Abstract

Non-destructive systems are recent trends for quality evaluation of fruits and vegetables. Information on post-harvest variations in electrical properties is needed to develop new instruments for this purpose. Electrical properties are finding increasing application in agriculture and food processing industries. Knowledge of dielectric properties of foods as a function of moisture content and temperature is essential in the design and control of drying systems. As simple, rapid and non-destructive measuring techniques, dielectric spectroscopy provides information about the dielectric response of materials to electromagnetic field. Electrical properties of agricultural materials have been of interest for many years. The interest in dielectric properties of materials has historically been associated with the design of electrical equipment. This review paper covers theoretical aspects of different electrical properties, their measurement techniques, applications of dielectric properties in agriculture/food processing sector and potential applications of thermal imaging (TI) for quality and safety assessment in food processing. The values of dielectric properties of a number of products including food grains, fruits and vegetables, and meat and meat products are presented in table form. This comprehensive coverage will be useful for academic, scientific and industrial community in treating and applying the facts in developing/testing new processes and products based on electromagnetic energy application.

Keywords: Electrical properties, Non-destructive, Measuring techniques, Dielectric constant, Loss factor, Thermal imaging technique, Food quality evaluation

The material investigation and moisture measurement using electromagnetic waves in wide spectrum serve for quality control and improvement in many branches like industry, forest and wood-working industry, civil engineering, agriculture, commerce and also foods e.g. for quality evaluation of meat, fruits, coffee etc (Hlavacova 2003; Venkatesh and Raghavan 2004). Non-destructive evaluation of quality based on constituents of fruits and vegetables has been successfully used (Chen et al. 1999; Jha et al.2001; Kawano 1998). Electrical characteristics of agricultural materials have been of interest for many years (Nelson 2006) and are utilized in many areas of human activities. Techniques for non-destructive determination of quality and related characteristics of agricultural products are helpful to producers, handlers and processors (Nelson et al. 2006). Permittivity and moisture can be closely correlated when water content is high. Knowledge of dielectric properties in partially frozen material is critical in determining the rates and uniformity of heating in microwave thawing. Electrical properties are important in processing foods with pulsed electric fields, ohmic heating, induction heating, radio frequency, and microwave heating. These properties are also useful in the detection of processing conditions or the quality of foods (Barbosa-Canovas et al. 2006). Considering the increased demands of quality and safety now, it is imperative to develop fast and efficient non-destructive methods to accomplish the food quality detection. The dielectric properties of cereals grain and oilseeds are essential for understanding their electrical behaviour, and the development of indirect non-destructive methods for determining their physical properties (Trabelsi and Nelson 2003) and are also important in the design of equipments for radiofrequency or microwave dielectric heating applications and potential agricultural applications such as grain drying, seed treatment to improve seed germination and insect control in stored grain using high-frequency and microwave electric field (Nelson 1992, 1999).

As a simple, rapid and non-destructive measuring technique, dielectric spectroscopy provides information about the dielectric response of materials to electromagnetic fields, thus, it is a convenient method for evaluating food quality, especially for detecting moisture content in foods (Toyoda 2003). This technology has been studied and used extensively in analysis and monitoring quality of biological materials (Nelson 1991, 2005). The measurement is rapid and it does not destroy the substance; it is therefore suitable for on-line measurements. The utilization of dielectric properties is also described in agricultural materials and food quality sensing. In this review, an attempt is made to review basic concepts of electrical properties, various measuring methodologies, their role in the agri-food sector and potential applications of thermal imaging (TI) for quality and safety assessment in food processing. The current status of research in this area is summarized with some notes on recent developments.

Basic concepts and principles of electrical properties

Electrical conductivity

Conductivity plays a fundamental role in ohmic heating, in which electricity is transformed to thermal energy when an alternating current (a.c.) flows through food. As it has potential use in fluid pasteurization, it is important to know the effective conductivity or the overall resistance of liquid-particle mixtures. The conductivity measurement is applied for determination of various characteristics of agricultural materials and food such as the frost sensitiveness, chilling and freezing tolerance, moisture content, seeds germination, mechanical stress, pasteurization, other properties of grains, seeds, meat, sugar, milk, wood, soil, fruit and vegetable, infected food (moisture content, maturity of fruit, freshness of eggs, potential insect control in seeds, radio frequency heating). It is a measure of electric current flows through a food of unit cross-sectional area A, unit length L, and resistance R. It is the inverse value of electrical resistivity (measure of resistance to electric flow) and is expressed in the following relation:

|

1 |

The conductivity of a material is generally measured by passing a known current at constant voltage through a known volume of the material and by determining resistance. The internal structure of agricultural products change substantially during their deformation (Dejmek and Miywaki 2002). The electrical conductivity of foods has been found to increase linearly with temperature, and water/ionic content. Maezawa and Akimoto (1996) utilized electrical conductivity to determine the characteristics of low-temperature sensitive vegetables.

Dielectric properties

Dielectric properties of food materials are those electrical properties which measure the interaction of food with electromagnetic fields (Ahmed et al. 2007). Relative permittivity, dielectric loss factor, loss tangent and the alternate current conductivity are of concern in heating, drying and storage of grains. However, the first dielectric properties for grain were not reported until 45 years ago (Nelson 1965). Electrical permittivity is a dielectric property that determines the interaction of electromagnetic waves with matter and defines charge density under an applied electric field (Barbosa-Canovas et al. 2006). In solids, liquid, and gases the permittivity depends on dielectric constant ε′, which is related to capacitance of a substance and its ability to store electrical energy; and the dielectric loss factor ε″, related to energy losses when the food is subjected to an alternating electrical field i.e., dielectric relaxation and ionic conduction (Barbosa-Canovas et al. 2006).

Permittivity and loss factor

In foods, permittivity can be related to chemical composition, physical structure, frequency, and temperature, with moisture content being the dominant factor (Ryynanen 1995). The absolute permittivity of a vacuum is ε0 and it is determined by the speed of light (c) and the magnetic constant (μ0)) which are linked together by the equation:

|

2 |

The numerical value for ε0, is about 8.854 × 10−12 F/m and for μ0 is 1.26 μHm−1. In other media (solid, liquid and gaseous), the permittivity has higher values and it is usually expressed relative to the value in vacuum (Nyfors and Vainikainen 1989): εabs = εrε0

Or, the relative permittivity, εr of a material equal to εabs/ε0

Where, εabs = absolute permittivity of a material, εr = relative permittivity of a material.

The high frequency and microwave fields are sinusoidal time dependent (time-harmonic) and common practice is to use complex notation to express the time dependence (Nyfors and Vainikainen 1989). Therefore, the permittivity will also be a complex quantity with real and imaginary components. The fundamental electrical property through which the interactions are desired is the complex relative permittivity of the material. The equation for complex permittivity is (Risman 1991):

|

3 |

Where, ε = relative complex permittivity, ε′ = relative real permittivity (dielectric constant), ε″ = dielectric loss factor, j = imaginary unit.

The real component of the permittivity (dielectric constant) is related to the capacitance of a substance and its ability to store electrical energy. The imaginary component, the dielectric loss factor is related to various absorption mechanisms of energy dissipation and is always positive and usually much smaller than dielectric constant. The substance is lossless if dielectric loss factor =0 (Mudgett 1986; Nyfors and Vainikainen 1989). The ratio of dielectric loss factor to dielectric constant (ε″/ε′) is called the loss tangent (tanσ) or dissipation factor, a descriptive dielectric parameter, which is also used as an index of the material’s ability to generate heat (Mudgett 1986).

Power density and penetration depth

The rate of heating can be expressed by the power equation:

|

4 |

where Pv = energy developed per unit volume (W/m3), f = frequency (Hz), and |E| = electric field strength inside the load (V/m).

The electric field inside the load is determined by the dielectric properties and the geometry of the load, and by the oven configuration. Therefore, this equation is generally impractical as the determination of the electric field distribution is very complex (Buffler 1993). To gain a better practical understanding of the meaning of the values of the dielectric properties, penetration depth can be calculated from the dielectric properties.

Wave impedance and power reflection

Transmission properties, which are related to the dielectric and thermal properties of the medium, determine the distribution of energy (Mudgett 1986). Since dielectric constant (absolute permittivity), decreases the speed of propagation, the wavelength in the dielectric medium is shorter than that in free space. This change in wavelength leads to a reflection at the interface between two media with different dielectric constants (Nyfors and Vainikainen 1989). The reflection phenomena can be analysed in terms of characteristic wave impedances and ε (Ohlsson 1989):

|

5 |

where η0 is the wave impedance of free space (~377 Ώ).

