paneer was packed in 64 μm thick, 20 cm × 14 cm size, two layered heat sealable pouch packaging material (PET/PE) procured from Shakthi Packaging, Bangalore. MAP was carried out by employing Reepack® and MAP mix 9000 Gas mixer manufactured by PBI DANSENSOR A/S, Denmark, by a combination of N2 and CO2 at a ratio of 50:50.

Shelf- life studies

For enhancing the shelf-life, aw and pH of paneer was reduced, packed in the packaging material (PET/PE) and subjected to MAP (CO2:N2 = 50:50) followed by storage at ambient (30° ± 1 C) and refrigeration (7 ± 1 C) temperatures. Samples were drawn at regular intervals and evaluated for physico-chemical and sensory qualities.

Analytical methods

Milk, cream and skim milk were analyzed for fat, SNF and titratable acidity and paneer samples for moisture, fat, protein, free fatty acids and ash as per ISI (1981b). Paneer aw was measured by using Rotronic probe type (AW-DIO) water activity meter (ROTRONIC® Instruments Corp., Switzerland). Paneer cubes were taken out after diffusion, and kept in refrigeration temperature for 30 min to remove excess moisture on surface of cubes. Paneer cubes were thoroughly ground by using pestle and mortar and the ground sample was taken into the sample container. After 5–10 min, aw of the product shown by the display was recorded. The pH was determined by grinding 10 g of paneer with 10 ml of glass distilled water and dipping the electrode directly into the slurry by using digital pH meter (Elico Ltd., Hydarabad, India) as per the procedure followed for cheddar cheese ISI (1981b).

The paneer samples were analyzed for standard plate count (SPC), coliforms, yeast and moulds (ISI 1981a). Agar media were procured from Hi-media Laboratories Pvt. Ltd., Mumbai, India. The sensory analysis was carried out by a panel of 5 judges. The samples were examined for colour and appearance, body and texture, flavour and overall acceptability on 9-Hedonic scale score-card. All the results in triplicate were analyzed for significance at 5% level using Statistical packages for Social Sciences (SPSS Version 8.0).

Results and discussion

Reduction of aw and pH of paneer by diffusion

Preliminary trials indicated that paneer diffused with 4% NaCl had very high salty taste and hence was rejected by judges. Therefore, for further studies, only up to 3% NaCl was used for diffusion trials. As the concentration of NaCl increased from 1–3%, aw decreased from 0.994 to 0.970 at the end of equilibration indicating that rate of diffusion increased with higher salt concentration (Table 1). This reduction in aw may be due to the fact that NaCl is a good humectant as it binds free water in paneer (Singh et al. 1989, Jayaraj Rao and Patil 1999a, Sudhir Singh and Rai 2004). Similarly pH decreased from 5.6 to 5.1 (Table 1) when paneer was diffused in increasing concentrations (0.01–0.10%) of CA also observed by Jayaraj Rao and Patil (1999b).

Table 1.

Water activity (aw) and pH of paneer after diffusion for about 12 h in NaCl and citric acid (CA) solutions of various concentrations at 7 C

| NaCl solution,% | aw | CA solution,% | pH |

|---|---|---|---|

| 0 | 0.994 | 0 | 5.6 |

| 1 | 0.99 | 0.01 | 5.5 |

| 2 | 0.98 | 0.05 | 5.3 |

| 3 | 0.97 | 0.1 | 5.1 |

(n = 3)

Effect of NaCl diffusion on sensory quality of paneer

Colour and appearance scores of salt diffused paneer were lower (p ≤ 0.05) compared to control at all concentrations of salt due to turning of colour of paneer cubes to dull white, probably because the reflection or scattering of light was dimmed by the dispersion of moisture droplets on the surface, but the scores did not decrease (p ≤ 0.05) with increase in salt concentration (Table 2). The flavour of paneer turned from pleasant nutty to more salty with increase in the salt concentration and these scores were similar to control up to 2% salt. This was expected as NaCl enhances the palatability up to certain level. The flavour scores decreased (p ≤ 0.05) from 7.9 to 7.0 at 3% salt. This concentration may not be objectionable considering the fact that the product is later used for paneer curry making causing dilution of salt content.

Table 2.

