Abstract

Rabadi, prepared by fermenting pearl millet (Pennisetum typhoideum (L.)) (PM) flour with butter milk, is a traditional popular beverage of North-Western states of India. A process for PM based Rabadi-like fermented milk beverage was attempted. Skim milk and flour of 24 h germinated PM grains (FGG-24 h) were used as sources of solids. FGG-24 h was mixed in skim milk before fermentation and level of flour and water were determined using Response Surface Methodology (RSM) with central composite rotatable design (CCRD). The product developed using 5.3% flour and 72% water on the basis of curd gave the most acceptable product. For further stabilization during storage, pectin and/or carboxy methyl cellulose were tried at different levels and a level of 0.6% pectin was selected. The standardized product was packaged in glass bottles and stored under refrigeration (5–7 °C). The shelflife of the product was 7 days.

Keywords: Rabadi, Pearl millet, Fermented milk beverage

Introduction

Fermented foods contribute to about one-third of the diet worldwide (Campbell-Platt 1994). Traditional fermented foods are made under primitive conditions, which result in low yield and poor quality. They can be “reinvented” by applying modern process technologies for mass production to meet the consumer’s new demand in response to changing life style. The fermented milk-cereal flour products are extremely popular in most of the African countries and Indian sub-continent. The process of manufacture of these products differs from place to place and even within the same country. For the manufacture of these products generally buttermilk or whey or curd and cereals like pearl millet (Pennisetum typhoideum L.), wheat (Triticum aestivum) and sorghum (Sorghum vulgare) are used. In addition, spices may be added along with salt with various combinations and levels. In the present study, PM was selected for the preparation of Rabadi. PM is a rich source of proteins and fat, as compared to other cereals (Kurien et al. 1973).

Rabadi is an indigenous natural cereal based lactic fermented milk beverage popular in North-Western semi-arid regions of India. Traditionally Rabadi is prepared by admixing cereal flour with sour buttermilk in different proportions. The mixture is further fermented by placing in sun light for 3–4 h and finally boiled. The product is consumed either directly or after dilution with milk or buttermilk. So far, the technology of producing Rabadi remains a household art, which results in wide variation and poor shelf-life. More ever, traditional method is not suitable for large-scale production. Great prospects exist in India for value-addition and improving health benefits of milk and milk by-products by combining with traditional cereals and applying advanced technologies for their processing and preservation. No work of technological or scientific significance has been reported in the literature on either standardization of method or large-scale production of Rabadi with standard composition. It was therefore, planned to develop processing technology for preparing Rabadi-like PM based fermented milk beverage.

Materials and methods

The basic ingredients like pearl millet (Pennisetum typhoideum), salt, cumin (Cuminum cyminum) and black pepper (Piper nigrum) were purchased from local market. Fresh mixed skim milk was collected from the Experimental Dairy, NDRI, Karnal. The fat and total solids (TS) content of skim milk ranged from 0.1% to 0.3% and 8.5% to 9.1%, respectively. The titratable acidity of skim milk was between 0.14 and 0.16%. Mesophilic mixed strain dahi culture NCDC-167 was supplied by National Collection of Dairy Cultures (NCDC), Dairy Microbiology Division, NDRI, Karnal. Sour buttermilk was prepared by churning dahi in hand churn. The buttermilk had 1.2% fat, 7.8% TS and 0.93% acidity as determined by AACC (2000) and AOAC (1995) methods. All chemicals used were of AR grade.

Forms of PM solids

PM was used in the form of flour of raw grains, germinated grains and in the form of slurry of cooked grains in water with 15% TS.

The PM solids and skim milk were blended before and after fermentation for the formulation of the Rabadi-like beverage, and buttermilk was blended only after fermentation stage according to traditional method.

