Abstract

The present study explored the possibility of using barley flour as an ingredient to incorporate soluble fibre (β-glucan) in chocolate-chip cookies. Some clinical studies have shown that β-glucan might reduce the serum cholesterol levels. The objective of this study was to determine the physical and sensory characteristics of chocolate chip cookies partly substituted with barley flour at different levels. Physical characteristics (water activity and L*a*b* colour) and sensory characteristics (descriptive and consumer analysis) were evaluated on the experimental cookies substituted with 0, 30, 40, 50, 60 and 70% barley flour for all-purpose flour. There were increases in the baked-barley aroma and flavour, thickness, colour intensity, dryness and graininess with increasing barley flour content. Consumer data showed that cookies made with 30% (0.5 g β-glucan/serving) and 50% (0.8 g β-glucan/serving) barley flour substitution were comparable in liking to the control (0% substitution) cookie and a commercial cookie. The presence of β-glucan in our chocolate-chip cookies might make them a healthier option for many consumers.

Keywords: Barley flour, Chocolate-chip cookie, Physical characteristics, Sensory characteristics, Consumer acceptability

Introduction

According to a recent article in Times of India (TOI 2010), on average Indians consume around 14 g of fibre per day. Most Americans, including children, fail to meet the recommended amounts of TDF per day according to the USDA’s Continuing Survey of Food Intakes by Individuals (1994–96). The Institute of Medicine of the National Academy of Science (2002) has recommended that the daily requirement of total dietary fibre (TDF) should be increased to 25, 30 and 38 g per day for children, adult women and adult men, respectively. Total dietary fibre or dietary fibre is defined as “the edible parts of plants or analogous carbohydrates that are resistant to digestion and absorption in the human small intestine with complete or partial fermentation in the large intestine. Dietary fibre includes polysaccharides, oligosaccharides, lignin, and associated plant substances. Dietary fibres promote beneficial physiological effects including laxation, and/or blood cholesterol attenuation, and/or blood glucose attenuation (AACC 2001).” Certain components such as β-glucans, pectins, and oligosaccharides constitute soluble dietary fibre or soluble fibre (SF). Approximately one-third of TDF is SF, and studies have shown that SF is physiologically active component that might help with blood cholesterol and glucose attenuation (Ahmed et al. 2010; AACC 2001).

Replacing refined wheat flour (2% TDF and 0% SF) with high-fibre alternatives, such as barley flour in cookie manufacturing could contribute to increasing children and adult daily fibre intake. Prowashonupana barley cultivar was developed using conventional breeding methods in the late 1970s at the Montana Agricultural Experiment Station, Montana State University, Bozeman, Montana (LaBell 1998). The β-glucan content (as much as 19.0 g/100 g has been reported) of Prowashonupana barley cultivar is much higher than that of oats and other barley cultivars (Björck and Elmståhl 2003). Because of the high acceptance of cookies (Swanson and Perry 2007), increasing the fibre content of snacks such as chocolate chip cookies can supplement fibre intake for both children and adults. In 2005, the Food and Drug Administration (FDA) has added whole grain barley and certain dry milled barley grain products to the health claim relating “Soluble Dietary Fibre From Certain Foods and Coronary Heart Diseases” for food labelling purposes. The FDA recommends consumption of 3 g of β-glucan soluble fibre from barley (whole grain barley and dry milled barley) or oat products per day to observe any significant lowering of serum cholesterol (Verma and Banerjee 2010; Yadav et al. 2010; Wood 2007).

The properties of popular baked foods, such as cookies, to deliver functional dietary fibre have been studied to a limited extent. Some research has been conducted on the rheological properties and baking performances of doughs containing added soluble fibre (Rasco et al. 1990; Lee et al. 2005). Lee et al. (2005) noted that cookies made with substituting pastry flour with oat β-glucan (10% substitution) had similar sensory properties to control cookies. Consumer acceptance studies conducted by Tsen et al. (1982) with chocolate chip cookies supplemented with 15% (by weight) distiller’s grain flour resulted in acceptable products. However these low levels of substitution provide only limited fibre in the products.

The present study explored the possibility of using barley flour as an ingredient to incorporate soluble fibre in chocolate chip cookies. The hypothesis was that the addition of barley flour to chocolate-chip cookies would lead to a good-tasting functional food. The objective of this study was to determine the physical and sensory characteristics of chocolate chip cookies partly substituted with barley flour at different levels. The water activity (Aw) and colour (L*, a*, and b*) was determined as part of the physical characteristics of the experimental cookies. The sensory characteristics of the experimental cookies were determined by descriptive and consumer sensory analyses.