The reflection and transmission at a plane boundary are primarily related to (√ε), and the principal determining factor for the magnitude of the reflection is from the real permittivity of the material. Characteristic impedance is important when different materials are heated simultaneously. The change in characteristic impedances at the food surface results in reflection of about 50% of the microwave power falling on the surface. Most of this energy is reflected back to the food via the metal cavity walls. For frozen food, the impedance matching is better, often resulting in higher power utilization for thawing than for heating (Ohlsson 1989).

Polarization of dielectrics

When two charges are separated by a distance, they constitute an electric dipole. The dipole can be represented by a vector called the dipole moment. Molecules with nonzero permanent electric dipole moments are called polar molecules. Non polar molecules may acquire a dipole moment in an electric field as a result of the distortion of their electronic distributions and nuclear positions. The polarization is the average dipole moment per unit volume. The relation between the permittivity and the polarization is (Nyfors and Vainikainen 1989):

|

6 |

where P = polarization, ε−1 = electric susceptibility, ε0 = absolute permittivity of a vacuum, E = electric field.

The relative permittivity ε (or electric susceptibility, ε−1) is thus a measure of the polarizing effect from an external field that is, how easily the medium is polarized. There are four types of polarization: ionic, orientation, atomic and electronic polarization. Electronic polarization occurs in atoms, where electrons can be displaced with respect to the nucleus. This polarization occurs in all substances. In atomic polarization, the atoms can be moved in crystals or molecules. Electronic polarization, together with atomic polarization, gives most dry solids a permittivity of the order of ε < 10. When only these two mechanisms are present, the material is almost lossless at microwave frequencies. Atomic or vibration polarization is closely related to electronic polarization but, because of the much greater mass to be moved, the resonant frequencies of atomic polarization are lower. Atomic polarization is found in the infrared band while electronic polarization is found in the optical band (Nyfors and Vainikainen 1989). In microwave or high frequency field, the dipoles try to follow the rapidly changing field. The energy is then lost to the random thermal motion of the water, which is equivalent to a temperature rise. This is orientation polarization. Hydrated ions try to move in the direction of the electrical field and they transfer energy by this movement (Nyfors and Vainikainen 1989; Ohlsson 1989). Polarization can be due to various effects ranging from charge accumulation at the surfaces between materials with different electrical properties (interfacial polarization) to dipole orientation and other effects (Markx and Davey 1999).

Factors affecting the dielectric properties

Various factors influence the dielectric properties of food materials such as frequency of the applied alternating electric field, moisture content, bulk density, temperature (Icier and Baysal 2004b; Nelson 1965; Ryynanen 1995; Venkatesh and Raghavan 2004) ionic nature, concentration (density), structure and constituents of food materials (Engelder and Buffler 1991; Feng et al. 2002; Guan et al. 2004; Nelson 1991, 1992; Nelson et al. 1994; Nelson and Bartley 2002; Ohlsson et al. 1974a; Venkatesh and Raghavan 2004; Sipahioglu et al. 2003). Dielectric properties as related to temperature and frequencies have been reported for different agricultural commodities, including grains and seeds (Nelson 1965), fruits and vegetables (Feng et al. 2002; Guan et al. 2004; Ikediala et al. 2000; Nelson 1983; Nelson et al. 1994; Wang et al.2003), juice and wine (Garcia et al. 2004), baked foods and flours (Kim et al. 1998; Zuercher et al. 1990), dairy products (Green 1997; Herve et al. 1998), fish and meat (Bengtsson and Risman 1971; Lyng et al. 2005), egg white solutions and thermal denatured egg albumen gels (Lu et al. 1998). Studies were also reported that assessed possibility of non-destructively predicting some physical characteristics of agri-food products such as fruits and eggs (Nelson et al. 1995; Dev et al. 2008). The dielectric constant and conductivity of carrots depends largely on moisture content as influenced by frequency, temperature, density, and particle size. Although moisture content is important, carbohydrate, ash and protein content can also affect dielectric properties (To et al. 1974; Zhang et al. 2007). The principal state variables that influence the dielectric properties at a given frequency are temperature and moisture content. Effects of the parameters such as moisture content, temperature, bulk density and frequency on the dielectric properties of agri-food materials summarized in tabular form (Table 1). The relationship between these factors, composition and the dielectric properties of food and food products are reviewed in the following sections:

Table 1.

Effects of the parameters such as moisture content, temperature, bulk density and frequency on the dielectric properties of food and food products

| Food/product source | Range of parameters | Comments | References |

|---|---|---|---|

| Food materials, Salty foods | 2800 MHz freq. | At constant temperatures, dielectric constant (ε′) and loss factor (ε″) of food materials increase with decreasing frequency. The penetration depth (PD) decreased with increasing frequency, temperature and moisture content. At higher microwave frequencies only salty foods show an increase in ε″ with temperature but at lower microwave frequencies there is a general increase in ε″. Both ε′ & ε″ of various foods increased with increasing moisture content. | Bengtsson and Risman (1971), Ohlsson et al. (1974a), Kent (1987) |

| Moist foods | 3 GHz freq. | Loss factor ( ε″) increases with falling frequency. | Bengtsson and Risman (1971), Ohlsson et al. (1974a, b), Nyfors and Vainikainen (1989), Ryynanen (1995) |

| Fruits and vegetables | Freq (1–1800 MHz), temp.(20–60 °C) | Generally, ε′ increases with temperature, whereas ε″ increased with increasing temperature and ε′ increased with temperature at lower frequencies, but decreased with temperature at the higher frequencies. | Calay et al. (1995), Nelson (2003), Sosa-Moralesa et al. (2009) |

| Mango | Freq. (1–1800 MHz), temp.(20–60 °C) | Dielectric properties values decreased with increasing frequency, but this reduction was larger for ε″ than for the dielectric constant. Loss factor increased but ε′ decreased with increasing temperature. Both values decreased with storage time. | Sosa-Moralesa et al. (2009) |

| Grape juice & wine | Freq. 200 MHz and 3 GHz | Both ε′& ε″of grape juice are greater than wine at 200 MHz . At 3 GHz, ε′ of grape juice is slightly less than of wine, whereas ε″, at 3 GHz is practically the same for grape juice and wine. | Garcia et al.( 2004) |

| Apples | 915 MHz or 2.45 GHz; moisture content range of 4% to 87.5% at 22 and 60 °C. | An increase in temperature at low moisture contents resulted in increased dielectric properties. The penetration depth increased as moisture was removed from the sample. | Feng et al. (2002) |

| Garlic | Freq 2450 MHz,m.c.(6%–185%,db), temp.( 35–75 °C) | Both ε′ & ε″ directly proportional to the moisture content. Both ε′ & ε″ decreased with increase in temperature at high moisture levels and a reverse trend in lower moisture range. The relationship of ε′ as well as ε″ was found to be linear with temperature. PD of microwaves increased with decrease in moisture content and the temperature had the insignificant effect on it. | Sharma and Prasad (2002) |

| Legume flours (chickpea, green pea, lentil and soybean flour) | Freq. (10–1800 MHz), temp. (20–90 °C) and m.c.(8–21 g/100 g)/water activities (0.3–0.9) | Both ε′ & ε″ of the four legume flours decreased with increasing frequency but increased with increasing temperature and moisture content. At low frequencies and high temperature and moisture content, negative linear correlations for both ε′ & ε″. | Guo et al. (2008, 2010a, b) |

| Common bean, nuts | Freq (75 kHz–5 MHz),moisture content range from 13.4% to15.5%w.b. | The value of relative permittivity at each moisture content decreased regularly with increasing frequency. The frequency dependence of ε″ and loss tangent was less regular than that of permittivity. Relative permittivity increased with moisture content at every frequency. Both ε′ & ε″ of nuts increased regularly with moisture content at all frequencies and decreased as the frequency increased. | Berbert et al. (2002); Lawrence et al. (1992, 1998) |

| Flaxseed | Freq (50 kHz–10 MHz), m.c. (5.92%–22.18%, db) | Both ε′& ε″ increased with an increase in moisture content and bulk density and with a decrease in frequency. | Sacilik et al. (2006) |

| Safflower | Freq. (50 kHz–10 MHz); m.c.(5.33%–16.48%,d b) | The ε′ increased with an increase in the moisture content and bulk density, whereas it decreased with an increase in the frequency. | Sacilik et al. (2007) |

