Abstract

Tamra Bhasma (incinerated copper) is one of the main weapons in the archery of Ayurvedic practitioners. Though several methods of preparation of Tamra Bhasma (TB) are found in Rasashastra classics, several difficulties occur during the preparation of a good-quality Bhasma. In this study, TB was prepared and analyzed to develop the standard manufacturing procedure. Each unit operative procedure was considered as an independent processing and an attempt was made to validate each procedure. Wire used for the purpose of electrical earthing was taken for the preparation of Bhasma. Procedures of Shodhana, Marana, and Amritikarana were followed as per the classical references. Specific temperature pattern was adopted for Puta in the electrical muffle furnace. From 500 g of Tamra, 483.4 g of black colored TB was obtained after subjecting to three Putas. Final product was detected to be cupric sulfide in X-ray diffraction. In particle size distribution analysis 10% of the material was below the size of 2 μm, while in inductive coupled plasma - atomic absorption spectrometry 58.56 wt% copper and 22.48 wt% of sulfur were found present in the final product along with the elements such as arsenic, lead, zinc, mercury, and manganese in traces.

Keywords: Bhasma, Puta, standard manufacturing procedure, Tamra, X-ray diffraction

Introduction

Present day demand of Ayurvedic formulations has been raised globally due to increased response toward Ayurvedic system of medicine. Hence, commercialization of Ayurvedic drug manufacturing has taken place. Therefore, certain things like standardization, quality control, and safety became essential requirements for Ayurvedic formulations. It is the need of the time to present, understand, and implement these things into Ayurvedic formulations more accurately for globalization of Ayurveda. Thus, the production of standard, effective, genuine, safe drugs of utmost quality should be given prime importance by the processing units of Ayurvedic drugs.[1] Unfortunately, Ayurvedic formulations prepared in above-said terms are fewer. This may be because of the scarcity of standard parameters to compare a prepared drug.

Metals and minerals, as such in an elemental form, cannot be used for the therapeutic purpose, since many of them are toxic to the human body.[2] But the Rasashastriya pharmaceutical processes like Shodhana (purification/detoxification), Marana (incineration/calcination), etc., make them into such form (compound) that they are highly effective without any untoward effects in the therapeutic dose.[3] Tamra Bhasma (incinerated copper) is important amongst the metallic Bhasmas used for the treatment of many diseases. Though numbers of methods of Tamra Bhasma (TB) preparation are described in Rasa literature; its preparation has always been a practical problem. Moreover, improperly prepared (Apakwa) TB has been quoted as poison or more than a poison, because of its hazardous effects on the body.[4] To indicate its toxic potential, Ayurveda Prakasha have quoted Ashtamahadoshas (eight major ill effects).[5] Therefore, it is extremely important to prepare TB of good quality by following the classical procedures, which include Shodhana, Marana, and Amritikarana. This particular work is the modest attempt in the direction of development and establishment of Standard Manufacturing Procedure (SMP) for TB. For validation, each unit operative procedure was considered as an independent processing. Final product (TB) was analyzed by classical tests, physicochemical parameters, and by applying some advanced analytical techniques.

Materials and Methods

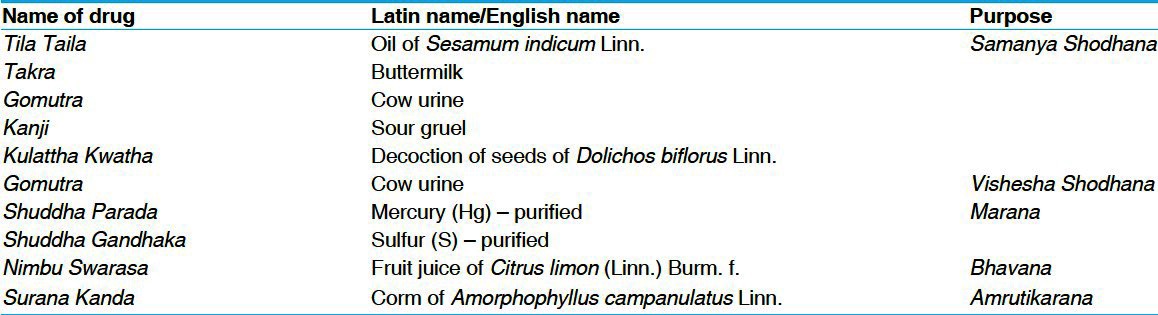

Tamra wire of 0.5 mm diameter was collected from an electrician. There was no coating over the wire. This wire was converted to thin sheet of 36 gauge thickness by passing it through a roller press. The sheet was then converted to pieces of 1 × 1 cm. A brief description of the materials used during the preparation of TB is given in Table 1.

Table 1.

Brief description of drugs used in preparation of Tamra Bhasma

Tila Taila (sesame oil), Parada (mercury), and Gandhaka (sulfur) were collected from Pharmacy, Gujarat Ayurved University, Jamnagar. Kulattha (Dolichos biflorus Linn.) seeds, Surana Kanda (corm of Amorphophyllus campanulatus Linn.) and Nimbu (Citrus medica Watt.) were procured from the local market of Jamnagar. All the herbal materials were identified and authenticated in the Pharmacognosy Laboratory of Institute for Post Graduate Teaching and Research in Ayurveda, Gujarat Ayurved University, Jamnagar. Gomutra (cow urine) was collected from local cow shed.

