Abstract

Air-drying characteristics of fresh and osmotically pretreated (40°B, 50°B and 60°B sucrose solutions for 9 h) four pepper cultivars namely, Rodo (Capsicum annuum), Shombo (Capsicum frutescens), Bawa (Capsicum frutenscens) and Tatashe (Capsicum annuum), and CIE L*a*b* parameters of air-dried (50, 60, 70 and 80 °C) peppers were investigated. Moisture diffusivity and activation energy (Ea) were calculated from Fick’s law and analogous Arrhenius equation, respectively. Colour difference, chroma and hue angle of fresh- and osmo-oven dried peppers were evaluated. Drying rates occurred predominantly in the falling rate. Moisture diffusivity varied from 8.071 × 10−10–1.048 × 10−8, 7.710 × 10−11–1.018 × 10−9, 9.807 × 10−9–1.746 × 10–8 and 8.748 × 10−10–1.464 × 10−9 m2/s for Bawa, Rodo, Shombo, and Tatashe, respectively. Ea for moisture diffusion during drying of peppers varied from 53.86 to 84.86 kJ/mol and was affected by cultivars and osmotic pretreatment concentration. Osmotic pretreatment and drying temperature had significant effect (p < 0.05) on a*, b*, chroma and hue angle values of dried peppers.

Keywords: Pepper cultivars, Osmotic dehydration, CIE L* a* b* colour, Effective moisture diffusivity, Activation energy

Introduction

Pepper as food popularly stems from the combination of colour, taste and heat. Peppers also called chillis, paprika, pimento, and cayenne are green but change to red, yellow or purple as they ripen. There are many different cultivars, colours, shapes, sizes and even names (Coon 2003). The colour of capsicum fruit is due to the presence of lycopene, xanthophylls and carotene, the latter being dominant in yellow types (Norman 1992). Peppers consumption provides vitamin A and C and antioxidant activity in the diet (Howard et al. 1994). Majority of the peppers cultivated in Nigeria are used in stews and local dishes. Two cultivars of peppers widely cultivated are Capsicum annuum and Capsicum frutescens, and are classified based on pungency and fruit size. Some of the common pepper cultivars in Nigeria include Capsicum annuum var. Rodo, Capsicum annuum var. Tatashe, Capsicum frutescens var. Bawa and Capsicum frutescens var. Shombo. Peppers are commonly dried for spice production, in order to stabilize the fresh product, prolong the keeping quality, reduce the storage volume and decrease transport costs (Govindarajan 1985).

The characteristic colour of dried red pepper is recognized as the essential quality indicator. Colour affects consumer acceptance of a product and can account for 40% of the criteria for acceptance (Baardseth et al. 1988). Colour of red pepper changes considerably during drying. Long dehydration times lead to poor quality products due to caramelisation, Maillard reactions, enzymatic reactions, pigment degradation and L-ascorbic acid oxidation. Selection of proper drying conditions and pretreatment are necessary for minimizing thermal stress, over-drying and retention of carotenoids and capsaicin, which determine the quality of the product (Ade-Omowaye et al. 2003).

The quality (colour, flavour and texture) of air dried fruits and vegetables could be improved by including a prior osmotic dehydration step (Heng et al. 1990; Ade-Omowaye et al. 2003; Azoubel and Murr 2004). Osmotic dehydration is an important process that enables the partial removal of water by direct contact of a product with a hypertonic solution (Lazarides et al. 1995), as well as modification of chemical composition of the material (Lewicki and Porzecka-Pawlak 2005). This gives rise to two major simultaneously countercurrent mass transfer fluxes, namely, water flow from the product to the surrounding solution and solute infusion into the product. Leakage of the product natural solutes (sugars, organic acid and minerals) is quantitatively neglectable, but may be important for the organoleptic and nutritional value of the product (Heng et al. 1990). Although, osmotic dehydration has been applied to pulsed electric field (PEF) treated pepper (Ade-Omowaye et al. 2003), pepper cultivars (Raji et al. 2010), however, little or no report exists on the air drying characteristics and colour of osmotically dehydrated peppers. Thus, the objectives of this work were to investigate the air-drying characteristics of fresh and osmosed pepper cultivars, and also the effect of osmotic pretreatment and drying temperature on colour of dried peppers.

Materials and methods

Fresh mature red pepper cultivars namely, Shombo (cayenne pepper, Capsicum frutescens), Bawa (long red cayenne pepper, Capsicum frutescens), Rodo (hot pepper, Capsicum annuum), and Tatashe (bell pepper, Capsicum annuum), were purchased from a local market. Moisture contents of fresh Shombo, Bawa, Rodo and Shombo were 82.3 ± 1.3, 85.9 ± 2.08, 78.5 ± 1.95, and 83.1 ± 1.15% w.b., respectively. Sucrose (commercial) was purchased from a local market. Known weights of dry sucrose were carefully dissolved in a known weight of distilled water to prepare osmotic sucrose solutions of 40°B, 50°B, and 60°B concentrations.

