Abstract

Peach (Prunus persica) fruits of cv. ‘Earli Grande’ were treated with CaCl2 (4 and 6%) and stored at 0–2 °C and 85–90% RH for 21 days followed by storage at ambient conditions (28–30 °C, 65–70% RH) for 72 h. CaCl2 at 6% effectively in reduced spoilage, physiological loss in weight (PLW) effectively reduced and maintained fruit firmness, palatability rating, acidity, vitamin A content and pectin methyl estrase (PME) activity during storage. Results revealed that peach fruits harvested at optimum stage followed by post-harvest dip in 6% CaCl2 solution for 10 min can be stored for 3 weeks in cold storage (0–2 °C, 85–90% RH) with post-storage shelf-life of 3 days at ambient conditions (28–30 °C, 65–70% RH) with acceptable edible quality of fruits.

Keywords: Peach, Quality, Calcium, Storage

Introduction

Peach fruits have short post harvest life. The high temperature accompanied by low RH during harvesting and marketing are the major factors which reduce the post harvest life of peach. Under normal storage conditions the life of fruit does not exceed 3–5 days (Tonini and Tura 1998). Different chemicals and growth regulators have been reported to extend the shelf life of many fruits (Ochel et al. 1993). Post-harvest application of CaCl2 reported to enhance the storage life of apples (Sams et al. 1993). Present investigations were undertaken to study the effect of post harvest treatment of CaCl2 on storage life and quality of peach fruits.

Materials and methods

The fruits of peach cv. ‘Earli Grande’ were harvested from 6 years old trees. Immediately after harvest, fruit samples were shifted in ventilated shed to remove field heat before giving chemical dip treatment. The fruits were dipped in aqueous solution of CaCl2 (4 and 6%) for 10 min. The control fruits were dipped in tap water for same duration. The fruits were air dried to remove the surface moisture and packed in corrugated fibre board cartons (2 kg capacity) at 0–2 °C and 85–90% RH. There were three replications for each treatment. The observations were made weekly for 3 weeks of storage and analysed for physico-chemical characteristics. The spoilage percentage of fruit was calculated on number basis by counting the fruits from each box that had spoiled during storage. The firmness of five fruits were measured with the help of a ‘Pressure tester’ hand penetrometer and results were expressed as kg/cm2. The physiological loss in weight (PLW) of the fruit was calculated on initial weight basis and expressed in per cent. The total sugars, vitamin A and acidity (AOAC 1990) and pectin methyl esterase (PME) (Mahadevan and Sridhar 1982) were estimated. Palatability rating was recorded on the basis of fruit shape, colour and taste by a panel of five judges as per 9-points Hedonic scale. The total soluble solids (TSS) were recorded by a hand refractometer (Erma Japan) with correction at 20 °C. The post-cold storage ambient shelf-life was studied by measuring TSS, acidity and palatability rating for cold stored fruits after 48 and 72 h to assess the market behavior of fruits. The data of three replications were analyzed statistically by factorial analysis in a randomized block design (Cheema and Singh 1990).

Result and discussion

Physiological loss in weight (PLW)

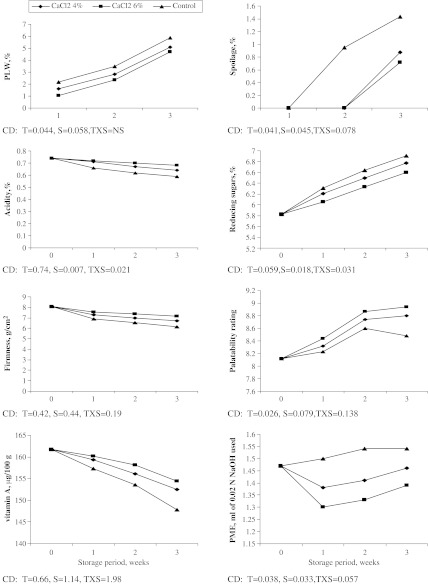

The PLW of fruit treated with 6% CaCl2 ranged from 1.0 to 4.7% during 3 weeks of storage and was lowest compared to others (Fig. 1). The control fruits recorded maximum PLW. The reduction in PLW in CaCl2 treated fruits might be due to the maintenance of fruit firmness and tissue rigidity by decreasing the enzyme activity responsible for disintegration of cellular structure, which decreases the gaseous exchange (Levy and Poovaiah 1979). Similarly, Kizil et al. (1991) found that a dip of 4% CaCl2 reduced the storage loss of apple by 6–7% over control. The PLW increased during storage irrespective of CaCl2 treatments. Robertson et al. (1990) reported that the weight of ‘Cresthaven’ peaches decreased significantly during storage with an average weight loss of 3.5% per week.