Materials and methods

Cookie preparation

Table 1 shows the formulations and ingredients used for the experimental cookies. Milled Prowashonupana barley flour (Sustagrain™, Average particle size distribution: 48.3% > 250 μm and 51.7% < 250 μm) was used for preparing the various cookies. Dough mixing was done in 250 g batches. Oil, sugars (golden brown and white granulated) and vanilla extract were creamed in a KitchenAid® mixer (Model K45SS; KitchenAid, St. Joseph, MI. U.S.A.) at “stir” setting for 30 s. Eggs were added and mixed for 60 s at setting 2. Salt and baking soda were added to sifted flours, and mixed in the egg mixture for 60 s. Chocolate chips (Nestlé® Toll House® semi-sweet mini chocolate morsel) were added to the mixture and stirred for 30 s. Mixed doughs were transferred into glass bowls, covered with three layers of plastic wrap to prevent moisture loss, and kept in a refrigerator. Before baking, the doughs were tempered to room temperature (22 ± 1 °C). A #60 ice cream scoop was used to drop the cookie doughs, and 12 portions (~13 g) of the same treatment were placed on a baking sheet and baked in a preheated gas oven (Model: GLGF377ASF; Frigidaire Gallery, Augusta, GA) at 182 °C for 13 min. Baked cookies were cooled to ~25 °C before storing each individual cookie in a re-sealable snack bag. The cookies were further double bagged in 1 L Ziploc® (S.C. Johnson & Son Inc., Racine, WI, U.S.A.) freezer bags to prevent gain or loss of moisture from or to the cookies. All bagged samples were stored in an airtight plastic container and kept inside a dark cabinet at room temperature (24 °C) until sensory and instrumental evaluations were performed (within 3 days). Three replicates of the experimental cookies were prepared for instrumental and sensory analyses.

Table 1.

Barley chocolate chip cookie formulations used in the study

| Ingredients (g/kg) | Treatments | Source or manufacturer | |||||

|---|---|---|---|---|---|---|---|

| 0%1 | 30% | 40% | 50% | 60% | 70% | ||

| Barley flour | 0.0 | 102.0 | 136.0 | 170.0 | 204.0 | 238.0 | ConAgra Foods, Omaha, NE, U.S.A. |

| All-purpose flour | 340.0 | 238.0 | 204.0 | 170.0 | 136.0 | 102.0 | Stator Bros, Colton, CA, U.S.A. |

| Baking soda | 2.5 | Stator Bros | |||||

| Table salt | 3.0 | Stator Bros, Colton | |||||

| Golden brown sugar | 176.0 | C&H Sugar Company Crockett, CA, U.S.A. | |||||

| Granulated sugar | 64.0 | C&H Sugar Company | |||||

| Canola oil | 182.0 | Stator Bros, Colton, CA, U.S.A. | |||||

| Eggs | 107.0 | Stator Bros | |||||

| Vanilla flavour | 4.5 | McCormick & Company, Hunt Valley, MD, U.S.A. | |||||

| Chocolate chips | 121.0 | Nestle USA Inc., Solon, OH, U.S.A. | |||||

1% refers to percentage substitution of total all-purpose flour weight by barley flour

Colour measurement

A hand-held Chroma Meter (Minolta, Model CR-410, Osaka, Japan) calibrated with standard white plate (Minolta, Model CR-A43; Y = 92.8, x = 0.3159, and y = 0.3321) was used to measure the lightness (L*), redness (a*), and yellowness (b*) colour value (using Standard Iluminant D65) of the test cookies. All the colour readings were taken before water activity testing because of the destructive nature of the water activity test. The measurements were replicated three times.

Water activity

Water activity (Aw) of samples (dough and cookie) was measured with a water activity meter (AquaLab, Model 3TE, Decagon Devices Inc., Pullman, WA). It was calibrated with lithium chloride standard solution (8.57 molal, at 25 C, Aw = 0.500, Decagon Devices). A 30 mm diameter round plug was punched from the centre of each cookie. The sample was crumbled inside the sample cup, and inserted into the meter chamber. The Aw was measured using the chilled-mirror method at sample temperature set to 25 ± 0.2 °C. The measurements were replicated three times.

