Abstract

Background

Differences between wear-scar features of simulator-tested and retrieved tibial total knee replacement (TKR) liners have been reported. This disagreement may result from differences between in vivo kinematic profiles and those defined by the standard.

Purpose

To determine the knee kinematics of a TKR subject group during level walking and compare them with the motion profiles produced by a wear test conducted according to the force-controlled knee wear testing ISO 14243-1 (ISO-1)standard.

Methods

Ten patients with a posterior cruciate ligament-retaining TKR design were gait tested using the point cluster technique (PCT) to obtain flexion-extension (FE) rotation, anterior-posterior (AP) translation and internal-external (IE) rotation motions during a complete cycle of level walking. Motion data were directly compared against the output kinematics from the wear test.

Results

The subjects exhibited a FE rotation pattern similar to the output from ISO-1; however had higher midstance knee flexion angles. For both AP translation and IE rotation, the standard profiles had significantly smaller total ranges of motion than seen in vivo, with noticeably different patterns of motions.

Conclusions

For this particular implant design, significant differences were found in both the pattern and magnitudes of in vivo motion during level walking compared with the ISO-1 standard.

Keywords: total knee replacement, kinematics, primary and secondary knee motions, gait analysis, wear simulator testing

1.0 Introduction

Total knee replacement (TKR) surgery is a successful procedure that provides pain relief and restoration of functional mobility for patients, typically aged 50 years and older, who are afflicted with degenerative joint diseases such as osteoarthritis. Based on a statistical projection study by Kurtz et al [1], the number of surgeries performed annually in the US is anticipated to double from 450,000 in 2005 by the year 2015. Prosthesis longevity is currently estimated at 10–15 years, with wear of the ultra-high molecular weight polyethylene (UHMWPE) tibial liner remaining a major cause of TKR failure [2]. Many patients essentially outlive their implant thereby requiring disruptive and costly revision surgery. A conservative estimation of a revision knee surgery was documented to be 11,922 USD [3] and a total of 0.87 billion USD was spent in 2005 on this operation [4]. Revision surgeries are projected to increase at the same rate as primary surgeries [1] and are anticipated to reach to 4.46 billion USD by 2015 [4]. Therefore, in order to reduce the anticipated revisions, discovering wear preventive measures to prolong implant life is essential. To develop and assess these measures, knee wear simulators are used to evaluate prosthesis performance prior to actual implantation and must be operated under physiologic testing conditions.

DesJardins et al. [5] conducted a study comparing fluoroscopically determined in vivo knee kinematics of seven PCL-retaining TKR (Natural Knee II, Standard Congruent, Zimmer, Warsaw, IN) patients during treadmill gait with the output motions from a force-controlled simulator wear test that followed the ISO force control standard (ISO 14243-1 [6], defined here as “ISO-1”). Separating their patients into “active” and “passive” subgroups (based on walking speeds), they found that there was good agreement in ranges of motion throughout the entire gait cycle for the “active” group. The authors therefore concluded that the study’s findings offered supporting evidence that the simulation of in vivo walking can be kinematically replicated following the ISO-1 standard – as long as the patients walked with normal gait. However, only four patients made up the active group, thus, the robustness of the conclusion is questionable. In addition, patients walked on a treadmill holding handle bars which has been shown to alter gait and does not reflect locomotion during daily living [7,8]. We therefore decided to repeat the experiment with a patient group wearing a related PCL-retaining implant device but of different design.

Based on the findings of DesJardins et al., we hypothesized that the knee kinematics of a representative TKR population would be well represented by the motions of the force-controlled ISO standard. The aims of the current study were (1) to conduct a wear test according to the ISO-1 standard and to determine the relative motions during an entire gait cycle using a PCL-retaining total knee prosthesis, (2) to gait test patients with the same prosthesis used in the wear test during level walking and to compare them with the motion profiles resulting from the force-controlled simulator protocol.

