Abstract

There are concerns regarding the longevity of resin composite restorations and the clinical relevance of in vitro bond strength testing to the durability of dentin bonds in vivo.

Objective

The objectives of this investigation were to: 1) develop a new method of experimental evaluation for quantifying the durability of dentin bonds, 2) apply this method to characterize the interfacial strength of a selected commercial system under both monotonic and cyclic loading, and 3) distinguish mechanisms contributing to the interface degradation and failure.

Methods

A new method for fatigue testing the resin-dentin interface was developed based on a four-point flexure arrangement that includes two identical bonded interfaces. Cyclic loading of specimens comprised of coronal dentin bonded to a commercial resin composite and controls of resin composite was performed to failure within a hydrated environment. Scanning electron microscopy and nanoscopic dynamic mechanical analysis were used to evaluate failure mechanisms.

Results

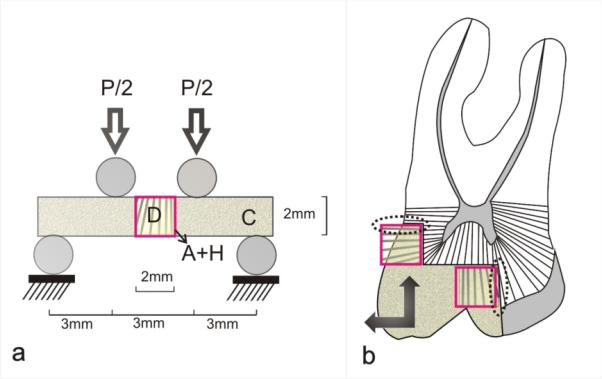

The fatigue strength of the resin-dentin interface was significantly lower (p≤0.0001) than that of the resin composite and reported for dentin over the entire finite life regime. Defined at 1×107 cycles, the apparent endurance limit of the resin-dentin interface was 13 MPa, in comparison to 48 MPa and 44 MPa for the resin composite and dentin, respectively. The ratio of fully reversed endurance limit to ultimate strength of the interface (0.26) was the lowest of the three materials.

Significance

The proposed approach for characterizing the fatigue strength of resin-dentin bonds may offer new insights concerning durability of the bonded interface.

Keywords: Adhesive Resin, Bonding, Durability, Fatigue, Hybrid Layer, Resin Composite

INTRODUCTION

Resin composites have become the most common material for direct posterior restorations [1]. Composites offer benefits over amalgam including aesthetics and more conservative preparation size, but there are concerns regarding their longevity [2,3]. The average clinical service life of bonded composite restorations is limited [2,4,5]. Secondary caries, degradation of the restorative margins and fracture of the restoration are the most common forms of failure, with secondary caries being the primary cause of failure overall [6-8]. As these failures appear to be largely related to the bond integrity or result from poor initial adhesion, the interface strength has emerged as the key performance metric.

Bond strength testing of restorative materials to dentin has been used to quantify the quality of adhesion since the invention of acid etching [9]. Micro-tensile and shear tests quickly became the primary approaches for evaluating the success of new materials and to assess the influence of bonding procedures to clinical performance [10,11]. Several variations of these two approaches are now used, from macroscopic methods with clinically relevant dimensions, to microscopic methods where the bonded surface area is well below 1 square millimeter [e.g. 12–14]. The dental materials community has adopted the quasi-static tensile testing of the interface to infer performance in the oral environment, i.e. with high strength indicative of longevity. However, the applicability of these methods is being questioned, with clinical relevance being the primary concern [15–18].

In recognition that there are shortcomings to the current testing methods, the community is now addressing their potential weaknesses (e.g. [19–22]). Improvement in testing methods and specimen preparation procedures may help foster new understanding of the mechanical behavior of the resin-dentin interface. Yet, others have called for the development of new test methods [9; 23] that will better represent oral challenges and provide researchers with tools to make advances in resin adhesion to dentin. A load-bearing restoration bonded to oral hard tissues has to resist damage over many years. Indeed, occlusal function has been identified as a significant factor to the age of restorations at failure [24]. Such an influence might simply be due to fatigue of the interface where cyclic stresses transmitted across the adhesive and hybrid layers accelerate degradation of the interface [25]. In comparison to evaluations of monotonic strength, fatigue properties of the resin-dentin interface and their clinical relevance have received far less attention [26–33]. Fatigue testing the interface could provide clinically relevant insight on dentin bond durability.

The present study introduces a novel approach for evaluating the strength of resin-dentin bonds under both monotonic and cyclic loading. The overall objective of this paper is to describe the merits of its application and supporting techniques for examining the degradation and failure of resin-dentin bonds as a result of fatigue. Here we present results for the fatigue strength achieved in dentin bonding with a specific commercial material, compare these results to the fatigue strength of dentin and resin composite, and discuss some of the primary contributors to fatigue failure of the interface.

MATERIALS AND METHODS

The investigation was aimed at developing a method for evaluating the fatigue strength of the resin-dentin bonded interface and validating the loading configuration using a finite element analysis. Thereafter, the newly developed method of evaluation was enrolled to assess the fatigue strength of the resin-dentin interface acheived using a commercial bonding system.

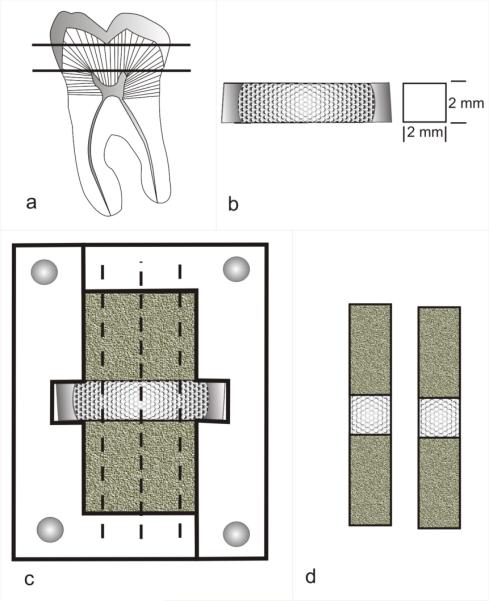

Bonded interface fatigue specimens were developed and involved coronal dentin, which was obtained from caries-free human second and third molars. The extracted molars were obtained with record of patient age (18≤age≤30) and gender from participating clinics within Maryland according to a protocol approved by the University of Maryland Baltimore County (#Y04DA23151). After extraction, the teeth were stored in Hank's Balanced Salt Solution (HBSS) for less than 1 month, and then sectioned using a computer-controlled grinder (Chevalier Smart-H818II, Chevalier Machinery, Santa Fe Springs, CA, USA) with diamond abrasive slicing wheels (#320 mesh abrasives) and water spray coolant. All teeth were sectioned axially to obtain a slice of 2 mm thickness. Secondary sections were performed mesio-distally to obtain rectangular beams from the mid-coronal dentin with nominal dimensions of 2×2×10 mm3 (Figure 1a). The dentin tubules of these beams were aligned perpendicular to their length (Figure 1b), which is consistent with selected regions of the interface created by introducing a Class 2 cavity on a molar (Figure 2a,b). After the secondary sections, primer and adhesive (Clearfil SE Bond, Lot 062127, Kuraray America, Houston, TX, USA) were applied to the two opposing surfaces of each beam according to the manufacturer's recommendations. Then the beams were placed within a dedicated mold (Figure 1c) such that the approximal surfaces were oriented with tubules parallel to the bonding interface. Restorative resin composite (Clearfil AP-X, A2 color, Lot 1136AA; Kuraray America) was applied incrementally from the dentin beam surface and distributed as necessary to fill the mold cavities on each side of the dentin beam. The composite was cured on both sides for 40 seconds using a quartz-tungsten-halogen light-curing unit (Demetron VCL 401, Demetron, CA, USA) with output intensity of 600 mW/cm2 and with tip diameter wider than 10 mm. The sections of bonded resin composite and dentin were released from the mold and sectioned using the slicer/grinder to obtain specimens with dimensions of roughly 2×2×12 mm3 (Figure 1d). The specimens were examined for defects using an optical microscope and each side was polished lightly with hydration using #600 mesh emory paper. The specimens were stored in HBSS at room temperature (22° C) for 24 hours prior to further evaluation. A control group of resin composite specimens was prepared using the same approach, including molding, sectioning and polishing.