Osmotic dehydration and oven-drying of peppers

Pepper cultivars were sorted for size, shape and colour. Peppers were washed and blotted dry. Triplicate samples of each pepper cultivar were weighed and placed in wire mesh. Pre-weighed pepper samples were immersed in sucrose solutions of 40°B, 50°B and 60°B at 30 ± 1 °C for 9 h. Osmotic pretreatment for 9 h was selected based on the work of Raji et al. (2010). Afterwards, samples were taken from the solutions, gently blotted dry with tissue paper to remove adhering solution and re-weighed. Pre-weighed fresh and osmotically pre-treated peppers were air dried at 50°C, 60°C, 70°C and 80 °C at 1.5 m/sec. During drying, samples were weighed at 0.33, 0.67, 1, 1.5 and 2 h, and subsequently at 1-h interval until equilibrium weight were attained. Equilibrium was assumed on three equal consecutive weights. On reaching equilibrium, samples were further dried at 100 °C for 24 h (Sankat et al. 1996). Equilibrium moisture content was calculated as the difference between equilibrium weight and bone dry weight divided by the bone dry weight. Drying data were expressed as drying rate versus moisture content (dry basis), and moisture ratio versus drying time. Drying rate was calculated as the amount of water removed per unit time.

Determination of equivalent radius of peppers

Equivalent radius of pepper sample was determined according to the Solvent displacement method of Hebbar and Rastogi (2001). Six samples from each of the four pepper cultivars were used for the determination. Each sample was immersed in a cylinder partly filled with water; the amount of water displaced was taken as the volume. The volume (V) was equated to the equivalent radius using the following equations:

|

1 |

|

2 |

where V = volume (m3) of the pepper cultivars; r = radius (m) of the pepper cultivars; h = height (m) of the pepper cultivars

Determination of effective moisture diffusion co-efficient (Deff)

Fick’s second law of diffusion was used to describe a moisture diffusion process in Eq. 3

|

3 |

Fick’s equation has simple analytical solutions when shrinkage is negligible or not taken into consideration, the internal movement is its main resistance (no external movement resistance) and negligible external and internal heat transfer effect (Sablani et al. 2002) and it also neglects the initial thermal transient effect. When the food product is assumed as one-dimensional and to have uniform initial moisture content, the solutions of Fickian equation for different geometrics are described by Eqs. 4 and 5 (Rossello et al. 1992). Bawa, Shombo, and Tatashe were assumed to be cylindrical, while Rodo was assumed to be spherical. These assumptions were based on the shape which closest resembles each cultivar.

For infinite cylinder:

|

4 |

Where, MR = dimensionless moisture ratio; m = moisture content (dry basis) (kg/kg db); mo = initial moisture content (dry basis) (kg/kg db); me = equilibrum moisture content (dry basis) (kg/kg db); β = roots of the Bessel function; Deff = diffusion coefficient (m2/sec); t = time (sec); rc = cylinder radius; n = positive integer.

For sphere

|

5 |

where, Deff = diffusion coefficient (m2/sec); t = time (sec); rs = sphere radius; n = positive integer

For long drying times (Mr < 0.6), when L, rc and rs are small and t is large, limiting forms of equation are obtained for cylindrical and spherical geometrics by considering only the first term in their series expansion.

A general form of Eqs. 4 and 5 can be written in logarithmic form

|

6 |

where, B is β21 Deff/r2c for a cylinder and π2 Deff/r2s for a sphere.

The slope (B) was calculated by plotting ln MR versus time according to Eq. 6. The effective diffusivity is derived from the slope.

The activation energy was estimated by plotting the values of the effective moisture diffusion coefficient (Deff) against the reciprocal of absolute temperature (1/Tabs), according to the method of Babalis and Belessiotis (2004).

|

7 |

Ea = activation energy (kJ/mol); Rg = universal gas constant (8.314 J/mol K); Tabs = absolute temperature (K); Do = constant

Evaluation of colour parameters of fresh- and osmo-oven dried peppers

Fresh and osmotically dehydrated peppers were air-dried at 50, 60, 70 and 80 °C to about 0.1 g water/g d. s. and sealed in 100 μm low-density polyethylene. CIE lab tristimulus values, L* (lightness), a* (redness), and b* (yellowness) were measured at three different points on the peppers using a Colour Tec—PCMTM Colorimeter (Accuracy Microsensors Inc., Pittsford, New York, USA). Measurements were done in triplicate. Colour difference value (ΔE), colour intensity (chroma) (ΔC) and Hue angle (H) were calculated according to Hunt (1991).