| Fresh eggs | Freq. (10–1800 MHz) at 24 °C temperature | The ε′ increases with temperature, whereas ε″ increased with increasing temperature and ε′ increased with temperature at lower frequencies, but decreased with temperature at the higher frequencies. | Guo et al. (2007b) |

| Ground beef | Freq. 915 MHz | Loss factor independent of moisture content <20% & >45% but linear increase with moisture content between 20% and 45%. | Van Dyke et al. (1969) |

| Beef and beef products | 2800 MHz freq. | Both ε′& ε″ increases with decreasing frequency at constant temperature; however, ε′ decreases and ε″ increases with increasing temperature at constant frequency. | Bengtsson and Risman (1971), To et al. (1974) |

| Beef burgers | 2430 MHz freq. | Adding 15% water had no effect on ε′ or ε″ as most of 15% water lost during deep frying. | Lyng et al. (2002) |

| Aqueous & beef | 27.12, 2450 MHz freq. | 25% water slightly increased both ε′& ε″ in beef blends at both frequencies. | Lyng et al. (2005) |

| Tuna fish, Catfish and shrimp, Fish meal | 2450 and 915 MHz freq | A sharp increase in dielectric properties was observed around the freezing point. Both ε′& ε″ increased with increased water content at constant temperature; ε′ & ε″ of lean tuna were larger than those of fatty tuna. PD as the temperatures below the freezing point increased rapidly as the temperature decreased. ε′ of marinated catfish and shrimp, generally decreased with increasing temperature whereas ε″ increased with temperature. Both ε′& ε″of fish meal increased non-linearly with moisture content and also increased with temperature in a relatively linear manner. | Liu and Sakai (1999), Zheng et al. (1998), Kent (1970, 1972) |

| Salmon fillets | Freq. (27–1800 MHz), temp.(20–120 °C) | At RF frequencies of 27 and 40 MHz, ε′ decreased with increasing temperature. But at microwave frequencies (e.g.,915,1800 MHz), an opposite trend was observed. ε″ increased with increasing temperature over the tested frequency range. | Wang et al.(2008) |

| Macaroni and cheese | Freq.(915–1800 MHz); 20–121 °C temperature | ε′ increased as temperature increased and ε″ increased sharply with increase in temperature. | Wang et al. (2003) |

| Cheeses | Freq. (0.3–3 GHz); temp (55–75 °C) | Both ε′& ε″ decreases with increasing frequency. Dielectric constants generally decreased with increasing temperature, within this frequency range. | Everard et al. (2006) |

| Sugar/ starch H2O | 1000, 3000 MHz freq. | ε′ increased with moisture content while ε″ changed with the addition of sugars and starch. | Roebuck et al. (1972) |

| Pure honeys and water-added honey | Freq. (10–4500 MHz) at 25 °C temp., m.c. (18%–42.6%) | ε′decreased monotonically with increasing frequency, and increased with increasing water content. Dielectric relaxation was evident in ε″. The critical frequency and the maximum ε″ increased with increasing water content. | Guo et al. (2010a, b) |

| Edible oils and fatty acids | Freq. (100 Hz–1 MHz), temp. (20–45 °C), m.c.(0.02%–0.31%) | Both ε′& ε″ of oils decreased with increasing temperature and ε′ increased with increasing moisture content. | Lizhi et al. (2008), Rudan-Tasic and Klofutar (1999) |

| Starch | ε″decreases rapidly with increasing temperature, ε′ increases slightly with decreasing frequency | Miller et al. (1991) | |

| Powder potato starch, locust bean gum | freq 2.45 GHz; 0–20% m.c, wb | The dielectric properties increase regularly with moisture content | Nelson (1991) |

| Salt solutions | 3000, 10,000 | ε′ of the salt solutions decreased as temperature increased. For salt contents greater than 2%, the predicted ε″ increased with temperature, which is in accord with the behaviour of aqueous salt solutions. | Hasted et al. (1948), Sun et al. (1995) |

| Soy protein isolate | 200–2500 MHz concentration (5, 10 and 15 g/100 g water), temperature (20–90 °C) | ε′ decreased with temperature (except at 90 °C) and frequency while increased with concentration. ε″ increased with frequency and concentration; however, temperature showed mixed effect. PD decreased with an increase in frequency, concentration, temperature and pH. | Ahmed et al. (2008) |

| Potato flour-water dispersions (slurry) | 500–2500 MHz; concentration (10%–25% w/w); temperature (20–75 °C) | ε′decreased with temperature and frequency while increased with concentration. ε″ increased with frequency and concentration; however, temperature showed mixed effect. PD decreased with an increase in frequency and non-systematic with temperature. Addition of salt substantially reduced Penetration depth of potato slurry. | Ahmed et al. (2009) |

The influence of salt, fat and other constituents

At higher moisture and lower fat contents, the loss factor increased somewhat with temperature (Datta and Nelson 2000). Increase in fat/lipid content was found to decrease the dielectric properties of different food and food products (Table 2). The influence of water and salt or ash content depends to a large extent on the manner in which they are bound or restricted in their movement by the other food components (Sun et al. 1995). The most common food products have a loss factor of less than 25, which implies a penetration depth of 0.6–1.0 cm. However, literature data are mostly limited to pure foods and food components. For complex and formulated foods, the dielectric properties must be measured or estimated (Ohlsson 1989; Buffler and Stanford 1991). An increase in flour slurry concentration of Indian Basmati rice, systematically reduced dielectric constants during the entire frequency range while variations in dielectric loss factor values were mixed (Ahmed et al. 2007). He observed that addition of 1% salt markedly increased loss factor of slurries. Salt addition decreased dielectric constant (ε′) and increased loss factor (ε″) in different food and food products (Table 3). Microwave permittivities of bread dough measured as a function of water-flour composition, proofing time, and baking time (Zuercher et al. 1990). Ohlsson et al. (1974a) found that for many foods, the influence of different water and salt content on dielectric properties was significantly large, especially at 450 and 900 MHz. it was also found that at temperatures above 60°C, dielectric constant decreased gently with temperature, whereas loss factor increased, particularly at lower frequencies for salty foods (Bengtsson and Risman 1971). The dielectric constant and decreasing trend of loss factor was observed in the lower moisture range in grapes (Tulasidas et al. 1995). At higher microwave frequencies 2,800 MHz only salty foods show an increase in dielectric loss, with temperature but at lower microwave frequencies there is a general increase in loss factor (Bengtsson and Risman 1971; Ohlsson et al. 1974b). The dielectric loss factors were found to increase with ash content and to decrease with fat content of oil (Rudan-Tasic and Klofutar 1999). Microwave permittivities of bread dough were measured over the frequency range from 600 to 2.4 MHz as a function of water-flour composition. The dielectric constant and loss factor both decreased as the water content and baking time reduced (Zuercher et al 1990). The penetration depth of bread dough was, however, surprisingly low (8–10 mm) in comparison with normal foods (10–15 mm) and in consideration of the low density. As the volume expands during proofing, the penetration depth increases up to 16–19 mm (Mellgren et al. 1988). Both dielectric constant and loss factor are low for flours at microwave frequencies as long as the water content is low (Kent 1987). The dielectric constant and the loss factor of baked dough, was a function of temperature and moisture at 27 MHz (Kim et al. 1998)

Table 2.

Effect of fat/lipid content on dielectric properties of food and food products

| Food/product source | Freq. (MHz) | Comments | References |

|---|---|---|---|

| Model meat emulsions | 900 | ε″ decreased with increasing fat was faster between 15%–35% vs. 0%–15% fat | Ohlsson et al. (1974b) |

| Potato | 300–3000 | Lipid content of food depresses dielectric activity by volume exclusion | Mudgett (1985) |

| Lard, corn oil | 0.01–100 | Both ε′& ε″ of fats are low and vary slightly with source | Ryynanen (1995) |

| Beef burgers | 2430 | 10% fat decreased both ε′ and ε″. | Lyng et al. (2002) |

| Pork fat & beef | 27.12, 2450 | 20% fat decreased both ε′& ε″ at both frequencies | Lyng et al. (2005) |

| Vegetable oils | – | ε″ found to increase with ash content and to decrease with fat content of oil | Rudan-Tasic and Klofutar (1999) |

Table 3.