Figure 1.

Preparation of the resin-dentin bonded interface specimens

(a) A primary section from the bucco-lingual plane with 2 mm thick section. Secondary sectioning is used to prepare a 2×2 mm2 cross-section beam of mid coronal dentin. (b) The resulting beam has orthogonal edges and enables bonding with tubules oriented “parallel” or “perpendicular” to the interface. All specimens in this study were bonded with the parallel orientation (c) Primer and adhesive is applied to the dentin beam outside of the mold, then inserted into the fixture and light-cured. The resin composite is applied incrementally on both sides and light cured. (d) Final sectioning is performed to obtain two or three interface specimens from the bonded sections. Final dimensions are approximately 2×2×12 mm3.

Figure 2.

The four-point flexure configuration for evaluating the bonded interface. Denoted are the resin composite (C), dentin (D) and the twin bonded interfaces comprised of resin adhesive and hybrid layer (A+H).

a) Geometry of the loading configuration and location of the interfaces. b) A class two restoration subjected to forces of mastication on vertical and horizontal plane. The squares represent the relevant sites of the dentin sections that are consistent with the current test method and the encircled portion represents the interfaces with configuration consistent with the bonded interface specimen.

The prepared specimens were loaded to failure in either quasi-static or cyclic four-point flexure (Figure 2a) using a universal testing system (EnduraTEC Model ELF 3200, Minnetonka, MN, USA), which has a load capacity and sensitivity of 225 N and ±0.01 N, respectively. Quasistatic loading was applied with the specimens maintained in HBSS at room temperature using displacement control feedback at a crosshead rate of 0.06 mm/min. The instantaneous load and load-line displacement were monitored throughout loading at a frequency of 4 Hz. The flexural strength of the beams was determined using conventional beam theory [34] in terms of the maximum measured load (P) and beam geometry (width b, thickness h) according to 3Pl/bh2, where l is the distance from interior and exterior supports (l=3 mm). Ten specimens of the interface (N=10) and the resin composite control (N=10) were evaluated using this approach. The flexure strengths were compared using a one-way ANOVA and Tukey's HSD post-hoc analysis with the critical value (alpha) set at 0.05.

Cyclic loading of the bonded interface and control specimens was conducted using the same flexure configuration (Figure 2a) under load control with frequency of 4 Hz and stress ratio (R = ratio of minimum to maximum cyclic load) of 0.1. Fatigue testing was initiated using a maximum cyclic stress of approximately 90% of the flexural strength identified from the quasistatic experiments. For successive specimens, the maximum cyclic load was decreased in increments ranging from 5 to 15 MPa according to the staircase method of evaluation [35]. The process continued until reaching the flexure stress amplitude at which specimens did not fail within 1.2×106 cycles. The stress-life (S-N) fatigue distribution was evaluated by plotting the cyclic stress amplitude against the number of cycles to failure. The fatigue life distribution of the specimens in each group that underwent fatigue failure was fitted using non-linear regression with a Basquin-type model [36] of the form where

| (1) |

A and B are the fatigue-life coefficient and exponent, respectively. These constants were obtained from a power law regression of the fatigue responses. The apparent endurance limit was estimated from the models for a fatigue limit defined at 1×107 cycles. The fatigue life distributions were compared using the Wilcoxon Sum Rank Test with p ≤ 0.05 considered significant. A total of 40 specimens were evaluated using this approach including the bonded interface specimens (N=20) and resin composite control (N=20).

Due to the presence of an interface in the resin-dentin beams, it was necessary to evaluate the stress distribution to confirm that beam theory provided a reliable measure of the flexural stress. Thus, a two-dimensional finite element analysis was performed using commercial software (ABAQUS 6.7-3; Dassault Systèmes Americas Corp., Waltham, MA, USA). Though not required, a full model was developed for the beam to simulate the resulting stress and strain distribution. The model beam was defined having three regions (Figure 3a), i.e. the resin composite, resin adhesive and dentin, and meshed with approximately 3600 nodes and 1200 type CPE4 elements. For convenience the materials were treated as linear elastic with elastic modulus (E) and Poisson's ratio (ν) defined for dentin (E=15 GPa, ν=0.29) [37], resin composite (6.0 GPa, 0.26) [AP-X, Kuraray USA] and resin adhesive (4.4 GPa, 0.24) [38]. Due to the limited information for the macroscopic elastic modulus of resin-infiltrated dentin, the hybrid layer and resin adhesive were combined and considered to have the same elastic properties (4.4 GPa, 0.24). It was recognized that viscoelastic deformation of the specimens may occur as a result of the non-zero mean stress generated by the fatigue loading protocol and duration of testing (0 to 3.5 days). However, the degree of viscoelastic deformation in each loading cycle was assumed to be small, which maintains applicability of the linear elastic model and its solution for the stress distribution. The beam was subjected to flexural loading according to the experimental configuration in Figure 2a through contact loading. The pins were defined as rigid body shells with frictionless contact between the pins and beam surfaces.

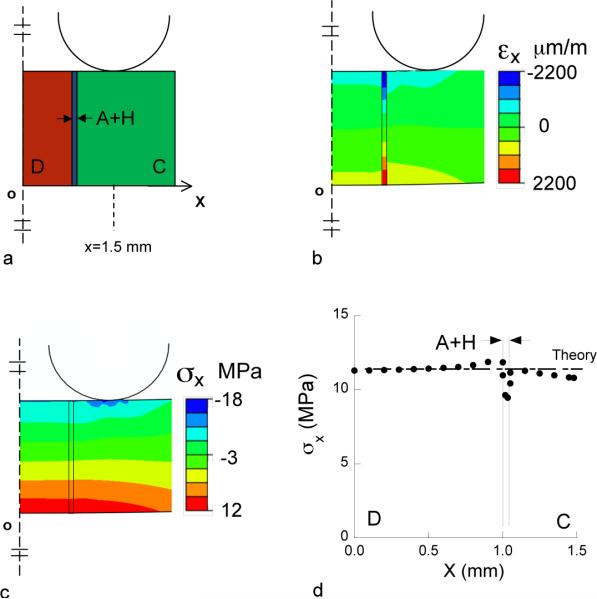

Figure 3.

The Finite Element Analysis (FEA) for four-point loading of the bonded interface specimens. Consistent with Figure 2, the resin composite (C), dentin (D) and the twin bonded interfaces comprised of resin adhesive and hybrid layer (A+H) are highlighted.

a) Model configuration. b) Normal strain distribution within the beam in the x direction. Red = tensile strain and Blue = compressive strain. c) Normal stress distribution of the beam in the x direction resulting from 10 N load flexure load. d) Normal stress distribution from the center (x=0) to the right along the tensile surface (i.e. the region of maximum normal stress). The stress distribution obtained from the FEA is compared with that from beam theory.