|

8 |

|

9 |

|

10 |

Results and discussion

Effect of drying temperature on moisture content, moisture ratio and drying rate of pepper cultivars

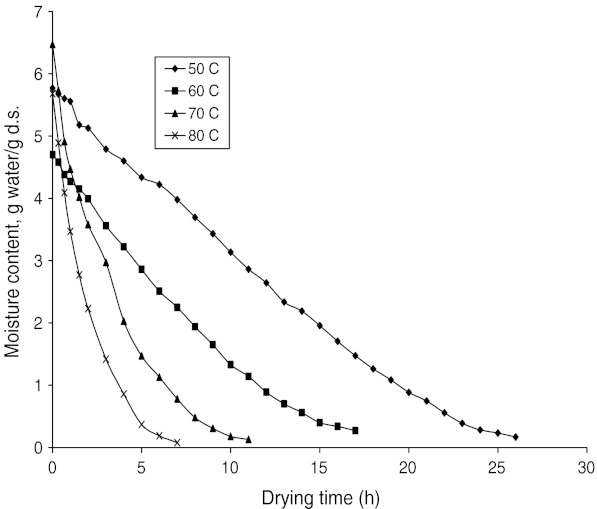

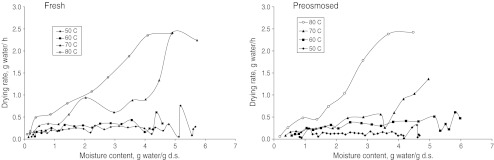

Higher drying temperatures resulted in steeper drying curves and shorter drying times (Fig. 1). Drying curves of Tatashe pepper air dried at 80 °C was steeper than at 70, 60 and 50 °C. The strong influence of high drying air temperature could be readily observed, showing a rapid decline in moisture content at 80 °C compared to 50 °C. Similar trends were observed in Rodo, Bawa and Shombo.

Fig. 1.

Effect of drying temperature on moisture content of fresh Tatashe pepper

Drying rate was highest at the commencement of drying when the moisture content was high. Higher drying temperature resulted in higher initial drying rate and steeper drying curves. Rapid initial drying occurred when moisture was highest, and drying rate decreased as moisture content lowered. The influence of temperature was less pronounced as moisture contents reduced to less than 0.2 g water/g d.s. Temperature has a major influence on the drying rate of both fresh and osmotically pretreated peppers. Figure 2 shows the effect of drying temperature on the drying rate of osmotically pretreated ‘Tatashe’ between 50 and 80 °C. Similar trends were observed in fresh and osmotically pretreated ‘Rodo’, ‘Bawa’ and ‘Shombo’. Steeper moisture content and moisture ratio curves and faster drying rate at higher drying temperature could be due to the increase in the heat supply to the product and acceleration of water migration from the pepper cultivars at higher drying temperatures. Temperature has been shown to be an important factor affecting drying rate (Babalis and Belessiotis 2004; Koyuncu et al. 2004; Falade and Solademi 2010). Drying of fresh and osmosed peppers did not show constant rate period. Drying rate curves of fresh and osmotically pretreated peppers predominantly showed falling rate periods. It is assumed that for the falling rate period to start all the free water is evaporated and the evaporation moves into the interior of the product. When this occurs, moisture transfer is then by molecular (liquid) diffusion or vapour diffusion or by capillary forces in the wet (interior) regions to the surface of the product where evaporation occurs. The diffusion process of water through the dry outer layer to the surface is influenced by high temperature (Karanthanos and Bellessiostis 1997). Thus, diffusion process was increased due to the high temperature of drying air; high temperature resulted in faster diffusion of water.

Fig. 2.

Effect of drying temperature on drying rate of fresh and osmotically pretreated (50°B) Tatashe pepper

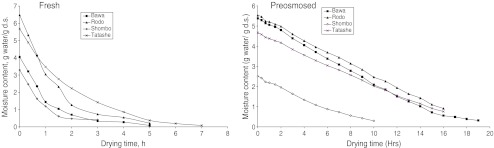

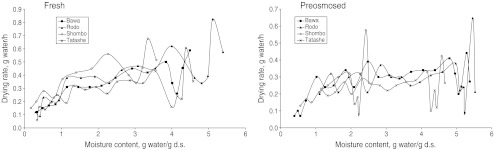

Effect of cultivar on moisture content, moisture ratio and drying rates of peppers

Shombo (Capsicum frutescens) showed the steepest drying curves and shortest drying time. However, during drying Tatashe showed a gradual reduction in moisture contents and a longer drying time (Fig. 3). Drying rates of fresh peppers showed similar trend. Shombo showed higher drying rate than other cultivars (Fig. 4). This observation is more pronounced during the drying of fresh pepper. The differences in the moisture contents, moisture ratio and drying rates of pepper cultivars could be attributed to the geometry (size, shape) and initial moisture contents of peppers. Shombo recorded the smallest equivalent radius (0.0046 m) compared to Rodo (0.0144 m), Bawa (0.0066 m) and Tatashe (0.0115 m). Shorter drying time observed for Shombo could be due to its smaller size and shorter distance it takes moisture to diffuse from the interior to the surface. Moreover, Shombo showed lowest initial moisture content prior to air-drying compared to other cultivars.

