Abstract

Large-scale, monoculture production systems dependent on synthetic fertilizers and pesticides, increase yields, but are costly and have deleterious impacts on human health and the environment. This research investigates variations in banana production practices in Costa Rica, to identify alternative systems that combine high productivity and profitability, with reduced reliance on agrochemicals. Farm workers were observed during daily production activities; 39 banana producers and 8 extension workers/researchers were interviewed; and a review of field experiments conducted by the National Banana Corporation between 1997 and 2002 was made. Correspondence analysis showed that there is no structured variation in large-scale banana producers’ practices, but two other banana production systems were identified: a small-scale organic system and a small-scale conventional coffee–banana intercropped system. Field-scale research may reveal ways that these practices can be scaled up to achieve a productive and profitable system producing high-quality export bananas with fewer or no pesticides.

Keywords: Production systems, Banana, Conventional, Organic, Costa Rica

Introduction

Large-scale monoculture agricultural systems around the world are heavily dependent on high inputs of synthetic fertilizers and pesticides to achieve and sustain high yields. Pesticide use is of grave concern because of its negative effect on both human and non-human organisms on and off the farm. Rice, cotton, soy bean, maize, wheat and barley, and vegetables and fruits, like bananas, are known to be especially intensive in their applications of pesticides; producers apply 85 % of the global consumption of pesticides on these crops (Ekström and Ekbom 2011). However, research on these production systems has led to some advances that have enabled producers to drastically reduce pesticide use. For example, research into integrated pest management (IPM) methods in rice production in Asia has lead to substantial reductions in pesticide use, with improved yield (FAO 2002). These advances, however, have yet to impact large-scale banana production systems.

The high intensity of pesticide use in Central America for the production of export bananas is well documented (Hernandez and Witter 1996; Hernández et al. 2000; Kema 2006; Churchill 2011). Agricultural exports comprise 33.9 % of Costa Rica’s foreign exchange earnings (FAOSTAT 2011), with bananas being the first most valuable export. In 2008, Costa Rica was the third largest exporter of bananas (FAOSTAT 2011). Approximately 35 000 workers are employed in banana production directly and another 63 000 workers are employed in supporting services (Corbana 2009). Costa Rica also has one of the highest intensities of pesticide use in the world (ha−1 agricultural land; FAOSTAT 2004) due in large part to their export banana production, which accounts for an estimated 50 % of the country’s pesticide consumption (Ramírez et al. 2009). High rates of pesticide use affect not only the surrounding environment via contamination (Hernandez and Witter 1996; Matson et al. 1997; Castillo et al. 2006; Geissen et al. 2010; Chelinho et al. 2012) but they also affect soil productivity (Hussain et al. 2009; Gianfreda and Rao 2011) and the human population that come into contact with these pesticides both on the farm and off (Henao and Arbelaez 2002; Kesavachandran et al. 2009; Wesseling et al. 2010). It is vital that producers utilize more sustainable means of production, i.e., one that does not degrade the resource base upon which it depends or that of the surrounding environment (Hamblin 1992; Matson et al. 1997), that reduce their reliance on pesticides and other synthetic inputs. This is also important for producers, who face increasing costs for pesticides.

Substantial amounts of research on banana production is conducted by the National Banana Corporation (Corbana), a non-governmental public entity encharged by law with the responsibility to help improve, promote, and market bananas; by EARTH University, a research university with a 350 ha commercial banana farm; and by the Center for Research and Education of Tropical Agronomy (CATIE). The basis for these studies is often to increase the efficiency of banana production and reduce the environmental impact. These organizations are concerned with identifying ways to control Black Sigatoka and burrowing nematodes, as the majority working in the banana sector see these as significant production problems.

While the above-mentioned organizations and research institutes focus on discovering ways of improving the export banana production system, the research presented in this article sets out to identify alternative systems for production of export bananas to highlight on-farm innovations that may result in decreased use of pesticides. I hypothesized that not all large-scale producers use the same set of production practices that rely heavily on pesticides and that there exists innovative export banana producers that utilize alternative production practices which result in a less chemical-intensive, yet profitable production system. Additional objectives of this research were: (1) to characterize other banana production systems in Costa Rica, with the aim of identifying more sustainable production practices for their potential applicability in export-directed banana production and (2) to assess existing research carried out in Costa Rica in relation to banana production practices for export bananas.

Background

Synergies of Production

Andow and Hidaka (1989) formulated the idea of a production syndrome, which is a set of management practices that are mutually adaptive and lead to high performance. Different syndromes of production represent “production peaks” in the continuum of agricultural production potential. The interaction among practices leads to improved system performance that cannot be explained by the additive effects of individual practices. For example, multiple cropping is one practice used in sustainable agriculture that leads to synergistic effects via facilitation. Facilitation occurs when the presence of one crop improves the production of a second crop by modifying the environment for the second crop (Vandermeer 1989). Another example is the Green Revolution technological package of inputs: high yielding seed varieties, fertilizers and irrigation applied in correct amounts and at the right time led to dramatically increased yields in monoculture cereal and grain crops (Borlaug 1958).

Thus, by breaking down the system into its components and utilizing only some of them, for example, by substituting synthetic chemicals with organic inputs, a farmer will lose the synergistic effect occurring between practices and overall production will be lower. Subsets of a production syndrome may be substantially less productive. In this article, I use production system as analogous to production syndrome.