The flexure specimen geometry adopted for evaluating the resin-dentin bonding was defined with twin interfaces, akin to that of the double-notched beam configuration commonly used for evaluating engineering and natural materials [39]. This configuration offers a special advantage in that both interfaces are subjected to a constant and equivalent bending moment. Symmetrical loading of the specimen was confirmed by using an articulating paper between the specimen and the loading pins, which ensured equi-distributed loading of the beam and equivalent normal stresses at each interface. As such, both interfaces were subjected to an equivalent macroscopic normal stress distribution during the loading history.

In both monotonic and cyclic loading one of the interfaces undergoes failure and the second interface, which has experienced the same stress history, effectively “freezes” the status of the microstructure at that moment. Though differences in the population and severity of defects can cause one of the two interfaces to undergo failure preferentially, the second interface survives and enables further evaluation. Here the specimens were evaluated using Scanning Electron Microscopy (SEM) and nanoscopic Dynamic Mechanical Analysis (nanoDMA) to assess the mechanisms of interface degradation caused by cyclic loading.

The fracture surfaces of selected specimens were inspected using a Scanning Electron Microscope (SEM: JEOL Model JSM-5600, Peabody MA, USA) in secondary electron imaging (SEI) mode. Prior to this analysis the specimens were dehydrated in an ascending ethanol series (70–100%), fixed in Hexamethyldisilazane, polished lightly using #600 mesh emory cloth and then sputtered with gold/palladium to enhance conductance of the dentin and resin adhesive. The fracture surfaces were inspected to distinguish differences between static and fatigue loading and to identify the origins of failure. It is important to note that due to the required dehydration of the specimens, the surviving interface dimensions were not evaluated using the SEM. Dehydration causes dimensional changes in the adhesive, and requires a relatively long period of time between completion of the testing and SEM evaluation. That enabled relaxation of the specimens and time to undergo further dimensional changes, which were not associated with the fatigue process.

To support nanoDMA evaluation of the interface that did not undergo failure, the portion of specimen containing the surviving resin-dentin interface was cold-mounted in Epofix epoxy resin (Struers, Cleveland, OH, USA). The side of the specimen was exposed, thereby revealing both the tension and compression areas of the specimen. Polishing was performed with diamond particle suspensions (Buehler) of sizes 9, 3, and 0.04 μm to produce a highly polished surface with a roughness of less than 50 nm RMS. Both mounting and polishing of the specimens were performed with hydration. NanoDMA was performed with a Triboindenter (Model TI 900, Hysitron, Minneapolis, MN, USA) and a Berkovich diamond indenter with a 100-nm tip radius. Scanning mode dynamic loading was conducted over scan areas of 30 μm × 30 μm with 4 μN contact load, 2 μN dynamic loading amplitude and dynamic loading frequency of 100 Hz. The evaluation was performed with hydration using a layer of ethylene glycol over the specimen surface to prevent water evaporation [40]. This is a critical difference between the SEM and nanoDMA analysis. In addition, application of nanoDMA enabled an assessment of changes in mechanical behavior of the interface resulting from fatigue. The contact load and displacement signals were used to calculate the phase angle and to generate maps of the complex (E*) modulus distribution for the dentin, resin adhesive and hybrid zone and restorative resin. An unloaded interface specimen (control) was also evaluated using these techniques after immersion in HBSS for 24 hours. Additional details regarding application of nanoDMA and evaluating the resin-dentin interface using this approach is described in [40,41].

RESULTS

Results from the finite element analysis for flexure loading of the bonded resin-dentin specimens are shown in Figure 3. The normal strain (εx) and normal stress (σx) distributions within the specimen from the axis of symmetry are shown in Figsure 3b and Figure 3c, respectively. The maximum normal stress on the surface of the specimen (tensile side) is plotted along the length of the beam in Figure 3d. That distribution is compared with the predicted stress using beam theory for a homogeneous specimen with identical geometry and loading configuration. Though the interfaces are located within one millimeter of the two interior loading pins, the tensile stress distribution is not influenced substantially by the contact stresses. The largest normal stress within the region of constant moment develops at the boundary of dentin and the hybrid layer, and is within 5% of that predicted using beam theory. Nevertheless, the normal stress is clearly not constant between the two loading pins and is substantially influenced by the adhesive interface. As expected, the largest strain develops within the hybrid layer and resin adhesive, and is nearly three times larger than that within the adjacent materials (Figure 3b).

The flexural strength of the resin composite and interface specimens are shown in Figure 4a; results reported for the flexure strength of coronal dentin are also presented in this figure for comparison [34]. Although there was no difference between results for the resin composite and dentin (p > 0.05), the flexural strength of the bonded interface (66.3 ± 9.1 MPa) was significantly lower (p ≤ 0.001) than the two controls. Results from fatigue testing of the beams is shown in Figure 4b in terms of fatigue life diagrams for the resin composite and bonded interface; experimental results for coronal dentin are presented for comparison in terms of the 95% confidence interval of the data [37]. These diagrams are plotted for lives of 500 cycles and greater; the fatigue responses at higher stresses are potentially dominated by inelastic deformation and of lower clinical relevance. Constants for the power law models of each material are also presented in Figure 4b for reference. Note that the bonded interface exhibited the lowest fatigue strength over the entire fatigue life regime. The fatigue life of the bonded interface specimens was significantly lower than that of the resin composite and dentin (Z = -5.98; p ≤ 0.0001); results for the dentin and resin composite were not significantly different (Z = −1.57; p=0.058). Defined at 1×107 cycles, the apparent endurance limit for the bonded interface, resin composite and dentin are 13 MPa, 48 and 44 MPa, respectively.

Figure 4.

Strength of the resin composite and bonded interface specimens determined from 4-pt flexure loading. Results for coronal dentin are also presented in terms of the 95% confidence intervals from [34].

a) Flexure strength resulting obtained from quasi-static loading to failure. Columns with different letters are significantly different (p ≤0.001). b) Stress life fatigue diagram from cyclic loading to failure. Data points with arrows represent specimens that did not fail. It is important to note that 20 specimens were tested for each material system and specimens that overlapped were displaced for visibility. The power law constants (A, B) describing the fatigue life distributions (according to Eqn. 1) are also provided.