Fig. 1.

Changes in quality parameters of peach fruit treated with 0,4 and 6% CaCl2 solution during storage at 0–2 °C, 85–90% RH for 3 weeks. (n = 3) PLW physiological loss in weight, PME pectin methyl esterase, T treatment, S storage, CD = Significant at p ≤ 0.05

Spoilage

The fruits treated with CaCl2 did not record any spoilage till 2 weeks of storage and only 0.72% fruits were found spoiled after 3 weeks of storage (Fig. 1). Control fruits recorded maximum spoilage (1.4%) after 3 weeks storage. Since Ca is the major cation of middle lamella in cell walls and modifies cell wall rigidity (Dey and Brinson 1984) by thickening the middle lamella of cell wall owing to increased formation and deposition of Ca-pectate and this reduced the rate of spoilage. Similar findings with spoilage of plum at low temperature were reported by Mahajan et al. (2008). However, the higher spoilage in untreated fruits was the result of lesser tissue strength and cellular disorganization. Fruit spoilage increased (p ≤ 0.05) during storage due to hydrolysis of metabolites (Saini et al. 2001).

Firmness

Fruit firmness decreased gradually during storage, but the rate of decrease in firmness was slower in CaCl2 treated fruits (Fig. 1). The fruits treated with 6% CaCl2 retained higher (p ≤ 0.05) firmness throughout the storage period as compared to control. It may be attributed to the role of calcium ions in reducing fruit softening by strengthening the cell walls. A positive correlation was observed between CaCl2 concentration of dipping solution and flesh firmness of pear fruits (Nickhah et al. 1999). This decrease in fruit firmness during storage may be due to hydrolysis of metabolites. These findings are in close conformity with the findings of Rombaldi et al. (2001) in peaches and Changhoo et al. (2001) in Kiwi fruits.

Palatability rating

Fruits treated with 6% CaCl2 maintained highest palatability rating of 8.9 whereas the fruits in control were soft with undesirable flavour and recorded lowest palatability rating of 8.5 after 3 weeks (Fig. 1). This may be attributed to development of better juiciness, flavour, texture, total sugars content and TSS in treated fruits as compared to control. Similar effect of CaCl2 on fruit quality was also reported by Mahajan and Dhatt (2004) in Asian pear. There was progressive increase in palatability rating of Ca treated fruits during storage up to 3 weeks whereas in untreated fruits an increase in palatability was observed during storage up to 2 weeks followed by decline thereafter. Higher palatability rating in untreated fruits at initial stages of storage has also been reported by Bhullar et al. (1985) in ‘Flordasun’ peaches.

Acidity

Higher acidity (0.68%) was observed in fruits treated with 6% CaCl2 after 3 weeks of storage (Fig. 1) and minimum acidity (0.59%) was observed under control after same period. The higher acidity in fruits treated with Ca compounds might be due to decreased hydrolysis of organic acids and subsequent accumulation of organic acids which were oxidized at a slower rate because of decreased respiration. The acidity of fruit declined with storage. Decline in acidity during storage might be due to the increased catabolism of organic acids present in fruit through the process of respiration. These findings are in conformation with those of Dundar et al. (1997) in peaches.

Reducing sugar

Reducing sugar content of the control fruits was maximum (6.9%) after 3 weeks of storage whereas fruits treated with 6% CaCl2 recorded the minimum reducing sugar content (6.6%). The increase in reducing sugar in untreated fruits during storage might be due to an increased concentration of organic solutes as a consequence of water loss. In contrast, CaCl2 treatment caused inactivation of hydrolyzing enzymes responsible for conversion of starch into sugars. These results are in agreement with those of Badshah et al. (1994) in apple. There was a progressive increase in the reducing sugar content of fruits during storage. The increase could probably be due to the rapid hydrolysis of starch into simple sugars and consequently the rate of conversion was higher than the utilization during earlier stages but during later stages, utilization of sugars in respiration was at much faster rate. Similar changes in reducing sugar content were also reported by Prashant and Masoodi (2009) in peaches.

Vitamin A

Higher (p ≤ 0.05) vitamin A content of 154.4 μg/100 g was present in fruits treated with 6% CaCl2 after 3 weeks of storage. It might be due to the delay in senescence and minimum enzyme activity in treated fruits. These results are in agreement with those of Drake and Spayd (1983) in ‘Golden Delicious’ apples. There was a progressive decrease in vitamin A content during storage. However, the rate of decrease was lesser in treated fruits than in control. The decrease in vitamin A content during storage may be due to the increased activity of certain enzymes like polyglacturonase and polyphenol oxidase with longer storage time that might caused for the breakdown of carotenoids during storage.

