Abstract

The effect of solid content (2.5–10%, w/v) and temperature (30–70°C) on the viscosity of tapioca meal from three cassava varieties was investigated in this study. Viscosity measurements were conducted using a digital rotational Brookfield viscometer. The viscosity of tapioca meal increased with increasing solid content and decreasing viscometer speeds. An empirical power-law equation fitted the viscosity data of the tapioca meals with correlation coefficients between 0.94 and 0.99. Our results indicated that tapioca meal can be characterized as a pseudo-plastic fluid and a mean value of 0.32 ± 0.18 was proposed as the power law index of tapioca meal from the three cassava varieties used in this study. Neither solid content, temperature nor shear rate altered the rheological characteristics of tapioca meal.

Keywords: Tapioca meal, Cassava, Temperature, Viscosity, Solid content

Introduction

Cassava (Manihot esculenta, Crantz) is a root crop cultivated and consumed as a staple in many regions of the developing world. The potential of the crop is wide because it offers the cheapest source of food calories and the highest yield per unit area. It also has multiple roles as a famine reserve, food and cash crop, industrial raw material and livestock feed (Berry 1993; Dahniya et al. 1994; Nweke 1994a, b, c). There are also many agronomic (relative resistance to pests and diseases, flexibility in planting and harvesting, etc.) and social reasons (income earner for women, flexible labour requirements) why cassava has become so important (Phillips et al. 2004). A major constraint to cassava root utilization is that it deteriorates rapidly after harvesting. Cassava has a shelf life of 24–48 h after harvest (Wenham 1995). Hence, fresh cassava roots must be processed into a more shelf stable product within 2 to 3 days after harvest. One of such cassava product is tapioca grits.

Tapioca grit is a partially gelatinized dried cassava starch, which appears as flakes or irregularly shaped granules (Adebowale et al. 2006). It is usually soaked, and cooked in water to form tapioca meal. Sugar and/or milk are added before consumption. It is consumed in many parts of West Africa and widely accepted as a convenience (Adebowale et al. 2006). Oyewole and Obieze (1995) reported some preliminary works on the traditional processing of cassava to tapioca grits. Our earlier studies investigated the effect of cassava variety and roasting methods, respectively on the sorption isotherms of tapioca grits (Adebowale et al. 2006 and 2007). While Adebowale et al. (2008) reported that peak and hot paste viscosities are the key pasting parameters in characterizing tapioca grits from different cassava varieties and roasting methods. However, there is a dearth of published scientific knowledge on the rheological or viscometry study of tapioca meal.

The rheological property of a food system is dependent on the composition or the ingredients of the system (Robinson 1990; Saenz and Costell 1990; Maskan and Göǧüș 2000). Sopade and Filibus (1995) reported the influence of solid and sugar content on rheological characteristics of akamu, a semi-solid maize food. Muller (1973) noted that when the total solid content of milk is increased, pronounced non-Newtonian behaviour occurs. Similar observation was confirmed with some fruit juices and concentrates (Khalil et al. 1989). This paper reports our findings on the effect of varying solid content and temperature on the viscosity of tapioca meal.

Materials and methods

Raw materials

Three cassava varieties (one improved variety; TMS30572, and two traditional varieties; Odongbo and Oko-iyawo) were obtained from the Teaching and Research Farm of the University of Agriculture, Abeokuta, Nigeria. The varieties were grown under rain-fed conditions. Neither fertilizer nor herbicides were used. Weeding was done manually when necessary. The three cassava varieties were harvested at 12 months after planting. Harvested roots were processed within 60 min after harvesting.

Preparation of tapioca grits

Tapioca grits were processed by the traditional Eastern Nigerian method (Oyewole and Obieze 1995). Fifty kilograms of cassava roots were peeled, washed in water and grated with a diesel engine powered mechanical grater. The resultant pulp was immediately sieved through a muslin cloth and suspended in 70 L of water. This separates the fibrous and other coarse root materials from the starch pulp. The starch pulp was allowed to settle for 4–6 h before decanting. The thick starch cake at the bottom of the bowl was pressed to remove water. This was screened through a screen (20 mesh/inch size) to produce coarse-grained moist flour and roasted in a flat hot pan with constant stirring at 120–150°C for 20 min. Vegetable oil was used to rub the pan before roasting to prevent stickiness and burning. The resulting irregular flakes and grains are the tapioca grits. The yield of tapioca grits was 10 g/100 g cassava root.