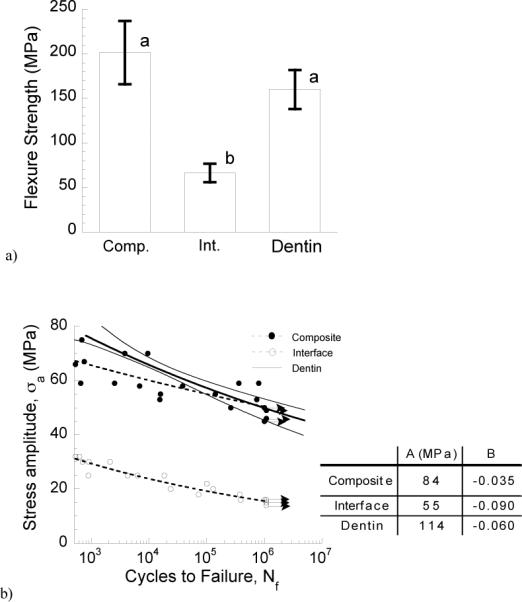

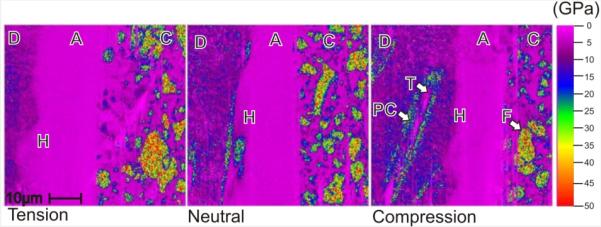

Results for the complex modulus distribution obtained from nanoDMA of a representative bonded interface specimen after 386 kcycles of loading is shown in Figure 5. Modulus maps are presented for the interface within the region of tensile normal stress, near the neutral axis, and within the region of maximum compressive normal stress. Clearly evident are the dentin (D), resin adhesive (A) and hybrid layer (H) and the resin composite (C). Dynamic modulus maps for the control specimens (not subjected to cyclic loading) showed similar features to those in Figure 5, with distinct filler particles in the composite, smooth transition of modulus from the resin adhesive to hybrid layer, and larger modulus within the dentin. The complex modulus for the dentin ranged from roughly 12 to 30 GPa with the lower and upper bounds representative of the intertubular and peritubular regions, respectively. The monomer and filler particles of the resin composite exhibited complex moduli of 9.8±2.2 GPa and 69.9±38.4 GPa, respectively. The average complex modulus of the adhesive and hybrid layer ranged between 4.5 and 6.5 MPa. Results from the nanoDMA mapping showed that there was no significant difference between the E* distributions of the control specimens and those subjected to fatigue. Thus, cyclic loading did not cause apparent degradation in the mechanical properties of the hybrid layer or resin adhesive. However, the specimens subjected to larger number of cycles (N ≥ 100 kcycles) exhibited a bonded interface thickness (combining resin adhesive and hybrid layer) that was elongated on the tensile side of the neutral axis. Evident in Figure 5, the interfacial thickness in the modulus map for the region subjected to cyclic tension is approximately 1.5 times greater than that in the region of cyclic compression.

Figure 5.

Complex modulus (E*) distributions determined from nanoDMA evaluation of a bonded interface specimen after 386162 cycles at a peak cyclic stress of 40 MPa. Each scanned area corresponds to a 50 μm × 50 μm nanoDMA analysis window. The windows represent portions of the interface subjected to cyclic tension, near the neutral axis and in the region of cyclic compression. D= dentin, H= hybrid layer, A=Adhesive, C= resin composite, T= resin tags, P= peritubular cuff, F= filler particles of the AP-X resin composite. Note the increased thickness of the adhesive/ hybrid layer on the tension side and the almost uniform 10 μm thickness of adhesive/ hybrid layer in the regions of neutral axis and compression.

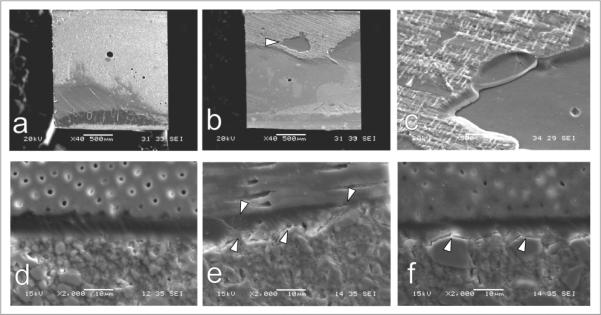

The fractured bonded interface specimens were examined to identify the origins of failure and characteristics of the interface after cyclic loading. Typical observed features are shown in Figure 6. Fracture surfaces corresponding to low cycle fatigue (i.e. high cyclic stress) and high cycle fatigue are shown in Figures 6a and 6b, respectively. Through the identification of compression shear lips it was noted that fatigue failure initiated on the tensile side of the neutral axis for all specimens. Fatigue failure corresponding to short lives (N ≤ 10 kcycles) initiated within the resin composite (Figure 6a). For specimens that endured longer lives (N ≥ 250 kcycles) under comparatively lower cyclic stress, failure generally initiated within the resin adhesive or hybrid layer (Figure 6b). Fatigue failure progressed within this region before transitioning onto the boundary between the resin adhesive and resin composite. An air void on the tensile side of the fracture surface, indicative of improper wetting, is presented under higher magnification in Figure 6c. Two sets of lines are evident in the resin adhesive, which represent resin penetration into the dentin tubules and in the abrasive tracks generated by the surface preparation.

Figure 6.

Images from the bonded interface specimens after fatigue failure.

a) Fracture surface from a low cycle interface specimen showing initiation of failure in the resin composite. b) Fracture surface from a high cycle interface specimen showing initiation of failure in the hybrid layer. In both (a) and (b) the tension side is upwards and the shear lip is evident at the bottom of the specimen. c) a magnified view of the region next to the void (arrow) in (b). Penetration of the resin into the dentin tubules and the abraded bonding surface is evident. d) the bonded interface from a control specimen (not subjected to cyclic loading). No signs of degradation are evident. e) the remaining intact bonded interface (tensile side) from a fatigue specimen showing microcracks in the adhesive and hybrid layer (arrows). f) the remaining intact bonded interface (tensil e side) from a fatigue specimen showing microcracks in the resin composite at the boundary of large filler particles (arrows).

The surviving interfaces from specimens that failed due to fatigue were also examined using the SEM. An intact interface from a selected specimen that was not subjected to cyclic loading is shown for reference in Figure 6d. The surviving resin-dentin interface of specimens that failed by fatigue exhibited signs of degradation, including microcracking within the hybrid layer and resin adhesive (Figure 6e) and microcracks at the periphery of larger reinforcing particles within the composite (Figure 6f). Overall, those specimens that endured a larger number of cycles to failure exhibited more extensive signs of degradation at the bonded interface than those that exhibited shorter fatigue lives; the most dominant feature was the appearance and number of microcracks about the reinforcing particles. However, there was no specific correlation between the number of cycles and the size of major cracks at the surviving interface. This could simply result from the statistical distribution of flaws at the bonding interface, i.e. those specimens with more intrinsic defects at the tension side will exhibit more microcracks at the interface, and potentially at a lower number of cycles as well.

DISCUSSION

A novel approach for characterizing the durability of resin-dentin bonds was developed that enables both determination of the fatigue strength and evaluation of the mechanisms contributing to fatigue failure. The flexure specimen was designed with twin interfaces, the weakest of which undergoes fatigue failure, and the surviving interface providing an opportunity to evaluate the microstructure after cyclic loading. The bonding configuration and corresponding tubule orientation in this specimen design (Figure 1c) is akin to a region frequently identified as the most problematic (Figure 2b) in class two restorations [42,43].

The strength of dentin adhesive bonds has been reported to be dependent on the microstructure of dentin [44,45]. The intertubular solid dentin and resin tags contribute to the bond strength differently [46], which also partly depends on the hydrophobicity of the bonding systems [47,48]. With the current bonding systems, the formation of hybrid layer and the availability of intertubular solid dentin have been reported to be important requirements for high bond strength [44,46]. Relevant to these reports, the testing configuration used in the present investigation has an interface with mostly uniform tubule orientation, and parallel to the bonded interface. There are some small variations in tubule orientation throughout the thickness of the bonding surface (Fig. 2a,b), but the effect of this variation was minimized as the portion of interface subjected to the largest tensile stress was always bonded to outer dentin (Figure 2a). It is also important to note that the majority of fatigue failures initiated within the resin composite or the resin adhesive, not on the dentin side. Nevertheless, the test method supports changing the specimen orientation to evaluate the effects of tubule orientations or tubule density on bond durability.