2.0 Materials and Methods

2.1 Implants

The artificial knee implant design assessed for this study was a Miller-Galante II (MGII) prosthetic device from Zimmer, Inc (Warsaw, IN, USA). This is a PCL-retaining knee implant, which is largely unconstrained in the frontal and sagittal planes, and has been in clinical use for several years.

2.2 Patients

As part of a larger scale project to develop more realistic testing protocols for total knee prostheses, 32 TKR patients were recruited successfully and a quantification of the frequency and duration of physical activities over a 12 hour day was conducted [9]. Of these 32 patients, 14 agreed to undergo gait analysis in the Human Motions Laboratory at Rush University Medical Center (Rush, Chicago, IL, USA) to obtain joint motions during level walking at self-selected speeds. Qualifying patients were gathered from the Rush Orthopedic database and patient consents were obtained for this Institutional Review Board approved study. Patients were excluded if they were unable to function or walk independently, had undergone revision surgery or had a history of neurological dISO-1 rders (i.e. stroke, multiple sclerosis, Parkinson’s disease). Of the 14 TKR patients gait tested, 4 patients were not incorporated in this study: one exclusion due to severe contralateral knee pain on the day of testing and one exclusion due to processing difficulties. Two patients were excluded due to having MG implants rather than MGII.

The remaining ten subjects (six males/four females), with well-functioning MGII implants (four right/six left), had an average age of 77(SD±5.6) years, average height of 1.7(SD±0.067) m, average weight of 85.0(SD±17.0) kg and an average implant in-situ time of 12(SD±0.92) years.

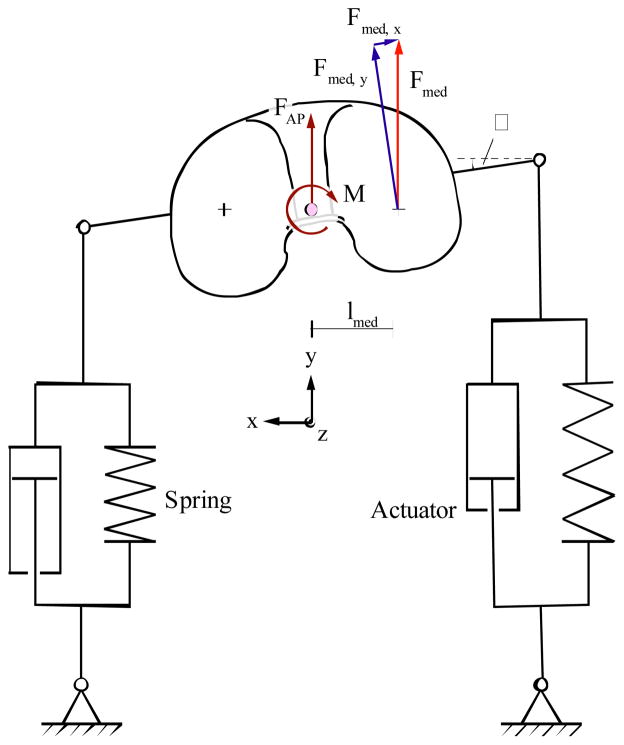

2.3 Wear Testing

A four-station servo-hydraulic knee joint simulator (Endolab Mechanical Engineering GmbH -Rosenheim, Germany) was used, meeting the specifications set forth in ISO 14243-1. This standard utilizes input waveforms that are supposed to simulate human gait. On the one master station, all four actuators to apply compressive force, flexion-extension (FE) movement, anterior-posterior (AP) force, and internal-external (IE) moment were closed-loop controlled. The other stations were either mechanically linked to the master station, or the actuators followed as slaves (i.e. same cylinder pressure that the master actuators applied). In line with requirements, the horizontal actuators, applying AP force and IE moment, worked against springs in both of their motion directions (Figure 1). Spring arrangement followed ISO-1 guidelines with stiffness’ equal in both directions, and no slack around the zero position was incorporated for this study. The spring positions were adjustable to ensure that their relaxed states coincided with zero positions of the tibial plateaus with respect to the femoral condyles. One station served as an active soak control (only compressive force was applied during testing). Every station was comprised of a temperature controlled chamber that also monitored fluid level. The chambers were fully closed and sealed during testing to minimize fluid evaporation and contamination. The simulator was connected to a computer that provided a user interface for machine usage, test supervision, and data acquisition. Load and motion data was recorded every 5000 cycles for four full cycles at a data acquisition rate of 120 Hz.

