Abstract

Processing parameters of feed including moisture content of feed (12, 15, 18, 21 and 24%), soy flour-rice blend ratio (10:90, 14:86, 18:82, 22:78 and 26:74), operational parameters of extruder like barrel temperature (100, 110, 120, 130 and 140 °C), die head temperature (160, 170, 180, 190 and 200 °C) and screw speed (100, 110, 120, 130 and 140 rpm) were optimized for physical and textural properties of soy-rice blend extrudates. The minimum value of longitudinal expansion index lied near 185 °C die head temperature at about 120 rpm. The minimum value of bulk density was observed in between 18:82 blend ratio and 115 °C barrel temperature.

Keywords: Extrusion, Snacks, Response surface methodology

Introduction

Extruded snacks contribute as an important part for many consumers in daily nutrient and calories intake (Teltweiler 1991). The defatted soybean (Glycine max L.) meal is the by-product of solvent extraction plant and rice brokens (Oryza sativa L.) are the by-product of rice milling industry. Rice flour prepared out of rice brokens can be used as an important ingredient for many ready-to-eat breakfast cereals and snacks. Soybean, the first vegetable proteinaceous feed material was used for making protein rich extruded food (Harper 1981). Extrusion cooking is capable of converting soluble globular legume protein into material having fibrous and chewy texture (Harper 1981). Indian soybean industry produces about 3 million tons of meal every year (SOPA 1999). Defatted soy flour contains about 50% protein and its protein digestible index is 60. In the extrusion of snacks and other food products, proper control of the extrusion process is important to quality of final product. In cereal-based products, the degree of starch processing is important for major quality aspects such as taste, digestibility, texture and appearance. Patil et al. (1990) studied on a dry extrusion cooker Insta Pro 2000 for extrusion of soy-rice blend. It was observed that extrusion at lower level of moisture (12% wb) is most suitable. The highly puffed product having bulk density of 266.23 kg/m3, water absorption index of 4.09 was obtained at this level of feed moisture. Dahlin and Lorenz (1993) examined seven whole grain cereals to study extrusion processing effects on in vitro protein digestibility. Eight extrusion conditions were applied and effects of cereal variety, extrusion temperature and feed moisture on protein digestibility were studied. The most protein-digested products were produced at 15% feed moisture, 100/150 °C product temperature and screw speed of 100 rpm. Bhattacharya et al. (1999) observed that incorporation of chickpea into rice flour decreased product expansion but increased bulk density and peak shear force of extrudates. Boonyasinikool and Charunuch (2000) developed a nutritious soy fortified snack with good texture and protein quality from 18% of soy flour (9% defatted soy flour + 9% full fat soy flour) in rice broken and corn grits blend, with 2% soybean oil fortified with vitamins, minerals and amino acid. The product obtained had expansion ratio, bulk density and compression force of 3.9, 58 g/m3 and 60.17 N, respectively. Protein content in the developed snack was 9.9%, which was 46.7–70.7% higher than the market snacks. Chang and EI-Dash (2003) studied some physical characteristics of extruded cassava starch using a single—screw extruder, by varying acid concentration, feed moisture content and barrel temperature and evaluated using surface response methodology. Singh et al. (2006a) optimized the processing parameters of extruded food prepared from Bengalgram broken and sorghum blends. They optimized parameters for maximum values of specific length, sectional expansion index and minimum value of mass flow rate. They suggested that the best quality extruded snacks were found at 100 °C barrel temperature, 15:85 blend ratio of Bengalgram broken to sorghum and 15% moisture content. Singh et al. (2006b) found that the physical properties and textural analysis of snacks prepared at 20% blending of soybean, 15% moisture content and 85 °C temperature was found as the best quality extrudates. The present study was undertaken to study the effect of moisture content, blend ratio and temperature (barrel and die head) on the physical properties (moisture content of extrudates, specific length, longitudinal expansion index, and bulk density) of rice and defatted soy flour based ready-to-eat extrudates.

