Abstract

Effects of heat treatment on physicochemical characteristics and sensory properties of different fruit juice concentrates (pekmez) were studied. Apricot pekmez had the highest viscosity followed by mulberry and date pekmez. Apricot and date pekmez had higher scores for odour, taste and consistency than others. Hydroxymethyl furfural concentration of all pekmez samples increased after heat treatments. Samples heated at 75°C showed highest L* values while at 65°C the lowest mean L* values. L* values of all pekmez samples were similar while carob Pekmez had higher L* values. Also a development of the Fuzzy Expert System (FES) was made for prediction. Using the experimental values, FES model of the system was designed. Accordance was found with experimental and FES results when compared statistically. This study provides advantage for prediction possibility of unknown sub-values’, which were not experimentally studied.

Keywords: Grape juice concentrate ‘pekmez’, Heat treatment, Fuzzy expert system

Introduction

Pekmez is a traditional product of Turkey. It can be defined as a concentrated grape juice, obtained by boiling in open vessels or under vacuum to decrease the water content (Arslan et al. 2005). Grape juice is commonly used as a raw material but it can be produced from all of the fruits that contain sugar. Mulberry, apricot, carob and persimmon are the common fruits used for pekmez production. Pekmez contains high amounts of sugar, minerals and organic acid and is very important in human nutrition (Bozkurt et al. 1999; Yoğurtçu and Kamışlı 2006).

It has been known that fruit juices darken during harvesting, transporting, processing and storage. Production is usually made in open vessels and with high heat treatment. Non-enzymatic browning reactions during processing and storage are the well known problem in pekmez production. Maillard reactions result in undesirable colour, odour and flavour changes and are followed by the formation of intermediates such as 5-hydroxymethyl furfural (HMF), particularly under acidic conditions and finally brown pigment formation (Bozkurt et al. 1999).

Types of sugars and their reducing capacity, types of amino acids, their concentrations, ratio and chemical nature of the reactants, pH, temperature, heating time, acidity, relative humidity and the concentrations of metal ions, particularly Ca, K, Mg, Na+2, Fe+2 and Fe+3 have significant effects on the Maillard reaction (Acevedo et al. 2005; Şimşek et al. 2007). Both heating procedures and storage conditions show synergy in Maillard reactions (Şimşek et al. 2007). In fresh foods, the HMF level is close to zero. HMF is also considered as one of the indicators of quality parameters of pekmez (Bozkurt et al. 1999).

Zadeh (1965) first reported on a novel way of characterizing nonprobabilistic uncertainties, which he called “fuzzy sets”. The applications, which are multidisciplinary in nature, include automatic control, data classification, chemical processes, and so on (Alvarez et al. 1999). Fuzzy logic embodies the nature of human’s mind in some sense, as the conception of possibility and probability is truly underlined in this logic in contrast with the traditional Boolean logic. Hence, any studied object in fact, can be described as a fuzzy system. A fuzzy system is based on fuzzy set, fuzzy membership and fuzzy variable, the three basic concepts of fuzzy logic (Sun and Brosnan 2003).

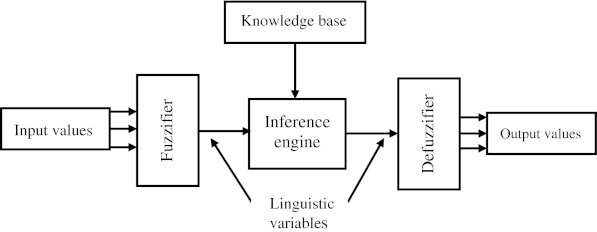

A fuzzy system consisting of a fuzzifier, a knowledge base (rule base), a fuzzy interference engine and defuzzifier has been considered (Fig. 1). The knowledge base of the fuzzy system is a collection of fuzzy IF-THEN rules. The term fuzzy logic denotes a modeling approach, where functional dependencies between the input and output variables are described by means of a set of IF-THEN rules following the reasoning with the operators AND, OR and NOT. The domain of both the input and output values is subdivided in the fuzzy sets according to technologically reasonable estimates. Fuzzification means that the degree of membership of a given crisp input value to its fuzzy sets is calculated. The fulfillment of the IF part, the premise, is calculated by fuzzy inference. The fuzzy sets and their combination by the operators AND, OR are used the standard models of minimum, maximum according to Eq. 1 and finally the fulfillment of the THEN part is calculated. Defuzzification ponders the several IF–THEN rules according to their degree of fulfillment, i.e., the degree of membership to the output sets and a crisp value is assigned to the output variable (Yalçın and Taşdemir 2007).

|

1 |

Fig. 1.

A block diagram of fuzzy logic controller with fuzzifier and defuzzifier

Use of fuzzy expert systems in the food processing industry has many advantages. It may reduce labour costs by eliminating labour-intensive tasks, provides a rapid, consistent and more accurate and objective results, may help when expert advise is needed but an expert may not be available and can help to support and verify human expert’s opinion. Fuzzy system is independent of human errors and can be used 24 h a day without a labour need. It can also operate in risky situations and under conditions unfit for human experts and can act quickly on the basis of huge databanks and knowledge banks (Hu et al. 1998; Linko 1998; Sun and Brosnan 2003; Du and Sun 2006).

In this study, effects of heat treatment on HMF occurrence in pekmez samples and some physical and chemical characteristics of them were determined. A new approach for HMF and other physical and chemical analysis with fuzzy system was developed. Then, fuzzy expert system (FES) was used for the determinations and analytical results were compared statistically with the results found by FES.

Material and methods

Chemicals and equipments

p-Toluidin and barbituric acid were obtained from Merck, Darmstadt, Germany. Nüve Instrument Model BM 302 (Ankara, Turkey) water bath was used for heating process. Viscosity measurements were carried out using AND Vibro Viscometer (SV-10, Oxfordshire, UK), pH meter (Santix 41 Electrode, WTW-315 ISET, Weilheim, Germany) was used for pH measurements, A chromameter (Minolta CR 400, Osaka, Japan), Refractometer (Atago Hand-Held HSR-500, Tokyo, Japan) and UV-vis spectrophotometer (Schimadzu 1240, Kyoto city, Japan) were used for colour, refractive index and HMF measurements, respectively.