Descriptive sensory analysis

Descriptive Analysis was performed to determine the sensory characteristics of the various cookies. A panel of six (five female and one male assessor in the age range of 20–50 years) semi-trained judges was trained by exposure to the six experimental cookies made with varying levels of barley flour (0, 30, 40, 50, 60, and 70%) in two training sessions of 2 h each. On the third day, a practice session was held with paper ballots with descriptors generated by all panellists through consensus on the previous two sessions. The panel generated 18 attributes (Table 2) that were used for the blind evaluations of the cookies. A set of 3-digit randomly-coded cookies were used separately is a booth for evaluation of “appearance.” A new set of 3-digit randomly-coded cookie samples in individual re-sealable bags were served to the panellists for evaluation of aroma, flavour, texture and aftertaste characteristics. The serving order of the samples was randomized. A 15-cm unstructured line scale with anchors was used for each descriptor on the sensory ballot and the panellists placed a vertical mark on the scales according to their perception of each sensory attribute. In between samples, panellists were given baby carrots and Arrowhead® (Nestlé Waters North America Inc., Greenwich, CT, U.S.A.) drinking water (22 ± 1 °C) to cleanse their palates. The descriptive analysis of the cookies was replicated three times with a fresh batch of cookies each time.

Table 2.

A glossary of attributes used for descriptive analysis of the experimental cookies

| Attributes | Explanation/definition |

|---|---|

| Appearance | |

| Visible chips | Amount of chips visible on the surface, from Few (Lab-made cookie with no chocolate chips) to Many (Chips Ahoy® Regular) |

| Colour intensity | Intensity of brown colour, from Light to Dark |

| Size | Diameter of cookie, from Small (2.5 cm) to Large (7.6 cm), a Ruler was provided. |

| Thickness | Height of cookie, from Thin to Thick |

| Uniformity of colour | Evenness of hue, from Uneven to Even |

| Surface cracks | Visible surface cracks on cookie, from None (Chips Ahoy® Chewy) to Many (Chips Ahoy® Regular) |

| Aroma | |

| Chocolaty | Aroma of Nestlé® Toll House® semi-sweet mini chocolate morsel from None to Strong |

| Baked barley | Aroma associated with the mixture of 80% baked barley flour and 20% all-purpose flour (in oven at 177 °C for 10 min), from None to Strong |

| Flavour | |

| Sweet | The sweet taste on the tongue, from Low (5% sucrose solution) to High (25% sucrose solution) |

| Chocolaty | The taste of Nestlé® Toll House® chocolate morsel on the tongue, from None to Strong |

| Baked barley | The taste of barley, from None to Strong (mixture of 80% baked barley flour and 20% all-purpose flour). |

| Texture | |

| Dryness | The amount of saliva absorbed by sample, from Moist to Dry |

| Hardness | Force required to break a sample into two pieces in mouth, from Soft to Hard |

| Graininess | Amount of small particles in the mouth after chewing, from None to Very |

| Denseness | Compactness of cross session after first bite, from Airy to Dense |

| Crumbliness | At first bite, sample stay in big pieces (Not crumby), or sample breaks into crumbs (Very Crumbly) |

| Aftertaste | |

| Sweet | Sweetness lingering in the mouth after swallowing, from None to Strong |

| Chocolaty | Chocolate flavour lingering in the mouth after swallowing; the aftertaste of Nestlé® Toll House® chocolate morsel, from None to Strong |

Consumer sensory analysis

One hundred consumers (over the age of 18 years) were recruited to determine the overall acceptability of four cookies (0%, 30%, 50% and 70% substitution by barley flour) and a commercial (regular) cookie (ChipsAhoy®; Kraft Foods, Northfield, IL, U.S.A.). A 9-point hedonic scale (1 = dislike extremely to 9 = like extremely) was used to record the liking scores of the consumers.

Data analysis

Analysis of variance (ANOVA) was performed on instrumental data (Aw and colour parameters), descriptive data (18 attributes), and consumer data (overall liking). The judges were used as a random effect in the overall statistical model and hence replicate by treatment was used as the error term for the treatments in the descriptive data. Fisher’s least square difference (LSD) was used as a post-hoc mean separation technique for the treatments (error term: replicate by treatment). Differences among data were determined at the 5% level of significance. Principal component analysis (PCA) was carried out on the descriptive data. A two-dimensional PCA biplot was graphed where cookie samples were placed in the sensory space created by the descriptive attributes. The data analysis (ANOVA and PCA) was completed using SAS® (Version 9.1.3; SAS Institute, Cary, NC).

