Abstract

Cassava or tapioca (Manihot esculenta Crantz) tubers having high amount of carbohydrate are utilized after boiling or processing into starch and flour. Textural properties of raw and cooked tubers depend on variety, maturity, growing environment, physico-chemical and starch properties. Starch is used in food preparations as gelling and thickening agent, stabilizer and texture modifier. This study aims at analyzing and modeling the textural, dynamic rheological and gelatinization properties of selected cassava varieties. The thermal softening behavior was analyzed by linear regression and fractional conversion techniques, rheological properties of the gelated starch by Maxwell and power law models. The varieties were classified based on their physico-chemical, texture profile, rheological and gelatinization properties by multivariate analysis. The textural, rheological and gelatinization properties were significantly affected by the varieties (p < 0.05). Thermal softening of tubers was modeled by dual mechanism first order kinetic model with rate constant values ranging from 0.081 to 0.105 min−1. Linear regression models with extremely good fit were obtained to explain the relationship between the degree of cooking and relative firmness. The dynamic spectra of the gelated starch showed the characteristics of concentrated biopolymer dispersion and described using Maxwell and power law model. The results showed that textural, rheological and gelatinization properties varied considerably among the varieties and besides the physico-chemical properties, interaction between them and structural make up of the tuber parenchyma had a great influence on cooking quality and rheological properties.

Keywords: Cassava, Texture, Rheology, Dual mechanism first order kinetic model, Maxwell model

Introduction

Cassava (Manihot esculenta Crantz), popularly known as tapioca, being the richest source of carbohydrate among the root and tuber crops, forms a staple or subsidiary food in many of the tropical and subtropical countries. Of the total harvest of 228.14 million tonnes from 18.67 million hectares globally, 51.67 and 63.78%, 31.48 and 20.57% and 16.13 and 14.33% of production and area, respectively are from Africa, Asia and South America. India has acquired a significant position in the global cassava scenario due to the high productivity level of 31.41 t/ha when compared to the world average of only about 12.22 t/ha (FAO 2009). Cassava tubers are generally used as human food in the form of fresh vegetable after boiling, by producing value added products from its dry flour, as starch or fermented product.

The understanding of the textural properties of the tubers are prerequisite for analyzing their behavior under mechanical forces, which in turn help in the design of appropriate post harvest machineries for processing. Among the various unit operations involved in cassava processing, mechanization is mainly needed in peeling, slicing and crushing. The design of such machineries depends on the engineering and mechanical properties of the tubers, for which several studies have been conducted (Odigboh 1983; Ohwovoriole et al. 1988; Raja et al. 1990; Nanda and Mathew 1996; Sajeev et al. 2008).

Cassava is directly consumed as vegetable after boiling the peeled and sliced tubers in water. Because of high starch content (20–35%) in the tubers, the physical and structural changes taking place in the starch due to boiling have a significant influence on the cooking quality of the tubers. Studies have been conducted to analyze the textural properties of boiled cassava tubers by compression test, shear tests and texture profile analysis (Beleia et al. 2004a, b; Sajeev et al. 2008). Besides maturity of the tubers, growth environment, physico-chemical constituents and starch structural properties may also affect the cooking quality (Safo and Owusu 1992; Eggleston and Asiedu 1994; Ngeve 2003; Padonou et al. 2005). The thermal softening behavior of roots and tubers can be explained by either a first order or a dual mechanism first order kinetic model (Paulus and Saguy 1980; Huang and Bourne 1983; Harada et al. 1985; Bourne 1987; Rizvi and Tong 1997; Sajeev et al. 2008).

Cassava starch forms an important ingredient in formulated food system functioning as a gelling and thickening agent, stabilizer and texture modifier. Starch when heated in the presence of excess water undergoes gelatinization which involves granule swelling, amylose leaching and amylopectin fusion and upon cooling due to retrogradation, solubilized starch forms a viscous dispersion or paste or gel depending on the temperature of processing and concentration of dispersion, varieties, harvesting age and growth season (Rickard et al. 1991; Asaoka et al. 1991, 1992; Defloor et al. 1998; Lagarigue and Alvarez 2001; Moorthy 2001; Fourmann et al. 2003). The viscoelastic behavior of starchy food systems is characterized by dynamic rheological tests and can be evaluated by Maxwell and power law models (Montalvo et al. 1996; Steffe 1996; Subramanian and Gunasekharan 1997; Cortes et al. 1999; Rao 1999; Ak and Gunesekharan 2001; Acharya et al. 2004; Cuppola et al. 2004; Ortega-Ojeda et al. 2004a, b, 2005; Nishinari 2007). Reports on the application of these models to quantify the viscoelastic behavior of gelated cassava starch dispersion are scanty.

Being a crop with multifaceted use in both home and industrial front, the textural properties of the raw and cooked cassava tubers and rheological properties of their starches need special attention. To arrive at a generalized model for the above properties, systematic studies using different varieties having varied physico-chemical, functional and gelatinization properties are needed. In this paper, an attempt was made to analyze the textural properties of the tubers of five local and four hybrid varieties of cassava of 10 months maturity and to model the kinetics of their thermal softening behavior. In addition, dynamic mechanical properties of the starches extracted from these tubers were analyzed using small amplitude oscillation experiments and quantified by applying Maxwell model and power law relationship. In addition to the textural and rheological properties, differential scanning calorimeter (DSC) thermograms and viscogram analysis were also carried out to classify the varieties by multivariate analysis.

Materials and methods

Nine cassava varieties including five locals (‘Venjaramoodan’, ‘Kaliamanja’, ‘Koliakodan’, ‘Adukkumuttan’, ‘Narayanakappa’) and four hybrids (‘Sree Rekha’, ‘Sree Prabha’, ‘H152’ and ‘H740’) harvested after 10 months of planting were used for the study. The tubers, free from any external damage or injury were washed thoroughly in tap water to remove the adhering soil, clay and foreign material and kept overnight under ambient condition to remove surface moisture. Care was taken not to remove periderm (skin) or peel from the tubers during washing and cleaning as it can affect the textural properties of the raw tubers.

Physico-chemical properties

Moisture, starch, sugar, fibre and ash contents were determined by AOAC (1975) methods. Total and apparent amylose contents were determined using spectrophotometric method (Sowbhagya and Batacharya 1971). Peel thickness was measured to an accuracy of 0.01 mm using a digital vernier caliper (Mitutoya, Kanafawa, Japan).

Textural properties of raw cassava tubers

Textural properties were measured using a food texture analyzer (TA HDi, Stable Micro Systems, Surrey, UK) with Texture Expert Exceed software under the following conditions: mode—measure force in compression, pre and post test speed-10 mm/s, test speed- 2 mm/s and distance of compression/penetration- 20 mm using a stainless steel cylindrical probe of 5 mm diameter (SMS P/0.5). The parameters calculated from the force-deformation (time) curve included first peak force as bio yield force (N), gradient of the curve from the origin to the peak force as stiffness (N/mm), maximum peak force as firmness (N) and area under the curve as toughness (N mm).

Textural properties of cooked samples

The samples of 10 × 10 × 10 mm size were cut using a hand slicer, and were cooked in a boiling water bath by placing them in a wire mesh basket to prevent the samples getting direct contact with the bottom part of the bath. Samples were removed from the water bath at regular intervals of 5 min for up to 45 min and cooled to room temperature. For texture profile analysis, samples cooked for 25 min were used, as preliminary experiment showed that changes in the degree of cooking were not significant after 25 min. Firmness of cooked samples was measured using 5 mm stainless steel cylindrical probe at a test speed of 2 mm/s for a distance of 5 mm under compression mode by maintaining the pre and post test speed as 10 mm/s.