Sample materials

Pekmez samples from grape, mulberry, carob, date and apricot were purchased from a local market. The samples were kept at +4°C till the analysis. Samples were withdrawn to room temperature (25°C) only before viscosity analysis.

Fuzzy system

The system was developed with the aid of using MATLAB 6.5 fuzzy logic toolbox in Windows XP running on Intel 2.4 Gh environment.

Heating process

The pekmez samples were kept in a water bath at room temperature (25°C-control), 55°C, 65°C and 75°C for 15, 25 and 35 min for each temperature condition. Before the heat treatments, some parts of untreated pekmez sample were separated as blanks and were named as crude samples. Heating was not applied to crude samples.

Physicochemical analysis

Viscosity values of samples were measured in triplicates and the mean values are reported. Colour (L*, a*, b*) determinations were carried out ten times for each sample. Total soluble solids (°Brix) and pH values were determined as per AOAC (2000) procedures.

HMF values in the pekmez samples were determined according to the Winkler method (Zappala et al. 2005). About 10 g of pekmez was dissolved in 20 ml water and transferred to a 50 ml volumetric flask. 2 ml of the solution and 5 ml of p-toluidin solution were put in two different test tubes. 1 ml of distilled water (blank) was added to one of the tubes and 1 ml of barbituric acid solution 0.5% (sample) was poured to the second one. The absorbance of solutions at 550 nm was determined by a spectrophotometer and the HMF values were calculated from the formula below:

|

Sensory analysis

The sensorial evaluation was done by untrained panelists (n = 35) with minor modifications to the methods applied in previous studies (Carpenter et al. 2000; Matsuda and Sabato 2004) using a 10—point scoring scale (color 0 “light” and 10 “dark”, odor 0 “weak” and 10 “strong”, taste 0 “low intense” and 10 “high intense” and consistency 0 “low viscosity” and 10 “high viscosity”).

Fuzzy analysis

Fuzzy sets were created with triangular and trapezoid membership functions; the defuzzification was carried out with centre of gravity method (centroid, COG). This method computes the center of area of the region under the curve defined by a fuzzy set and selects the first component. If C is the fuzzy set in question and C is integrable, then the defuzzified value of C by this method is Eq. 2, where [a, b] is an interval containing the support of C. This kind of defuzzification determines z* point as the middle of area (Nguyen et al. 2003; Dincer et al. 2008).

|

2 |

Numerical parameters of input and output variables were fuzzificated as linguistic variable as: very very high (L16), very high (L15), high (L14), little high (L13), few high (L12), a bit high (L11), very positive medium (L10), positive medium (L9), medium (L8), negative medium (L7), very negative medium (L6), low (L5), little low (L4), few low (L3), very low (L2) and too much low (L1).

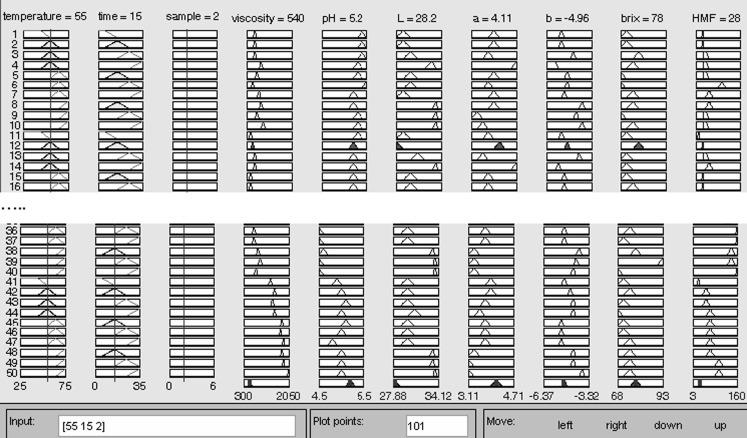

General structure of developed fuzzy expert system is shown in Fig. 2. The fuzzy membership functions for each of the three input variables, namely: temperature, time and sample are as shown in Fig. 2. For output variables viscosity, pH, °Brix, L*, a*, b* and HMF in pekmez samples were determined as shown in Fig. 2. For this system we obtained 50 rules with help of expert by these linguistic variables. Also Mamdani max–min inference was used for the inference mechanism (Table 1).

Fig. 2.

General structure of developed fuzzy expert system

Table 1.

Rules table

| Rule No | Samples | Temperature | Time | Viscosity | pH | L* | a* | b* | Brix | HMF | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | if | L1 | and | L5 | and | L5 | then | L4 | L14 | L4 | L8 | L4 | L4 | L6 |

| 2 | if | L1 | and | L8 | and | L8 | then | L4 | L14 | L4 | L8 | L4 | L4 | L6 |

| 3 | if | L1 | and | L8 | and | L14 | then | L4 | L14 | L5 | L7 | L9 | L7 | L7 |

| 4 | if | L1 | and | L8 | and | L16 | then | L7 | L13 | L9 | L15 | L2 | L5 | L7 |

| 5 | if | L1 | and | L14 | and | L8 | then | L5 | L13 | L5 | L6 | L7 | L2 | L7 |

| 6 | if | L1 | and | L14 | and | L14 | then | L3 | L15 | L5 | L7 | L7 | L2 | L11 |

| 7 | if | L1 | and | L14 | and | L16 | then | L6 | L10 | L4 | L8 | L5 | L5 | L8 |

| 8 | if | L1 | and | L16 | and | L8 | then | L7 | L10 | L13 | L8 | L13 | L5 | L8 |

| 9 | if | L1 | and | L16 | and | L14 | then | L5 | L13 | L13 | L4 | L10 | L2 | L7 |

| 10 | if | L1 | and | L16 | and | L16 | then | L8 | L13 | L13 | L5 | L13 | L5 | L7 |

| 11 | if | L5 | and | L5 | and | L5 | then | L2 | L13 | L4 | L7 | L4 | L4 | L3 |