Fig. 3.

Effect of cultivar on moisture content of fresh and preosmosed (60°B) air dried pepper at 60 °C

Fig. 4.

Effect of cultivar on drying rate of fresh and preosmosed (60°B) pepper air dried at 60 °C

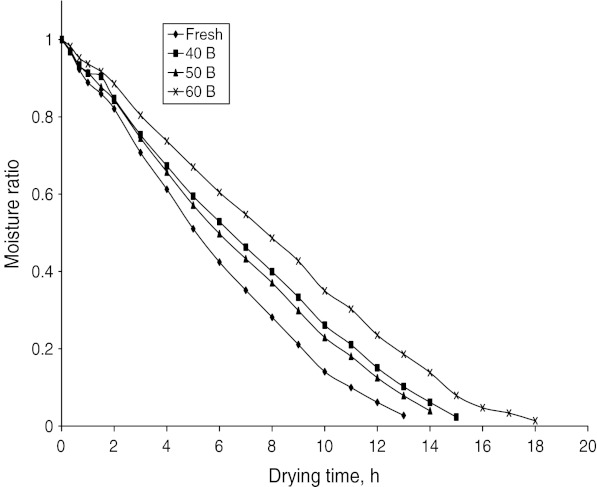

Effect of osmotic pretreatment on moisture content, moisture ratio and drying rate of peppers

Fresh Bawa gave steeper moisture content and moisture ratio curves compared to its osmotically pretreated counterpart (Fig. 5). The difference in initial moisture contents of fresh and osmotically pretreated peppers could be due to moisture removal during the osmotic pretreatment. Samples of pepper pretreated in higher sucrose solution concentration showed lower moisture contents at the commencement of air-drying. This result shows the potential of osmotic dehydration to reduce initial moisture prior to dehydration.

Fig. 5.

Effect of osmotic pretreatment on moisture ratio of Bawa cultivar during air-drying at 60 °C

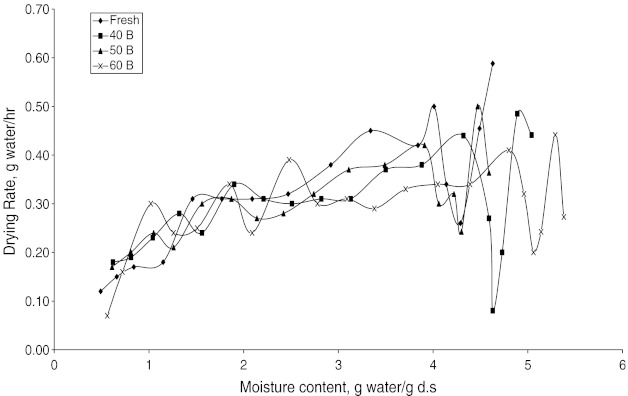

Drying of fresh and osmotically pretreated peppers took place in the falling rate period (Fig. 6). Fresh-oven dried Tatashe pepper showed lower equilibrium moisture content compared to the pre samples pretreated in sucrose solutions. Fresh peppers indicated higher drying rate compared to osmotically pretreated peppers. Generally, peppers pretreated in higher concentration of sucrose solution showed lower drying rates. Differences in the moisture profile and drying rates of fresh and osmosed peppers may be related to the solute uptake that occurred during the osmotic step, which resulted in an increase in the internal resistance to mass transfer and lower physico-chemical, water/sugar interaction in the fresh product because of lower sugar content. This water binding capacity of sugar in foods is referred to as humectancy (Fennema 1985). Mazza (1983), working with carrot, attributed the lower rates to the depression of water vapour pressure in the product due to dissolved sugar and the impairment of heat transfer and the crystallization of sucrose during the subsequent air-drying. Neito et al. (2001), working with mango, attributed the changes to the increased resistance to water flux caused by shrinkage, solid uptake and/or starch gelatinization and protein-carbohydrate mucilage degradation. Basically, physical and chemical changes in the fruit during osmosis caused differences in the drying rate in the subsequent air-drying process when compared to fresh peppers.

Fig. 6.

