Abstract

Idli is a traditional fermented rice and black gram based food. Idli batter is prepared by soaking polished parboiled rice and decorticated black gram for 4 h at 30 ± 1 °C in water. The soaked mass was ground using a grinder with adequate amount of water. The blend ratios of 2:1, 3:1 and 4:1 (w/w) batter were allowed for fermentation for different periods with the addition of 2% (w/w) of salt. The rheology of the product was assessed using a Brookfield Viscometer having disc spindles. Shear stress values were in the range of 0.22 and 4 Pa and reached a maximum value at 7 h of fermentation. The density, pH, and percentage total acidity of batter during fermentation for different blend ratios ranged between 0.93 and 0.59 gm cm−3, 4.21 and 5.9 and 0.44 and 0.91% respectively. During fermentation, maximum production of riboflavin and thiamine were found to be 0.76 mg/100 gm and 0.73 mg/100 gm in 3:1 blend ratio of idli batter; and the folic acid content was found to be at a maximum of 0.75 mg/100 gm of idli batter after 10 h of fermentation. Digestibility in terms of amino N2 content was analysed by formol titration.

Keywords: Idli batter, Blend ratio, Fermentation, Viscosity, B vitamins, Formol titration

Introduction

Idli is a very popular fermented breakfast food consumed in the Indian subcontinent made mainly of rice and black gram. Soybean, green gram and chick pea can be substituted for the black gram (Ramakrishnan 1979, Steinkraus 1996). Traditionally, idli preparation is as follows: i) rice and black gram were soaked separately, ii) after draining the water, rice and black gram were grind separately with occasional addition of water during grinding process, iii) the rice and black gram batters were then mixed together with addition of a little salt, iv) the mixture was allowed to ferment overnight at room temperature, v) the fermented batter was dispensed in special idli pans and allowed for steaming for 5–8 min (Balasubramanium et al. 2006). During fermentation of idli batter overnight the naturally occurring microorganisms viz. Leuconostoc mesenteroides and Streptoccous thermophilus in grains/legumes/utensils grow rapidly, outnumbering the initial contaminants and dominating the fermentation. These microorganisms produce lactic acid (≥1.0%) and carbon dioxide that make the batter anaerobic and leaven the product. Several aspects such as effect of raw materials, effect of fermentation or processing temperature and microorganisms involved in biochemical and nutritive changes have been investigated (Balasubramanium et al. 2006, Desikachar et al. 1962, Joseph et al. 1993, Steinkraus et al. 1967, Steinkraus 1983, Thyagaraja et al. 1991). Methods of idli preparation have been reviewed by many authors (Soni and Sadhu 1990). It has also been reported that during fermentation, vitamins B and C increase, and also phytate is hydrolyzed almost to 50%. L. mesenteroides (leavening) and S. faecalis (acid production) develop concomitantly at soaking stage and continue to multiply following grinding (Mukherjee et al. 1965). The reported changes during fermentation include an increase in free sugar, non-protein nitrogen (Desikachar et al. 1962), free nicotinic acid (Rajalakshmi et al. 1964), methionine and choline in idli (Doughty 1964) and a breakdown of phytate in bread dough (Davidson et al. 1963) and of trypsin inhibitors in certain fermented legume preparations (Aykroyd 1963). These changes during fermentation are highly significant for nutritional point of view. An increase in methionine, a limiting essential amino acid in legumes, greatly improves protein value. The vitamins content of idli batter per 100 g are 0.59 mg riboflavin, 0.59 mg thiamine and 0.76 mg folic acid.