Preparation of tapioca meal

Tapioca meal was prepared by soaking different concentrations (2.5, 5.0, 7.5 and 10%, w/v) of tapioca grits in measured amount of water for 10 h (overnight) and cooked on fire using a kerosene stove for 15 min with constant stirring to obtain a consistent paste.

Rheological Measurements

The viscosities of the tapioca meals were measured using a digital rotational Brookfield viscometer (Brookfield Engineering Laboratories, Middleboro, USA, Model DV-E). Three readings were taken per sample at 1 min rotation at five speeds (10, 20, 30, 50 and 60 rpm). A 600 ml beaker was used for the measurement with the viscometer guard leg on. The samples were poured into the beaker to reach a level that covers the immersion groove on the spindle shaft. All viscosity measurements were carried out at different temperatures (30–70°C), immediately after cooking the tapioca meal. Spindle #6 was used for all measurements. Since the viscometer did not give direct shear rate and shear stress values for disc-type spindles, shear rate and shear stress values were obtained from the torque-rpm readings by calculation following the procedure described by Mitschka (1982) and Gbosh and Chattopadhyay (2010). The procedure involves taking measurements of many pairs of torques (αi) with a spindle for fixed values of viscometer speed Ni (rpm). Values of αi were converted to shear stresses τi (Pa) using equation 1.

|

1 |

Values of log τi were then plotted against log Ni. The slope of the graph (n) was then calculated. The corresponding values of the shear rates (s−1) were then calculated using equation 2.

|

2 |

Results and discussion

The viscosity of tapioca meal from three cassava varieties with different solid content is presented in Table 1. The effect of solid content on the tapioca meal was significant at 5% probability level. The viscosity increased with increasing solid content irrespective of cassava variety. The same observation was reported by Bhatacharya and Bhatacharya (1994) on cooked maize flour suspension, and Sopade and Filibus (1995) for akamu, a semi-solid meal from fermented maize starch. Costaldo et al. (1990) as well as Saenz and Costell (1990) reported no marked changes in non-Newtonian behaviour of some fruit juices as Brix was varied. However, this study showed that at lower solid content, tapioca meal tends to exhibit Newtonian behaviour (Sopade and Filibus 1995). This behaviour can be likened to a very dilute system which has been reported to be generally Newtonian (Sopade and Filibus 1995). Tapioca grits content of 2.5% was considered by this study to give a paste that is not thick enough for the form in which tapioca meal is customarily consumed. However, at 10% tapioca solid concentration, the paste produced was very thick and very close to a stiff paste which was too thick for the form in which tapioca meal is usually consumed.

Table 1.

Viscosity of tapioca meal from three cassava varieties with different solid content

| Shear rate (s−1) | Viscosity (Pa.s) at different solid content | |||

|---|---|---|---|---|

| 2.5% | 5.0% | 7.5% | 10.0% | |

| Odongbo variety | ||||

| 13.7 | 0.70j | 2.9fg | 22.2n | 26.2ef |

| 27.3 | 0.40gh | 2.0f | 15.6ij | 12.3ab |

| 41.0 | 0.27ef | 1.8e | 11.6ef | 10.4a |

| 68.3 | 0.17bcd | 1.4d | 9.1abc | 9.1a |

| 82.0 | 0.12ab | 1.1bcd | 8.8ab | 8.9a |

| TMS 30572 variety | ||||

| 13.7 | 0.77k | 2.9fg | 36.2m | 75.7i |

| 27.3 | 0.45h | 2.f | 24.4l | 48.2h |

| 41.0 | 0.21cde | 1.7e | 20.3k | 32.0gh |

| 68.3 | 0.10ab | 1.2cd | 12.5fg | 26.9ef |

| 82.0 | 0.10ab | 1.1abc | 12.0fg | 16.2cde |

| Oko-iyawo variety | ||||

| 13.7 | 0.57i | 6.3j | 20.5k | 92.6j |

| 27.3 | 0.40gh | 4.2h | 14.1h | 29.7fg |

| 41.0 | 0.21cde | 3.3g | 10.9de | 25.1e |

| 68.3 | 0.11abc | 2.8fg | 8.8ab | 18.0de |

| 82.0 | 0.09a | 2.6f | 8.1a | 14.4bc |

Values are mean of three replicates

Mean values having different superscript within column are significantly different (P < 0.05)

