Abstract

Potatoes can be an important part of a balanced diet because they are an excellent source of many nutrients, including nutrients that are commonly underconsumed (dietary fiber and potassium). Despite the existence of many positive nutrients in potatoes, the popular press has recently aligned potatoes, and particularly fried potatoes, with an unhealthy diet. This article examines the nutritional content of potatoes and how these nutrients are affected by cooking and other food-processing operations. In addition, it examines how the nutritional content of potatoes is altered by cooking methods and how fried potatoes can have wide variations in fat content depending on the cooking method. Finally, the potential of new food-processing technologies to improve the nutritional content of cooked potatoes is evaluated.

Introduction

White potatoes are an excellent source of key macronutrients (carbohydrate), micronutrients (vitamin C and potassium), and potentially healthful phytochemicals (1). However, traditional processing and preparation methods (peeling, boiling, frying, and baking) can have a significant impact on the overall nutritional quality of white potato products including loss of key micronutrients, adsorption of fat, and conversion of natural resistant starch (RS)5 into highly digestible starch. Although potatoes are an important dietary source of many essential nutrients, there are opportunities to use food-processing operations and food science technology to enhance the overall nutritional profile of white potatoes in all forms.

Consumer desire for “better for you” products has driven interest in development and application of food science approaches to improve the overall nutritional profile of white potato products. To date, these efforts have focused on the development of technologies to both preserve the nutritional value of the raw product and improve the profile of finished “processed” products by altering both macronutrient profile and micronutrient content through food chemistry and -processing approaches. This article highlights strategies that can be leveraged to improve the nutritional profile of white potato products in all forms. Specific focus is given to the following areas: how cooking techniques affect nutritional content; the potential use of micronutrient-dense potato skins; physical, chemical, and processing strategies to limit fat absorption during frying; processing strategies to reduce the glycemic response of white potato products by altering RS content; and varietal and agricultural practices that result in variations of nutritional content.

Impact of cooking on the nutritional content of potatoes

Potatoes are cooked by a variety of methods including boiling, roasting, baking, microwaving, and frying. These cooking techniques can affect the profile of endogenous nutrients in potatoes by the leaching of water-soluble nutrients, degradation of heat-sensitive nutrients, and removal of water, which can concentrate nutrients. Nutrient data cited in this article are from the USDA Nutrient Database version 24 (2) unless otherwise noted. To understand the nutrient profile of cooked potatoes it is first important to understand how cooking influences the water content (Table 1). Raw potatoes contain 79% water. As one would expect, the water content of boiled potatoes is similar to raw potatoes at 77%. Cooking in a dry environment reduces moisture content but not always as much as one would expect. For example, the water content of baked potatoes is 75% and that of microwaved potatoes is 72%. Frying causes the highest level of water loss, resulting in a 39% water loss in French fries to as little as a 2% water loss in potato chips. Because cooked potatoes have such a large difference in water content, they also have a large difference in serving size: boiled and microwaved potatoes have a serving size of 90 g and a small baked potato has a serving size of 138 g (Table 1). French fries have a serving size of 85 g, whereas potato chips have a serving size of 28 g.

Table 1.

Percentage of water in potatoes cooked by different techniques1

| Cooking method | Water content | Serving size |

| % | g | |

| Uncooked | 79 | 90 |

| Boiled without peel | 77 | 0.5 cup, 90 |

| Oven-baked with skin | 75 | 138–299 |

| Oven-baked without skin | 75 | 138–299 |

| Microwaved | 72 | 0.5 cup, 90 |

| Par-fried | 66 | 15–18 pieces, 85 |

| Fried | 39 | 15–18 pieces, 85 |

| Chips | 1.9 | 28 |

Data adapted from reference 2.