Results and discussion

Water activity

Water activity (Aw) of the various cookie doughs and baked cookies are shown in Table 3. The Aw of the cookie dough decreased with increasing amounts of barley flour. The Aw of baked cookies was slightly higher (p < 0.05) in cookies with added barley flour as compared to the control cookie. The difference in Aw observed with addition of barley flour is probably because of the greater water holding capacity of barley flour. The barley flour (Prowashonupana) used in our study is known to absorb moisture at around three times its dry weight compared to refined wheat flour which absorbs around one and a half times its dry weight (Matz 1978; Manley 2000). The water absorption is higher in Prowashonupana barley because of the higher β-glucan content. The higher Aw of baked barley cookies could be also because of the ability of the soluble fibre to hold water at high temperatures associated with baking (Manley 2000). A similar study done on fibre-enriched cookies by Soto-Mendívil and Vidal-Quintanar (2001) showed that moisture content of the cookies increased with higher substitution of regular flour with nixtamalized (softening process by soaking corn in hot lye solution) corn hull. Some other studies have also shown that increasing fiber content of the flour increased Aw or moisture content of baked goods (Ranhotra et al. 1991; Grigelmo-Miguel et al. 1999).

Table 3.

The means (n = 3) for the instrumental analyses of barley cookies

| Treatment1 | Instrumental terms | ||||

|---|---|---|---|---|---|

| Water activity (Dough) | Water activity (Cookies) | Colour parameters | |||

| Lightness (L*) | Redness (a*) | Yellowness (b*) | |||

| 0% | 0.80a | 0.46c | 61.0a | 9. 6bc | 30.6a |

| 30% | 0.80ab | 0.50a | 56.2c | 8.9c | 27.2b |

| 40% | 0.79b | 0.47bc | 56.3c | 10.8a | 30.1a |

| 50% | 0.79c | 0.50a | 57.1bc | 10.1b | 28.9a |

| 60% | 0.78c | 0.49ab | 56.5bc | 11.5a | 30.5a |

| 70% | 0.78c | 0.50a | 59.4ab | 10.0b | 29.4a |

1% refers to percentage substitution of total all-purpose flour weight by barley flour

a,b,cColumn means with no common superscript differ (p < 0.05).

Colour

The tristimulus colour parameters (L*, a* and b*) did not show any consistent trends for the experimental cookies (Table 3). The lightness (L*) of the control and 70% barley cookies was similar, and higher than the rest of the samples. The cookies with 30 and 40% substitution with barley flour were darker than rest of the cookies containing barley flour. The 70% barley cookie was significantly (p < 0.05) lighter than the 30% barley cookie, which might indicate that the cookies become lighter in colour with increasing substitution with barley flour. Vratanina and Zabik (1978) noted a decrease in L* values for sugar-snap cookies with increasing substitution with red and white bran. Both the fibres were substituted for wheat flour at 10, 20, and 30% levels in the cookies. Higher L* values indicate whiter or lighter colour in the products. There was no consistent trends in either redness (a*) or yellowness (b*). Rasco et al. (1990) reported that the crust colour of breads made with barley distillers’ grain were darker and redder. The colour differences, although small, increased with the increase in substitution of bread flour with barley distillers’ grain. The colour difference in their products could be because of using barley spent grain, which is darker in colour and not barley flour.

Descriptive sensory analysis

The results of the descriptive analysis of the cookies are shown in Table 4. Ten of the 18 descriptors were statistically significant (p < 0.05). All the appearance attributes were significantly different (p < 0.05) for the cookie samples, except for visible chocolate chips. The perceived colour intensity, and thickness of the cookie samples increased with increasing barley flour substitution in the cookies. The increase in thickness caused a reduction in the size of the barley cookies. Visually, the colour was perceived to less uniform in the barley cookies. The control cookie and the 30% barley cookie were similar to each other in most attributes, the notable exceptions being baked-barley aroma and flavour, and also grainy texture. The presence of surface cracks was highest in the cookie with 30% barley flour. Except for the control with 0% barley flour, the score for surface cracks steadily became less with increasing barley flour substitution in the cookie samples. There was no difference (p ≥ 0.05) in surface cracks between the control cookie and the 70% barley cookie. The water-holding capacity, and hence the moisture content, of baked products increases with increasing fibre content (Ranhotra et al. 1991; Grigelmo-Miguel et al. 1999; Manley 2000). The disappearance of surface cracks with increasing β-glucan content might be because of increase in the water-holding capacity of the cookies.

