Abstract

Mn modified rhombohedral Pb(In0.5Nb0.5)O3-Pb(Mg1/3Nb2/3)O3-PbTiO3 (PIN-PMN-PT:Mn) single crystals poled along [011]C crystallographic direction exhibit a “2R” engineered domain configuration, with macroscopic mm2 symmetry. The complete sets of material constants were determined using combined resonance and ultrasonic methods, and compared to [001]C poled PIN-PMN-PT:Mn crystals. The thickness shear piezoelectric coefficient d15 and electromechanical coupling factor k15 were found to be on the order of ∼3000 pC/N and 0.92, respectively, with longitudinal piezoelectric coefficient d33 and coupling factor k33 being on the order of ∼1050 pC/N and 0.90. Of particular importance is that PIN-PMN-PT:Mn single crystals exhibited high mechanical quality factor Q33 ∼ 1000, comparable to “hard” PZT8 ceramics, which can also be confirmed by the low extrinsic contribution, being ≤2% from the Rayleigh analysis.

INTRODUCTION

Relaxor-based single crystals, such as Pb(Mg1/3Nb2/3) O3-PbTiO3 (PMN-PT), have attracted much attention over the past decades owing to their ultrahigh piezoelectric coefficients (d33 > 1500 pC/N) and electromechanical coupling factors (k33 ∼ 0.90).1, 2, 3, 4, 5, 6 However, the relatively low rhombohedral to tetragonal phase transition temperatures (TRT ∼ 60–95 °C) and Curie temperatures (TC ∼ 130–170 °C) of PMN-PT limit their usage temperature range. Pb(In0.5Nb0.5) O3-Pb(Mg1/3Nb2/3)O3-PbTiO3 (PIN-PMN-PT) based ternary single crystals have been reported to have TRT more than 30 °C higher than that of PMN-PT, with comparable piezoelectric coefficients (d33 > 1500 pC/N) and electromechanical coupling factors (k33 ∼ 0.90). In addition, the coercive fields EC were found to be around 5 kV/cm, twice of the binary PMN-PT crystals, offering much higher field stability and larger electric field operating range.7, 8, 9, 10

Both PMN-PT and PIN-PMN-PT single crystals show low mechanical quality factors Qm ∼ 100, which restricted their applications for high power transducers. Analogous to modified “hard” lead zirconate titanate (PZT) ceramics, it is expected that acceptor dopants, such as Mn2+,3+, can improve the mechanical quality factor by the formation of acceptor-oxygen vacancy defect dipoles.11, 12 Recently, manganese modified relaxor-PT crystals have been reported to exhibit enhanced mechanical quality factors Qm and increased field stability.13, 14 To date, however, the full matrix of electromechanical properties for rhombohedral PIN-PMN-PT:Mn single crystals has not been measured and the effect of Mn2+,3+ on relaxor-PT crystals is still not fully understood.

In this paper, the complete set of material constants was determined for [011]C poled rhombohedral PIN-PMN-PT: Mn crystals with two different compositions. The mechanical quality factors Qm were evaluated for various vibration modes. Polarization and unipolar strain under high field were studied as a function of electric field. In addition, the intrinsic and extrinsic contributions to the longitudinal piezoelectric response were evaluated using Rayleigh analysis.

EXPERIMENTAL

Mn modified PIN-PMN-PT single crystals with a nominal starting composition of 0.26PIN-0.42PMN-0.32PT were grown using the modified Bridgman technique. The doped level of Mn was in the range of 1–5 mol. %. The as grown PIN-PMN-PT:Mn crystals were found to exhibit different phases along the growth direction due to the segregation of Ti. In this work, two sections of rhombohedral crystal were studied. Part A was compositionally far away from the nominal morphotropic phase boundary (MPB) with low PT, while part B was in close proximity to MPB composition with high PT. All samples were oriented by real-time Laue X-ray orientation system with an accuracy of 0.5°. Vacuum sputtered gold was applied to the desired surfaces as electrodes. The samples were poled at a dc electric field of 10 kV/cm at room temperature. For the [011]C poled crystals, the macroscopic symmetry is orthorhombic mm2, so there are 17 independent material constants: 9 elastic constants, 5 piezoelectric constants, and 3 dielectric permittivities. According to the IEEE standards on piezoelectricity,15 the pseudo-cubic crystallographic C direction is defined as the X axis, and [100]C, [011]C are defined as the Y and Z axes, respectively. The complete set of material constants was determined by combined resonance and ultrasonic methods. The resonance and antiresonance frequencies were measured using an HP4194A impedance-phase gain analyzer.16 Longitudinal and shear wave transducers were used to measure the phase velocities on cube samples with the dimensions of 5.0 × 5.0 × 5.0 mm3, from which, corresponding elastic stiffness constants: , , , , , , , and could be calculated. The temperature dependence of the dielectric permittivity was determined on kt type samples using HP4284A precision LCR meter at 1 kHz and 10 kHz, which were connected to a computer controlled high temperature furnace. Polarization and strain under high electric field were determined using a modified Sawyer-Tower circuit and linear variable differential transducer (LVDT) driven by a lock-in amplifier (Stanford Research system, Mode SR830). The Rayleigh analysis was performed on longitudinal bars using the same system.