| 12 | if | L5 | and | L8 | and | L8 | then | L3 | L10 | L2 | L9 | L7 | L7 | L6 |

| 13 | if | L5 | and | L8 | and | L14 | then | L4 | L10 | L7 | L5 | L12 | L4 | L7 |

| 14 | if | L5 | and | L8 | and | L16 | then | L4 | L10 | L13 | L15 | L3 | L4 | L8 |

| 15 | if | L5 | and | L14 | and | L8 | then | L2 | L10 | L5 | L7 | L5 | L4 | L6 |

| 16 | if | L5 | and | L14 | and | L14 | then | L2 | L10 | L5 | L7 | L5 | L5 | L6 |

| 17 | if | L5 | and | L14 | and | L16 | then | L4 | L9 | L4 | L7 | L4 | L5 | L8 |

| 18 | if | L5 | and | L16 | and | L8 | then | L5 | L9 | L9 | L4 | L10 | L5 | L6 |

| 19 | if | L5 | and | L16 | and | L14 | then | L6 | L9 | L9 | L2 | L10 | L5 | L7 |

| 20 | if | L5 | and | L16 | and | L16 | then | L9 | L9 | L13 | L4 | L12 | L4 | L8 |

| 21 | if | L8 | and | L5 | and | L5 | then | L3 | L15 | L4 | L8 | L5 | L4 | L5 |

| . . . . . . . . . . . . | ||||||||||||||

| . . . . . . . . . . . . | ||||||||||||||

Statistical program

For comparison of the effects of heat treatment on chemical and physical properties of samples and also for expressing the significant differences between the analytical and fuzzy system results, a statistical software SPSS (Version 13) was used.

Results and discussion

In terms of viscosity, apricot pekmez had the highest value (1618.1 mPas) followed by mulberry and date Pekmez (947.9 and 970.0 mPas), respectively and finally by grape (692.6 mPas) and carob (688.1 mPas) Pekmez, which had closer viscosity values (Table 2). Gradually an increase in viscosity values of apricot, grape, carob and mulberry Pekmez were obtained by the increase in temperature and duration of heating, but the viscosity values of date Pekmez were slightly affected by heating time as the difference in viscosity values of date Pekmez samples heated for 25 and 35 min were not significant as well as the difference between viscosity values of unheated and low time heated (15 min) samples.

Table 2.

Changes in physico-chemical characteristics of pekmez samples due to heat treatments

| Input parameters | Experımental results | Fuzzy results | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temp, °C | Time, min | Viscosity | pH | L* | a* | b* | °Brix | HMF | Viscosity | pH | L* | a* | b* | °Brix | HMF |

| Grape pekmez | |||||||||||||||

| Control | 0 | 581 ± 24 | 5.5 ± 0.02 | 29.1 ± 2.11 | 3.9 ± 0.14 | −5.4 ± 0.3 | 71.8 ± 11.0 | 28.8 ± 2.1 | 620 | 5.4 | 28.9 | 3.9 | −5.4 | 71.3 | 28.0 |

| 55 | 15 | 589 ± 33 | 5.4 ± 0.01 | 29.1 ± 2.05 | 3.9 ± 0.22 | −5.3 ± 0.4 | 72.0 ± 9.4 | 29.4 ± 3.0 | 620 | 5.4 | 28.9 | 3.9 | −5.4 | 71.3 | 28.0 |

| 55 | 25 | 607 ± 26 | 5.4 ± 0.01 | 29.7 ± 3.01 | 3.7 ± 0.10 | −4.6 ± 0.3 | 78.4 ± 8.8 | 37.0 ± 3.5 | 620 | 5.4 | 29.9 | 3.7 | −4.6 | 78.0 | 37.6 |

| 55 | 35 | 833 ± 39 | 5.3 ± 0.15 | 32.7 ± 1.22 | 4.7 ± 0.17 | −6.4 ± 0.5 | 73.6 ± 7.8 | 38.6 ± 2.9 | 860 | 5.3 | 32.7 | 4.6 | −6.0 | 74.7 | 37.6 |

| 65 | 15 | 686 ± 26 | 5.3 ± 0.02 | 29.8 ± 2.00 | 3.8 ± 0.11 | −5.1 ± 0.4 | 68.0 ± 8.1 | 40.2 ± 3.5 | 700 | 5.3 | 29.9 | 3.9 | −5.0 | 68.9 | 37.6 |

| 65 | 25 | 533 ± 38 | 5.5 ± 0.01 | 30.2 ± 3.64 | 3.7 ± 0.09 | −5.0 ± 0.3 | 68.0 ± 6.9 | 35.4 ± 2.7 | 540 | 5.5 | 29.9 | 3.7 | −5.0 | 68.9 | 95.0 |

| 65 | 35 | 763 ± 22 | 5.2 ± 0.01 | 29.0 ± 1.81 | 4.0 ± 0.25 | −5.2 ± 0.4 | 76.0 ± 7.8 | 43.5 ± 3.7 | 780 | 5.2 | 28.9 | 3.9 | −5.2 | 74.7 | 50.0 |

| 75 | 15 | 859 ± 37 | 5.2 ± 0.03 | 33.1 ± 3.31 | 3.8 ± 0.13 | −3.9 ± 0.3 | 73.5 ± 7.3 | 40.1 ± 3.0 | 860 | 5.2 | 33.3 | 3.9 | −4.0 | 74.7 | 50.0 |

| 75 | 25 | 726 ± 30 | 5.3 ± 0.01 | 33.5 ± 3.75 | 3.2 ± 0.09 | −4.3 ± 0.4 | 68.8 ± 9.3 | 35.1 ± 3.4 | 700 | 5.3 | 33.3 | 3.3 | −4.4 | 68.9 | 37.6 |

| 75 | 35 | 972 ± 47 | 5.3 ± 0.03 | 33.4 ± 2.94 | 3.6 ± 0.11 | −3.9 ± 0.3 | 75.6 ± 9.1 | 37.2 ± 3.1 | 940 | 5.3 | 33.3 | 3.5 | −4.0 | 74.7 | 37.6 |