Materials and methods

The study was conducted at soy processing lab of Department of Post-harvest Process and Food Engineering, College of Agricultural Engineering, Jabalpur, India. The single-screw extruder (D47055 Duisburg, Brabender, Germany), consisted of grooved barrel covered with heating and cooling elements. The constructional elements of the extruder included motor and gear unit, coupling, loading unit, extruder barrel with screw and control cabinet. The length to diameter ratio of the extruder was 20:1. During experimentation the compression ratio (3:1) temperature of barrel zone I (90 °C) and barrel zone II (120 °C) were kept constant. The defatted soy-flour and rice flour were procured from local market. The experimental design is dependent on the symmetrical selection of variation increments about the centre composition (Cochran and Cox 1957; Myres 1976). These levels of variation were selected to be within the range of reasonable formulations and the increments were carefully selected. The selected levels were also based on the conclusions of previous studies (Chauhan and Bains 1988; Patil et al. 1990; Singh et al. 2006b) and preliminary trails.

Results and discussion

Moisture Content of Extrudates (MCE)

The second degree polynomial equation obtained by response surface analysis of the data showing the effect of MCE versus feed moisture content (MCF), blend ratio (BR), barrel temperature (TBrl), die head temperature (TDie) and screw speed (SS) resulted in following equation

|

1 |

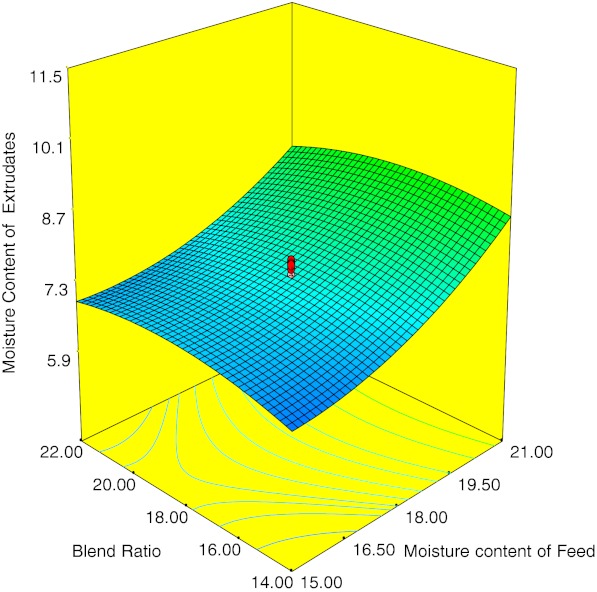

The R2 value was 0.93 and F-value was 7.31 for the model. It is depicted from Fig. 1 that there is positive correlation between the moisture content of feed and MCE. At the lower value of MCE and blend ratio, the value of moisture content of extrudate was lowest and when the value of moisture content of feed increased keeping blend ratio at constant level, the value of moisture content of extrudate also increased (Singh et al. 2005).

Fig. 1.

Effect of feed moisture content and blend ratio on moisture content of extrudates

Specific Length (SL) of extrudates

The second degree polynomial model for SL versus feed moisture content (MCF), blend ratio (BR), barrel temperature (TBrl), die head temperature (TDie) and screw speed (Ss) resulted into an equation

|

2 |

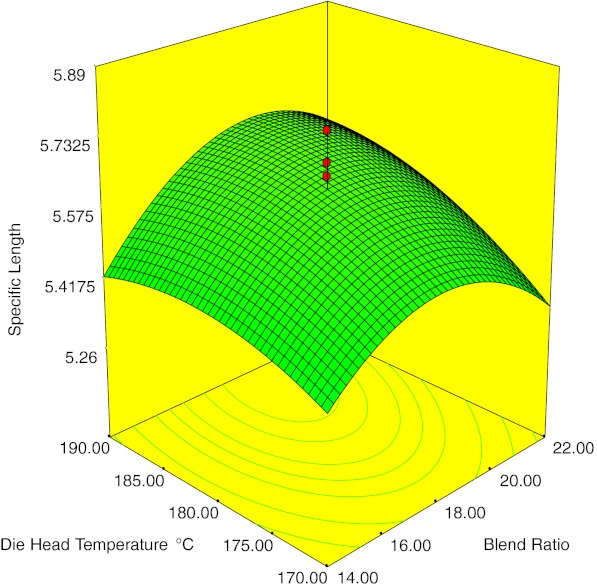

The R2 value was 0.922 for the model and F-value was 6.53, which implied that the model is significant. In this case, linear term of moisture content of feed and square terms of blending ratio, and screw speed were found highly influencing variables on the SL of extrudates. Singh et al. (2006b) reported that SL was highly affected by moisture content and temperature of feed. Figure 2 shows the maximum value of specific length in the range of 18 to 20% blend ratio and 185 to 190 °C die head temperature.

Fig. 2.

