Abstract

Objectives

Falls from heights are a leading cause of mortality and morbidity in the construction industry, especially among inexperienced workers. We surveyed apprentice carpenters to identify individual and organizational factors associated with falls from heights.

Methods

We developed a 72-item fall prevention survey with multiple domains including fall experience, fall prevention knowledge, risk perceptions, confidence in ability to prevent falls, training experience, and perceptions of the safety climate and crew safety behaviors. We administered the questionnaire to apprentice carpenters in this cross-sectional study.

Results

Of the 1,025 respondents, 51% knew someone who had fallen from height at work and 16% had personally fallen in the past year, with ladders accounting for most of the falls. Despite participation in school-based and on-the-job training, fall prevention knowledge was poor. Ladders were perceived as low risk and ladder training was rare. Apprentices reported high levels of unsafe fall-related behaviors on their work crews. Apprentices working residential construction were more likely to fall than those working commercial construction, as were apprentices working on crews with fewer senior carpenters to provide mentorship, and those reporting more unsafe behaviors among fellow workers.

Conclusions

Despite participation in a formal apprenticeship program, many apprentices work at heights without adequate preparation and subsequently experience falls. Apprenticeship programs can improve the timing and content of fall prevention training. This study suggests that organizational changes in building practices, mentorship, and safety culture must also occur in order to decrease worker falls from heights.

Keywords: safety and health, construction safety, injury prevention, ladder, construction

INTRODUCTION

In 2007 the US construction industry experienced more fatalities than any other industry (1), with falls accounting for 37% of these fatalities(2). Falls accounted for an even larger proportion of the fatalities in residential construction, causing 42% of fatalities in new single-family home construction, and 55% in residential framing (2). Deaths due to falls in construction have risen in the past decade, contrary to national trends of declining mortality from other occupational fatalities. (3,4).

In a three year active surveillance project with over 5,000 unionized residential carpenters, falls from height accounted for 20% of all the Occupational Safety and Health Administration’s (OSHA) recordable injuries (4). These fall occurred most often from ladders, scaffolding, roofs, unsecured surfaces, and unprotected openings (5). Fall protection strategies mandated by OSHA construction standards (6)and alternative strategies described in the OSHA residential guidelines(7), such as guardrails, toe boards, tying off to appropriate anchors, and guarding openings, would have prevented many of these falls; unfortunately, these practices were not the norm (5). Many of these non-fatal events (5) bear striking similarity to the fatal falls described in the Fatality Assessment and Control Evaluation Program at the National Institute of Occupational Safety and Health (8).

The fall safety of construction workers depends upon a multitude of factors, including individual factors such as physical agility, vigilance, knowledge, attitudes, and beliefs; organizational factors at the contractor level such as coworker attitudes, equipment, and management practices; and societal factors such as federal inspections, safety standards, and economical conditions. Individual factors necessary to succeed in construction are developed through school-based instruction and on-the-job mentorship. Organizational factors, such as firm size (9), observed safety environment (5), and safety culture (10) influence worker safety and vary greatly among contracting companies. Societal factors drive the pace of the construction trade and strongly affect both the organization and the individual.

The goals of this study were to describe the distribution of individual and organizational factors related to fall safety in a large cross-sectional study of apprentice carpenters, and to examine associations between these factors and reported falls from height. Our study focused on residential construction workers, a high risk population that has not been widely studied. Results from this project will help researchers, union leaders, apprenticeship trainers, and residential contractors identify and design interventions to improve the fall safety of residential construction workers at both the individual level, through apprenticeship training experiences, and at the organizational level, through worksite assessment, mentorship and supervision, and modification of building practices.

METHODS

Population

The study population for our survey was apprentice carpenters attending regularly scheduled training at the Carpenters’ Joint Apprenticeship Program (CJAP) in St. Louis, Missouri, USA during a 6-month period between December 2005 and May 2006. We initially sampled all apprentices to reach a goal of 200 apprentices in each year of the four-year union-based training program, then over-sampled second and third year apprentices to provide a comparison group for future intervention studies. The CJAP is supported by the Carpenters’ District Council of Greater St. Louis and Vicinity and the Home Builders Association of Greater St. Louis. At the time of the study, there were 2,400 apprentice carpenters in this 4-year apprenticeship program. Ninety (90) percent of these apprentices performed residential construction.