The viscosity of tapioca meal decreased with increasing shear rate irrespective of the solid content. The reduction in viscosity with increasing shear rate or viscometer speed has been related to the increased alignment of the constituent molecules as shear rate increases (Maskan and Göǧüș 2000). The relationship between viscosity and shear rate for the tapioca meals indicated that tapioca meal is a non-Newtonian fluid material irrespective of the solid content. Non-Newtonian flow can be elucidated by imagining any fluid to be a mixture of molecules with different sizes and shapes. As the molecules pass by each other as a result of applied force (shearing), the size, shape and cohesiveness will determine how much force is required to initiate motion (Sopade and Filibus 1995; Maskan and Göǧüș 2000). At each specific rate of shear, the alignment may be different and more or less force may be required to maintain motion.

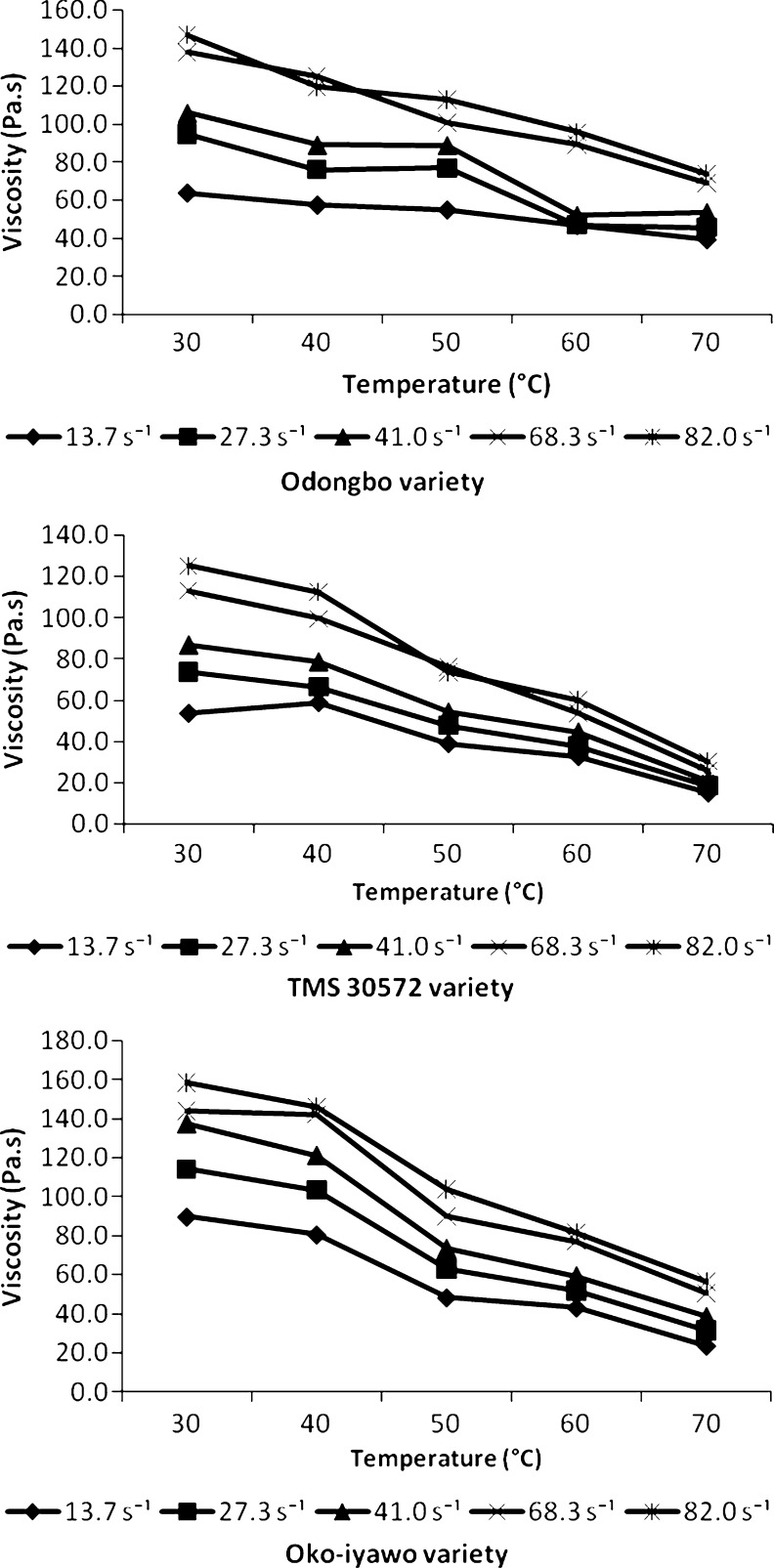

The viscosity of tapioca meal decreased with increasing shear irrespective of the paste temperature. Investigation of the effect of temperature on viscosity is very essential in evaluating materials that will be subjected to varying temperatures during processing or consumption, such as tapioca meal. Viscosity of tapioca meal increased with decreasing temperature irrespective of cassava variety and shear rate (Fig. 1). This observation agreed with earlier studies (Sopade and Kassum 1992a, b; Sopade and Filibus 1995; Maskan and Göǧüș 2000). Sopade and Filibus (1995) and Maskan and Göǧüș, (2000) likened this inverse relationship between viscosity and temperature to the incidence of a freer molecule to molecule interaction at elevated temperatures. And since viscosity can be described as a resistance to flow, such a freer interaction is expected to minimize the resistance.

Fig. 1.

Effect of temperature on the viscosity of tapioca meal