Degree of cooking was measured by the method given by Ramesh et al. (1997). Relative firmness was calculated as the ratio of the firmness of the cooked sample at any time to that of the raw samples. Texture profile analysis (TPA) of the cooked tubers was carried out at a test speed of 2 mm/s for 50% compression with a time lag of 1 s. From the TPA curve, hardness, adhesiveness, springiness, cohesiveness and chewiness were calculated.

Gelatinization properties of cassava starches

Starch was extracted from the fresh tubers by wet processing methods. The tubers were washed, peeled and rewashed thoroughly with water to remove all the dirt and adhering impurities attached to tubers. They were cut into small pieces of 2–3 cm thickness and crushed using a wet mixer-grinder (REMI, Mumbai, India) after adding enough water (approximately ten times the weight of tubers). The material was ground until a uniform mash was obtained and it was screened sequentially through 80 and 150 mesh sieves adding excess water to obtain the pure starch. The suspension passing through the sieve was collected in a basket and allowed to settle overnight and the supernatant water was decanted out. The settled starch was scooped out and dried in an oven at 50°C for 24 h and the dried starch was used for further analysis.

Thermal properties were determined by using DSCe 822 Differential Scanning Calorimeter (Mettler Toledo, Analytical GmbH, Schwerzembach, Switzerland) equipped with built in STAR-e software. A weighed (using a micro balance with least count 0.01 mg) quantity of starch was transferred into a previously weighed aluminium pan. Distilled water was added to give a water/starch ratio of 2:1. The pan was sealed hermetically and placed on the DSC sensor in the furnace. An empty aluminium pan was used as reference and indium was used as standard. The sample was heated from 25°C to 100°C at 10°C/min. From the DSC thermogram, gelatinization onset (To), peak (Tp) and conclusion (Tc) temperature and enthalpy of gelatinization (ΔH) were calculated. From these primary parameters, the gelatinization temperature range was calculated as the difference between Tc and To. The ratio  gives the value of peak height index, an indication of the uniformity of gelatinization. Experiments were done in duplicate and average values reported.

gives the value of peak height index, an indication of the uniformity of gelatinization. Experiments were done in duplicate and average values reported.

Pasting characteristics of the starch were determined with Rapid Visco Analyser (RVA) (New port Scientific, Warriehood, Australia) at a fixed starch concentration of 10% and a constant speed of 160 rpm using Standard I profile. The viscosity profile recorded by RVA gives the peak, trough and final viscosities, and pasting temperature. Swelling volume and solubility were determined by the method of Schoch (1964) using 400 mg starch in 40 ml distilled water. Experiments were replicated twice and average values are reported.

Rhelogical properties

The gelated starch obtained from the RVA experiments after cooling to ambient temperature of 30°C was subjected to dynamic viscoelastic tests by frequency sweep at 0.1–10 Hz (0.623–62 s−1) at 0.1% strain (with in the linear viscoelastic range) using a rheometer with parallel plate (20 mm diameter) geometry (PP20 SN 5912) with a gap of 1 mm using Rheoplus MCR 51 Rheometer (Anton Paar, Germany). The rheogram obtained from the study gives storage modulus (G′), loss modulus (G″), complex modulus (G*) and phase angle.

Statistical analyses

The data were analyzed using the statistical package SAS 8.0 (SAS Institute Inc, Cary, NC, USA) to perform analysis of Variance and Duncan’s Multiple Range Test (DMRT). The mean values obtained from ANOVA were subjected to DMRT for pair wise comparison. Principle component analysis and cluster analysis were carried out on the correlation matrix using Genstat DE 3. Simple linear regression models were fitted to study the relationship between degree of cooking and relative firmness of cooked tubers of different varieties.

Results and discussion

Textural properties of raw tubers

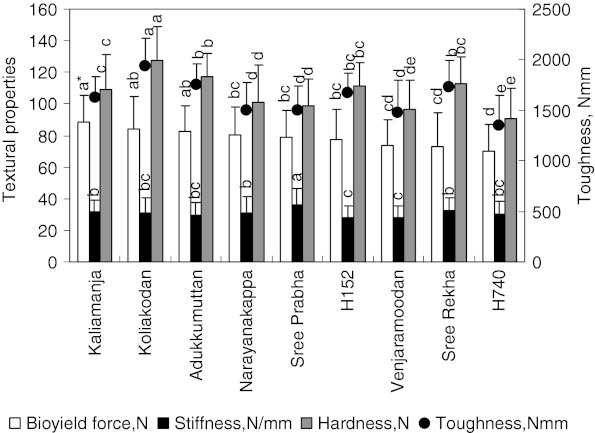

The textural properties of raw tubers as represented by bio yield force, stiffness, firmness and toughness are given in Fig. 1. The highest value of bio yield force (88.6 N) was observed for ‘Kaliamanja’ which was at par with ‘Koliakodan’ (83.9 N) and ‘Adukkumuttan’ (82.5 N) and was significantly higher than the other varieties ‘Narayanakappa’ (80.1 N), ‘Sree Prabha’ (78.6 N) and ‘H152’ (77.3 N); ‘Venjaramoodan’ (73.8 N) and ‘Sree Rekha’ (73.2 N). The lowest value of 70.3 N was obtained for ‘H740’. These results clearly indicated that the force required to produce maximum deformation of the tubers before the start of rupture/penetration varied considerably. Stiffness measures the pre rupture/failure deformation of the tubers and wide variability exists for the stiffness values, maximum being 36.3 N/mm for ‘Sree Prabha’, which was significantly higher than the other varieties and a minimum for 27.8 N/mm for ‘Venjaramoodan’. No significant variation in stiffness was observed between ‘Koliakodan’, ‘Adukkumuttan’ and ‘H740’ or between ‘Kaliamanja’, ‘Narayanakappa’ and ‘Sree Rekha’ or between ‘H152’ and ‘Venjaramoodan’ (p < 0.05). There is a significant difference in the firmness values, highest being 127 N for ‘Koliakodan’ and lowest 90.9 N for ‘H740’; however, between ‘Narayanakappa’ and ‘Sree Prabha’ no significant difference was noticed, the values being 101.0 and 98.6 N, respectively. Among the different varieties studied, the toughness of ‘Adukkumuttan’, ‘H152’ and ‘Sree Rekha’; ‘Narayanakappa’, ‘Sree Prabha’ and ‘Venjaramoodan’ is statistically on par. The wide variability in the static mechanical or textural properties may be attributed to the presence of varying amount of starch, cellulose, pectin, composition of cell wall, cell size, inter cellular spacing, turgor pressure, over all structure and shape of the cell (Tijskens et al. 1999; Kilcast 2004). This is also true in the present study as evidenced from the noticeable variation in the physico-chemical properties (Table 1). Moisture content was maximum for ‘Sree Prabha’ and ‘Sree Rekha’ (72.5%) and minimum for ‘Koliakodan’ (62.0%) and further, no significant difference was observed between ‘Adukkumuttan’, ‘H152’, ‘Venjaramoodan’ and ‘H740’. Starch content was highest in ‘Kaliamanja’ (27.6%) and ‘Koliakodan’ (27.5%) and lowest in ‘Sree Prabha’ (20.9%). The fiber content was maximum for ‘H740’ and minimum for ‘Koliakodan’ and significant variation existed between different varieties (p < 0.05).

Fig. 1.

Textural properties of raw tubers from different varieties of cassava. Columns with same letters for each properties are not significantly different (p < 0.05). Vertical line represents standard deviation

Table 1.