Figure 1.

Depiction of actuators and springs set-up in knee simulator

The MGII implants were received in their original packaging and were opened immediately prior to testing. The tibial liners were all pre-soaked for eight weeks prior to testing to reduce the error due to fluid absorption during the test [10]. Pre-soaking was performed by submersing the liners in the same lubricant as would be used for testing at 37°C and in unloaded conditions. The testing lubricant was based on bovine serum (Hyclone, Inc. - Logan, UT, USA) that was diluted with a buffer solution to a final protein content of 30 g/l. The distilled water based buffer solution contained sodium chloride (NaCl), tris(hydroxymethyl) aminomethane (TRIS) and ethylenediaminetetraacetic acid (EDTA) to sequester metal ions (e.g. calcium). The starting pH-value was adjusted to 7.6 by adding small amounts of hydrochloric acid. No other additives, antimicrobial or antifungal agents, were used. Cleaning and weighing of the components, as per ASTM 2025 [11], took place at regular intervals using a precision scale (AX205DR, Mettler-Toledo – Greifensee, Switzerland; resolution: 0.01 mg; repeatability: 0.015 mg). This pre-soaking was concluded when the weight gain between two measurements was below 10% of the overall weight gain for that component. Following pre-soaking, implants were mounted onto the knee joint simulator and tested to 5 million cycles (mc) at a frequency of 1 Hz, following the standard. The test and load-soak components were submerged in 250 ml of testing lubricant at 37°C. The experiment was interrupted every 0.5 mc (generating 10 testing intervals), dismounted and specimens were again cleaned and weighed. The test was subsequently continued using freshly prepared testing lubricant. In order to compare FE, AP and IE motion data with in vivo data, motion data captures during the wear test were obtained from all 3 testing stations and averaged at eight different time points, namely in the midst of testing intervals 3 to 10. The first one mc were not considered to exclude running-in period, allowing generation of a discrete wear scar (which might affect motion). The averaged motion data per station were then averaged to obtain overall motion profiles. Further details of the wear test are reported in Schwenke et al. 2009 [16].

2.4 In vivo Kinematics

In vivo kinematics of the sample TKR population were obtained through gait testing, using the point cluster technique (PCT) [12,13]. This technique monitors and records secondary knee motions, AP translation and IE rotation, with the primary movement, the FE rotation. Three separate trials of level walking were conducted and motions were averaged for each subject. PCT gait testing entails placing twenty-one reflective markers on the thigh and shank, creating two cluster groups with corresponding orthogonal sets of axes, referred to as the cluster coordinate systems [14]. These coordinate systems were then related to the femoral and tibial anatomical coordinate systems, which were defined by palpating specific osseous landmarks [15]. The origin of the femoral coordinate system was defined as the midpoint of the transepicondylar line of the distal femur, which is close to the instantaneous axis of motion [8]. This position is similar to the femoral center of rotation position for the knee simulator standard. The anatomic origin of the tibial coordinate system was located at the midpoint of the line connecting the medial and lateral points of the tibial plateau [14]. Secondary motions of the knee were then measured based on the displacements between the origins of the tibial coordinate system relative to the femoral coordinate system and then projected onto the axis of the tibia. Final motions describe the movement of the tibia relative to the femur. The marker clusters allowed determination of detailed femoral and tibial motion, while extracting non-rigid skin motion artifact. This extraction was performed by comparing eigenvalues from each cluster at each time step with the eigenvalues calculated with the subject in a static reference position [12]. The movement of the reflection markers were tracked and recorded by a four camera optoelectronic system (Qualisys, Gothenburg, Sweden). Stance and swing phases of gait were defined using a multi-component force plate (Bertec, Columbus, OH). Data acquisition and processing were conducted using a specialized computer system (Computerized Functional Testing Corporation, Chicago, USA).