Banana Production Management Practices

The majority of export banana production in Costa Rica occurs in the Atlantic zone (98.2 % of the total amount of bananas exported; Corbana 2005). According to Corbana (2005), at the end of 2004 there were 137 banana farms producing for export in Costa Rica, with the largest farm at 1367 ha and the smallest farm at only 12 ha. Overall, 42 255 ha were under banana production, averaging 308 ha per farm, and 58 % of the farms were owned by independent producers, whereas 42 % were owned by firms receiving their capital from foreign sources, i.e., multinational companies.

Banana production in Costa Rica consists of the following principal activities: establishing and replanting banana plants, fertilization, managing canal ways, managing the banana bunch, hanging bags around the maturing banana bunches, and pest control. After the banana bunch emerges, a bag is tied around it, serving multiple functions: it is a physical barrier to protect against insect damage; when treated with the insecticide, chlorpyrifos, it is also a chemical barrier to insect damage; and it creates a microclimate that allows the banana bunch to mature more rapidly.

There are three principal pest problems: fungus, weeds, and nematodes. The air-borne fungus, Black Sigatoka (Mycosphaerella fijiensis Morelet) is a problematic disease for banana producers, not only in Costa Rica but throughout Latin America, Africa, and India. The following fungicides (active ingredient) are applied aerially to large plantations: azoxystrobin, bitertanol, difenoconazole, imazalil, mancozeb, propinconazole, pymetrozine, pyraclostrobin, tebuconazol, tiabendazol, tridemorph, and trifloxistrobina. Planting bananas in a mixed system, with other resistant, taller species of trees helps decrease spread because the other trees intercept aerial spores. There are also many manual practices that can help reduce humidity and reduce the spread of Black Sigatoka: cutting away old or infected leaves, the density of banana plants, and eliminating weeds. Weeds are commonly controlled by two methods: chopping the weeds or applying herbicides with a backpack applicator. Herbicides used by banana producers are (listed as active ingredient): diuron, glufosinato ammonium, glyphosate, and paraquat. A third alternative is the use of cover crops, which suppress weed growth, provide structural complexity and habitat for insects, and in some cases can fix nitrogen in the soil. The following are some examples of cover crops that could provide these services in banana farms: Alysicarpus ovaliforlius (Alyceclover), Brachiaria decumbens (signal grass), Chamaecrista rotundifolia (wynn cassia), Cynodon dactylon (couch grass), Dichondra repens (kidney weed), Macroptilium atropurpureum (siratro), and Pueraria phaseoloides (puero/kudzu) (Tixier et al. 2011).

Another significant pest problem for producers in Costa Rica is the burrowing nematode (Radopholus similis). These are microscopic worms that burrow into and damage the roots of banana plants, which also facilitates the attack of other organisms like fungus and bacteria. Nematodes are usually treated with regular applications of nematicides, including the following active ingredients: cadusafos, carbofuran, ethoprophos, oxamyl, phenamiphos, and terbufos. Some cultural control options are: using arbuscular mycorrhizal fungi (AMF; Jaizme-Vega 1998); using nematode-free plant material (in vitro meristems); letting the land lie in a natural fallow or using crop rotation with a non-host cultivar (Sarah 1998); improving drainage in areas of high rainfall (Pinochet 1986); and maintaining good soil fertility, including incorporation of organic matter into the soil (Sarah 1998).

Methodological Approach and Study Site

The methodological approaches used for this research were structured and semi-structured interviews and observation of farm managers during daily activities on the farm. As farm-specific data on management practices in banana production is not made publically available by export producers, interview methods and observations were the most reliable means of obtaining information to test the research hypothesis.

Semi-structured interviews were used in spring 2005 to learn more about the banana sector in Costa Rica. I consulted researchers and extension workers in banana production from: EARTH University; CATIE; Corbana; BASF, a leading chemical supplier; Eco-LOGICA, a certification agency for EurepGAP and organic standards; the Ministry of Agriculture and Cattle (National Program for Plantains); and the Institute for Regional studies on Toxic Substances (IRET). I also spent 1 week observing workers on banana farms to improve my understanding of farm activities for the purposes of developing a comprehensive interview. Based on these consultations and observations, I drafted a structured interview form for banana producers with regards to their production management and I tested the interview on one banana producer.

According to Escobar and Berdegué (1990, cf Köbrich et al. 2003), there are six steps to identify different farm systems: deciding on a theoretical framework for typification, selection of variables, collection of data, factor analysis, cluster analysis, and validation. As earlier stated, the theoretical framework for this research is Andow and Hidaka’s syndromes of production. Thus, the focus for typification is on production practices, production output, and the costs of production. The interview was designed to collect quantitative data regarding management practices that affect productivity and costs. As this encompasses most farm activities, the interview addressed all aspects of farm management: (1) farm characteristics, e.g., farm size, density of banana plants, and variety of bananas grown; (2) productivity and price received; (3) establishment/renovation of the plantation; (4) management of canals; (5) fertilization; (6) pest management, e.g., which pesticides were used, when they were applied, how they were applied, how much they cost, and alternative pest management practices used; (7) costs for labor for different activities performed on the farm; and qualitative data regarding (8) information services.