Physico-chemical properties of raw tubers of different varieties of cassava

| Varieties | Moisture, % | Starch, % wb | Sugar, %db | Fibre, %db | Ash, %db | Apparent amylose,% | Total amylose, % |

|---|---|---|---|---|---|---|---|

| ‘Kaliamanja’ | 68.6 ± 0.52c | 27.6 ± 0.48a | 2.0 ± 0.01e | 1.01 ± 0.04d | 2.0 ± 0.09b | 18.2 ± 0.07b | 19.6 ± 0.64bc |

| ‘Koliakodan’ | 62.0 ± 0.93e | 27.5 ± 0.35a | 1.9 ± 0f | 0.46 ± 0.03f | 1.8 ± 0.02c | 15.6 ± 0.14de | 19.1 ± 0.14c |

| ‘Adukkumuttan’ | 67.0 ± 0.09d | 25.2 ± 0.7c | 1.6 ± 0.03b | 0.97 ± 0.01d | 1.9 ± 0.04bc | 16.8 ± 0.07bcd | 21.3 ± 0.29b |

| ‘Narayanakappa’ | 70.6 ± 0.19b | 24.9 ± 0.10cd | 1.9 ± 0f | 0.95 ± 0.1d | 2.0 ± 0b | 17.7 ± 0.21bc | 19.8 ± 0.35bc |

| ‘Sree Prabha’ | 72.4 ± 0.89a | 20.9 ± 0.11f | 2.4 ± 0.01c | 1.28 ± 0.03b | 2.4 ± 0.09a | 14.5 ± 0.21ef | 16.7 ± 0.99d |

| ‘H 152’ | 66.1 ± 0.04d | 26.5 ± 0.22b | 2.8 ± 0a | 0.97 ± 0.01d | 1.5 ± 0.05d | 20.6 ± 1.63a | 23.4 ± 1.98a |

| ‘Venjaramoodan’ | 67.1 ± 1.06d | 23.2 ± 0e | 2.3 ± 0.01d | 1.19 ± 0.04c | 1.8 ± 0c | 16.3 ± 0.49cd | 19.8 ± 0.71bc |

| ‘Sree Rekha’ | 72.5 ± 0.40a | 21.4 ± 0.54f | 1.8 ± 0.02g | 0.78 ± 0.03e | 2.3 ± 0.09a | 15.3 ± 0.78de | 18.8 ± 0.28c |

| ‘H 740’ | 67.5 ± 0.35cd | 24.3 ± 0.19d | 2.5 ± 0.01b | 1.57 ± 0.07a | 2.4 ± 0.02a | 13.4 ± 0.035f | 15.6 ± 0.85d |

Means followed by same superscripts in a column are not significantly different (p < 0.05)

Thermal softening of tubers

Softening of the tubers occurred due to cooking which is measured as the percent reduction in firmness with respect to cooking time and is depicted in Fig. 2. Reduction in firmness (%) varied significantly between varieties during the lower cooking time up to 20–25 min. Firmness was reduced at a faster rate at the initial stages of cooking i.e. up to 25 min irrespective of the varieties as evidenced from the steep slope of the firmness reduction-cooking time curve, thereafter the rate of decrease was not very much indicating the optimum cooking time of 25 min for these varieties. After 25 min of cooking, the firmness was reduced by 95.1, 93.0, 88.8, 92.0, 93.6, 89.8, 94.3, 86.2 and 85.0%, respectively for ‘Adukkumuttan’, ‘H152, ‘H740’, ‘Kaliamanja’, ‘Koliakodan’, ‘Narayanakappa’, ‘Sree Prabha’, ‘Sree Rekha’ and ‘Venjaramoodan’. These results indicated that tubers were softened maximum for ‘Adukkumuttan’ and minimum for ‘Venjaramoodan’.

Fig. 2.

Thermal softening behaviour of tubers from different varieties of cassava measured as percentage reduction in firmness due to cooking

Optimum cooking time can also be predicted by noting the degree of cooking, which was found to increase at an increasing rate up to 25 min of cooking and thereafter a slightly diminishing or constant rate was obtained (data not shown). From the data on degree of cooking with relative firmness when fitted by linear regression method, an inverse linear relationship was obtained which is as follows:

|

where, Dc= degree of cooking, %, Fr= relative firmness, A and B = constants, the values of which for different varieties are given in Table 2. It is worth mentioning that for the same variety, the values of A and B are same, but among the varieties the values were different, registering a minimum value of 102.8 for ‘H152’ and maximum of 111.7 for ‘Venjaramoodan’. Similar results were also reported for carrot (A = 114.9, B = 115.1) and radish (A = 116.3, B = 116.0) by Ramesh et al. (1997) and for cassava tubers of short duration varieties (A = 105.7–127.5, B = 105.7–127.5) by Sajeev et al. (2008). The validity of such models was ascertained by estimating the modulus values as explained by Ramesh et al. (1997) and is given in Table 2. The very low values of modulus for each variety showed that these equations were extremely good fit for individual varieties. However, as explained earlier, the varietal dependence on the constants necessitated the development of a generalized model without giving weightage to individual varieties i.e., by considering these data as a whole for cassava tubers. The linear regression of the total data gave the value of A as 104.5 and B as 93.7, which were found to be lower than that of the short duration lines of cassava for which Sajeev et al. (2008) got A = 113.0 and B = 110.8. When this general model was compared with the individual models, the modulus values were all below 5%, also showing extremely good fit to explain the variation of relative firmness with degree of cooking.

Table 2.

Model constants in the linear regression equations relating degree of cooking and relative firmness

| Varieties | Constants | Modulusa (individual model) | Modulusa (general model) | |

|---|---|---|---|---|

| A | B | |||

| ‘Kaliamanja’ | 105.0 | 105.0 | 0.002 | 0.67 |

| ‘Koliakodan’ | 104.7 | 104.7 | 0.004 | 0.67 |

| ‘Adukkumuttan’ | 103.0 | 103.2 | 0.049 | 2.5 |

| ‘Narayanakappa’ | 106.7 | 106.7 | 0.003 | 0.9 |

| ‘Sree Prabha’ | 104.3 | 104.3 | 0.001 | 1.06 |

| ‘H 152’ | 102.8 | 102.8 | 0.004 | 2.74 |

| ‘Venjaramoodan’ | 111.7 | 111.7 | 0.002 | 4.18 |

| ‘Sree Rekha’ | 107.5 | 107.5 | 0.004 | 1.42 |

| ‘H 740’ | 108.1 | 108.1 | 0.001 | 2.01 |

| General model | 104.5 | 93.7 | – | 0.925 |

aIf the modulus values <5, the equation is extremely good fit, between 5 and 10: reasonably good fit and >10: poor fit

Modeling of texture degradation due to cooking

A simple first order equation for the texture degradation due to cooking at constant temperature is given as:

|

where, Ft = the firmness at heating time ‘t’ min, N; Fo = initial firmness of the product, N; ko = rate constant, min−1. From the plot of Ft/Foversus cooking time, the exponential trend line was calculated for each variety and is presented in Table 3. The model showed low correlation coefficient (r2) values to explain the kinetics of thermal softening behavior of cassava tubers which could be improved by applying fractional conversion techniques to the data on the firmness of tubers for different time interval as explained by Rizvi and Tong (1997) by applying the following equation:

|

where, Fe = firmness at equilibrium or the non zero maximum retainable firmness, N; k1- constant and k2 = rate constant, min−1. The value of (Ft-Fe)/(Fo-Fe) is plotted against cooking time (graph not shown) and the trend line is calculated with values of k1 and k2 and correlation coefficient (r2) are given in Table 3, and the highest r2 values compared with that of the first order equation showed the suitability of dual mechanism first order model over the first order equation for the textural degradation. The rate constant k2 varied from 0.081 to 0.108 min−1. The varieties can be grouped into two categories by noting the proximity of the varieties to the higher side and lower side as Group I- ‘Sree Rekha’ (0.100), ‘Koliakodan’ (0.101), ‘H740’ (0.102), ‘Adukkumuttan’ (0.105) and ‘Venjaramoodan’ (0.108); Group II- ‘H152 (0.081), ‘Narayanakappa’ (0.081), ‘Kaliamanja’ (0.082) and ‘Sree Prabha’ (0.087). Beleia et al. (2004a, b) reported varietal influence on the rate constant values for cassava and an inverse relation between rate constant and cooking time was also observed. Accordingly, the varieties falling under the first group have low cooking time than the second group as their rate constant values were comparatively higher than those of the varieties in group II. Hence the varieties can be grouped based on their rate constant values for their ease of cooking as follows: ‘Venjaramoodan’, ‘Adukkumuttan’, ‘H740’, ‘Koliakodan’, ‘Sree Rekha’, ‘Sree Prabha’, ‘Kaliamanja’, ‘Narayanakappa’ and ‘H152

Table 3.

