Abstract

Mozzarella cheese was placed in two types of packaging materials (Cryovac, P1 and linear low density polyethylene/BA/Nylon-6/BA/Low density polyethylene, P2) under 5 different atmospheres, air (A1), vacuum (A2), 100% CO2 (A3), 100% N2 (A4) and mixture of 50% N2 and 50% CO2 (A5). The product was evaluated periodically for microbiological quality. Among the different gases studied, A3 showed minimum microbial count during storage, thus proving superior followed by A5, A4, A2 and A1.

Keywords: Modified atmosphere packaging, Mozzarella cheese, Vacuum packaging, Microbiological quality

Introduction

Modified atmosphere packaging (MAP) is an enclosure of food products in high barrier materials in which gaseous environment has been modified as a result of dynamic interaction between atmosphere and product (Brody 1989; Tanweer and Goyal 2006, 2007; Gammariello et al. 2009). MAP is capable of substantially extending the shelf life of many perishable foods and has accordingly undergone developments to meet the growing consumer demand for fresh and high quality convenience foods (Tanweer and Goyal 2006). MAP technology has been successfully used to extend the shelf life of wide range of commodities including meat, fish, milk and milk products, sandwiches, salads and vegetables (Church and Parson 1995; Sahoo and Anjaneyulu 1999; Tanweer and Goyal 2004; Gammariello et al. 2009). Mozzarella cheese is an essential ingredient of pizza. The shelf life of Mozzarella cheese is only14–15 days at refrigeration condition which is affected by the atmospheric air and swamped by surface growth of yeast and mould. Presence of atmospheric air and O2 affect the overall quality of Mozzarella cheese during storage. Hence this study was undertaken to ensure the information on the microbiological characteristics of Mozzarella cheese and the interaction of the product, packaging and modified atmospheres (different composition of gases) during storage under refrigeration conditions.

Materials and methods

Cow milk was collected from the herd of crossbred and Indian cows, while buffalo milk was from ‘Murrah’ herd.

Preparation of Mozzarella cheese

For preparation of Mozzarella cheese the standard method as reported by Kanawjia et al. (1996) with slight modification was followed. The milk was first filtered/clarified and then standardised as buffalo: cow 60:40 and fat was adjusted to 3%. The standardized milk was pasteurized by low temperature long time method and cooled to 5–6 °C. The chilled milk was acidified with 25% HCl @3.25 ml conc HCl/l milk to get pH of 5.5–5.6.

Renneting and cutting of curd

The temperature of acidified milk was raised to 27 °C. Then diluted microbial rennet, i.e. Meito (1:40 in distilled water) was added @ 0.75–0.80 g/100 l milk. The renneted milk was left undisturbed for 15 min for setting of curd. The properly set curd was cut with sterilized cheese knives and then allowed to stand in whey for 5 min.

Cooking, stirring and draining

The temperature of curd was raised @1 °C for every 5 min till 38 °C and maintained for 30 min with continuous stirring to achieve uniform cooking and to avoid lump formation. Then the whey was drained to aggregate the curd particles.

Stretching, moulding, brining and surface drying

For proper stretching and elasticity, Mozzarella cheese was stretched in hot water (82–85 °C) for 10 min and moulded into ball shape (300 g each), which were then immersed in pasteurised chilled (8–10 °C) brine solution (20% w/v) for 4 h followed by surface drying in cold storage maintained at 5–6 °C for 6 h.

Packaging materials

High barrier bags namely, Cryovac (70 μ) (P1) and linear low density polyethylene/BA */Nylon-6/BA */low density polyethylene (110 μ) (* poly binding agent) (P2), which are indigenously made were used. The water vapour transmission rate and oxygen transmission rate of P1 were 0.5–0.6 g/sq in./24 h and 3–6 ml/sq m/24 h respectively, while that of P2 were 3.96 g/sq m/24 h and 36 ml/sq m/24 h, respectively as specification.

Packaging equipment

Packaging under modified atmosphere (MA) was accomplished by using a vacuum chamber Quick 2000 machine (α– Laval, Kramer Grebe, GmbH & Co, KG Maschinefabrik, 3560 Biedenkopf-Wallau, Germany), with gas injection after establishing a vacuum of 25″ Hg (ca.85 Pa). Packaging under atmosphere (air) was done by using vertical heat-sealing machine (KSF350, Foot Pedal Impulse Sealer, Pack Sealer TMEC UK Ltd, Bumingham, UK).

