Abstract

Defatted rice bran (DRB), a byproduct of rice milling is a rich source of dietary fiber and minerals. In the present study, the physico-chemical characteristics, antioxidant potential of defatted rice bran (Laboratory-LDRB and Commercial -CDRB) and its utilization in preparation of bread were studied. The effect of incorporation of CDRB at varying levels (5, 10 & 15%) on the quality characteristics of bread including physical, rheological and sensory attributes were evaluated and the dietary fiber content and antioxidant activity were determined. The results indicated that LDRB had better nutrient profile, physical and antioxidant properties than CDRB. On the basis of physical characteristics, breads with 5% and 10% CDRB were found to be acceptable as such and those containing 15% were acceptable with addition of bread improvers. The dietary fiber content and total antioxidative activity of bread increased with increasing levels of CDRB, which also improved the shelf life. The results reveal that DRB can be incorporated in breads upto 10% and 15% as such or with bread improvers respectively, as source of fiber and natural antioxidant, as a functional ingredient.

Keywords: Defatted rice bran, Dietary fiber, Nutrient profile, Antioxidant activity, Bread, Farinograph

Introduction

In recent years, there has been a global trend towards the use of natural substances present in foods as a source of antioxidant and functional ingredients Kim (2005). Efficient utilization of food products, food wastes and unconventional food sources of human consumption would result in increased nutritional value of products made from available resources Houston (1972). The nutritive value and health enhancing properties of rice bran has been well documented Sharma and Chauhan (2002). Rice bran is light brown, slightly oily, unstable meal produced as a byproduct of the rice milling process. It contains approximately 17% fat, 6% crude fiber Houston (1972). Current research has showed that rice bran may contain even 100 different antioxidants, as new ones are being discovered. Among the most powerful of these are Oryzanols, Tocopherols and Tocotrienols. Defatting/lipid extraction markedly increases the proportion of dietary fiber and crude protein contents of rice bran Godber et al. (2002), Iqbal et al. (2005), but still rice bran is an underutilized co-product from rice milling.

As foods become more highly processed, the consumption of natural fibers decreases and it is necessary to add these ingredients back into foods Skurray and Wooldridge (1986). Being one of the cheaper cereal byproduct, rice bran offers good potential to supplement the costly fiber and protein sources such as oat bran, wheat bran in the Indian diets. Bakery products have provided vehicles for incorporation of bran from cereals, and hence bread products are most suitable for this application and the keeping quality of baked foods such as breads, crackers, cookies and biscuits are of great economic importance since these products are widely used and are often stored for extended periods before consumption. There are limited studies on rice bran composition in food applications, specifically their effect on the functional properties and keeping quality of bread. It is reported defatted rice bran (DRB) had higher stability, water holding, fat holding and foaming capacities than full fat rice bran. These properties may affect the quality of bread made with added bran James and Sloan (1984).

With this background, the present study has been carried out to evaluate the physico-chemical characteristics of DRB, and its utilization in bread as a source of dietary fiber and natural antioxidants.

Materials and methods

Full fat (FRB) and defatted rice bran (CDRB) were procured from local rice mill. Full fat bran was extracted with petroleum ether in a soxhlet apparatus to obtain Laboratory defatted rice bran (LDRB). The bran were powdered, passed through 60 mesh sieve (BS) and stored in an air tight container till further use.

Preparation of extracts

Methanol and hexane extracts were prepared by extracting samples (20 g) with respective solvents (250 ml) in a mechanical shaker for 24 h, filtered and evaporated to dryness under reduced pressure in a rotary evaporator. All the other chemicals used were of analytical grade.

Physico-chemical characteristics

Proximate composition of the samples i.e., moisture, ash, fat, protein, fiber and minerals (calcium, iron and phosphorous) and physical properties like bulk density, water absorption capacity and fat absorption capacity were determined by standard AOAC methods (1984, 1986).