Potatoes contain a variety of minerals and vitamins that can be influenced by cooking. To show the potential effect of cooking on nutritional composition, potassium and vitamin C were used as examples of nutrients that are water soluble yet vary in their heat sensitivity. Cooking in water can reduce both potassium and vitamin C due to leaching into the cooking water and, in the case of vitamin C, thermal degradation. For example, potassium decreases from 421 mg/100 g in raw potatoes to 328 mg/100 g in boiled potatoes, a 22% reduction (Table 2). Vitamin C, which can leach into the water and thermally degrade, decreases from 19.7 mg/100 g in raw potatoes to 7.4 mg/100 g in boiled potatoes, a 62% reduction. Baking has little impact on potassium concentrations because there is no leaching, but it causes thermal degradation of vitamin C from 19.7 to 12.8 mg/100 g, a 35% reduction. Microwave cooking has the least effect on vitamin C due to its short cooking times, with a reduction of 23%. Frying will degrade heat-labile nutrients due to its high temperature (180°C). However, frying times are generally short, and frying causes a large reduction in water content which can concentrate nutrients when compared on a 100-g basis. For example, the concentrations of potassium and vitamin C increase 3.0- and 1.6-fold in potato chips. However, one must remember that the serving size also decreases due to water removal. A small baked potato, which loses very little water, has 540 and 17.7 mg/serving of potassium and vitamin C, respectively, whereas a serving of potato chips has 357 and 8.7 mg of potassium and vitamin C, respectively (Table 3).

Table 2.

Amount of potassium and vitamin C in potatoes cooked by different techniques1

| Cooking method | Potassium | Vitamin C |

| mg/100 g | ||

| Uncooked | 421 | 19.7 |

| Boiled without peel | 328 | 7.4 |

| Oven-baked | 391 | 12.8 |

| Microwaved | 411 | 15.1 |

| Par-fried | 408 | 17.3 |

| Chips | 1275 | 31.1 |

Data adapted from reference 2.

Table 3.

Concentrations of potassium and vitamin C in potatoes cooked by different techniques1

| Cooking method | Potassium | Vitamin C |

| mg/serving | ||

| Uncooked | 421 | 19.7 |

| Boiled without peel (90 g) | 295 | 6.7 |

| Oven-baked (small, 138 g) | 540 | 17.7 |

| Microwaved (small, 137 g) | 567 | 20.8 |

| Par-fried (85 g) | 347 | 14.7 |

| Chips (28 g) | 361 | 8.8 |

Data adapted from reference 2.

Influence of fat on the nutritional profile of processed potatoes

Potatoes are often served with a variety of other ingredients to increase their palatability. Probably the most common nutrient in these ingredients is fat in the form of oil, butter, and dairy products. Fat is important to the sensory properties of foods because it can carry fat-soluble flavors, enhance viscosity, provide lubrication in the mouth, and produce melt-away characteristics (e.g., the feeling of butter or chocolate melting in the mouth). When potatoes are thermally processed, the energy provided by cooking causes the amylose and amylopectin in the starch granules to disassociate, allowing water to penetrate into the starch granule. This process is called gelatinization and is important in the texture of cooked potatoes because the starch granules go from small, compact structures that have a sandy texture in the raw potato to large, swelled structures that have a soft texture in the cooked potato. Because most of the water in a cooked potato is entrapped in the starch granule, it has a dry texture. Therefore, many ingredients and sauces are served along with cooked potatoes to provide moistness and lubrication. Fat is especially compatible with enhancing the texture of cooked potatoes as one can see in dishes such as buttered, boiled potatoes; mashed potatoes with milk and butter; and baked potatoes with a variety of high-fat dairy products (butter, sour cream, and cheese). Therefore, although a plain potato has an excellent nutritional profile, this can be negatively altered by the addition of condiments high in fat, especially condiments high in SFAs. For example, although a boiled potato has only 0.1 g of fat, mashed potatoes made with whole milk and butter have 4.2 and 2.1 g/100 g of total fat and saturated fat, respectively (Table 4). Surprisingly, par-fried potatoes (potatoes that are only partially fried and then baked to finish cooking) have moderate levels of fat (4–5 g/100 g) compared with fully fried potatoes (17 g/100 g) and potato chips (35 g/100 g). This means that oven-baked par-fries have a much better nutritional profile than a fully fried potato, and because they still have significant concentrations of important nutrients such as potassium, they may be a more appropriate food item than is portrayed in the popular press.

Table 4.

| Cooking method | Total fat | Saturated fat |

| g/100 g | ||

| Uncooked | 0.09 | 0.03 |

| Boiled, baked, and microwaved | 0.1 | 0.03 |

| Mashed with whole milk | 0.6 | 0.25 |

| Mashed with whole milk and butter | 4.2 | 2.1 |

| Par-fried/baked | 4.7 | 0.9 |

| Fully fried | 17.1 | 4.0 |

| Chips | 34.6 | 11.0 |

Data adapted from reference 2.

