Abstract

Effect of heat shrinkable films on shelf life and quality of apples under ambient conditions was studied. Fully mature Royal Delicious apples (starch index 2.5 on 4.0 point scale) were either shrink-wrapped in 3 heat shrinkable films like Cryovac (9 μ), polyolefin (13 μ) and LDPE (25 μ) or were not wrapped at all (control) and then stored at ambient conditions (22–28°C and 52–68% RH). Observations on physiological loss in weight (PLW), decay loss, firmness, juice recovery, total soluble solids (TSS), acidity, ascorbic acid content and overall sensory quality were recorded immediately before packing, and after packing at weekly intervals. Best results were obtained with Cryovac (9 μ) films, which exhibited least PLW (2.3%) and decay loss (2.8%) and higher juice recovery (65.2%) and TSS (16.4%) over other films or control. Apples wrapped in Cryovac films also had higher overall sensory acceptability (8.3 out of 9) over other films or control. These studies indicated that apples could be very well packed in Cryovac heat shrinkable films for about 35 days with least PLW or decay loss, and without any adverse effect on fruit quality.

Keywords: Heat shrinkable film, Physical changes, Chemical changes, Sensory quality, Shelf life

Introduction

Apple (Malus domestica Borkh.) occupies a place of pride amongst temperate fruit crops of India. In India, Royal Delicious cultivar of apple is grown largely because it is liked very much by the consumers and fetches very good price in the market. It matures by mid-August or early September in mid-hill conditions of India, which often results in the glut of fruits in the market (Chadha and Awasthi 2005; Wijewardane and Guleria 2009). Further, after harvesting, fruits are transported to plains for storage and marketing. It causes high post harvest losses. Further, rough handling and transportation usually shorten its storage life. Many techniques are used to extend its storage life, but refrigeration and controlled atmosphere (CA) storage are mostly used in different parts of the world including India. With the use of these techniques, apple can easily be stored for 5–6 months in cold storage up to 6–8 months in CA or hypobaric storage conditions (Chadha and Awasthi 2005). However, these facilities are very costly and sometimes become out of reach of the marginal farmers. Moreover, most of these facilities are available in plains and the producers had to bring their produce to these areas for storage. Number of chemicals have also been tried to extend the shelf life of apples, which as such may be injurious to health due to their residual effect. To overcome these problems, shrink-wrapping, which is a new technique, has been used to reduce post harvest losses and to extend the shelf or storage life in some fruits (Ben-Yehoshua 1983, 1985; Ladaniya and Singh 2001; Mangaraj and Goswami 2009). It provides a barrier for the spread of microbial infection from infected lot to the healthy lot. Anzueto and Rizvi (1985) and Geeson and Smith (1998) reported the usefulness of shrink-wrapping of apples after cold storage to extend the life of apples during retail marketing.

The available literature reveals that a little research work has been done on shrink wrapping of fruits in India. However, some work on individual and tray wrapping of citrus fruits with heat shrinkable films have been done at NRC for citrus at Nagpur, particularly for extending the shelf-life of Nagpur mandarin and Mosambi sweet orange (Ladaniya et al 1997; Ladaniya and Singh 2001; Ladaniya 2003). Batagurki et al (1995) have strongly recommended that refrigeration and controlled atmosphere (CA) facilities are not only relatively expensive, but are not readily available and hence, it becomes imperative to go for plastic film packaging of apples for extending their shelf or storage life in developing countries like India. However, no work has been conducted on apple in India on this aspect. Hence, we conducted these studies with the objective to evaluate different heat shrinkable films in Royal Delicious apples.

Materials and methods

Fully mature Royal Delicious apples were harvested at 2.5 starch index point of maturity from a private orchard at Kullu (Himachal Pradesh), packed in corrugated fibre board boxes (CFB) and transported to Delhi. After sorting and grading, 100 fruits were individually either shrink-wrapped in heat shrinkable films such as Cryovac (9 μ), polyolefin (13 μ ) and LDPE (25 μ) or were not wrapped at all (control) and then stored at ambient conditions (22–28 °C and 52–68% RH). Observations on PLW, decay loss, firmness, juice recovery and quality parameters like TSS, acidity, ascorbic acid content etc., were recorded at 7 days interval.

The experiment was laid out in completely randomized design (CRD) with 4 treatments having 5 replications per treatment. Initial records of firmness, weight, juice, TSS, acidity, total sugars and ascorbic acid content were recorded before lay-out of the experiment.