Questionnaire development and administration

We identified domains of interest relevant to fall prevention through review of US construction safety standards (6, 7, 13, 14, 15), fall statistics and literature exploring fall causation, consultation with subject matter experts, and focus groups with apprentice carpenters at various stages of their training (16). We reviewed existing measurement tools in the process of constructing questionnaire items, including some that were specific to construction (4, 17, 18, 19, 20) and others used with other occupational groups that explored relevant concepts (21). We administered a preliminary version of the questionnaire to the CJAP trainers and several apprentices, facilitating feedback in focus group format. Our final questionnaire had 72 items with 11 domains including: demographic data, employment data, fall history, task performance and equipment use history and training, risk perceptions, knowledge, confidence, work crew behaviors, workplace safety climate, barriers to fall protection, and training effectiveness.

The employment data section identified the amount of time worked in residential construction in the last year, employer size, and average number of journeymen and apprentices in a work crew. In exploring fall history, a fall from height was defined as “falling from one height to another, like falling from a ladder or down stairs, but not a fall to the floor you are standing on”. If apprentices reported a fall from height in the past year, they identified the type of surface from which they fell, distance fallen, medical treatment and work status after the fall, factors that contributed to the fall and what could be done to prevent others from experiencing this type of fall.

Apprentices reported if they received school-based and on-the-job training prior to performing 11 work tasks or using specific equipment. Eight multiple-choice questions assessed fall prevention knowledge of OSHA construction standards. Apprentices rated the degree of fall risk for 12 common work tasks and rated confidence in their abilities to use safety equipment (2 items) and prevent falls (2 items). The frequency of five crew behaviors while working at heights was rated on a 5-point scale. Five items measured the apprentices’ perceptions of their workplace safety climate on a 5-point scale. These items represented various levels of organizational factors described by Bolman and Deal (22)

Instructors handed out the survey and informed consent form to apprentices attending regularly scheduled school-based training at CJAP and briefly explained the project and its voluntary nature. All surveys, completed or not, were placed by the apprentices in sealed envelopes, and placed into a box in the classroom, where they were retrieved by a university researcher. All procedures were approved by the Institutional Review Board at Washington University.

Data Management and Analysis

Initial descriptive statistics were generated for all variables including frequencies of categorical responses and distributions of continuous variables. Employer size was categorized into small (< 25 carpenters), medium (26–75 carpenters), and large (> 75 carpenters) employers. The percentage of knowledge questions answered correctly was calculated for each participant. In order to calculate scores for the safety climate, crew behavior, risk perception, and confidence domains, we added the score for each item within the domain (item scores ranged from 1 to 4 or 5), equally weighting each item, and divided by the number of items in the domain. For domains with missing items, we computed the mean score for that domain and imputed this mean value for the missing value(s) if at least 75% of the items were completed. Scale reliability was assessed using Cronbach’s alpha to assess the internal consistency of items within the scales in our apprentice sample.

We hypothesized that falls would be more common 1) in apprentices with less carpentry experience, 2) among residential carpenters as compared to commercial carpenters, 3) at sites where the ratio of apprentices to journeymen was high, 4) and at sites with high rates of unsafe worker behaviors when working at heights. Since our scales were internally consistent based on Cronbach’s alpha (0.92 risk perception, 0.78 safety climate, 0.67 confidence, and 0.60 crew behavior), we used domain scores to combine individual variables for analysis. We explored relationships between fall experience and the individual and organizational domains of the survey using standard parametric and non-parametric statistics. We computed crude odds ratios for each domain/variable and for the employer size categories for all falls from heights and ladder falls, and entered all variables/scales into multivariate logistic regression models using forward stepwise and backward selection methods. Variables with p-values less than 0.05 were considered to be statistically significant. We assessed the model fit using Hosmer and Lemeshow test. All analyses were pre-specified and performed using SAS (Version 9.2; SAS Institute, Cary, NC).

RESULTS

Descriptive Results

The questionnaire was distributed to 1,037 apprentices and completed by 1,025 apprentices in all stages of training (98.9% response rate). Respondents comprised 43% of the 2,400 apprentices in the CDC at the time. The mean age was 26 years (SD 5.8, range 18–49). The majority of apprentices were white males. Twenty-one percent (21%) of respondents were first year apprentices, 30% second year, 31% third year, and 19% fourth year apprentices. The majority of the apprentice respondents framed single-family homes for large sized contractors.