Before fermentation

Skim milk was heated to 40 °C and PM solids (flour, slurry and germinated flour) at 5% on milk basis were added. This blend was then further heated to 90 °C for 5 min and cooled to 37 °C. It was then inoculated with starter culture at 3% and incubated at 37 °C for 12 h. The set curd was then mixed properly and blended with water to have viscosity of 45–65 cp. The mixture was blended with salt (0.85%), cumin (0.285%) and black pepper (0.05%) in an electric mixer (Sumeet Machines Pvt. Ltd., Nasik, India). The levels of these ingredients were decided on the basis of preliminary trials. The final product was cooled to 5 °C and stored in refrigerator (5–7 °C).

After fermentation

Skim milk was heated to 90 °C for 5 min and cooled to 37 °C. It was then inoculated with starter culture at 2% and incubated at 37 °C for 12 h. The set curd was then mixed properly and blended with PM solids (flour, slurry and germinated flour) at 5% on milk basis and water to have viscosity of 45–65 cp. The mixture was blended with salt (0.85%), cumin (0.285%) and black pepper (0.05%) in an electric mixer (Sumeet Machines Pvt. Ltd., Nasik, India). The final product was cooled to 5 °C and stored in refrigerator (5–7 °C).

Beverage prepared by both methods was evaluated for its sensory characteristics by a panel of 8 judges from the faculty of Dairy Technology Division; using 9-point Hedonic scale (Stone et al. 1974). The combination of germinated flour addition before fermentation had maximum average overall acceptability. Thus, it was selected for further investigation.

Formulation of beverage

The beverage was prepared using the before fermentation method as described earlier with 3–8% germinated flour and curd is set. The set curd was then mixed and added with water at 50–100% by weight of the curd formed and blended, added with spices and stored as described under before fermentation method.

Experimental design

The central composite rotatable design was used for designing the experimental combinations (Yadav et al. 2007). The experiment was designed using software Design Expert version 6.0.10. The variables used were flour of 24-h germinated PM and water by weight of curd and level of these variables along with experimental plan consisting of two variables at five levels has been shown in Table 1. The variables were standardized to simplify computation and to deduce the relative effect of variables on response. The magnitude of the coefficients in second order polynomial shows the effect of that variable on the response.

Table 1.

Process variables and their coded and uncoded levels

| −1.414 | −1 | 0 | 1 | 1.414 | |

|---|---|---|---|---|---|

| FGG-24 h, % of skim milk, X1 | 3.0 | 3.88 | 6.0 | 8.12 | 9.0 |

| Water,% of curd,X2 | 50 | 57.32 | 75.0 | 92.68 | 100 |

Storage study of optimized sample

Selected final product was filled in cleaned and sanitized 200 ml glass bottles. Filled glass bottles were crown corked with the help of manual operated crown-corking machine in the UG/PG lab, DT Division, NDRI, Karnal. Then these bottles were kept at refrigerated temperature (5–7 °C) and analyzed daily for changes in acidity, viscosity, sedimentation and sensory attributes.

Analysis of sedimentation value and wheying-off

Ten milliliter of the beverage was taken in a clean 15 ml graduated capped tube and kept undisturbed in the refrigerator for 24 h. The amount of cereal flour settled in ml was noted as sediment and amount of whey separated was noted and expressed as ml sediment and% wheying-off respectively.

Viscosity

The viscosity of the samples was determined at 25 ± 0.1° C using 1-1 system of coaxial cylinder viscometer (Contraves Rheomat 108 ER, Switzerland). The viscosity was measured at shear rate of 100 s−1. The experiment was conducted using thermo statistically controlled water bath. The result obtained in Pa.s. was then converted into cP using following formula:

|

Statistical analysis

The experiment was designed and responses were analyzed using software Design Expert version 6.0.10. All physic-chemical determinations were average of three replicates, whereas sensory data were average of eight replicates.

Results and discussion

Effect of milk solid source

The beverage made from buttermilk and skim milk were acceptable in terms of sensory quality (scores 7.2–7.5). The viscosity of beverage prepared from buttermilk (58 cp) was higher than that of skim milk (53 cp) based beverage. No sedimentation or wheying-off was observed in either case. The preparation of sour buttermilk is a time consuming and tedious process in addition to losses of fat in it. On account of this aspect and better compatibility, skim milk was selected as base for preparation of Rabadi-like beverage for further experiments.