Model constants in the first order and dual mechanism first order kinetic equations to explain the texture degradation due to cooking of cassava tubers

| Varieties | First order equation | Dual mechanism first order equation | ||||

|---|---|---|---|---|---|---|

| k | ko, min−1 | r2 | k1 | k2, min−1 | r2 | |

| ‘Kaliamanja’ | 0.349 | 0.052 | 0.74 | 0.231 | 0.082 | 0.95 |

| ‘Koliakodan’ | 0.286 | 0.050 | 0.67 | 0.209 | 0.101 | 0.93 |

| ‘Adukkumuttan’ | 0.353 | 0.064 | 0.78 | 0.292 | 0.105 | 0.92 |

| ‘Narayanakappa’ | 0.386 | 0.047 | 0.76 | 0.279 | 0.081 | 0.98 |

| ‘Sree Rekha’ | 0.278 | 0.053 | 0.67 | 0.188 | 0.100 | 0.96 |

| ‘H 152’ | 0.542 | 0.039 | 0.85 | 0.298 | 0.081 | 0.93 |

| ‘Venjaramoodan, | 0.543 | 0.043 | 0.84 | 0.643 | 0.108 | 0.96 |

| ‘Sree Prabha’ | 0.538 | 0.049 | 0.89 | 0.542 | 0.087 | 0.93 |

| ‘H 740’ | 0.385 | 0.044 | 0.71 | 0.340 | 0.102 | 0.87 |

Texture profile analysis

The firmness, adhesiveness and springiness of the cooked tubers as measured from the texture profile analysis showed significant variation among different varieties (p < 0.05) as shown in Table 4 whereas cohesiveness and chewiness were not significantly different. The firmness values ranged form 43.0 N for the cooked tubers of ‘Narayanakappa’ to 90.2 N for ‘Sree Prabha’. Adhesiveness was maximum for ‘Koliakodan’ (−1.83 N s) which was at par with ‘Adukkumuttan’ (−1.25 N s) and minimum was recorded by ‘Sree Prabha’ (−0.313 N s). Springiness varied from 0.76 to 1.23 showing the recoverable deformity during biting. Cohesiveness varied from 0.259 to 0.340 showing the narrow range of variation among the varieties. The time or energy required to masticate the sample to make it suitable for swallowing measured as chewiness was maximum for ‘Sree Prabha’ (24.5) and minimum for ‘Kaliamanja’ (13.9). The variability in texture of the cooked tubers are mainly due to the chemical composition, physico-chemical properties, morphology and molecular structure of starch, quality and quantity of other root components, macro structure of cassava root, interaction between various physico-chemical components and the structural make up of the tuber tissues like cell solid content, turgour pressure of the cell, mechanical capacity of deformation of cell walls and cohesiveness provided by the cementing material of the middle lamella and also by the hydration rate of the cooked tubers (Asaoka et al. 1991; Eggleston and Asiedu 1994; Beleia et al. 2004a, b; Charoenkul et al. 2006; Sajeev et al. 2008).

Table 4.

Texture profile parameters of cooked tubers of cassava varieties

| Varieties | Hardness, N | Adhesiveness,Ns | Springiness | Cohesiveness | Chewiness |

|---|---|---|---|---|---|

| ‘Kaliamanja’ | 55.1 ± 22.74ab | −0.49 ± 0.38a | 1.23 ± 0.35a | 0.260 ± 0.06a | 13.9 ± 7.13 a |

| ‘Koliakodan’ | 58.2 ± 24.28ab | −1.83 ± 1.58b | 1.23 ± 0.35a | 0.332 ± 0.15a | 21.7 ± 11.23 a |

| ‘Adukkumuttan’ | 84.2 ± 14.17a | −1.25 ± 0.78ab | 0.82 ± 0.09bc | 0.340 ± 0.04a | 23.3 ± 5.13 a |

| ‘Narayanakappa’ | 43.0 ± 19.78b | −0.58 ± 0.70a | 1.10 ± 0.37ab | 0.321 ± 0.09a | 14.0 ± 7.25 a |

| ‘Sree Prabha’ | 90.2 ± 44.71a | −0.31 ± 0.23a | 0.89 ± 0.17ab | 0.317 ± 0.07a | 24.5 ± 11.73 a |

| ‘H 152’ | 66.2 ± 47.26ab | −0.38 ± 0.47a | 1.02 ± 0.36abc | 0.320 ± 0.06a | 18.7 ± 13.78 a |

| ‘Venjaramoodan’ | 78.4 ± 28.13ab | −0.94 ± 1.76a | 1.02 ± 0.18abc | 0.282 ± 0.07a | 22.7 ± 9.62 a |

| ‘Sree Rekha’ | 59.7 ± 37.19ab | −0.34 ± 0.351a | 0.85 ± 0.32bc | 0.332 ± 0.08a | 15.1 ± 8.12 a |

| ‘H 740’ | 72.0 ± 33.78ab | −0.43 ± 0.56a | 0.76 ± 0.25c | 0.305 ± 0.12a | 14.8 ± 8.05 a |

Means followed by same superscripts in a column are not significantly different (p < 0.05)

Dynamic rheological properties

The mechanical spectra of the gelated starch obtained from different varieties using the frequency sweep experiments are presented in Fig. 3. From the values of storage modulus (G′) and loss modulus (G″), it is understood that at lower frequencies the viscous component of the viscoelastic nature is more predominant as evidenced from the G″ > G′ for all the varieties. And at a particular frequency called as cross over, both viscous and elastic component of the rheological response was same (G′=G″) and afterwards as the frequency increased, the values of G′ became greater than G″ illustrating the more solid like behaviour. The cross over frequency calculated for different varieties did not change much and the values of the cross over frequency and the corresponding modulus were 16.2 s−1 and 392.2 Pa, 17.2 s−1 and 423.2 Pa, 18.3 s−1 and 431.6 Pa, 17.5 s−1 and 432.5 Pa, 17.8 s−1 and 476.1 Pa, 16.5 s−1 and 423.0 Pa, 16.3 s−1 and 362.6 Pa, 17.3 s−1 and 432.7 Pa, and 17.8 s−1 and 441.9 Pa for ‘Kaliamanja’, ‘Koliakodan’, ‘Adukkumuttan’, ‘Narayanakappa’, ‘Sree Prabha’, ‘H152, ‘Venjaramoodan’, ‘Sree Rekha’ and ‘H740’, respectively. The increasing trend of dynamic moduli with the frequency after the cross over is the characteristic of concentrated biopolymer solution or an entangled network of disordered polymer coil or time scale of molecular entanglement (Ferry 1980; Morris 1995; Steffe 1996; Rao 1999). At higher frequencies, the networks behave like a cross linked gel as the interchain entanglements do not have sufficient time to come apart within the period of oscillation, whereas at low frequencies, the chains do have sufficient time for substantial disentanglement and rearrangement and hence for the viscous flow (Ferry 1980; Morris 1995; Cardenas et al. 1997). For a comparative statistical evaluation, the values of rheological properties obtained at the maximum frequency of 62.3 s−1 (10 Hz) are presented in Table 5. It is evident from the Table that significant differences are observed in their values for different varieties (p < 0.05). The storage modulus was maximum (3,160 Pa) for ‘Narayanakappa’ and is significantly different from other varieties, the minimum value of 1,690 Pa is obtained for ‘Venjaramoodan’. Among the nine varieties, the loss modulus for ‘Kaliamanja’, ‘Adukkumuttan’, ‘Narayanakappa, ‘H152’, ‘Sree Rekha’ and ‘H740’ are statistically on par and maximum of 1,955 Pa for ‘Sree Prabha’ and minimum of 1,440 Pa for ‘Venjaramoodan’ are obtained. The higher values of G′ over G″ showed that the gelated starch dispersion had a more solid like nature or more energy absorbing capacity. This is in agreement with the low values of phase angle ranging from 30.2° for ‘H152’ to 40.5° for ‘Venjaramoodan’ i.e. as the values from 0 to 90 give an indication of the transition from solid to liquid nature. The complex modulus ranged from 2,230 Pa for ‘Venjaramoodan’ to 3,550 Pa for ‘Narayanakappa’. The rheological response of the gelatinsed starch suspension has been correlated to the swelling of the granules and to the solubilities of materials from the granules. Being the retrograded starch used for the present analysis, starch rheology is primarily determined by the formation of networks of solubilised and highly entangled macromolecules released from the granules during gelatinization. Gelatinized starch paste is considered as a composite material with the starch granules as the filler in a polysaccharide matrix for which the rheological properties depend on the dispersed phase (starch granule), continuous phase (amylose-amylopectin matrix) and on the interaction between these phases (Eliasson and Bohlin 1982; Eliasson 1986). Among the various properties influencing the rheology are granule size and size distribution, shape and surface of granules, swelling pattern, granule rigidity and deformability, amount and type of amylose/amylopectin leached out from the granule during gelatinization, entanglement, granule-granule contact, granule-amylose/amylopectin interaction and granule-amylose/amylopectin-granule interaction (Eliasson 1986). This study indicates a considerable variability of these properties for the starches from different cassava varieties and hence attributed to the difference in rheological response.