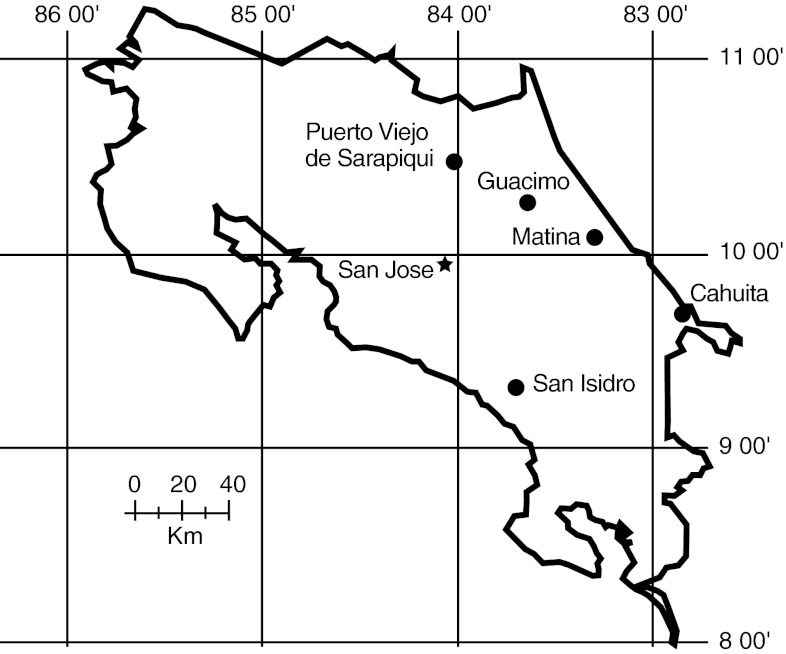

Overall, 39 interviews were conducted with banana producers. Seventeen export banana producers, representing 61 farms (45 % of all farms exporting bananas) in Costa Rica were interviewed for this study in November 2005 (Fig. 1). Interviews were also conducted with small-scale (<20 ha) banana producers: seven organic producers in Talamanca were interviewed in March 2007 and 15 conventional producers in the district of Perez Zeledon were interviewed in November 2007 (Fig. 1). The small-scale producers were clustered geographically based on the availability of support services and infrastructure; there is an organic fruit producers association located in Talamanca, providing certification support to organic producers, leading to the concentration of many small-scale banana producers in this region. With regards to the small-scale conventional banana producers, there is a market network that enables producers in this region to have their bananas collected and sold in San Jose, the capital city.

Fig. 1.

Map of Costa Rica. Most export banana producers are located between Puerto Viejo de Sarapiqui and Matina. Organic producers were all located around Cahuita and small-scale conventional producers were located north of San Isidro

Contact information for producers was very difficult to obtain; in this capacity, valuable support was received from Corbana. I contacted organic producers through the Association of Organic Producers and I contacted small-scale conventional producers through the local Ministry of Agriculture office. Producers were contacted in a random fashion; efforts were made to contact every producer whose number I received. During the interview, producers recalled some of the data from memory, while the more detailed information was provided by producers from their computer and archive records. Each interview was conducted face-to-face, by the author and in Spanish, with either the farm owner or the farm manager and lasted 1–3 h. The same structured interview form was used in all 39 of the interviews. I recorded 35 of the 39 interviews (four producers did not give permission for recording) for later transcription.

Analysis for variation in management practices between different farms was done using correspondence analysis (CA) and cluster analysis with the statistical freeware, Past (Hammer et al. 2009). Analysis for variation among producers was done by examining the different categories of management for different methods used, for example under weed control management, different methods for control can be herbicide application, manually chopping weeds, or the use of cover crops. Variation within each of these activities was also included in the analysis.

Finally, a review was made of all of the research studies conducted by Corbana between 1997 and 2002. A large part of Corbana’s activities is conducting field research on how to improve production practices. These studies were published in Corbana’s annual reviews (1997–2002). The studies were reviewed and recorded for: whether or not it was a field study, if it focused on one or multiple factors, if it was conducted under conventional growing conditions, if it focused on improving the efficiency of production, and whether or not it focused on substituting one practice for another.

Results

The farm-based production data collected was analyzed for variation in practices to identify whether or not structured variation exists, indicating alternative production systems. The results of the analysis reveal that there is no structured variation, i.e., alternative farming systems, within the export banana sector. There was a considerable range of variability within the management practices used by large-scale producers, but there was a lack of systematic implementation of alternative practices that would indicate an alternative production system. Table 1 is a list of all of the different practices that can be used to address different production problems. In the case of the export banana producers, it is only a subset of these practices that are used in the production system and all of the producers use the same set of practices. For example, all export producers make weekly aerial applications of fungicides for the control of Black Sigatoka, at an average cost of 1299 USD ha yr−1.

Table 1.

Different management practices that can be used in banana production for fertilization and pest control

| Category | Type | Activity/application methods |

|---|---|---|

| Fertilization | Synthetic complete package NPK | Many applications with smaller dose or fewer applications with larger dose |

| Organic/chicken manure | ||

| Recycled banana wastes | ||

| Foliar fertilizer | Aerially | |

| Green manure | Cultivated for 3 months, then dug up and mixed back into the soil | |