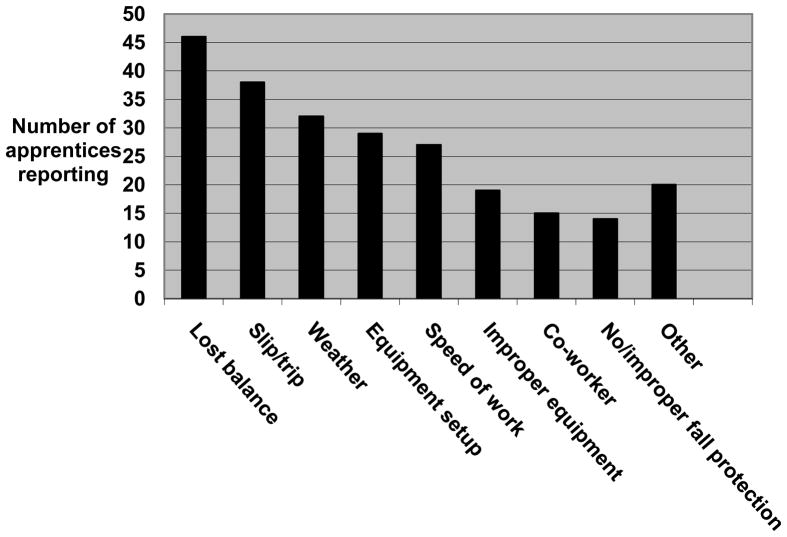

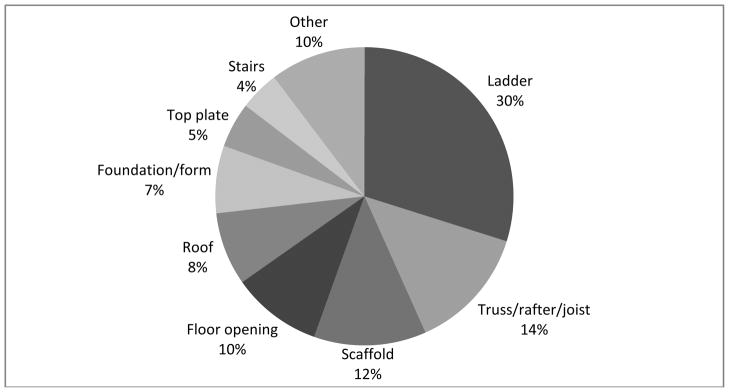

Over half of the apprentices reported an acquaintance who experienced a serious work-related fall from height. Sixteen percent (n=164) had personally fallen from a height in the past year. Of those who fell, 17 (10.4%) lost work time, 9 (5.6%) returned to restricted work, 26 (15.9%) received medical care, and 13 (7.9%) received prescription medication. The average distance fallen was 3 meters, with a range from 0.6 to 9 meters. Thirty percent (30%) of the falls occurred from ladders (figure I). Loss of balance, slip/trip, and weather conditions were the most common contributing factors (figure II). When asked what could be done to prevent someone else from experiencing the type of fall they experienced, organizational factors described were increased availability of proper working equipment and avoid working in bad weather, individual factors included working extra carefully, while other factors could be attributed to both the organizational and individual level; such as proper installation of equipment, slowing the work pace, and consistently using fall protection methods.

Figure I.

Surfaces apprentice fell from or through (n=164 apprentices who fell from height)

Figure II.

Reported factors contributing to falls from height (n=164 apprentice falls)

We asked about common work tasks and equipment use related to falls or fall prevention. While most apprentices were trained prior to performing these tasks, their training did not align with required work tasks (table I). Use of step and extension ladders were the two most common work tasks reported (97% and 96%), yet the least common tasks apprentices were trained in prior to performance on the job (53% and 56%). Only two thirds of apprentices reported that they were trained before performing other common tasks at height, including roof sheathing and setting trusses, joists, and outside walls. Conversely, 87% of apprentices were trained to use personal fall arrest systems (PFAS), yet apprentices reported that these systems were used commonly at only 13% of worksites.

Table I.