PME

Minimum PME activity (1.39) was observed in fruits treated with 6% CaCl2 after 3 weeks of storage whereas, maximum PME activity (1.54) was under control after same storage period. PME acts on pectin but the Ca compound forms complex with it and bind the pectin as Ca-pectate. Sams and Conway (1993) had also reported that the post harvest pressure infiltration of apples with CaCl2 minimized the PME activity in fruits during storage. Above results are in agreement with those of Bicalho et al. (2000). An increase in PME activity as observed during storage was also reported by Randhawa et al. (1987).

Post-cold storage shelf-life

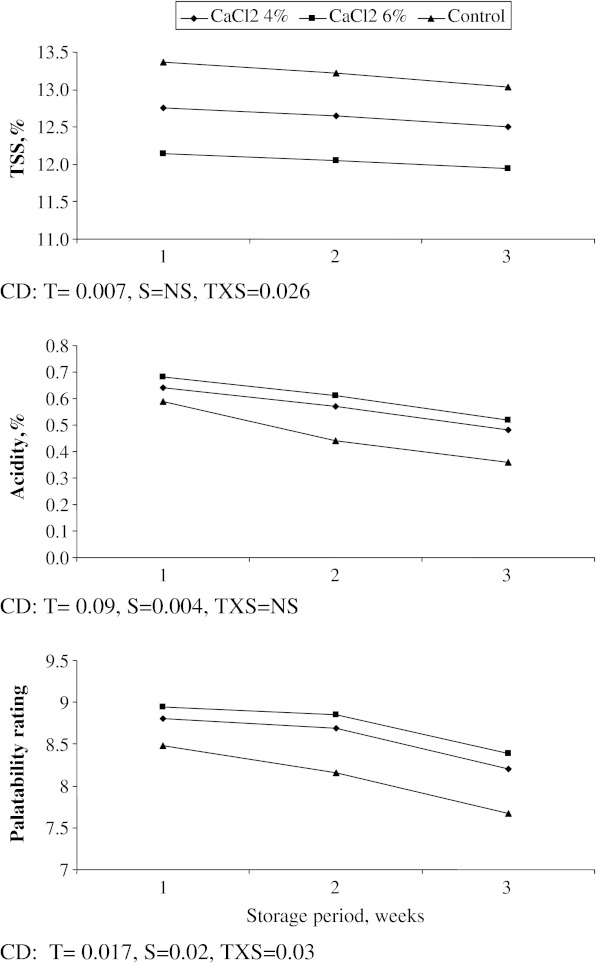

The TSS during ambient storage (28–30 °C, 65–70% RH) was lower (p ≤ 0.05) in fruits treated with 6% CaCl2 (Fig. 2). A decline in TSS of fruits was observed during storage. The fruits treated with 6% CaCl2 recorded higher acidity as compared to other treatments and control. The acidity of fruits also showed declining trend during storage, which may be due to utilization of acids during respiration. Similar decline in acidity under ambient conditions was also reported by Meena et al. (2009). Peach fruits treated with 6% CaCl2 recorded higher palatability rating (Fig. 2) whereas minimum palatability rating was observed in control.

Fig. 2.

Changes in quality of cold stored (0–2 °C, 85–90% RH for 3 weeks) peach fruit during further storage under ambient conditions (28–30 °C, 65–70% RH) (n = 3). TSS total soluble solids, T, S: as in Fig. 1

Conclusion

Peach fruits harvested at optimum stage followed by post-harvest dip in 6% CaCl2 solution for 10 min, can be stored for 3 weeks in cold storage (0–2 °C, 85–90% RH) with post-storage shelf life of 3 days at ambient temperature (28–30 °C, 65–70% RH) with acceptable edible quality of fruits.