2.5 In vivo motion profiles vs. ISO-1 Standard

Primary and secondary motion data for all walking trials for each subject were averaged to obtain the mean motions per patient. To obtain average curves to represent the subject population, the mean motion data of all subjects were averaged for every 1% gait to obtain average FE, AP and IE profiles. In vivo and simulator output secondary motions were all moved to start at zero to allow relative comparisons. After evaluating normality of the data distribution and using Levene’s Test for equality of variances, the student’s t-test was used to test the in vivo motions against the output motions from the wear test operated under the ISO-1 standard. A 0.05 significance level was used for all statistical tests. Statistical analyses were performed with SPSS (Chicago, IL, USA). All motion data are expressed as mean ± standard error.

3.0 Results

3.1 Simulator Kinematics

The output FE motion pattern from the load controlled wear test closely conformed to the defined input [6]. Similarly, the output axial and AP force profiles and IE torque profiles were well within the required ±5% tolerance stipulated in the standard, hence representing the programmed profiles. The input of tangential (tractive) force generated an AP translation with a peak-to-peak range of 5.85±0.39 mm. The maximum tibial external rotation occurred during the second third of the gait cycle for the load controlled test. Peak-to-peak IE rotation range was 4.12±0.29°.

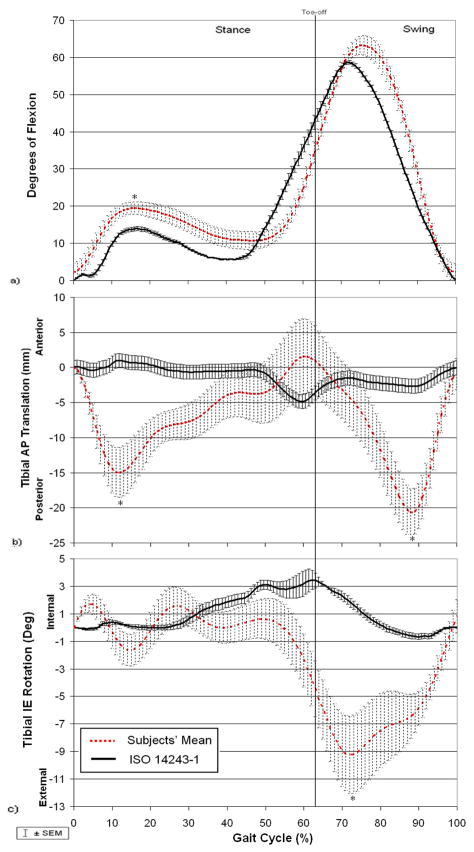

3.2 In vivo TKR Kinematics

Based on averaging motion every 1% gait, the FE profile displayed nearly full extension (2.4±2.3°) at heelstrike, 19.5±1.6° knee flexion in midstance and 10.8±2.4° knee flexion during terminal stance (Figure 2a). Peak knee flexion of 63.3±2.6° occurred at 76% gait. The average AP pattern showed posterior tibial travel immediately after heelstrike of 15.0±3.6 mm, followed by an anteriorly directed tibial translation. The total AP displacement during stance phase was 16.6 mm. At toe-off, the subjects switched to again translate posteriorly and finally concluded swing phase with an anteriorly directed tibial movement. The maximum AP translation during swing phase was 22.2 mm (Figure 2b). The averaged rotational profile during walking indicated less than 4° of total rotation during stance, leading into a total 9.4° of external tibial rotation from terminal stance to peak swing. The subjects then displayed a final direction change to internal tibial rotation to the end of swing phase, for a maximum total range of rotation of 10.0° (Figure 2c).

Figure 2.