Process validation of Samanya Shodhana (general purification) of Tamra

Samanya Shodhana of Tamra was carried out by Nirvapa (heating and quenching).[6] Kanji (sour gruel), Kulattha Kwatha (decoction of horse gram), and Takra (buttermilk) were prepared as per the references of Parada Samhita,[7] Sharangadhara Samhita,[8] and Sushruta Samhita[9] respectively. The 500 g of Tamra (pieces of 1 × 1 cm and 36 gauge thickness) was heated in an iron ladle to red-hot stage and quenched in each liquid media for 7 times. Temperature at the time of red-hot stage was taken by a thermocouple. Each time, liquid media was taken fresh and gravimetrically equal to the Tamra (500 ml × 1 × 7 = 3500 ml).

Process validation of Vishesha Shodhana (specific purification) of Tamra

Vishesha Shodhana of Tamra was carried out as per the reference of Rasaratnasamucchaya.[10]) Samanya Shodhita Tamra (3 batches) was boiled in freshly collected Gomutra (3 L × 3 batches = 9 L) for 3 h in Dola Yantra. It was then washed with warm water and dried.

Process validation of Parada Shodhana

Parada Shodhana was done as per the classical reference of Rasatarangini.[11] Ashuddha Parada (impure mercury): 500 g × 3 batches = 1500 g, Sudha Raja (lime powder): 500 g × 3 batches = 1500 g, Nistusha Lashuna (garlic): 500 g × 3 batches = 1500 g, and Saindhava Lavana (rock salt): 250 g × 3 batches = 750 g were taken as ingredients. Parada was triturated with Sudha Raja for 3 days. On the 4th day, it was filtered through a cotton cloth and procured Parada was triturated with Nistusha Lashuna and Saindhava Lavana until the Kalka (paste) became black. Then it was washed with hot water and filtered through a cloth, weighed and stored in a glass bottle.

Process validation of Gandhaka Shodhana

The classical reference of Rasatarangini was followed throughout the procedure.[12] Ashuddha Gandhaka: 1 kg × 6 batches = 6 kg, Godugdha (cow milk): 2 L × 3 times × 6 batches = 36 L (gravimetrically double to the Gandhaka each time), Goghrita (cow ghee): 250 g × 3 times × 6 batches = 4500 g (gravimetrically 1/4th to Gandhaka each time) were taken for the practical work. In the reference, volume of Godugdha is not mentioned. Here, the volume was considered, so as to dip the melted Gandhaka completely. Furthermore, the amount of Goghrita was not taken as per the reference, because it was observed in pilot study that only 1/4th of Goghrita is sufficient to melt the Gandhaka. Powdered Gandhaka was heated with Goghrita over Mandagni (mild heating). After melting, it was poured into hot Godugdha through Goghrita smeared cotton cloth. A solid mass with some granular Gandhaka was taken out and washed with hot water. The procedure was repeated twice. After drying, it was powdered, weighed and kept in a glass bottle.

Process validation of preparation of Kajjali

Shuddha Parada: 500 g × 3 batches = 1500 g, Shuddha Gandhaka: 500 g × 3 batches = 1500 g were taken for the preparation of Samaguna Kajjali. In a Khalvayantra, Shodhita Parada, and Shuddha Gandhaka were taken in equal quantity and triturated. It was continued until the powder became black, smooth, and lusterless.

Process validation of Tamra Bhasma

TB was prepared as per the reference of Rasaratnasamucchaya by the principle of Puta (incineration) in an Electrical Muffle Furnace (EMF).[13] Samaguna Kajjali equal to the amount of Shuddha Tamra was taken in mortar and Nimbu Swarasa Bhavana (wet trituration with lemon juice) was given. When paste like consistency appeared, the mixture of Shuddha Tamra was added in it and triturated. After drying in shade, it was kept in Sharava (earthen saucer) and covered by another Sharava and junction was sealed by double fold of Multany Mitty smeared clothes. It was subjected for Puta in EMF. On the next day, after Swangasheetikarana (self-cooling) Sharava Samputa was removed, material was collected and triturated. In subsequent Puta equal amount, to that of one Puti Bhasma, of Samaguna Kajjali was added and triturated well by giving Bhavana of sufficient quantity of Nimbu Swarasa. After drying, this powder was subjected to Puta. Total three Puta were given to complete the preparation of Bhasma. Following temperature pattern was followed: 1st Puta – 700°C for 20 min, 2nd Puta – 600°C for 25 min, 3rd Puta – 500°C for 30 min.

Process validation of Amrutikarana of Tamra Bhasma

Amrutikarana of TB was done as per the reference of Rasa Tarangini.[14,15] Surana Kanda, Shuddha Gandhaka, and Nimbu Swarasa were used in this procedure. TB was triturated with ½ part of Shuddha Gandhaka in mortar and Bhavana of Nimbu Swarasa given. After proper trituration, a round bolus was prepared and dried in sunlight. Surana weighing 2.5 kg was cut into two halves horizontally. A round pit was made in the middle of both the halves. Dried bolus was kept in it and the two halves were joined together. A thick layer of Kapadmitty (mud smeared cloth) was done over it. It was then dried in sunlight. This was kept in EMF at the temperature of 500°C for 15 min. After Swangasheetikarana it was removed, triturated and stored in an airtight glass bottle.