The objective was made to investigate the behaviour of idli batter prepared from polished parboiled rice and decorticated black gram in different ratio during fermentation and to analyse the data required for improving nutritional profile of idli. The present study deals with the following aspects: a) rheological characteristics of batter during the course of fermentation, b) volume changes of idli batter formed in the idli pans, c) effect of rice and black gram ratio on the above said parameters and d) changes in the nutrient contents during the course of fermentation. The consumption of sprouted cereals is becoming popular in various parts of the world. Sprouting of grains for a limited period causes increased activities of hydrolytic enzymes, improvement in the contents of certain essential amino acids, total sugars, and B-group vitamins, and a decrease in dry matter, starch, and antinutrients. The digestibilities of storage proteins and starch are improved due to their partial hydrolysis during sprouting (Chavan et al. 1989). Meeting the demand among the fermented foods (idli), an attempt was made to investigate the behaviour of idli batter made of polished parboiled rice and decorticated black gram blends in different ratio during its fermentation and to generate the basic data required for automation of this traditional and high nutritional domestic process of idli making (Balasubramanium and Viswanathan 2007).

Materials and methods

Raw materials

The raw materials selected for this study were polished parboiled rice (Oryza sativa) and decorticated black gram (Vigna radiate) that were procured from a local market.

Preparation of idli batter and idli

Rice to black gram in the ratios of 2:1, 3:1 and 4:1 by wt were taken, carefully washed and soaked separately for 5 h. After draining the water, rice and black gram were separately grounded in a wet grinder. Water was added as and when necessary. This formed a batter for the preparion of fermented idli.

Fermentation of the batter

After addition of salt (NaCl) 2% of total wt of raw material, the batter was allowed to ferment for different period (0, 4,7,10,13,16,19 and 22 h) in a stainless steel vessel. No effort was made to control the temperature during the course of fermentation (the aim was to study the physical characteristics of idli fermentation as done traditionally); the temperature varied between 20 °C and 26 °C. The volume was recorded at 4,7,10,13,16,19 and 22 h with the help of a measuring cylinder.

Rheological studies

About 100 ml of the batter was taken for viscosity measurements. The viscosity of the fermented batter was measured using Brookfield Viscometer model DV-E at disc spindle speeds of 5, 6,10,12,20,30,50,60 and 100 rpm. The readings were taken only after 1 min of revolution. The appropriate disc spindle was selected so that the torque readings were not below 10% of the total scale. Since the instrument did not give the direct shear rate readings for disc type spindle geometry, shear rate readings were calculated from torque rpm readings according to the procedure described below (Nagarjuna and Manohar 2000, Mitschka 1982):

|

1 |

Where γ = shear rate, sec−1, ω = angular velocity of spindle (π N/30) radians/sec, N = r.p.m of spindle, Rg = inner radius of guardleg, cm, Rs = radius of spindle, cm; x = radius at which shear rate is being calculated.

|

2 |

M = torque input by the instrument (dyne cm); L = effective length of spindle, cm.

The values of shear stress and shear rate from the readings of torque vs. spindle speed, was calculated using Eqs. 1 and 2 (Holdsworth 1971).

The flow behaviour index (n) and consistency coefficient (k) of idli batter at different blend ratios and fermentation times were calculated by the power law equation

|

3 |

Where, k = consistency co efficient; dynes cm−2, n = Flow Behavior Index, dimensionless.

Taking log of both sides of Eq. (3) we get log τ = log k + n log γ

The flow behavior index and consistency coefficient were derived by plotting a graph between the values of shear stress and shear rate in the log-log scale figures. The best fit equation similar to power law equation in the logarithmic scale is of the type

|

4 |

Where y = shear stress for different fermentation times (0, 4, 7, 10, 13, 16, 19, and 22 h); (τ)

m = slope of the line (flow behavior index); (n), x = shear rate (sec−1); (γ), c = anti-logarithm of intercept of line (consistency coefficient, pascal).

Determination of idli batter properties

For the different fermentation times and blend ratios the idli batter properties viz. density, pH, percent total acidity, flow behaviour i.e., viscosity, shear stress, shear rate were studied. The density was calculated as the ratio of mass to volume of the idli batter. The pH of the batter at different fermentation time was recorded using Digital pH meter (model no. L1-120, Elico Pvt Limited; Hyderabad, India). The pH of the samples was measured initially and at the end of the fermentation. For idli batter the pH was analyzed at regular time intervals during fermentation. This measurement was performed in triplicate for each set of idli batter.