| Pest control | Weeds | Herbicide application |

| Chopping weeds | ||

| Cover crop | ||

| Shade cover | ||

| Fungus | Aerial application of fungicides (systemic and protective) | |

| Planting in a mixed agroforestry system | ||

| Cutting away old and infected leaves | ||

| Density of banana plants | ||

| Eliminating weeds | ||

| Nematodes | Nematicides applied as dried granules or injected into plant | |

| AMF | ||

| In vitro meristems | ||

| Planting in a mixed agroforestry system | ||

| Natural fallow or crop rotation | ||

| Drainage | ||

| Maintaining good soil fertility with organic matter | ||

| Planting alternative host plants | ||

| Biological control program | ||

| Insects | Plastic bag treated with chlorpyrifos | |

| Biological control program | ||

| Planting in a mixed agroforestry system |

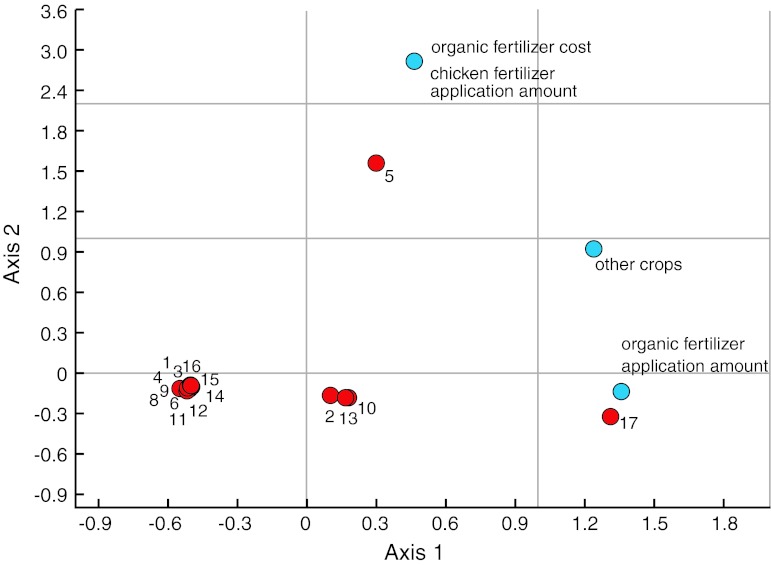

Although there was a lack of variability in practices used to address production problems, CA and cluster analysis were used to investigate the variability that existed within the large-scale banana production system. Both analyses yielded similar results. In the cluster analysis, using unweighted pair-group average (UPGMA) based on the Euclidean distance, farms 5 and 17 were clustered at the last two steps in the hierarchical clustering. In the CA, the first two axes accounted for 90.2 % of the similarity; most of the farms clustered near the origin of the axis, while farms 5 and 17 lay much further from the origin, along opposite axes (Fig. 2). By plotting the variables onto the coordinate system, we see that the use and cost of organic fertilizer and the use of chicken fertilizer were the variables that separated these two farms from the rest (Fig. 2). Farm 5 used organic manure and was the only farm that used chicken manure. In the case of farm 17, its use of organic manure was more than five times greater than the other four farms that reported using organic manure. Their management practices otherwise fell within the average range, as shown in Table 2.

Fig. 2.

Ordination plot generated from CA, with variables also plotted

Table 2.

Descriptive statistics [mean (SD)] of management practices for three different banana production regimes

| Banana (ha) | Density (plant ha−1) | Productivity (boxes yr ha−1) | Fertilizer type | Fertilizer amount (kg yr ha−1) | Fertilizer cycles | Herbicide (L yr ha−1) | |

|---|---|---|---|---|---|---|---|

| Organic | 3.7 (3.7) | 602.8 (161) | 211.5 (114) | Chicken manure, cobalt–magnesium, phosphorus | 65 (154) | 2 (3.3) | 0 |

| Banana–coffee inter-crop | 2.6 (1.7) | 405.7 (101) | 345.1 (141) | Complete formula, nitrogen | 96.8 (30.5) | 2.2 (1.4) | 1.5 (2.9) |

| Export bananas | 294 (230) | 1738 (66) | 2666 (380) | Complete formula, organic/compost, chicken manure | 2775 (511) | 14.3 (4.7) | 3.2 (3.9) |

| Herbicide cycles | Cycles of chopping weeds | Nematicide cycles | Fungicide cycles | Cost of inputsa (USD ha−1) | Gross income from banana sales | Market | Type of farm | Other crops grown with bananas | |

|---|---|---|---|---|---|---|---|---|---|

| Organic | 0 | 3.2 (1.5) | 0 | 0 | 8 | 407 | Sold for processing | Small-scale non-conventional | Avocado, beans, guayabana, cocoa, corn, citrus, mango, pineapple, sunflower seeds, tangerine, timber, yucca |

| Banana–coffee inter-crop | 2 (2.1) | 1.5 (1.4) | 0 | 0 | 34 | 528 | Sold domestically | Small-scale conventional | Coffee, wood trees, plantains |

| Export bananas | 4.4 (4) | 2.7 (3.7) | 2.7 (.9) | 50.4 (21.5) | 4268 | 14 396 | Sold for export | Large-scale conventional | None |

a Includes costs to purchase fertilizers, herbicides, nematicides, fungicides and insecticide-lined bags, and labor costs for application

The results show that there is only one type of farm system for the production of export bananas in Costa Rica, characterized by its extensive area (100+ ha) of monoculture bananas, high productivity, and high intensity of chemical inputs. There are, however, other types of farming systems in Costa Rica, which produce bananas that are sold domestically or sold for processing. Two other systems identified during this study are a small-scale organic agroforestry system and a small-scale conventional banana–coffee intercropped system (see Table 2).

The organic agroforestry banana production system is characterized by small farm size, diversity of crop and tree species, the use of organic fertilizers, low density and low productivity of banana plants compared to export banana producers, and manual chopping of weeds (Table 2). The seven organic producers that were interviewed grew both subgroups Gros Michel and Cavendish, and several grew one to three cultivars of Cavendish. The producers were all members of an organic producers association, through which they received their certification and sold their bananas. They had 1–10 ha of bananas, planted in densities of 500–900 banana plants ha−1. Productivity varied between 57 and 331 boxes ha−1 in 2004. The diversity of other foods cultivated on the farms was used both for private consumption and for sale to provide extra income to producers. Their income earned from banana production was modest, and as a result, some producers could not afford to use fertilizers. Three of the seven producers applied organic fertilizers between two and nine times.