Fig. 3.

Dynamic mechanical spectra of the gelated starch from different varieties of cassava

Table 5.

Dynamic mechanical properties of starches extracted from tubers of different varieties of cassava measured at 10 Hz

| Varieties | Storage modulus, Pa | Loss modulus, Pa | Complex modulus, Pa | Phase angle, ° |

|---|---|---|---|---|

| ‘Kaliamanja’ | 2,490 ± 42bc | 1,535 ± 7bc | 2,925 ± 35bcd | 31.8 ± 0.49ab |

| ‘Koliakodan’ | 2,200 ± 269bc | 1,735 ± 21ab | 2,805 ± 191bcd | 38.4 ± 3.75a |

| ‘Adukkumuttan’ | 2,335 ± 149bc | 1,520 ± 42bc | 2,785 ± 148cd | 33.2 ± 0.92ab |

| ‘Narayanakappa, | 3,160 ± 14a | 1,615 ± 191bc | 3,550 ± 99a | 27.0 ± 2.62b |

| ‘Sree Prabha’ | 2,550 ± 325ab | 1,955 ± 64a | 3,215 ± 219abc | 37.6 ± 4.45ab |

| ‘H 152’ | 2,805 ± 573ab | 1,605 ± 177bc | 3,245 ± 403ab | 30.2 ± 7.78ab |

| ‘Venjaramoodan’ | 1,690 ± 269c | 1,440 ± 99c | 2,230 ± 141e | 40.6 ± 6.44a |

| ‘Sree Rekha’ | 2,225 ± 92bc | 1,610 ± 184bc | 2,750 ± 28d | 35.8 ± 4.24ab |

| ‘H 740’ | 2,245 ± 134bc | 1,640 ± 42bc | 2,780 ± 85cd | 36.2 ± 2.33ab |

Means followed by same superscripts in a column are not significantly different (p < 0.05)

Modeling of the viscoelastic properties

The viscoelastic properties of the samples can be described by either using a generalized Maxwell model (Montalvo et al. 1996; Steffe 1996; Subramanian and Gunasekharan 1997; Rao 1999; Ak and Gunesekharan 2001; Cuppola et al. 2004) or by using power law relationship (Ortega-Ojeda et al. 2004a, b, 2005; Nishinari 2007). Maxwell model consists of a spring to represent the elastic and dashpot to represent the viscous nature of the viscoelastic materials connected in series. The storage modulus (G′) and loss modulus (G″) of a Maxwellian fluid is represented by the following equations:

|

|

where, ω= frequency of measurement, λ= relaxation time, η= viscosity of the Maxwell elementFrom these equations,  .

.

The relaxation time “λ” is a measure of the time required for the energy stored in the spring to shift to the dash pot and dissipate which can be obtained from the slope of the plot of G′/G″ vs. ω, which is shown in Fig. 4 for different varieties. As evident from the Figure, the trends are not straight lines throughout the studied frequency, showing an increasing trend for the values of G′/G″ at lower frequency, attains a maximum value and thereafter decreases. The results fit to the Maxwellian model where the plot of G′/G″ vs. ω is a straight line. Hence Maxwellian character is assumed to take place at the lower frequency levels and the slope of the straight line up to the maximum value of G′/G″ is calculated for the relaxation time. The values were 0.076 for ‘Venjaramoodan’, 0.063 for ‘See Prabha’, 0.075 for ‘H152’, 0.070 for ‘Adukkumuttan’, 0.069 for ‘H740’, 0.078 for ‘Sree Rekha’, 0.066 for ‘Narayanakappa’, 0.061 for ‘Koliakodan’ and 0.075 for ‘Kaliamanja’. It is worth mentioning that correlation coefficient for the models were greater than 0.97 in all cases. The lower values of relaxation time also give an indication of the nature of a concentrated suspension of the starch system.

Fig. 4.

Variation of ratio of storage modulus to loss modulus with respect to angular frequency

Power law models

Power law equation can be used to examine the fluid or solid like behaviour of a dilute or concentrated solution as:

|

|

where, a and c are the intercepts, b and d are the slope of the log (G′, G″) vs. Log (ω) curve. Hence, the trend line of the power equation for the plot of log (G′, G″) vs. log (ω) is calculated using Micro Soft Excel programme, the values of a, b, c and d with corresponding correlation coefficient are presented in Table 6.

Table 6.

The values of constants in the power law relationship of mechanical spectra with angular frequency

| Varieties | Storage modulus | Loss modulus | ||||

|---|---|---|---|---|---|---|

| a | b | r2 | c | d | r2 | |

| ‘Narayanakappa’ | 2.198 | 1.787 | 0.992 | 21.489 | 1.00 | 0.979 |

| ‘Adukkumuttan’ | 2.934 | 1.674 | 0.986 | 22.153 | 0.973 | 0.971 |

| ‘Venjaramoodan’ | 2.755 | 1.674 | 0.972 | 18.122 | 1.00 | 0.972 |

| ‘H 152’ | 3.293 | 1.680 | 0.987 | 27.681 | 0.924 | 0.970 |

| ‘Sree Prabha’ | 4.755 | 1.575 | 0.991 | 27.924 | 0.962 | 0.973 |

| ‘Kaliamanja’ | 2.793 | 1.720 | 0.986 | 22.833 | 0.964 | 0.976 |

| ‘Sree Rekha’ | 2.403 | 1.749 | 0.977 | 23.359 | 0.969 | 0.969 |

| ‘Koliakodan’ | 4.881 | 1.535 | 0.987 | 22.759 | 0.989 | 0.976 |

| ‘H 740’ | 2.916 | 1.683 | 0.981 | 23.185 | 0.977 | 0.973 |

The values of “b” for a starch gel system generally varies from 0 to 2 and when it is close to 2 or 0 represents liquid or solid behavior. Similarly, the value of “d” varies from 0 to 1 and when it is close to 1 or 0 represents liquid or solid behaviour (Ortega-Ojeda et al. 2004a, b, 2005). In the present study, among the different varieties, there is not much variation in the values of “b” and “d”, i.e. “b ” ranging from 1.535 to 1.787 and “d” from 0.969 to 1.000. The higher values of b and d closer to 2 and 1, respectively showed the predominance of the liquid nature of the concentrated gelated starch system which is in agreement with the low relaxation time obtained from the Maxwell model.