For determining percent total acidity, 5 g of freshly prepared batter was diluted in 10 ml of water and titrated against 0.1(N) NaOH following the method of A.O.A.C (1970).

Chemical evaluation of idli batter

Determination of Riboflavin content

Concentration of Riboflavin was determined at different period of fermentation by spectrofluorometric method of Kodicek and Wang (1949)). 1 ml homogenized sample was used for this purpose.

Spectrophotometric analysis of folic acid and thiamine in idli batter

Folic acid and thiamine contents were measured by the method of A.O.A.C (1970).

All chemicals used were of MERCK, India.

Determination of amino nitrogen

25 ml of solution of the idli batter weighing 5 g of 3:1 (rice: black gram) blend ratio in 20 ml water was titrated with standard 0.1 N barium hydroxide solution. The volume of the blank (which was usually negligible for amino groups) was deducted from the actual volume in the formol titration (Vogel et al. 1990).

The amino N2 present in the idli batter and its change during fermentation was calculated according to the following equation.

|

Where, V1 = volume of baryta solution (ml.) less blank for acid impurities, N1 = normality of baryta solution, M = molecular weight of amino nitrogen, W = weight (g) of idli batter used in the titration.

Statistical analysis

The experiments were conducted for three replications of each of blend ratio and fermentation times. The experimental data were statistically analyzed using SPSS 16.0 for Windows (general) linear model, univariate analysis and Microsoft Excel 2007 (Microsoft Corp., Redmond, WA, USA).

Results and discussion

Density

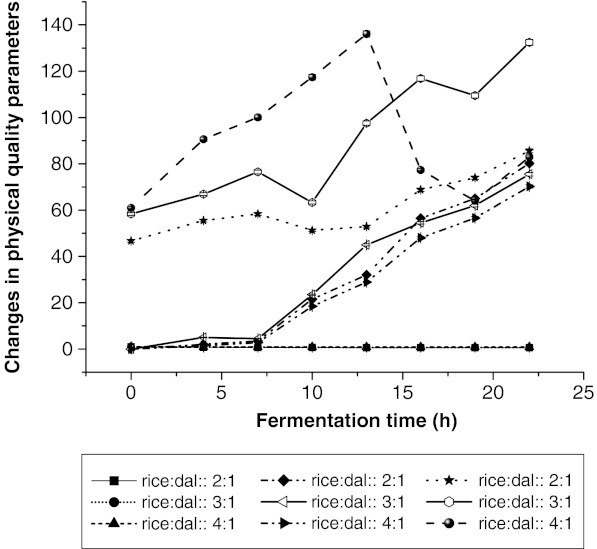

The density of parboiled rice and decorticated black gram batter at different fermentation times and blend ratios ranged from 0.93 to 0.59 g cm−3. The density decreased as the fermentation time increased. This was because of the entrapment of the air/in gas pockets and the functions of the microorganisms responsible for the different functionality of batter density (Mukherjee et al. 1965). Mean values of idli batter density for different blend ratio (2:1, 3:1 and 4:1) (Fig. 1) at 22 h of fermentation are 0.592, 0.682 and 0.831 g cm−3 respectively. During fermentation the volume of idli batter increases from 1.62 to 3.2 times its original volume (Fig. 1). This increased volume of idli batter is due to the incorporation of lactic acid bacteria into the batter during fermentation and entrapment of air.

Fig. 1.