Effect of blend ratio and die head temperature on specific length of extrudates

Longitudinal Expansion Index (LEI)

Multiple regression model of longitudinal expansion index LEI versus feed moisture content (MCF), blend ratio (BR), barrel temperature (TBrl), die head temperature (TDie) and screw speed (SS) resulted into the following equation

|

3 |

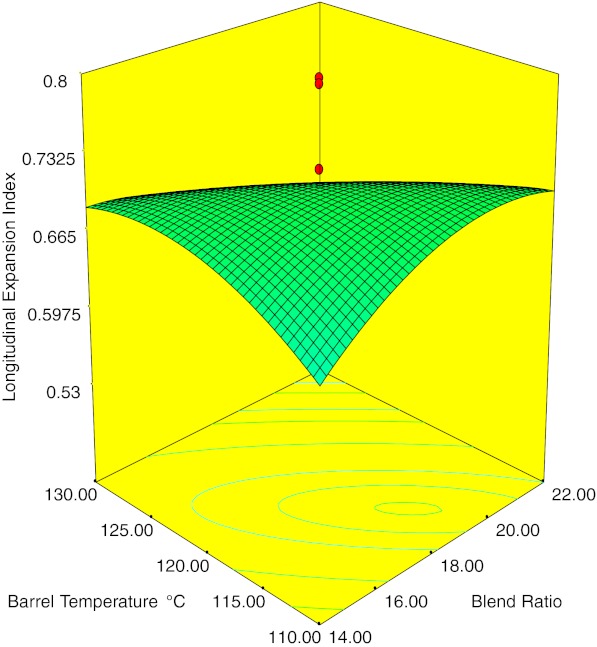

The R2 value was 0.80 and F-value was 2.22 for the model. The maximum value of LEI lies at 110–115 °C barrel temperature and 18–20% blend ratio beyond that the value of LEI decreased (Fig. 3). Manoharkumar et al. (1978) reported that blending with legume flours decreased the expansion ratio. Figure 3 shows the barrel temperature has more effect on LEI in comparison to blend ratio. The value of LEI was lowest at maximum value of barrel temperature and blend ratio within the experimental range.

Fig. 3.

Effect of blend ratio and barrel temperature on longitudinal expansion index of extrudates

Volumetric Expansion Index (VEI)

Regression analysis of VEI versus feed moisture content (MCF), blend ratio (BR), barrel temperature (TBrl), die head temperature (TDie) and screw speed (SS) yielded following polynomial model

|

4 |

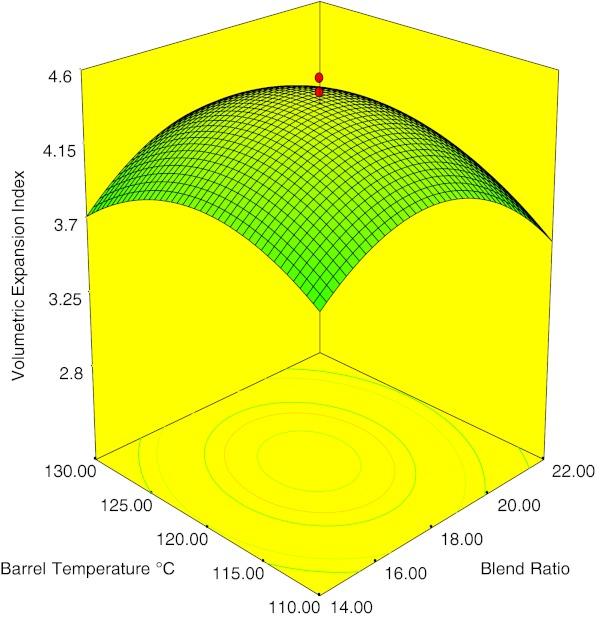

The R2 was 0.895 and F-value was 4.70, which implies that the model is significant. Figure 4 shows the look of umbrella shape where the contours are spreading in outward direction which means the highest value of VEI lies near feed moisture content of 12%, 18:82 blend ratio, 120 °C barrel temperature, 180 °C die head temperature and 120 rpm screw speed, nearly in the centre of contour graph and moving either side will increase the VEI (Patil et al. 1990).

Fig. 4.