| Mulberry pekmez | |||||||||||||||

| Control | 0 | 460 ± 19 | 5.3 ± 0.13 | 29.3 ± 1.62 | 3.7 ± 0.14 | −5.3 ± 0.4 | 70.0 ± 8.0 | 14.8 ± 2.0 | 460 | 5.3 | 28.9 | 3.7 | −5.4 | 71.3 | 13.0 |

| 55 | 15 | 540 ± 34 | 5.2 ± 0.02 | 27.9 ± 2.30 | 4.2 ± 0.08 | −5.0 ± 0.4 | 78.4 ± 8.5 | 28.6 ± 2.6 | 540 | 5.2 | 28.2 | 4.1 | −5.0 | 78.0 | 28.0 |

| 55 | 25 | 589 ± 44 | 5.2 ± 0.04 | 30.9 ± 2.92 | 3.6 ± 0.13 | −4.3 ± 0.3 | 72.8 ± 6.9 | 32.1 ± 3.1 | 620 | 5.2 | 30.9 | 3.5 | −4.2 | 71.3 | 37.6 |

| 55 | 35 | 648 ± 37 | 5.2 ± 0.01 | 33.5 ± 2.84 | 4.7 ± 0.06 | −5.6 ± 0.5 | 72.0 ± 7.4 | 43.5 ± 3.9 | 620 | 5.2 | 33.3 | 4.6 | −5.6 | 71.3 | 50.0 |

| 65 | 15 | 475 ± 35 | 5.2 ± 0.03 | 29.5 ± 1.86 | 3.7 ± 0.14 | −5.2 ± 0.4 | 72.0 ± 8.2 | 31.6 ± 3.1 | 460 | 5.2 | 29.9 | 3.7 | −5.2 | 71.3 | 28.0 |

| 65 | 25 | 487 ± 51 | 5.2 ± 0.11 | 29.9 ± 1.02 | 3.7 ± 0.10 | −5.1 ± 0.5 | 76.0 ± 9.3 | 30.7 ± 3.2 | 460 | 5.2 | 29.9 | 3.7 | −5.2 | 74.7 | 28.0 |

| 65 | 35 | 583 ± 31 | 5.1 ± 0.02 | 29.1 ± 2.64 | 3.8 ± 0.16 | −5.3 ± 0.5 | 76.0 ± 8.7 | 43.2 ± 4.0 | 620 | 5.1 | 28.9 | 3.7 | −5.4 | 74.7 | 50.0 |

| 75 | 15 | 718 ± 47 | 5.1 ± 0.02 | 32.9 ± 1.67 | 3.3 ± 0.07 | −4.3 ± 0.4 | 76.0 ± 7.4 | 30.9 ± 3.2 | 700 | 5.1 | 32.7 | 3.3 | −4.4 | 74.7 | 28.0 |

| 75 | 25 | 815 ± 67 | 5.1 ± 0.04 | 32.9 ± 4.02 | 3.2 ± 0.10 | −4.3 ± 0.4 | 74.4 ± 7.7 | 33.2 ± 3.3 | 780 | 5.1 | 32.7 | 3.2 | −4.4 | 74.7 | 37.6 |

| 75 | 35 | 1,070 ± 91 | 5.1 ± 0.01 | 33.4 ± 2.55 | 3.3 ± 0.31 | −4.1 ± 0.3 | 72.0 ± 6.8 | 44.4 ± 3.8 | 1,020 | 5.1 | 33.3 | 3.3 | −4.2 | 71.3 | 50.0 |

| Carob pekmez | |||||||||||||||

| Control | 0 | 534 ± 19 | 5.5 ± 0.01 | 29.2 ± 2.67 | 3.8 ± 0.12 | −5.2 ± 0.5 | 71.0 ± 16.0 | 25.3 ± 1.12 | 540 | 5.5 | 28.9 | 3.9 | −5.2 | 71.3 | 23.0 |

| 55 | 15 | 640 ± 33 | 5.5 ± 0.03 | 29.9 ± 1.84 | 3.8 ± 0.34 | −4.4 ± 0.4 | 73.6 ± 9.12 | 7.4 ± 0.15 | 620 | 5.5 | 29.9 | 3.7 | −4.2 | 74.7 | 8.1 |

| 55 | 25 | 729 ± 47 | 5.5 ± 0.01 | 30.4 ± 2.99 | 3.6 ± 0.23 | −4.3 ± 0.1 | 72.0 ± 7.33 | 3.3 ± 0.53 | 700 | 5.5 | 30.9 | 3.7 | −4.2 | 71.3 | 4.2 |

| 55 | 35 | 932 ± 76 | 5.5 ± 0.01 | 33.8 ± 1.26 | 3.3 ± 0.44 | −3.3 ± 0.7 | 80.0 ± 10.03 | 5.4 ± 0.67 | 940 | 5.5 | 33.7 | 3.3 | −3.5 | 81.0 | 4.2 |

| 65 | 15 | 685 ± 58 | 5.4 ± 0.02 | 30.4 ± 0.93 | 3.8 ± 0.09 | −4.8 ± 0.4 | 76.8 ± 9.44 | 12.3 ± 2.30 | 700 | 5.4 | 29.9 | 3.7 | −4.8 | 78.0 | 13.0 |

| 65 | 25 | 641 ± 32 | 5.4 ± 0.02 | 30.4 ± 2.51 | 3.9 ± 0.11 | −4.7 ± 0.4 | 68.0 ± 13.02 | 4.4 ± 0.31 | 620 | 5.4 | 30.9 | 3.9 | −4.8 | 68.9 | 4.2 |

| 65 | 35 | 711 ± 73 | 5.4 ± 0.01 | 29.6 ± 1.07 | 3.8 ± 0.34 | −5.1 ± 0.3 | 72.0 ± 17.05 | 7.5 ± 0.60 | 700 | 5.4 | 29.9 | 3.9 | −5.0 | 71.3 | 8.0 |

| 75 | 15 | 814 ± 59 | 5.4 ± 0.01 | 33.6 ± 3.03 | 3.5 ± 0.10 | −3.5 ± 0.2 | 72.8 ± 9.9 | 9.6 ± 1.17 | 780 | 5.4 | 33.7 | 3.5 | −3.8 | 71.3 | 8.0 |