Apprentices who reported performing tasks on the job and percent who received training prior to performing task on the job

| Task | Had performed task on-the-job | Were trained prior to task performance |

|---|---|---|

| Use personal fall arrest | 81.4% | 87.1% |

| Use pump jack scaffold | 66.2% | 76.4% |

| Use ladder jack scaffold | 78.9% | 68.0% |

| Work near unprotected openings/edges | 82.1% | 67.7% |

| Set outside walls | 86.5% | 67.6% |

| Set trusses | 85.0% | 65.8% |

| Set joists | 84.3% | 65.6% |

| Sheath roof | 78.8% | 61.8% |

| Use extension ladder | 96.1% | 56.5% |

| Use step ladder | 96.7% | 53.0% |

The mean knowledge score (percentage correct) was 56%, with a range from 72% for the height requirements for fall protection, to 35% for the size of a hole in the floor that must be covered. Most apprentices believed the size of a floor opening that required covering was 12″ (30 cm) or larger in diameter, rather than 2″ (4.4 cm). Approximately half of the apprentices knew that standing on the external top plate (top of the outside house wall) was never permitted, although 27% believed it was allowed to install roof trusses or floor joists and to lay out rafters. Correct extension ladder setting methods were known by less than 2/3rd of apprentices surveyed.

Respondents rated step ladders as the work task or equipment which posed the least risk of falling, while truss setting and working on the top plate were rated as having a high fall risk (Table II). Confidence ratings were high among apprentices surveyed, even among those who reported falling in the previous year; most believed they could use PFAS correctly and prevent a fall from heights.

Table II.

Apprentices’ perception of fall risk for different work tasks

| Mean | S.D. | |

|---|---|---|

| Work on roof > 9 in 12 pitch | 7.2 | 2.5 |

| Set trusses | 6.4 | 2.5 |

| Work on top plate | 6.3 | 2.7 |

| Work at unprotected opening/edge | 5.6 | 2.7 |

| Work on roof between 5 & 9 in 12 pitch | 5.4 | 2.5 |

| Frame roof structure | 5.2 | 2.6 |

| Work near unprotected stair opening | 5.2 | 2.8 |

| Use extension ladder | 4.8 | 2.4 |

| Use scaffolding | 4.3 | 2.4 |

| Work near unprotected window | 3.9 | 2.7 |

| Work on roof < 4 in 12 pitch | 3.2 | 2.3 |

| Use step ladder | 3.2 | 2.2 |

Ratings on 1–10 Scale, 1=no risk, 10=extreme risk

When asked about work crew behaviors, apprentices reported that they always or often observe crew members performing unsafe acts, such as standing on the exterior top plate (40%), walking on floor joists (36%), and using unopened step-ladders leaned against a wall (39%). PFAS were reported as not used at the worksite by 48% of the apprentices and used often or always by only 13% of all apprentices surveyed; however, 28% of the siding installers and 22% of the roofers reporting using PFAS often or always. Despite OSHA’s residential guidelines’ requirement for controlled access zones to be monitored by a designated worker or foreman, 21% of apprentices reported that unprotected floor openings were never monitored.

Regarding safety climate, most respondents agreed journeymen teach them how to do the job safely, safety was a priority with management/foremen, there was adequate time to work safely and meet production deadlines, and they felt free to report safety violations. Sixteen percent (16%) of the respondents reported that they had been asked to “sign off” on safety training that they did not attend. The mean number of crew members reported by respondents was four, including two journeymen and two apprentices, resulting in a mean journeyman to apprentice ratio of 1:1.

Factors Associated With Crew Behaviors and Falls From Heights

Safer work climate ratings demonstrated a moderate correlation (0.43) with safer crew behavior ratings (table III). Variables which demonstrated weak correlations with safer crew behaviors included receiving training in a greater number of tasks, higher confidence ratings, and working for a large size employer (versus a small or medium size). Weak, negative correlations were noted between higher percentage of apprentices at the worksite, higher risk perception ratings, and greater amount of residential work (versus commercial). Knowledge and age were not correlated with crew behaviors.

Table III.