Sensory scores (max 9) of paneer diffused in NaCl and citric acid (CA) solution of different concentrations

| NaCl solution,% | Colour and appearance | Flavour | Body and texture | Overall acceptability |

|---|---|---|---|---|

| 0 | 7.7a | 7.5a | 7.9a | 7.8a |

| 1 | 7.5b | 7.5a | 7.5b | 7.4b |

| 2 | 7.4b | 7.4a | 7.2c | 7.4b |

| 3 | 7.4b | 7.0b | 7.0d | 7.0c |

| 4 | 7.0c | 5.5c | 6.0e | 6.0d |

| CD0.05 | 0.19 | 0.18 | 0.15 | 0.19 |

| CA,% | ||||

| 0 | 7.7a | 7.7a | 7.7a | 7.6a |

| 0.01 | 7.6b | 7.6ab | 7.6ab | 7.6a |

| 0.05 | 7.5c | 7.6b | 7.5b | 7.5a |

| 0.1 | 7.5c | 7.0c | 7.0c | 7.2b |

| CD0.05 | 0.076 | 0.17 | 0.13 | 0.12 |

Means with different superscripts in a column differ significantly at p ≤ 0.05 (n = 3)

The body and texture scores of NaCl diffused paneer decreased (p ≤ 0.05) with increase in salt concentration (Table 2) possibly due to softening and dissolving effect of salt on proteins in paneer. Overall acceptability scores decreased (p ≤ 0.05) with increased salt concentration, but these were within acceptable limit of 7 (liked moderately). Hence for all further studies 3% NaCl diffusion solution was used.

Effect of CA diffusion on sensory quality of paneer

Colour and appearance scores of CA diffused paneer were lower (p ≤ 0.05) than control at all concentrations of CA due to the presence of dispersed moisture droplets on the surface (Table 2). Similar trend was noticed with respect to flavour scores also, however it was non-significant up to 0.05% level. Probably at this level CA did not impart sour acidic taste. At 0.1% level the scores were different (p ≤ 0.05) from control, which may be due to acidic sour taste imparted by CA (Bhattacharya et al. 1971). But the panelists felt that the taste was within the acceptable limit.Body and texture scores decreased (p ≤ 0.05) from 7.7 for control to 7.0 for 0.1% CA diffused samples (Table 2), possibly due to solubalization and softening of proteins by CA at the surface of the product (Bhattacharya et al. 1971).

The overall acceptability scores also decreased (p ≤ 0.05) from 7.9 to 7.2 with increase in CA concentration in diffusion solution (Table 2), but they were non-significant up to 0.05%. The score of 7 and above (liked moderately) for 0.1% CA level indicated that the product is still very much acceptable. Hence, 0.1% CA and 3% NaCl were selected for further studies.

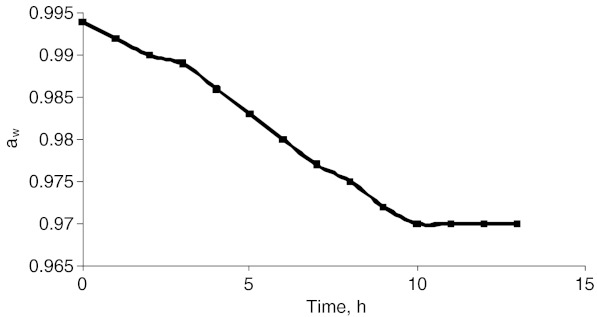

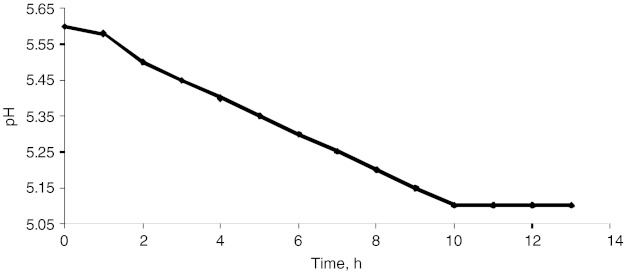

Equilibration of NaCl and CA concentration in paneer

From Figs 1 and 2, it is clear that the diffusion of NaCl and CA were continuous up to 10 h as indicated by continuous drop in aw and pH, further continuation of diffusion process up to 12 h didn’t reduce the aw and pH of paneer indicating that equilibrium had been attained at 10 h itself at 5°C.

Fig. 1.

Changes in aw of paneer during diffusion in 3% sodium chloride solution at 5°C (n = 3)

Fig. 2.