| 75 | 25 | 944 ± 76 | 5.3 ± 0.04 | 34.1 ± 2.53 | 3.4 ± 0.26 | −3.8 ± 0.1 | 76.0 ± 7.8 | 5.6 ± 0.81 | 940 | 5.3 | 34.0 | 3.3 | −3.8 | 74.7 | 8.0 |

| 75 | 35 | 995 ± 33 | 5.4 ± 0.12 | 34.0 ± 0.97 | 3.4 ± 0.15 | −4.0 ± 0.5 | 80.0 ± 8.4 | 7.9 ± 0.52 | 1,020 | 5.3 | 34.0 | 3.3 | −4.0 | 81.0 | 8.0 |

| Date pekmez | |||||||||||||||

| Control | 0 | 703 ± 70 | 4.6 ± 0.03 | 28.9 ± 1.14 | 4.0 ± 0.25 | −4.7 ± 0.4 | 70.0 ± 8.6 | 99.4 ± 12.01 | 700 | 4.6 | 28.9 | 3.9 | −4.8 | 71.3 | 95.0 |

| 55 | 15 | 491 ± 46 | 4.7 ± 0.02 | 30.7 ± 1.25 | 3.6 ± 0.10 | −4.3 ± 0.3 | 71.0 ± 9.3 | 107.7 ± 10.33 | 460 | 4.7 | 30.9 | 3.5 | −4.4 | 71.3 | 110.0 |

| 55 | 25 | 519 ± 35 | 4.6 ± 0.01 | 30.3 ± 2.31 | 3.6 ± 0.21 | −4.4 ± 0.4 | 72.4 ± 7.8 | 133.3 ± 14.21 | 540 | 4.6 | 29.9 | 3.7 | −4.4 | 71.3 | 140.0 |

| 55 | 35 | 617 ± 36 | 4.6 ± 0.02 | 31.0 ± 1.45 | 3.6 ± 0.31 | −4.2 ± 0.4 | 74.8 ± 8.4 | 155.4 ± 17.28 | 620 | 4.6 | 30.9 | 3.5 | −4.2 | 74.7 | 152.0 |

| 65 | 15 | 770 ± 28 | 4.5 ± 0.03 | 30.1 ± 1.05 | 3.8 ± 0.23 | −5.0 ± 0.5 | 72.0 ± 9.0 | 120.2 ± 13.88 | 780 | 4.5 | 29.9 | 3.7 | −5.0 | 71.3 | 125.0 |

| 65 | 25 | 695 ± 42 | 4.5 ± 0.12 | 30.1 ± 2.24 | 3.7 ± 0.18 | −5.1 ± 0.4 | 75.6 ± 8.7 | 159.0 ± 15.67 | 700 | 4.5 | 29.9 | 3.7 | −5.0 | 74.7 | 159.0 |

| 65 | 35 | 707 ± 15 | 4.5 ± 0.01 | 30.0 ± 1.77 | 3.7 ± 0.41 | −5.1 ± 0.5 | 70.0 ± 8.5 | 159.7 ± 12.82 | 700 | 4.5 | 29.9 | 3.7 | −5.0 | 71.3 | 159.0 |

| 75 | 15 | 835 ± 45 | 4.6 ± 0.03 | 33.2 ± 2.45 | 3.4 ± 0.11 | −4.0 ± 0.4 | 78.0 ± 7.8 | 139.2 ± 11.24 | 860 | 4.6 | 33.3 | 3.3 | −4.0 | 78.0 | 140.0 |

| 75 | 25 | 918 ± 21 | 4.5 ± 0.01 | 33.5 ± 1.36 | 3.3 ± 0.23 | −4.2 ± 0.4 | 92.8 ± 9.3 | 146.6 ± 10.35 | 940 | 4.5 | 33.7 | 3.3 | −4.2 | 92.1 | 140.0 |

| 75 | 35 | 800 ± 28 | 4.5 ± 0.01 | 33.7 ± 1.80 | 3.3 ± 0.16 | −4.4 ± 0.3 | 68.0 ± 7.2 | 158.9 ± 15.09 | 780 | 4.5 | 33.7 | 3.3 | −4.4 | 68.9 | 159.0 |

| Apricot pekmez | |||||||||||||||

| Control | 0 | 1,340 ± 52 | 4.9 ± 0.02 | 29.8 ± 0.85 | 3.8 ± 0.25 | −4.9 ± 0.4 | 72.8 ± 7.0 | 22.3 ± 2.1 | 1,340 | 4.9 | 29.9 | 3.9 | −5.0 | 71.3 | 23.0 |

| 55 | 15 | 1,470 ± 49 | 5.0 ± 0.14 | 29.4 ± 1.43 | 3.9 ± 0.10 | −4.6 ± 0.4 | 75.2 ± 8.3 | 49.5 ± 4.3 | 1,500 | 5.0 | 29.9 | 3.9 | −4.6 | 74.7 | 50.0 |

| 55 | 25 | 1,420 ± 58 | 5.1 ± 0.02 | 30.3 ± 1.62 | 3.6 ± 0.15 | −4.4 ± 0.3 | 72.0 ± 9.1 | 51.8 ± 4.8 | 1,420 | 5.1 | 29.9 | 3.7 | −4.4 | 71.3 | 50.0 |

| 55 | 35 | 1,500 ± 76 | 5.0 ± 0.02 | 30.4 ± 1.00 | 3.6 ± 0.11 | −4.4 ± 0.4 | 68.8 ± 7.2 | 67.3 ± 5.2 | 1,500 | 5.0 | 30.9 | 3.5 | −4.4 | 68.9 | 65.0 |

| 65 | 15 | 1,790 ± 73 | 5.1 ± 0.01 | 29.7 ± 2.17 | 3.7 ± 0.14 | −5.2 ± 0.5 | 72.0 ± 7.7 | 60.1 ± 4.9 | 1,790 | 5.1 | 29.9 | 3.7 | −5.2 | 71.3 | 65.0 |