Analysis of final product

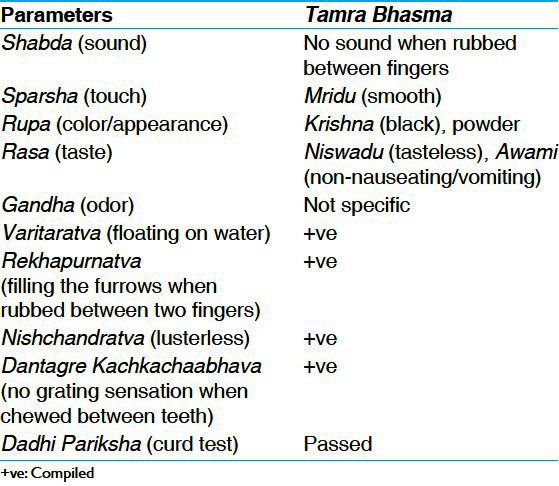

To lay down the standards, raw Tamra, in process material and final product were analyzed physico-chemically. Final product (TB) was analyzed by using different organoleptic parameters like Varna (color), Rasa (taste), etc.; classical tests like Varitaratwa, Rekhapurnatwa, Apunarbhavatwa, Uttama/Unama, Niruttha, etc.,[16] and Dadhi Pariksha (curd test)[17] were performed. Other parameters like Avami, Niswaduta, etc., were also applied.[18] Modern physico-chemical parameters like loss on drying, ash value, acid insoluble ash, and water soluble extractive, etc., were performed on three samples of TB.[19] Sophisticated instrumental analytical techniques like scanning electron microscopy (SEM), particle size distribution (PSD), and inductive coupled plasma - atomic absorption spectrometry (ICP-AES) of one sample of TB was carried out. Instrument used for the particle PSD was Sympatec HELOS (H1004) SUCELL. Instrument used to perform quantitative elemental evaluation (ICP-AES) of the sample was - Inductive Coupled Plasma Spectrometer, Model: ARCOS from M/s. Spectro, Germany, R.F. Generator: Maximum of 1.6 KW, 27.12 MHz.

Observations and Results

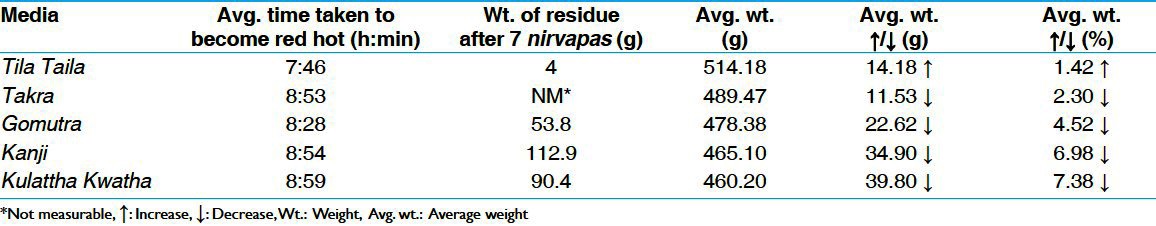

During the Samanya Shodhana of Tamra, all Tamra flakes became red-hot at 460°C. As soon Tamra Patra were quenched in media typical “hissing” sound was produced with boiling of that media. After every quenching some residue in the form of powder was observed. After complete Shodhana, Tamra turned into a mixture of black coarse powder and pieces of Tamra. The average time taken by Tamra to became red and change in weight during the procedure is depicted in Table 2.

Table 2.

Average time to become red hot and change in weight after Samanya Shodhana

During the Vishesha Shodhana of Tamra, froth was observed on Gomutra after 10 min of boiling. Temperature of Gomutra was recorded between 96°C and 102°C throughout the procedure. After Swedana, Tamra became greenish in color. Color of Gomutra turned to blackish green with a strong irritating smell. The weight loss of Tamra after Vishesha Shodhana is depicted in Table 3.

Table 3.

Average weight loss after Vishesha Shodhana of Tamra

In Parada Shodhana procedure, after trituration with Sudha, almost all Parada mixed with it after 4 h of trituration and color of the mixture turned gray. White Lashuna Kalka changed to black within 2 h of trituration. After this procedure, 451.5 g of Shuddha Parada was procured and 48.5 g (9.7%) of weight loss was observed in Parada.

During the Gandhaka Shodhana procedure, Gandhaka melted in 14 min (average) and the temperature recorded at its time of melting was 116°C. Crystalline dark yellow Gandhaka turned granular and dull yellow after Shodhana. Average 16.40 g (1.64%) decrease in weight was observed.

During the Kajjali preparation, color of the mixture started to become black after 12 h of trituration which turned dark black after 16 h trituration. Varitaratva (floating on stagnant water), Rekhapurnatva (filling the furrows when rubbed between two fingers), and Nischandratva (lustreless) were found after average 26.33 h of Mardana (trituration). On an average, 960 g of Kajjali was obtained and 40 g (4%) loss in weight was observed.