Changes in physical quality parameters of idli batters (n=3). The first set of different rice and dal blend ratios above indicates density changes (gm.cm-3), similarly the second set above indicates volume changes (cm3) and the third set indicates apparent viscosity changes (Pa.s) respectively at different period of fermentation. The experiment was carried out in triplicate

pH value

The pH value of idli batter at different fermentation period ranged between 5.9 and 4.2 already mentioned in the earlier study (Ghosh and Chattopadhyay 2010). There is an increasing trend of acidity level, i.e., decrease in the pH value. This is mainly associated with the development of S. faecalis producing lactic acid which lowers the pH, and production of carbon dioxide, which leavens the batter (Mukherjee et al. 1965). Black gram soaked in water has a high concentration of soluble nutrients to support the growth of lactic acid bacteria. The role of lactic acid bacteria is to reduce pH of the batter to an optimum level (4.4 to 4.5) for yeast activity (Soni and Sadhu 1990).

Percent total acidity

The percent total acidity of idli batter at different period of fermentation ranged between 0.44 to 0.91% (Ghosh and Chattopadhyay 2010). Black gram, the leguminous component of idli batter serves not only as an effective substrate but also provides the maximum number of microorganisms for fermentation. With the fermentation time there is an increase in the percent total acidity value whereas, during 19 and 20 h of fermentation there is less variation in the percent of total acidity of idli batter.

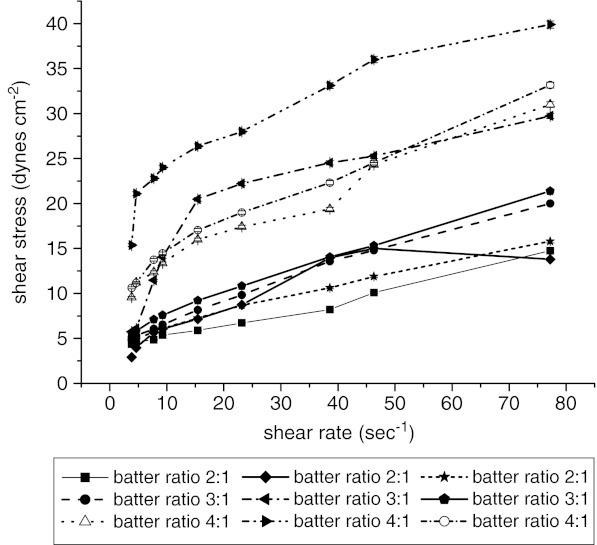

Rheological characteristics

Apparent viscosity of idli batter at different fermentation time (h) and flow curve of idli batter with respect to shear rate and viscosity plot at different fermentation time (0 h, 7 h and 10 h) were shown in Figs. 1 and 2 respectively. In general, both parameters have shown a declining trend with fermentation time irrespective of blend ratio. However, the increase of rice content in the batter shown marginally increased values of consistency index (Table 1). The power law model with shear stress and shear rate fitted the data well (P < 0.05) for all the batter types and fermentation periods, flow behaviour indices were in the range of 0.208–0.856, which indicated strong non Newtonian behaviour (pseudo plastic or shear thinning) of the idli batter. Volume increase during the course of the fermentation is shown in Fig. 1 for the batter types 2:1, 3:1 and 4:1 of ratios. There was a rapid volume increase up to 13 h of fermentation and then it slowed down.

Fig. 2.

Shear Stress vs. Shear Rate of idli batter of different blend ratios (parboiled rice: black gram, 2:1, 3:1, and 4:1) subjected to 0 h, 7 h and 10 h of fermentation at 37 ºC. The experiment was carried out in triplicate

Table 1.

Changes in flow behavior, consistency and vitamin B in idli batters of different blend ratios (parboiled rice: black gram) subjected to different period of fermentation at 37 °C

| Blend ratio | Fermentation time (h) | Flow Behaviour Index | Consistency Index | Concentration of Vitamin B (mg/100 ml of idli batter) | ||