There are many food ingredients that can mimic the sensory properties of fat at a reduced caloric content, such as micro-particulated proteins, nondigestible fats (e.g., olestra), and gums. However, very few, if any, processed potato products that are on the market today contain these fat mimetics either due to lack of consumer demand or regulatory hurdles. These fat mimetics could represent an opportunity to produce potato products with high sensory appeal yet reduced calories.

The fatty acid composition of processed potatoes reflects the oil they are cooked in and/or the fat added during cooking. The 2010 Dietary Guidelines for Americans (3) recommends decreasing the consumption of trans fatty acids due to their link to the development of heart disease. Overall, the food industry has been actively seeking technologies to decrease the trans fatty acid content of foods before and since the requirement to label trans fatty acid concentration on the nutritional facts panel. This effort has been quite successful, with a reduction in trans fatty acid concentrations of up to 73% (4). There has also been a major effort by the food industry to improve the fatty acid profile of fried potatoes. The large majority of commercially prepared par-fried potatoes are no longer fried in partially hydrogenated oils, which means that they do not contain significant amounts of trans fatty acids. This can also be seen in the fast-food industry where trans fatty acids have been significantly reduced in French fries (5); for example, 5 of the 7 French fry samples from fast-food restaurants in Prince George’s County Maryland had a trans fatty acid content of <0.2 g/serving.

The 2010 Dietary Guidelines for Americans (3) also recommends decreasing the consumption of SFAs due to their link to the development of heart disease. One concern about the elimination of hydrogenated fats from foods was that this could result in an increase in the saturated fatty content if food processors tried to replace the hydrogenated oils with fats that have similar melting properties and oxidative stability. However, a survey (5) of the fatty acid content of French fries from fast-food restaurants from 1996 to 2008 found that SFAs actually decreased along with trans fatty acids, indicating that hydrogenated fats were being replaced with vegetable oils high in MUFAs and PUFAs. This also seems to be the case with commercially frozen par-fried/oven-baked French fries, which generally have <1 g SFAs/100 g, compared with mashed potatoes made with whole milk and butter, which contain 2 g SFAs/100 g.

Further reduction in SFAs in cooked potatoes could be accomplished by using nondairy fats or oils with higher amounts of MUFAs and PUFAs. This could be advantageous from a nutritional standpoint but may alter sensory properties such as texture and could be more expensive because these oils will oxidize faster and thus shelf life could be reduced. The best opportunity for further reduction in SFAs lies in new high–oleic acid oils. These oils have the advantage of both decreasing SFA concentrations and increasing the shelf life of the product because oleic acid is more resistant to oxidative rancidity than are PUFAs (6). Most of the high oleic oils originate from genetically modified organisms, so this may limit their use in some products and countries, and they are generally more expensive compared with conventional oils.

Strategies to control fat absorption and content in fried potato products

The absorption of fat into fried potatoes occurs as the water leaves the product. This means that, as the potato is cooked longer, more water is removed and the fat content increases. For example, par-fried or completely fried potatoes have fat concentrations of 3–5% and 16–18%, respectively (2). Fat absorption primarily occurs after the product is removed from the fryer. Because fat is not absorbed into the potato until after cooking, fat content can be reduced by draining the product immediately after processing (7). This can be accomplished by simple draining. Centrifugation operations after frying have recently been shown to be an effective method to further reduce fat content before fat absorption (8). Fat absorption can also be decreased by removal of water from the potatoes before cooking so that less oil replaces the water after frying. Vacuum frying can decrease fat content by 43–57% by using reduced frying temperatures that remove less water (9). The use of a combination of vacuum frying and centrifugal draining of the oil can decrease fat content by 75% (10).

Fat content can also be reduced by coating the potatoes with food biopolymers that form gels during frying (6). Examples of such polymers include gellan gum, modified cellulose, and proteins. These biopolymers work by decreasing the evaporation of water from the crust of the potato, which, in turn, decreases fat absorption (10). Methyl cellulose is one of the best biopolymers for decreasing fat absorption. Methyl cellulose is uniquely suited for this purpose because it is able to form thermo-reversible gels. In other words, it forms a gel at high temperatures, thus decreasing water loss from the product being fried during cooking; the gel is then lost at lower temperatures, thus minimizing its effect on sensory quality.