RESULTS AND DISCUSSION

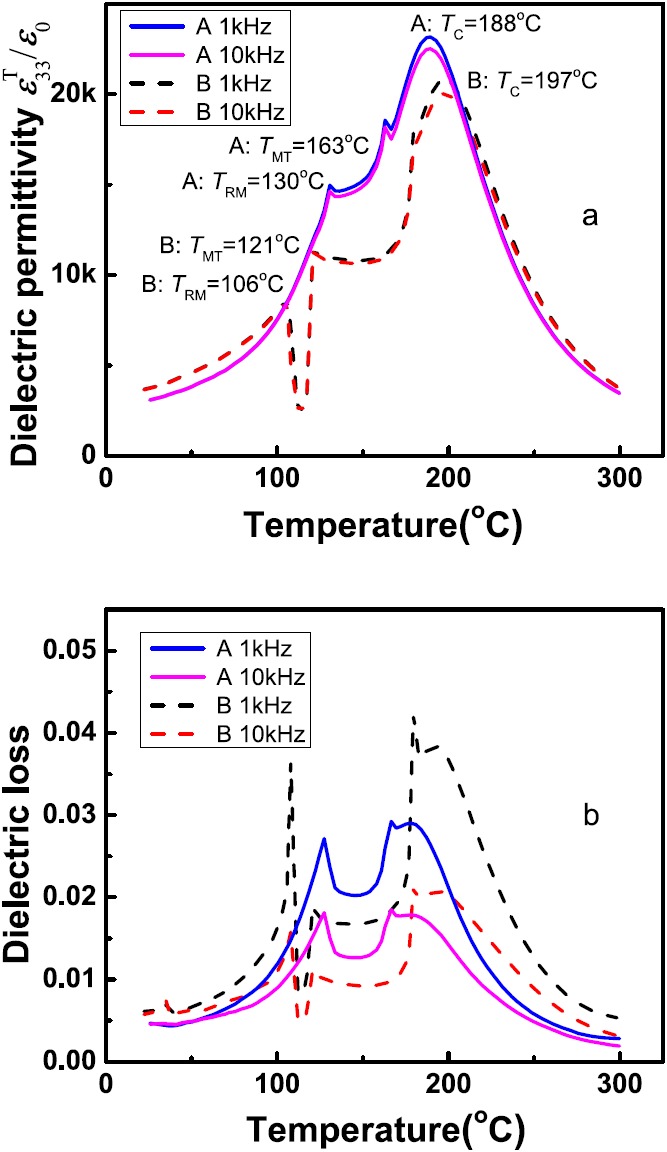

Fig. 1a shows the temperature dependence of dielectric permittivity and dielectric loss for two compositions of rhombohedral PIN-PMN-PT:Mn single crystals. The dielectric permittivity at room temperature was found to increase with increasing PT, due to the composition approaching to MPB. The Curie temperature of composition B was found to be ∼197 °C, while the Curie temperature of composition A was found to be ∼188 °C. For composition A, rhombohedral-monoclinic (TRM) and monoclinic-tetragonal (TMT) phase transitions were found to be ∼130 °C and 163 °C, respectively, while for composition B, TRM and TMT phase transitions were found to be ∼106 °C and 121 °C, respectively. The dielectric loss for PIN-PMN-PT:Mn single crystals exhibited peak values at the associated phase transitions, as given in Fig. 1b.

Figure 1.

Dielectric permittivity (a) and dielectric loss (b) as a function of temperature for [011]C poled rhombohedral PIN-PMN-PT:Mn single crystals.