The conventional banana–coffee intercropped production system shared some characteristics with organic producers, but was quite different in other respects. These farms also tended to be small; the 15 producers interviewed in this study owned between .35 and 6 ha of banana and coffee. Banana plants were interspersed at regular intervals amongst the coffee trees (Fig. 3). Like in the organic system, producers grew the Gros Michel subgroup of banana. The density and productivity of bananas was also low compared to the export banana production system. Producers used varying amounts of fertilizers and herbicides on the farms, but in most cases, these products were used for the benefit of coffee productivity, with banana plants being an indirect beneficiary of their application. Banana plants are beneficial for coffee production because they provide shade for coffee trees and the surrounding area, protecting coffee trees from too much direct exposure to sunlight and helping to block out light to the ground, thus reducing weed growth. Profit earned from the sale of banana bunches also helps to diversify and increase producers’ income sources.

Fig. 3.

Three different banana production systems: a organic, b banana-coffee intercropped, c export. Photos by Angelina Sanderson Bellamy

When the interview data was analyzed to assess existing research carried out in Costa Rica in relation to banana production practices, it was found that Corbana is the primary driver in research, extension and outreach within the export banana sector. Corbana works with both independent and multinational export banana producers; every farm is visited by extension workers from Corbana every two weeks. Half of the producers interviewed responded that they turn to Corbana when they need help with some management aspect on the farm. When I reviewed the field studies conducted by Corbana, all of them were single-factor studies in conventionally managed banana plantations. Of the 53 reviewed research studies conducted by Corbana, the majority of them aimed at improving the efficiency of production while six of them could also be categorized as addressing the substitution of chemical practices. None of these studies looked at the effect of using multiple practices together or made any attempts at system redesign.

Discussion

Commercial banana plantations in Costa Rica are heavily dependent on several inputs throughout the production phases of a banana plant. Most of the inputs used on the farm are imported to Costa Rica. Over time, the costs of imported inputs have steadily risen, because most of them are based in fossil fuels, the cost of which has also been increasing (Hernández et al. 2000). To continue achieving profitability, producers have managed to streamline production and reduce the amount of inputs into the system. Despite these increases in efficiency, results from this study show that the average cost to control Black Sigatoka still consumes 10 % of gross income from banana sales, while overall, 30 % of income is spent on inputs. Technological innovation in the production system has enabled farmers to increase their efficiency and improve banana yields, and thus maintain profitability. However, these trends can not continue indefinitely, creating a need for alternatives.

This is where valuable lessons may be learned from the alternative farm systems identified here. Although banana productivity is low in the organic and banana–coffee intercropped systems, the diversity of crops and tree species present makes the production system less susceptible to pests (Lin 2011; Tscharntke et al. 2011) and diversifies producers’ income sources. Furthermore, the integration of different trees and crops in an agroforestry system can also enhance soil fertility, reduce erosion, improve water quality, enhance biodiversity, increase esthetics (with value for ecotourism, an important source of income in Costa Rica), and sequester carbon (Garrett and McGraw 2000; Garrity 2004; Williams-Guillén et al. 2008; Nair et al. 2009). As Costa Rica already has a well-established system for Payment for Ecosystem Services, it may also be possible for producers to receive payments for maintaining an agroforestry system (Pagiola 2008). The benefits of agroforestry systems also help to create a more resilient system. Enhanced resilience refers to the production systems’ increased capability to absorb disturbances without losing its structural characteristics (Gunderson 2000 and references therein), which in this case results in high crop productivity. Improved resilience is important because current global change patterns mean that producers are more likely to experience greater climate variability and shifts in temperature and precipitation patterns, possibly leading to effects such as changes in nutrient cycling and shifts in pest occurrences and plant diseases, which greatly influences food production (Fuhrer 2003; Jones and Thornton 2003).

There is a need for research to investigate how much these alternative agroforestry systems can be scaled up; at what size do you lose the benefits of diversity and become more susceptible to pest problems and where lies the economic threshold? A farm with other species of trees intercropped becomes more difficult to manage with regards to uniformity of management activities, but it offers many other benefits, including reduced dependence on pesticides and diversified income sources.

There are crop studies of the effects of scaling-up organic production, both of large-scale conventional producers converting to organic production (Smukler et al. 2008) and of small-scale organic producers increasing landholding size (Styger et al. 2011). The success of such efforts is not to be predicted by the outcome from other projects of scaling-up, but rather from the processes involved in achieving successful larger scale sustainable crop production. Farm-scale site conditions vary and each production system has to be developed accordingly, as opposed to following a model of crop production, as is done today within the export banana industry. However, producers already have a very detailed knowledge about climatic, soil, and pest conditions on their farm, and if supplemented by training and extension assistance based in agroforestry, it may be possible to convert large-scale banana farms to a profitable, diverse agroforestry system. This will, however, take innovative leaders to help create a new way of producing export bananas more sustainably.

As shown in the results of the analysis of research conducted within the banana sector, this is exactly where the gap exists. There is a need for more multi-factored research that examines how a collective set of alternative practices can effectively work together. A field-scale approach would enable researchers to undertake a comprehensive analysis by considering the production system at many scales; modeling approaches can allow researchers to also examine the interactions that occur between scales at the landscape level (Ewert et al. 2011). The goal of this research would be to redesign the production system so that it can achieve a new set of synergies resulting in acceptable yields, reduced vulnerability to banana pests and reduced chemical-use intensity.