Gelatinization properties

Significant differences exist for the DSC gelatinization characteristics among different varieties (p < 0.05) (Table 7). ‘Narayanakappa has the lowest onset (64.1°C) temperature while the highest value was recorded for ‘Sree Rekha’ and ‘Adukkumuttan’ (66.7°C). The gelatinization range was highest for ‘Sree Rekha’ (16°C) and lowest for ‘Narayanakappa’ (12.2°C). These values were 3–4°C higher compared to the short duration varieties of cassava. Though the onset for the short duration varieties were higher compared to the current varieties, the gelatinization range was higher for these set of varieties (Sajeev et al. 2008). The enthalpy values were very similar ranging from 11.1 J/g for ‘H152’ to 12.3 J/g for ‘Koliakodan’, indicating that the crystalline nature are nearly similar. These values are slightly higher than those of the short duration lines which possess the values ranging from 8.9 to 10.0 J/g (Sajeev et al. 2008). The higher enthalpy and the higher gelatinization range of these starches can be attributed to the longer duration in the field which can bring about changes in the starch structural arrangements.

Table 7.

Gelatinization properties of cassava starches as measured by the DSC thermograms

| Varieties | Enthalpy | Gelatinisation temp, °C | Gelatinization temp range, °C | Peak height index | Swelling volume, ml/g | Solubility, % | ||

|---|---|---|---|---|---|---|---|---|

| Onset, °C | Peak, °C | Endset, °C | ||||||

| ‘Kaliamanja’ | 11.6 ± 0.47bc | 64.9 ± 0.56bc | 68.3 ± 0.26c | 79.4 ± 1.10bc | 14.5 ± 1.67abc | 3.5 ± 0.99ab | 56.2 ± 0.0a | 14.4 ± 1.10a |

| ‘Koliakodan’ | 12.3 ± 0.04a | 66.1 ± 0.36a | 70.5 ± 0.47a | 80.8 ± 0.62ab | 14.7 ± 0.98abc | 2.8 ± 0.08ab | 43.8 ± 0.0e | 20.8 ± 0.00b |

| ‘Adukkumuttan’ | 12.2 ± 0.33ab | 66.7 ± 0.23a | 70.1 ± 0.28ab | 80.1 ± 0.76bc | 13.4 ± 0.53bc | 3.7 ± 0.45ab | 50.0 ± 0.0e | 21.5 ± 0.71b |

| ‘Narayanakappa’ | 12.2 ± 0.4ab | 64.1 ± 1.22c | 68.7 ± 1.19bc | 76.3 ± 0.94d | 12.2 ± 0.24c | 2.6 ± 0.10b | 36.9 ± 0.9e | 15.2 ± 0.68cd |

| ‘Sree Prabha’ | 12.0 ± 0.14ab | 65.6 ± 0.06ab | 69.3 ± 0.01abc | 79.4 ± 0.03bc | 13.7 ± 0.03abc | 3.3 ± 0.01ab | 52.5 ± 0.0b | 16.9 ± 0.33cd |

| ‘H152’ | 11.1 ± 0.10c | 64.2 ± 0.15c | 68.7 ± 0.83bc | 77.9 ± 2.29cd | 13.6 ± 2.14abc | 2.5 ± 0.58b | 47.5 ± 0.0d | 18.4 ± 0.74bc |

| ‘Venjaramoodan’ | 11.9 ± 0.02ab | 65.7 ± 0.01ab | 68.7 ± 0.69bc | 80.5 ± 0.39ab | 14.8 ± 0.39ab | 4.1 ± 0.97a | 47.5 ± 0.0d | 27.3 ± 1.48a |

| ‘Sree Rekha’ | 12.1 ± 0.02ab | 66.7 ± 0.02a | 70.4 ± 0.12a | 82.7 ± 0.59a | 16.0 ± 0.62a | 3.2 ± 0.12ab | 43.7 ± 0.0e | 14.4 ± 1.19d |

| ‘H740’ | 11.2 ± 0.13c | 65.6 ± 0.01ab | 69.2 ± 0.25abc | 78.9 ± 0.33bc | 13.4 ± 0.35bc | 3.1 ± 0.27ab | 50.0 ± 0.0c | 25.8 ± 3.89a |

Means followed by same superscripts in a column are not significantly different (p < 0.05)

Swelling volume of the starches showed considerable variation among the varieties. The lowest value of 36.9 ml/g was obtained for ‘Narayanakappa’ and highest for ‘Kaliamanja’ (56.2 ml/g). Considerable variations in these values indicate the difference in the associative forces of the starch molecules. The solubility values also showed noticeable variation from 14.3% for ‘Sree Rekha’ and ‘Kaliamanja’ to 27.3% for ‘Venjaramoodan’. It is to be noted that the swelling volume and solubility do not show any direct relationship among the varieties.

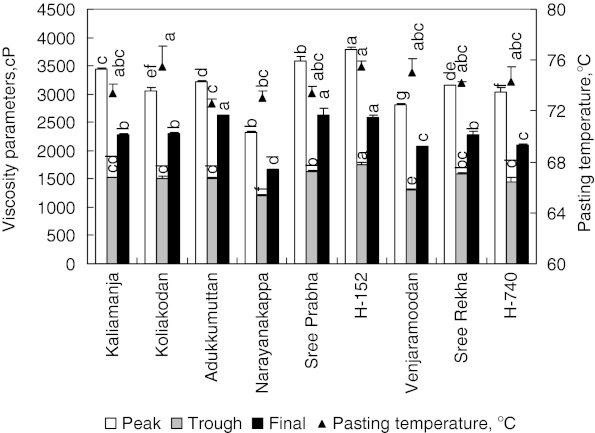

The peak viscosity values obtained from RVA exhibited considerable variation with Narayanakappa had the lowest value of 2,323 cP while ‘H152’ had a highest value of 3,789 cP (Fig. 5). The trough viscosity values also followed the same trend having 1,211 and 1,748 cP respectively for the above varieties showing that break down is minimum for ‘Narayanakappa’ and highest for ‘H152’. Here also the differences in the associative linkage among the varieties are evident with starch from ‘Narayanakappa’ having relatively stronger associative forces when compared to ‘H152’ starch. The final viscosity nearly follows the same trend with ‘Narayanakappa’ having lowest final viscosity of 1,668 cP and ‘Sree Prabha’ the highest (2,622 cP). The pasting temperature showed only very minor variation of 2–3°C among the varieties in conformity with the values obtained by the DSC onset. The variation in the thermal and pasting properties is caused by the genetic make up and structural variability of the starch extracted from the tubers. Variation in the associated force in the starch granules can also be responsible for the observed differences in the pasting properties among varieties which are in conformity with the results of Rickard et al. (1991), Asaoka et al. (1992). Defloor et al. (1998) and Moorthy (2001) on the varietal difference in the pasting properties.

Fig. 5.