Fig. 2 shows the polarization hysteresis loops for the two compositions of PIN-PMN-PT:Mn single crystals measured at 1 Hz. The remnant polarization for composition B was found to be on the order of 0.42 C/m2, slightly higher than that of composition A, which was 0.39 C/m2, while the coercive fields were found to be 5.1 kV/cm and 5.8 kV/cm, respectively, more than twice the value of binary PMN-PT crystals (∼2.5 kV/cm) and comparable to that of pure PIN-PMN-PT crystals (∼5.5 kV/cm).8, 9 Of particular interest is that the internal bias was found to be on the order of 0.5–0.6 kV/cm. Mn modified relaxor-PT single crystals possess acceptor-oxygen defect dipoles, forming anisotropic centers locally within a domain. When the crystals were poled, the dipoles realign along a preferential direction for the spontaneous polarization and move to the high stress areas of domain walls by diffusion. Thus, the internal bias is built up, which is believed to play an important role in clamping of domain wall motions and restricting polarization rotations, accounting for the enhanced mechanical Qm and decreased dielectric loss.11, 13

Figure 2.

Polarization hysteresis loops of PIN-PMN-PT:Mn single crystals measured at ac electric field of 15 kV/cm at 1 Hz.

The high field strain behavior as a function of electric field is given in Fig. 3. The electric field induced phase transition field level was found to be 27 kV/cm at room temperature for composition A. As expected, the induced phase transition field level of composition B was significantly lower, being ∼17 kV/cm, owing to its composition at the proximity of MPB. It can be seen that the electric field threshold for the inducing orthorhombic phase was decreased with increasing the PT content (closer to MPB), with similar induced strain level being on the order of 0.26%, analogous to pure PIN-PMN-PT crystals.10 The piezoelectric coefficients d33 obtained from low fields were found to be 750–1100 pm/V, corresponding to the d33 values for PIN-PMN-PT: Mn crystals obtained from the resonance method. When the crystals transformed to orthorhombic phase under high electric field, the piezoelectric coefficient (d33 ∼ 150 pm/V) was found to drop significantly, corresponding to the values for the single domain orthorhombic crystals.

Figure 3.

Unipolar strain as a function of electric field for compositions A and B of “2R” PIN-PMN-PT:Mn crystals at 1 Hz.

Table TABLE I. gives the complete set of elastic, piezoelectric, and dielectric constants of [011]C poled PIN-PMN-PT:Mn rhombohedral single crystals and compared to [001]C poled counterpart. All of the piezoelectric properties for composition B with “2R” engineered domain configuration were found to be higher than the values of composition A, where the piezoelectric coefficient d33 and electromechanical coupling factor k33 were found to be ∼1050 pC/N and 0.90 for composition B crystals, respectively. Compared to “4R” domain engineered crystals ([001] poled), higher thickness shear piezoelectric d15 and electromechanical coupling factor k15 were observed, being on the order of ∼3000 pC/N and 92%, respectively. The mechanical quality factors Qm were evaluated for various vibration modes, where the mechanical coupling factors Q31 (Q32) for “4R” domain engineered crystals were found to be higher than those of “2R” crystals. In addition, the Q32 was lower than Q31 for “2R” crystals, exhibiting strong anisotropic mechanical properties in [011] poled crystals. The longitudinal mechanical Q33 for “2R” domain engineered crystals was found to be ∼1000, comparable to “hard” PZT8 ceramics, and much higher than that of unmodified PIN-PMN-PT single crystals.17 All the studied shear mechanical quality factors were found to be low, due to the facilitated “polarization rotation” and large rotation angle (90°) in the thickness shear vibration mode.1, 18 In addition, the mechanical quality factors for composition B were found to be higher than the values of composition A. This may be due to the fact that the Mn dopant has large segregation along the growth direction, thus produced higher Mn doped level in composition B, leading to larger internal bias and enhanced mechanical Qm.

TABLE I.

Measured and derived material constants for composition A [2R (A)] and composition B [2R (B)] of [011]C poled rhombohedral PIN-PMN-PT:Mn single crystals. The data for [001]C poled PIN-PMN-PT:Mn single crystals were listed for comparison.