Fruit firmness was recorded by measuring firmness force with the help of Instron texture analyser (Instron Universal Texture Machine, Model 4201, USA) and represented as N (Newton). TSS (%) was recorded with hand refractometer. Acidity was determined by titrating known amount of fruit juice with 0.1 N NaOH solution. Ascorbic acid contents (mg/100 g pulp) were also determined by following AOAC (1990) procedure. For recording all these parameters, 5 fruits were randomly selected from a single lot, which was replicated 5 times. Overall acceptability of stored apples was conducted by a panel of 5 experts and represented on hedonic scale (0–9).

Data obtained from different parameters were subjected to analysis and differences among the treatments were compared by calculating critical difference (C.D.) (Gomez and Gomez 1994).

Results and discussion

PLW and decay loss

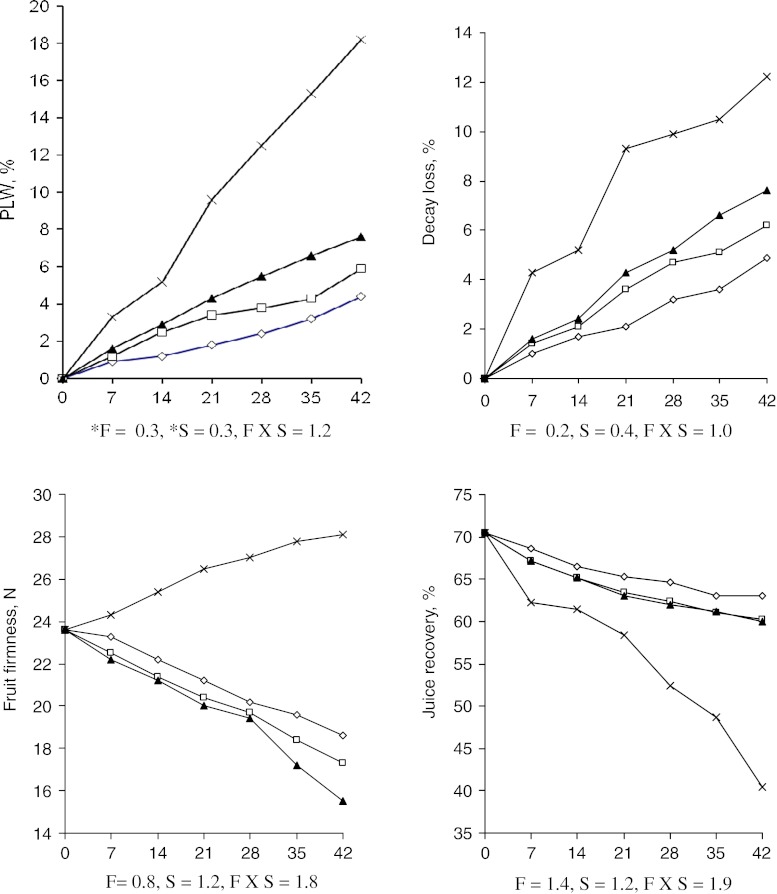

Among films, Cryovac (9 μ) was the most effective in reducing the PLW (2.3%) and decay loss (2.8%) over unwrapped apples (10.7 and 8.7%, respectively). Further, an increase in PLW and decay loss was observed with the increase in storage period from 7 to 42 days (Fig. 1). PLW was 12.5% even on 28th day of storage in unwrapped apples, which increased to 18.2% on 42nd day. Similarly, decay loss was quite high in unwrapped apples (10.5%) on 35th day of storage, which increased to 12.2% on 42nd day of storage. These observations suggest that heat shrinkable films were quite effective in reducing the PLW and decay loss in apples stored under ambient conditions. Reduction in PLW or decay loss may primarily be due to creation of modified atmosphere around apples by the shrinkable films and Cryovac films were more effective (Ben-Yehoshua 1985; Ben-Yehoshua et al 1998). Cryovac films are known to have better gas transmission and water vapour transmission rate than other films (Ladaniya et al 1997) and hence have greater effect on reducing PLW over other films or control. Further, lesser decay of apples in these films may be due reduction in condensation by Cryovac films (Ben-Yehoshua et al 1998). Ladaniya et al (1997) and Ladaniya and Singh (2001) had also reported such trends in PLW and decay in citrus fruits following shrink-wrapping. Similarly, increase in PLW with the increase in storage period in apples has also been reported by Hussain et al (2008) and Wijewardane and Guleria (2009) and in strawberry by Asrey et al (2008).

Fig. 1.