Determination of antioxidant components and activity

The Oryzanol content of the samples were estimated as per the method of Gopala Krishna et al. (2001). Free radical scavenging activity of various extracts was measured from the bleaching of purple colored methanol solution of DPPH by the method of Yen and Chen (1995). Reducing power of the extracts was determined by the method of Yildirim et al. (2003).

Formulation and preparation of bread

Formulation of blends

Refined wheat flour (RWF) was procured from the local market. RWF was blended with CDRB at levels of 5, 10 and 15%. The blends were mixed well and sieved through a 60 mesh sieve (BS) for uniform mixing.

Dough rheological characteristics, preparation and evaluation of bread quality

The dough properties of RWF samples incorporated with CDRB at different levels were determined using a farinograph according to standard AACC method (2000). Breads were prepared using the straight dough method according to the standard ‘Remix’ baking test Irvine and McMillan (1960). The ingredients used for baking of bread are: RWF (200 g), Yeast (4 g), Salt (3 g), Sugar (5 g), Fat (2 g), Water (Variable), bread improvers (α-Amylase and Sodium Stearoyl Lactylate (SSL)) and CDRB (at 5, 10 &15% levels). Dough was fermented for 2 h after mixing all ingredients, remixed and further fermented for 25 min, followed by sheeting, moulding, proofing at 30 °C, 85% RH for 55 min and baking at 230 °C for 25 min. After cooling, the breads were packed in polythene pouches and used for evaluation, the next day. Breads were assessed for their weights and loaf volume by the rapeseed displacement method AACC (1983). Objective measurement of the texture was carried out in a using Instron Universal Testing Machine (Instron Ltd., U.K., Model No. 1140) with following conditions—25% Compression and 100% speed. Ten trained panelists carried out evaluation of bread for crust—color and appearance, crumb color, grain (texture), texture (finger feel), mouth feel and overall quality.

Chemical analysis

The breads were analyzed for dietary fiber content according to the method of Asp et al. (1983). The total antioxidant activity i.e., the degree of oxidation of fat in bread was measured by the 2- thiobarbituric acid (TBA) assay Siu and Hegarty (1978). During the oxidation process, peroxide is gradually decomposed to lower molecular compounds, one being malanoldehyde, which was measured by TBA method.

Statistical analysis

The data was analyzed by ANOVA followed by Tukey’s test for significant differences (n = 4, P < 0.05).

Results

Physico-chemical characteristics of Defatted Rice Bran

The nutrient profile and physical characteristics of two varieties of DRB i.e., LDRB and CDRB are given in Table 1. Among the two varieties, the moisture and ash contents of LDRB were higher than CDRB. Whereas the protein, dietary fiber and fat contents were higher in CDRB and similar trend was observed for mineral contents (iron, phosphorus and calcium). CDRB (0.47 g/cc) had higher bulk density than LDRB (0.34), whereas CDRB exhibited higher water and fat absorption capacity. The reason could be due to high amount of dietary fiber and protein on CDRB.

Table 1.

Nutrient profile and physical properties of DFRB (g/100 g)

| Nutrients | LDRB | CDRB |

|---|---|---|

| Moisture (%) | 13.3 | 11.1 |

| Protein | 16.6 | 17.2 |

| Fiber TDF | 7.41 | 11.44 |

| SDF | 2.24 | 2.24 |

| IDF | 5.17 | 9.19 |

| Fat | 0.33 | 0.66 |

| Ash | 15.6 | 14.65 |

| Calcium (ppm) | 240 | 255 |

| Phosphorous (ppm) | 160 | 166 |

| Iron (ppm) | 285 | 290 |

| Bulk Density (g/cc) | 0.47 | 0.34 |

| Water Absorption | ||

| Capacity (ml/100 g) | 210 | 240 |

| Fat Absorption | ||

| Capacity (ml/100 g) | 180 | 210 |

LDRB Laboratory defatted rice bran, CDRB Commercial defatted rice bran, TDF Total Dietary Fiber, IDF Insoluble Dietary Fiber, SDF Soluble Dietary Fiber