Effect of salt or ash on dielectric properties of food and food products

| Food/product source | Range of parameters | Comments | References |

|---|---|---|---|

| NaCl solutions | 3000, 10,000 MHz | Salt addition can decrease dielectric constant (ε′) | Hasted et al. (1948) |

| Beef, pork | 915 MHz | 4% salt more than doubled loss factor ( ε″) while 1% salt increased ε″ by 20% | Van Dyke et al. (1969) |

| Gravy | 2800 MHz | Adding 1% salt to gravy increased ε″ by about 20%and also slightly increased ε′ | Bengtsson and Risman (1971) |

| Ham | 2450 MHz | Salt content (0.5%–3.5%) increased ε″ while ε′ remained relatively constant | Li and Barringer (1997) |

| 0.27% Guar solution | 30,100 MHz | Salt concentration (0.2%–0.7%) was not significant vs. ε″ while ε′ may be lowered | Piyasena and Dussault (1999) |

| Beef burgers | 2430 MHz | 3% salt depressed ε′ and ε″ | Lyng et al. (2002) |

| Aqueous & beef | 27.12, 2450 MHz | Salt depressed ε″ and increased ε″ most noticeably at 5% and 27.12 MHz in aqueous solution | Lyng et al. (2005) |

| Flour slurry concentration of Indian Basmati rice | 500–2500 MHz (temp. 30 and 80 °C) | Addition of 1% salt markedly increased ε″ of slurries. | Ahmed et al. (2007) |

The influence of moisture content, temperature and frequency

Temperature dependence of dielectric properties was not observed for dried granular solids but increased dramatically at higher moisture contents over 9.4 GHz (Stuchly and Stuchly 1980). Both the dielectric constant and loss factor of various foods increased with increasing moisture content (Bengtsson and Risman 1971). In general dielectric constant of fruits and vegetables increases with temperature, whereas loss factor may either increase or decrease depending on the operating frequency (Calay et al. 1995). generally increased with increasing temperature (Nelson 2003; Sosa-Moralesa et al. 2009) and dielectric constant increased with temperature at lower frequencies, but decreased with temperature at the higher frequencies and, temperature dependence of dielectric constant was minimal in the frequency range between 0.01 and 1.8 GHz (Nelson 2003). The dielectric constant and loss factor of flaxseed increased with an increase in moisture content and bulk density and with a decrease in frequency (Sacilik et al. 2006). The rate of change of dielectric constant and loss factor with temperature depends on the free and bound water content of the food materials (Calay et al. 1995). The dielectric constant of fatty acids increased with an increase in the number of double bonds or molecular chain length. Both dielectric constant and dielectric loss of oils decreased with increasing temperature and dielectric constant increased with increasing moisture content (Lizhi et al. 2008). The loss factor increases with temperature and with transition from solid to liquid phase (Stier 2004). The dielectric constant of oils decreased with increasing temperature (Rudan-Tasic and Klofutar 1999). Both the dielectric constant and loss factor of nuts increased regularly with moisture content at all frequencies and decreased as the frequency increased. At low moisture contents, the temperature dependence was minimal, but both the dielectric constant and loss factor increased rapidly with temperature at high moisture levels (Lawrence et al. 1992, 1998). For salty foods at lower microwave frequencies, dielectric constant shows a sharper decrease with increasing temperature. For moist foods, loss factor increases with falling frequency (Bengtsson and Risman 1971; Ohlsson et al. 1974a; Nyfors and Vainikainen 1989). At constant temperatures, dielectric constant and loss factor increase with decreasing frequency (Kent 1987). The penetration depth decreased with increasing frequency, temperature and moisture content, which was large enough at 27 MHz to develop large-scale industrial radio frequency (RF) treatments. Dielectric constants of many cereal grains and soybeans as functions of frequency, moisture content, and bulk density have been reported (ASAE 2000; Nelson 1987; Kraszewski and Nelson 1989). For moist foods, loss factor decreases with increasing frequency Ryynanen (1995). Ohlsson et al. (1974a) observed that dielectric constant and loss factor increased significantly with falling frequency for most foods tested and in most cases, dielectric properties increased sharply with temperature during the transition from −10 to 0°C (thawing). At temperatures below the freezing point, dielectric constants of codfish increased slightly from values below 10 to values between 10 and 20 before the abrupt increase, on thawing, to values between 60 to 90, depending on the frequency (Bengtsson and Risman 1971). Dielectric properties of fish meal as a function of the temperature and moisture content (Kent 1970, 1972). Both the dielectric constant and loss factor increased non-linearly with moisture content and also increased with temperature in a relatively linear manner (Kent 1970, 1972). The dielectric constant of marinated catfish and shrimp, generally decreased with increasing temperature whereas the loss factor increased with temperature (Zheng et al. 1998). The dielectric constant and loss factor of tuna fish varied with the composition of a substance and the temperature (Liu and Sakai 1999). A sharp increase in dielectric properties was observed around the freezing point. The dielectric constant and loss factor increased with increased water content at constant temperature; the dielectric constant and loss factor of lean tuna were larger than those of fatty tuna. Penetration depths as the temperatures below the freezing point increased rapidly as the temperature decreased (Liu and Sakai 1999). For beef products, both dielectric constant and loss factor increase with decreasing frequency at constant temperature; however, dielectric constant decreases and loss factor increases with increasing temperature at constant frequency (To et al. 1974).

Physical structure of material

Dielectric properties vary with a number of physical attributes including bulk density, particle size and homogeneity. Bulk density has been identified as a major source of variation for dielectric constant and loss factor (Kent 1977; Kent and Kress-Rogerss 1986; Nelson 1983, 1984; Nelson and You 1989). The density dependence of the dielectric properties of materials must be accounted for in elaborating functions determining grain moisture content and this relation could also be used in the control of continuous on-line processing of the grain (Meyer and Schilz 1980). Measurements of various sieve fractions of powder of crushed grains obtained by Venkatesh et al. 1998. One of the problems in concluding particle size effects is to ensure that the moisture content and compositions of the various particle size fractions are the same and that there are no changes due to heating during grinding. If there is a pure particle size effect, it appears to be very small compared to the influence of bulk density and other factors.

Applications of dielectric properties

Knowledge of the relationship between frequency and dielectric properties is helpful in determining the optimum frequency range in which the material has the desired dielectric characteristics for intended applications and useful in studying and developing heating processes or grading techniques based on electromagnetic energy (Nelson and Payne 1982; Nelson 2005; Wang et al. 2001, 2006a) and also helps in the selection of proper packaging materials and cooking utensils and in the design of microwave and radio frequency heating equipment (Ohlsson 1989). The moisture-dependent dielectric properties in specific frequency ranges can be used to develop online moisture meters (Nelson 1992), which may be applied not only in drying processes but also in other unit operations in the food industry (Berbert et al. 2002; Nelson 1984). Dielectric properties can be used to understand food materials behaviour in radio frequency bands and during microwave processing, heating and cooling (Ryynanen 1995). These properties influence the level of interaction between food and high frequency electromagnetic energy. Therefore, these are important in the design of radio frequency and microwave processing equipment and in the design of foods and meals intended for microwave preparation (Mudgett 1985). These properties are very important in evaluating the penetration depth of energy that can be achieved in a certain food and characterizing physical properties of biomaterials. The possible selective dielectric heating for control of insects that infest stored grain (Nelson and Whitney 1960; Nelson 1996). Nelson (1965) suggested that dielectric properties data are also important in the investigation of seed treatment to improve germination. Engelder and Buffler (1991) reported that dielectric measurements can also be used to measure density and water activity. Few examples of such applications in the literature are described below.

Water quality detection

Microwave technology was adopted to study and assess water quality aspects (Raveendranath and Mathew 1995). They suggested that the dielectric behaviour of artificially polluted water and polluted water collected from various industrial locations could be related for detecting the pollutants in water at 2.685 GHz microwave frequencies based on the measurement of complex permittivity of polluted water at 27°C. This technique could also be used to evaluate oil—water mixtures of food applications.

Dielectric behaviour of food and food products

The permittivities or dielectric properties of food materials are important in understanding the behaviour of agri-food materials when exposed to electromagnetic fields during microwave cooking or in other processes involving radio-frequency or microwave dielectric heating (Hlavacova 2003). These properties and the quality of a substance can be correlated for example, either high frequency or lower frequencies can be used to measure the quality of fish and meat (Kent and Kress-Rogerss 1986). Since than much data and information on the dielectric properties of grain and other agricultural products have become available and the influence of important variables on these dielectric properties has been evaluated (Nelson 1991; Mudgett 1985).