Effect of form and stage of addition of PM solids to skim milk

Out of total 9 combinations tried (Raw flour, slurry, 24 and 48 h germinated flour in 2 stage before and after fermentation and re-fermentation of raw flour), flour of 24 h germinated grains when added to milk solids before fermentation was found better than other forms and stage of addition with average overall acceptability score of 7.2 on 9-point Hedonic scale. Hassan et al. (2006) reported that germination followed by fermentation was more effective in increasing the protein digestibility of PM. For further experiments this form and stage of addition was used.

Raw PM flour and wet ground slurry in all forms provided astringent flavour to the beverage, thus the scores were low. FGG-48 h caused excessive settling thus increasing sedimentation in both stages of addition i.e. before and after fermentation. Thus, in all subsequent trials beverage was prepared by adding PM flour obtained by grinding 24 h germinated grains (FGG-24 h) to skim milk before fermentation.

Effect of variables on beverage properties

Sensory scores of Rabadi-like beverage for colour and appearance varied from 6.1 to 7.5, consistency 6.3 to 7.3, flavour 6.5 to 7.2 and overall acceptability 6.6 to 7.5. The scores of physicochemical responses varied 0.52–0.68% lactic acid, 0–1.5 ml/10 ml and 33–62 cp for acidity, sedimentation and viscosity, respectively. A second order polynomial was fitted into the data for all responses and the results are reported in Table 2.

|

where β0,βi,βii,β1j = regression coefficients, xi,xj = independent variables, Y = dependent variable.

Table 2.

Coefficient of second order polynomial regression models

| Coefficient | C & A | Consistency | Flavour | OA | Acidity | Sediment | Viscosity |

|---|---|---|---|---|---|---|---|

| β0 | 7.358 | 7.078 | 7.14 | 7.25 | 0.604 | 0 | 56.4 |

| β1 | −0.33* | 0.079 | −0.174* | −0.143* | −0.0216* | 0.453* | 6.505* |

| β2 | 0.0137 | −0.177* | 0.0127 | −0.0341 | −0.033* | 0.453* | −8.2* |

| β11 | −0.417* | −0.082 | −0.164* | −0.243* | – | 0.344* | −1.763 |

| β22 | −0.234* | −0.223* | −0.197* | −0.23* | – | 0.344* | −5.012* |

| β12 | 0.078 | 0.03 | 0.075 | 0.073 | – | 0.375* | 1.5 |

| R2 | 0.9464 | 0.8522 | 0.8706 | 0.8565 | 0.7566 | 0.9764 | 0.9357 |

| F | 24.73 | 8.07 | 9.42 | 8.35 | 13.29 | 58.026 | 20.39 |

*p ≤ 0.05, C & A Colour and appearance score, OA Overall acceptability

R2 > 0.80 for sensory attributes is statistically adequate for developing a model or equation (Henika 1982). Presently R2 was > 0.80 for all the sensory responses (Table 2). The probability value (p) showed the adequacy of the models so used to describe the effect of variables on different responses. The effect of flour (FGG-24 h) and water on the responses is shown in Table 2. The sign and magnitude of coefficients indicate the effect of the variable on the responses. The total effect of individual variable and combined effect of the variables at all levels are presented in Table 3.

Table 3.

Analysis of variance data for the overall effect of process variables

| Total individual effect | Sum of squares | ||||||

|---|---|---|---|---|---|---|---|

| C & A | Consistency | Flavour | OA | Acidity | Sediment | Viscosity | |

| Process variables | |||||||

| FGG-24 h,X1 | 0.87* | 0.05 | 0.24* | 0.16* | 0.0037* | 1.64* | 338.54* |

| Water, X2 | 0.0015 | 0.25* | 0.0013 | 0.0093 | 0.0085* | 1.64* | 537.89* |

| Variables combined effect | |||||||

| Linear level | 0.87 | 0.30 | 0.24 | 0.17 | 0.012* | 3.28* | 876.43* |

| Quadratic level | 1.44* | 0.37* | 0.41* | 0.69* | 0.0003 | 1.45* | 183.48* |

| Interactive level | 0.024 | 0.0036 | 0.023 | 0.021 | – | 0.56* | 9.00 |

*p ≤ 0.05, C & A Colour and appearance score, OA Overall acceptability

Effect of variables on sensory responses

Table 2 shows that, flour (FGG-24 h) affected most of the sensory responses except consistency at linear level and water decreased consistency at linear level. The interaction between the variables had no effect on the sensory responses.