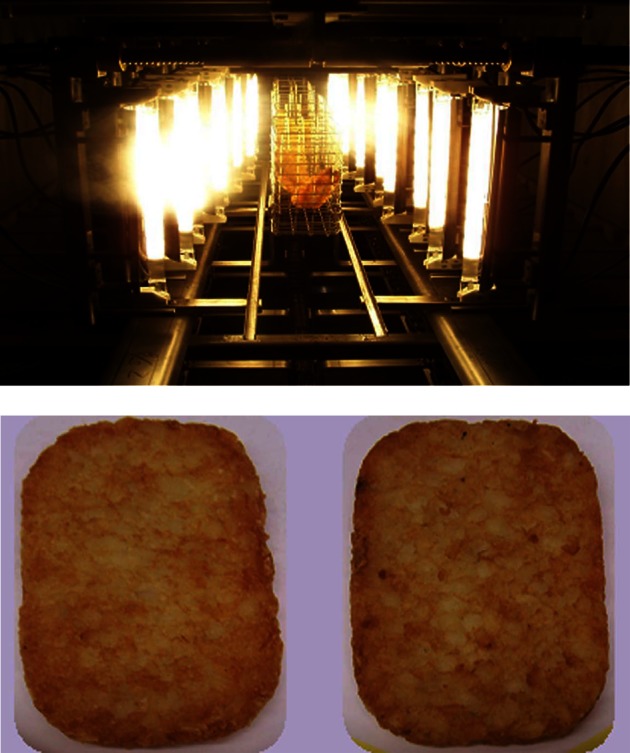

A new approach to reducing the fat content of fried potatoes is controlled dynamic radiant frying (CDRF). CDRF is an alternative to the immersion frying process, which can reduce oil content by 30 to 50% relative to traditional immersion-fried counterparts. CDRF uses high-temperature radiant emitters to generate high-flux infrared radiation to heat the product (11) (Fig. 1). This method differs from convection and microwave approaches by mimicking the heat flux and load experienced during immersion frying, thereby providing sufficient heat to cause water evaporation, crust formation, and browning. CDRF technology is now in the pilot phases of production and has been successfully used to produce fried-food products including chicken nuggets, potato cakes, and French fries (12).

Figure 1.

(Top panel) Front view of food traveling through the FryLess 100K Controlled Dynamic Radiant fryer. (Bottom panel) Immersion-fried potato cake (left) compared with controlled dynamic radiant–fried potato cakes (right). Photographs courtesy of Kevin Keener, Department of Food Science, Purdue University.

Food-processing technologies for leveraging white potato rs content

RS is defined as the portion of starch that escapes digestion in the small intestine and is thereby made available for fermentation by the microbiota present in the large intestine/colon. Naturally occurring RS is broadly characterized into 3 categories: RS1, physically entrapped starch; RS2,-ungelatinzed starch granules that are highly resistant to digestion by α-amylase; and RS3, retrograded starch produced after a cycle of gelatinization and cooling (9). Interest in preservation or formation of RS in foods has increased due to the similarities between RS functionality and potential health benefits and those of dietary fiber. For example, intake of RS has been associated with reduction of gastrointestinal cancer risk (13, 14) and improvement in inflammatory bowel disease (15). These benefits are believed to be due, in part, to the ability of certain RS types (including RS3) to promote production of SCFAs, including butyrate, through fermentation in the lower gut by human colonic bacteria (16, 17). RS3 type RS has also demonstrated activities consistent with the ability to increase bile acid turnover and limit reabsorption (18), highlighting its potential in cholesterol lowering.

Considering the potential benefits associated with RS, it is not surprising that interest in the development of RS-based ingredients and food-processing strategies to favor formation of physiologically active RS forms has expanded. Raw potatoes are a rich source of RS, characterized primarily as “RS2,” ungelatinized starch granules that remain highly resistant to normal small intestinal digestion. After thermal processing, RS2 granules are gelatinized and potato starch becomes rapidly digestible, resulting in the high glycemic response characteristic of white potato products. However, gelatinized potato starch can retrograde and become slowly digestible starch (SDS) or resistant to digestion (RS3 type) (19–21). This means that potatoes would be expected to have differences in RS levels depending on how they are cooked and served. For instance, a cold potato salad would be expected to have more RS than hot mashed potatoes. In addition to a lower glycemic response, other potential health benefits have been reported for potato-based RS. RS-rich potato flakes were found to increase SCFA production and fecal bile acid secretion in a rodent model (22). Longer terms studies (4–14 wk) in pigs fed raw potato starch (RS2) reported similar increases in SCFA production/concentration, and improvements in colonic length and mucosal integrity were observed (23, 24). Although these benefits will require additional clinical evaluation, it appears as though the use of processing and storage conditions to increase the amount of RS in finished potato products can potentially be leveraged to provide a reduced glycemic response and potentially support for a fiber claim in the finished potato product.