Determination of antioxidant component and evaluation of antioxidant activity

The Oryzanol contents were determined in methanol extracts of FRB, LDRB, CDRB and hexane extracts of LDRB and CDRB. The FRB (0.16 g/100 g) showed highest oryzanol content, followed by hexane extracts and methanol extracts. CDRB had higher levels of oryzanol than LDRB. Hexane extracts of CDRB and LDRB (0.013 g > 0.006 g/100 g) had higher concentrations of oryzanol than methanol extracts of CDRB and LDRB (0.003 g > 0.001 g/100 g). This difference in concentrations may be attributed to different methods of extraction used, and also to the presence of small amount of oil present in hexane extracts.

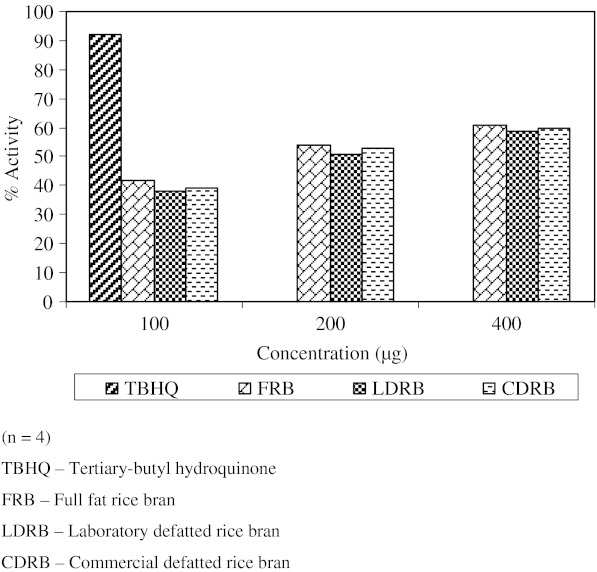

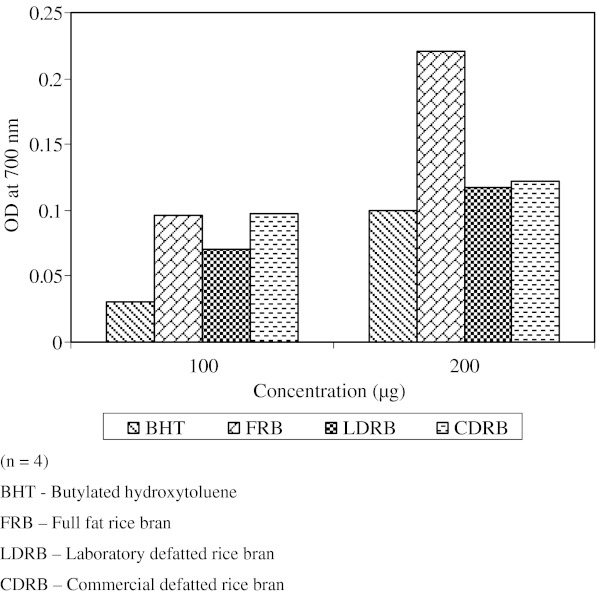

The radical scavenging activity (RSA) of the methanol extracts of FRB, LDRB, CDRB and synthetic antioxidant TBHQ, as determined by DPPH assay at different concentrations [100, 200 and 400 μg] is shown in Fig. 1. The scavenging ability of extracts against DPPH was concentration dependent. TBHQ (91.86%) exhibited higher RSA and among the extracts, FRB (60.83%) showed high RSA followed by CDRB (59.69%) and LDRB (58.93%). The reductive capabilities of the methanolic extracts at two concentrations (100 and 200 μg) of FRB, LDRB, and CDRB was observed and compared with synthetic antioxidant BHT as shown in Fig. 2. A high absorbance indicates high reducing power (RP). The RP of the extracts increased with increase in concentration. BHT showed maximum RP followed by the FRB, CDRB and LDRB. The reducing power of a compound is related to its electron transfer ability and may therefore serve as a significant indicator of its potential antioxidant activity Yildirim et al. (2003). Literature reports are evident that the reducing power of bioactive compounds is associated with antioxidant activity Dorman and Peltoketo (2003).