Colour and appearance of the product affected significantly by flour (FGG-24 h), while water affected colour and appearance at higher level only. The maximum score of colour and appearance was observed when 6% flour (FGG-24 h) and 75% water were used in formulation. Consistency of the product was well explained by both flour (FGG-24 h) and water. Higher levels of water and flour (FGG-24 h) have inverse effect on consistency score of product. The water had significant negative effect while flour (FGG-24 h) had positive effect. Flavour of the product was significantly influenced by levels of both parameters, with the increase in flour (FGG-24 h) above a certain level; significant decrease in flavour score was observed.

Overall acceptability of the beverage was found dependent mostly on flour (FGG-24 h), the significance of level of water at higher level indicated the decrease in overall acceptability after attaining a particular value.

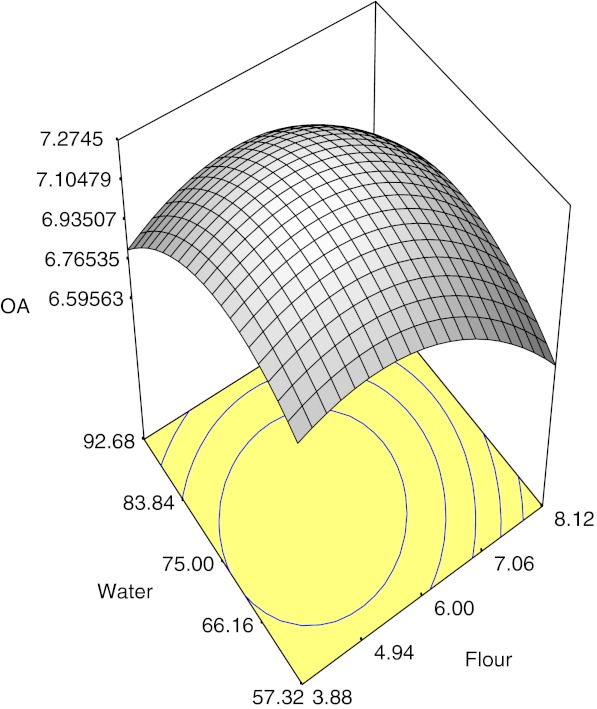

The response surface for overall acceptability scores in relation to flour (FGG-24 h) and water is shown in Fig. 1. The overall effect of flour (FGG-24 h) was maximized on responses followed by water, except consistency, where it was vice versa.

Fig. 1.

Effect of flour of 24 h germinated pearl millet and water on overall acceptability of Rabadi-like beverage (Design-expert plot) OA Overall acceptability

Effect of variables on physicochemical responses

All the physico-chemical responses were affected significantly by both the parameters (Table 2). Acidity of the beverage was significantly influenced by level of both flour (FGG-24 h) and water, but the effect of water was more significant. There was a decrease in acidity as the amount of water and flour (FGG-24 h) increased.

Sedimentation and viscosity were also affected by both flour (FGG-24 h) and water, both variables tend to favour sedimentation in the beverage, while flour (FGG-24 h) increased and water decreased the viscosity.

Optimization of independent variables

The optimum level obtained for flour (FGG-24 h) was 5.3% by weight of skim milk, and for water 72.3% by weight of set curd. The predicted and actual response values (obtained after making the product using the optimum level of ingredients) have been presented in Table 4 from which it can be observed that both the values were almost similar, hence, the above levels of ingredients were recommended. Optimized Rabadi-like beverage contained 0.65% fat, 8.8% TS, 2.2% protein and 1.3% ash. The acidity of beverage was 0.594% lactic acid. The standard plate count was 6.9 log cfu/ml, the yeast and mold count was to be 1.6 log cfu/ml and no coliforms were found in the beverage.