| 65 | 25 | 1,730 ± 64 | 5.0 ± 0.02 | 29.8 ± 1.55 | 3.7 ± 0.15 | −5.1 ± 0.5 | 72.0 ± 8.1 | 61.8 ± 5.5 | 1,730 | 5.0 | 29.9 | 3.7 | −5.2 | 71.3 | 65.0 |

| 65 | 35 | 1,820 ± 49 | 4.8 ± 0.02 | 29.7 ± 1.62 | 3.6 ± 0.07 | −5.1 ± 0.4 | 74.4 ± 8.3 | 61.1 ± 5.8 | 1,850 | 4.8 | 29.9 | 3.7 | −5.2 | 74.7 | 65.0 |

| 75 | 15 | 1,770 ± 65 | 5.0 ± 0.04 | 33.3 ± 0.85 | 3.2 ± 0.05 | −4.3 ± 0.4 | 76.0 ± 7.9 | 61.8 ± 4.7 | 1,790 | 5.0 | 33.3 | 3.3 | −4.4 | 74.7 | 65.0 |

| 75 | 25 | 1,840 ± 49 | 5.0 ± 0.01 | 33.5 ± 1.21 | 3.2 ± 0.10 | −4.4 ± 0.3 | 74.4 ± 8.1 | 90.8 ± 7.8 | 1,850 | 5.0 | 33.3 | 3.2 | −4.4 | 74.7 | 95.0 |

| 75 | 35 | 2,050 ± 87 | 5.0 ± 0.12 | 33.6 ± 3.11 | 3.1 ± 0.11 | −3.9 ± 0.3 | 75.2 ± 8.4 | 90.0 ± 8.2 | 2,040 | 5.0 | 33.7 | 3.2 | −3.8 | 74.7 | 95.0 |

pH values were similar in grape, mulberry, carob and apricot Pekmez (from 5.0 to 5.1) while date Pekmez had lower pH value (4.8) than the values of other samples. All unheated Pekmez samples had higher pH values than the values of heated samples. pH values gradually decreased by the increase in temperature and duration. But pH values of apricot and date Pekmez samples were not significantly affected by the heating time. Şengül et al. (2007) reported the pH values of commercial carob and mulberry Pekmez as 5.1 and 5.2, respectively. These values are higher than those obtained in this study.

Pekmez samples heated at 75°C showed highest L* values, followed by the samples heated at 55°C, but the lowest L* values were measured at 65°C. L* values of all the Pekmez samples were similar (30.6–30.8) except carob Pekmez, which had higher L* values (mean 31.1) than others. The lower the L* values mean darker the colour of samples. Increasing duration of heat treatment did not show significant differences between the L* values of date and apricot Pekmez samples, but the L* values of the rest of the samples increased with longer duration of heat treatment. Grape Pekmez showed the highest a* value (mean 3.8), apricot Pekmez showed the lowest (mean 3.6); while mulberry, carob and date Pekmez showed similar a* values (3.6–3.7); a* values of mulberry, apricot and grape Pekmez increased when the samples were treated at higher temperatures. But, a* values of date and carob Pekmez did not change gradually with the temperature increase. The unheated samples of apricot, date and carob Pekmez had the lowest a* values and these values showed an increase when heating duration increased. However, a* values of mulberry and grape Pekmez did not show a proportional change with increasing time of heating. Grape and mulberry (−5.0) Pekmez had lower b* values than the values of carob (−4.4), date (−4.6) and apricot (−4.7). High heating temperatures (75°C) revealed higher b* values for all the Pekmez samples. Also, the unheated samples had lower b* values than the heated samples. The heating time did not cause sharp changes in b* values. A high redness (a) value is not desired in Pekmez as it occurs as a result of caramelization of sugars at high temperatures or Maillard reaction which occurs between amino acids and reducing sugars present. Therefore, a low redness (a*) and a high brightness (L*) values indicate a good quality Pekmez (Yoğurtçu and Kamışlı 2006; Şengül et al. 2007).

After heat treatments, apricot (mean 73.2) and mulberry (mean 70.7) Pekmez had the highest soluble dry matter (°Brix), followed by date (mean 69.2) and grape (mean 66.2) Pekmez and the lowest °Brix value was with carob Pekmez (mean 65.0). The sharpest increase in °Brix value by heating was obtained in date pekmez (70.0–80.3) while there was not a significant increase in °Brix value of apricot pekmez (72.8–74.4).

HMF formation after heat treatment was at the highest level in date pekmez (99.4–158.0 mg/kg) and in apricot pekmez (22.3–72.8 mg/kg). The HMF concentration was very high even in unheated date pekmez (99.4 mg/kg). Mulberry, carob, apricot and pekmez samples had the lowest starting value (14.8, 25.3 and 22.3 mg/kg, respectively) in terms of HMF. HMF concentration of all the pekmez samples increased by heat treatment as expected as for example the samples heated at 75°C and heated for longer time showed the highest HMF values. The high HMF content of date pekmez may be attributed to its lower pH than the other pekmez samples. Hase et al. (1973) and Fallico et al. (2004) reported that honey of low pH value produced more HMF by heating. In the Turkish Pekmez Standard, maximum HMF content shall not be more than 25 mg/kg (Anon 1989). All the heated pekmez samples had higher HMF concentrations exceeding this limit, except for heated carob pekmez samples.

Effect of temperature and heating time was noticed by the panelists only from the consistency point of view (Table 3). Apricot and date pekmez had higher scores for odour, taste and consistency than the other pekmez samples. Carob pekmez had the lowest scores for all the attributes analyzed, followed by grape pekmez. Unheated grape pekmez had higher colour scores than heated samples. Grape pekmez samples heated for longer time (35 min) had lower scores than the samples heated for 15 and 25 min as well as unheated samples. Unheated carob, apricot and date pekmez got lower consistency scores than heated samples while there were not significant differences between the consistency scores of unheated and heated grape and mulberry samples. The panelists noticed differences between the unheated and heated date pekmez samples regarding the odour characteristics. The unheated samples got higher odour scores than the heated samples. But unheated date pekmez had lower colour scores than the heated samples.