Food grains

Use of dielectric properties of grain for moisture measurement has been the most prominent agricultural application (Nelson 2006). The dielectric properties of cereal grains and oilseeds are essential for understanding their electric behaviour, and the development of indirect non-destructive methods for determining their physical properties (Trabelsi and Nelson 2003). The first quantitative data on the dielectric properties of grain were reported for barley along with a method for reliable measurement of those properties in the 1 to 50 MHz frequency range (Nelson et al. 1953). The dielectric properties of food grains are known to be dependent on moisture content, bulk density, temperature and frequency used. Dielectric spectroscopy measurements were carried out on ground hard red winter wheat at frequencies from 10 to 1,800 MHz over the temperature range from 25 to 95°C (Nelson et al. 2006). In agriculture, the dielectric properties of grains have been widely used to determine the moisture content of grain because of their usefulness for rapid moisture content sensing (Kim et al. 2003).

The dielectric properties of grains are also of importance in the design of equipment for radiofrequency or microwave dielectric heating applications and potential agricultural applications such as grain drying, seed treatment to improve germination and insect control in stored grain using high-frequency and microwave electric fields (Nelson 1992, 1996). In general, dielectric constant and loss factor are greater for grain and seed samples of higher bulk densities and higher equilibrium moisture content. There are also models for the dielectric constant of cereal grains and soy beans (Chugh et al. 1973; Nelson 1973, 1987). Dielectric properties of chickpea, green pea, lentil and soybean flour samples at different frequencies (10–1,800 MHz), temperatures (20–90°C) and moisture contents (about 8–21 g/100 g)/water activities (0.3–0.9) were measured by an open-ended coaxial-line probe and impedance analyzer (Guo et al. 2008). The dielectric properties of flax seed were measured in the ranges of 5.92%–22.18% on dry basis (d.b.) for moisture content, 586.7%–722.9 kilograms/m3 for bulk density and 50 kHz–10 MHz for frequency of applied electric field using a parallel-plate capacitor sample holder (Sacilik et al. 2006). Dielectric constant of Indian Basmati rice samples (dry ground flour and wet aqueous slurry) generally did not vary with frequency while the loss factor showed an increasing trend over the frequency range 500–2500 MHz (Ahmed et al. 2007).

Microwave and radio-frequency heating have also been used for baking processes (Kent 1987; Mellgren et al. 1988; Zuercher et al. 1990). The dielectric properties for bread and flour have been measured mostly at high frequencies. The dielectric constant and loss factor of baked dough at 27 MHz was found to be significantly useful for the baking industry operating at both radio frequency and microwave spectrums (Kim et al. 1998).

Literature on dielectric properties of nuts is quite limited. Dielectric constants and loss factors for peanuts have been reported for the 1–50 MHz frequency range (Nelson 1973) showing the expected variation with frequency and moisture content. More detailed information is available for chopped pecans (Nelson 1991) and these data are reported for the frequency range from 50 kHz to 12 GHz over the moisture range from 3% to 9%, wet basis at 22°C. The temperature dependence at 0–40°C of the dielectric constant and loss factor were determined for the frequency range from 100 kHz to 110 MHz over a similar range of moisture contents (Lawrence et al. 1992, 1998).

The ever increasing consumption of oil and fat based foods calls for methods to monitor the quality of frying oils and fats effectively. Simple and rapid methods for the detection of thermal abuse of oil are need of the hour. Many research works were carried out on dielectric properties of frying fats and oils (EI-Shaml et al. 1992; Paul and Mittal 1996; Inoue et al. 2002; Cataldo et al. 2010). They reported that the dielectric constant is the most significant indicator for monitoring frying oil quality (quality control) in commercial deep fat frying operations. Extensive studies are needed for application of dielectric properties in oil processing, storage, food making besides the major application of evaluation of quality deterioration of frying oils (Venkatesh and Raghavan 2004). Dielectric properties of ten edible oils and six fatty acids were measured over the frequency range 100 Hz–1 MHz (Lizhi et al. 2008). This study could be useful in oil identification, quality evaluation, and quality monitoring during oil processing and storage. Dielectric spectroscopy discriminated the olive oil adulterated with different types of oils at levels of adulteration below 5% (Lizhi et al. 2010). A patented instrument called Food Oil Sensor (FOS) to measure a change in the dielectric constant of deep-frying oils was reported to be a useful tool in determining heat abuse for frying fats and oils in comparison with conventional analytical techniques and investigate the characteristics of the oil/fats and assess their quality and for monitoring purposes (Fritsch et al. 1979; Hein et al. 1998). Other similar dielectric measurement instruments have been also developed for evaluating the quality of deep-frying fats and oils (Stier 2004). For fats and oils, both dielectric constant and loss factor are very low. A low cost condition-monitoring sensor was designed for direct measurement of the overall quality of the used oil (contaminants and oxidation) as compared to that of the unused oil (Carey and Hayzen 2008). Pace et al. (1968) reported that the differences in dielectric properties among tested fats and oils appear to be attributable to the phase of the material and generally correspond to the degree of unsaturation as evidenced by iodine values. Rudan-Tasic and Klofutar (1999) investigated the dielectric properties and physical and chemical constants of 11 edible oils. They reported that the values of dielectric constant lie in the range of about 3.0–3.2 at 298.15 K for most oils.

Fruits and vegetables

In order to understand interaction between the fruit and vegetables and electromagnetic energy, dielectric properties of fresh fruits and vegetables have been explored by several researchers (Garcia et al. 2001; Kato 1997; Nelson et al. 1994; Nelson 2003; Sosa-Moralesa et al. 2009; Tran et al. 1984). Microwave permittivities, or dielectric properties of fresh fruits and vegetables have been considered for potential use in non-destructive sensing of quality factors, such as maturity in peaches and chilling injury in sweet potatoes (Nelson 1980). Because of the need for rapid non-destructive quality measurements for fresh fruits and vegetables, the dielectric properties of a few products were measured at microwave frequencies (Nelson 1980, 1983, 1992). Possible permittivity-based maturity indices were identified for tree-ripened peaches (Nelson et al. 1995), but much further research and development would be needed to assess the practicality of such techniques. Vegetables have quite high absolute permittivity in accordance with their high water content: for cooked peas and mashed potato from about 54 to 65 and for cooked carrots from 61 to 76, at temperatures from 3 to 6°C and frequency 2.8 GHz (Bengtsson and Risman 1971). For dried vegetables, dielectric constant is low as the water content is low. The measurements did not show any promise for detecting peach maturity or hardcore condition in sweet potatoes by measurements at single frequencies (Nelson 1980). Therefore, broadband permittivity measurements were initiated to study the dielectric properties of several fruits and vegetables over the frequency range from 200 MHz to 20 GHz (Nelson et al. 1994). Dielectric properties of potato, carrot, apple, and peach tissue were measured at frequencies form 1 to 40 MHz (Shaw and Galvin 1949).

Dielectric properties of mangoes were measured using an open-ended coaxial-line probe with an impedance analyzer at frequency of (1–1,800 MHz), temperature of (20–60°C) and ripening at 21°C for 16 days storage (Sosa-Moralesa et al. 2009). Dielectric properties values decreased with increasing frequency, but this reduction was larger for the loss factor than that for the dielectric constant. This measurement can be useful in selecting the optimal ripening stage of mangoes in storage at which dielectric heating is suited for postharvest pest control. Penetration depth decreased with increasing frequency and temperature. Radio frequency energy penetrates deeper in mangoes compared to microwaves and, thus, is more suited for potential postharvest disinfestation treatment of this fruit (Sosa-Moralesa et al. 2009). Measured dielectric properties and sweetness of freshly harvested melons by soluble solids content with an open ended coaxial-line probe and an impedance analyser over the frequency range from 10 MHz to 1.8 GHz at 25°C and reported that correlations were low for both the dielectric constant and the loss factor at most frequencies (Nelson et al. 2006, 2007). A new electrical method is proposed for density sorting of spherical fruits, which measures the volume by electric capacity and mass by electronic balance. A new automatic density sorting system was developed for measuring the degree of hollowness, which enables low density watermelons with cavities or deteriorated porous flesh to be removed and permits the soluble solids content of watermelons to be estimated (Kato 1997). The dielectric properties of apples at frequencies of 300 to 900 MHz were found to vary with maturity and showed appreciable drop in dielectric property in the process of aging (Thompson and Zachariah 1971). Dielectric properties of apples were measured at 24°C over 10 weeks in storage at 4°C might be useful in sensing quality of stored apples and concluded that dielectric properties of the apples remained relatively constant during the 10-week refrigerated storage period (Guo et al. 2007a). Dielectric properties of four apple cultivars measured between 30 and 3,000 MHz at 5 to 55°C, using the open-ended coaxial-line probe technique and reported that dielectric constant decreased with frequency and decreased slightly with increasing temperature (Ikediala et al. 2001). Minimum dielectric loss factor of apples was observed at about 915 MHz. Dielectric constant and loss factor were not influenced by cultivar, pulp section or degree of ripeness of apples. Dielectric constant and loss factor of the insect were much higher than that of the apples at frequencies lower than 2,450 MHz, suggested that differential heating may be untenable at 2,450 MHz or higher frequency for codling moth larvae in the apple host (Ikediala et al. 2001). Dielectric properties of a commercial apple juice product were also measured over the 200 MHz to 20 GHz frequency range (Nelson and Bartley 2002). The temperature dependence of the dielectric properties of the apple juice at the higher frequencies is also very similar to that of pure liquid water, with the relaxation frequency for pure water shifting from below 20 GHz to higher frequencies as temperature increases (Hasted 1973). The electrical resistance, gloss and weight of eggplant during storage were determined using a galvanometer, a spectroradiometer and a precision electronic balance, respectively (Jha et al. 2004). The surface electrical resistance increased quadratic ally with storage period, while following the reverse trend with the weight and gloss index, and the values varied vbetween 14·5 and 1,612·6 kΩ during the storage for 0–96 h at 20 ± 2°C and 80%–84% relative humidity. Dielectric properties of raw potato at frequencies from 300 to 3,000 MHz dropped appreciably with increasing frequency (Pace et al. 1968). The dielectric properties of raw potato, potato starch, and milk were measured at microwave frequencies from 1.2 to 18 GHz (de Loor and Meijboom 1966).