In evaluating the fatigue life distributions, the bonded interface specimens underwent fatigue failure at stresses between one third to one half that for the resin composite and dentin (Figure 4b). The apparent endurance limit estimated for the resin-dentin interface (13 MPa) is less than 30% of the dentin and composite controls, thereby identifying it as the most likely to undergo fatigue failure under cyclic stresses caused by occlusal function. The interface is also most “sensitive” to fatigue degradation. Using the Goodman model [36] to account for the mean stress effects imposed by cyclic loading with a stress ratio (R) of 0.1, the equivalent endurance limit for fully reversed loading (R= −1) of the interface is 17 MPa; that value for the resin composite and dentin is 69 MPa and 64 MPa, respectively. The aforementioned correction assumes that the Goodman model is applicable to account for mean stress effects, which has been confirmed for dentin [49]. The ratio of fully reversed endurance limit to the flexure strength, a value that reflects the relative resistance to fatigue degradation [50], is 0.26, 0.35 and 0.40 for the three materials, respectively. Clearly the bonded interface is the weakest link of resin-dentin bonds under cyclic loading conditions. Due to the relatively short period of cyclic loading (1 to 3 days) in comparison to the expected period of oral function, the estimates should be considered quite liberal. They do not include the detrimental physio-chemical factors that potentially further degrade both the integrity and durability of resin-dentin bonds [51,52]. Fatigue failure of the bonded interface specimens in this in vitro study would be expected to have originated from mechanical degradation only. Future evaluations should be conducted after aging of the interfaces to assess to influence of extended hydrolytic degradation on durability [53,54], and the potential synergism between cyclic loading and water movement on degradation of the interface.

Surprisingly few studies have examined the influence of cyclic loading on resin-dentin bond strength [e.g. 55,56], or characterized the interface fatigue strength [26–29,31–33]. One potential drawback of previously reported studies is the number of cycles chosen with which to evaluate fatigue strength. Most of the experiments were limited to less than 1×105 cycles, which is substantially lower than that experienced in one year of oral function [57]. Frankenberger et al. [28] adopted cyclic shear and cyclic push-out tests, both showing that the interface fatigue strength was weaker than that obtained from monotonic tests to failure. Their fatigue limit was defined at 1 or 5 kcycles and resulted in strengths of between roughly 5 and 17 MPa. Belli et al. [33] obtained fatigue limits between 36 and 50 MPa in flexure loading after 10 kcycles, but these evaluations were conducted using 3-point loading and potentially not involving hydration. Staninec et al. [31,32] used four-point flexure with a single bonded interface specimen to evaluate the fatigue strength of resin-dentin bonds incorporating SE Bond. Their apparent endurance limit was approximately 25 MPa, which is over 50% greater than that (16 MPa) estimated using the present configuration and at their definition of life (1×106 cycles). The reported flexure strength (91 MPa) was also 50% greater than that identified here. While there are potential differences in the tubule orientation between the present study and that of Staninec et al [31,32], the most immediate difference is in the bonded area. The prior investigation was conducted with beams having 0.87 mm square cross-section and bonding area less than one tenth that achieved with the twin interfaces.

Using a larger specimen size has various advantages. According to the SEM evaluations, voids were present at the interface (Figure 6b) and occupied up to nearly 0.45 mm2 of the bonded interface. This is nearly half the area of a typical microtensile specimen [12–14] and of the specimen used in the previous study of interface fatigue strength [31,32]. Voids of this type are indicative of defects that have developed during bonding. Yet, in the larger specimen they do not result in premature failure prior to cyclic loading - no specimens were lost during preparation. If these voids are in the vicinity of the interface they may serve as the origin of failure due to the inherent stress concentration. Nevertheless, the difference in fatigue responses between these two studies is most likely attributed to the size effects (i.e. of the bonding area), which is well known in bond strength testing [20,58]. The remaining difference is the resin composite, as the studies by Staninec et al [31,32] involved specimens developed using Filtek Z-250. The latter has smaller average filler size and could be an important contributing factor to the initiation of fatigue damage, as evident in Figure 6f.

Finite Element Analysis (FEA) has been adopted for predicting the fatigue life of the dentin-resin adhesive interface [59]. This is a very attractive alternative to experiments as it permits parametric analysis of potentially important factors to bonding and interfacial integrity. Recent predictions of the endurance limit of the resin-dentin interface from Singh et al. [59] with graded and uniform hybrid layer modulus (12 to 25 MPa) are consistent with that obtained from the present experimental evaluation. That questions whether an experimental investigation is worth the effort. Cleary, the answer is affirmative! It is important to note that FEA can provide a detailed understanding of the stress distribution in a system with complicated geometry and loading conditions. For instance, the analysis conducted in the present study was useful for understanding the stress and strain distribution at the interface (Figure 3b and 3c). However, finite element investigations have difficulty in providing mechanistic findings; in this case, the mechanisms contributing to degradation of the bonded interface with cyclic loading. The micro-mechanical finite element investigation reported in [59] indicated that fatigue failure for the resin-dentin interface occurs within the adhesive resin tags adjacent to the hybrid layer. That mechanism was not identified in the present investigation, nor is it relevant as the dentin tubules were oriented parallel to the bonded interface. Examination of the failed specimens suggested that fatigue failures could be loosely characterized in two regimes, i.e. the low cycle regime where failure initiated at the boundary of the reinforcing particles in the resin composite (Figure 6a), and the high cycle regime where failure initiated within the adhesive (Figure 6b) and occasionally within the hybrid layer. Identification of microcracks in the adhesive and hybrid layer (Figure 6e) and at the margin (Figure 6f) were key observations from the experimental analysis, and important aspects of degradation that limit the durability of adhesive bonds to dentin under cyclic loading. These forms of damage could provide a path for bacterial penetration, which potentially causes accelerated degradation of the interface. Further evaluations appear warranted with focus on the variability in bond behavior with tubule orientation.

Identification of cracks in the interface as a result of cyclic loading suggests that a fracture mechanics approach is appropriate for evaluating the bonded interface integrity, supporting previous recommendations by Söderholm [18,23]. In this cursory evaluation of the fatigue failures, well-defined discrete cracks at the interface more often appeared in the resin composite, adjacent to the resin adhesive, and in specimens that were subjected to larger periods of cyclic loading (N ≥ 250 kcycles). Nevertheless, it was not clear whether failures corresponding to long lives occurred due to the presence of cracks. The initiation of failure in these specimens appeared to reside within the hybrid layer and resin adhesive, a region where fractography is difficult to apply. A previous evaluation of the interface using a fracture mechanics approach showed that the resistance to the initiation of fatigue crack growth in the resin adhesive was significantly lower than that in the resin composite and dentin [30]. Thus, when the driving force is large enough to initiate cyclic crack growth from interfacial flaws, the fracture resistance of the interface is critically important. However, a potentially more robust approach would be to minimize the generation of flaws at the interface by cyclic loading, or to repair them as they develop if the former is not possible [52].

There was evidence that cyclic loading caused viscoelastic deformation within the interface specimens. Both microscopic inspection and nanoDMA suggested that the surviving bonded interfaces underwent elongation on the tensile side of the neutral axis (Figure 5). Viscoelastic deformation of the resin adhesive and hybrid layer is not unexpected [60] and could occur due to the mean stress component of cyclic loading. It could also be promoted by hydrolytic degradation of the resin adhesive and hybrid layer, thereby causing a reduction in the elastic modulus due to plasticization of the polymer [61]. That would cause corresponding larger strain magnitudes to develop and a greater potential for interface failure to occur by strain [62], rather than by stress. While plausible, that mechanism should be comparatively small in this in vitro study with respect to that in bonding to caries affected dentin. In addition, results of the nanoDMA scanning showed that there was no apparent reduction in the elastic moduli of the resin adhesive or hybrid layer due to fatigue. Hydrolytic degradation is a greater issue in bonding to caries affected dentin than those involving sound dentin [63]. Thus, future work should consider evaluating the durability of resin-dentin bonds involving caries affected dentin and the contributions of viscous deformation.