Table 3.

Changes in sensory quality attributes of pekmez samples due to heat treatments (n = 35)

| Temp, °C | Time, min | Colour | Odour | Consistency | Taste |

|---|---|---|---|---|---|

| Grape Pekmez | |||||

| Control | 0 | 8 | 6 | 6 | 7 |

| 55 | 15 | 8 | 7 | 6 | 6 |

| 25 | 8 | 7 | 6 | 6 | |

| 35 | 8 | 6 | 8 | 5 | |

| 65 | 15 | 7 | 7 | 7 | 7 |

| 25 | 8 | 6 | 7 | 7 | |

| 35 | 6 | 6 | 7 | 4 | |

| 75 | 15 | 7 | 6 | 7 | 6 |

| 25 | 9 | 6 | 7 | 7 | |

| 35 | 7 | 6 | 7 | 6 | |

| Mulberry Pekmez | |||||

| Control | 0 | 7 | 7 | 5 | 8 |

| 55 | 15 | 8 | 7 | 6 | 7 |

| 25 | 8 | 7 | 6 | 8 | |

| 35 | 8 | 7 | 6 | 7 | |

| 65 | 15 | 6 | 6 | 5 | 5 |

| 25 | 8 | 8 | 6 | 6 | |

| 35 | 7 | 7 | 6 | 7 | |

| 75 | 15 | 7 | 7 | 7 | 8 |

| 25 | 7 | 8 | 6 | 6 | |

| 35 | 7 | 7 | 7 | 8 | |

| Carob Pekmez | |||||

| Control | 0 | 7 | 6 | 5 | 7 |

| 55 | 15 | 7 | 6 | 8 | 7 |

| 25 | 7 | 6 | 6 | 7 | |

| 35 | 7 | 6 | 7 | 6 | |

| 65 | 15 | 8 | 6 | 5 | 6 |

| 25 | 7 | 7 | 6 | 7 | |

| 35 | 7 | 7 | 5 | 7 | |

| 75 | 15 | 8 | 6 | 6 | 6 |

| 25 | 8 | 7 | 8 | 7 | |

| 35 | 7 | 7 | 8 | 7 | |

| Date Pekmez | |||||

| Control | 0 | 6 | 8 | 7 | 7 |

| 55 | 15 | 8 | 7 | 6 | 7 |

| 25 | 8 | 7 | 6 | 7 | |

| 35 | 7 | 7 | 7 | 8 | |

| 65 | 15 | 8 | 7 | 8 | 8 |

| 25 | 7 | 7 | 8 | 8 | |

| 35 | 8 | 7 | 7 | 8 | |

| 75 | 15 | 7 | 7 | 8 | 8 |

| 25 | 7 | 6 | 6 | 7 | |

| 35 | 8 | 7 | 6 | 8 | |

| Apricot Pekmez | |||||

| Control | 0 | 8 | 7 | 6 | 7 |

| 55 | 15 | 8 | 7 | 8 | 7 |

| 25 | 8 | 7 | 7 | 8 | |

| 35 | 8 | 7 | 7 | 7 | |

| 65 | 15 | 8 | 7 | 6 | 7 |

| 25 | 8 | 7 | 7 | 7 | |

| 35 | 8 | 7 | 7 | 7 | |

| 75 | 15 | 8 | 7 | 9 | 7 |

| 25 | 8 | 7 | 7 | 8 | |

| 35 | 8 | 6 | 9 | 8 | |

Fuzzy Logic (FL) system was developed for the prediction of some physicochemical characteristics (viscosity, pH, L*, a*, b*, °Brix and HMF). There is no significant difference with experimental and FES results when compared by using independent t test (p > 0.05) (Table 4). Taking all results into consideration, it is rendered that sensitive results may be achieved through the modeling made with FL method in determination of physicochemical characteristics of pekmez species and that the method may be adapted to experimental studies performed with the analysis in laboratory.

Table 4.

Independent sample t test

| t-test for equality of means | ||||||||

|---|---|---|---|---|---|---|---|---|

| t | df | Sig. (2-tailed) | Mean difference | Std. error difference | 95% confidence interval of the difference | |||

| Lower | Upper | |||||||

| Viscosity | FES - EXP. | −,006 | 98 | ,995 | −,52000 | 85,57646 | −170,34370 | 169,30370 |

| pH | FES - EXP. | ,003 | 98 | ,997 | ,00020 | ,06226 | −,12335 | ,12375 |

| L* | FES - EXP. | ,009 | 98 | ,993 | ,00320 | ,36888 | −,72883 | ,73523 |

| a* | FES - EXP. | −,100 | 98 | ,920 | −,00640 | ,06394 | −,13329 | ,12049 |

| b* | FES - EXP. | −,110 | 98 | ,945 | −,00800 | ,11464 | −,23550 | ,21950 |

| °Brix | FES - EXP. | ,234 | 98 | ,816 | ,19000 | ,81331 | −1,42400 | 1,80400 |

| HMF | FES - EXP. | −,070 | 98 | ,913 | −1,03460 | 9,43042 | −19,74895 | 17,67975 |

If this system is applied for temperature = 55°C, time = 15 min and mulberry pekmez then the viscosity, pH, L*, a*, b*, °Brix, and HMF values can be predicted. For this position, rule 12 was applied. Mamdani max-min approach was applied as an inference engine.

With the fuzzy sets defined, it is now possible to associate the fuzzy sets in the form of fuzzy rules. When there are three inputs and seven outputs, it is easy to visualize the associations in the form of a table, called a fuzzy associative memory or decision table. For this system, we can obtain such a table as shown Table 1. Knowledge base of the FES has 50 rules and some of these rules are given in Table 1. Also for different input values multiple rules can be applied.

Then we can calculate the crisp output. The crisp value of the viscosity, pH, L*, a*, b*, °Brix and HMF were calculated by the method COG defuzzifier by the Eq. 2. The crisp results calculated were, viscosity = 540, pH = 5.2, L* = 28.2, a* = 4.11, b* = −4.96, °Brix = 78, HMF = 28. Matlab 6.5 Fuzzy logic Toolbox is used for this calculation and calculated result is shown in Fig. 3.