Effect of osmotic pretreatment on drying rate of Bawa pepper variety air-dried at 60 °C

Effect of pretreatment on moisture diffusivity and activation energy of pepper cultivars

Effective moisture diffusion coefficient (Deff) of fresh and osmo-oven dried peppers at different temperatures were extrapolated from the plots of ln MR versus drying time. Calculated effective moisture diffusivity (Deff) varied with drying temperature, osmotic pretreatment and pepper cultivars (Table 1). Generally, Deff increased with increasing temperature. This is because drying at higher temperature provides a higher driving force causing rapid transfer of water vapour from the core to the surface resulting in high diffusivity (Karanthanos et al. 1990). Deff decreased with increase in concentration of pretreatment solution. The higher the concentration of osmotic solution, the greater the amounts of water removed and solute gain infused during the osmotic pre-concentration, resulting in lower moisture diffusivity. Deff varied from 8.071 × 10−10–1.048 × 10−8, 7.710 × 10−11–1.018 × 10−9, 9.807 × 10−9–1.746 × 10−8 and 8.748 × 10−10–1.464 × 10−9 m2/sec for Bawa, Rodo, Shombo, and Tatashe, respectively. Calculated Deff of fresh peppers were higher than osmotically pretreated peppers. For example, effective diffusivities were 8.14 × 10−10 and 6.56 × 10−10 m2/sec for fresh and osmosed (60°B) Shombo, respectively, oven-dried at 50 °C. Calculated apparent moisture diffusivites at 60 °C ranged from 34.8 × 10−10 to 8.8 × 10−10 m2/sec for fresh and dried banana, respectively (Sankat et al. 1996). Moreover, the effective diffusivities of water calculated from the diffusional model were higher for fresh fruits than those for osmosed papaya and varied from 1.72 × 10−9 to 4.98 × 10−9 m2/sec for fresh papaya and 1.03 × 10−9 to 1.78 × 10−9 m2/sec for osmosed fruits (El-Aouar et al. 2003). Comparison of diffusivities reported in the literature is difficult because of different estimation methods and models employed together with the variation in food composition and physical structure (El-Aouar et al. 2003).

Table 1.

Effect of drying temperature and cultivar on effective moisture diffusivity (m2/s) of fresh and osmotically pretreated peppers

| Cultivars | Drying Temp, °C | Fresh | Osmotic pretreatment concentration | ||

|---|---|---|---|---|---|

| 40°B | 50°B | 60°B | |||

| Bawa (Capsium frutenscens) | 50 | 7.635 × 10−10 | 8.071 × 10−10 | 5.118 × 10−10 | 5.917 × 10−10 |

| 60 | 2.871 × 10−9 | 1.897 × 10−9 | 2.097 × 10−9 | 1.443 × 10−9 | |

| 70 | 6.638 × 10−9 | 4.996 × 10−9 | 4.984 × 10−9 | 3.393 × 10−9 | |

| 80 | 9.502 × 10−9 | 1.048 × 10−8 | 7.250 × 10−9 | 8.699 × 10−9 | |

| Rodo (Capsium annuum) | 50 | 2.022 × 10−10 | 1.026 × 10−10 | 7.710 × 10−11 | 7.403 × 10−11 |

| 60 | 2.883 × 10−10 | 1.810 × 10−10 | 1.818 × 10−10 | 1.677 × 10−10 | |

| 70 | 7.966 × 10−10 | 1.018 × 10−9 | 3.854 × 10−10 | 4.495 × 10−10 | |

| 80 | 9.558 × 10−10 | 9.221 × 10−10 | 9.689 × 10−10 | 9.508 × 10−10 | |

| Shombo (Capsium frutenscens) | 50 | 2.701 × 10−9 | 2.136 × 10−9 | 2.156 × 10−9 | 2.178 × 10−9 |

| 60 | 3.775 × 10−9 | 2.743 × 10−9 | 2.297 × 10−9 | 3.442 × 10−9 | |

| 70 | 1.185 × 10−8 | 9.807 × 10−9 | 5.830 × 10−9 | 7.951 × 10−9 | |

| 80 | 2.384 × 10−8 | 3.220 × 10−8 | 2.282 × 10−8 | 1.746 × 10−8 | |

| Tatashe (Capsium annuum) | 50 | 8.748 × 10−10 | 5.324 × 10−10 | 5.808 × 10−11 | 5.324 × 10−10 |