Scale and Item Correlations to Safer Crew Behavior Score

| Variable/Scale* | Correlation coefficient | p-value |

|---|---|---|

| Safer work climate score | 0.43 | <0.0001 |

| Percent of task trained prior to performance | 0.22 | <0.0001 |

| Higher confidence levels | 0.23 | <0.0001 |

| Percent apprentices on crew | −0.10 | 0.003 |

| Higher risk perception score | −0.11 | 0.0002 |

| Greater residential work in past year | −0.12 | 0.004 |

| Higher OSHA knowledge score | 0.05 | 0.146 |

| Age in years | 0.001 | 0.976 |

| Employer size** | Median crew behavior score*** | p-value |

| Small (< 25 carpenters) | 2.3 | <0.0001 |

| Medium (26–75 carpenters) | 2.3 | |

| Large (>75 carpenters) | 2.7 |

Spearman’s rho

Wilcoxon nonparametric test

Higher scores denote safer behaviors on a 1–5 scale

Crude odd ratios for all falls from height and ladder falls are described in table IV. Apprentices who worked residential construction experienced more falls than those working commercial construction (17.7% versus 9.3%), and apprentices with less than 1 year in the carpentry trade experienced more falls than those with over 5 years experience (6.8% versus 18%). Apprentices working on crews with safer work behaviors and work climates were less likely to experience falls from heights and ladder falls, as were those on crews with fewer apprentices. Knowledge was not associated with falls from heights. There was no difference in falls at different size contractors.

Table IV. Associations between falls from heights for all apprentices surveyed.

| Variables | All Falls Crude Odds Ratio (95% CI) | Ladder Falls Crude Odds Ratio (95% CI) |

|---|---|---|

|

| ||

| Length worked in trade versus ≤5 years | ||

| <1 year | 3.11 (1.42, 6.80) | 2.26 (0.69, 7.39) |

| 2–5 years | 2.80 (1.39, 5.66) | 1.79 (0.63,5.14) |

|

| ||

| Percent apprentice, per 10% increase | 1.12 (1.02, 1.23) | 1.25 (1.08, 1.45) |

|

| ||

| Number of tasks performed | 1.08 (1.00, 1.16) | 1.25 (1.06, 1.48) |

|

| ||

| Safer crew behaviors score | 0.92 (0.88, 0.97) | 0.90 (0.83, 0.98) |

|

| ||

| Safer work climate score | 0.92 (0.86, 0.97) | 0.90 (1.06, 1.48) |

|

| ||

| Worked residential construction past yr. | 2.10 (1.27, 3.48) | 3.13 (1.13, 8.83) |

Logistic regression

Excludes those who fell from a surface other than a ladder

Only variables/scales significant at p ≤ 0.05 are reported.

Among apprentices working residential construction, having less than 1 year of work experience was the strongest independent risk factor predicting falls in the multiple regression models (table V). Apprentices who performed a wider variety of work task were 52% more likely to experience ladder falls. For every 10% increase in the percentage of apprentices at the worksite, there was a 27% increase in ladder falls. Safer crew behaviors were protective, with a 1 point improvement in crew behavior resulting in a 10% decreased likelihood of all falls from heights and ladder falls.

Table V. Predictors of all falls from height for residential apprentices surveyed.

All falls from height population = 815, Ladder falls population* = 722

| Variables | All Falls Adjusted Odds Ratio (95% CI) | Ladder Falls Adjusted Odds Ratio (95% CI) |

|---|---|---|

|

| ||

| Length worked in trade versus ≤5 years | ||

| <1 year | 3.50 (1.54, 7.95) | 4.75 (1.33, 16.95) |

| 2–5 years | 2.43 (1.18, 4.50) | 1.85 (0.63, 5.42) |

|

| ||

| Percent apprentice, per 10% increase | 1.13 (1.02, 1.24) | 1.27 (1.08, 1.49) |

|

| ||

| Number of tasks performed | NS | 1.52 (1.16, 1.98) |

|

| ||

| Safer crew behaviors score | 0.91 (0.86, 0.96) | 0.91 (0.83, 0.99) |

Excludes those who fell from a surface other than a ladder

All variables/scales were entered into the multiple logistic regression models, only significant variables/scales are reported.

NS – not statistically significant at p ≤ 0.05

DISCUSSION

We surveyed 1,025 apprentice carpenters to measure their fall prevention knowledge, beliefs, crew behaviors, safety climate, fall experiences, and other factors associated with falls from height. Despite participation in a formal apprenticeship program that included both school-based and on-the-job training, apprentices performed tasks on the job prior to training, and many lacked essential fall prevention knowledge, suggesting that the timing and content of carpenter apprenticeship training can be improved.