Fig. 3.

Viscosity, pH, L, a, b, °Brix and hydroxymethyl furfural with centroid defuzzification

Conclusion

Heat treatment (temperature and heating duration) generally affected all the physicochemical properties of pekmez samples. In some samples, temperatures were more effective than the heating time. But in some, no differences were observed as a result of the chemical composition. HMF values were increased by increasing time and temperature. So, it can be concluded that heat treatment affects the important quality characteristics of pekmez. On the other hand, the experimental results and the results determined by FES, were similar and this provides several advantages. The main advantage is possibility of prediction of unknown sub-values, which are not studied in the experiment. This approach is a simple way (mathematical functions are easy to implement) to integrate operator reasoning whenever the operator is involved in measurement. Also, this study may base other studies in related subject and further studies may be focused on different parameters. This system can be developed further with adding intelligence system (neural network, genetic algorithm).

References

- Acevedo N, Schebor C, Buera MP. Water-solids interactions, matrix structural properties and rate of non-enzymatic browning. J Food Eng. 2005;77:1108–1115. doi: 10.1016/j.jfoodeng.2005.08.045. [DOI] [Google Scholar]

- Alvarez E, Cancela MA, Correa JM, Navaza JM, Riverol C. Fuzzy logic control for the isomerized hop pellets production. J Food Eng. 1999;39:145–150. doi: 10.1016/S0260-8774(98)00153-8. [DOI] [Google Scholar]

- Anon (1989) Standart of grape Pekmez. TSE 3792. Institute of Turkish Standarts, Ankara-Turkey

- Official methods of analysis. 17. Washington DC: Association of Official Agricultural Chemists; 2000. [Google Scholar]

- Arslan E, Yener ME, Esin A. Rheological characterization of tahin/pekmez (sesame paste/concentrated grape juice) blends. J Food Eng. 2005;69:167–172. doi: 10.1016/j.jfoodeng.2004.08.010. [DOI] [Google Scholar]

- Bozkurt H, Göğüş F, Eren S. Nonenzymic browning reactions in boiled grape juice and its models during storage. Food Chem. 1999;64:89–93. doi: 10.1016/S0308-8146(98)00081-8. [DOI] [Google Scholar]

- Carpenter RP, Lyon DH, Hasdell TA. Guidelines for sensory analysis in food product development and auality control. Maryland: Apsen Publ. Inc; 2000. p. 212. [Google Scholar]

- Dincer K, Taşdemir Ş, Başkaya Ş, Üçgül İ, Uysal BZ. Fuzzy modeling of performance of counter-flow ranque-hilsch vortex tubes with different geometric constructions. Numerical Heat Transfer. Part B: Fundamentals. 2008;54:499–517. doi: 10.1080/10407790802483432. [DOI] [Google Scholar]

- Du CJ, Sun DW. Learning techniques used in computer vision for food quality evaluation. J Food Eng. 2006;72:39–55. doi: 10.1016/j.jfoodeng.2004.11.017. [DOI] [Google Scholar]

- Fallico B, Zappala M, Arena E, Verzera A. Effects of conditioning on HMF content in unifloral honeys. Food Chem. 2004;85:305–331. doi: 10.1016/j.foodchem.2003.07.010. [DOI] [Google Scholar]

- Hase S, Suzuki O, Odate M, Suzuki S. Changes in quality of honey on heating and storage. I. Changes in hydroxymethylfurfural (HMF) content of honey. J Food Sci Technol. 1973;20:248–256. [Google Scholar]

- Hu BG, Gosine RG, Cao LX, Silva CW. Application of a fuzzy classification technique in computer grading of fish products. IEEE Trans Fuzzy Syst. 1998;6:144–152. doi: 10.1109/91.660814. [DOI] [Google Scholar]

- Linko S. Expert systems—what can they do for the food industry? Tr Food Sci Technol. 1998;9:3–12. doi: 10.1016/S0924-2244(97)00002-2. [DOI] [Google Scholar]

- Matsuda AH, Sabato SF. Effect of irradiation on Brazilian honey’s consistency and their acceptability. Radiation Physics Chem. 2004;71:107–110. [Google Scholar]

- Nguyen HT, Prasad NR, Walker CL, Walker EA. Fuzzy logic for control. A first course in fuzzy and neural control. Florida: Chapman & Hall; 2003. pp. 85–128. [Google Scholar]

- Şengül M, Ertugay MF, Şengül M, Yüksel Y. Rheological characteristics of carob pekmez. Int J Food Prop. 2007;10:39–46. doi: 10.1080/10942910600627996. [DOI] [Google Scholar]

- Şimşek A, Poyrazoğlu ES, Karacan S, Velioğlu YS. Response surface methodological study on HMF and fluorescent accumulation in red and white grape juices and concentrates. Food Chem. 2007;101:987–994. doi: 10.1016/j.foodchem.2006.02.051. [DOI] [Google Scholar]

- Sun DW, Brosnan T. Pizza quality evaluation using computer vision—Part 1. Pizza base and sauce spread. J Food Eng. 2003;57:81–89. doi: 10.1016/S0260-8774(02)00275-3. [DOI] [Google Scholar]

- Yalçın H, Taşdemir Ş. Fuzzy expert system approach for determination of α-linoleic acid content of eggs obtained from hens by dietary flaxseed. Food Sci Technol Int. 2007;13:217–223. [Google Scholar]

- Yoğurtçu H, Kamışlı F. Determination of rheological properties of some pekmez samples in Turkey. J Food Eng. 2006;77:1064–1068. doi: 10.1016/j.jfoodeng.2005.08.036. [DOI] [Google Scholar]

- Zadeh L. Fuzzy sets. Information and Control. 1965;8:338–353. doi: 10.1016/S0019-9958(65)90241-X. [DOI] [Google Scholar]

- Zappala M, Fallico B, Arena E, Verzera A. Methods of determination of HMF in honey: a comparison. Food Control. 2005;16:273–277. doi: 10.1016/j.foodcont.2004.03.006. [DOI] [Google Scholar]