Table 4.

The means (n = 18: 6 judges × 3 replicates) for the descriptive analysis attributes of chocolate-chip cookies

| Attributes | Treatments1 | |||||

|---|---|---|---|---|---|---|

| 0% | 30% | 40% | 50% | 60% | 70% | |

| Appearance | ||||||

| Visible chipsNS | 3.2 | 2.6 | 4.9 | 4.8 | 4.3 | 4.1 |

| Colour intensity | 2.3c | 4.5bc | 6.2ab | 4.7b | 6.2ab | 7.3a |

| Size | 7.9a | 7.7a | 7.3a | 6.4b | 6.2b | 5.6b |

| Thickness | 7.7c | 7.6c | 9.5b | 10.1b | 10.6b | 12.6a |

| Uniformity of colour | 12.2a | 9.6ab | 9.0b | 9.9ab | 7.7b | 8.3b |

| Surface cracks | 6.4b | 9.5a | 9.6a | 8.2ab | 8.2ab | 6.0b |

| Aroma | ||||||

| ChocolatyNS | 3.5 | 3.0 | 3.1 | 3.0 | 2.2 | 2.7 |

| Baked barley | 2.8b | 5.9a | 6.0a | 5.9a | 7.4a | 7.3a |

| Flavour | ||||||

| SweetNS | 5.5 | 4.7 | 5.0 | 5.2 | 5.4 | 5.4 |

| ChocolatyNS | 5.0 | 4.2 | 3.4 | 3.0 | 4.1 | 3.9 |

| Baked barley | 2.3e | 5.1d | 5.2 cd | 6.5bc | 6.6b | 8.0a |

| Texture | ||||||

| DrynessNS | 9.4 | 9.5 | 9.9 | 9.9 | 9.4 | 9.9 |

| HardnessNS | 5.9 | 5.5 | 5.4 | 5.2 | 4.8 | 5.6 |

| Graininess | 4.0d | 5.4c | 6.3bc | 6.8b | 6.6b | 8.4a |

| Denseness | 7.8a | 6.9ab | 6.6ab | 5.9b | 5.8b | 6.0b |

| Crumbliness | 6.3b | 7.2ab | 7.5ab | 7.8ab | 7.8ab | 8.2a |

| Aftertaste | ||||||

| SweetNS | 4.7 | 3.6 | 4.4 | 3.7 | 3.7 | 4.4 |

| ChocolatyNS | 3.1 | 2.2 | 2.1 | 2.2 | 2.5 | 2.3 |

1% refers to percentage substitution of total all-purpose flour weight by barley flour

NSNon-significant (p ≥ 0.05)

a,b,c,d,eRow means with no common superscript differ (p < 0.05).

Baked-barley aroma and flavour was perceived in all the barley cookies, and there was a steady increase in the mean scores of the baked-barley flavour with increasing barley flour substitution. Other attributes including ‘chocolaty aroma’, ‘sweet flavour’, ‘chocolaty flavour’ and ‘other flavour’ were not affected by the addition of barley flour. Lee et al. (2005) noted that when pastry flour was replaced by 30% C-trim20 (β-glucan hydrocolloid), the mean sweetness score was 1.6 compared to a mean score of 3.6 for the control (without any substitution with C-trim20). Our study did not find differences in sweetness of the experimental cookies. The control cookie did have the highest mean scores for ‘sweet aftertaste’, although overall there were no significant differences (p ≥ 0.05) among the experimental cookies.

Adding barley to cookies dough affected cookie texture significantly (p < 0.05) by increasing graininess and crumbliness, and decreasing denseness of the barley cookies. Other texture attributes (dryness and hardness) of the barley cookies were not affected. There were no differences in the experimental cookies because of the aftertaste attributes. Contrary to our results, Lee et al. (2005) observed that there was an increase in moistness of the cookies when pastry flour was substituted by C-trim20 (β-glucan hydrocolloid). They also noted that there was an increase in the density of the cookies made with C-trim20.