Ladders accounted for most of the falls in our sample, which is similar to findings of previously published studies (23, 24, 25). Worker training prior to ladder use on the job was rare. Apprentices reported unsafe ladder climbing behaviors by other crew members, which was confirmed by worksite observations at sites employing these apprentices, where extension ladders were secured only 22% of the time and step ladders were used inappropriately at 49% of the sites audited (26). Our finding that apprentices perceived the risk of falling from ladders as low is an example of inexperienced workers mistakenly perceiving that routinely used equipment does not require special knowledge or skills (27). The low rates of ladder training suggest that contractors and apprenticeship trainers may also underestimate these risks.

Our results confirm that carpenters working residential construction and apprentices with less than one year of experience are at greater risk of falling from heights. Apprentices on work crews characterized by a high number of apprentices are more likely to fall from heights, suggesting that adequate on the job mentorship is essential. Apprentices working on crews that practice safe behaviors when working at heights are less likely to fall than those working with unsafe crew members, stressing the role of safe peer behaviors in fall prevention.

This work has a number of strengths and limitations. We used surveillance data, fall prevention safety standards, previous instruments, and subject matter expert feedback to improve the content and construct validity of our survey, and the scales demonstrated reasonable reliability. We surveyed 43% of the total apprentice population in our region and had very high response rates, suggesting that the internal and external validity of this work are good. The majority of our sample worked in residential construction, which gave us the opportunity to identify the fall safety needs of this high risk, but infrequently studied worker population. Although we used self-report to measure crew behaviors, results from this survey closely parallel behaviors which we observed during the same time interval when auditing residential worksites (26). This study was not able to examine the conditions at the worksite at the time of the fall; however, Lipscomb and colleagues (5) found that fall protection strategies were not in place when they visited worksites soon after falls from heights. Although our population of small contractors was too small to detect a difference in falls by contractor size, we did see a trend towards greater falls in smaller-sized contractors, as suggested by Kines’ (9), and safer crew behaviors were present in larger-sized contractors. Since this study surveyed only union carpenters, most of whom were young, white males, our findings may not generalize to the non-union environment or to older and more experienced carpenters, women, or minorities. Because of the cross-sectional design of our study, the survey occurred after the apprentices had fallen, and their responses on the survey may have changed as a result of the fall.

Our findings add to the growing literature on the unacceptably high rate of falls in residential construction. Since falls account for most of the construction worker deaths in residential framing and the highest costs per injury claim (23), interventions to address the personal and organizational factors associated with falls from heights are needed. Our research points to several factors that could improve the fall safety of home building sites. Use of the construction methods outlined in the OSHA residential guidelines (7) can decrease worker falls from heights; however, these methods are practiced inconsistently at best. Increasing contractor and carpenter awareness and understanding of the methods described in these guidelines, and increasing use of available technologies at residential worksites is recommended. Personal fall arrest systems prevent worker falls to lower surfaces, yet they are not widely used during residential framing (26).

Our research echoes findings from other industries that organizational factors and safety culture strongly influence worker behaviors (28, 29). Previous work by our team (5) and Lipscomb (16) suggests that inexperienced carpenters do not receive the type and amount of mentorship they would like from journeymen on their work crews. Limiting the number of apprentices working at residential construction sites will increase the opportunities for mentorship; however many contractors have increased the number of apprentices on their residential crews in order to remain competitive in the current home building market. In addition, journeymen may underestimate their role in providing supervision and training to inexperienced workers.

It is apparent that there are many opportunities to improve the fall safety of residential carpenters, especially inexperienced workers. Carpenters can assume a more active role in ensuring their fall safety. Apprenticeship training programs can improve the timing and content of fall prevention training. Contractors can ensure that their work crews are optimally staffed and there is adequate time, training, supervision, and resources to maintain the fall safety of the workers during all phases of the construction process. Researchers can partner with contractors to improve the safety culture, provide optimal supervision and mentorship, and infuse safe construction methods and technologies into the residential construction process. Policy makers can increase the levels of enforcement of standards designed to protect workers from falls.