Effect of heat shrinkable films on physical quality of Delicious apples stored under ambient conditions (22–28 °C, 52–68% RH) (n = 5); *F = Film, *S = Storage period

Firmness and juice recovery

Unwrapped apples had higher firmness force (26.5 N) over those wrapped in films (Fig. 1). Apples wrapped in Cryovac films had higher firmness force (18.6 N) than other films. Further, the firmness force first increased and then decreased during storage. Higher firmness force in unwrapped apples might due to greater loss of water from fruits resulting into higher force for puncturing the fruits. Similarly, decrease in firmness force in apples wrapped in Cryovac films during storage must be due to the fact that there is development of mealyness in the fruit with the advancement in storage period. Apples wrapped in Cryovac films have highest juice recovery (65.2%) followed by apples wrapped in polyolefin (63.2%) and LDPE films (63.1%). The percentage of extractable juice decreased during storage from 7 (66.3%) to 42 days (56.0%). Such influence of heat shrinkable films on juice recovery may partly be due to differential rate of water loss from the fruit and gas permeability properties of heat shrinkable films. Heat shrinkable films are known to influence juice recovery in Mosambi orange and Kinnow mandarin, primarily due to curve on PLW over unwrapped fruits (Ladaniya and Singh 2001; Ladaniya 2003). Hussain et al (2008) reported decrease in fruit firmness of different apple cultivars during storage under ambient and refrigerated storage conditions. Pandey et al (2006) observed decline in juice recovery following increase in storage period in apples.

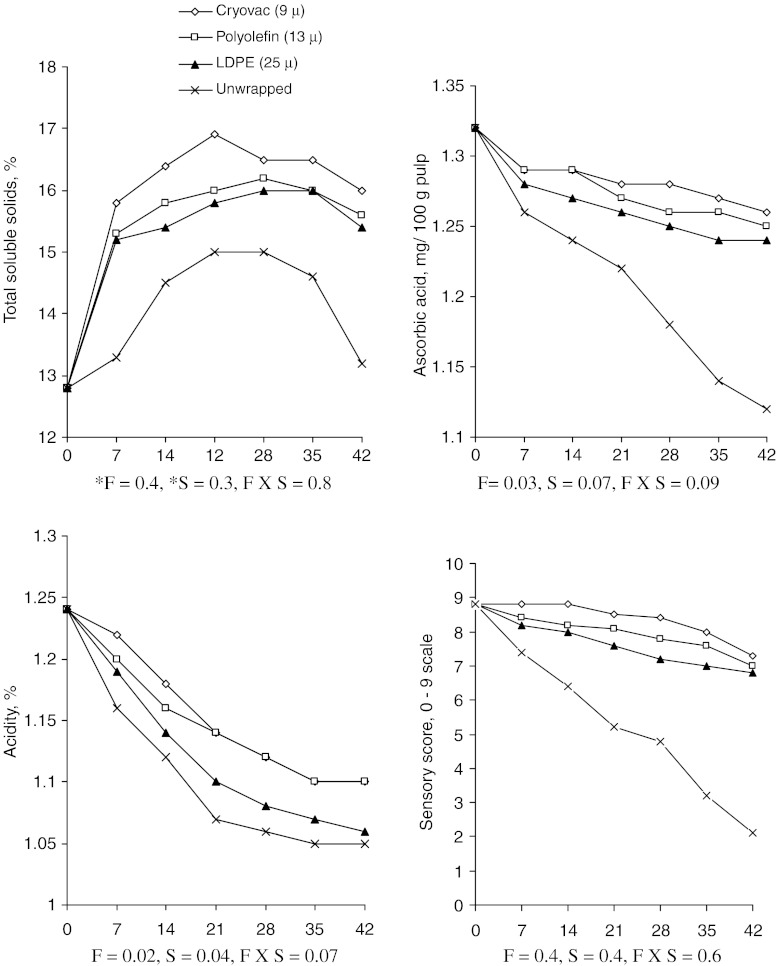

Chemical and sensory quality

Apples wrapped in Cryovac films had highest TSS (16.4%) and those in control had the least (14.3%) (Fig. 2). TSS content increased sharply in apples packed in Cryovac films from 7 to 21 days and then progressively declined during storage than those packed in films or those under control (Unwrapped) (Fig. 2). However, in general, TSS content increased during storage from 7 (14.9%) to 35 days (16.8%) and then decreased on 42 days of storage (15.1%) (Fig. 2). Ben-Yehoshua et al (1998) also reported positive influence of heat shrinkable films on TSS in citrus fruits and of LDPE films in Nagpur mandarin (Ladaniya 2007) and litchi (Semeerbabu et al 2007). Increase in TSS with increase in storage has also been reported by Asrey et al (2008) in strawberry and Wijewardane and Guleria (2009) in apple. Juice acidity showed declining trend during storage but heat shrinkable films had no significant effect on it (Fig. 2). Similarly, acidity declined during storage but was not significantly influenced by the period. However, apples packed in Cryovac films have significantly higher content of ascorbic acid (1.28 mg/100 g pulp) over those kept under control (1.19 mg/100 g pulp) (Fig. 2). Such influence of heat shrinkable films on ascorbic acid content of citrus fruits had also been reported by Ladaniya and Singh (2001) and Ladaniya (2003) or packaging Nagpur mandarin in LDPE films (Ladaniya 2007). Increase in TSS initially and then decrease during storage either at ambient or refrigerated conditions has been reported by Hussain et al (2008) in different apple cultivars.