|---|---|---|---|---|---|---|

| Riboflavin | Thiamine | Folic acid | ||||

| 2:1 | 0 | 0.406 | 1.12 ± 0.05 | 0.22 ± 0.11 | 0.26 ± 0.03a | 0.29 ± 0.05a |

| 04 | 0.504 | 1.53 ± 0.09 | 0.43 ± 0.09a | 0.54 ± 0.05 | 0.60 ± 0.11a | |

| 07 | 0.614 | 2.03 ± 0.11 | 0.48 ± 0.10 | 0.59 ± 0.09 | 0.65 ± 0.12 | |

| 10 | 0.412 | 1.20 ± 0.02 | 0.54 ± 0.10a | 0.62 ± 0.09a | 0.70 ± 0.15 | |

| 13 | 0.426 | 1.37 ± 0.06 | 0.46 ± 0.06 | 0.48 ± 0.08 | 0.54 ± 0.09 | |

| 16 | 0.856 | 5.06 ± 0.15 | 0.44 ± 0.06 | 0.42 ± 0.08 | 0.41 ± 0.09 | |

| 19 | 0.397 | 1.08 ± 0.08 | 0.38 ± 0.05a | 0.36 ± 0.08a | 0.38 ± 0.06 | |

| 22 | 0.415 | 1.33 ± 0.06 | 0.31 ± 0.10 | 0.33 ± 0.07 | 0.31 ± 0.06 | |

| 3:1 | 0 | 0.248 | 0.55 ± 0.04 | 0.42 ± 0.08a | 0.46 ± 0.09 | 0.48 ± 0.06a |

| 04 | 0.263 | 0.58 ± 0.05 | 0.68 ± 0.10 | 0.69 ± 0.07 | 0.69 ± 0.13 | |

| 07 | 0.348 | 0.88 ± 0.04 | 0.76 ± 0.08a | 0.73 ± 0.07a | 0.75 ± 0.14 | |

| 10 | 0.276 | 0.62 ± 0.06 | 0.75 ± 0.07 | 0.72 ± 0.07 | 0.70 ± 0.14 | |

| 13 | 0.367 | 0.97 ± 0.14 | 0.61 ± 0.07a | 0.59 ± 0.06 | 0.56 ± 0.12a | |

| 16 | 0.328 | 0.75 ± 0.08 | 0.60 ± 0.06 | 0.52 ± 0.06 | 0.54 ± 0.12 | |

| 19 | 0.316 | 0.74 ± 0.04 | 0.46 ± 0.09a | 0.49 ± 0.06a | 0.51 ± 0.10 | |

| 22 | 0.379 | 1.05 ± 0.17 | 0.44 ± 0.08 | 0.43 ± 0.05 | 0.47 ± 0.08 | |

| 4:1 | 0 | 0.357 | 0.96 ± 0.08 | 0.21 ± 0.06 | 0.23 ± 0.07 | 0.30 ± 0.05 |

| 04 | 0.208 | 0.38 ± 0.02 | 0.46 ± 0.08a | 0.52 ± 0.10a | 0.56 ± 0.10 | |

| 07 | 0.218 | 0.44 ± 0.06 | 0.48 ± 0.11a | 0.59 ± 0.10 | 0.62 ± 0.11a | |

| 10 | 0.227 | 0.51 ± 0.04 | 0.44 ± 0.10 | 0.48 ± 0.06 | 0.60 ± 0.11 | |

| 13 | 0.231 | 0.53 ± 0.04 | 0.41 ± 0.11 | 0.43 ± 0.09 | 0.56 ± 0.08 | |

| 16 | 0.306 | 0.69 ± 0.06 | 0.40 ± 0.11 | 0.41 ± 0.08a | 0.44 ± 0.06a | |

| 19 | 0.296 | 0.64 ± 0.02 | 0.35 ± 0.12 | 0.38 ± 0.09 | 0.34 ± 0.04 | |

| 22 | 0.403 | 1.27 ± 0.17 | 0.34 ± 0.09a | 0.36 ± 0.09a | 0.32 ± 0.04 | |

Means ± SD with the same superscript within each column are not significantly different (P <0.05) (n = 3). 2:1, 3:1, 4:1: As in text