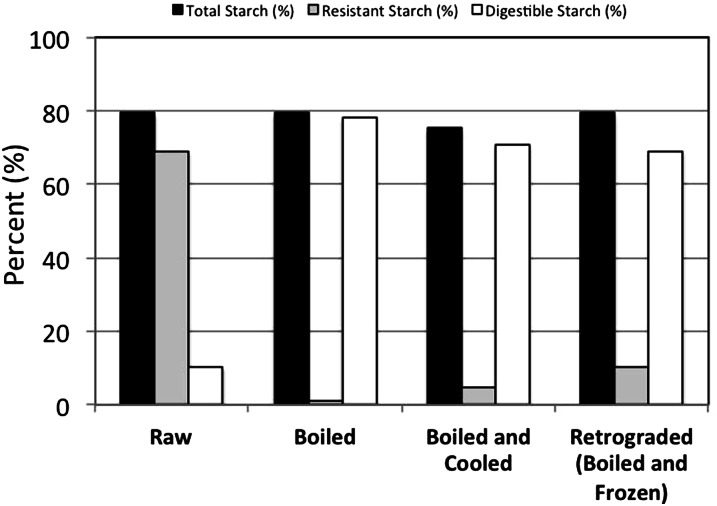

Overall, the fraction of remaining RS is dependent on several factors, including the type of processing, extent of gelatinization, and the extent of retrogradation during cooling of the cooked potato products. Potatoes processed by mashing, boiling, baking, and frying had low but variable RS content (∼1.2–10.4%) compared with raw potatoes (∼69%), indicating that the method of preparation may play a critical impact in terms of glycemic response (25). Several strategies have been studied to improve the proportion of RS to total starch in potato products, including preservation of starch granule structure (RS2) and generation of RS3 RS through cooling after cooking, frying, freeze-drying, and extrusion (16, 17, 21). Mishra et al. (21) demonstrated that cooling treatments, including freezing or freeze-drying, can be used to increase both SDS and RS3 content in cooked potatoes. The rate of cooling is critical in determining final ratio of SDS to RS3. García-Alonso and Goni (25) observed similar increases in RS content of boiled potatoes through cooling or freeze/freeze-drying–induced retrogradation (Fig. 2). These results suggest that, for specific applications where cooling can be applied (such as potato salads), potato products can be designed with a decreased glycemic response and relative increase in RS, resulting in an enhanced nutritional profile of processed potato products.

Figure 2.

Impact of processing on formation of resistant starch in potatoes. Adapted from reference 25 with permission.

Use of potato peel to enrich micronutrient content of white potato products

Potato skins are the major byproduct of the potato-processing industry. Because the skins are an excellent source of fiber, minerals, vitamins, and antioxidants (2), they represent a nutritionally rich food ingredient that could potentially add value for the potato industry (26). However, the addition of the skin to potato products is often not suitable because it can alter both texture and color. One potential solution to this problem is to finely mill potato skins into a very fine flour, which has less impact on sensory properties. Orr et al. (27) ground potato skins in a Wiley mill with a 20-mesh sieve and added the resulting flour to bread at concentrations of 5–30%. They reported that at levels of up to 15% potato skin flour there were no decreases in sensory scores for texture or flavor of the bread. This research suggests that there may be some opportunities to use potato skin flours in bread and possibly other potato products. Research has also been conducted to extract antioxidants from potato skins for addition to other products as nutritional fortificants or as functional food ingredients. Extraction can be done with water or food-grade organic solvents. Extracted antioxidants can include phenolics and carotenoids depending on the solvent type and potato variety (26).

Difference in nutritional composition as a function of potato variety and agricultural practices

There are >4000 cultivars of potatoes so it is not surprising that variations in nutritional content would be observed between potato varieties (1). Potassium concentrations have been reported to vary >9-fold in different potato varieties that are grown in New Brunswick, Canada (28). For example, with regard to 2 common retail potatoes grown in New Brunswick, Canada, the Russet Burbank has 1897 mg potassium/148 g serving, whereas the Red Pontiac has 240 mg potassium/148 g serving. Although this suggests that the nutritional density of potatoes could easily be maximized by selection of the appropriate cultivar, this is not always practical because different potato varieties can have quality variables that make them more suited for different potato products (e.g., fried vs. mashed potatoes). This is primarily due to factors such as differences in amylose to amylopectin ratio in the starch granule, which affects texture.