Effect of blend ratio and barrel temperature on volumetric expansion index of extrudates

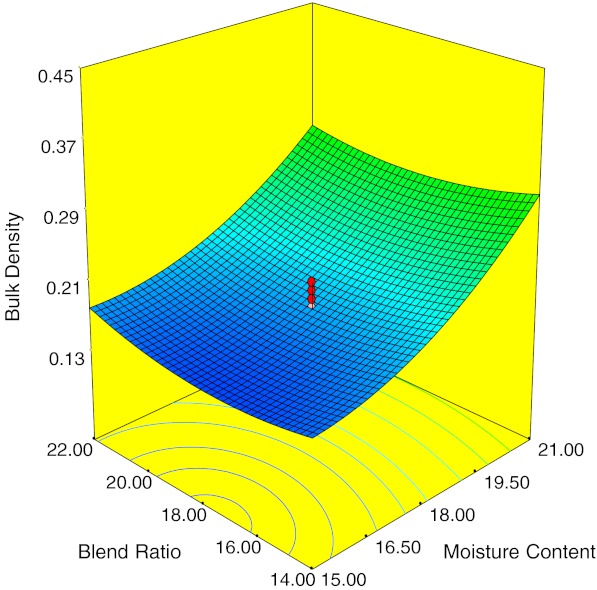

Bulk Density (BD)

The multiple regression analysis of BD versus feed moisture content (MCF), blend ratio (BR), barrel temperature (TBrl), die head temperature (TDie) and screw speed (SS) yielded following polynomial model

|

5 |

The R2 value was 0.93 and F-value was 7.4 for the model. In this case, the linear terms of feed moisture content, interaction term of moisture content and die head temperature and square terms of moisture content, blend ratio and die head temperature of feed were highly influencing variable coefficients affected the model of bulk density of extrudates. There was strong correlation between the feed moisture content and bulk density of extrudates (Fig. 5). As the value of feed moisture content increased the value of bulk density decreased and vice versa (Kulkarni and Joshi 1992). Hence the bulk density had positive correlation with moisture content of feed.

Fig. 5.

Effect of feed moisture content and blend ratio on bulk density of extrudates

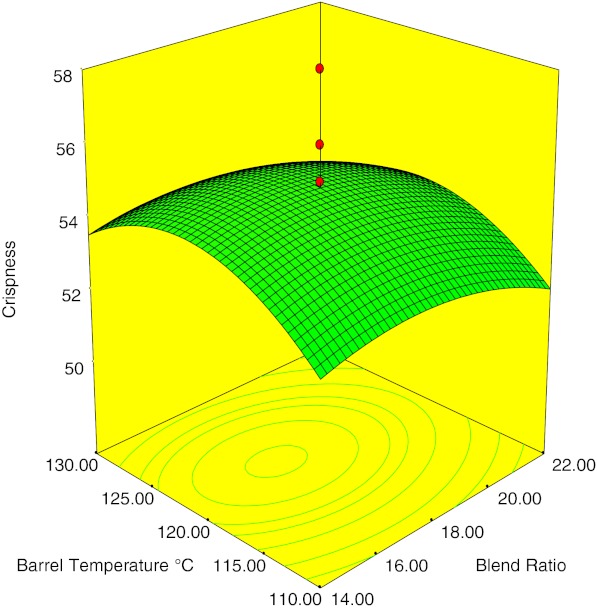

Crispness

The data showed that crispness was highest at 12% feed moisture content, 18:82 blend ratio of defatted soy flour to rice, 120 °C barrel temperature, 180 °C die head temperature and 120 rpm screw speed. The second degree polynomial was obtained and the effect of crispness versus feed moisture content (MCF), blend ratio (BR), barrel temperature (TBrl), die head temperature (TDie) and screw speed (SS) resulted in following relationship

|

6 |

The R2 value was 0.932 for the model and F-value was 7.48, which implies that the model is significant. Figure 6 showed the shape of umbrella where the contours are spreading in outward direction, which means, the highest value of crispness lies nearly in the range of 16 to 18% blend ratio and 120–125 °C barrel temperature, moving either side will reduce the value. Singh et al. (2005) reported that crispness increased with increase in temperature and decreased with increase in moisture content.

Fig. 6.