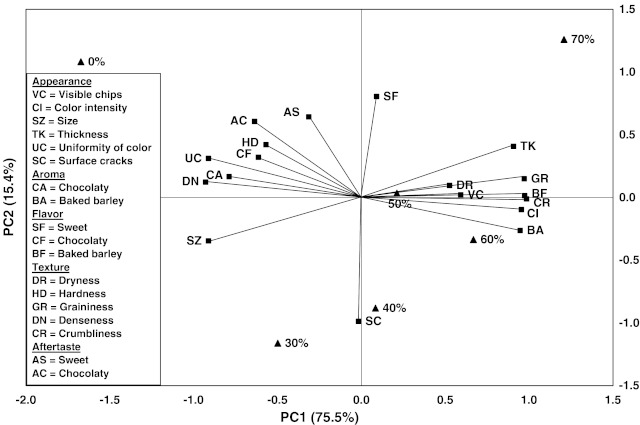

To further analyze for trends that were not noticeable from the univariate analysis, principal component analysis was performed on the descriptive data (Fig. 1). The first two principal components (PC 1 and PC 2) explained 75.5 and 15.4% variation in data set, respectively. The control cookie was characterized by chocolate-related attributes. Those attributes (chocolate aroma, flavour and aftertaste) were judged as similar (p ≥ 0.05) using a univariate data analysis, but the mean scores tended to be higher for the control cookie. The control cookie, which seems like an outlier on the PCA map (Fig. 1), is still on the same side of the x-axis (negative) with the 30% barley cookie. The 30% and 40% barley cookies, and the 50% and 60% barley cookies were placed together in the PCA map (Fig. 1). The univariate analysis did show that the 30% and 40% barley cookies, and the 50% and 60% barley cookies were very similar. The 50%, 60% and 70% barley cookies had pronounced baked-barley aroma and flavour, and were dry and grainy in texture. The graininess of cookies with barley flour might be because of the higher distribution of larger flour particle size of the high β-glucan barley flour (40.7% in the 250–425 μm) versus smaller particle size of AP flour (>90% under 150 μm) (Bhatty 1999). This might suggest that 30% substitution is more appropriate than 50% for the level of barley flour.

Fig. 1.

Principal components analysis (PCA) biplot showing the barley cookies (▲;% refers to percentage substitution of total all-purpose flour weight by barley flour) in relation to the descriptive attributes (■) based on the descriptive sensory data (n = 18: 6 judges × 3 replicates)

The 70% barley cookie seemed to be affected by thickness, size and denseness. These three attributes might have caused the placement of the 70% barley cookie in the top-right corner of the PCA map (Fig. 1), opposite the control cookie. The reduction in size of barley cookies might be caused by a lower spread factor caused by higher fibre and protein content of dough (Matz 1978; Miller and Hoseney 1997), and the coarser particle size of barley flour (Gaines and Donelson 1985). Lee et al. (2005) also observed reduced spreading characteristics of cookies containing various levels of oat β-glucan hydrocolloid. They attributed this effect to the increase in elastic properties of the cookie doughs containing β-glucan hydrocolloid.

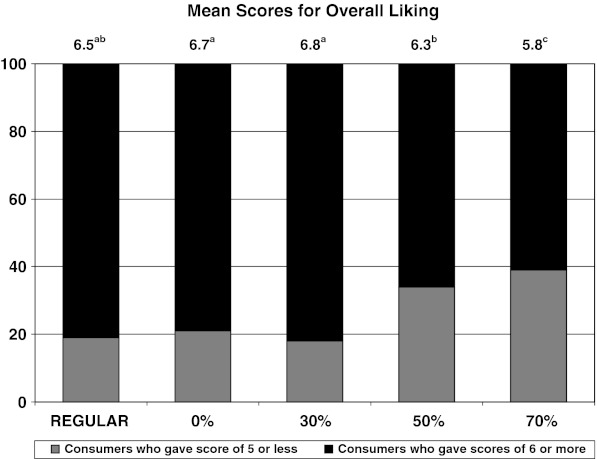

Consumer sensory evaluation

Figure 2 shows the consumer acceptability results. The control (0% barley), 30% barley cookie and the regular (commercial) cookie (ChipsAhoy® Chocolate-Chip cookie) were liked by most of the consumers. The figure also shows that more than 82 consumers gave a score of six or above to the 30% barley cookie. Eighty-one consumers gave a score of six or more to the regular cookie and 79 consumers to the control cookie. The 50% barley cookie was statistically (P ≥ 0.05) similar to the regular cookie. For cookies enriched with fibre, such as nixtamalized corn hulls (Soto-Mendívil and Vidal-Quintanar 2001), aqueous extracted wheat bran (Haque et al. 2002), and brewer’s spent grain (Öztürk et al. 2002), the maximum level of substitution that resulted in well-acceptable cookie was 20–25%, 6%, and 15%, respectively. The consumer acceptance was lower for cookies with higher levels of barley flour. This might be because of the higher intensity of barley aroma and flavour in these cookies (Fig. 1).