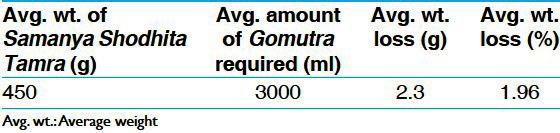

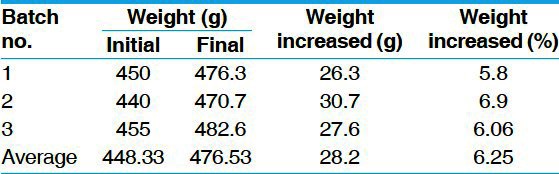

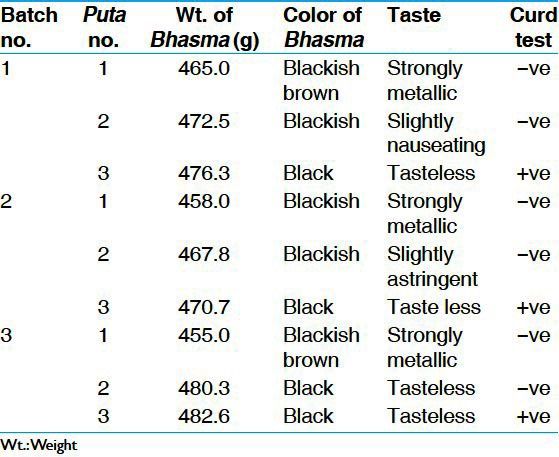

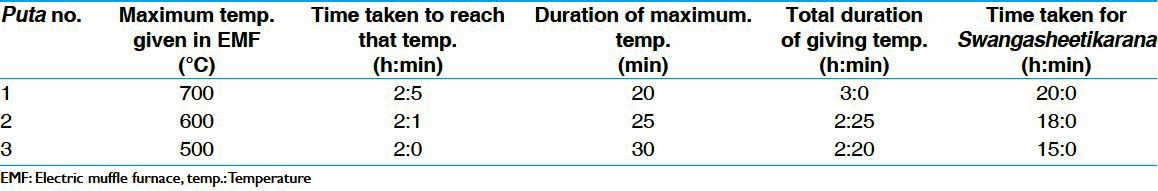

During the Bhasma preparation, cracks were observed on Sharava after taking out from EMF. Whitish layer of mercury was observed near the door of EMF. After first Puta, Tamra Patra became so brittle that it was getting powdered on rubbing between two fingers. Black, smooth, and very fine Bhasma was obtained after 3 Puta. Particulars of Marana procedure, duration of temperature given to Puta, specific observations and other observations regarding change in weight, etc., are depicted in Tables 4-7.

Table 4.

Particulars of Tamra Marana

Table 7.

Increase in weight of Tamra Bhasma

Table 6.

Specific observations and results of Tamra Bhasma preparation after each Puta

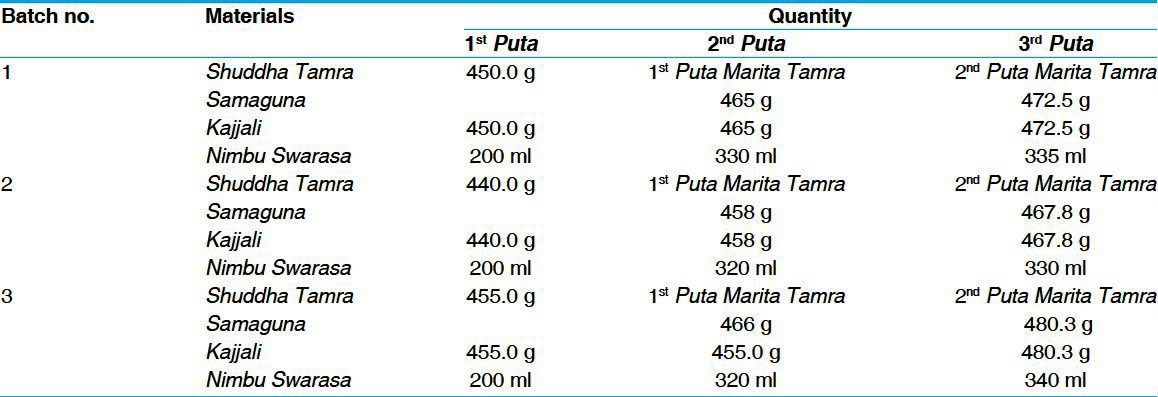

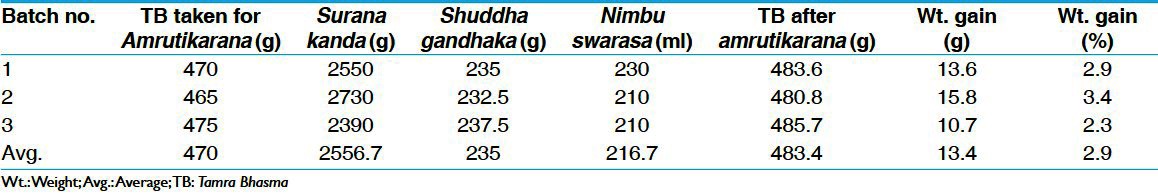

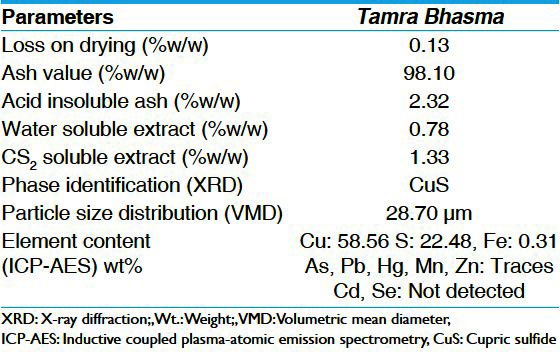

In the process of Amritikarana, three hours of trituration was required for the consistency of bolus formation. After Putapaka, Surana was found totally burnt. Bolus inside was black and breakable by some pressure. After trituration it converted to black, smooth, and fine powder [Table 8]. When different samples of Tamra analyzed quantitatively, 99.89%, 90.84% of copper and 0.10%, 5.53% of iron was detected in raw and Shuddha Tamra respectively. TB complied with all the classical parameters [Table 9]. Physicochemical and advances analytical characters of TB are depicted in Table 10.