Kinematic profiles for ISO-1 vs. Subjects’ Average for:

a) Flexion-extension rotation b) Anterior-posterior translation c) Internal-external rotation

Note: * denotes statistical significant difference between in vivo motion and ISO-1

3.3 In vivo Motion Profiles vs. ISO-1-Standard

The average subject FE profile was similar to that defined by ISO-1 (Figure 2a), with the subjects exhibiting statistically similar knee flexion angles at heelstrike (p=0.342), terminal stance (p=0.060) and in swing phase (p=0.107). However, the subjects did have increased knee flexion angles during midstance (p=0.008).

For AP translation, differences in the pattern of motion between the ISO-1 output curve and that of the subjects were apparent (Figure 2b). While the subjects displayed a 15.0±3.56 mm posterior tibial travel after heelstrike and a switch to anterior tibial displacement in early midstance (initiated @12 %gait), ISO-1 showed minimal movement during this period of gait with only a 0.41±0.07 mm posterior tibial travel right after heelstrike, which was significantly smaller than seen in vivo (p=0.003). As the subjects continued to tibially translate 16.6 mm anteriorly from midstance until toe-off, ISO-1 showed a posterior translation of the tibia. The patients did not change translation direction until approximately toe-off, peaking at 20.6±3.4 mm of posterior tibial translation at 88%gait. ISO-1 also showed posterior tibial translation, however this translation did not start until 71%gait and the peak reached of 2.67±0.20 mm (also at 88%gait) was significantly smaller (p<0.001). A final direction change to anterior tibial translation was displayed by both the subjects and ISO-1 to the end of swing. In general, the subjects displayed three points of direction changes while ISO-1 had four changes of direction. The times at which these changes occurred during the gait cycle and the magnitudes also differentiated the ISO-1 profile from the TKR subjects.

For IE rotation, the ISO-1 output curve again had very little movement until midstance while the subjects displayed a higher variability of rotations (Figure 2c). At toeoff, the subjects exhibited 4.4±2.0° of external tibial rotation, whereas ISO-1 displayed 3.4±0.5° of internal tibial rotation. The output IE motion pattern of ISO-1 somewhat conformed to that of the subjects at the end of stance to the end of swing, with an external-tibial rotation followed by an internal-tibial rotation; however, timing and magnitude of the motion was noticeably different. The peak external tibial rotation reached by the subjects was 9.2±2.8°, which was significantly larger than the ISO-1 peak of 0.66±0.20° (p<0.001).

4.0 Discussion

The relative motions during an entire gait cycle using a PCL-retaining total knee prosthetic design were obtained from force-controlled knee wear testing according to ISO 14243-1 and from in vivo gait testing. Significant differences in the pattern and the magnitudes of movement were found for the primary and secondary motions between those defined by the ISO-1 standard and the in vivo kinematics, contradicting our study hypothesis.

For FE rotation, the pattern of motion between the subjects and the standard was similar, with insignificant differences in the knee flexion angle at heelstrike, terminal stance and peak flexion in swing. However, the knee flexion at midstance was found to be significantly different between two groups. For the secondary knee motions, the ISO-1 profiles somewhat reflected similar AP and IE movements to that of the subjects in swing, however the in vivo magnitudes of motion were significantly larger. Despite of the unconstrained design of the prosthetic device, there was little secondary motion in stance phase when applying the ISO-1 protocol (2 mm during the first half of stance and 5 mm during the second half of stance). This could be either related to high “soft tissue” spring force in combination with friction while high compressive forces are active, or, since slight wear of the anterior lip of the PE liner was observed [16], to constraining forces between tibial plateau and femoral condyles during testing.