In addition to variations between cultivars, potassium concentrations can also vary as a function of the geographic region in which they are grown (28). For example, the Russet Burbank can vary between 1683 and 2224 mg potassium/148 g serving when grown in different regions of Canada. This suggests that the nutritional content of potatoes could be manipulated by careful selection of growing climate/soil or agricultural practices. It could be possible to grow potatoes in soil fertilized with potassium to improve nutritional profiles. However, it is not known how these practices would affect the physiology of the potato plant because high-potassium environments can interfere with the absorption and metabolism of other minerals such as magnesium and calcium, which could affect potato yield and quality variables. However, these differences in nutritional content as a function of where the potato is grown suggest that more research on agricultural practices could provide opportunities to improve the nutritional content of potatoes.

Conclusions

As part of a balanced diet, white potato products contribute key macronutrients and micronutrients, including those that are commonly underconsumed (dietary fiber and potassium). However, despite the positive nutritional characteristics of white potatoes, the popular image of these vegetables is negative due in large part to the high glycemic response and caloric load of fried potato products. However, evidence suggests that the nutritional profile of potatoes can be altered by preparation and processing methods. For example, techniques including oven-baked par-frying can significantly reduce fat content and enhance retention of sensitive nutrients often lost in immersion frying. In addition, the application of food ingredient technologies such as biopolymer coatings to limit fat absorption and processing technologies such as vacuum frying, centrifugal draining, and CDRF have been applied to reduce fat content and improve the overall nutritional profile of fried potato products. Furthermore, technologies are being developed to enhance RS and fiber content of potato products that include the use of potato skins and cooling after processing. The approach to development and application of new food technologies to improve the nutritional content of cooked potatoes offers the potential to generate improved potato products with enhanced nutritional profiles.

Acknowledgments

All authors read and approved the final manuscript.

Footnotes

Abbreviations used: CDRF, controlled dynamic radiant frying; RS, resistant starch; SDS, slowly digestible starch.

Literature Cited

- 1.Camire ME, Kubowb S, Donnell DJ. Potatoes and human health. Crit Rev Food Sci Nutr. 2009;49:823–40 [DOI] [PubMed] [Google Scholar]

- 2. USDA, Agricultural Research Service. USDA National Nutrient Database for Standard Reference, release 24. USDA, Agricultural Research Service; 2011. Available from: http://www.ars.usda.gov/Services/docs.htm?docid=8964.

- 3.USDA; US Department of Health and Human Services Dietary guidelines for Americans, 2010. 7th ed Washington (DC): US Government Printing Office; 2010 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Rahkovsky I, Martinez S, Kuchler F. New food choices free of trans fats better align US diets with health recommendations. USDA, Economic Research Service. Economic Information Bulletin Number 95. April 2012 [cited 2012 May 14]. Available from: http://www.ers.usda.gov/Publications/EIB95/EIB95.pdf.

- 5.Tyburczy C, Delmonte P, Fardin-Kia AR, Mossoba MM, Kramer JKG, Rader JI. Profile of trans fatty acids (FAs) including trans polyunsaturated fas in representative fast food samples. J Agric Food Chem. 2012;60:4567–77 [DOI] [PubMed] [Google Scholar]

- 6.Smith SA, King RE, Min DB. Oxidative and thermal stabilities of genetically modified high oleic sunflower oil. Food Chem. 2007;102:1208–13 [Google Scholar]

- 7.Mellema M. Mechanism and reduction of fat uptake in deep-fat fried foods. Trends Food Sci Technol. 2003;14:364–73 [Google Scholar]

- 8.Moreira RG, Da Silva PF, Gomes C. The effect of a de-oiling mechanism on the production of high quality vacuum fried potato chips. J Food Eng. 2009;92:297–304 [Google Scholar]

- 9.Dueik V, Bouchon P. Development of healthy low-fat snacks: understanding the mechanisms of quality changes during atmospheric and vacuum frying. Food Rev Int. 2011;27:408–32 [Google Scholar]

- 10.Varela P, Fiszman SM. Hydrocolloids in fried foods: a review. Food Hydrocoll. 2011;25:1801–12 [Google Scholar]