It is important to discuss the advantages and drawbacks of the proposed method for assessing the durability of dentin bonds. Four-point flexure is an attractive format for evaluating the interface under cyclic loading, as it provides a region of uniform normal stress between the two inner contacts. In addition, the straight-sided beams are easy to prepare and do not require additional geometric features that may serve as spurious defects and foster premature failure in cyclic loading conditions. The geometry and method of loading also overcome issues related to misalignment from the axis of the applied load, the specimen alignment during tests, and the problem of gripping specimens. These issues are notorious in micro-tensile testing [22]. The use of twin bonded interfaces enables an increase in the total bonding area, with total interface area of 8 mm2, which is more consistent with that of common Class I and II restorations in comparison to micro-tensile approaches. Having an additional surviving interface to evaluate enables further understanding of the primary mechanisms contributing to fatigue failure after that period of cyclic loading. However, there are limitations to the approach. For example, the loading configuration causes the largest stress to exist within the dentin (Figure 3c and 3d) adjacent to the interface. That is true for the micro- and macro-tensile tests, and the bonded interface in vivo as well, which stems from the compliance of the resin adhesive (Figure 3b). Another concern is the proximity of the interior loading pins to the bonded interfaces. The chosen specimen and loading configuration reduces the volume of resin necessary for preparing these specimens. Yet, the interior loading pins contact the specimens at a distance in which, according to Saint-Venant's Principle [34], contact stresses should not be ignored. Results from the finite element analysis showed that the influence of contact stresses is negligible on the tensile side of the interface (Figure 3c) and the largest deviation in the flexure stress is caused by the interface (Figure 3d). Taken together, though there are limitations to the proposed method for evaluating the durability of resin-dentin bonds, there are many attractive features.

Kelley [16,64] urged that prior to adopting in vitro methods for testing of dental materials they should be validated against clinical performance. Specimens that underwent fatigue failure showed evidence of marginal degradation and fracture of the restoration (Figure 6), two of the most common forms of restoration failure. However, the evaluation did not include the effects from secondary caries and/or bonding to caries affected dentin, the primary cause for the failure of resin composite restorations [6–8]. That does not devalue the present approach. Secondary caries that develop at the tooth-restoration margins arise from the acid production of biofilms [e.g. 65,66] and enzymatic degradation [25]. The influence of biofilm activity on mechanical behavior of the bonded interface has yet to be addressed, but is essential. Additional studies are presently underway to include this important component of the oral environment in the analysis of the bonded interface durability. The present study presents an essential component of the evaluation by first clearly understanding the effect of cyclic loading on interface performance, prior to examining the effects of synergistic degradation imposed by bacterial activity.

CONCLUSIONS

A new method for evaluating the durability of resin-dentin bonds was developed that consists of cyclic four-point flexure loading of a specially designed bonded interface specimen. The specimen contains twin bonded interfaces that enable a determination of the fatigue strength and evaluation of the mechanisms contributing to its degradation via inspection of the surviving interface. Using this approach, the apparent endurance limit of the resin-dentin interface obtained with a selected commercial composite was 13 MPa, which was more than 70% lower than that of coronal dentin and of the resin composite (control). Fatigue failure of the resin-dentin interface was found to initiate at voids in the resin adhesive and composite located about the interface, to initiate at filler particles in the resin composite on the interface boundary, and to occur via degradation of the adhesive and hybrid layer that resulted in failure within the adhesive joint. NanoDMA scanning of the interface showed that cyclic loading caused viscoelastic deformation across the adhesive and hybrid layer in regions of tension, which could cause increased hydrolytic degradation and reduction of durability. It is hoped that this new approach will facilitate further investigations that are aimed at assessing the influence of these oral challenges to dentin adhesion, and foster new understanding of the mechanical behavior and durability of the resin-dentin interface.

ACKNOWLEDGEMENTS

This study was supported in part by matching seed grants from the University of Maryland Baltimore County and the University of Maryland, Baltimore, and by an award from the National Institutes of Health (NIDCR DE016904). The authors also gratefully acknowledge Kuraray America for their generous donation of bonding supplies and resin composite and Prof. Frederick Rueggeberg of the Georgia Health Sciences University for kindly supplying and calibrating the light curing unit.

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

REFERENCES

- 1.Beazoglou T, Eklund S, Heffley D, Meiers J, Brown LJ, Bailit H. Economic impact of regulating the use of amalgam restorations. Public Health Reports. 2007;122:657–663. doi: 10.1177/003335490712200513. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Bernardo M, Luis H, Martin MD, Leroux BG, Rue T, Leitão J, et al. Survival and reasons for failure of amalgam versus composite posterior restorations placed in a randomized clinical trial. J Am Dent Assoc. 2007;138:775–83. doi: 10.14219/jada.archive.2007.0265. [DOI] [PubMed] [Google Scholar]

- 3.Demarco FF, Corrêa MB, Cenci MS, Moraes RR, Opdam NJ. Longevity of posterior composite restorations: not only a matter of materials. Dent Mater. 2012;28:87–101. doi: 10.1016/j.dental.2011.09.003. [DOI] [PubMed] [Google Scholar]

- 4.Mjör IA, Dahl JE, Moorhead JE. Age of restorations at replacement in permanent teeth in general dental practice. Acta Odontol Scand. 2000;58:97–101. doi: 10.1080/000163500429208. [DOI] [PubMed] [Google Scholar]

- 5.Soncini JA, Maserejian NN, Trachtenberg F, Tavares M, Hayes C. The longevity of amalgam versus compomer/composite restorations in posterior primary and permanent teeth: findings From the New England Children's Amalgam Trial. J Am Dent Assoc. 2007;138:763–72. doi: 10.14219/jada.archive.2007.0264. [DOI] [PubMed] [Google Scholar]

- 6.Deligeorgi V, Mjör IA, Wilson NH. An overview of reasons for the placement and replacement of restorations. Prim Dent Care. 2001;8:5–11. doi: 10.1308/135576101771799335. [DOI] [PubMed] [Google Scholar]

- 7.Brunthaler A, König F, Lucas T, Sperr W, Schedle A. Longevity of direct resin composite restorations in posterior teeth. Clin Oral Investig. 2003;7:63–70. doi: 10.1007/s00784-003-0206-7. [DOI] [PubMed] [Google Scholar]

- 8.Sunnegårdh-Grönberg K, van Dijken JW, Funegård U, Lindberg A, Nilsson M. Selection of dental materials and longevity of replaced restorations in Public Dental Health clinics in northern Sweden. J Dent. 2009;37:673–8. doi: 10.1016/j.jdent.2009.04.010. [DOI] [PubMed] [Google Scholar]

- 9.Buonocore MG. A simple method of increasing the adhesion of acrylic filling materials to enamel surfaces. J Dent Res. 1955;34:849–53. doi: 10.1177/00220345550340060801. [DOI] [PubMed] [Google Scholar]

- 10.Pashley DH, Sano H, Ciucchi B, Yoshiyama M, Carvalho RM. Adhesion testing of dentin bonding agents: a review. Dent Mater. 1995;11:117–25. doi: 10.1016/0109-5641(95)80046-8. [DOI] [PubMed] [Google Scholar]

- 11.Pashley DH, Carvalho RM, Sano H, Nakajima M, Yoshiyama M, Shono Y, et al. The microtensile bond test: a review. J Adhes Dent. 1999;1:299–309. [PubMed] [Google Scholar]