Effect of blend ratio and barrel temperature on crispness of extrudates

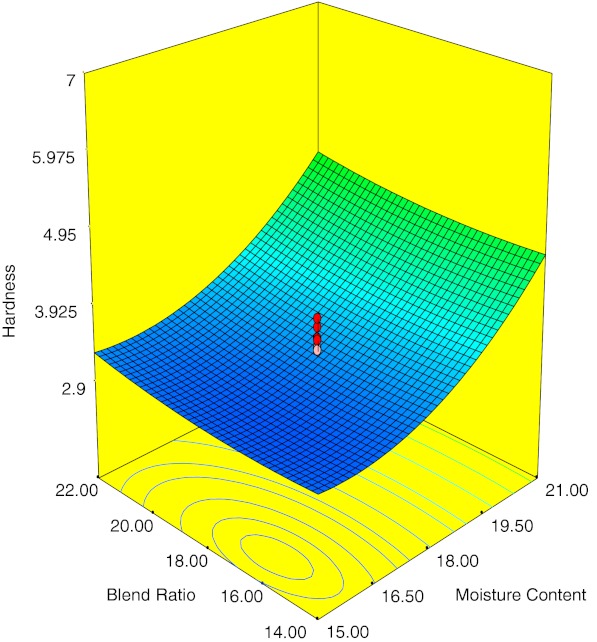

Hardness

The data showed that hardness was highest at 24% feed moisture content, 18:82 blend ratio of defatted soy flour to rice, 120 °C barrel temperature, 180 °C die head temperature and 120 rpm screw speed. The second degree polynomial for hardness versus feed moisture content (MCF), blend ratio (BR), barrel temperature (TBrl), die head temperature (TDie) and screw speed (SS) resulted in the following model

|

7 |

The R2 value was 0.877 with F-value was 3.93 for the model, which implied that the model is significant. There is a positive correlation between these parameters on hardness of the extrudate (Fig. 7). The lowest value of hardness lies nearly at 16% blend ratio and middle of 15 to 16.5% moisture content of extrudates. When the value of moisture content of feed increased by keeping blend ratio at constant level, the value of hardness increased (Jha and Prasad 2003) and when the value of blend ratio increased gradually by keeping moisture content of feed at constant level, the value of hardness also increased up to 18% moisture content and beyond that it remained unchanged.

Fig. 7.

Effect of feed moisture content and blend ratio on hardness of extrudates

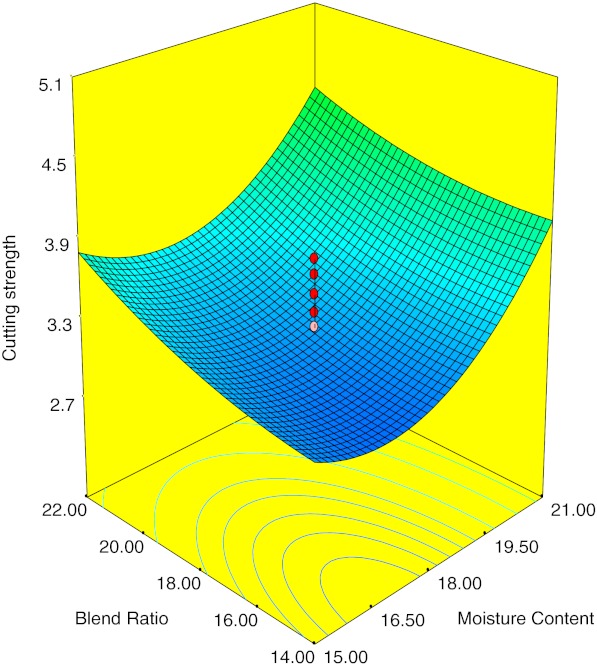

Cutting strength

The observed data showed that cutting strength was highest at 21% feed moisture content, 22:78 blend ratio of defatted soy flour to rice, 110 °C barrel temperature, 170 °C die head temperature and 130 rpm screw speed. Regression analysis of cutting strength versus feed moisture content (MCF), blend ratio (BR), barrel temperature (TBrl), die head temperature (TDie) and screw speed (SS) yielded following polynomial model

|

8 |

The R2 gave a value of 0.786 and F-value was 3.45, which implied that the model is significant. There was strong correlation between the feed moisture content and cutting strength of extrudates (Fig. 8). As the value of feed moisture content increased, the value of cutting strength increased which means product becomes harder at higher moisture content. Hence, the cutting strength had positive correlation with moisture content of feed because the linear, interactive and quadratic term had significant role over the model (Singh et al. 2005).

Fig. 8.