Livestock and fishery produce

The dielectric technique can be used as an easy, rapid and accurate method for the assessment of quality parameters of fish, seafood and meat (Bengtsson and Risman 1971; Ghatass et al. 2008; Kent 1970, 1972, 1977, 1987; Liu and Sakai 1999; Lyng et al. 2005; Mudgett 1985; Nelson 2008; Ohlsson et al. 1974b; To et al. 1974; Zheng et al. 1998). The dielectric method for freshness assessment of meat has several advantages: it is non-destructive, easy, rapid, effective, reliable and practical. Measurement of various meats and fish, including raw beef, pork, beef and pork fat, codfish, and herring at radio frequencies from 10 to 100 MHz were made by Ohlsson et al. (1974b). Dielectric properties of codfish were measured at frequencies from 10 to 200 MHz at temperatures from −25 to 10°C (Bengtsson and Risman 1971). Zheng et al. (1998) reported dielectric properties of raw non-marinated and marinated catfish and shrimp at temperatures from about 10–90°C at 915 MHz and 2.45 GHz. The dielectric properties of tuna fish measured at 2,450 and 915 MHz and from −30 to 60°C by using open ended coaxial probe method reported by Liu and Sakai (1999). Selected published dielectric property data for red meat and red meat products over the temperature range +10 to −20°C are presented in Table 4. Use of dielectric properties for assessing meat quality has got high potential (Nelson 2008). Ohlsson et al. (1974b) studied meat emulsions at 900 and 2,800 MHz. Lyng et al. (2005) interacted between microwave and radio frequency radiation and meat/meat products. Bengtsson and Risman (1971) found no significant difference in dielectric properties between ground and whole meat. To et al. (1974) have measured the dielectric properties for beef and turkey products at 300, 915 and 2,450 MHz. The loss factor of turkey is higher than that of beef, which is due mainly to the moisture content. Both dielectric constant and loss factor are small for frozen meat, under ten and two, respectively. Both the permittivity and loss factor for cooked beef are about 60% of those for raw beef (Kent 1987). Mudgett (1985) reported the dielectric constant and loss of factor of meats and vegetables at temperatures above and below the freezing point and found large differences in the properties of frozen and unfrozen samples. Some dielectric spectroscopy measurements have been carried out recently on poultry and pork products in exploratory work on quality sensing (Zhang et al. 2007; Castro-Giráldez et al. 2010). Dielectric properties values for fresh chicken breast meat in the 10 to 1,800-MHz frequency range at temperatures from 5 to 65°C. Dielectric spectroscopy measurements were also carried out on the albumen and yolk of fresh chicken eggs at weekly intervals during 5 weeks of storage (Guo et al. 2007b). Dielectric properties from 10–1,800 MHz for the fresh eggs were found, where the albumen has higher values for both the dielectric constant and loss factor than the yolk at any given frequency. Dielectric properties changed during the storage period, but they did not correlate well with traditional quality factors for the eggs. Luigi Ragni et al. (2007) investigated changes of the dielectric parameters of fresh hen eggs during storage for the development of a method to assess the main quality indices.

Table 4.

Dielectric property data for red meat and red meat products

| Source | Frequency (MHz) | Product | Frequency (MHz) | Temperature, °C | Dielectric constant | Dielectric loss factor | |

|---|---|---|---|---|---|---|---|

| RF(<300 MHz) | MW(>300 MHz) | ||||||

| Van Dyke et al. (1969) | – | 915 | Beef | 915 | 0–1 | – | 15 |

| Bengtsson and Risman (1971) | – | 3000(2800) | Beef | 2800 | 0 | 47.8 | 16.5 |

| 2800 | −10 | 5 | 2 | ||||

| 2800 | −20 | 4 | 1 | ||||

| To et al. (1974) | – | 300 | Beef | 300 | +5 | 48 | 58.4 |

| 915 | 915 | +5 | 56 | 21 | |||

| 2450 | 2450 | +5 | 52.5 | 17.5 | |||

| Tran and Stuchly (1987) | 100 | – | Beef | 100 | +1.2 | 63.6 | 115.3 |

| Sipahioglu et al. (2003) | – | 2450 | Ham | 2450 | −10 | 7 | 3 |

| 2450 | +5 | 46.6 | 526.7 | ||||

| Zhang et al. (2004) | 27.12 | 896 | Pork Luncheon, roll | 2450 | +5 | 36.08 | 17.14 |

| 915 | |||||||

Dielectric constant and loss factor were measured in the frequency range 20–1,800 MHz using an open-ended coaxial probe on thick albumen and yolk of eggs. Dielectric constant and loss factor of yolk generally increased with the storage time. Basaran et al. (2010) determination of dielectric properties of chicken and fish muscle treated with microbial transglutaminase and concluded that dielectric properties at radio frequency (27 and 40 MHz) and microwave (433, 915 and 1,800 MHz) frequencies for transglutaminase (MTGase, 0.5% w/w) in restructured chicken breast, salmon and trout muscle products, prepared from a muscle mince, over a range of 20 to 130°C were determined.

Dairy products

Dielectric properties of dairy products are relatively scarce. Nunes et al. (2006) studied the complex permittivity of milk at room temperature (17–20°C) over the frequency range of 1–20 GHz, and suggested that they may be useful to roughly determine the milk’s content in terms of ionic compounds, fats, and carbohydrates and proteins. The dielectric properties of milk and its constituents at 2.45 GHz were given by Kudra et al. (1992). Dielectric measurement techniques have been used extensively in the analysis of cheese composition and cheese maturity (Everard et al. 2006; Green 1997; Herve et al.1998). Dielectric methods are utilized at detection of mastitis in milk (Hlavacova 2003). The dielectric properties of a macaroni and cheese food product and found that dielectric constant decreased with increasing temperature and loss factor increased at higher temperatures at frequencies of 27, 40, 915 and 1,800 MHz (Nelson and Bartley 2000). Wang et al. (2003) found that the dielectric constant increased at 27 and 40 MHz and decreased at 915 and 1,800 MHz as the temperature increased from 20 to 121°C and loss factor increased sharply with this increase in temperature at 27 and 40 MHz, but increased mildly at 915 and 1,800 MHz, for macaroni and cheese. Seasonal variation in dielectric properties of butter showed no significant changes (O’Connor and Synnot 1982). Prakash and Armstrong (1970) showed a linear increase in dielectric constant with moisture content over a small range of moisture content. The dielectric constant and loss factor of butter at 2.45 GHz were functions of temperature (Rzepecka and Pereira 1974). Permittivity of bound water at 2.45 GHz had a positive temperature coefficient, while the permittivity of free water decreased with temperature. Dielectric constant decreased gradually as frequency increased for cheeses over the frequency range 0.3–3 GHz and loss factor generally increased with increasing temperature for high and medium moisture/fat ratio cheeses (Everard et al. 2006). The complex permittivity of milk at room temperature (17–20°C) was studied over the frequency range of 1–20 GHz (Nunes et al. 2006). On-line monitoring of moisture and salt contents of butter in its manufacturing process is possible (Shiinoki et al. 1998). Dielectric properties of butter with and without salt over the Microwave frequency range covering 500–3,000 MHz were studied (Ahmed et al. 2007). They found that dielectric spectra of unsalted butter differed significantly from the salted one as a function of temperature and moisture content. The effects of dissolved salts on dielectric loss in milk were also investigated in chemical simulation studies, which showed that predictions of milk dielectric loss factor based on conductivities implied by ash contents needed to be corrected for binding and non-binding interactions of milk salts (Kudra et al. 1992).