- 12.Armstrong S, Geraldeli S, Maia R, Raposo LH, Soares CJ, Yamagawa J. Adhesion to tooth structure: a critical review of “micro” bond strength test methods. Dent Mater. 2010;26:e50–62. doi: 10.1016/j.dental.2009.11.155. [DOI] [PubMed] [Google Scholar]

- 13.Braga RR, Meira JB, Boaro LC, Xavier TA. Adhesion to tooth structure: a critical review of “macro” test methods. Dent Mater. 2010;26:e38–49. doi: 10.1016/j.dental.2009.11.150. [DOI] [PubMed] [Google Scholar]

- 14.Scherrer SS, Cesar PF, Swain MV. Direct comparison of the bond strength results of the different test methods: a critical literature review. Dent Mater. 2010;26:e78–93. doi: 10.1016/j.dental.2009.12.002. [DOI] [PubMed] [Google Scholar]

- 15.Van Meerbeek B, De Munck J, Yoshida Y, Inoue S, Vargas M, Vijay P, et al. Buonocore memorial lecture. Adhesion to enamel and dentin: current status and future challenges. Oper Dent. 2003;28:215–35. [PubMed] [Google Scholar]

- 16.Kelly JR, Benetti P, Rungruanganunt P, Bona AD. The slippery slope: critical perspectives on in vitro research methodologies. Dent Mater. 2012;28:41–51. doi: 10.1016/j.dental.2011.09.001. [DOI] [PubMed] [Google Scholar]

- 17.Roulet JF. Is in vitro research in restorative dentistry useless? J Adhes Dent. 2012;14:103–4. doi: 10.3290/j.jad.a23445. [DOI] [PubMed] [Google Scholar]

- 18.Söderholm KJ. Time to abandon traditional bond strength testing? J Adhes Dent. 2012;14:3–4. doi: 10.3290/j.jad.a23317. [DOI] [PubMed] [Google Scholar]

- 19.Betamar N, Cardew G, Van Noort R. Influence of specimen designs on the microtensile bond strength to dentin. J Adhes Dent. 2007;9:159–68. [PubMed] [Google Scholar]

- 20.Ghassemieh E. Evaluation of sources of uncertainties in microtensile bond strength of dental adhesive system for different specimen geometries. Dent Mater. 2008;24:536–47. doi: 10.1016/j.dental.2007.06.022. [DOI] [PubMed] [Google Scholar]

- 21.Roeder L, Pereira PN, Yamamoto T, Ilie N, Armstrong S, Ferracane J. Spotlight on bond strength testing-unraveling the complexities. Dent Mater. 2011;27:1197–203. doi: 10.1016/j.dental.2011.08.396. [DOI] [PubMed] [Google Scholar]

- 22.Raposo LH, Armstrong SR, Maia RR, Qian F, Geraldeli S, Soares CJ. Effect of specimen gripping device, geometry and fixation method on microtensile bond strength, failure mode and stress distribution: laboratory and finite element analyses. Dent Mater. 2012;28:e50–62. doi: 10.1016/j.dental.2012.02.010. [DOI] [PubMed] [Google Scholar]

- 23.Söderholm KJ. Review of the fracture toughness approach. Dent Mater. 2010;26:e63–77. doi: 10.1016/j.dental.2009.11.151. [DOI] [PubMed] [Google Scholar]

- 24.Burke FJ, Cheung SW, Mjör IA, Wilson NH. Restoration longevity and analysis of reasons for the placement and replacement of restorations provided by vocational dental practitioners and their trainers in the United Kingdom. Quintessence Int. 1999;30:234–42. [PubMed] [Google Scholar]

- 25.Pashley DH, Tay FR, Breschi L, Tjäderhane L, Carvalho RM, Carrilho M, et al. State of the art etch-and-rinse adhesives. Dent Mater. 2011;27:1–16. doi: 10.1016/j.dental.2010.10.016. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Drummond JL, Sakaguchi RL, Racean DC, Wozny J, Steinberg AD. Testing mode and surface treatment effects on dentin bonding. J Biomed Mater Res. 1996;32(4):533–41. doi: 10.1002/(SICI)1097-4636(199612)32:4<533::AID-JBM6>3.0.CO;2-S. [DOI] [PubMed] [Google Scholar]

- 27.Frankenberger R, Krämer N, Petschelt A. Fatigue behaviour of different dentin adhesives. Clin Oral Investig. 1999;3(1):11–7. doi: 10.1007/s007840050072. [DOI] [PubMed] [Google Scholar]

- 28.Frankenberger R, Strobel WO, Krämer N, Lohbauer U, Winterscheidt J, Winterscheidt B, et al. Evaluation of the fatigue behavior of the resin-dentin bond with the use of different methods. J Biomed Mater Res B Appl Biomater. 2003;67:712–21. doi: 10.1002/jbm.b.10052. [DOI] [PubMed] [Google Scholar]

- 29.De Munck J, Braem M, Wevers M, Yoshida Y, Inoue S, Suzuki K, Lambrechts P, Van Meerbeek B. Micro-rotary fatigue of tooth-biomaterial interfaces. Biomaterials. 2005;26(10):1145–53. doi: 10.1016/j.biomaterials.2004.04.013. [DOI] [PubMed] [Google Scholar]

- 30.Soappman MJ, Nazari A, Porter JA, Arola D. A comparison of fatigue crack growth in resin composite, dentin and the interface. Dent Mater. 2007;23:608–14. doi: 10.1016/j.dental.2006.05.003. [DOI] [PubMed] [Google Scholar]

- 31.Staninec M, Kim P, Marshall GW, Ritchie RO, Marshall SJ. Fatigue of dentin-composite interfaces with four-point bend. Dent Mater. 2008;24:799–803. doi: 10.1016/j.dental.2007.09.008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Staninec M, Nguyen H, Kim P, Marshall GW, Rithchie RO, Marshall SJ. Four-point bending evaluation of dentin-composite interfaces with various stresses. Med Oral Patol Oral Cir Bucal. 2008;13:E81–4. [PubMed] [Google Scholar]

- 33.Belli R, Baratieri LN, Braem M, Petschelt A, Lohbauer U. Tensile and bending fatigue of the adhesive interface to dentin. Dent Mater. 2010;26:1157–65. doi: 10.1016/j.dental.2010.08.007. [DOI] [PubMed] [Google Scholar]

- 34.Popov EP. “Mechanics of Materials”. 2nd Edition Prentic Hall Inc.; New Jersey: 1978. [Google Scholar]

- 35.Collins JA. “Fatigue Testing Procedures and Statistical Interpretations of Data,” in Fatigue of Metals in Mechanical Design. John Wiley and Sons; 1981. [Google Scholar]

- 36.Stephens RI, Fatemi A, Stephens RR, Fuchs HO. “Metal Fatigue in Engineering”. 2nd Edition John Wiley and Sons, Inc.; New York: 2001. [Google Scholar]

- 37.Arola DD, Reprogel RK. Tubule orientation and the fatigue strength of human dentin. Biomaterials. 2006;27:2131–40. doi: 10.1016/j.biomaterials.2005.10.005. [DOI] [PubMed] [Google Scholar]

- 38.Magni E, Ferrari M, Hickel R, Ilie N. Evaluation of the mechanical properties of dental adhesives and glass-ionomer cements. Clin Oral Investig. 2010;14:79–87. doi: 10.1007/s00784-009-0259-3. [DOI] [PubMed] [Google Scholar]

- 39.Nalla RK, Kinney JH, Ritchie RO. On the fracture of human dentin: is it stress- or strain-controlled? J Biomed Mater Res A. 2003;67:484–95. doi: 10.1002/jbm.a.10079. [DOI] [PubMed] [Google Scholar]