The empirical power-law model was used to estimate the empirical consistency (K) and power-law indices of tapioca meal with different solid contents. Table 2 shows the estimated empirical consistency (K), power-law indices (n), and the coefficients of determination (r2) for tapioca meals from three cassava varieties. The coefficients of determination (r2) were between 0.96 and 0.99. While power-law index was less than 1 for all the tapioca meals. An exponential equation was also used to model the rheological characteristics of the tapioca meals. The parameters of the exponential equation are presented in Table 3. The coefficients of determination (r2) ranged from 0.90 to 0.96 and the exponential constant (a) ranged between 0.41 and 0.58. Table 4 shows the parameters of empirical power-law equation for tapioca meal at different temperatures. The average r2 values were approximately 0.99. The empirical power-law index (n) was not materially affected by cassava variety, solid content and temperatures. Similar findings have been reported by other authors (Heikal and Chhinnan 1990; Sopade and Filibus 1995; Maskan and Göǧüș 2000). Since complete gelatinization was achieved in the tapioca meal during processing before rheological measurement, changes in temperature was not expected to cause marked alteration in the rheological characteristics of tapioca meal.

Table 2.

Rheological parameter of tapioca meal from three cassava varieties

| Solid content (%) | Consistency index (K) (N.sn/m2) | Power law index (n) | r2 |

|---|---|---|---|

| Odongbo variety | |||

| 2.5 | 8.9 | 0.05 | 0.99 |

| 5.0 | 11.3 | 0.49 | 0.99 |

| 7.5 | 89.1 | 0.46 | 0.99 |

| 10.0 | 135.6 | 0.42 | 0.96 |

| 0.4 ± 0.18 | |||

| TMS 30572 variety | |||

| 2.5 | 21.5 | 0.24 | 0.99 |

| 5.0 | 12.8 | 0.45 | 0.99 |

| 7.5 | 198.3 | 0.36 | 0.99 |

| 10.0 | 614.0 | 0.21 | 0.97 |

| 0.3 ± 0.10 | |||

| Oko-iyawo variety | |||

| 2.5 | 11.4 | 0.08 | 0.98 |

| 5.0 | 22.0 | 0.51 | 0.99 |

| 7.5 | 76.7 | 0.48 | 0.99 |

| 10.0 | 963.0 | 0.03 | 0.97 |

| 0.3 ± 0.22 | |||

± Standard Deviation

Table 3.

Estimates of Exponential equation parameters for tapioca meals from three cassava varieties

| Tapioca meal | Consistency index at different grits content s Ksolid(N.sn/m2) | Constant (a) | r2 |

|---|---|---|---|

| Odongbo | 2.6 | 0.41 | 0.95 |

| TMS 30572 | 3.1 | 0.51 | 0.90 |

| Oko-iyawo | 1.7 | 0.58 | 0.96 |

| 0.50 ± 0.09 |

± Standard Deviation

Table 4.