Viscometric properties of starch extracted from tubers of different varieties of cassava * Columns with same letters for each property are not significantly different (p < 0.05). Vertical line represents standard deviation

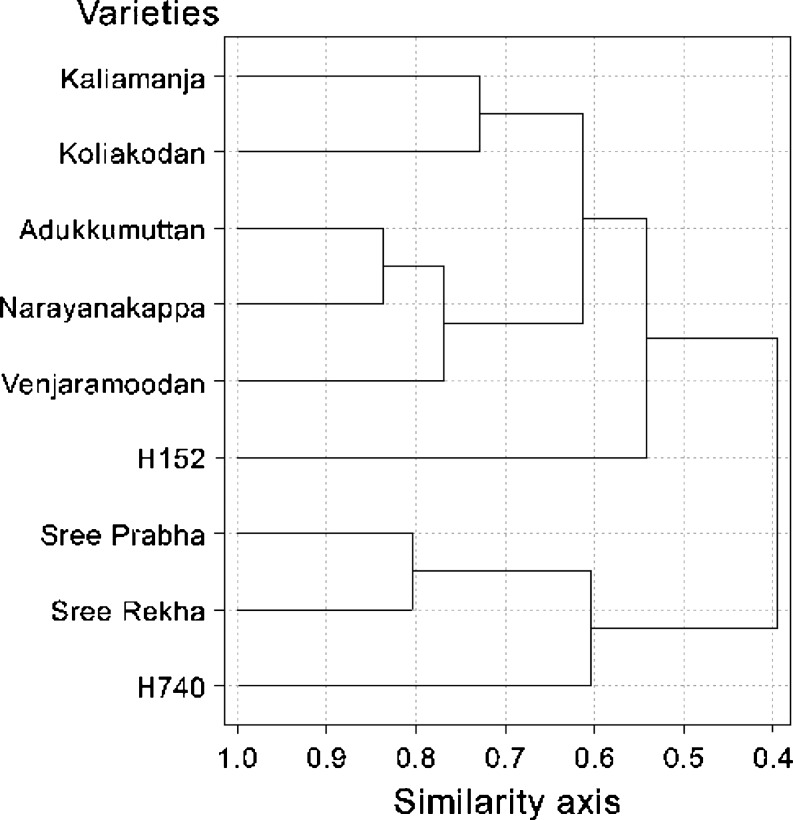

Multivariate analyses

Cluster analysis was carried out to group the varieties based on their textural and physico-chemical properties. The results obtained by hierarchical clustering with city block distance matrix and complete linkage method for grouping is represented by a dendrogram as shown in Fig. 6. At 60% cent similarity, three groups were obtained which are as follows: Group I- ‘Sree Prabha’, ‘Sree Rekha’ and ‘H740’; Group II- ‘H152’; Group III: ‘Venjaramoodan’, ‘Kaliamanja’, ‘Koliakodan’, ‘Adukkumuttan’ and ‘Narayanakappa’. ‘H152’ showed a wide variation when compared to other two groups and hence was placed in a separate group. On the basis of these results, a clear cut grouping between the local and hybrid varieties could be done.

Fig. 6.

Classification of cassava varieties based on the textural and physico-chemical properties of the tubers by cluster analysis

Principal component analysis was carried out on the texture profile parameters, dynamic rheological properties, gelatinization and physico-chemical properties of the varieties. It was found that the first 4 PCs (24.8, 19.5, 17.2 and 13.1% explained variances for axes 1, 2, 3 and 4) accounted for about 74.3% of the total variation. Score plot of the varieties based on 1st and 2nd principal components are presented in Fig. 7. Based on this plot, the varieties can be grouped into five, Group I - ‘Adukkumuttan’, ‘Venjaramoodan’ and ‘Sree Rekha’-located in the left positive quadrant; ‘Koliakodan’ was also located in the same quadrant, but at higher distance in PCA2 and hence grouped separately (Group II); Group III- ‘Sree Prabha’ and ‘H 740’ located in the third quadrant Group IV- ‘Kaliamanja’ and ‘H152’ in the fourth quadrant , almost same distance from the origin; Group V- ‘Narayanakappa’ showed a distinct behavior compared to other varieties as it is clear from the location at the first quadrant and more contribution towards PCA 1. These grouping are in agreement with that of the results obtained by comparing the rate constant values by applying the dual mechanism first order kinetic models to the thermal softening behavior.

Fig. 7.

Score plot of varieties of cassava based on physico-chemical, rheological, gelatinization and texture profile parameters of cooked tubers

Conclusion

The study on the various textural, rheological and gelatinization properties showed a significant difference among the different varieties of cassava. A dual mechanism first order kinetic model was applied to explain the reduction in firmness of the cooked tubers and based on the value of rate constants, the cooking quality of the tubers can be compared objectively and grouping done as Group I- ‘Sree Rekha’, ‘Koliakodan’, ‘H740’, ‘Adukkumuttan’ and ‘Venjaramoodan’; Group II- ‘H152’, ‘Narayanakappa’, ‘Kaliamanja’ and ‘Sree Prabha’. Degree of cooking can be predicted by using the linear model developed between degree of cooking and relative firmness. Principal component analysis of the texture profile parameters, dynamic mechanical spectra, differential scanning calorimetric properties, pasting properties and physico-chemical properties could be used to group the varieties and the groups obtained by this method were almost similar to those obtained by dual mechanism first order kinetic model.

References

- Acharya DP, Hossain MK, Jin-Feing ST, Kunieda H. Phase and rheological behaviour of viscoelastic worm like micellar solutions formed in mixed nonionic surfactant system. Phys Chem Chem Phys. 2004;6:1627–1631. doi: 10.1039/b312940c. [DOI] [Google Scholar]

- Ak MM, Gunesekharan S. Linear viscoelastic methods. In: Gunasekharan S, editor. Nondestructive food evaluation: techniques to analyse properties and quality. New York: Marcel Dekker Inc; 2001. [Google Scholar]

- Official methods of analysis. 2. Washington DC: Association of Official Analytical Chemists; 1975. [Google Scholar]

- Asaoka M, Blanshard JMV, Rickard JE. Seasonal effects on the physico-chemical properties of starch from flour cultivar of cassava. Starch/ Stärke. 1991;43:455–459. doi: 10.1002/star.19910431202. [DOI] [Google Scholar]

- Asaoka M, Blanshard JMV, Rickard JE. Effect of cultivar and growth season on the gelatinization properties of cassava (Manihot esculenta) starch. J Sci Food Agric. 1992;59:53–58. doi: 10.1002/jsfa.2740590108. [DOI] [Google Scholar]

- Beleia A, Prudencio-Ferreira SH, Yamashita F, Sakamoto TM, Ito L. Sensory and instrumental texture analysis of cassava (Manihot esculenta Crantz) roots. J Texture Stud. 2004;35:542–553. doi: 10.1111/j.1745-4603.2004.35505.x. [DOI] [Google Scholar]

- Beleia A, Yamashita F, de Moraes SR, de Silveira CA, Miranda LA. Textural changes during cooking of cassava (Manihot esculenta Crantz.) roots. J Sci Food Agric. 2004;84:1975–1978. doi: 10.1002/jsfa.1917. [DOI] [Google Scholar]

- Bourne MC. Effect of blanch temperature on kinetics of thermal softening of carrots and green beans. J Food Sci. 1987;52:667–668. doi: 10.1111/j.1365-2621.1987.tb06699.x. [DOI] [Google Scholar]

- Cardenas A, Ciapara H, Goycoolea FM. Rheology and aggregation of cactas (Opuntia ficus—indica) mucilage in solution. J Prof Assn Cactus Develop. 1997;2:152–158. [Google Scholar]

- Charoenkul N, Uttapap D, Pathipanawat W, Takeda Y. Molecular structure of starches from cassava varieties having different cooked root textures. Starch/Stärke. 2006;58:443–452. doi: 10.1002/star.200600515. [DOI] [Google Scholar]

- Cortes AB, Valiente M, Rodenas E. Properties of the L and lyotropic phases in CTAB/Glycerol/water and CTAB/Glyceraldehyde/water systems. Langmuir. 1999;15:6658–6663. doi: 10.1021/la9817516. [DOI] [Google Scholar]

- Cuppola L, Gianferri R, Nicotera I, Olivero C, Ranieri GA. Structural changes in CTAB/ H2O mixtures using a rheological approach. Phys Chem Chem Phys. 2004;6:2364–2372. doi: 10.1039/b316621j. [DOI] [Google Scholar]