| Elastic stiffness constants: and (1010 N/m2) | |||||||||||||||||||||||||||||||||||

| 2R (A) a | 19.1 | 12.2 | 7.43 | 13.3 | 11.9 | 15.2 | 6.44 | 0.86 | 5.00 | ||||||||||||||||||||||||||

| 2R (B) a | 19.5 | 13.6 | 8.32 | 15.1 | 13.0 | 15.1 | 6.16 | 0.53 | 4.67 | ||||||||||||||||||||||||||

| 4R b | 12.8 | 11.1 | 10.8 | 12.8 | 10.8 | 11.3 | 6.5 | 6.5 | 3.6 | ||||||||||||||||||||||||||

| 2R (A) a | 19.2 | 12.0 | 7.75 | 14.6 | 9.61 | 19.2 | 7.19 | 4.64 | 5.00 | ||||||||||||||||||||||||||

| 2R (B) a | 19.5 | 13.4 | 8.64 | 16.4 | 10.7 | 19.1 | 6.99 | 3.56 | 4.67 | ||||||||||||||||||||||||||

| 4R b | 13.3 | 11.7 | 9.0 | 13.3 | 9.0 | 17.0 | 7.2 | 7.2 | 3.6 | ||||||||||||||||||||||||||

| Elastic compliance constants: and (10–12 m2/N) | |||||||||||||||||||||||||||||||||||

| 2R (A) a | 18.0 | −28.0 | 13.1 | 68.1 | −39.4 | 30.9 | 15.5 | 116 | 20.0 | ||||||||||||||||||||||||||

| 2R (B) a | 23.5 | −39.0 | 20.6 | 90.4 | −56.4 | 43.8 | 16.2 | 189 | 21.1 | ||||||||||||||||||||||||||

| 4R b | 45.4 | −15.9 | −28.1 | 45.4 | −28.1 | 62.4 | 15.4 | 15.4 | 27.8 | ||||||||||||||||||||||||||

| 2R (A) a | 10.7 | −8.83 | 0.10 | 17.5 | −5.20 | 7.79 | 13.9 | 21.6 | 20.0 | ||||||||||||||||||||||||||

| 2R (B) a | 11.7 | −9.59 | 0.09 | 17.5 | −5.46 | 8.27 | 14.3 | 28.1 | 21.4 | ||||||||||||||||||||||||||

| 4R b | 34.4 | −26.9 | −3.9 | 34.4 | −3.9 | 9.2 | 13.9 | 13.9 | 27.8 | ||||||||||||||||||||||||||

| Piezoelectric coefficients: (10−12 C/N), (C/m2), (10−3 Vm/N), and (108 V/m) | |||||||||||||||||||||||||||||||||||

| 2 R (A) a | 2030 | 125 | 455 | −1200 | 810 | 17.5 | 8.05 | 1.23 | −8.52 | 14.8 | |||||||||||||||||||||||||

| 2R (B) a | 2986 | 160 | 608 | −1508 | 1053 | 15.8 | 9.86 | 1.08 | −7.83 | 13.4 | |||||||||||||||||||||||||

| 4R b | 133 | 133 | −609 | −609 | 1341 | 8.6 | 8.6 | −5.2 | −5.2 | 16.8 | |||||||||||||||||||||||||

| 2R (A) a | 46.7 | 13.0 | 16.0 | −42.2 | 28.5 | 21.6 | 9.37 | 2.19 | −15.2 | 26.4 | |||||||||||||||||||||||||

| 2R (B) a | 53.8 | 12.1 | 19.5 | −48.7 | 33.8 | 19.1 | 8.43 | 2.37 | −17.2 | 29.5 | |||||||||||||||||||||||||

| 4R b | 11.3 | 11.3 | −18.1 | −18.1 | 39.7 | 8.3 | 8.3 | −10.7 | −10.7 | 34.2 | |||||||||||||||||||||||||

| Dielectric: /, β(10−4/) | |||||||||||||||||||||||||||||||||||

| 2R (A) a | 912 | 970 | 635 | 4916 | 1084 | 3213 | 11.0 | 10.3 | 15.7 | 2.03 | 9.23 | 3.11 | |||||||||||||||||||||||

| 2R (B) a | 934 | 1321 | 515 | 6274 | 1499 | 3523 | 10.7 | 7.57 | 19.4 | 1.59 | 6.67 | 2.84 | |||||||||||||||||||||||

| 4R b | 1169 | 1169 | 553 | 1326 | 1326 | 3811 | 8.55 | 8.55 | 18.1 | 7.54 | 7.54 | 2.62 | |||||||||||||||||||||||

| Electromechanical coupling factors: | ||||||

| 2R (A) a | 0.90 | 0.32 | 0.64 | 0.86 | 0.86 | 0.45 |

| 2R (B) a | 0.92 | 0.34 | 0.71 | 0.90 | 0.90 | 0.46 |

| 4R b | 0.31 | 0.31 | 0.49 | 0.49 | 0.92 | 0.58 |

| Mechanical quality factors: Qm | ||||||

| 2R(A) a | 90 | 70 | 220 | 100 | 1000 | 200 |

| 2R(B) a | 130 | 110 | 260 | 140 | 1000 | 220 |

| 4R a | 60 | 60 | 500 | 500 | 700 | 100 |

This work.