The results of the current study are different from those of DesJardins et al. [5]. As mentioned in the introduction, DesJardins et al. found that there was good agreement in the ranges of motion throughout the entire gait cycle based on an “active” subgroup of four patients. Although they also studied a PCL-retaining TKR patient group, which matched the height and weight of our group very well, differences in component surface geometry between their implant design and the one in the current study could explain variations in kinematics. Again, treadmill walking while holding the handlebars has been shown to be different from level walking [7,8]. Holding onto handlebars during walking changes the balance and body posture and, consequently, does not reflect locomotion during daily living [8]. Though the current subject group is considered elderly and may be considered more sedentary, they walked at much faster speeds than the “active” subjects in the DesJardins et al. study (avg. 1.08 m/s±0.05 vs. 0.76 m/s). Walking speed has been shown to influence joint angles [17], knee axial loading and adduction torque [18], and thus may alter kinematics. The higher walking speed of our patients was accompanied with a higher cadence (52.3±1.2 steps/s) compared with DesJardins’ study, which translated into an average frequency of 0.9 Hz. The ISO-1 testing frequency is specified to be 1.0±0.1 Hz, thus encompassing the subjects of the current study.

A retrieval analysis study conducted on 46 MGII revision retrievals and from 21 MGII postmortem retrievals [19,20] reported high wear regions (defined as areas of complete removal of machining marks) on all retrievals and an average AP wear scar stretch of 21.8±2.67 mm and 22.6±2.76 mm measured for the medial and lateral plateaus, respectively. The total in vivo AP displacement traveled during stance phase in the present study (16.6 mm) corresponds well to the AP wear scar stretch and is considered to be a meaningful finding. The retrieval analysis also determined low wear regions (defined as areas of contact area with machining marks still present), which usually surrounded the high wear regions. The total wear scar (high + low wear regions) had average AP wear scar stretches of 39.0±4.76 mm medially and 37.6±4.60 mm laterally. The highest ranges of knee motion, producing the maximum displacements, occurred during swing phase, though the high compression forces were not present. Knee contact may still be present due to muscle forces and soft tissue restraints, thereby possibly explaining the low wear regions. The maximum total range of AP translation occurred in swing phase (22.2 mm), which again is in the range of the total AP wear scar stretches measured for the retrievals. The corresponding total AP wear scar dimensions for the simulated components were 27.3±0.77 mm for the medial plateau and 25.6±0.30 mm on the lateral plateau [16], and more anteriorly located than the retrieved tibial plateaus [19]. The considerably smaller wear scar stretches on the simulated components mimic the statistically decreased AP ranges of motion executed in vitro from following the ISO-1 standard. The medial-lateral (ML) wear scar stretches for the retrieved medial and lateral plateaus were 30.9±3.78 mm and 30.4±3.71 mm, respectively. For the simulated components, the ML stretches were 22.5±0.99 mm on the medial side and 23.0±1.13 mm on the lateral side. The ML dimensions allow insight into the IE motion experienced by the implant. Again, although the IE profiles of the subjects during stance were highly variable (COV 60.9%) [21], the average maximum in vivo total range of rotation for the entire gait cycle was 10.9°, which was larger than the in vitro total range of rotation of 4.1°.

Another knee wear testing standard based on displacement control exists and is referred to as ISO 14243-3 (ISO-3). Both ISO standards input identically defined FE and axial (compressive) force patterns for an entire cycle of gait, however, where ISO-1 utilizes AP shear force and IE torque as input, ISO-3 defines the AP displacement and IE rotation as input. A kinematic comparison between ISO-3 and the motions obtained in vivo was not addressed in the current manuscript, however, would be highly relevant to overall assessment of knee wear testing methods. Only one implant design was investigated in this study. Resulting kinematics from ISO-1 driven wear tests may vary depending on prosthesis type and the chosen reference position at heelstrike. It is likely that the reference position was set too far anterior for this largely sagittally unconstrained device. Furthermore, as suggested by Andriacchi et al. [14] (as well as the raw, untreated data of this study), contact of the femoral condyles at heelstrike occur in the posterior portion of the tibial plateau. Therefore, the results of this study cannot be generalized for all implant designs. Other limitations of this study include possible inaccuracies incurred with skin-marker gait testing, which can only estimate the positions of the underlying osseous structures. The method of averaging in vivo motion to represent the TKR population allowed for kinematic representation of the average subject for every 1% gait. However, timing differences of motion maxima and minima between patients were not taken into consideration.