MacRae et al. (1990) define three steps to making the transition from conventional systems to more sustainable systems: increased efficiency, substitution, and redesign. Increased efficiency refers to alterations in the production system to reduce chemical inputs. One example of this is more frequent applications of smaller doses of fertilizers so that more nutrients are delivered to the plant instead of being washed away with rain, and less fertilizer is used overall. Only one of the export producers used this approach, while three others applied fertilizers more frequently, but not in reduced dosages. The second step is to substitute agrochemicals and practices that depend on them with materials and practices that have a lower impact on the environment. The last step, redesign, refers to the design of a system that relies on an alternative set of practices different from those used in conventional agriculture. However, none of the Corbana studies looked at the effect of using multiple practices together, let alone made any attempts at system redesign. The substitution of these individual practices may lead to a deceptively lower production level than conventional practices, because the synergy that occurs in an alternative system only occurs when all of the pieces are implemented together.

Lin (2011) outlines three reasons for why producers are resistant to switching to a more diverse, both structurally and biologically, production system despite the advantages given above: (1) economic policy incentives for the production of monoculture crops outweigh the perceived incentives to implement diversified farming systems, (2) efforts to adapt agriculture focus on the development of biotech solutions, and (3) there is a mistaken perception that biomass production is substantially greater in monoculture systems than in multispecies systems. In the case of export banana production in Costa Rica, management practices are largely driven by both the multinational companies, who often dictate chemical control regimes, even among independent producers, and Corbana, which tends to focus on the development of biotech solutions to address on-farm production problems. There are many studies that have been conducted in other crop systems showing that greater crop diversity leads to increased overall yields as well as greater stability in yield levels (Tilman et al. 2006; Picasso et al. 2008; Smith et al. 2008). Field-scale studies of banana production systems could help farm managers identify an appropriate balance of diversification to satisfy both production needs (i.e., set quotas based on filling shipping containers) and environmental protection needs (i.e., enhanced resilience against increasing precipitation variability or pest incidence). There are many ways in which diversification can occur within the production system; field-scale studies and experimentation can help producers identify the methods that best serve their individual needs, which may vary from producer to producer, potentially leading to a landscape of various different types of banana production systems, and ultimately creating diversification at the landscape scale.

Conclusion

There is currently only one production system for Costa Rican export bananas: a large-scale monoculture, agrochemically intensive form of production. Owing to the current systems’ susceptibility to pests and the damage and reduced growth that they cause, producers are dependent on high rates of applications of fertilizers, fungicides, and nematicides to produce export bananas. Currently, research conducted to assist banana producers and improve production techniques, while aimed at improving efficiency, only addresses solutions that are applicable to the present production system. Thus, while the research addresses step one, and in some cases, step two of the transition to a more sustainable system, it fails to look critically at the entire production system and ask the question, “how can it be different?”

There are indicators, however, that bananas can be produced differently. The organic agroforestry and the banana–coffee intercropping production systems illustrate that bananas can be produced profitably using methods that are less intensive with regards to chemical inputs. It remains, however, to investigate whether or not these practices can be scaled up with profit levels comparable to the current system.

Acknowledgments

I would like to thank Jose Sauma at Corbana, Adriana Rodriguez at Earth University, Miguel Rivera at ACAPRO, Victor Solano and Roberto Chacon at the Ministry of Agriculture, Viria Bravo at IRET, Iriana Martinez, and Romano Orlich and all of the other banana producers who took the time to answer my extensive interview questions.

Angelina Sanderson Bellamy

is currently a post-doctoral researcher at Stanford University, working with land-use change and forest cover in Costa Rica. She has her PhD in Ecotoxicology from the Department of Systems Ecology at Stockholm University. Her research interests include identifying viable and sustainable alternative production systems (both small- and large-scale) for chemical-intensive farm management systems in Latin America.

References

- Andow DA, Hidaka K. Experimental natural history of sustainable agriculture: syndromes of production. Agriculture, Ecosystems & Environment. 1989;27:447–462. doi: 10.1016/0167-8809(89)90105-9. [DOI] [Google Scholar]

- Borlaug NE. The impact of agricultural research on Mexican Wheat Production. Transactions of the New York Academy of Science. 1958;20:278–295. doi: 10.1111/j.2164-0947.1958.tb00588.x. [DOI] [Google Scholar]

- Castillo LE, Martinez E, Ruepert C, Savage C, Gilek M, Pinnock M, Solis E. Water quality and macroinvertebrate community response following pesticide applications in a banana plantation, Limon, Costa Rica. Science of the Total Environment. 2006;367:418–432. doi: 10.1016/j.scitotenv.2006.02.052. [DOI] [PubMed] [Google Scholar]

- Chelinho S, Lopes I, Natalda-Luz T, Domene X, Nunes ME, Espindola ELG, Ribeiro R, Sousa JP. Integrated ecological risk assessment of pesticides in tropical ecosystems: A case study with carbofuran in Brazil. Environmental Toxicology and Chemistry. 2012;31:437–445. doi: 10.1002/etc.738. [DOI] [PubMed] [Google Scholar]

- Churchill ACL. Mycosphaerella fijiensis, the Black leaf streak pathogen of banana: progress towards understanding pathogen biology and detection, disease development, and the challenges of control. Molecular Plant Pathology. 2011;12:307–328. doi: 10.1111/j.1364-3703.2010.00672.x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Corbana. 1997–2002. Annual review. San Jose: Corporación Bananera Nacional (in Spanish).