Changes in concentration of B Vitamins in different batter ratios of idli

Table 1 shows the concentration of B vitamins viz. riboflavin, thiamine and folic acid at different period of fermentation and different blend ratios of idli batter and it is evident from the table that 10 h of fermentation of idli batter provided maximum production of all vitamins and the preferred ratio of idli batter is 3:1 which produced considerable amount of B vitamins. Earlier workers (Desikachar et al. 1965) found no change in thiamine content during fermentation of idli, possibly because of the technique of fermentation employed by them was different, and yeast and a Lactobacillus organism participating in the fermentation, whereas in our study the organisms involved was L. mesenteroides (Mukherjee et al. 1965).

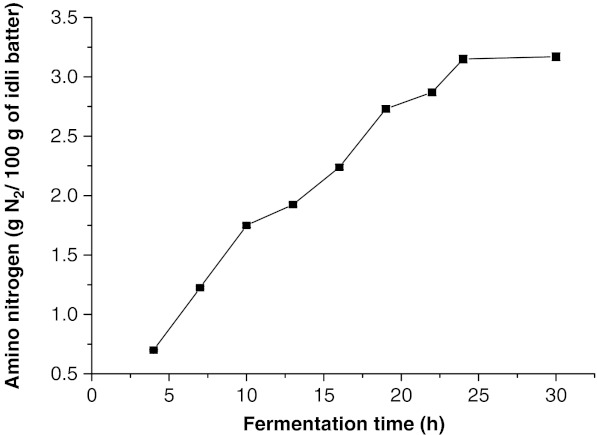

Formol titration of idli batter

By formol titration, it was observed that (Fig. 3), with increasing fermentation time (4–30 h), more free amino groups was released due to hydrolysis of protein from black gram due to the activity of the lactic acid bacteria which hydrolysed protein of idli batter into free amino acids during fermentation. Free amino groups in the food samples made it more acceptable for consumption due to their improved digestibility (Chavan et al. 1989).

Fig. 3.

Formol titration to determine the amount of amino N2 in idli batter. The experiment was carried out in triplicate

Conclusion

Idli batter has been prepared with the blend ratios of 2:1, 3:1 and 4:1 (parboiled rice: black gram). Physical properties of this idli batter viz. density, pH and percent total acidity at different fermentation times and blend ratios were observed in the range of 0.93–0.59 g cm−3, 4.21 and 5.9 and 0.44–0.91% respectively. The flow behavior indicated the Non Newtonian characteristics of idli batter at different period of fermentation and blend ratios (pseudoplastic). The chemical behavior of idli batter has shown enhanced amount of vitamin B production during fermentation and 7 h is the recommended time for the production of maximum amount of B vitamins with the blend ratio of 3:1 and amino N2 content was found to be maximum i.e. 3.25% at 25 h of fermentation.

Acknowledgement

The authors gratefully acknowledge the University Grants Commission, New Delhi, India for providing financial assistance to carry out the research work.

Contributor Information

Debasree Ghosh, Email: d.debasree@gmail.com.

Parimal Chattopadhyay, Email: parimalchattopadhyay@yahoo.com.

References

- Aykroyd WR (1963) Special Report ICMR. No. 42. 6th edn. New Delhi

- Balasubramanium S, Viswanathan R. Properties of idli batter during its fermentation time. J Food Process Preserve. 2007;31:32–40. doi: 10.1111/j.1745-4549.2007.00104.x. [DOI] [Google Scholar]

- Balasubramanium S, Singh N, Ilys SM, Wanjari OD. Effect of selected decorticated legumes protein on rheology of maize extrudate pastes. J Food Sci Technol. 2006;43:590–594. [Google Scholar]

- Chavan JK, Kadam SS, Beuchat LR. Nutritional improvement of cereals by fermentation. Crit Rev Food Sci Nutr. 1989;28:349–400. doi: 10.1080/10408398909527507. [DOI] [PubMed] [Google Scholar]