Effect of feed moisture content and blend ratio on cutting strength of extrudates

Conclusion

After complete evaluation of all the attributes for physical parameters like moisture content, specific length, longitudinal expansion index, volumetric expansion index and bulk density and textural properties like crispness, hardness and cutting strength of extrudates, it was found that there were strong positive correlations between the moisture content of feed and blend ratio, while barrel temperature, and die head temperature had significant influence and screw speed had the negligible influence on the physical and textural properties of extrudates. The maximum value of specific length existed at 18:82 blend ratio, 125 °C barrel temperature, 185 to 190 °C die head temperature and 120–125 rpm screw speed. The minimum value of longitudinal expansion index was near 185 °C die head temperature and about 120 rpm. The highest value of volumetric expansion index was near 120 °C barrel temperature and 180 °C die head temperature and near 120 rpm screw speed. The minimum value of bulk density was observed between 18:82 blend ratio and 115 °C barrel temperature the maximum value of crispness was found near higher side of die head temperature i.e. 185–190 °C and 120 rpm screw speed. The lowest hardness was obtained near 16% blend ratio and middle of 15 to 16.5% moisture content of extrudates. The minimum cutting strength was observed at 170 °C die head temperature and 120–130 °C barrel temperature. The optimum conditions for maximum acceptable extrudates were 16.0–16.5% moisture content, 22:78 blend ratio, 130 °C barrel temperature, 190 °C die head temperature and 110 rpm screw speed followed by 171 moisture content, 22:78 blend ratio, 130 °C barrel temperature, 190 °C die head temperature and 110 rpm screw speed.

References

- Bhattacharya S, Sudha ML, Rahim A. Pasting characteristics of an extruded blend of potato and wheat flours. J Food Eng. 1999;40:107–111. doi: 10.1016/S0260-8774(99)00046-1. [DOI] [Google Scholar]

- Boonyasinikool P, Charunuch C. Development of nutritious soy fortified snack by extrusion cooking. J Kasetsart Nat Sci. 2000;34:279–288. [Google Scholar]

- Chauhan GS, Bains GS. Effect of some extrudes variables on physico–chemical properties of extended rice-legume blend. Food Chem. 1988;27:213–224. doi: 10.1016/0308-8146(88)90064-7. [DOI] [Google Scholar]

- Chang YK, EI-Dash AA. Effects of acid concentration and extrusion variables on some physical characteristics and energy requirements of cassava starch. Brazil J Chem Eng. 2003;20(2):129–137. [Google Scholar]

- Cochran WG, Cox GW. Experimental design. New York: Wiley; 1957. [Google Scholar]

- Dahlin K, Lorenz K. Protein digestibility of extruded cereal grains. Food Chem. 1993;48:13–18. doi: 10.1016/0308-8146(93)90214-Z. [DOI] [Google Scholar]

- Harper JM (1981) Starch-based extended foods. In: Extrusion of foods, Vol II, CRC Press Inc. Florida, p 83–87

- Jha SK, Prasad S. Studies on extrusion cooking of rice and mung blend with salt and sugar. J Food Sci Technol. 2003;40:257–261. [Google Scholar]

- Kulkarni SD, Joshi KC. Potato starch soy-blends: possible effects of starch properties on few aspects of and products. Indian Food Pack. 1992;46:38–47. [Google Scholar]

- Manoharkumar B, Seileer K, Gerstenkorn P. Pressure extrusion of Indian maize and maize legume composite flours. J Food Sci Technol. 1978;15:173–174. [Google Scholar]

- Myres HP. Response surface methodology. Boston: Altyn and Bacon; 1976. [Google Scholar]

- Patil RT, Singh DS, Tribelhorn RE. Effect of processing conditions on extrusion cooking of soy-rice blend with a dry extrusion cooker. J Food Sci Technol. 1990;27:376–378. [Google Scholar]

- Singh DS, Garg SK, Singh M, Kalpana D. Optimization of processing parameters of soy-sorghum blends extrudates. J Agric Eng. 2005;42(4):45–49. [Google Scholar]

- Singh DS, Garg SK, Singh M, Goyal N. Optimization of the processing parameters of extrudate prepared from Bengalgram brokens and sorghum blends by using Wenger X-5 extruder. J Food Sci Technol. 2006;43:301–304. [Google Scholar]

- Singh DS, Garg SK, Singh M, Goyal N. Effect of major processing parameters on the quality of extrudates made out of soy-kodo blends. J Food Sci Technol. 2006;43:434–437. [Google Scholar]

- SOPA digest. Indore: Soybean Processors Association; 1999. [Google Scholar]

- Teltweiler P. Snack food world wide. Food Technol. 1991;45(2):58–61. [Google Scholar]