Packaging of Mozzarella cheese

Freshly prepared Mozzarella cheese balls were individually packaged in sterilized packages under different atmospheres, i.e. air (A1), vacuum (A2), 100% CO2 (A3), 100% N2 (A4) and 50% CO2/50% N2 (A5). Initially the gas headspace to cheese weight ratio was ≈2 l of gas per kg of product. The packaged samples were stored at 7 ± 1 °C. The gases used were of industrial grade.

Microbiological analysis

Standard plate count (SPC), Yeast and moulds (Y and M), coliform and psychotrophic counts of Mozzarella cheese samples were determined by following APHA (1992) procedures.

Results and discussion

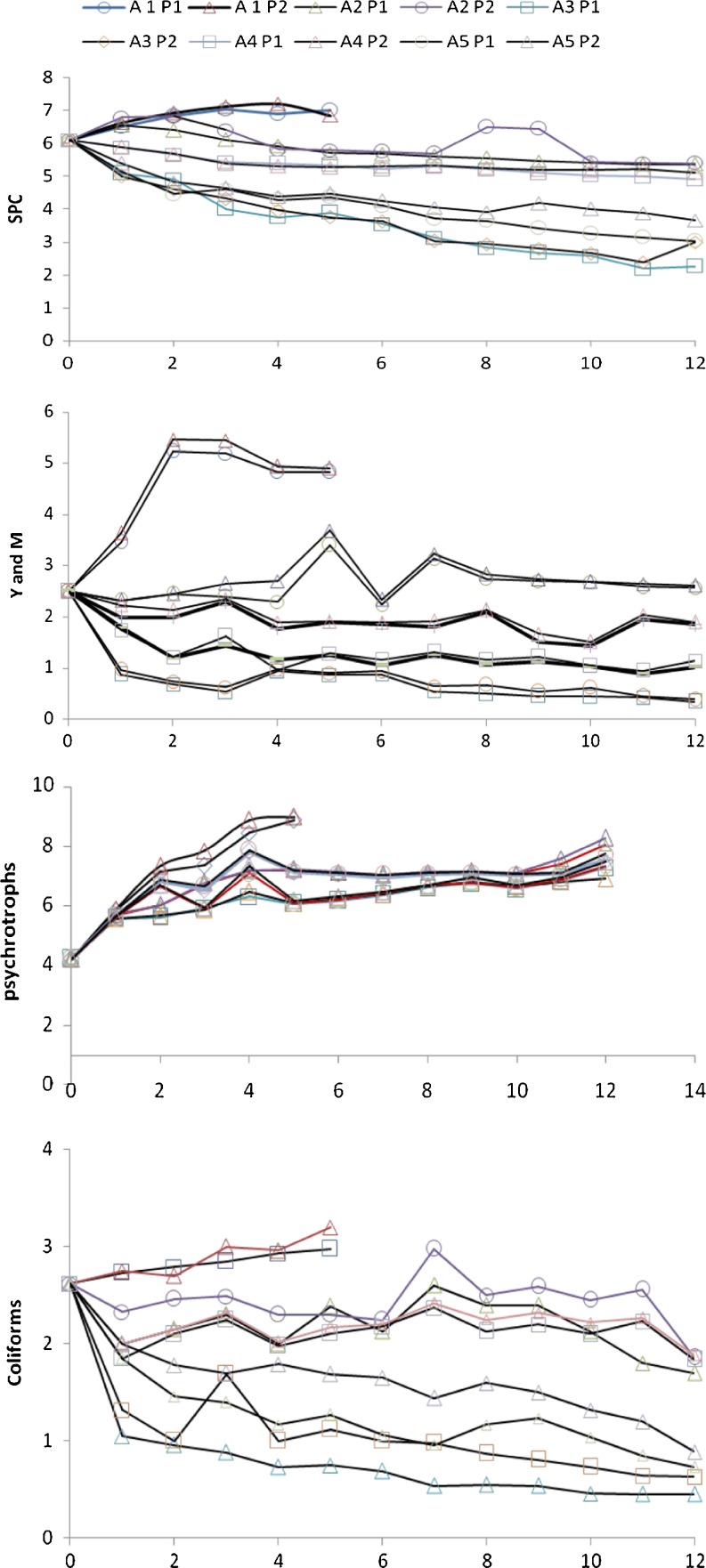

Changes in microbiological counts are presented in Fig. 1.

Fig. 1.