Fig. 2.

Consumer acceptability results (n = 100) for the barley cookies (% refers to percentage substitution of total all-purpose flour weight by barley flour; ‘REGULAR’ refers to ChipsAhoy® chocolate-chip cookie)

Conclusions

Our results showed that up to 50% substitution with high-fibre barley flour might be feasible to manufacture acceptable chocolate-chip cookies that will provide 0.8 g of soluble fibre per serving (30 g). Consuming four cookies (~2 servings) with 50% barley flour substitution will provide the consumer 1.6 g of β-glucan soluble fibre which is ~50% of the recommended level by FDA (Table 5). Although the chocolate-chip cookies from our study have almost the same amount of calories as regular chocolate-chip cookies, the presence of β-glucan makes them a healthier option for many consumers because of its cholesterol-lowering properties.

Table 5.

Nutritional content of the barley cookies used for the consumer sensory analysis

| Nutrition facts | Barley cookies | Reference (commercial) cookie4 | |||

|---|---|---|---|---|---|

| 0%1 | 30% | 50% | 70% | ||

| Serving size (g)2 | 30 | 30 | 30 | 30 | 33 |

| Calories | 135 | 133 | 132 | 130 | 160 |

| Calories from fat | 63 | 64 | 65 | 66 | 70 |

| Total fat (g) | 7 | 7 | 7 | 7 | 8 |

| Saturated fat (g) | 1 | 1 | 1 | 1 | 2.5 |

| Polyunsaturated fat (g) | 2 | 2 | 2 | 2 | – |

| Monounsaturated fat (g) | 4 | 4 | 4 | 4 | – |

| Cholesterol (mg) | 0 | 0 | 0 | 0 | 0 |

| Sodium (mg) | 65 | 65 | 65 | 65 | 110 |

| Total carbohydrate (g) | 17 | 16 | 15 | 14 | 22 |

| Dietary fibre (g) | 0.6 | 1.3 | 1.9 | 2.4 | 1 |

| Soluble fibre (g)3 | 0.1 | 0.5 | 0.8 | 1.1 | – |

| Sugars (g) | 9 | 9 | 9 | 9 | 11 |

| Other carbohydrate (g) | 7 | 5 | 4 | 2 | – |

| Protein (g) | 2 | 2 | 2 | 2 | 2 |

1% refers to percentage substitution of total all-purpose flour weight by barley flour

2Serving Size is determined using the Reference Amount (RA) (21 CFR 101.12(b)) for both cookie/snack calculated by FDA derived from the 1977–1978 and the 1987–1988 Nationwide Food Consumption Surveys conducted by the USDA

3Soluble fibre content of barley cookies was generated by Food Processor® software, the actual level might be higher because the figures did not include “resistant starch” formed in the baking process

4http://www.nabiscoworld.com/Brands/ProductInformation.aspx?BrandKey=chipsahoy&Site=1&Product=4400000659. Accessed: 07/12/2008

Acknowledgments

The authors want to thank ConAgra Foods and Agricultural Research Initiative (ARI, California State Polytechnic University – Pomona) for funding this research study.

References

- AACC The definition of dietary fiber. AACC Report. Cereal Foods World. 2001;46(3):112–126. [Google Scholar]

- Ahmed F, Sairam S, Urooj A. In vitro hypoglycaemic effects of selected dietary fiber sources. J Food Sci Technol. 2010 doi: 10.1007/s13197-010-0153-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bhatty RS. The potential of hull-less barley. Cereal Chem. 1999;76:589–599. doi: 10.1094/CCHEM.1999.76.5.589. [DOI] [Google Scholar]

- Björck I, Elmståhl HL. The glycaemic index: importance of dietary fibre and other food properties. Proc Nutr Soc. 2003;62:201–206. doi: 10.1079/PNS2002239. [DOI] [PubMed] [Google Scholar]

- Gaines CS, Donelson JR. Evaluating cookies spread potential of whole wheat flours from soft wheat cultivars. Cereal Chem. 1985;62:134–136. [Google Scholar]

- Grigelmo-Miguel N, Carreras-Boladeras E, Martin-Belloso O. Development of high-fruit-dietary-fibre muffins. Eur Food Res Technol. 1999;10:123–128. doi: 10.1007/s002170050547. [DOI] [Google Scholar]