Changes in pH of paneer during diffusion in 0.1% citric acid solution at 5°C (n = 3)

Effect of MAP on HT paneer

Sensory scores of all samples decreased (p ≤ 0.05) during storage period (Tables 3 and 4) irrespective of storage temperatures due to surface discolouration and dry shrunken surface appearance, slightly hard body and spongy texture and the off-flavour (Bhattacharya et al. 1971). The raw (R1), diffused (R2), raw + Map (R3) and diffused + MAP (R4) paneer remained acceptable for 1, 4, 6 and 12 days at room (30 ± 1°C) and 6, 8, 18 and 20 days at refrigeration (7 ± 1°C) temperature respectively (Rai et al. 2008), with respect to all sensory attributes. The hurdles along with MAP helped to enhance the shelf-life. Same effect was also notice by Conte et al. (2009) in cheese packed using MAP.

Table 3.

Effect of modified atmospheric packaging (MAP) on sensory score of diffused paneer packed in PET/PE during storage at 30 ± 1 C

| Paneer type | Storage period, days | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | |

| Colour and appearance | |||||||||

| R1 | 7.8ap | 6.8aq | 5.2ar | – | – | – | – | – | – |

| R2 | 7.5bp | 7.1bq | 6.5br | 6.1as | 5.5at | – | – | – | – |

| R3 | 7.5bp | 7.2bq | 7.0cr | 6.7bs | 6.4bt | 5.6au | – | – | – |

| R4 | 7.4bp | 7.3cp | 7.2dp | 7.0cq | 6.8cr | 6.5bs | 6.3t | 6.1u | 5.9v |

| Flavour | |||||||||

| R1 | 7.7ap | 6.5aq | 5.1ar | – | – | – | – | – | – |

| R2 | 7.5bp | 7.0bq | 6.4br | 6.0as | 5.4at | – | – | – | – |

| R3 | 7.5bp | 7.3cp | 7.0cq | 6.6br | 6.2bs | 5.3at | – | – | – |

| R4 | 7.2cp | 7.2dp | 7.0cp | 6.9cq | 6.8cq | 6.6br | 6.5r | 6.2s | 5.8t |

| Body and texture | |||||||||

| R1 | 7.9ap | 6.7aq | 5.5ar | – | – | – | – | – | – |

| R2 | 7.6bp | 7.2bp | 6.7bq | 6.3ar | 5.8as | – | – | – | – |

| R3 | 7.5bp | 7.2bq | 7.0cq | 6.7br | 6.3bs | 5.4at | – | – | – |

| R4 | 7.2cp | 7.1bp | 7.0cp | 6.9cpq | 6.8cq | 6.6bqr | 6.4r | 6.3rs | 5.9t |

| Overall acceptability | |||||||||

| R1 | 7.8ap | 6.7aq | 5.3ar | – | – | – | – | – | – |

| R2 | 7.5bp | 7.1bq | 6.6br | 6.2as | 5.5at | – | – | – | – |

| R3 | 7.5bp | 7.2bq | 7.0cq | 6.7br | 6.3bs | 5.4at | – | – | – |

| R4 | 7.2cp | 7.2bp | 7.1cp | 6.9cpq | 6.8cq | 6.7bq | 6.5r | 6.3r | 5.9s |

R1-raw paneer + air, R2-diffused paneer + air, R3-raw paneer + MAP, R4-diffused paneer + MAP, (n = 3)

Means with different superscripts (a,b.c…) in a column and means with different superscripts (p,q,r….) in a row differ significantly (p ≤ 0.05)

Table 4.

Effect of MAP in sensory score of diffused paneer packed in PET/PE during storage at 7 ± 1 C

| Paneer type | Storage period, days | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 4 | 6 | 8 | 10 | 15 | 18 | 20 | 25 | |

| Colour and appearance | |||||||||||

| R1 | 7.8ap | 7.7ap | 7.5aq | 7.0ar | 6.5as | 5.5at | – | – | – | – | – |

| R2 | 7.5bp | 7.4bp | 7.2bq | 6.9br | 6.8br | 6.5bs | 5.8at | – | – | – | – |

| R3 | 7.6cp | 7.4bq | 7.3cq | 7.2cr | 7.0cs | 6.9cs | 6.8bt | 6.5au | 6.2av | 5.8aw | – |