5.0 Conclusion

The output kinematics of a wear test conducted according to the current force-controlled standard protocol for knee prosthesis testing were compared with the in vivo knee kinematics of a sample TKR population, with the same implant as wear tested, during a complete cycle of level walking. Both the pattern and magnitudes of in vivo motion were significantly different from those obtained using the standard, which was further demonstrated through wear scar analyses of retrieved versus the simulated components. The effect on wear of these kinematic differences is currently unknown. In the current wear test, an average wear rate of 21 mg per million cycles was generated [16], which is well in the range of reported knee wear rates [22,23]. However, it was also demonstrated that wear scar size and wear are correlated [16], suggesting that the current wear test may have underestimated clinical wear. Therefore, the characteristics of the “soft tissue constraints” (restraining springs) should be revised to allow more motion in the sagittal and transverse planes as suggested previously [24]. In addition, it should be considered that the tibiofemoral contact at heelstrike occurs in the posterior portion of the tibial plateau, which is not necessarily represented by the ISO-1-defined “reference position”. A further posterior contact position allows pronounced anteriorly-directed sliding. Last but not least, the AP force and IE moment input should be carefully reviewed and compared with the measurements of telemetric knee implants, which are just beginning to become available. Eventually, this will lead to more realistic kinematics for all implant designs, thereby, providing more accurate wear assessment under standardized testing conditions.

Acknowledgments

We would like to acknowledge Dr. K. Foucher, Dr. M. P. Laurent and Dr. T. P. Andriacchi for their input into this study. We would also like to thank I. Rojas, R. Trombley, Dr. H. Lundberg and D. Orozco (from Rush Human Motions and Tribology Laboratories) and C. Dyrby (Stanford University) for their technical assistance. This work was financially supported by NIH R03 AR052039. Authors Ngai, Schwenke and Wimmer have received research funding from Zimmer Inc.

References

- 1.Kurtz S, Ong K, Lau E, et al. Projections of primary and revision hip and knee arthroplasty in the United States from 2005 to 2030. JBJS. 2007;89:780–785. doi: 10.2106/JBJS.F.00222. [DOI] [PubMed] [Google Scholar]

- 2.Sharkey PF, Hozack WJ, Rothman RH. Why Are Total Knee Arthroplasties Failing Today? Clin Orth Rel Res. 2002;404:7–13. doi: 10.1097/00003086-200211000-00003. [DOI] [PubMed] [Google Scholar]

- 3.Crowninshield R, Rosenberg AG, Sporer SM. Changing Demographics of Patients with Total Joint Replacement. Clin Orth Rel Res. 2006;443:266–272. doi: 10.1097/01.blo.0000188066.01833.4f. [DOI] [PubMed] [Google Scholar]

- 4.Kurtz S, Ong K, Schmier J, Mowat F, Saleh K, Dybyik E, Karrholm J, Garellick G, Havelin L, Furnes O, Malchau H, Lau E. Future clinical and economic impact of revision total hip and knee arthroplasty. Am JBJS. 2007;89(Suppl 3):144–151. doi: 10.2106/JBJS.G.00587. [DOI] [PubMed] [Google Scholar]

- 5.DesJardins JD, Banks SA, Benson LC, et al. A direct compar ISO-1n of patient and force-controlled simulator total knee replacement kinematics. J Biomech. 2007;40:3458–3466. doi: 10.1016/j.jbiomech.2007.05.022. [DOI] [PubMed] [Google Scholar]

- 6.ISO-1 14243-1. Implants for surgery – wear of total knee-joint prostheses – part 1: Loading and displacement parameters for wear-testing machines with load control and corresponding environmental conditions for test, 2002.