Acknowledgments

Grant sponsor: Centers for Disease Control/National Institute of Occupational Safety and Health through the Center for Construction Research and Training, Grant #U54OH008307. National Institutes of Health/National Center for Research Resources through Washington University Institute of Clinical and Translational Sciences, Grant #1UL1 RR024992-01

Footnotes

Authors Contributions to the study

Kaskutas, V – coordinator of the day to day operation of the study, including data collection and management, data entry, data analysis, and communications with the carpenters training center; led focus groups with apprentices to assess usability of the questionnaire, assisted in design of the questionnaire, prepared the manuscript

Dale, AM – co-authored the grant submission for the study, fostered and maintained relationship with the carpenters training center and carpenters union, managed research funds, assisted in design of the questionnaire, assisted in manuscript preparation

Lipscomb, H – co-authored the grant submission for the study, assisted in design of the questionnaire, provided data analysis guidance, assisted in manuscript preparation

Gaal, J – co-authored the grant submission for the study, provided support and leadership from the carpenters’ union, distributed funding for the carpenters training center

Fuchs, M – provided support and leadership from the carpenters’ apprenticeship training center

Evanoff, B – principal investigator for the grant, co-authored the grant submission for the study, assisted in design of the questionnaire, directed the data analysis plan, directed the grant coordinator on day-to-day operations, maintained relationship with the carpenters training center and carpenters union, assisted in manuscript preparation

Faucette, J – provided assistance with data management and analysis to the first author during internship

Gillen, M – provided assistance with data management and analysis to the first author during internship

Deych. E - statistician

References

- 1.National Census of Fatal Occupational Injuries in 2007. Bureau of Labor Statistics, US Department of Labor; 2007. [cited 28 December 2008]. Available from: http://www.bls.gov/news.release/pdf/cfoi.pdf. [Google Scholar]

- 2.Fatal occupational injuries by industry and event or exposure. Bureau of Labor Statistics, US Department of Labor; 2007. [cited 28 December 2008]. Available from: http://www.bls.gov/iif/oshwc/cfoi/cftb0223.pdf. [Google Scholar]

- 3.Bureau of Labor Statistics, US Department of Labor; 2007. Census of Fatal Occupational Injuries Charts, 1992–2006. [cited 0 November 2007]. Available from: http://www.bls.gov/iif/oshwc/cfoi/cfch0005.pdf. [Google Scholar]

- 4.Derr J, Forst L, Chen HY, Conroy L. Fatal falls in the US Construction Industry. Journal of Occupational and Environmental Medicine. 2001;43:853–60. doi: 10.1097/00043764-200110000-00004. [DOI] [PubMed] [Google Scholar]

- 5.Lipscomb HJ, Dement JM, Nolan J, Patterson D, Li L, Cameron W. Falls in residential carpentry and drywall installation: findings from active injury surveillance with union carpenters. Journal of Occupational and Environmental Medicine. 2003;45:881–90. doi: 10.1097/01.jom.0000083037.56116.d4. [DOI] [PubMed] [Google Scholar]

- 6.U.S. Department of Labor, Occupational Safety and Health Administration. Code of Federal Regulations. 2006 2006. OSHA Construction Standards. Title 29, Part 1926. [Google Scholar]

- 7.U.S. Department of Labor, Occupational Safety and Health Administration. Plain language revision of OSHA Instruction STD 3.1, interim fall protection compliance guidelines for residential construction. Jun 18, 1999. OSHA Directives, STD 3--.1A. [Google Scholar]

- 8.U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health. Worker deaths by falls: A summary of surveillance findings and investigative case reports. 2000. Publication No. 2000–116. [Google Scholar]

- 9.Kines P, Mikkelsen K. The effects of firm size on reporting of elevation fall injury in construction trades. Journal of Occupational and Environmental Medicine. 2003;45(10):1074–1078. doi: 10.1097/01.jom.0000085887.16564.3a. [DOI] [PubMed] [Google Scholar]

- 10.Dedobbeleer N, Champagne F, German P. Safety performance among union and nonunion workers in the construction industry. Journal of Occupational Medicine. 1990;32:1099–1103. doi: 10.1097/00043764-199011000-00009. [DOI] [PubMed] [Google Scholar]

- 11.Neal A, Griffin M, Hart P. The impact of organizational climate on safety climate and individual behavior. Safety Science. 2000;34:99–109. [Google Scholar]

- 12.Nissen B, Annee A, Weinstein M. Immigrant Construction Workers and Health and Safety. Labor Studies Journal. 2008;33:48–62. Retrieved 28 December, 2008. Available from: http://lsj.sagepub.com/cgi/reprint/33/1/48. [Google Scholar]

- 13.U.S. Department of Labor,Occupational Safety and Health Administration. Stairways and Ladders: A Guide to OSHA Rules OSHA. p. 3124. 2003 revised. [Google Scholar]