Table 8.

Observations during Amrutikarana of Tamra Bhasma

Table 9.

Organoleptic and other classical characters of Tamra Bhasma

Table 10.

Physicochemical and advanced analytical characters of Tamra Bhasma

Discussion

Aim of the present study was to standardize the preparation method of TB. The Bhasmas prepared with Parada or Parada Bhasma as media are considered superior to others.[20] In this study, Kajjali (black sulfide of mercury - HgS)[21] was used as media for TB preparation.

99.89% of copper was found in raw Tamra which indicates the high purity of raw material. Thin sheets of copper were satisfying almost all the classical parameters for Nepalaka Tamra.[22] Copper wire taken for the study is used for electrical earthing and that is why it was in a very pure form. Slight impurity in it decreases its electric conductivity.[23] Hence these types of wires should be used as raw material for the preparation of TB.

For Samanya Shodhana of Tamra, it was heated and after the red-hot it was quenched for 7 times in Tila Taila, Takra, Gomutra, Kanji, and Kulattha Kwatha in order. These are acidic, acidic, basic, acidic and basic media in order. This specific order disrupts the internal structure of Tamra during the process. During Shodhana, color of Tamra became black. This is because during red-hot state, Tamra reacts with atmospheric oxygen and steam to form cupric oxide (CuO) which is black in color,[24] and reaction of Tamra occurs mainly on surface. It was observed that as Shodhana procedure advances Tamra takes comparatively more time to get complete red hot [Table 4]. Conductivity of heat is more in metallic form than compound state. So at later state of Shodhana, Tamra and its compound (CuO which is formed on the surface of Tamra flakes) took more time to become complete red hot.

At early stage of Shodhana, cracks were seen at the surface of Tamra flakes and finally, some coarse powder was observed. Repeated heating and cooling of Tamra flakes causes disruption in compression-tension equilibrium leads to cracks on the flake surface (stress corrosion theory).[25] During red hot state, compounds are formed on the surface of Tamra flakes. Expansibility differs from metal to compound on heating [generally expansibility of compound is less than metal (theory of thermal expansion).[26] So on repeated heating cracks are seen on the surface leading to breaking of Tamra flakes into coarse and some fine powder. After every seven Nirvapas this powder was found as sediment in media. Maximum amount of sediment (average 112.9 g) was found in Kanji medium [Table 3]. Kanji falls under the strong acidic category and also it has Tikshna property.[27] In Takra medium sediment was not observed but black particles were seen suspended in it, which was difficult to collect. In Tila Taila media, 1.42% weight gain was observed in spite of weight loss after Nirvapa process. This may be because of the adhered Tila Taila; which could not be removed even after thorough wash with hot water.

Out of six liquid media used for Shodhana procedure, three were acidic (pH ranging from 3 to 3.5) and others were weak bases (pH ranging from 7.3 to 8.9). The alternate heating and quenching in these media lead to corrosive changes in the metal and may also cause removal of acid and alkali soluble impurities from the metal. It should also be noted that these media were among the naturally and easily prepared source of acid and base at the ancient times.

Vishesha Shodhana of Tamra is a simple process of Swedana in Dola Yantra, specific to Tamra. Possible hypothesis for conduction of this process may be further micropurification and impregnation of qualities for Bhasma preparation. In this process, components of Gomutra may pierce through the micropores and cracks created during Samanya Shodhana and may produce the required change specific to Tamra for further process. After Vishesha Shodhana, observed weight loss was may be due to the reaction between ammonia from Gomutra and copper to form the cuprammonium ion [Cu(NH3)4], a chemical complex which is water-soluble.[28] This complex gets washed away during washing with hot water.

Ingredients used in the Parada Shodhana contained Kshariya (alkaline) materials like Sudha (lime) and Saindhava (rock salt). They may be removing the alkaline soluble impurities along with trace elements present in Parada. It was observed that when Parada was triturated with Sudha, it was converted to powder form, which may be referred as Grey powder (calomel). It is difficult to procure the whole amount of Parada by Vastra Galana (straining through cloth) process as mentioned in classics. So it was washed with hot water. During this procedure loss of Parada with water should be checked.

For the process of Gandhaka Shodhana, powdered sulfur was taken for the sake of easy melting. Mandagni was given to avoid burning of sulfur. Cloth was smeared with Ghee to avoid sticking of Gandhaka to the cloth. Hot Godugdha was taken for pouring of melted Gandhaka since it facilitates the granule formation while cold milk forms hard mass of Gandhaka. After each Dhalana (melting and pouring), Gandhaka was thoroughly washed with hot water to remove fat contents of milk and Ghee.

Loss in weight of Kajjali was observed because of dusting of mixture during trituration and some of it remained adhered to Khalva (mortar) which was difficult to collect.

Due to unavailability of Jambira (Citrus limon Linn. Burm.f.) in Jamnagar region, Nimbu (Citrus medica Watt.) was used. EMF was used for Puta to avoid variations such as weight and quality of cow dung cakes, seasonal variations that occur in classical Puta. EMF is a modified instrument by which a desired highest temperature and duration of heat can be adjusted; chance of heat loss is less and a homogeneous temperature pattern can be provided. Nowadays, many of the Ayurvedic pharmacies are using this instrument for preparing Bhasmas. Therefore it was preferred for Putapaka to provide a standard heating pattern.

