Abstract

Vermicelli is a product prepared by using whole or refined wheat flour. Hard dough is prepared, extruded and dried in the sun. Since wheat flour is deficient in lysine, one of the essential amino acids, the protein quality remains poor. Refining of wheat further reduces nutritional quality. Therefore value addition of vermicelli is of prime importance to improve nutrient content and to save its delicacy. Secondly, use of value added convenient/processed foods can be a solution to the problem of supplementary feeding and under nutrition Gernah et al. (Am J Food Technol 6:404–412, 2011). Three variations of vermicelli were prepared using whole wheat flour (WWF); malted wheat flour (MWF); malted wheat flour, green gram, spinach and sago (MGSS). A spice mix containing powders of tomato, coriander, chillies, turmeric, salt, raw mango powder, black pepper, cloves and asafetida was also prepared. Results revealed that the overall acceptability scores for WWF, MWF and MGSS were 7.3 ± 6.13, 6.5 ± 0.06 and 8.1 ± 0.01 on 9 point hedonic scale. MGSS vermicelli was most acceptable by the panel members than the other counterparts. WWF, MWF and MGSS contained moisture 6.9 to 7.7%, protein 9.3 to 13.5%, fat 1.2–2.7%, ash 2.9 to 5.8%, crude fibre 2.2 to 2.4%, carbohydrates 69.8 to 75.2% and energy 344 to 362 kcal/100 g respectively. MGSS vermicelli was highest in protein content (13.5%) while energy content was high in WWF. MWF vermicelli had highest amount of total (8.91%), reducing (2.41%) and non-reducing sugars (6.57%). Quality of protein was improved by mutual supplementation of amino acid. Regarding minerals, higher contents of sodium (100 mg), calcium (30 mg), iron (5.9 mg), zinc (1.4 mg) were found in MGSS. Vermicelli could be safely stored for 2 months period at room temperature (25–30 °C).

Keywords: Vermicelli, Malted flour, Value addition, Shelf life, Spinach, Mutual supplementation

Traditional foods are expression of culture, history and life style. Challenges ahead in the development of heritage foods are value addition, convenience and health promotion. Vermicelli is a traditional product prepared by using whole or refined wheat flour. Hard dough is prepared, cold extruded and dried in the sun. Since wheat flour is deficient in lysine, one of the essential amino acids, the protein quality remains poor. Refining of wheat further reduces nutritional quality. Therefore value addition of vermicelli is of prime importance to improve nutrient content and to save its delicacy (Naik 2004). Secondly, use of value added convenient/processed food can be a solution to the problem of supplementary feeding and under nutrition. In India, majority of people live in rural areas and under such economic conditions that they cannot afford readymade or market processed food. Under these circumstances, the effective use of traditional processing methods, locally available and inexpensive food is very essential. Roasting and malting of grains are traditional and village level processing technologies. They improve acceptability, flavour and texture of food, destroy anti nutritional factors and increase the shelf-life of food. Malting improves vitamin C, availability of phosphorus and tryptophan. Besides this, during malting, elaboration of amylase results in lowering of viscosity and thinning down of starch slurry which reduces bulk of the final product (Manay and Sadaksharaswamy 2000). It has special significance with reference to foods for malnourished children, who should be given nutrient dense and easily digestible foods. The present study is an attempt to improve the nutritive value of vermicelli by using locally available, cheaper food items and by following traditional method like malting so that these can be used to solve the problem of malnutrition and other micronutrient deficiency among the population.