Table 4.

Predicted and actual response values obtained using compromise optimum condition of Rabadi-like beverage

| Attributes | Predicted resultsa | Actual resultsb | t-value* |

|---|---|---|---|

| Colour and appearance | 7.4 | 7.4 | 1.5 |

| Consistency | 7.1 | 7.0 | 2.0 |

| Flavour | 7.2 | 7.3 | 3.9 |

| Overall acceptability | 7.3 | 7.2 | 2.3 |

| Acidity,% LA | 0.62 | 0.60 | 1.96 |

| Viscosity, cP | 55.24 | 53.67 | 1.78 |

aPredicted values of Design Expert 6.0.10 package

bActual values (average of 3 trials) of optimized product

*t-values non significant at 5% level of significance (Table value of t = 4.303)

Effect of addition stabilizer on stability of beverage

Though in the beverage prepared by using solution suggested by response surface methodology, the sedimentation of cereal solids was zero on day 1, it gradually increased on storage. Sedimentation in fermented/cultured milk beverages is a major hurdle for storage of product. Because of low pH, acidic milk products suffer from protein sedimentation, which leads to whey separation on storage (Amice-Quemeneur et al. 1995). Also, in cereal based products, the cereal particles tend to settle forming three layers of whey, milk solids and cereal particles. The aggregation of casein particles with decreasing pH is the result of two major destabilizing actions: the elimination of steric repulsion and neutralization of electrostatic repulsions (Roefs and Van Vliet 1990). This phenomenon in cultured milk could be eliminated or reduced by increasing viscosity through the introduction of hydrocolloids in the system (Glahn 1982; Basset 1983; Towler 1984). The unique stabilizing ability of acidic polysaccharides is probably due to the negative charge the casein particles acquire. The Columbic repulsion between the particles counteracts both tendency of the particles to adhere to each other and the gravitational pull (Glahn 1982).

Carboxy methyl cellulose (CMC) and pectin were used separately to attain stability in the beverage. CMC at 0.05%, 0.1% and 0.15%, while pectin at 0.4%, 0.5% and 0.6% of the final beverage were used.

Effect on sedimentation

The sedimentation increased when CMC alone was used. It was less than the control when used at 0.1 and 0.15% (Table 5). Our results agree with the observation of Towler (1984).

Table 5.

Effect of stabilizers on sedimentation and wheying-off

| Stabilizer | Concentration% | Avg. sediment | Avg. wheying-off |

|---|---|---|---|

| Pectin | 0.6 | 0a | 3.1a |

| Pectin | 0.5 | 0a | 5.3a |

| Pectin | 0.4 | 0a | 6.2ab |

| CMC | 0.15 | 1.19b | 12.2bc |

| CMC | 0.1 | 1.19b | 12.2bc |

| CMC | 0.05 | 1.38b | 12.2bc |

| Control | - | 1.38b | 13.4c |

Sediment and wheying-off (p ≤ 0.05) (n = 3), CMC Carboxy Methyl Cellulose

Avg. Sediment and Avg. wheying-off shown with different superscripts in a column were significantly different at p ≤ 0.05 (n = 3)

All the levels of pectin tried showed preventive effect on sedimentation. Sathish Kumar et al. (2005) also reported that addition of pectin in lassi-like beverage decreasd the sedimentation.

Effect on wheying-off

Incorporation of CMC alone increased the wheying off at all the 3 levels (Table 5). While addition of pectin decreased wheying off at higher levels of 0.5 and 0.6% (Table 5). Lucey et al. (1999) reported reduction in whey separation with the increase in the concentration of pectin in acid milk beverage.

The sensory score of beverage was higher (7.4) for the product made using pectin at 0.6% level as compared to 0.5% level (7.1). So, pectin at 0.6% level was selected for beverage preparation.