Rheological parameter of tapioca meal at different temperatures

| Temperature (°C) | Consistency index at different temperature (K) (N.sn/m2) | Power index (n) | r2 |

|---|---|---|---|

| Odongbo variety | |||

| 30.0 | 108.5 | 0.50 | 0.99 |

| 40.0 | 101.9 | 0.50 | 0.99 |

| 50.0 | 91.8 | 0.42 | 0.99 |

| 60.0 | 86.5 | 0.40 | 0.99 |

| 70.0 | 70.5 | 0.35 | 0.99 |

| 0.4 ± 0.06 | |||

| TMS 30572 variety | |||

| 30.0 | 179.5 | 0.35 | 0.99 |

| 40.0 | 129.0 | 0.35 | 0.99 |

| 50.0 | 87.4 | 0.36 | 0.99 |

| 60.0 | 79.0 | 0.32 | 0.99 |

| 70.0 | 74.4 | 0.27 | 0.99 |

| 0.3 ± 0.03 | |||

| Oko-iyawo variety | |||

| 30.0 | 196.4 | 0.37 | 0.99 |

| 40.0 | 188.7 | 0.35 | 0.99 |

| 50.0 | 92.8 | 0.42 | 0.99 |

| 60.0 | 90.9 | 0.37 | 0.99 |

| 70.0 | 38.1 | 0.49 | 0.99 |

| 0.4 ± 0.05 | |||

± Standard Deviation

Power-law index obtained in this study was less than 1 irrespective of cassava variety. Hence, tapioca meal can be characterized as a pseudo-plastic fluid and changes in solid content or temperature did not alter the rheological class of tapioca meal. A similar observation has been reported for akamu at different levels of solid, sugar contents or paste temperature (Sopade and Filibus 1995). However, the empirical consistency index (K) was affected by solid content and temperature. The higher the solid content, and the lower the temperature the higher the empirical consistency index. A similar trend has been reported by previous authors for varying solid, sugar content or temperature (Heikal and Chhinnan 1990; Saenz and Costell 1990; Sopade and Kassum 1992a; Sopade and Filibus 1995; Maskan and Göǧüș 2000). The constant of the exponential equation (a) which is an indication of the sensitivity of the tapioca meal to changes in solid content did not vary much across the solid contents and temperatures studied.

The Arrhenius-type equation had been used to assess the temperature sensitivity of foods (Sopade and Filibus 1995; Maskan and Göǧüș 2000). Table 5 shows the parameters obtained from Arrhenius equation for tapioca meal at varying solid content and temperature. The Arrhenius equation is suitable for describing the relationship between temperature and consistency index as the r2 values ranged from 0.79 to 0.96. The Activation energy ranged between 10.51 and 34.38 MJ/mol.

Table 5.

Application of Arrhenius equation to the consistency index at different temperatures (KT) for tapioca meal

| Tapioca meal | KT(N.sn/m2) | Activation Energy (Ea) (MJ/mol) | r2 |

|---|---|---|---|

| Odongbo | 0.01 | 10.0 | 0.79 |

| TMS 30572 | 0.07 | 19.8 | 0.96 |

| Oko-iyawo | 0.0028 | 34.4 | 0.94 |

| 21.5 ± 12.04 |

± Standard Deviation

Conclusion

The effect of solid content and temperature on the viscosity of tapioca meal was presented. The power law index and flow behaviour index showed that tapioca meal exhibited non-Newtonian flow characteristics (pseudoplastic) irrespective of solid content and temperature. Empirical power law model and Arrhenius equation fitted the viscosity data well.

Acknowledgement

The authors wish to acknowledge the financial support by EU/INCDEV/UNAAB Cassava SME project. And the Integrated Cassava Project, International Institute of Tropical agriculture, Ibadan, Nigeria.

References

- Adebowale AA, Sanni LO, Kuye A. Effect of roasting methods on sorption isotherm of tapioca grits. Elect J Enviro Agric Food Chem. 2006;5:1649–1653. [Google Scholar]

- Adebowale AA, Sanni LO, Awonorin SO, Daniel IO, Kuye A. Effect of cassava varieties on the sorption isotherm of tapioca grits. Int J Food Sci Technol. 2007;42:448–452. doi: 10.1111/j.1365-2621.2007.01261.x. [DOI] [Google Scholar]

- Adebowale AA, Sanni LO, Onitilo MO. Chemical composition and pasting properties of tapioca grits from different cassava varieties and roasting methods. Afric J Food Sci. 2008;2:077–082. [Google Scholar]

- Battacharya S, Battacharya S. Flow behaviour of cooked maize flour suspensions and applicability of mathematical models. J Food Proc Eng. 1994;17:263–278. doi: 10.1111/j.1745-4530.1994.tb00339.x. [DOI] [Google Scholar]