Solutions and suspensions

Many agricultural and food materials contain water as the major constituent. Roebuck et al. (1972) studied the dielectric properties of potato starch, sucrose, glucose, ethanol and glycerol, at 1 and 3 GHz and 25°C and found that, especially in an intermediate water concentration, gelatinized potato starch has higher dielectric constant and loss factor values than starch in granular form; the granular form has about 10% less permittivity and up to a 20% smaller loss factor. The dielectric loss for most starches generally decreased during heating; however it remained constant within the temperature range associated with the thermal transition of starch. The type of chemical modification seems to have a strong influence on the dielectric behaviour and reported that loss factor decreases rapidly with increasing temperature, dielectric constant increases slightly with decreasing frequency for starches (Miller et al. 1991). The dielectric properties of powder potato starch, locust bean gum and carrageenan were found to increase regularly with moisture content in the range of 0%–20% wet basis, at 2.45 GHz (Nelson 1991). The dielectric properties of these hydro-colloids were also found to increase markedly with increase in temperature difference at higher moisture contents (Nelson 1991).

Salt ions can also affect the dielectric properties significantly, especially the dielectric loss factor and it is useful to study the dielectric properties of salt solutions (Hasted et al. 1948; Sun et al. 1995). The dielectric constants of the salt solutions decreased as temperature increased. However, the sign of the temperature coefficient of the dielectric loss factor depends on the concentration for the temperatures selected. For salt contents greater than 2%, the predicted dielectric loss increased with temperature, which is in accord with the behaviour of aqueous salt solutions (Sun et al. 1995).

Measuring techniques for dielectric properties

The measurement of dielectric properties has gained importance because it can be used for non-destructive monitoring of specific properties of materials undergoing physical or chemical changes. Measurement of the dielectric properties of materials is finding increasing application as new electro-technology is adapted for use in the agriculture and food processing industries. A comprehensive overview of different measuring techniques can be found elsewhere (Venkatesh and Raghavan 2005). The dielectric properties of food materials in the microwave region can be determined by several methods using different microwave measuring sensors (Kraszewski 1980). Measurement techniques can be categorized as reflection or transmission types using resonant or non-resonant systems, with open or closed structures for sensing of the properties of material samples (Kraszewski 1980). Waveguide and coaxial line transmission measurements represent closed structures while the free-space transmission measurements and open-ended coaxial-line systems represent open-structure techniques, respectively.

The more practical measurement method appears to be that utilizing the measurement of the dielectric properties of the agri-food products and the grain; more specifically its relative permittivity and loss factor (Hlavacova 2003). These techniques include wave guide measurements, resistivity cell, parallel plate, lumped circuit, coaxial probe, transmission line, resonant cavity, free space, parallel plate capacitor, cavity resonator, and time domain spectroscopy, each having unique advantages and disadvantages (Icier and Baysal 2004a; Nyfors and Vainikainen 1989). The lumped circuit techniques are no longer used to any great extent since they were only suitable for low frequencies and high loss materials. All material types, except gases, can be measured, but the method is not suitable for very low-loss materials. Among these techniques, open-ended coaxial probe has been the most commonly used method to determine the dielectric properties of high loss liquid and semi-solid foods (Nelson et al. 1994; Herve et al. 1998), and fresh fruits and vegetables (Nelson and Bartley 2000). The particular relevant measurement and the choice of a method for any desired application depend on the nature of the dielectric material (type of target) to be measured, sample physical state (liquid or solid), shape (thickness, flatness) and electrically, desired range of frequency and the degree of accuracy required (Agilent Technologies 2005; Nelson 1999). The choices of measurement equipment and sample holder design depend upon the dielectric materials to be measured, the extent of the research, available equipment, and resources for the studies. The advantages and disadvantages of various methods are compiled to aid selection of measuring technique in Table 5. The particular measurement methods used in agri-food sector are described here with their principles and limitations:

Table 5.

Advantages and disadvantages of different electrical measurement techniques

| Technique | Advantages | Disadvantages |

|---|---|---|

| Cavity Perturbation technique | Frequently used for measuring dielectric properties of homogeneous food materials because of its simplicity, easy data reduction, accuracy, and high temperature capability. Also well suited to low dielectric loss materials. Can be very accurate and they are also sensitive to low loss tangents. Calculations are rapid. Sample preparation is relatively easy and a large number of samples can be measured in a short time. This method is also easily adaptable to high (up to +140 °C) or low (−20 °C) temperatures. Both solid and liquid measurements can be accurately measured. | The resonant cavity systems restrict the measurements to a single frequency. |

| Open-ended coaxial probes | Most commonly used method to determine the dielectric properties of high loss liquid and semi-solid foods and fresh fruits and vegetables. Quite easy to use and can be used for liquid and semi-solid materials including biological and food materials. This method is convenient and often little or no sample preparation. | Due to density variations in material, such techniques are not free of errors. Not suitable for determining permittivities of granular and pulverized samples. |

| Transmission line technique | More accurate and sensitive than the more recent coaxial probe method. Liquids and viscous-fluid type foods can be measured. The dielectric properties can be easily and inexpensively obtained. | Sample preparation is also more difficult and time consuming. |

| Resonators and transmission line | The method applies to all liquid and solid materials. | Does not apply to gases since their permittivities are too low. Problems with the sample preparation of solid materials. The accuracy is not as good. |

| Time domain spectroscopy/ reflectometry | The measurement is very rapid and accuracy is high, within a few per cent error. The sample size used is very small and the substance to be measured must be homogeneous. They are excellent tools for advanced research on the interaction of the electromagnetic energy and materials over a wide frequency range | These methods are expensive. |

| Free space transmission techniques | Do not require special sample preparation, therefore they are particularly suitable for materials at high temperature and for inhomogeneous dielectrics. They may be easily implemented in industrial applications for continuous monitoring and control e.g., moisture content determination and density measurement. Accurate measurement of the permittivity over a wide range of frequencies can be achieved. | |

| Six-port reflectometer (SPR) using an open-ended coaxial probe | SPR can provide non-destructive broadband permittivity measurements with accuracy comparable to commercial. Data acquisition and reduction are fully automatic. | This method involves a more complex mathematical procedure in order to translate the signal characteristics into useful permittivity data. |

| Colloid dielectric probe | This electrical technology can quickly and accurately measure dielectric properties evaluation of colloidal liquid materials in the food, chemical, pharmaceutical, and biochemical industries. | |

| The lumped circuit techniques | All material types, except gases, can be measured. | Not used widely since they were only suitable for low frequencies and high loss materials. |

Cavity perturbation technique

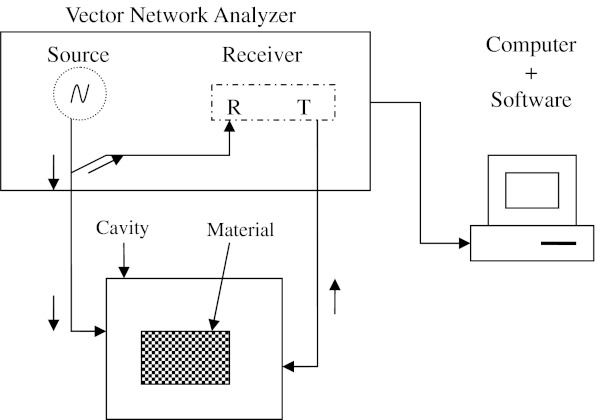

The cavity perturbation technique is frequently used for measuring dielectric properties of homogeneous food materials because of its simplicity, easy data reduction, accuracy, and high temperature capability (Bengtsson and Risman 1971; de Loor and Meijboom 1966). The technique is also well suited to low dielectric loss materials and can be very accurate and they are also sensitive to low loss tangents (Hewlett-Packard 1992; Kent and Kress-Rogers 1986, 1987). The resonant cavities are designed in the standard TM (transverse magnetic) or TE (transverse electric) mode of propagation of the electro-magnetic fields. It is based on the shift in resonant frequency and the change in absorption characteristics of a tuned resonant cavity, due to insertion of a sample of target material. The measurement is made by placing a sample completely through the centre of a waveguide (rectangular or circular) that has been made into a cavity (Fig. 1). Changes in the centre frequency and width due to insertion of sample are related to dielectric constant. For ease of measurement, the vector network analyzer (VNA) can be used to automatically display changes in frequency and width (Engelder and Buffler 1991). The measurement details and the perturbation equations adapted for calculation of dielectric constant and loss factor along with accuracy information were reported by Liao et al. (2001) and Venkatesh (2002). The resonant cavity systems restrict the measurements to a single frequency. Each cavity needs calibration but, once the calibration curves have been obtained, calculations are rapid. Sample preparation is relatively easy and a large number of samples can be measured in a short time. This method is also easily adaptable to high (up to +140°C) or low (−20°C) temperatures (Ohlsson and Bengtsson 1975; Risman and Bengtsson 1971). Sharma and Prasad (2002) have used the cavity perturbation method to measure the dielectric properties of garlic at selected levels of moisture content and at 35 to 75°C.