- 7.Zhao D, Banks SA, D’Lima DD, et al. In vivo medial and lateral tibial loads during dynamic and high flexion activities. JOR. 2007;25:593–602. doi: 10.1002/jor.20362. [DOI] [PubMed] [Google Scholar]

- 8.Andriacchi TP, Dyrby CO, Johnson TS. The use of functional analysis in evaluating knee kinematics. Clin Orth Rel Res. 2003;410:44–53. doi: 10.1097/01.blo.0000062383.79828.f5. [DOI] [PubMed] [Google Scholar]

- 9.Schwenke T, Nechtow W, Moisio K, et al. Daily activity profile of patients with total knee replacements. Trans ORS. 2006;52:0625. [Google Scholar]

- 10.American Society of Testing and Materials (ASTM) Standard test method for wear testing of polymeric materials used in total joint prostheses. Designation F 732-00 2006 [Google Scholar]

- 11.American Society of Testing and Materials (ASTM) Standard practice for gravimetric measurement of polymeric components for wear assessment. Designation F. 2006:2025-06. [Google Scholar]

- 12.Andriacchi TP, Alexander EJ, Toney MK, et al. A point cluster method for in vivo motion analysis: applied to a study of knee kinematics. J Biomech Eng. 1998;129(6):743–749. doi: 10.1115/1.2834888. [DOI] [PubMed] [Google Scholar]

- 13.Alexander EJ, Andriacchi TP. Correcting for deformation in skin-based marker systems. J Biomech. 2001;34:355–361. doi: 10.1016/s0021-9290(00)00192-5. [DOI] [PubMed] [Google Scholar]

- 14.Andriacchi TP, Dyrby CO. Interactions between kinematics and loading during walking for the normal and ACL deficient knee. J Biomech. 2005;38:293–298. doi: 10.1016/j.jbiomech.2004.02.010. [DOI] [PubMed] [Google Scholar]

- 15.Hoppenfeld S, Huton R. Physical examination of the knee. In: Hoppenfeld S, editor. Physical Examination of the Spine and Extremities. Engle woodcliffs, NJ: Appleton-Century-Crofts/Prentice-Hall; 1976. pp. 171–196. [Google Scholar]

- 16.Schwenke T, Orozco D, Schneider E, Wimmer MA. Differences in wear between load and displacement control tested total knee replacements. Wear. 2009 doi: 10.1016/j.wear.2009.01.028. [DOI] [Google Scholar]

- 17.Stansfield BW, Hillman SJ, Hazlewood ME, et al. Normalized speed, not age, characterizes ground reaction force patterns in 5-to 12-year-old children walking at self-selected speeds. J Ped Ortho. 2001;21(3):395–402. [PubMed] [Google Scholar]

- 18.Zhao D, Banks SA, Mitchell KH, et al. Correlation between the knee adduction torque and medial contact force for a variety of gait patterns. JOR. 2007;25:789–797. doi: 10.1002/jor.20379. [DOI] [PubMed] [Google Scholar]

- 19.Paul P. Bioengineering MS Thesis. University of Illinois; Chicago: 2004. Differences in Polyethylene Wear of Revised, Autopsy Retrieved and Simulator Tested Tibial Knee Implants. [Google Scholar]

- 20.Wimmer MA, Paul P, Haman J, et al. Differences in damage between revision and postmortem retrieved TKA implants. Trans ORS. 2005;51:1204. [Google Scholar]

- 21.Ngai V, Wimmer MA. Variability in secondary motions of the knee following total joint replacement. Trans ASB. 2007:391. [Google Scholar]

- 22.Haider H, Alberts LR, Laurent MP, et al. Compar ISO-1n between force-controlled in-vivo wear testing on a widely used TKR implant. Trans ORS. 2002;48:1007. [Google Scholar]

- 23.Benson LC, DesJardins JD, Harman MK, et al. Effect of stair descent loading on ultra-high molecular weight polyethylene wear in a force-controlled knee simulator. Proc Inst Mech Eng [H] 2002;216:409–418. doi: 10.1243/095441102321032201. [DOI] [PubMed] [Google Scholar]

- 24.van Houtem M, Clough R, Khan A, et al. Validation of the soft tissue restraints in a force-controlled knee simulator. Proc Inst Mech Eng [H] 2006;220:449–456. doi: 10.1243/09544119JEIM57. [DOI] [PubMed] [Google Scholar]