- Berry SA (1993) Socio-economic aspect of cassava cultivation and use in Africa: Implications for development of appropriate technology. COSCA working paper No. 8. Collaborative Study of Cassava in Africa. International Institute of Tropical Agriculture, Ibadan, Nigeria

- Costaldo D, Plamer L, Lo Voi A, Costabile O. Rheological characterisation of purees and concentrates of babaco. In: Spiss WEL, Schubert H, editors. Engineering and food: physical properties and process control. London: Elsevier Science; 1990. pp. 143–150. [Google Scholar]

- Dahniya MT, Akoroda MO, Alvarez MN, Kalndaneh PM, Ambe-Tumanteh J (1994) Development and dissemination of appropriate root crops packages to farmers in Africa. In: Ofort F, Hahn SK (eds) Proceedings of Ninth Symposium of The International Society for Tropical Root crops. 20–26 October 1999, Accra, Ghana. pp. 2–9

- Gbosh D, Chattopadhyay P. Preparation of idili batter, its properties and nutritional improvement during fermentation. J of Food Sci Technol. 2010 doi: 10.1007/s13197-010-0148-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Heikal YA, Chhinnan MS. Rheological characterization of tomato puree at different temperatures using using two types of viscometers. In: Spiss WEL, Schubert H, editors. Engineering and food: physical properties and process control. London: Elsevier Science; 1990. pp. 133–142. [Google Scholar]

- Khalil KE, Ramakrishna P, Nanjundaswamy AM, Patwardhan MV. Rheological behaviour of clarified banana juice: effect of temperature and concentration. J Food Eng. 1989;10:231–240. doi: 10.1016/0260-8774(89)90028-9. [DOI] [Google Scholar]

- Maskan M, Göǧüș F. Effect of sugar on the rheological properties of sunflower oil-water emulsions. J Food Eng. 2000;43:173–177. doi: 10.1016/S0260-8774(99)00147-8. [DOI] [Google Scholar]

- Mitschka P. Simple conversion of Brookfield R.V.T. readings into viscosity functions. Rheological Acta. 1982;21:207–209. doi: 10.1007/BF01736420. [DOI] [Google Scholar]

- Muller HG. An introduction to food rheology. 1. London: Heinemann; 1973. pp. 112–145. [Google Scholar]

- Nweke FI (1994a) Cassava distribution in Africa. COSCA Working Paper No. 12. Collaborative Study of Cassava in Africa, International Institute of Tropical Agriculture, Ibadan, Nigeria

- Nweke FI. Farm level practices relevant to cassava plant protection. Afric Crop Sci Journal. 1994;2:563–582. [Google Scholar]

- Nweke FI (1994c) Processing potentials for cassava production and growth in Africa. COSCA working papers No 3. Collaborative study of cassava in Africa, International Institute of Tropical Agriculture, Ibadan, Nigeria

- Oyewole OB, Obieze N. Processing and characteristics of tapioca from cassava. Tropical Sci. 1995;35:19–22. [Google Scholar]

- Phillips T, Taylor DS, Sanni L, Akoroda M. A cassava industrial revolution in Nigeria: the potential for a new industrial crop. Rome: IFAD/FAO; 2004. pp. 43–45. [Google Scholar]

- Robinson G (1990) Rheological testing of fluid foods. Euro Food Drink Rev (summer) 51–5

- Saenz C, Costell E. Rheology of prickly pear (Opuntia ficus indica) concentrated juices. In: Spiss WEL, Schubert H, editors. Engineering and food: physical properties and process control. London: Elsevier Science; 1990. pp. 133–42. [Google Scholar]

- Sopade PA, Filibus TE. The influence of solid and sugar contents on rheological characteristics of Akamu, a semi-liquid maize food. J Food Eng. 1995;24:197–211. doi: 10.1016/0260-8774(94)P2643-J. [DOI] [Google Scholar]

- Sopade PA, Kassum AL. Rheological characterization of Nigerian liquid and semi-liquid foods: Kunun Zaki and Kunun Gyaga. Nigerian Food Journal. 1992;10:23–33. [Google Scholar]

- Sopade PA, Kassum AL. Rheological characterization of Akamu, a semi-solid liquid food from maize, millet and sorghum. Cereal chem. 1992;15:193–202. doi: 10.1016/S0733-5210(09)80071-4. [DOI] [Google Scholar]

- Wenham JE (1995) Postharvest deterioration of cassava, a biotechnology perspective. FAO Plant production and Protection Paper 130. FAO, Rome