Fig. 1.

DPPH radical scavenging activity

Fig. 2.

Reducing power assay (Methanolic Extract of FRB, LDRB & CDRB)

Dough rheological characteristics and evaluation of bread quality

The farinograph characteristics of wheat flour dough as influenced by the addition of CDRB at different levels are illustrated in Table 2. Addition of CDRB to wheat flour had a marginal effect on the water absorption of flour, dough stability and dough development time, except in variation with 15% CDRB where dough development time decreased to 2.2 min. Dough stability values were not much affected by the addition of CDRB, but as the levels of CDRB increased, the mechanical tolerance index increased from 53 (control) to 67 (at 15%), and the breakdown time decreased indicating poor stability of dough at higher levels.

Table 2.

Farinographic characteristics of dough with and without incorporation of CDRB

| Source | Water absorption (%) | Development time (min) | Stability (min) | Tolerance index (MTI) | Time to breakdown (min) |

|---|---|---|---|---|---|

| Control | 62.4 | 3.3 | 2.5 | 53 | 5.2 |

| 5% | 62.4 | 3.3 | 2.6 | 56 | 5.2 |

| 10% | 62.6 | 3.3 | 2.9 | 59 | 4.9 |

| 15% | 63.0 | 2.2 | 2.6 | 67 | 4.1 |

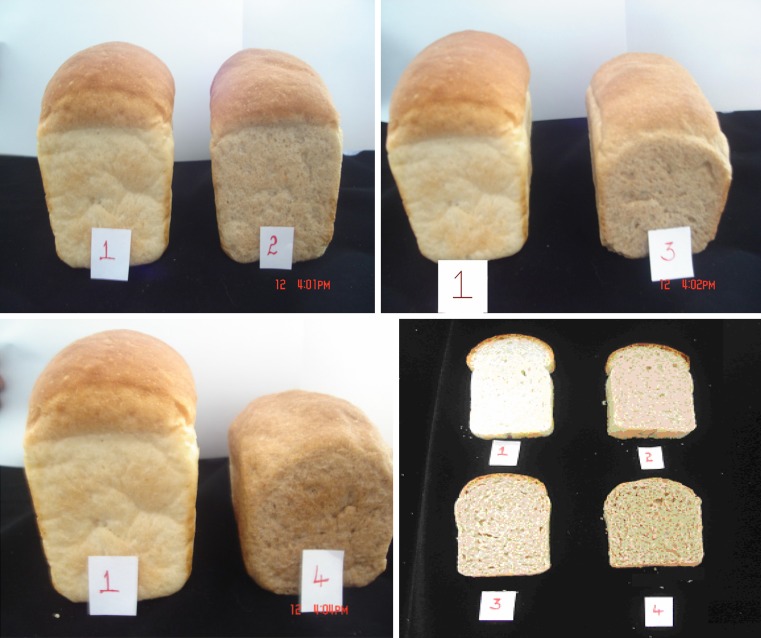

Bread-making quality, as affected by different levels of CDRB, is presented in Table 3 and Fig. 3. Addition of CDRB had least effect on dough weights and bread weights. The bread from RWF (control) had a volume of 465 cc. The addition of bread improvers had significant effect on the quality of the bread, with loaf volume increasing from 425 to 432 cc (5%), 367 to 427 cc (10%) and 317 to 422 cc (15%).The objective evaluation of texture analyzed in breads without improvers showed that the compression force increased with increase in the CDRB levels.

Table 3.