| 60 | 1.826 × 10−9 | 1.596 × 10−9 | 1.546 × 10−9 | 1.464 × 10−9 | |

| 70 | 4.989 × 10−9 | 3.141 × 10−9 | 2.551 × 10−9 | 2.190 × 10−9 | |

| 80 | 7.485 × 10−9 | 9.817 × 10−9 | 9.296 × 10−9 | 9.292 × 10−9 | |

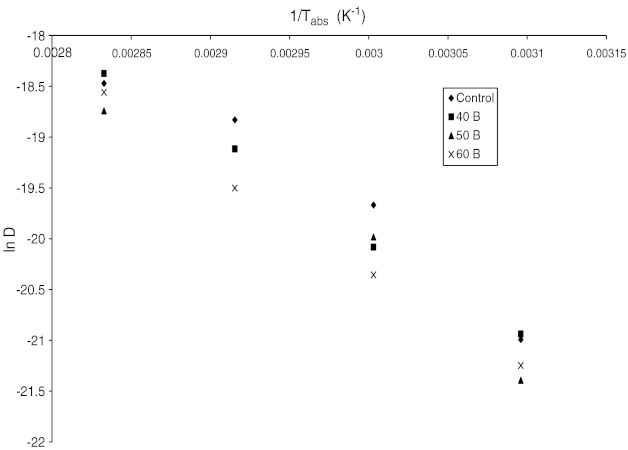

The natural logarithm of the calculated effective moisture diffusivities (ln Deff) was plotted against the reciprocal of the temperature (1/Tabs). From the slope of the lines in Fig. 7, the energy of activation (Ea) (KJ/mol) was calculated and the values obtained are reported in Table 2. Calculated activation energies were rather high with a range of 53.86–84.86 kJ/mol, probably due to the waxy surface skin layer of pepper and surface sugar coating. While it has been recommended the use of additives or mechanical means to reduce the effect of the waxy surface of peppers, the adoption of these techniques could however result in leaching of solubles from peppers. Fresh (untreated) peppers showed lower Ea than the osmotically pretreated peppers. Generally, activation energy increased with increasing concentration of pretreatment sucrose solution. Surface coating of sugar acts as a barrier to moisture migration during drying. Higher concentration of osmotic solution resulted in higher solute uptake and the subsequent higher the activation energy to effect moisture diffusion during air drying. The values for the activation energy falls within the general range 12.7–110 kJ/mol for most food materials. Activation energies for moisture diffusion of prune (57 kJ/mol) and mint (82.93 kJ/mol) exist in literature (Park et al. 2002; Doymaz 2004).

Fig. 7.

Plot of ln D vs 1/K for fresh and osmotically pretreated Bawa pepper cultivar

Table 2.

Effect of cultivar on activation energy of fresh and osmotically pretreated peppers

| Pre-treatment condition | Activation energy, Ea, kJ/mol | |||

|---|---|---|---|---|

| Bawa | Rodo | Shombo | Tatashe | |

| Fresh | 80.15 | 53.86 | 72.53 | 70.72 |

| 40°B | 82.10 | 79.14 | 88.65 | 89.23 |

| 50°B | 84.13 | 79.03 | 75.15 | 83.39 |

| 60°B | 84.47 | 81.94 | 66.91 | 84.86 |

Effect of pretreatment and drying temperatures on CIE colour parameters of pepper

CIE tristimulus (L* a* b*) values of fresh- and osmo- oven dried peppers were determined at three different points on the dried products. Generally, L* (lightness), a* (redness), and b* (yellowness) decreased with increased drying air temperature. Colour intensity (E), chroma (C) and hue angle, generally, decreased with increased drying air temperature (Table 3). Drying temperature and osmotic pretreatment showed no significant difference on lightness (L*), colour intensity, chroma and hue angle of fresh- and osmo-oven dried peppers of all cultivars. Osmotic pretreatment and drying temperature had a significant effect (p < 0.05) on a* (redness) value, a mark of quality of pepper, and b* (yellowness) of fresh- and osmo-oven dried Rodo, Shombo and Tatashe. Moreoever, osmotic pretreatment and drying temperature showed significant effect on a* chroma value of fresh- and osmo-oven dried Bawa, Rodo and Tatashe pepper.

Table 3.

Effects of osmotic pretreatment and drying air temperature on CIE colour parameters of fresh and pre-osmosed peppers

| Cultivar | Treatment | Drying air temp, °C | L* | a* | b* | ∆E | ∆C | Hue angle |

|---|---|---|---|---|---|---|---|---|

| Shombo | Fresh | 50 | 35.2 ± 0.61a | 14.3 ±1.32ab | 3.7 ± 1.44 a | 38.1 a | 14.8 a | 14.3 |

| 60°B | 50 | 35.3 ± 0.40 a | 17.9 ±1.83 b | 7.6 ± 3.17 a | 40.3 a | 19.5 a | 23.1 | |

| Fresh | 80 | 31.9 ± 0.45 a | 9.3 ± 1.79 ab | 7.9 ± 1.00 a | 34.0 a | 11.9 ab | 40.5 | |

| 600B | 80 | 36.3 ± 3.34 a | 4.0 ± 3.73 a | 8.8 ± 4.56 a | 37.5 a | 9.6 b | 65.7 | |

| Bawa | Fresh | 50 | 41.0 ± 0.16 a | 8.2 ± 1.53 a | 20.7 ±1.33 a | 46.6 a | 22.3 a | 68.3 |

| 60°B | 50 | 45.0 ±3.32 a | 13.4 ± 4.29 a | 17.2 ± 8.05 a | 50.0 a | 21.8 a | 52.0 | |