- Defloor I, Dehing I, Deliour JA. Physicochemical properties of cassava starch. Starch/ Stärke. 1998;50:58–64. doi: 10.1002/(SICI)1521-379X(199803)50:2/3<58::AID-STAR58>3.0.CO;2-N. [DOI] [Google Scholar]

- Eggleston G, Asiedu R. Effects of boiling on the texture of cassava clones—a comparison of compressive strength, intercellular adhesion and physico-chemical composition of the tuberous roots. Trop Sci. 1994;34:259–273. [Google Scholar]

- Eliasson AC. Viscoelastic behaviour during gelatinization of starch. Comparison of wheat, maize, potato and waxy barley starches. J Text Stud. 1986;17:253–265. doi: 10.1111/j.1745-4603.1986.tb00551.x. [DOI] [Google Scholar]

- Eliasson AC, Bohlin L. Rheological properties of concentrated wheat starch gel. Starch/Stärke. 1982;34:267–271. doi: 10.1002/star.19820340805. [DOI] [Google Scholar]

- FAO (2009) FAOSTAT, Statistical database. http://faostat.fao.org (20 April)

- Ferry JD. Viscoelastic properties of polymers. 3. New York: John Wiley; 1980. [Google Scholar]

- Fourmann SB, Carrot C, Mignard N. Gelatinization and gelation of corn starch followed by dynamic mechanical spectroscopy analysis. Rheol Acta. 2003;42:110–117. doi: 10.1007/s00397-002-0261-z. [DOI] [Google Scholar]

- Harada T, Tirtohusodo H, Paulus K. Influence of temperature and time on cooking kinetics of potatoes. J Food Sci. 1985;50:462–459. [Google Scholar]

- Huang YT, Bourne MC. Kinetics of thermal softening of vegetables. J Text Stud. 1983;4:1–5. doi: 10.1111/j.1745-4603.1983.tb00329.x. [DOI] [Google Scholar]

- Kilcast D. Texture in foods: solid foods. Cambridge: Woodhead Pub. Ltd.; 2004. [Google Scholar]

- Lagarigue S, Alvarez G. The rheology of starch dispersions at high temperatures and high shear rate: a review. J Food Eng. 2001;50:189–202. doi: 10.1016/S0260-8774(00)00239-9. [DOI] [Google Scholar]

- Montalvo G, Valiente M, Rodenas E. Rheological properties of the L phase and the hexagonal lamellar and cubic liquid crystals of the CTAB/ Benzyl alcohol/ water system. Langmuir. 1996;12:5202–5208. doi: 10.1021/la9515682. [DOI] [Google Scholar]

- Moorthy SN (2001) Tuber starches. Technical Bulletin No18, Central Tuber Crops Research Institute, Thiruvananthapuram-695017, India

- Morris ER. Polysaccharide rheology and in mouth perception. In: Stephan AM, editor. Food polysaccharide and their application. New York: Marcel Dekker Inc; 1995. [Google Scholar]

- Nanda SK, Mathew G. Physical aspects of softening of cassava tubers upon fermentation with a mixed culture inoculum. J Food Eng. 1996;29:129–134. doi: 10.1016/0260-8774(95)00075-5. [DOI] [Google Scholar]

- Ngeve JM. Cassava root yields and culinary qualities as affected by harvest age and test environment. J Sci Food Agric. 2003;83:249–257. doi: 10.1002/jsfa.1307. [DOI] [Google Scholar]

- Nishinari K (2007) Rheological and related studies on industrially important polysaccharides and protein. J Cent South Univ Technol. doi:10/1007/S11771-007-0315-6

- Odigboh EV. Cassava production, processing and utilization. In: Chan HT, editor. Handbook of tropical foods. New York: Marcel Dekker; 1983. pp. 145–200. [Google Scholar]

- Ohwovoriole EN, Oboli S, Mgbeke ACC. Studies and preliminary design for a cassava tuber peeling machine. Trans ASAE. 1988;31:380–385. [Google Scholar]

- Ortega-Ojeda FE, Larsson H, Eliasson AC. Gel formation in mixtures of high amylopectin potato starch and potato starch. Carbohyd Polym. 2004;56:505–514. doi: 10.1016/j.carbpol.2004.03.021. [DOI] [Google Scholar]

- Ortega-Ojeda FE, Larsson H, Eliasson AC. Gel formation in mixtures of amylose and high amylopectin potato starch. Carbohyd Polym. 2004;57:55–66. doi: 10.1016/j.carbpol.2004.03.024. [DOI] [Google Scholar]

- Ortega-Ojeda FE, Larsson H, Eliasson AC. Gel formation in mixtures of hydrophobically modified potato and high amylopectin potato starch. Carbohyd Polym. 2005;59:313–327. doi: 10.1016/j.carbpol.2004.10.011. [DOI] [Google Scholar]

- Padonou W, Mestress C, Coffi Nago M. The quality of boiled cassava roots: instrumental characterization and relationship with physicochemical properties and sensorial properties. Food Chem. 2005;89:261–270. doi: 10.1016/j.foodchem.2004.02.033. [DOI] [Google Scholar]

- Paulus K, Saguy I. Effect of heat treatments on the quality of cooked carrots. J Food Sci. 1980;45:239–241. doi: 10.1111/j.1365-2621.1980.tb02585.x. [DOI] [Google Scholar]

- Raja KCM, Sukumaran K, Ram Mohan TR. Studies on force deformation properties of fresh cassava (Manihot esculenta Crantz) J Food Sci Technol. 1990;27:65–67. [Google Scholar]

- Ramesh MN, Sathyanarayana K, Girish AB. Determination of degree of cooking of vegetables by compression testing. J Food Sci Technol. 1997;34:218–221. [Google Scholar]

- Rao MA. Rheology of fluid and semi solid foods. Principles and application. New York: Springer; 1999. pp. 59–152. [Google Scholar]

- Rickard JE, Asaoka M, Blanshad JMV. The physico-chemical properties of cassava starch. Trop Sci. 1991;31:189–207. [Google Scholar]

- Rizvi AF, Tong CH. Fractional conversion for determining texture degradation kinetics of vegetables. J Food Sci. 1997;62:1–7. doi: 10.1111/j.1365-2621.1997.tb04356.x. [DOI] [Google Scholar]

- Safo S, Owusu J. Cassava varietal screening for cooking quality. Relationship between dry matter starch content, mealiness and certain microscopic observations of the raw and cooked tubers. J Sci Food Agric. 1992;60:99–104. doi: 10.1002/jsfa.2740600116. [DOI] [Google Scholar]

- Sajeev MS, Sreekumar J, Moorthy SN, Suja G, Shanavas S. Texture analysis of raw and cooked tubers of short duration lines of cassava by multivariate and fractional conversion techniques. J Sci Food Agric. 2008;88:569–580. doi: 10.1002/jsfa.3055. [DOI] [Google Scholar]

- Schoch TJ. Swelling power and solubility of granular starches. In: Whistler RL, Smith JR, Wolform ML, editors. Methods in carbohydrate chemistry. New York: Academic; 1964. pp. 106–108. [Google Scholar]

- Sowbhagya CM, Batacharya KR. Simplified colourimetric method for determination of amylase content in rice. Starch/Stärke. 1971;23:53–56. doi: 10.1002/star.19710230206. [DOI] [Google Scholar]

- Steffe JF. Rheological methods in food process engineering. 2. East Lansing: Freeman; 1996. [Google Scholar]

- Subramanian N, Gunasekharan S. Small amplitude oscillatory shear stress on mozzarella cheese. Part II. Relaxation spectrum. J Text Stud. 1997;28:643–656. doi: 10.1111/j.1745-4603.1997.tb00144.x. [DOI] [Google Scholar]

- Tijskens LMM, Hertog MLATM, Vanschaik ACR, De Jager A. Modeling the firmness of Elstar apples during storage and transport. Acta Hortic. 1999;48:363–372. [Google Scholar]