Changes in sensory and physic-chemical parameters during storage of beverage

The average scores of colour and appearance, sedimentation, consistency, flavour and overall acceptability of beverage on 7th day decreased from 7.6 to 7.1, 6.95 to 6.8, 7.2 to 6.95, 7.3 to 6.9 and 7.2 to 6.9, respectively (Table 6). This change in scores of sensory attributes during storage of beverage was however non-significant and may be due to slight sedimentation and wheying-off. Decrease in viscosity of the beverage during storage should be obvious for decrease in consistency score. The decrease in flavour scores may be mainly attributed to increase in acidity of beverage during storage period. Slight decrease in overall acceptability scores may be due to marginal increase in wheying-off and sedimentation, decrease in viscosity and increase in acidity of the beverage during storage.

Table 6.

Changes in sensory and physic-chemical properties of Rabadi-like beverage during storage

| Parameter | Storage interval at 5–7 °C (days) | |||||||

|---|---|---|---|---|---|---|---|---|

| Fresh | 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| Colour and appearance | 7.6NS | 7.4 NS | 7.3 NS | 7.2 NS | 7.2 NS | 7.2 NS | 7.1 NS | 7.1 NS |

| Sedimentation | 7.0 NS | 7.1 NS | 6.9 NS | 6.8 NS | 6.8 NS | 6.8 NS | 6.8 NS | 6.8 NS |

| Consistency | 7.2 NS | 7.2 NS | 7.2 NS | 7.2 NS | 7.1 NS | 7.1 NS | 7.1 NS | 7.0 NS |

| Flavour | 7.3 NS | 7.2 NS | 7.2 NS | 7.1 NS | 7.0 NS | 6.9 NS | 6.9 NS | 6.9 NS |

| Overall acceptability | 7.2 NS | 7.2 NS | 7.2 NS | 7.1 NS | 7.0 NS | 7.0 NS | 6.9 NS | 6.9 NS |

| Acidity,% LA | 0.6a | 0.65ab | 0.66b | 0.67b | 0.679b | 0.683b | 0.695b | 0.702b |

| Viscosity, cP | 57NS | 60NS | 58.5NS | 58NS | 56.5NS | 55.5NS | 54.5NS | 53NS |

| Sediment, ml | 0NS | 0NS | 0NS | 0NS | 0NS | 0.125NS | 0.125NS | 0.125NS |

| Wheying-off,% | 0a | 0a | 0a | 0a | 1.2a | 3.8b | 6.2c | 8.8d |

NS non-significant, All the sensory properties are non-significant at 5% level. Acidity and wheying off (p ≤ 0.05) (n = 8 panelists)

Acidity and Sediment shown with different superscripts in a row were significantly different at p ≤ 0.05 (n=8)

Viscosity of fresh beverage was 57 cP which increased to 60 cP on second day of storage but subsequently showed decreasing trend reaching 53 cP on 7th day (Table 6). However, the changes were non-significant. Initially, the slight increase in viscosity may be due gelatinization of starch (Hoover et al. 1996) and interaction of protein with pectin having negative charge. The possible reason for decrease in viscosity could be the degradation of starch by microorganisms during storage of beverage. Microorganism breakdown starch to smaller molecules (Mono, di or oligosaccharide), which are soluble and unable to hold water (Cronk et al. 1977). Thus, water bonded to starch becomes free and help in decreasing the viscosity.

Change in sedimentation was not significant at 5% level of significance (Table 6). No wheying-off was observed up to 3 days of storage in the beverage. After 4 days, an increase (p < 0.05) in wheying-off was noticed. This may be due to breakdown of starch (Cronk et al. 1977) during storage. The extent of breakdown increased with the rate of fermentation and so the wheying-off. Another reason for increase in wheying-off could be the decrease in viscosity during storage.

The study was terminated at the end of 7th day because on 8th day the wheying-off increased to 10.25%, which showed clear liquid and curd particles when kept undisturbed at refrigeration temperature just after shaking. It had bad effect on appearance of product inpackage.