- Haque M, Shams-Ud-Din M, Haque A. The effect of aqueous extracted wheat bran on the baking quality of biscuit. Int J Food Sci Technol. 2002;37:453–462. doi: 10.1046/j.1365-2621.2002.00583.x. [DOI] [Google Scholar]

- IMONA (Institute of Medicine of the National Academy of Science) (2002) Dietary, functional and total fiber. In: Dietary reference intakes for energy, carbohydrates, fiber, fat, protein and amino acids (macronutrients). The National Academy of Sciences, Washington DC, pp 339–421. http://www.nal.usda.gov/DRI//DRI_Energy/339-421.pdf. Visited 6 July 2010

- LaBell F (1998) Higher-fiber barley − barley in functional and fortified food products. http://www.findarticles.com/p/articles/mi_m3289/is_n7_v167/ai_21033787. Visited 6 July 2010

- Lee S, Warner K, Inglett GE. Rheological properties and baking performance of new oat β-glucan-rich hydrocolloids. J Agric Food Chem. 2005;53:9805–9809. doi: 10.1021/jf051368o. [DOI] [PubMed] [Google Scholar]

- Manley D. Technology of biscuits, crackers and cookies. 3. Florida: CRC Press; 2000. [Google Scholar]

- Matz SA. Cookie & cracker technology. 3. Westport: AVI Publishing Company; 1978. [Google Scholar]

- Miller RA, Hoseney RC. Factors in hard wheat flour responsible for reduced cookie spread. Cereal Chem. 1997;74:330–336. doi: 10.1094/CCHEM.1997.74.3.330. [DOI] [Google Scholar]

- Öztürk S, Özboy Ö, Cavidoğlu İ, Köksel H. Effects of brewer’s spent grain on the quality and dietary fibre content of cookies. J Inst Brew. 2002;108:23–27. [Google Scholar]

- Ranhotra GS, Gelroth JA, Eisenbraun GJ. High-fiber white flour and its use in cookie products. Cereal Chem. 1991;68:432–434. [Google Scholar]

- Rasco BA, Rubenthaler G, Borhan M, Dong FM. Baking properties of bread and cookies incorporating distillers’ or brewer’s grain from wheat or barley. J Food Sci. 1990;55:424–429. doi: 10.1111/j.1365-2621.1990.tb06778.x. [DOI] [Google Scholar]

- Soto-Mendívil EA, Vidal-Quintanar RL. Evaluation of nixtamalized corn hulls as fiber source in baking products. Food Sci Technol Int. 2001;7:355–361. [Google Scholar]

- Swanson RB, Perry JM. Modified oatmeal and chocolate chip cookies: evaluation of the partial replacement of sugar and/or fat to reduce calories. Int J Consum Stud. 2007;31:265–271. doi: 10.1111/j.1470-6431.2006.00547.x. [DOI] [Google Scholar]

- TOI (Times of India) (2010) Healthy ways to get your daily fibre. http://timesofindia.indiatimes.com/life-style/health-fitness/diet/Healthy-ways-to-get-your-daily-fibre/articleshow/5299249.cms. Visited August 2010

- Tsen CC, Eyestone W, Weber JL. Evaluation of the quality of cookies supplemented with distillers’ dried grain flours. J Food Sci. 1982;47:684–685. doi: 10.1111/j.1365-2621.1982.tb10156.x. [DOI] [Google Scholar]

- Verma AK, Banerjee R. Dietary fibre as functional ingredient in meat products: a novel approach for healthy living—a review. J Food Sci Technol. 2010;47:247–257. doi: 10.1007/s13197-010-0039-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Vratanina DL, Zabik ME. Dietary fiber sources for baked products: bran in sugar-snap cookies. J Food Sci. 1978;43:1590–1594. doi: 10.1111/j.1365-2621.1978.tb02550.x. [DOI] [Google Scholar]

- Wood PJ. Cereal β-glucans in diet and health. J Cereal Sci. 2007;46:230–238. doi: 10.1016/j.jcs.2007.06.012. [DOI] [Google Scholar]

- Yadav DN, Rajan A, Sharma GK, Bawa AS. Effect of fiber incorporation on rheological and chapatti making quality of wheat flour. J Food Sci Technol. 2010;47:166–173. doi: 10.1007/s13197-010-0036-y. [DOI] [PMC free article] [PubMed] [Google Scholar]