Changes in microbial counts (log cfu/g) of Mozzarella cheese packed in different packages and stored at 7 ± 1 °C (n = 3). SPC = Standard plate count, Y and M = Yeasts and moulds, P1 = Cryovac, P2 = Linear low density polyethylene/BA/Nylon-6/BA/Low density polyethylene, A1 = atmosphere air, A2 = vacuum, A3 = 100% CO2, A4 = 100% N2, A5 = mixture of 50% N2 and 50% CO2

The initial SPC was 6.1 (log cfu/g) in air packed (A1) Mozzarella cheese which increased to 6.8 log cfu/g in P1 and P2 after 5 weeks of storage. Asperger (1991) also reported that the total bacterial count in Mozzarella cheese stored at 4 °C increased and was >107 cfu/g after 1 week of storage. In case of samples stored for 12 weeks, the SPC was minimum in samples packed under A3 (100% CO2) and highest in A2 (vacuum).

Table 1 indicates that the storage, interactions of atmospheres × packages and intervals × packages and intervals × atmospheres × packages had significant effect (p < 0.05) on changes in SPC. Type of package and interaction intervals × atmospheres however, were not significant. The initial mean value of Y and M counts (log cfu/g) of Mozzarella cheese increased from 2.5 to 5.2 and 5.5, respectively in P1 and P2 after 3 weeks of storage at 7 ± 1 °C. However, the count decreased to 4.8 and 4.9 (log CFU/g) in respect of these two packages after 5 weeks of storage (A1). In samples stored for 12 weeks Y and M counts were minimum (0.4 for P1 for 0.4 for P2) in samples packed under A3 and maximum in A2 (2.6 for P1, 2.7 for P2). Alves et al. (1996) reported only the development of yeasts in the sliced Mozzarella cheese packed in air and under atmosphere of 100% N2 and 50% CO2/50% N2. No growth of Yand M was detected in Mozzarella cheese stored under 100% CO2 (A3) during 58 days at 7 ± 1 °C, and the growth of yeasts in Mozzarella cheese in air and under 100% N2 (A4) was observed after the 8th day. From the 14th day, the counts of yeasts stabilized at 8.4 log cfu/g for the product in air (A1). The cheese under 100% N2 (A4) presented lower counts of yeasts than cheese stored in air throughout the study. The growth in the product under 50% CO2/50% N2 (A5) occurred at a slower rate than the growth in the product in air (A1) and under 100% N2 (A4). That could also be due to the action of CO2, i.e. what really inhibited the growth of yeasts was CO2. Eliot et al. (1998) also confirmed that the growth of Y and M in Mozzarella cheese was inhibited under MAP condition (>50% CO2) upto 8 weeks at 7 °C. Storage, two types of packages, interactions of atmospheres × packages and storage × atmospheres significantly (p < 0.01) influenced the Y and M counts.

Table 1.

Analysis of variance for microbiological parameters of MAP Mozzarella cheese stored in different packages at 7 ± 1 °C

| Source of variation | Mean sum of square | ||||

|---|---|---|---|---|---|

| df | SPC-Standard plate counts | Y&M-Yeasts and moulds | Psychrotrophs | Coliform | |

| Among intervals of storage period (S) | 12 | 39048** | 10703** | 21559** | 6573** |

| Among atmospheres (A) | 4 | 7274* | 4465** | 26619** | 1155* |

| Between packages (P) | 1 | 0253 | 0060 | 0045 | 0380 |

| SxA | 48 | 1782 | 1120 | 3514 | 0388 |

| SxP | 12 | 0012** | 0001 | 0002 | 0005 |

| AxP | 4 | 17799** | 8840** | 45608** | 3333** |

| SxAxP | 48 | 3040* | 1860** | 5917** | 0670 |

| Error | 260 | 2573 | 1172 | 3767 | 0630 |

*p ≤ 0.0 5%, **p ≤ 0.01

The psychrotrophic count of Mozzarella cheese exhibited increasing trend during storage in both the packaging materials under all atmospheres. The initial psychrotrophic count of 4.2 increased to 8.9 and 9.0 (log cfu/g), respectively in P1 and P2 after 5 weeks of storage. At the end of 12 weeks, A3 (100% CO2) showed lower increase in psychrotrophs compared to others revealing that the growth was retarded when the atmosphere inside the package contained higher concentration of CO2. Similar results were observed by Eliot et al. (1998) that the initial psychrotrophic count (4.4 log cfu/g) of shredded Mozzarella cheese reached 7 log cfu/g after 3 weeks and then stabilized around 7.2 log cfu/g under modified atmosphere. However, these results did not confirm the inhibitory effect of CO2 on psychrotrophs, which has been demonstrated by Chen and Hotchkiss (1991) and Fedio et al. (1994).