- Corbana. 2005. Costa Rica: Banana export statistics 2004. San Jose: Corporación Bananera Nacional, 58 pp (in Spanish).

- Corbana. 2009. Origins of the banana industry in Costa Rica. www.corbana.co.cr. Accessed 28 Jan 2009 (in Spanish).

- Ekström G, Ekbom B. Pest control in agro-ecosystems: an ecological approach. Critical Reviews in Plant Sciences. 2011;30:74–94. doi: 10.1080/07352689.2011.554354. [DOI] [Google Scholar]

- Escobar, G., and J. Berdegué, eds. 1990. Classification of agricultural production systems. Santiago: RIMISP (in Spanish).

- Ewert F, van Ittersum MK, Heckelei T, Therond O, Bezlepkina I, Andersen E. Scale changes and model linking methods for integrated assessment of agri-environmental systems. Agriculture, Ecosystems & Environment. 2011;142:6–17. doi: 10.1016/j.agee.2011.05.016. [DOI] [Google Scholar]

- Ten years of IPM training in Asia—from farmer field school to community IPM. Rome: FAO; 2002. [Google Scholar]

- FAOSTAT. 2004. FAOSTAT website. http://faostat.fao.org/. Accessed 2 June 2011.

- FAOSTAT. 2011. FAOSTAT website. http://faostat.fao.org/. Accessed 15 Jan 2012.

- Fuhrer J. Agroecosystem responses to combinations of elevated CO2, ozone, and global climate change. Agriculture, Ecosystems & Environment. 2003;97:1–20. doi: 10.1016/S0167-8809(03)00125-7. [DOI] [Google Scholar]

- Garrett HE, McGraw RL. Alley cropping practices. In: Garrett HE, Rietveld WJ, Fisher RF, editors. North American agroforestry: an integrated science and practice. Madison: ASA; 2000. pp. 149–188. [Google Scholar]

- Garrity DP. Agroforestry and the achievement of the millennium development goals. Agroforestry System. 2004;61:5–17. doi: 10.1023/B:AGFO.0000028986.37502.7c. [DOI] [Google Scholar]

- Geissen V, Ramos FQ, de J. Bastidas-Bastidas P, Díaz-González G, Bello-Mendoza R, Huerta-Lwanga E, Ruiz-Suárez LE. Soil and water pollution in a banana production region in tropical Mexico. Bulletin of Environmental Contamination and Toxicology. 2010;85:407–413. doi: 10.1007/s00128-010-0077-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gianfreda L, Rao MA. The influence of pesticides on soil enzymes. Soil Enzymology. 2011;22:293–312. doi: 10.1007/978-3-642-14225-3_16. [DOI] [Google Scholar]

- Gunderson LH. Ecological resilience—in theory and application. Annual Review of Ecological Systems. 2000;31:425–439. doi: 10.1146/annurev.ecolsys.31.1.425. [DOI] [Google Scholar]

- Hamblin, A. 1992. How do we know when agricultural systems are sustainable? In Environmental indicators for sustainable agriculture, report on a national workshop, November 28–29, 1991, ed. A. Hamblin. Canberra, Australia: Bureau of Rural Resources, Land and Water Resource Research and Development Corporation.

- Hammer, Ø., D.A.T Harper, and P.D. Ryan. 2009. PAST—palaeontological statistics, ver. 1.90. http://folk.uio.no/ohammer/past/. Accessed March 2011.

- Henao S, Arbelaez P. Epidemiological situation of acute pesticide poisoning in the Central American Isthmus, 1992–2000. Epidemiological Bulletin. 2002;23:5–9. [PubMed] [Google Scholar]

- Hernández, C., S.G. Witter, C.A.S. Hall, and C. Fridgen. 2000. The Costa Rican banana industry. In Quantifying sustainable development: The future of tropical economies, ed. C.A.S. Hall, 761 pp. San Diego: Academic Press.

- Hernandez CE, Witter SG. Evaluating and managing the environmental impact of banana production in Costa Rica: A systems approach. AMBIO. 1996;25:171–178. [Google Scholar]

- Hussain S, Siddique T, Saleem M, Arshad M, Khalid A. Chapter 5: Impact of pesticides on soil microbial diversity, enzymes, and biochemical reactions. Advances in Agronomy. 2009;102:159–200. doi: 10.1016/S0065-2113(09)01005-0. [DOI] [Google Scholar]

- Jaizme-Vega, M.C. 1998. Application of arbuscular mycorrhizal fungi in micropropagated banana. In Organic/Environmentally Friendly Banana Production. Proceedings of a Workshop Held at EARTH, Guacimo, Costa Rica, 27–29 July 1998, eds. F.E. Rosales, S.C. Tripon, J. Cerna, 250 pp. France: INIBAP.

- Jones PG, Thornton PK. The potential impacts of climate change on maize production in Africa and Latin America in 2055. Global Environmental Change. 2003;13:51–59. doi: 10.1016/S0959-3780(02)00090-0. [DOI] [Google Scholar]

- Kema, G.H.J. 2006. The pesticide reduction plan for banana. In XVII Annual International Reunion ACORBAT, eds. E. Soprano, F.A. Tcacenco, L.A. Lichtemberg, M.C. Silva, pp. 3–4. Joinville, Santa Catarina: Bananicultura: um negócio sustentável ACORBAT.