Fig. 2.

Effect of heat shrinkable films on chemical and sensory quality of Delicious apples stored under ambient conditions (22–280 °C, 52–68% RH) (n = 5); *F = Film, *S = Storage period

Apples packed in Cryovac films had highest sensory score (8.3) and the least score was recorded by the unwrapped apples (Fig. 2), primarily because apples packed in Cryovac films have attractive colour, and texture and were juicier and sweeter than those packed in other heat shrinkable films or unwrapped ones. Similarly, the sensory score decreased during storage from 7 (8.2) to 42 days (5.8). Ladaniya and Singh (2001) and Ladaniya (2003) had also reported that shrink-wrapped citrus fruits had better sensory score over un-wrapped ones.

On the basis of these studies, it can be concluded that Cryovac heat shrinkable films were the best for extending the shelf life of apples for about 2 weeks.

References

- Official methods of analysis. Association official of analytical chemists. 13. Washington: Benjamin Franklin Station; 1990. [Google Scholar]

- Asrey R, Singh R, Jain RK, Kumar A. Maturity, transportation and storage study in strawberry fruit. J Food Sci Technol. 2008;45:543–545. [Google Scholar]

- Anzueto CR, Rizvi SSH. Individual packaging for shelf-life extension. J Food Sci. 1985;50:897–904. doi: 10.1111/j.1365-2621.1985.tb12975.x. [DOI] [Google Scholar]

- Batagurki SB, Raghavan GSV, Smith JP, Orsat V. Plastic film packaging of apples and mangoes. Phala Samskarana. 1995;5:172–177. [Google Scholar]

- Ben-Yehoshua S. Extending life of fruit by individual seal packaging in plastic film-status and prospects. Plasticulture. 1983;58:45–58. [Google Scholar]

- Ben-Yehoshua S. Individual seal packaging of fruit and vegetables in plastic film-A new Post-harvest technique. Hort Sci. 1985;20(1):32–37. [Google Scholar]

- Ben-Yehoshua S, Rodov V, Fishman S, Peretz J. Modified atmosphere packaging of fruits and vegetables: reducing condensation of water in bell peppers and mangoes. Acta Hortic. 1998;464:387–392. [Google Scholar]

- Chadha KL, Awasthi RP. The apple. New Delhi: Malhotra; 2005. [Google Scholar]

- Geeson JD, Smith SM. Retardation of apple ripening during distribution by the use of modified atmospheres. Acta Hortic. 1998;478:245–253. [Google Scholar]

- Gomez AK, Gomez AA. Statistical procedures for agricultural research. New York: Wiley; 1994. [Google Scholar]

- Hussain PR, Dar MA, Meena RS, Mir MA, Safi F, Wani AM. Changes in quality of apple (Malus domestica) cultivars due to γ–irradiation and storage conditions. J Food Sci Technol. 2008;45:44–49. [Google Scholar]

- Ladaniya MS. Shelf-life of seal-packed Mosambi sweet orange fruits in heat shrinkable and stretchable films. Haryana J Hortic Sci. 2003;32:50–53. [Google Scholar]

- Ladaniya MS. Quality and carbendazim residues of Nagpur mandarin fruit in modified atmosphere package. J Food Sci Technol. 2007;44:85–89. [Google Scholar]

- Ladaniya MS, Singh S. Tray over-wrapping of Mosambi sweet orange. J Food Sci Technol. 2001;38:362–365. [Google Scholar]

- Ladaniya MS, Sonkar RK, Dass HC. Evaluation of heat-shrinkable film wrapping of Nagpur mandarin (Citrus reticulata) for storage. J Food Sci Technol. 1997;34:324–327. [Google Scholar]

- Mangaraj S, Goswami TK. Modified atmospeher packaging—an ideal food preservation technique. J Food Sci Technol. 2009;40:399–410. [Google Scholar]

- Pandey G, Verma MK, Tripathi AN. Studies on storage behaviour of apple cultivars. Indian J Hort. 2006;63:368–371. [Google Scholar]

- Semeerbabu MT, Kudachikar VB, Baskaran R, Ushadevi A, Matche RS, Ramana KVR. Effect of post-harvest treatments on shelf-life and quality of litchi fruit stored under modified atmosphere at low temperature. J Food Sci Technol. 2007;44:106–109. [Google Scholar]

- Wijewardane RMNA, Guleria SPS. Effect of various post-harvest coating treatments on storage quality of apple. J Food Sci Technol. 2009;46:549–553. [Google Scholar]