Fig. 1.

Schematic representation of a resonant cavity method (R = reflected power, T = transmitted power (adapted from Venkatesh and Raghavan 2005)

Open ended coaxial probe technique

The coaxial probe method is basically a modification of the transmission line method. It uses a coaxial line, which has a special tip that senses the signal reflected from the material. The tip is brought into contact with the substance by touching the probe to a flat face of a solid or by immersing it in a liquid. The reflected signal is related to the dielectric properties of the substance. While the method is quite easy to use and it is possible to measure the dielectric properties over a wide range of frequencies (500 MHz–110 GHz), it is of limited accuracy particularly with materials with low values of absolute permittivity i.e. dielectric constant and loss factor (Engelder and Buffler 1991; Hewlett-Packard 1992). This technique is valid for 915 and 2,450 MHz, for materials with loss factors greater than one (Sheen and Woodhead 1999; Hewlett-Packard 1992). Typical open-ended probes utilize 3.5 mm diameter coaxial line. For measurement of solid samples, probes with flat flanges may be utilized (Hewlett-Packard 1992).

An open-ended coaxial probe technique was used to measure the dielectric properties as thermal treatments for controlling insects in fruits at temperature range of 20 to 60°C over a frequency range from 1 to 1,800 MHz (Wang et al. 2003). For liquid and semi-solid materials including biological and food materials, open-ended coaxial-line probes have been used for broadband permittivity measurements (Blackham and Pollard 1997; Grant et al. 1989). A similar technique is used for permittivity measurements on fresh fruits and vegetables (Nelson et al. 1994; Ohlsson et al. 1974a). Due to density variations in material, such techniques are not free of errors, if there are air gaps or air bubbles between the end of the coaxial probe and the sample. The technique is not suitable for determining permittivities of granular and pulverized samples when bulk densities of such samples were established by auxiliary permittivity measurements. This method is convenient, relatively easy to use because of its ability to scan through a wide range of frequencies with desired accuracy and little or no sample preparation (Feng et al. 2002; Ikediala et al. 2000; Nelson 2003; Venkatesh and Raghavan 2004; Wang et al. 2003, 2005).

Transmission line technique

In transmission line methods, a sample of the substance is put inside an enclosed transmission line. Both reflection and transmission are measured. Although this method is more accurate and sensitive than the more recent coaxial probe method, it has a narrower range of frequencies. As the substance must fill the cross-section of the transmission line (coaxial or rectangular), sample preparation is also more difficult and time consuming (Engelder and Buffler 1991; Hewlett-Packard 1992). When such methods are used to determine moisture content, the frequency used should be above 5 GHz to avoid the influence of ionic conductivity and bound water relaxation (Kraszewski 1996). Liquids and viscous-fluid type foods can be measured with this method by using a sample holder at the end of a vertical transmission line. The dielectric properties can be easily and inexpensively obtained by this technique, particularly if one utilizes a slotted line and standing wave indicator (Nelson et al. 1974). A more sophisticated implementation of the technique utilizes a swept-frequency network analyzer, where the impedance is measured automatically as a function of frequency. This technique is cumbersome because the sample must be made into a slab or annular geometry. At 2,450 MHz, the sample size is somewhat large, particularly for fats and oils (Venkatesh and Raghavan 2005).

Resonators and transmission line

A microwave resonator, partly or completely filled with a material can also be used to determine permittivity. The resonator (perturbation technique) is usually calibrated with materials whose dielectric properties are known, usually with organic solvents such as methanol, ethanol, etc. The measurement frequency range is from 50 MHz to more than 100 GHz. If the transmission line is enclosed (i.e., it is a waveguide), the permittivity of a material can also be measured without the resonator by putting it directly inside the waveguide. The method applies to all liquid and solid materials, but not to gases since their permittivities are too low. There are, however, problems with the sample preparation of solid materials. The accuracy is not as good as that of the transmission line with resonator (Venkatesh and Raghavan 2005).

Waveguide and coaxial transmission line method

Early efforts to characterize the dielectric properties of materials were made at the Massachusetts Institute of Technology (Roberts and von Hipple 1946). Coaxial-line and rectangular wave-guide sample holders were used with various microwave measurement systems assembled for dielectric properties determination on grain, seed, and fruit and vegetable tissue samples at frequencies from 1 to 22 GHz (Nelson 1973, 1983, 1991). The same sample holders were also found to be useful for measurements on pulverized coal and mineral samples (Nelson 1983).

Time domain spectroscopy /reflectometry (TDR) method

Time domain spectroscopy/reflectometry methods have been developed in the 1980s. They cover a frequency range from 10 MHz to 10 GHz. This method also utilizes the reflection characteristic of the food material under test to compute the dielectric properties. The measurement is very rapid and accuracy is high, within a few per cent error (Afsar et al. 1986). The sample size used is very small and the substance to be measured must be homogeneous. Although these methods are expensive, they are excellent tools for advanced research on the interaction of the electromagnetic energy and materials over a wide frequency range (Mashimo et al. 1987; Ohlsson et al. 1974b). The dielectric properties of honey-water mixture have been investigated and tabulated using this technique in the frequency range of 10 MHz to 10 GHz at 25°C by Puranik et al. (1991).

Free space transmission techniques

In this method sample is placed between a transmitting antenna and receiving antenna and the attenuation and phase shift of the signal are measured. The dielectric sample holders with rectangular cross-section were placed between the horn antennas and similar radiating elements (Trabelsi et al. 1997). The usual assumption made during this technique is that a uniform plane wave is normally incident on the flat surface of a homogenous material, and that the planar sample has infinite extent laterally (Venkatesh and Raghavan 2005). This method, do not require special sample preparation. Therefore, they are particularly suitable for materials at high temperature and for inhomogeneous dielectrics. In addition, they may be easily implemented in industrial applications for continuous monitoring and control e.g., moisture content determination and density measurement (Kraszewski 1980). Accurate measurement of the permittivity over a wide range of frequencies can be achieved by this technique.

Micro strip transmission line

Micro strips have long been used as microwave components, making it suitable for use in dielectric permittivity measurement and shows many properties which overcome some of the limitations, thus it is well known that the effective permittivity (a combination of the substrate permittivity and the permittivity of the material above the line) of a micro strip transmission line (at least for thin width to height ratios) is strongly dependent on the permittivity of the region above the line (Venkatesh and Raghavan 2005). This effect has been utilized in implementing microwave circuits and to a lesser extent investigation of dielectric permittivity. Furthermore the measurement of effective permittivity is relatively straightforward and well suited to implementation in industrial equipment. Such a system could be based on determining the effective permittivity of a micro strip line covered by an unknown dielectric substance (Keam and Holmes 1995).

Six-port reflectometer (SPR) using an open-ended coaxial probe

SPR can provide non-destructive broadband permittivity measurements with accuracy comparable to commercial instruments (Venkatesh and Raghavan 2005). Non-destructive broadband permittivity measurements using open-ended coaxial lines as impedance sensors, which are of great interest in a wide variety of biomedical applications (Ghannouchi and Bosisio 1989). The device under test is an open-ended coaxial test probe immersed in the test liquid kept at a constant temperature. Data acquisition and reduction are fully automatic. This effective transmission line method, used to represent the fringing fields in the test medium, provided a good model to interpret microwave permittivity measurements in dielectric liquids. Using such a model, the precision on relatively high-loss dielectric liquid measurements is expected to be good. However this method involves a more complex mathematical procedure in order to translate the signal characteristics into useful permittivity data (Venkatesh and Raghavan 2005).

Colloid dielectric probe