Physical characteristics of bread (with and without added CDRB and bread improvers) (n = 4)

| Source | Dough weight (g) | Bread weight (g) | Loaf volume (cc) | Texture reading** |

|---|---|---|---|---|

| WOI | ||||

| Control | 165.5 ± 0.02a | 144.0 ± 0.05a | 465 ± 0.01a | 509 ± 0.02a |

| 5% | 165.5 ± 0.02a | 145.0 ± 0.02a | 425 ± 0.03b | 603 ± 0.03b |

| 10% | 166.0 ± 0.01a | 144.0 ± 0.01a | 367 ± 0.04c | 977 ± 0.06c |

| 15% | 166.9 ± 0.01a | 147.5 ± 0.03a | 317 ± 0.02d | 1423 ± 0.02d |

| WI | ||||

| Control | 169.0 ± 0.03a | 144.5 ± 0.01a | 465 ± 0.01a | ND |

| 5% | 170.0 ± 0.03a | 146.0 ± 0.02a | 432 ± 0.01a | ND |

| 10% | 170.0 ± 0.01a | 148.0 ± 0.02a | 427 ± 0.04a | ND |

| 15% | 171.0 ± 0.02a | 149.0 ± 0.01a | 422 ± 0.01a | ND |

Values carrying different superscripts a, b, c..... in columns differ significantly (P < 0.05)

** Measured in Instron Texturometer

WOI Without added Improvers, WI With added Improvers, ND Not Determined

Fig. 3.

Comparison of Loaf Volumes and physical characteristics of Control (1); 5% (2); 10% (3); & 15% (4) variation breads

The mean sensory scores of bread with different levels of CDRB, on day 1 (D1) and day 3 (D3) are given in Table 4. The mean sensory scores of all the key attributes, (crust-color and appearance, crumb color, grain, texture, mouth feel) differed significantly for all the bread variations on D1 and as well on D3, however bread with 5% CDRB was found to be similar to control. The overall quality scores thus reduced with an increase in the CDRB levels, but were acceptable with addition of bread improvers.

Table 4.

Sensory characteristics of bread (n = 10)

| Source | Crust color & appearance | Crumb color | Grain | Texture | Mouth feel | Overall quality |

|---|---|---|---|---|---|---|

| D1 | ||||||

| Control | 8.58a | 8.91a | 8.91a | 9.00a | 8.91a | 44.33a |

| ±0.37 | ±0.20 | ±0.20 | ±0.63 | ±0.58 | ±1.50 | |

| 5% | 7.42b | 6.83b | 7.66b | 7.01b | 6.41b | 35.41b |

| ±0.49 | ±1.43 | ±0.51 | ±1.11 | ±0.95 | ±4.45 | |

| 10% | 5.92c | 6.25c | 6.33c | 5.83c | 5.50c | 29.83c |

| ±1.28 | ±1.75 | ±1.16 | ±1.36 | ±1.00 | ±6.49 | |

| 15% | 5.17d | 5.00d | 4.33d | 4.33d | 4.16d | 23.00d |

| ±1.60 | ±1.97 | ±1.63 | ±1.50 | ±1.55 | ±7.86 | |

| D3 | ||||||

| Control | 8.00a | 7.91a | 8.08a | 8.00a | 8.16a | 40.16a |

| ±0.0 | ±0.20 | ±0.49 | ±0.31 | ±0.29 | ±1.03 | |

| 5% | 6.42b | 5.58b | 6.41a | 5.58b | 4.83b | 28.83b |

| ±0.37 | ±0.91 | ±0.49 | ±0.91 | ±0.81 | ±3.32 | |

| 10% | 3.92c | 3.75c | 4.41c | 3.83c | 3.25b | 19.16c |

| ±0.8 | ±0.61 | ±0.97 | ±0.68 | ±0.83 | ±2.25 | |

D1 Day 1, D3 Day 3

Values carrying different superscripts a, b, c..... in columns differ significantly,

P < 0.05,

Chemical analysis

Breads (control, 5% and 10% CDRB incorporated) were analyzed for their dietary fiber content and total antioxidant activity. There was increase in the total dietary fiber content (soluble and insoluble) with increase in CDRB levels. The presence of CDRB in bread exhibited higher antioxidant activity than Control, and with increased level of incorporation the antioxidant activity also increased (Table 5). The formation of malonaldehyde was high in control (10.1 μg) followed by 5% (5.7 μg), and 10% (4.7 μg) variation, which indicates less peroxide formation in 10% CDRB incorporated bread. Hence the antioxidative effect can be attributed to the presence of CDRB.