Chakrikas were not prepared. In pilot study, it was observed that when Chakrikas were prepared, they became hard after every Puta and took nine Putas to form Bhasma. However, in a batch where Chakrikas were not prepared and only mixture was layered; it took only four Putas to form Bhasma. Thickness of layered mixture was around 1 cm. Although, thickness of the layer (1 cm) was more than that of traditional Chakrika (0.5 cm), which may cause less heat flow through the layered mixture according to Fourier's law.[29] However, in layered method also temperature was given for more time to complete the chemical reaction and to form a desired compound.

For the first Puta, Nimbu Swarasa was required gravimetrically 1/4th of the total amount of Shuddha Tamra and Samaguna Kajjali. This amount of Nimbu Swarasa increased from second Puta onwards. This is because of reduced particle size and increased surface area of the material.

In Rasamrutam, Yadavaji has told that higher temperature in initial Putas and lower temperature in later should be given during preparation of TB.[30] Hence, EMF was selected for the Putas to regulate the temperature owing to its convenience. First, Puta was given 700°C and maximum temperature of Putas was reduced to 600°C and 500°C in later Putas [Table 5]. This particular temperature pattern was followed as a result of a pilot study for preparation of TB, which was carried out before going through this study.

Table 5.

Duration and temperature given for Putas

The color of TB is black (Krishna).[31] In the process of TB preparation, copper is converted to its sulfide form in major since the sulfur (dissociation product of HgS) is an accompaniment to the metal in the processing. During the heat treatment for multiple times (Puta), some sulfides may get converted to oxide. Because metallic sulfides when heated in air get converted to oxide of the metal and sulfur dioxide.[32] Therefore, TB may be considered as a mixture of copper oxides (Cu2O, CuO), copper sulfides (Cu2S, CuS) and other trace elements. CuO is brown in color;[33] hence after first two Putas color of Bhasma was brownish black. It can be said that it was a combination of all these compounds. When Bhasma was properly formed, it was black in color. CuO and cupric sulfide (CuS) are black in color.[31] Therefore, it can be inferred that TB is either CuO or cuprous sulfide or combination of both. Average 476.53 g of TB was obtained from 448.33 g of Shuddha Tamra. 6.25% increase in weight after Marana may be attributed to formation of the oxides and sulfides of copper as mentioned earlier. Inorganic contents of Nimbu Swarasa (9.45% w/w) also lead to increase in weight of TB.

For the Amrutikarana 470 g of TB Surana Kanda of 2.5 kg was required. Same temperature was applied at which the Bhasma was formed. 2.9% increase in weight after Amrutikarana may be attributed to inorganic contents (mainly calcium oxalate crystals) of Surana Kanda. Organic contents of Surana act as a source of carbon. An unstable metallic compound (especially oxides) can be reduced to metallic state during this procedure by the carbon reduction process.[34]

![]()

This metallic copper can be further reduced to sulfide in presence of sulfur. However, as metallic compound should not be changed on the particular temperature in which it is formed. Hence it can be inferred that the process of Amrutikarana removes any unstable compound (CuO in this case) and makes the product more stable (CuS).

The color of TB obtained was black [Figure 1]. Color indicates the formation of specific compound. Here black color indicates the formation of either CuO or CuS of copper or both. Tests like Rekhapurnatva and Varitaratva indicate the lightness and fineness of the Bhasma. Awami nature of TB indicates that there is no free copper or any unwanted compound (like copper sulfate) in it. Further no discoloration in curd test even after 48 h proves that there is no free copper or copper sulfate in final product. Awami and no discoloration in curd test should be considered as main tests to assess the properly prepared TB.

Figure 1.

Appearance of final product (Tamra Bhasma)

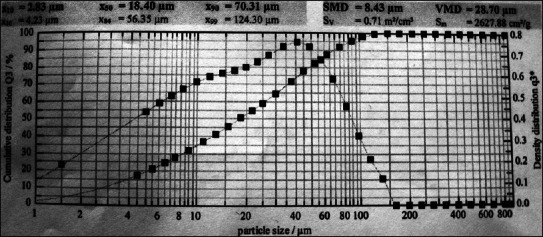

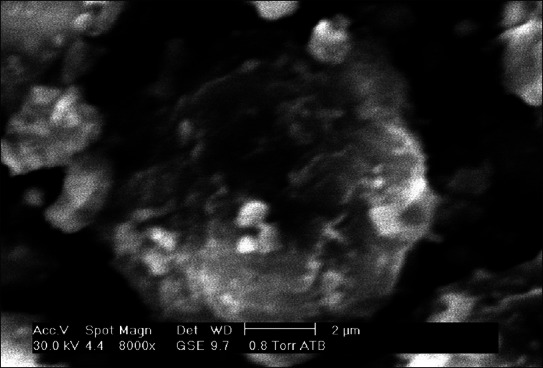

In PSD analysis 10% of the material was found below 2.83 μm where as maximum material was below 124.30 μm [Figure 2]. Small particle size enhances the absorption,[35] hence the bioavailability and thus potency of the drug increases resulting in decrease in its dose. This eventually leads to decrease in dose-related side effects of the drug.

Figure 2.