| Fresh | 80 | 30.5 ± 0.53 a | 12.6 ± 2.31 a | −17.9 ± 12.54b | 43.5 a | 31.0 a | −54.9 | |

| 60°B | 80 | 32.2 ±1.38 a | 15.1 ± 3.31 a | −1.7 ±0..02b | 33.6 a | 9.5 a | −6.3 | |

| Rodo | Fresh | 50 | 38.5 ± 0.95 a | 21.0 ±0.14 a | 14.6 ± 3.18 a | 46.2 a | 25.5 a | 34.9 |

| 60°B | 50 | 36.8 ± 0.41 a | 13.3 ± 3.70 ab | 8.0 ± 2.29 ab | 39.9 a | 15.5 ab | 31.1 | |

| Fresh | 80 | 36.0 ± 0.96 a | 11.6 ± 2.01 ab | 20.1 ± 7.71 a | 42.1 a | 23.2 a | 60.1 | |

| 60°B | 80 | 32.4 ± 0.53 a | 3.2 ± 1.68 b | 5.8 ± 2.58 b | 33.0 a | 6.6 c | 60.8 | |

| Tatashe | Fresh | 50 | 38.7 ± 0.86 a | 10.3 ± 1.68 a | 22.7 ± 6.02 a | 41.2 a | 14.0 ab | 65.6 |

| 60°B | 50 | 37.3 ±0.44 a | 6.7 ± 0.31 ab | 4.1 ± 1.67 b | 38.1 ab | 7.8 b | 31.7 | |

| Fresh | 80 | 29.0 ± 0.28 a | −3.2 ± 0.33 b | 2.5 ± 0.10 b | 29.3 b | 4.1 b | −38.0 | |

| 60°B | 80 | 36.7 ±0.30 a | 10.5 ±1.54 a | 18.3 ±4.31 a | 42.3 a | 20.9 ab | 60.0 |

Colour parameter having similar superscripts are not significantly different (p < 0.05) as shown by Tukey’s test.

Conclusion

Drying rate of fresh and osmosed peppers occurred predominantly in the falling rate, showing two falling rates. Slopes of the second falling rate were, generally, higher than first falling rate. However, fresh and osmosed Rodo and Shombo cultivars air dried at 70 and 80 °C showed only a falling rate. Differences in the drying rates of pepper cultivars could be attributed to geometry and initial moisture content of peppers. Calculated effective moisture diffusivity decreased with increase in concentration of sucrose solution. Effective moisture diffusivity of fresh (un-osmosed) peppers was higher than pre-osmosed peppers. Activation energies required for moisture diffusion for fresh and osmosed peppers lie within the range expected for most food materials. Osmotic pretreatment and drying temperature had significant effect (p < 0.05) on a* (redness) value, a mark of quality of pepper, and b* (yellowness) of fresh- and osmo-oven dried Rodo, Shombo and Tatashe.

References

- Ade-Omowaye BIO, Rastogi NK, Angersbach A, Knorr D. Combined effect of pulsed electric field pre-treatment and partial osmotic dehydration on air drying behavior of red bell pepper. J Food Eng. 2003;60:89–98. doi: 10.1016/S0260-8774(03)00021-9. [DOI] [Google Scholar]

- Azoubel PM, Murr FEX. Mass transfer kinetics of osmotic dehydration of cherry tomato. J Food Eng. 2004;61:291–295. doi: 10.1016/S0260-8774(03)00132-8. [DOI] [Google Scholar]

- Baardseth P, Skrede G, Naes T, Thomassen MS, Iversen A, Kaaber L. A comparison of CIE L*a*b* values obtained from two different instruments on several food commodities. J Food Sci. 1988;53:1737–1742. doi: 10.1111/j.1365-2621.1988.tb07830.x. [DOI] [Google Scholar]

- Babalis SJ, Belessiotis VG. Influence of drying conditions on the drying constants and moisture diffusivity during the thin-layer drying of figs. J Food Eng. 2004;65:449–458. doi: 10.1016/j.jfoodeng.2004.02.005. [DOI] [Google Scholar]

- Coon D. Chile peppers: healing up Hispanic foods. Food Technol. 2003;57(1):39–43. [Google Scholar]

- Doymaz I. Convective air drying characteristics of thin layer carrots. J Food Eng. 2004;61:359–364. doi: 10.1016/S0260-8774(03)00142-0. [DOI] [Google Scholar]

- El-Aouar AA, Azoubel PA, Murr FEX. Drying kinetics of fresh and osmotically treated papaya (Carica papaya L.) J Food Eng. 2003;59:85–91. doi: 10.1016/S0260-8774(02)00434-X. [DOI] [Google Scholar]