- 14.U.S. Department of Labor, Occupational Safety and Health Administration. A Guide to Scaffold Use in the Construction Industry OSHA. p. 3150. 2002 revised. [Google Scholar]

- 15.U.S. Department of Labor, Occupational Safety and Health Administration. Fall Protection in Construction OSHA. p. 3146. (1998 revised) [Google Scholar]

- 16.Lipscomb H, Dale A, Kaskutas V, Sherman-Voellinger R, Evanoff B. Challenges in residential fall prevention: Insight from apprentice carpenters. American Journal of Industrial Medicine. 2008;51:60–8. doi: 10.1002/ajim.20544. [DOI] [PubMed] [Google Scholar]

- 17.Sokas R, Simmens S, Sophar K, Welch L, Liziewski T. Lead levels in Maryland construction workers. American Journal of Industrial Medicine. 1996;31:188–94. doi: 10.1002/(sici)1097-0274(199702)31:2<188::aid-ajim8>3.0.co;2-w. [DOI] [PubMed] [Google Scholar]

- 18.Rosecrance JC, Cook TM, Zimmermann CL. Work-related musculoskeletal symptoms among construction workers in the pipe trades. Work. 1996;7:13–20. doi: 10.3233/WOR-1996-7103. [DOI] [PubMed] [Google Scholar]

- 19.US Department of Health and Human Services. Franks J, Stephenson M, Merry C, editors. [Accessed 28, December, 2008];Preventing occupational hearing loss – a practical guide. 1996 Available from: http://www.cdc.gov/niosh/docs/96-110/pdfs/96-110.pdf.

- 20.Lusk S, Kerr M, Kauffman S. Use of hearing protection and perceptions of noise exposure and hearing loss among construction workers. Americal Industrial Hygiene Association Journal. 1998;59:466–70. doi: 10.1080/15428119891010217. [DOI] [PubMed] [Google Scholar]

- 21.Jeffe DB, Mutha S, L’Ecuyer PB, Kim LE, Singal RB, Evanoff BA, Fraser VJ. Health-care workers’ attitudes and compliance with Universal Precautions: Gender, occupation, and specialty differences. Infection Control and Hospital Epidemiology. 1997;18:710–2. doi: 10.1086/647517. [DOI] [PubMed] [Google Scholar]

- 22.Hale A, Hovden J. In: Occupational injury: risk, prevention and intervention. Feye AM, Williamson A, editors. Taylor and Francis, Inc; Bristol, PA: 1998. [Google Scholar]

- 23.Lipscomb H, Leiming L, Dement J. Work-related falls among union carpenters in Washington State before and after the vertical fall arrest standard. American Journal of Industrial Medicine. 1003;44:157–65. doi: 10.1002/ajim.10254. [DOI] [PubMed] [Google Scholar]

- 24.Cattledge GH, Schneiderman A, Stanevich R, Hendricks S, Greenwood J. Nonfatal occupational fall injuries in the West Virginia construction industry. Accident Analysis Prevention. 1996;28:655–63. doi: 10.1016/0001-4575(96)00026-7. [DOI] [PubMed] [Google Scholar]

- 25.Lipscomb HJ, Leiming L, Dement JM. Falls among union carpenters. American Journal of Industrial Medicine. 2003;44:148–56. doi: 10.1002/ajim.10255. [DOI] [PubMed] [Google Scholar]

- 26.Kaskutas V, Dale A, Nolan J, Patterson D, Lipscomb H, Evanoff B. Fall Hazard Control Observed on Residential Construction Sites. American Journal of Industrial Medicine. 2009;52:491–499. doi: 10.1002/ajim.20698. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Kines P. Case studies of occupational falls from heights: Cognition and behavior in context. Journal of Safety Research. 2003;34:263–71. doi: 10.1016/s0022-4375(03)00023-9. [DOI] [PubMed] [Google Scholar]

- 28.Griffin MA, Neal A. Perceptions of safety at work: A framework for linking safety climate to safety performance. Journal of Occupational Health Psychology. 2000;5:347–58. doi: 10.1037//1076-8998.5.3.347. [DOI] [PubMed] [Google Scholar]

- 29.Zohar D. A group-level model of safety climate: testing the effect of group climate on microaccidents in manufacturing jobs. Journal of Applied Psychology. 2000;85:587–96. doi: 10.1037/0021-9010.85.4.587. [DOI] [PubMed] [Google Scholar]