- 40.Ryou H, Niu LN, Dai L, Pucci CR, Arola DD, Pashley DH, et al. Effect of biomimetic remineralization on the dynamic nanomechanical properties of dentin hybrid layers. J Dent Res. 2011;90:1122–8. doi: 10.1177/0022034511414059. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Ryou H, Romberg E, Pashley DH, Tay FR, Arola D. Nanoscopic dynamic mechanical properties of intertubular and peritubular dentin. J Mech Behav Biomed Mater. 2012;7:3–16. doi: 10.1016/j.jmbbm.2011.08.010. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Asmussen E, Peutzfeldt A. Class I and Class II restorations of resin composite: an FE analysis of the influence of modulus of elasticity on stresses generated by occlusal loading. Dent Mater. 2008;24:600–5. doi: 10.1016/j.dental.2007.06.019. [DOI] [PubMed] [Google Scholar]

- 43.Dejak B, Mlotkowski A. Three-dimensional finite element analysis of strength and adhesion of composite resin versus ceramic inlays in molars. J Prosthet Dent. 2008;99:131–40. doi: 10.1016/S0022-3913(08)60029-3. [DOI] [PubMed] [Google Scholar]

- 44.Giannini M, Carvalho RM, Martins LR, Dias CT, Pashley DH. The influence of tubule density and area of solid dentin on bond strength of two adhesive systems to dentin. J Adhes Dent. 2001;3:315–24. [PubMed] [Google Scholar]

- 45.Masri M, Pilo R, Brosh T. The influence of convergence angle and dentin micromorphology on shear bond strength of adhesive resin luting cement. J Adhes Dent. 2008;10:277–84. [PubMed] [Google Scholar]

- 46.Lohbauer U, Nikolaenko SA, Petschelt A, Frankenberger R. Resin tags do not contribute to dentin adhesion in self-etching adhesives. J Adhes Dent. 2008;10:97–103. [PubMed] [Google Scholar]

- 47.Pereira PN, Okuda M, Sano H, Yoshikawa T, Burrow MF, Tagami J. Effect of intrinsic wetness and regional difference on dentin bond strength. Dent Mater. 1999;15:46–53. doi: 10.1016/s0109-5641(99)00013-5. [DOI] [PubMed] [Google Scholar]

- 48.Yoshiyama M, Carvalho R, Sano H, Horner J, Brewer PD, Pashley DH. Interfacial morphology and strength of bonds made to superficial versus deep dentin. Am J Dent. 1995;8:297–302. [PubMed] [Google Scholar]

- 49.Nalla RK, Kinney JH, Marshall SJ, Ritchie RO. On the in vitro fatigue behavior of human dentin: effect of mean stress. J Dent Res. 2004;83(3):211–5. doi: 10.1177/154405910408300305. [DOI] [PubMed] [Google Scholar]

- 50.Dowling NE. Mechanical behavior of engineering materials. 3rd ed Pearson Prentice Hall; Upper Saddle River, NJ: 2007. [Google Scholar]

- 51.Spencer P, Ye Q, Park J, Topp EM, Misra A, Marangos O, Wang Y, Bohaty BS, Singh V, Sene F, Eslick J, Camarda K, Katz JL. Adhesive/Dentin interface: the weak link in the composite restoration. Ann Biomed Eng. 2010;38:1989–2003. doi: 10.1007/s10439-010-9969-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 52.Liu Y, Tjäderhane L, Breschi L, Mazzoni A, Li N, Mao J, Pashley DH, Tay FR. Limitations in bonding to dentin and experimental strategies to prevent bond degradation. J Dent Res. 2011;90:953–68. doi: 10.1177/0022034510391799. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 53.Breschi L, Mazzoni A, Ruggeri A, Cadenaro M, Di Lenarda R, De Stefano Dorigo E. Dental adhesion review: aging and stability of the bonded interface. Dent Mater. 2008;24:90–101. doi: 10.1016/j.dental.2007.02.009. [DOI] [PubMed] [Google Scholar]

- 54.De Munck J, Mine A, Poitevin A, Van Ende A, Cardoso MV, Van Landuyt KL, et al. J Dent Res. 2012;91:351–7. doi: 10.1177/0022034511431251. [DOI] [PubMed] [Google Scholar]

- 55.Cavalcanti AN, Mitsui FH, Silva F, Peris AR, Bedran-Russo A, Marchi GM. Effect of cyclic loading on the bond strength of class II restorations with different composite materials. Oper Dent. 2008;33:163–8. doi: 10.2341/07-65. [DOI] [PubMed] [Google Scholar]

- 56.Yamazaki PC, Bedran-Russo AK, Pereira PN. Importance of the hybrid layer on the bond strength of restorations subjected to cyclic loading. J Biomed Mater Res B Appl Biomater. 2008;84:291–7. doi: 10.1002/jbm.b.30837. [DOI] [PubMed] [Google Scholar]

- 57.Anusavice KJ. Phillips Science of Dental Materials. 11th ed. Saunders; Philadelphia: 1996. pp. 90–91. [Google Scholar]

- 58.Burrow MF, Thomas D, Swain MV, Tyas MJ. Analysis of tensile bond strengths using Weibull statistics. Biomaterials. 2004;25:5031–5. doi: 10.1016/j.biomaterials.2004.01.060. [DOI] [PubMed] [Google Scholar]

- 59.Singh V, Misra A, Marangos O, Park J, Ye Q, Kieweg SL, et al. Fatigue life prediction of dentin-adhesive interface using micromechanical stress analysis. Dent Mater. 2011;27:e187–95. doi: 10.1016/j.dental.2011.05.010. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 60.Sadr A, Shimada Y, Lu H, Tagami J. The viscoelastic behavior of dental adhesives: a nanoindentation study. Dent Mater. 2009;25:13–9. doi: 10.1016/j.dental.2008.05.001. [DOI] [PubMed] [Google Scholar]

- 61.Hosaka K, Nakajima M, Takahashi M, Itoh S, Ikeda M, Tagami J, et al. Relationship between mechanical properties of one-step self-etch adhesives and water sorption. Dent Mater. 2010;26:360–7. doi: 10.1016/j.dental.2009.12.007. [DOI] [PubMed] [Google Scholar]

- 62.Singh V, Misra A, Marangos O, Park J, Ye Q, Kieweg SL, et al. >Viscoelastic and fatigue properties of model methacrylate-based dentin adhesives. J Biomed Mater Res B Appl Biomater. 2010;95:283–90. doi: 10.1002/jbm.b.31712. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 63.Erhardt MC, Toledano M, Osorio R, Pimenta LA. Histomorphologic characterization and bond strength evaluation of caries-affected dentin/resin interfaces: effects of long-term water exposure. Dent Mater. 2008;24:786–98. doi: 10.1016/j.dental.2007.09.007. [DOI] [PubMed] [Google Scholar]

- 64.Kelly JR. Perspectives on strength. Dent Mater. 1995;11:103–10. doi: 10.1016/0109-5641(95)80043-3. [DOI] [PubMed] [Google Scholar]

- 65.Sakaguchi RL. Review of the current status and challenges for dental posterior restorative composites: clinical, chemistry, and physical behavior considerations. Dent Mater. 2005;21:3–6. doi: 10.1016/j.dental.2004.10.008. [DOI] [PubMed] [Google Scholar]

- 66.ten Cate JM. Biofilms, a new approach to the microbiology of dental plaque. Odontology. 2006;94:1–9. doi: 10.1007/s10266-006-0063-3. [DOI] [PubMed] [Google Scholar]