The initial coliform count (log cfu/g) of 2.6 in air packed (A1) Mozzarella cheese increased to 3.0 in P1 and P2 after 5 weeks of storage. More increase in coliform count was noted in P2 compared to P1. Mozzarella cheese stored for 12 weeks at refrigeration temperature revealed that the coliform count (log cfu/g) had been minimum in A3 (0.5 for P2, 0.6 for P1) and maximum in A2 (1.9 for P2, 1.7 for P1). The lower coliform count was most likely due to bacteria killed by membrane destructive plasmolysis by CO2. Similar observation was reported by Rosenthal et al. (1991).

Conclusion

The 5 types of atmospheres and storage influenced the microbiological count and growth on Mozzarella cheese. The 100% CO2 gas was most effective in controlling the microbial growth during storage, thus proving best, followed by the samples packed in gas mixture of 50% N2 and 50% CO2, 100% N2, vacuum and air in descending order.

References

- Alves MVR, Sarantopoulos CIGDL, Van Dender AGF, Faria JDAF. Stability of sliced Mozzarella cheese in modified atmosphere packaging. J Food Prot. 1996;59:838–844. doi: 10.4315/0362-028X-59.8.838. [DOI] [PubMed] [Google Scholar]

- Compendium of methods for the microbiological examination of foods. 3. Washington: American Public Health Association; 1992. [Google Scholar]

- Asperger H. Microbiological hygienic evaluation of Mozzarella cheese. Milchwirtschaft. 1991;10(8):138–144. [Google Scholar]

- Brody AL. Modified atmosphere/vacuum packaging of meat. In: Brody AL, editor. Controlled/modified atmosphere/vacuum packaging of foods. Trumbully, CT: Food and Nutrition Press Inc; 1989. pp. 1–37. [Google Scholar]

- Chen JH, Hotchkiss JH. Effect of dissolved CO2 on the growth of psychrotrophic organisms in cottage cheese. J Dairy Sci. 1991;74:2941–2945. doi: 10.3168/jds.S0022-0302(91)78478-6. [DOI] [Google Scholar]

- Church IJ, Parson AL. Modified atmosphere packaging technology: a review. J Sci Food Agric. 1995;67:143–152. doi: 10.1002/jsfa.2740670202. [DOI] [Google Scholar]

- Eliot SC, Vuillemard JC, Emond JP. Stability of shredded Mozzarella cheese under modified atmosphere packaging. J Food Sci. 1998;63:1075–1080. doi: 10.1111/j.1365-2621.1998.tb15858.x. [DOI] [Google Scholar]

- Fedio WM, Macleod A, Ozimek L. The effect of modified atmosphere packaging on the growth of microorganisms in cottage cheese. Milchwissenschaft. 1994;49:622–629. [Google Scholar]

- Gammariello D, Conte A, Giulio DS, Attanasio M, Del Nobile MA. Shelf-life of Stracciatella cheese under modified-atmosphere packaging. J Dairy Sci. 2009;92:483–490. doi: 10.3168/jds.2008-1571. [DOI] [PubMed] [Google Scholar]

- Kanawjia SK, Sabikhi L, Singh S. Textural profile changes in Mozzarella cheese. Korean J Dairy Sci. 1996;18:17–24. [Google Scholar]

- Rosenthal IB, Rosen BS, Popel G. Preservation of fresh cheeses in a CO2 enriched atmosphere. Milchwissenschaft. 1991;46:706–708. [Google Scholar]

- Sahoo J, Anjaneyulu ASR. Modified atmosphere packaging of meat and meat products-aspects of packaging material, packaging environment and storage temperature. Indian Food Industry. 1999;18:299–310. [Google Scholar]

- Tanweer A, Goyal GK. MAP- A new frontier packaging in dairy and food industry. Indian Dairym. 2004;56(8):53–60. [Google Scholar]

- Tanweer A, Goyal GK. Influence of MAP on the chemical quality of Mozzarella cheese stored in different packages at refrigeration condition. J Food Sci Technol. 2006;43:342–349. [Google Scholar]

- Tanweer A, Goyal GK. Influence of MAP and storage at deep freeze conditions on the sensory characteristics of Mozzarella cheese. Milchwissenschaft. 2007;62:311–314. [Google Scholar]