- Falade KO, Solademi OJ. Modelling of air drying of fresh and blanched sweet potato slices. Int J Food Sci Technol. 2010;45:278–288. doi: 10.1111/j.1365-2621.2009.02133.x. [DOI] [Google Scholar]

- Fennema OR. Food Chemistry. New York: Marcel Dekker; 1985. pp. 105–106. [Google Scholar]

- Govindarajan VS. Capsium production, technology, chemistry, and quality. Part 1. History and primary processing. Crit Rev Food Sci Nutr. 1985;22:109–175. doi: 10.1080/10408398509527412. [DOI] [PubMed] [Google Scholar]

- Hebbar H, Rastogi NK. Mass transfer during infrared drying of cashew kernel. J Food Eng. 2001;47:1–5. doi: 10.1016/S0260-8774(00)00088-1. [DOI] [Google Scholar]

- Heng W, Guilbert S, Cuq JL. Osmotic dehydration of papaya: influence of process variables on the product quality. Sci Aliment. 1990;10:831–848. [Google Scholar]

- Howard LR, Smith RT, Wagner AB, Villalon B, Burns EE. Provitamin A. and ascorbic acid content of fresh pepper cultivars (Capsicum annuum) and processed Jalapenos. J Food Sci. 1994;59:362–365. doi: 10.1111/j.1365-2621.1994.tb06967.x. [DOI] [Google Scholar]

- Hunt RWG. Measuring colour. 2. New York: Ellis Horwood; 1991. pp. p75–76. [Google Scholar]

- Karanthanos VT, Bellessiostis VG. Sun and artificial drying kinetics of some agricultural products. J Food Eng. 1997;31:35–46. doi: 10.1016/S0260-8774(96)00050-7. [DOI] [Google Scholar]

- Karanthanos VT, Villalobos G, Saravacos GD. Comparison of two methods of estimation of effective moisture diffusivity from drying data. J Food Sci. 1990;55:218–223. doi: 10.1111/j.1365-2621.1990.tb06056.x. [DOI] [Google Scholar]

- Koyuncu T, Sedar U, Tosun I. Drying characteristics and energy requirement for dehydration of chestnuts (Castanea sativa Mill.) J Food Eng. 2004;62:165–168. doi: 10.1016/S0260-8774(03)00228-0. [DOI] [Google Scholar]

- Lazarides HN, Katsanidis E, Nickolaidis A. Mass transfer during osmotic preconcentration aiming at minimal solid uptake. J Food Eng. 1995;25:151–166. doi: 10.1016/0260-8774(94)00006-U. [DOI] [Google Scholar]

- Lewicki PP, Porzecka-Pawlak R. Effect of osmotic dewatering on apple tissue structure. J Food Eng. 2005;66:43–50. doi: 10.1016/j.jfoodeng.2004.02.032. [DOI] [Google Scholar]

- Mazza G. Dehydration of carrots: Effects of pre-drying treatments on moisture transport and product quality. J Food Technol. 1983;18:113–123. doi: 10.1111/j.1365-2621.1983.tb00249.x. [DOI] [Google Scholar]

- Neito AB, Castro MA, Alzamora SM. Kinetics of moisture transfer during air drying of blanched and/or osmotically dehydrated mango. J Food Eng. 2001;50:175–185. doi: 10.1016/S0260-8774(01)00026-7. [DOI] [Google Scholar]

- Norman JC. Tropical vegetable crops. Devon: Arthur Stockwell Ltd; 1992. pp. 78–87. [Google Scholar]

- Park KJ, Vohnokova Z, Brod FPR. Evaluation of drying parameters and desorption isotherm of garden mint leaves (Mentha crispa L.) J Food Eng. 2002;51:193–199. doi: 10.1016/S0260-8774(01)00055-3. [DOI] [Google Scholar]

- Raji A, Falade KO, Abimbolu F (2010) Effect of sucrose and binary solution on osmotic dehydration of pepper varieties (Capsicum spp.). J Food Sci Technol (India) 47(3):305–309 [DOI] [PMC free article] [PubMed]

- Rosello C, Canellas J, Simas S, Berna A. Simple mathematical model to predict the drying rates of potato. J Agric Food Chem. 1992;40:2374–2378. doi: 10.1021/jf00024a010. [DOI] [Google Scholar]

- Sablani SS, Rahman MS, Al-Sadeiri DS. Equilibrium distribution data for osmotic drying of apple cubes in sugar-water solution. J Food Eng. 2002;52:193–199. doi: 10.1016/S0260-8774(01)00103-0. [DOI] [Google Scholar]

- Sankat CK, Castaigne F, Maharaj R. The air drying behaviour of fresh and osmotically dehydrated banana slices. Int J Food Sci Technol. 1996;31:123–135. doi: 10.1111/j.1365-2621.1996.332-35.x. [DOI] [Google Scholar]