| R4 | 7.5bp | 7.5cp | 7.4dp | 7.2cq | 7.1dq | 7.0dr | 6.9cr | 6.6bs | 6.4bt | 6.1bu | 5.9 |

| Flavour | |||||||||||

| R1 | 7.8ap | 7.7ap | 7.4aq | 6.9ar | 6.2as | 5.1at | – | – | – | – | |

| R2 | 7.5bp | 7.4bp | 7.2bq | 7.1bq | 6.8br | 6.4bs | 5.5at | – | – | – | – |

| R3 | 7.5bp | 7.4bp | 7.3cq | 7.1br | 7.0cr | 6.8cs | 6.7bs | 6.2at | 5.9au | 5.5av | – |

| R4 | 7.5bp | 7.4bp | 7.3cq | 7.2cq | 7.1dr | 6.9ds | 6.8cs | 6.5bt | 6.3bu | 6.0bv | 5.8 |

| Body and texture | |||||||||||

| R1 | 7.8ap | 7.7ap | 7.5aq | 7.0ar | 6.3as | 5.2at | – | – | – | – | – |

| R2 | 7.6bp | 7.4bq | 7.3bq | 7.2bq | 6.9br | 6.5bs | 5.6at | – | – | – | – |

| R3 | 7.5cp | 7.4bp | 7.3bq | 7.2bq | 7.0cr | 7.0cr | 6.8bs | 6.4at | 6.1au | 5.7av | – |

| R4 | 7.5cp | 7.5cp | 7.4cp | 7.2bq | 7.1dr | 7.0cr | 6.9cr | 6.5bs | 6.3bt | 6.1bu | 5.9 |

| Overall acceptability | |||||||||||

| R1 | 7.8ap | 7.7ap | 7.5aq | 7.0ar | 6.3as | 5.4at | – | – | – | – | – |

| R2 | 7.5bp | 7.4bp | 7.3bq | 7.0ar | 6.8bs | 6.5bt | 5.6au | – | – | – | – |

| R3 | 7.5bp | 7.4bp | 7.3bp | 7.1bq | 7.0cq | 6.9cr | 6.8br | 6.4as | 6.1at | 5.7au | – |

| R4 | 7.5bp | 7.5cp | 7.3bq | 7.2cq | 7.1dq | 7.0dr | 6.9cr | 6.6bs | 6.4bt | 6.1bu | 5.8 |

R1-raw paneer + air, R2-diffused paneer + air, R3-raw paneer + MAP,R4-diffused paneer + MAP (n = 3)

Means with different superscripts (a,b.c…) in a column and means with different superscripts (p,q,r….) in a row differ significantly (p ≤ 0.05)

Physico chemical and sensory characteristics of HT paneer

Application of hurdles altered the sensory characteristics like yellowish to dull white colour and appearance, slightly salty acidic flavour and slightly hard body as also observed by Kanawjia et al. (2000) and Dermiki et al. (2008). Changes in moisture, fat and protein contents in HT paneer due to diffusion and MAP were marginal while diffused and MAP paneer had lower (p ≤ 0.05) aw, SPC and yeast and mould counts and higher ash contents compared to raw paneer (Table 5).

Table 5.

Physico-chemical and microbiological characteristics of HT-paneer

| Paneer type | Moisture,% | Fat,% | Protein,% | Ash,% | aw | pH | SPC, log10cfu/g | YMC, log10cfu/g |

|---|---|---|---|---|---|---|---|---|

| Raw | 52.5a | 23.4a | 21.0a | 1.6a | 0.994a | 5.5a | 5.3a | 2.4a |

| D | 52.0b | 23.0b | 20.5b | 3.5b | 0.970b | 5.1b | 3.1a | 2.0b |

| D + MAP | 51.5c | 23.0b | 21.0a | 3.5b | 0.970b | 5.1b | 2.3c | Nil |

D Diffused, MAP modified atmospheric packaging, HT Hurdle technology, SPC standard plate count, YMC yeast and mould counts (n = 3).

Means with different superscripts in a column differ significantly at p ≤ 0.05, (n = 3)

Preparation of paneer by adopting HT and MAP is presented in Fig. 3.

Fig. 3.