- Kesavachandran CN, Fareed M, Pathak MK, Bihari V, Mathur N, Srivastava AK. Adverse health effects of pesticides in agrarian populations of developing countries. Reviews of Environmental Contamination and Toxicology. 2009;200:33–52. doi: 10.1007/978-1-4419-0028-9_2. [DOI] [PubMed] [Google Scholar]

- Köbrich C, Rehman T, Khan M. Typification of farming systems for constructing representative farm models: Two illustrations of the application of multi-variate analyses in Chile and Pakistan. Agricultural Systems. 2003;76:141–157. doi: 10.1016/S0308-521X(02)00013-6. [DOI] [Google Scholar]

- Lin BL. Resilience in agriculture through crop diversification: Adaptive management for environmental change. BioScience. 2011;61:183–193. doi: 10.1525/bio.2011.61.3.4. [DOI] [Google Scholar]

- MacRae RJ, Hill SB, Mehuys GR, Henning J. Farm-scale agronomic and economic conversion from conventional to sustainable agriculture. Advanced Agronomy. 1990;43:155–198. doi: 10.1016/S0065-2113(08)60478-2. [DOI] [Google Scholar]

- Matson PA, Parton WJ, Power AG, Swift MJ. Agricultural intensification and ecosystem properties. Science. 1997;277:504–509. doi: 10.1126/science.277.5325.504. [DOI] [PubMed] [Google Scholar]

- Nair PKR, Kumar BM, Nair VD. Agroforestry as a strategy for carbon sequestration. Journal of Plant Nutrition Soil Science. 2009;172:10–23. doi: 10.1002/jpln.200800030. [DOI] [Google Scholar]

- Pagiola S. Payments for environmental services in Costa Rica. Ecological Economics. 2008;65:712–724. doi: 10.1016/j.ecolecon.2007.07.033. [DOI] [Google Scholar]

- Picasso VD, Brummer EC, Liebman M, Dixon PM, Wilsey BJ. Crop species diversity affects productivity and weed suppression in perennial polycultures under two management strategies. Crop Science. 2008;48:331–342. doi: 10.2135/cropsci2007.04.0225. [DOI] [Google Scholar]

- Pinochet J. A note on nematode control practices on bananas in Central America. Nematropica. 1986;16:197–203. [Google Scholar]

- Ramírez, F., E. Chaverri, E. de la Cruz, C. Wesseling, L. Castillo, and V. Bravo. 2009. Importation of pesticides in Costa Rica: Period 1977–2006. Heredia, Costa Rica: IRET, Universidad Nacional (in Spanish).

- Sarah, J.L. 1998. Cultural practices as a way of nematode control in banana. In Organic/Environmentally Friendly Banana Production. Proceedings of a Workshop Held at EARTH, Guacimo, Costa Rica, 27–29 July 1998, eds. F.E. Rosales, S.C. Tripon, J. Cerna, 250 pp. France: INIBAP.

- Smith R, Gross K, Robertson G. Effects of crop diversity on agroecosystem function: Crop yield response. Ecosystems. 2008;11:355–366. doi: 10.1007/s10021-008-9124-5. [DOI] [Google Scholar]

- Smukler SM, Jackson LE, Murphree L, Yokota R, Koike ST, Smith RF. Transition to large-scale organic vegetable production in the Salina Valley, California. Agriculture, Ecosystems & Environment. 2008;126:168–188. doi: 10.1016/j.agee.2008.01.028. [DOI] [Google Scholar]

- Styger E, Aboubacrine G, Attaher MA, Uphoff N. The system of rice intensification as a sustainable agricultural innovation: Introducing, adapting and scaling up a system of rice intensification practices in the Timbuktu region of Mali. International Journal of Agricultural Sustainability. 2011;9:67–75. doi: 10.3763/ijas.2010.0549. [DOI] [Google Scholar]

- Tilman D, Reich PB, Knops JMH. Biodiversity and ecosystem stability in a decade-long grassland experiment. Nature. 2006;441:629–632. doi: 10.1038/nature04742. [DOI] [PubMed] [Google Scholar]

- Tixier P, Lavigne C, Alvarez S, Gauquier A, Blanchard M, Ripoche A, Achard R. Model evaluation of cover crops, application to eleven species for banana cropping systems. European Journal of Agronomy. 2011;34:53–61. doi: 10.1016/j.eja.2010.10.004. [DOI] [Google Scholar]

- Tscharntke T, Clough Y, Bhagwat SA, Buchori D, Faust H, Hertel D, Hölscher D, Juhrbandt J, et al. Multifunctional shade-tree management in tropical agroforestry landscapes—a review. Journal of Applied Ecology. 2011;48:619–629. doi: 10.1111/j.1365-2664.2010.01939.x. [DOI] [Google Scholar]

- Vandermeer J. The ecology of intercropping. Cambridge: Cambridge University Press; 1989. p. 237. [Google Scholar]

- Wesseling C, de Joode BW, Keifer M, London L, Mergler D, Stallones L. Symptoms of psychological distress and suicidal ideation among banana workers with a history of poisoning by organophosphate or n-methyl carbamate pesticides. Occupational and Environmental Medicine. 2010;67:778–784. doi: 10.1136/oem.2009.047266. [DOI] [PubMed] [Google Scholar]

- Williams-Guillén K, Perfecto I, Vandermeer J. Bats limit insects in a tropical agroforestry system. Science. 2008;320:70. doi: 10.1126/science.1152944. [DOI] [PubMed] [Google Scholar]