Table 5.

Dietary fiber content (TDF, SDF, IDF) and Total antioxidant activity (Malonaldehyde formation) in bread incorporated with various levels of CDRB (n = 4)

| Source | Dietary fiber (g/100 g) | Malonaldehyde | ||

|---|---|---|---|---|

| Total | Soluble | Insoluble | Formation (μg)* * | |

| Control | 6.31 | 1.06 | 5.25 | 10.1 |

| ± 0.02 | ± 0.03 | ± 0.07 | ± 0.06 | |

| 5% | 8.42 | 1.37 | 7.05 | 5.7 |

| ± 0.04 | ± 0.10 | ± 0.10 | ± 0.02 | |

| 10% | 10.91 | 1.66 | 9.25 | 4.7 |

| ± 0.07 | ± 0.05 | ± 0.21 | ± 0.09 | |

* * μg of Malonaldehyde/100 g of bread sample

The results of the present study indicate that, DRB can be used as a nutrient rich source of fiber and also that it is possible to formulate high fiber bread by incorporating DRB at 10–15% levels with addition of bread improvers, with good antioxidant activity which exerts positive effect on the storage stability of the product.

The physico-chemical characteristics of DRB were found to be higher than the reported values of FRB. Defatting markedly increases the nutrients content of the rice bran Prakash and Ranganatham (1995). The results of the physical characteristics indicate that DRB had the highest water and oil absorption capacities, and foaming capacity than FRB James and Sloan (1984). Since defatting further increases the insoluble fiber and protein content, the water absorption capacity increases almost five times its bulk in liquid Linda (1990). Foaming capacity of the bran was expressed as the increase in volume due to whipping. The DRB might be incorporated into foods such as baked products for which a high water absorption capacity is desired to help maintain moisture and freshness. Foaming capacity and stability enables air incorporation, leavening and texturization properties. Therefore, the defatted bran sample would be the best bran to contribute not only to this property, but also to water and fat absorption capabilities of bread James and Sloan (1984).

Addition of DRB increases the contents of protein, lysine and dietary fiber proportionately to the level of substitution. But when DRB is substituted for a portion of the wheat flour, the gluten content of the formulation reduces which may decrease the bread volume Sharp and Kitchens (1990). The farinograph data indicated that adding bran to whole meal flour did not significantly increase the water absorption Skurray and Wooldridge (1986). Texture profile analysis showed not much difference as far as cohesiveness and springiness, but bread hardness, gumminess and chewiness increased with increased levels of DRB incorporation. Crumb color was darker and less yellow with the addition of bran. Darkness of the crumb was directly related to the increased bran content, while yellowness significantly decreased only when bread contained 15% bran levels. Skurray and Wooldridge (1986) reported that there was reduction in sensory scores of breads containing defatted rice bran. Subsequent research has indicated that with certain manipulations of the basic formula, 15% and as much as 30% of bran can be used without sacrificing loaf volume. These data suggest that rice bran can be substituted successfully for at least 15% of the wheat flour in bread formulations, without affecting the loaf height, weight, or volume Talwalker and Garg (1965).

The results of the present study also showed that incorporation of CDRB in the bread formulation increased the dietary fiber content of bread which increased with increase in CDRB levels. The presence of CDRB in bread exhibited higher antioxidant activity compared with that of control bread. The malanoldehyde formation was high in control than other variations which indicates less peroxide formation in 10% CDRB incorporated bread, hence the antioxidative effect can be attributed to the presence of CDRB.

Conclusion

From this study, it may be concluded that DRB can be used as a source of fiber, and nutrients such as protein, vitamins and minerals. The physico-chemical characteristics exhibited by DRB would be desirable in the preparation of various bakery products especially in breads up to 15%, with added improvers without affecting the loaf volume, and also can be used as an functional ingredient for developing high fiber breads, with good antioxidant activity which improves the storage stability of the breads.