Reference 14.

The electromechanical coupling factors and piezoelectric coefficients (pC/N) for “2R” domain engineered PIN-PMN-PT:Mn, PIN-PMN-PMN,19 and PMN-PT20 crystals are listed in Table TABLE II. for comparison. Analogous to “1O” single domain PIN-PMN-PT:Mn crystals, the piezoelectric properties for “2R” domain engineered crystals were found to be slightly lower than those values of unmodified binary PMN-PT and ternary PIN-PMN-PT crystals, due to the fact that the accepter dopants Mn2+,3+ induce internal bias, which pinned the domain wall motions and the “polarization rotation,” account for the decreased piezoelectric properties.

TABLE II.

Comparison of electromechanical coupling factor and piezoelectric coefficient (pC/N) for “2R” domain engineered PIN-PMN-PT:Mn, PIN-PMN-PMN, and PMN-PT crystals.

| (pC/N) | (pC/N) | (pC/N) | (pC/N) | (pC/N) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2R (A) a | 2030 | 125 | 455 | −1200 | 810 | 0.90 | 0.32 | 0.64 | 0.86 | 0.86 | 0.45 | |

| 2R (B) a | 2986 | 160 | 608 | −1508 | 1053 | 0.92 | 0.34 | 0.71 | 0.90 | 0.90 | 0.46 | |

| PIN-PMN-28%PT b | 2203 | 114 | 460 | −1156 | 782 | 0.90 | 0.30 | 0.67 | 0.86 | 0.87 | 0.49 | |

| PIN-PMN-32%PT b | 3354 | 162 | 744 | −1781 | 1363 | 0.95 | 0.36 | 0.75 | 0.90 | 0.92 | 0.50 | |

| PMN-28%PT c | 2816 | 234 | 723 | −1761 | 1766 | 0.90 | 0.30 | 0.65 | 0.89 | 0.91 | 0.50 | |

| PMN-30%PT c | 3262 | 289 | 813 | −2116 | 1916 | 0.95 | 0.36 | 0.71 | 0.94 | 0.92 | 0.52 | |

In order to understand the intrinsic and extrinsic contributions to the piezoelectric response of PIN-PMN-PT:Mn single crystals with “2R” domain engineered state, Rayleigh analysis was performed. The piezoelectric coefficient d33 was calculated from the slope of the unipolar strain measured at small amplitudes of electric field. The electric field dependence of piezoelectric coefficients d33 exhibiting a linear behavior can be described using the Rayleigh formula: ,21 where E0 is the amplitude of the electric field. The dinit is considered to arise from the intrinsic contribution and αE0 represents the extrinsic contribution to the total piezoelectric response. Fig. 4 shows the ac electric field dependent piezoelectric coefficient d33 for compositions A and B of [011] poled PIN-PMN-PT:Mn single crystals. For A crystals, the values of dinit and α were found to be 850 pm/V and 10 cm/kV, respectively, with the extrinsic contribution being on the order of 1.2% (at applied filed of 1 kV/cm). Correspondingly, the values of dinit and α for B crystals were found to be 1090 pm/V and 17 cm/kV, respectively, with the extrinsic contribution being on the order of 1.5% (at applied field of 1 kV/cm). The extrinsic contributions for the “2R” PIN-PMN-PT:Mn crystals were found to be lower than the value of [001]C poled binary PMN-PT and ternary PIN-PMN-PT crystals, due to the reduced domain wall motions, which was effectively clamped by the internal bias.10, 22

Figure 4.

AC electric field dependent piezoelectric coefficient d33 for PIN-PMN-PT:Mn single crystals at 1 Hz for compositions A (a) and B (b). The comparison between the measured and calculated strain-electric field loops is given in the insets.

CONCLUSIONS

In summary, the full set of material constants for [011]C poled rhombohedral PIN-PMN-PT:Mn single crystals was determined using the combined resonance and ultrasonic methods. The internal bias for Mn modified PIN-PMN-PT crystals was found to be 0.5–0.6 kV/cm, leading to higher mechanical quality factors Qm ∼ 1000 and smaller extrinsic contributions ≤2% compared to their pure counterparts. The high mechanical quality factor, together with the comparable piezoelectric and electromechanical properties, make PIN-PMN-PT:Mn crystals potential candidate for high power transducer applications.