Particle size distribution of Tamra Bhasma

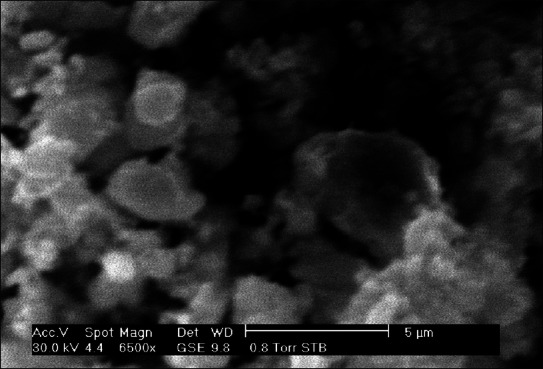

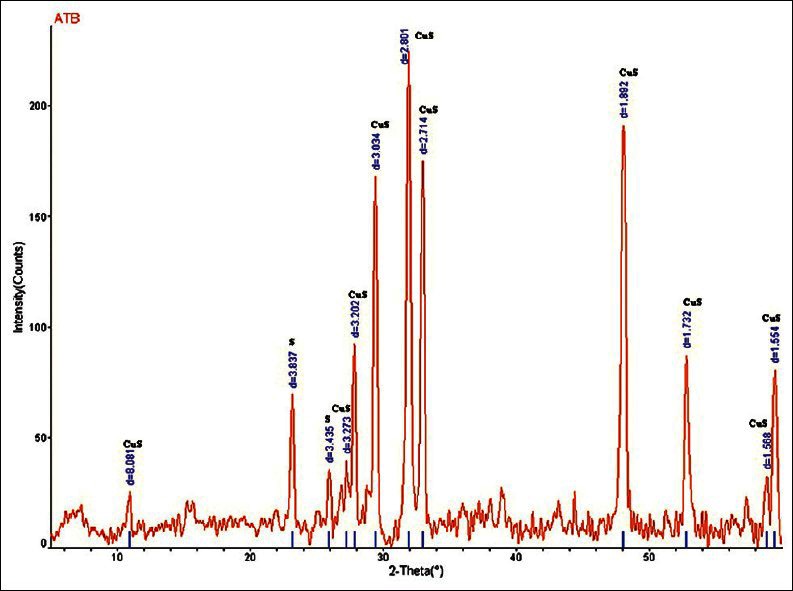

Bhasma analyzed under scanning electron microscope showed particle size less than 2μm [Figures 3 and 4]. In X ray diffraction [Figure 5] prominent peaks of CuS were seen, which confirms that final product is sulfide form of copper. Presence of oxides cannot be denied because other peaks were also present. Furthermore, in ICP-AES 58.56 wt% of copper against 22.48 wt% of sulfur was present. As the procedure of Tamra Shodhana was carried out in an iron pan 0.31 wt% of iron was traced in Bhasma. Heavy metals like cadmium, selenium were not detected while others like arsenic, lead and mercury were present in traces. Hence TB can be considered as blend of micronutrients.

Figure 3.

SEM image of Tamra Bhasma(at resolution 2 μm and magnification 8000×)

Figure 4.

SEM images of Tamra Bhasma (at resolution 5 μm and magnification 6500×)

Figure 5.

XRD analysis of Tamra Bhasma

Conclusion

The adopted method for preparation of TB can be considered as easy, convenient and SMP. The temperature pattern adopted in EMF to prepare TB in this study can be considered as a standard heating pattern. TB should be considered as combination of copper and sulfur in CuS form though presence of oxides cannot be denied. Curd test is the simple household test to finalize the preparation of TB. After three Puta and Amritikarana, particle size of TB reaches up to micron level. In TB, along with copper and sulfur as main elements other elements like manganese, zinc, lead, and arsenic are also present in traces.

Acknowledgment

Authors are thankful to RSIC, IIT, Powai, Mumbai for carrying out XRD, SICART, Vallabh Vidyanagar for carrying out SEM, PSD and ICP, Metalab, Jamnagar for helping in copper estimation of the samples.

References

- 1.Shankar D, Unnikrishnan PM, Venkatasubramanian P. Need to develop inter-cultural standards for quality, safety and efficacy of traditional Indian System of Medicine. Curr Sci. 2007;92:1499–505. [Google Scholar]

- 2.WIKIPEDIA. The free encyclopedia. Wikimedia Foundation, Inc. 2003. [Last updated 2012 Feb 22]. Available from: http://www.en.wikipedia.org/wiki/Toxic_metal .

- 3.Kohli KR. Ayurvedic medicines and heavy metals issue. Ayurveda Heritage (Association of Manufacturers of Ayurvedic Medicines, AMAM, Ghaziabad) 2005;1:5–6. [Google Scholar]

- 4.Upadhyaya Madhava. Ayurved Prakasha, 3/115. reprint. Varanasi: Chaukhamba Bharatiya Academy; 1999. p. 368. [Google Scholar]

- 5.Ibidem. Ayurved Prakasha, 3/116; 368 [Google Scholar]

- 6.Vagbhattacharya . In: Rasaratna Samuchchaya, 5/13. reprint. Kulkarni DA, editor. New Delhi: Meharchand Laxmandas Publication; 2007. p. 93. [Google Scholar]

- 7.Gupta NP. Paradasamhita, 8/61. Mumbai: Khemraj Shri Krishnadas; 2007. p. 59. [Google Scholar]

- 8.Sharngadhara . Sharangdhara Samhita, Madhyama Khanda, 2/1, Adhamalla Commentetor. 5th edition. Varanasi: Chaukhamba Orientalia; 2005. p. 144. [Google Scholar]