References

- Methods of analysis. 8. St. Paul: American Association of Cereal Chemistry; 1983. [Google Scholar]

- Methods of analysis. St. Paul: American Association of Cereal Chemistry; 2000. [Google Scholar]

- Methods of analysis. 14. Washington DC: Association of Official Agricultural Chemists; 1984. [Google Scholar]

- Methods of analysis. 7. St. Paul: Association of Official Agricultural Chemists; 1986. [Google Scholar]

- Asp NG, Johansson CG, Hollmer H, Siljestram M. Rapid enzymatic assay of insoluble and soluble dietary fibers. J Agric Food Chem. 1983;33:476–482. doi: 10.1021/jf00117a003. [DOI] [PubMed] [Google Scholar]

- Dorman HJD, Peltoketo A (2003) Characterization of the antioxidant properties of de-odorized aqueous extracts from selected Laminaceae herbs 83:255–262

- Godber SJ, Xu Z, Hegsted M, Walker T (2002) Rice bran and rice bran oil. In: Functional foods development. Fall of Louisiana Agriculture

- Gopala Krishna AG, Khatoon S, Sheila PH, Sarmandal CV, Indira TN, Mishra A. Effect of refining of crude rice bran oil on the retention of oryzanol in the refined oil. J AOCS. 2001;78(2):127–131. [Google Scholar]

- Houston DF (1972) In: Rice chemistry and technology. American Association of Cereal Chemists. St. Paul, MN

- Iqbal S, Bhanger MI, Anwar F. Antioxidant properties and components of some commercially available varieties of rice bran in Pakistan. Food Chem. 2005;93:265–272. doi: 10.1016/j.foodchem.2004.09.024. [DOI] [Google Scholar]

- Irvine GN, McMillan MF. The remix baking test. Cereal Chem. 1960;37:603–613. [Google Scholar]

- James C, Sloan S. Functional properties of edible rice bran in model systems. J Food Sci. 1984;29:310. doi: 10.1111/j.1365-2621.1984.tb13741.x. [DOI] [Google Scholar]

- Kim JS. Radical scavenging capacity and antioxidant activity of the E vitamer fraction in rice bran. J Food Sci. 2005;70(3):208–213. doi: 10.1111/j.1365-2621.2005.tb07127.x. [DOI] [Google Scholar]

- Linda EC (1990) Functional properties and applications of stabilized rice bran in bakery products. Food Technol. April:74–76

- Prakash J, Ranganatham G. Proximate composition and protein quality of stabilized rice bran. J Food Sci Technol. 1995;32(5):416–419. [Google Scholar]

- Sharma HR, Chauhan GS. Effects of stabilized rice bran-fenugreek blends on the quality of breads and cookies. J Food Sci Technol. 2002;39(3):225–233. [Google Scholar]

- Sharp CQ, Kitchens KJ. Using rice bran in yeast bread in a home baker. Cereal Foods World. 1990;35(10):1021–1204. [Google Scholar]

- Siu GM, Hegarty HH. A survey of malonaldehyde content of retail meat and fish. J Food Sci. 1978;43:1147–1149. doi: 10.1111/j.1365-2621.1978.tb15256.x. [DOI] [Google Scholar]

- Skurray DA, Wooldridge NM. Rice bran as a source of dietary fiber in bread. J Food Technol. 1986;21:727–730. [Google Scholar]

- Talwalker RT, Garg NK (1965) Rice bran—a source material for pharmaceuticals. J Food Sci Technol 2(Oct–Dec):117–119

- Yen GC, Chen HC. Antioxidant activity of various tea extracts in relation to their antimutagenicity. J Agric Food Chem. 1995;43:27–32. doi: 10.1021/jf00049a007. [DOI] [Google Scholar]

- Yildirim A, Ahmet M, Kara AA. Antioxidant and antimicrobial activities of Polygonum cognatum. J Sci Food Agric. 2003;83:64–69. doi: 10.1002/jsfa.1288. [DOI] [Google Scholar]