Conclusion

The PM based fermented milk beverage developed by the optimized process was found to contained 0.65% fat, 8.7% TS, 2.2% protein, and 1.3% ash. The average overall acceptability score of final beverage was 7.4. The current study resulted in the development of a fermented PM based milk beverage of sensorily acceptable quality and shelf-life of 7 days without any preservative at refrigerated storage (5–7 °C) when packed in glass bottles. The method standardized for production of Rabadi beverage is very simple and can be applied for industrial production.

References

- AACC (2000) Approved methods of the American Association of Cereal Chemists, 10th edn. Washington DC

- Amice-Quemeneur N, Haluk JP, Hardy J, Kravtchenko TP. Influence of the acidification process on the colloidal stability of acidic milk drinks prepared from reconstituted non-fat dry milk. J Dairy Sci. 1995;78:2683–2690. doi: 10.3168/jds.S0022-0302(95)76899-0. [DOI] [Google Scholar]

- Official methods of analysis. 11. Washington DC: Association of Official Analytical Chemists; 1995. [Google Scholar]

- Basset HJ. Use of stabilizers in cultured dairy foods. Cult Dairy Prod J. 1983;18:27–30. [Google Scholar]

- Campbell-Platt G. Fermented foods—a world perspective. Food Res Intl. 1994;27:253–257. doi: 10.1016/0963-9969(94)90093-0. [DOI] [Google Scholar]

- Cronk TC, Steinkraus KH, Hackler LR, Mattick LR. Indonesian tape ketan fermentation. Appl Environ Microbiol. 1977;33:1067–1073. doi: 10.1128/aem.33.5.1067-1073.1977. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Glahn PE. Hydrocolloid stabilization of protein suspensions at low pH. Progr Food Nutr Sci. 1982;6:171–177. [Google Scholar]

- Hassan AB, Ahmed IAM, Osman NM, Eltayeb MM, Osman GA, Babiker EE. Effect of processing treatments followed by fermentation on protein content and digestibility of pearl millet (Pennisetum typhoideum) cultivars. Pakistan J Nutr. 2006;5:86–89. doi: 10.3923/pjn.2006.86.89. [DOI] [Google Scholar]

- Henika RG. Use of response surface methodology in sensory evaluation. Food Technol. 1982;36(1):96–101. [Google Scholar]

- Hoover R, Swamidas G, Kok LS, Vasanthan T. Composition and physicochemical properties of starch from pearl millet grains. Food Chem. 1996;56:355–367. doi: 10.1016/0308-8146(95)00099-2. [DOI] [Google Scholar]

- Kurien PP, Swaminathan M, Subrahmanian V. The chemical composition and nutritive value of bajra and bajra diets. J Food Sci Technol. 1973;10:3–6. [Google Scholar]

- Lucey JA, Tamehana M, Singh H, Munro PA. Stability of model acid milk beverage: effect of pectin concentration, storage temperature and milk heat treatment. J Texture Stud. 1999;30:305–318. doi: 10.1111/j.1745-4603.1999.tb00219.x. [DOI] [Google Scholar]

- Roefs SPFM, Van Vliet T. Structure of acid casein gels 2. Dynamic measurements and type of interaction forces. Colloids Surfaces. 1990;50:161–175. doi: 10.1016/0166-6622(90)80260-B. [DOI] [Google Scholar]

- Sathish Kumar MH, Sabikhi L, Thompkinson DK, Singh AK. Determination of stabilizer levels for a whey-based fermented beverage. Indian J Dairy Sci. 2005;58:139–140. [Google Scholar]

- Stone H, Sidel H, Oliver S, Woodesey A, Singlehon RC. Sensory evaluation by quantitative descriptive analysis. Food Technol. 1974;28(1):24–26. [Google Scholar]

- Towler C. Sedimentation in cultured milk beverage. NZ J Dairy Sci Technol. 1984;19:205–211. [Google Scholar]

- Yadav DN, Sharma GK, Bawa AS. Optimization of soy-fortified instant sooji halwa mix using response surface methodology. J Food Sci Technol. 2007;44:297–300. [Google Scholar]