References

- Official methods of analysis. 15. Washington: Association of Official Analytical Chemists; 1990. [Google Scholar]

- Badshah N, Rashid H, Sofi S. Role of calcium in prolonging the shelf life of apple. Sarhad J Agric. 1994;10:639–645. [Google Scholar]

- Bhullar JS, Dhillon BS, Randhawa JS. Role of pre-harvest calcium application in extending the post harvest life of sub-tropical peach. Punjab Hortic J. 1985;25:76–81. [Google Scholar]

- Bicalho UO, Chitarra AB, Chitarra MIF, Coelho AHR. Changes in the texture of papaya fruits subjected to post harvest calcium application and wrapping in PVC. Cienc Agrotecnol. 2000;24:136–146. [Google Scholar]

- Changhoo L, Kim S, Ko J, Kim C. Changes in cell wall metabolism of kiwi fruits during low temperature storage by post harvest calcium application. J Korean Soc Hort Sci. 2001;42:91–94. [Google Scholar]

- Cheema HS, Singh B. A user’s manual to CPCSI-A computer programme package for analysis and commonly used experimental designs. Ludhiana: Punjab Agricultural University; 1990. [Google Scholar]

- Dey PM, Brinson K. Plant cell walls. Adv Carbohydr Chem Biochem. 1984;43:215–281. [Google Scholar]

- Drake ST, Spayd SE. Influence of calcium treatment on ‘Golden Delicious’ apple quality. J Food Sci. 1983;48:403–405. doi: 10.1111/j.1365-2621.1983.tb10752.x. [DOI] [Google Scholar]

- Dundar O, Kuden AB, Dennis FG., Jr Investigations on cold storage and post harvest physiology of J. H. Hale peach. Acta Hortic. 1997;441:411–441. [Google Scholar]

- Kizil IS, Binnetaliev SA, Shcherbets BI, Todirash VP. A method for increasing fruit storability. Sadovostvovinogradarstvo. 1991;9:5–8. [Google Scholar]

- Levy D, Poovaiah BW. Effect of calcium infiltration of senescence of apples. Hortic Sci. 1979;14:466. [Google Scholar]

- Mahadevan A, Sridhar R. Methods in physiological plant pathology. Madras: Sivagami Publ; 1982. [Google Scholar]

- Mahajan BVC, Dhatt AS. Studies on postharvest calcium chloride application on storage behaviour and quality of Asian pear during cold storage. J Food Agr Environ. 2004;2:157–159. [Google Scholar]

- Mahajan BVC, Randhawa JS, Kaur H, Dhatt AS. Effect of post-harvest application of calcium nitrate and gibberellic acid on the storage life of plum. Indian J Hortic. 2008;65:94–96. [Google Scholar]

- Meena HR, Kingsly ARP, Jain RK. Effect of post-harvest treatments of shelf life of ber fruits. Indian J Hortic. 2009;66:58–61. [Google Scholar]

- Nickhah S, Azerang HP, Maskoki A. Investigation into the role of calcium chloride on quality characteristics of pear varieties in cold storage. Agric Sci Technol. 1999;13:149–158. [Google Scholar]

- Ochel CO, Basiouny FM, Woods FM. Calcium mediated post-harvest changes in storage ability and fruit quality of peaches. Proc Fla State Hort Soc. 1993;106:266–269. [Google Scholar]

- Prashant B, Masoodi FA. Effect of various storage conditions on chemical characteristics and processing of peach cv. ‘Flordasun’. J Food Sci Technol. 2009;46:271–274. [Google Scholar]

- Randhawa JS, Dhillon BS, Bal JS, Bhullar JS. Studies on the pectin methylesterase activity during cold storage of ‘Patharnakh’ pear. J Food Sci Technol. 1987;24:71–73. [Google Scholar]

- Robertson JA, Meredith FI, Horvat RJ, Senter SD. Effect of cold storage and maturity on the physical and chemical characteristics and volatile constituents of peaches (cv. ‘Cresthavan’) J Agric Food Chem. 1990;38:620–624. doi: 10.1021/jf00093a008. [DOI] [Google Scholar]

- Rombaldi CV, Silva JA, Machado LD, Parussolo A, Kaster LC, Girardi CL, Danieli R. Harvesting stage and cold storage influences on the quality of Chiripa peaches (Prunus persica L.) Cienc Rural. 2001;31:19–25. doi: 10.1590/S0103-84782001000100004. [DOI] [Google Scholar]

- Saini RS, Chanana YR, Singh G. Crop regulation effects on the cold storage of peaches. Effect on physical characteristics of fruits. Haryana J Hortic Sci. 2001;30:177–181. [Google Scholar]

- Sams CE, Conway SW. Post harvest calcium infiltration improves fresh and processing quality of apples. Acta Hortic. 1993;326:123–129. [Google Scholar]

- Sams CE, Conway SW, Abbott JA, Lewis RJ, Benshalon N. Firmness and decay of apples following post-harvest pressure infiltration of calcium and heat treatment. J Am Soc Hortic Sci. 1993;118:623–627. [Google Scholar]

- Tonini G, Tura E. Influence of storage and shelf-life time on rots of peaches and nactarines. Acta Hortic. 1998;464:364–367. [Google Scholar]