Preparation of paneer by HT and MAP

Conclusion

Shelf-life of paneer could be significantly enhanced by adopting MAP with a gas mixture (CO2:N2 = 50:50) prepared by adopting HT comprising of 3% NaCl, 1% CA and 0.1% potassium sorbate. Keeping quality of paneer was extended from 1 to 12 days at room (30 ± 1°C) and 6 to 20 days at refrigeration (7 ± 1°C) temperature without much affecting the sensory and physico-chemical characteristics of paneer.

References

- Aneja RP, Mathur BN, Chandan RC, Banerjee AK. Technology of Indian milk products. Delhi: Dairy India Publ; 2002. pp. 134–142. [Google Scholar]

- Bhattacharya DC, Mathur ON, Srinivasan M, Sanlik O. Studies on the method of production and shelf life of paneer. J Food Sci Technol. 1971;8:117–120. [Google Scholar]

- Conte A, Gammariello D, di Giulio S, Attanasio M, del Nobile MA. Active coating and modified-atmosphere packaging to extend the shelf life of Fior di Latte cheese. J Dairy Sci. 2009;92:887–894. doi: 10.3168/jds.2008-1500. [DOI] [PubMed] [Google Scholar]

- Dermiki M, Ntzimani A, Badeka A, Savvaidis IN, Kontominas MG. Shelf-life extension and quality attributes of the whey cheese 'Myzithra Kalathaki' using modified atmosphere packaging. LWT Food Sci Technol. 2008;41:284–294. doi: 10.1016/j.lwt.2007.02.014. [DOI] [Google Scholar]

- IS 1224 (Part I and II). Methods for test of dairy industry. Bacteriological analysis of milk and milk products. New Delhi: Bureau of Indian Standards; 1981. [Google Scholar]

- SP 18, Part XI, ISI handbook of food analysis. New Delhi: Dairy products, Bureau of Indian Standards; 1981. [Google Scholar]

- Jayaraj Rao K, Patil GR. Water activity lowering ability of some humectants in paneer. Indian J Dairy Biosci. 1999;10:121–122. [Google Scholar]

- Jayaraj Rao K, Patil GR. Development of ready to eat paneer curry by hurdle technology. J Food Sci Technol. 1999;36:37–41. [Google Scholar]

- Kanawjia SK, Roy SK, Singh S. Technological advances in paneer making. Indian Dairyman. 2000;52(10):45–45. [Google Scholar]

- Kaur J, Bajwa U, Sandhu KS. Effect of brining on the quality characteristics of plain and vegetable impregnated paneer. J Food Sci Technol. 2003;40:534–537. [Google Scholar]

- Leistner L. Food design by hurdle technology. Kulmbacj: Adalbert Raps- Foundation; 1994. [Google Scholar]

- Mangarj S, Goswami TK. Modified atmospheric packaging—an ideal food preservation technique. J Food Sci Technol. 2009;46:399–410. [Google Scholar]

- National statistics index, department of animal husbandry, dairying & fisheries, ministry of agriculture. New Delhi: Govt. of India; 2009. [Google Scholar]

- Rai S, Goyal GK, Rai GK. Effect of modified atmosphere packaging (MAP) and storage on the chemical quality of paneer. J Dairying Foods Home Sci. 2008;27(1):65. [Google Scholar]

- Rao KJ (2000) Application of hurdle technology. In: Advances in food technology, Compendium of 6th training course, CAS in Dairy Technology, NDRI, Karnal, pp 173–177

- Rao KJ, Patil GR. A study on the effect of different Hurdles on the rheological properties of fried paneer by response surface methodology. J Food Sci Technol. 2001;38:207–212. [Google Scholar]

- Singh S, Rai T. Process optimization for diffusion process and microwave drying of paneer. J Food Sci Technol. 2004;41:487–491. [Google Scholar]

- Singh L, Mohan MS, Puttalingamma V, Sankaran R. Preservation of paneer by sorbic acid. J Food Sci. 1989;29:129–132. [Google Scholar]

- Thakral S, Prasad MM, Ghodekar DR (1990) Effect of incorporation of potassium sorbate and nisin for improvement in shelf-life of paneer. XXIII International Dairy Congress, Monteal, 8–12 October, Vol 1, p 150

- Venkateshaiah BV (2003) Status and scope of value added indigenous dairy products. In: Summer school on recent advances in value added indigenous dairy products, Department of Dairy Technology, University of Agricultural Sciences, Bangalore, 9–29 July, pp 4–12