ACKNOWLEDGMENTS

This work was supported by the ONR and NIH under Grant No. 2P41EB002182-15A1.O. The authors from HIT thank the support from National Key Basic Research Program of China under Grant No. 2013CB632900, and the author (X. Q. Huo) wants to thank the support from China Scholarship Council.

References

- Zhang S. J. and Li F., J. Appl. Phys. 111, 031301 (2012). 10.1063/1.3679521 [DOI] [Google Scholar]

- Park S. E. and Shrout T. R., J. Appl. Phys. 82, 1804 (1997). 10.1063/1.365983 [DOI] [Google Scholar]

- Damjanovic D., Budimir M., Davis M., and Setter N., Appl. Phys. Lett. 83, 527 (2003). 10.1063/1.1592880 [DOI] [Google Scholar]

- Zhang R., Jiang B., and Cao W., J. Phys. Chem. Solids 65, 1083 (2004). 10.1016/j.jpcs.2003.10.072 [DOI] [Google Scholar]

- Zhang S. J., Luo J., Xia R., Rehrig P. W., Randall C. A., and Shrout T. R., Solid State Commun. 137, 16 (2006). 10.1016/j.ssc.2005.10.023 [DOI] [Google Scholar]

- Zhang S., Lee S., Kim D., Lee H., and Shrout T. R., J. Am. Ceram. Soc. 91, 683 (2008). 10.1111/j.1551-2916.2007.02190.x [DOI] [Google Scholar]

- Xu G. S., Chen K., Yang D. F., and Li J. B., Appl. Phys. Lett. 90, 032901 (2007). 10.1063/1.2431706 [DOI] [Google Scholar]

- Zhang S. J., Luo J., Hackenberger W., and Shrout T. R., J. Appl. Phys. 104, 064106 (2008). 10.1063/1.2978333 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liu X. Z., Zhang S. J., Luo J., Shrout T. R., and Cao W. W., J. Appl. Phys. 106, 074112 (2009). 10.1063/1.3243169 [DOI] [Google Scholar]

- Li F., Zhang S. J., Lin D. B., Luo J., Zhou X., Wei X. Y., and Shrout T. R., J. Appl. Phys. 109, 014108 (2011). 10.1063/1.3530617 [DOI] [Google Scholar]

- Carl K. and Hardtl K. H., Ferroelectrics 17, 473 (1978). 10.1080/00150197808236770 [DOI] [Google Scholar]

- Zhang S. J., Xia R., Lebrun L., Anderson D., and Shrout T. R., Mater. Lett. 59, 3471 (2005). 10.1016/j.matlet.2005.06.016 [DOI] [Google Scholar]

- Zhang S. J., Lee S. M., Kim D. H., Lee H. Y., and Shrout T. R., Appl. Phys. Lett. 93, 122908 (2008). 10.1063/1.2992081 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Luo J., Hackenberger W., Zhang S., and Shrout T., in IEEE Ultrasonic Symposium (IEEE, San Diego, California, 2010), pp. 68–71.

- IEEE Standards on Piezoelectricity (ANSI/IEEE, New York, 1987), p. 176. [Google Scholar]

- Zhang R., Jiang B., and Cao W. W., J. Appl. Phys. 90, 3471 (2001). 10.1063/1.1390494 [DOI] [Google Scholar]

- Zhang S. J., Sherlock N. P., R. J.Meyer, Jr., and Short T. R., Appl. Phys. Lett. 94, 162906 (2009). 10.1063/1.3125431 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li F., Zhang S. J., Xu Z., Wei X. Y., and Shrout T. R., Adv. Funct. Mater. 21, 2118 (2011). 10.1002/adfm.201002711 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sun E. W., Zhang S. J., Luo J., Short T. R., and Cao W. W., Appl. Phys. Lett. 97, 032902 (2010). 10.1063/1.3466906 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shanthi M., Lim L. C., Rajan K. K., and Jin J., Appl. Phys. Lett. 92, 142906 (2008). 10.1063/1.2907702 [DOI] [Google Scholar]

- Damjanvoic D., The Science of Hysteresis (Elsevier, New York, 2005), Vol. 3, p. 337. [Google Scholar]

- Li F., Zhang S., Zhou X., Wei X., Luo J., and Shrout T., J. Appl. Phys. 108, 034106 (2010). 10.1063/1.3466978 [DOI] [PMC free article] [PubMed] [Google Scholar]