- 11.Lloyd BJ. Analysis of radiant heating to produce an alternative frying process [dissertation]. Raleigh (NC): North Carolina State University; 2003 [Google Scholar]

- 12.Lloyd BJ, Farkas BE, Keener KM. Quality comparison of French fry style potatoes produced by oven heating, immersion frying and controlled dynamic radiant heating. J Food Process Preserv. 2004;28:460–72 [Google Scholar]

- 13.Ridlon JM, Hylemon PB. A potential role for resistant starch fermentation in modulating colonic bacterial metabolism and colon cancer risk. Cancer Biol Ther. 2006;5:273–4 [DOI] [PubMed] [Google Scholar]

- 14.Govers MJ, Gannon NJ, Dunshea FR, Gibson PR, Muir JG. Wheat bran affects the site of fermentation of resistant starch and luminal indexes related to colon cancer risk: a study in pigs. Gut. 1999;45:840–7 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Jacobasch G, Schmiedl D, Kruschewski M, Schmehl K. Dietary resistant starch and chronic inflammatory bowel diseases. Int J Colorectal Dis. 1999;14:201–11 [DOI] [PubMed] [Google Scholar]

- 16.Topping DL, Clifton PM. Short-chain fatty acids and human colonic function: roles of resistant starch and nonstarch polysaccharides. Physiol Rev. 2001;81:1031–64 [DOI] [PubMed] [Google Scholar]

- 17.Bird AR, Conlon MA, Christophersen CT, Topping DL. Resistant starch, large bowel fermentation and a broader perspective of prebiotics and probiotics. Benef Microbes. 2010;1:423–31 [DOI] [PubMed] [Google Scholar]

- 18.Dongowski G, Jacobasch G, Schmiedl D. Structural stability and prebiotic properties of resistant starch type 3 increase bile acid turnover and lower secondary bile acid formation. J Agric Food Chem. 2005;53:9257–67 [DOI] [PubMed] [Google Scholar]

- 19.Englyst HN, Kingman SM, Cummings JH. Classification and measurement of nutritionally important starch fractions. Eur J Clin Nutr. 1992;46:S33–50 [PubMed] [Google Scholar]

- 20.Thed ST, Phillps RD. Changes of dietary fibre and starch composition during domestic cooking. Food Chem. 1994;52:301–4 [Google Scholar]

- 21.Mishra S, Monro J, Hedderley D. Effect of processing on slowly digestible starch and resistant starch in potato. Starch. 2008;60:500–7 [Google Scholar]

- 22.Han KH, Hayashi N, Hashimoto N, Shimada K, Sekikawa M, Noda T, Fukushima M. Feeding potato flakes affects cecal short-chain fatty acids, microflora and fecal bile acids in rats. Ann Nutr Metab. 2008;52:1–7 [DOI] [PubMed] [Google Scholar]

- 23.Nofrarías M, Martínez-Puig D, Pujols J, Majó N, Pérez JF. Long-term intake of resistant starch improves colonic mucosal integrity and reduces gut apoptosis and blood immune cells. Nutrition. 2007;23:861–70 [DOI] [PubMed] [Google Scholar]

- 24.Martinez-Puig D, Pérez JF, Castillo M, Andaluz A, Anguita M, Morales J, Gasa J. Consumption of raw potato starch increases colon length and fecal excretion of purine bases in growing pigs. J Nutr. 2003;133:134–9 [DOI] [PubMed] [Google Scholar]

- 25.García-Alonso A, Goni I. Effect of processing on potato starch: in vitro availability and glycaemic index. Nahrung. 2000;44:19–22 [DOI] [PubMed] [Google Scholar]

- 26.Schieber A, Saldana ADA. Potato peels: a source of nutritionally and pharmacologically interesting compounds—a review. Food 3. 2009;2(Special issue):23–9. [Google Scholar]

- 27.Orr PH, Toma RB, Munson ST, Appolonia BD. Sensory evaluation of breads containing various levels of potato peels. Am J Potato Res. 1982;59:605–11 [Google Scholar]

- 28.Nassar AMK, Sabally K, Kubow S, Leclerc YN, Donnelly DJ. Some Canadian-grown potato cultivars contribute to a substantial content of essential dietary minerals. J Agric Food Chem. 2012;60:4688–96 [DOI] [PubMed] [Google Scholar]