- 9.Sushruta . In: Sushruta Samhita, Sutrasthana, Dravadravya Vidhi Adhyaya, 45/85. Jadvaji Trikamji Acharya., editor. Varanasi: Chaukhambha Sanskrit Sansthana; 2009. p. 203. [Google Scholar]

- 10.Vagbhattacharya . In: Rasaratna Samuchchaya, 5/52. reprint. Kulkarni DA, editor. New Delhi: Meharchand Laxmandas Publication; 2007. p. 101. [Google Scholar]

- 11.Sharma SN. In: Rasa Tarangini, 5/27-30. reprint. Shastri KN, editor. Delhi: Motilal Banarasi Das; 2004. p. 79. [Google Scholar]

- 12.Ibidem. Rasa Tarangini, 8/7; 176 [Google Scholar]

- 13.Vagbhattacharya . In: Rasaratna Samuchchaya, 5/53. reprint. Kulkarni DA, editor. New Delhi: Meharchand Laxmandas Publication; 2007. p. 101. [Google Scholar]

- 14.Sharma SN. In: Rasa Tarangini, 2/58. reprint. Shastri KN, editor. Delhi: Motilal Banarasi Das; 2004. p. 24. [Google Scholar]

- 15.Ibidem. Rasa Tarangini. 17:40–42. 418. [Google Scholar]

- 16.Vagbhattacharya . In: Rasaratna Samuchchaya, 8/26-30. reprint. Kulkarni DA, editor. New Delhi: Meharchand Laxmandas Publication; 2007. p. 148. [Google Scholar]

- 17.Shastri DN, Sharma SN. In: Rasa Tarangini, 17/32-33. reprint. Shastri KN, editor. Delhi: Motilal Banarasi Das; 2004. p. 416. [Google Scholar]

- 18.Mishra SN. 15th edition. Varanasi: Chaukhamba Orientalia; 2006. Ayurvediya Rasashastra; p. 94. [Google Scholar]

- 19.Anonymous. The Ayurvedic Pharmacopoeia of India, e-book, Part I. V(Appendix2.2) [Google Scholar]

- 20.Vagbhattacharya . In: Rasaratna Samuchchaya, 5/14. reprint. Kulkarni DA, editor. New Delhi: Meharchand Laxmandas Publication; 2007. p. 94. [Google Scholar]

- 21.Ray PC. History of Chemistry in Ancient and Medieval India. In: Ray P, editor. Varanasi: Chaukhamba Krishnadas Academy; 2004. p. 110. [Google Scholar]

- 22.Vagbhattacharya . In: Vagbhattacharya, Rasaratna Samuchchaya, 5/45. reprint. Kulkarni DA, editor. New Delhi: Meharchand Laxmandas Publication; 2007. p. 99. [Google Scholar]

- 23.Bentor Yinon. Chemical Element.com-Copper. 1996-2009. [Last updated 2012 May 23; cited 2012 Mar 27]. Available from: http://www.chemicalelements.com/elements/cu.html .

- 24.Greenwood NN, Earnshaw A. 2nd ed. Oxford, UK: Butterworth-Heinemann; 1997. Chemistry of the Elements. [Google Scholar]

- 25.Anderson OL, Grew PC. Stress corrosion theory of crack propagation with applications to geophysics. Rev Geophys. 1977;15:77–104. Available from: http://www.agu.org/pubs/crossref/1977/RG015i001p00077.html . [Google Scholar]

- 26.WIKIPEDIA. The free encyclopedia. Wikimedia Foundation, Inc. 2003. [Last updated 2012 May 14]. Available from: http://www.en.wikipedia.org/wiki/Thermal_expansion .

- 27.Sushruta . In: Sushruta Samhita, Sutrasthana, Dravadravya Vidhi Adhyaya, 45/215. Jadvaji Trikamji Acharya., editor. Varanasi: Chaukhambha Sanskrit Sansthana; 2009. p. 210. [Google Scholar]

- 28.YAHOO ANSWERS. Yahoo Inc. 2012. [Last retrieved 2012 May 23]. Available from: http://www.answers.yahoo.com/question/index?qid=20100304144304AA9Pitx .

- 29.Fourier's law of conduction. Taftan Data. 1998. [Last retrieved on 2012 May 23]. Available from: http://www.taftan.com/thermodynamics/FOURIER.htm .

- 30.Acharya YT. Rasamritam, 3. 1st edition. Varanasi: Chaukhamba Surbharati Prakashan; 2008. p. 21. [Google Scholar]

- 31.Anonymous. Yogaratnakara. In: Shastri BS, editor. Varanasi: Chaukhamba Prakashan; 2009. p. 128. [Google Scholar]

- 32.Hicks J. New Delhi: Macmillan India Ltd; 1978. Comprehensive Chemistry. [Google Scholar]

- 33.Iowa State University; 2003. [Last retrieved on 2007 Jan 26]. Material safety data sheet: Copper (II) oxide. Available from: http://www.avogadro.chem.iastate.edu/MSDS/CuO.html . [Google Scholar]

- 34.WIKIPEDIA. The free encyclopedia. Wikimedia Foundation, Inc. 2003. [Last updated 2012 May 15]. Available from: http://www.en.wikipedia.org/wiki/Redox .

- 35.Satoskar RS, Bhandarkar SD, Rege NN. 20th edition. Mumbai: Popular Prakashan Pvt. Ltd; 2007. Pharmacology and Pharmacotherapeutics; p. 11. [Google Scholar]