- Davidson S, Meiklejohn AP, Passmore R. Human nutrition and dietetics. 2. Edinburgh: Livingstone; 1963. [Google Scholar]

- Desikachar HSR, Radhakrishnamurthy R, Rao GR, Kadol SB, Srinivasan M, Subramanyan V. Studies on idli fermenteation. Part I. Some accompanying changes in the batter. J Sci Ind Res (India) 1962;19C:168–172. [Google Scholar]

- Desikachar HSR, Raghavandra Rao SN, Ananthachar TK. Effect of degree of milling on water absorption of rice during cooking. J Food Sci Technol. 1965;2:110112. [Google Scholar]

- Doughty J (1964) F.A.O. Nutr. Studies 19, Rome, Italy

- Ghosh D, Chattopadhyay P (2010) Application of principal component analysis (PCA) as a sensory assessment tool for fermented food products. J Food Sci Technol JFST-D-09-00006 [DOI] [PMC free article] [PubMed]

- Holdsworth SD. Applicability of rheological models to the interpretation of flow and processing behavior of fluid food products. J Tex Studies. 1971;2:393–418. doi: 10.1111/j.1745-4603.1971.tb00589.x. [DOI] [PubMed] [Google Scholar]

- Joseph E, Crites SG, Swanson BG. Microstructure of idli. Food Struct. 1993;12:483–488. [Google Scholar]

- Kodicek E, Wang YL. The fluorimetric estimation of riboflavin in foodstuffs and other biological material. Biochem J. 1949;44:340–343. doi: 10.1042/bj0440340. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mitschka P. Simple conversion of Brookfield R. V. T readings into viscosity functions. Rheol Acta. 1982;21:207–209. doi: 10.1007/BF01736420. [DOI] [Google Scholar]

- Mukherjee SK, Albury MN, Perderson CS, Van Veen AG, Stinekraus KH. Role of Leuconostoc mesenteroides in leavening the batter of idli, a fermented food in India. Appl Microbiol. 1965;13:227–231. doi: 10.1128/am.13.2.227-231.1965. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nagarjuna VD, Manohar B. Rheology and particle size changes during Idli fermentation. J Food Eng. 2000;43:167–171. doi: 10.1016/S0260-8774(99)00146-6. [DOI] [Google Scholar]

- Official Methods of Analysis of Official Analytical Chemists (A.O.A.C.) published by the A.O.A.C. (1970) Benjamin Franklin. 11th edn. Washington, DC 20044

- Rajalakshmi R, Nanavaty K, Gumastha A. J Nutr Diet India. 1964;1:276. [Google Scholar]

- Ramakrishnan CV. Terminal report of American PL 480-project Nr GF-IN-491. Study of Indian fermented foods from legumes and production of similar fermented foods from U.S. soybean. Baroda: Biochemistry Dept. Baroda University; 1979. [Google Scholar]

- Soni SK, Sadhu DK. Indian fermented foods: microbiological and biochemical aspects. Indian J Microbiol. 1990;30:135–157. [Google Scholar]

- Steinkraus KH. Handbook of indigenous fermented foods. New York: Marcel Dekker; 1983. pp. 132–146. [Google Scholar]

- Steinkraus KH. Handbook of Indigenous fermented foods. 2. New York: Marcel Dekker Inc; 1996. [Google Scholar]

- Steinkraus KH, Van Veen AG, Thiebeau DB. Studies on idli- an Indian fermented black-gram rice food. Food Technol. 1967;21:916–919. [Google Scholar]

- Thyagaraja N, Otani H, Hosono A. Microflora in idli, a traditional fermented cereal pulse product from India. Lebensm Wiss Technol. 1991;24:916–919. [Google Scholar]

- Vogel AI, Tatchell AR, Furnis BS, Hannaford AJ, Smith PWG. Vogel’s textbook of practical organic chemistry. Determination of amino acids by formol titration. 5. London: The English Language Book Society; 1990. [Google Scholar]