Materials and methods

Development

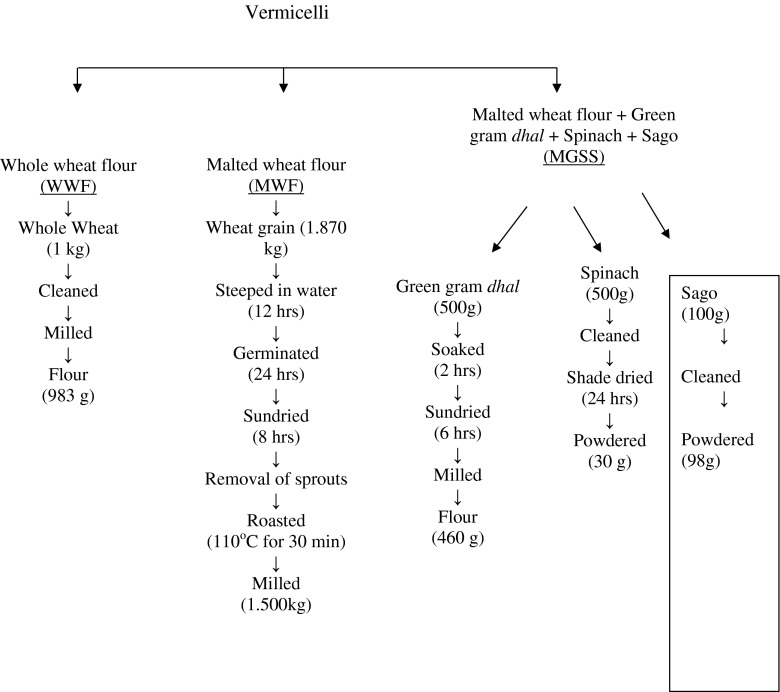

Whole wheat (Triticum aestivum), green gram dhal (Phaseolus aureus Roxb), spinach (Spinacia oleracea) and sago (Manihot esculenta crantz) were used to prepare three variations of vermicelli (1) whole wheat flour (100%): WWF, (2) malted wheat flour (100%): MWF and (3) malted wheat, greengram dhal, spinach and sago (50.9, 33.0, 2.1 and 14% percent respectively) (Fig. 1): MGSS. The Ingredients were purchased from local markets of Udaipur in a single lot to avoid variations. Wheat was cleaned and divided into three portions; one potion was milled while the other two portions were malted as described by Gopaldas et al. (1988). Green gram dhal was cleaned and powdered while spinach leaves were cleaned, chopped and dried in the shade. Hard dough was prepared separately for all variations and cold extruded. Vermicelli was dried in the sun for 6 h. A mixture of spices containing powders of red chilli (5%), salt (18%), turmeric (2.7%), cumin seeds (1%), coriander seeds (1%), onion (18.9%), garlic (10%), tomato (27.2%), garam masala (1%) and sugar (4.5%) was also developed. Developed vermicelli was reconstituted in boiling water with a weighed amount of spice mix and then subjected to sensory evaluation by a panel of 10 judges on 9 point Hedonic scale (Swaminathan 1987) ranging from 9 (liked extremely) to 1 (disliked extremely). Preparation of vermicelli was standardized for its organoleptic characteristic like color, texture, appearance, taste, flavour and portion size (one serving). A score of 7 out of 9 was considered acceptable.

Fig. 1.

Processing of ingredients for preparation of vermicelli

Nutrient composition

The developed products were analyzed for their proximate composition (AOAC 1995). Carbohydrate content was determined by difference method. Starch content was estimated colorimetrically using anthrone reagent as described by Nelson and Somoygi (1957) and from this sugar content was calculated. Phosphorus, calcium, iron, zinc and copper were estimated by using atomic absorption spectrophotometer (Lindsey and Norwal 1969) and sodium and potassium by using flame photometer.

Shelf life

Developed vermicelli were packed in low density polyethylene pouches (100 gauge) and stored at room temperature (65% RH and 30–35 °C) for a period of 2 months. Samples were drawn periodically and moisture, organoleptic quality and microbial load—total viable counts, yeast and mold (APHA 2001) were assessed at 0, 1 and 2 months of storage.

Statistical analysis

All analysis was performed in triplicate. The sensory scores were statistically analysed for mean and standard deviation. Analysis of variance (Snedecor and Cocharan 1967) was used to assess the effect of storage on shelf life of the products.

Results and discussion

Nutrient composition

Tables 1 and 2 presents the chemical composition and protein quality of vermicelli. WWF, MWF and MGSS contained moisture 6.9 to 7.7%, protein 9.3 to 13.5%, fat 1.2–2.7%, ash 2.9 to 5.8%, crude fibre 2.2 to 2.4%, carbohydrates 69.8 to 75.2% and energy 344 to 362 kcal/100 g. Significant difference between protein content of WWF and MWF was not found. Protein content of MGSS vermicelli was significantly higher (p < 0.05) while energy content was high in WWF. Gill et al. (2006) reported that wheat flour containing 10–11% protein were suitable for noodle preparation and high protein content have been reported to mean a reduced starch content through oxidation. Whole wheat flour vermicelli was low in protein quality with Net Dietary Protein Calories (NDpCal percent) of 3.4 only which improved on malting (7.7%) and incorporation of green gram dhal and spinach (18.3%). MGSS contained higher amounts of all essential amino acids than other counterparts. Lysine was the most limiting amino acid in all the variations. Chemical score of Lysine was higher (37.5) in MGSS. FAO/WHO/UNU (2007) has recommended NDpCal as 8% for children for their growth and maintenance and 5% for adults. Dewar et al. reported that malting improved digestibility of protein, nitrogen solubility index and true lysine content in sorghum by 8.5%, 251 and 32% respectively. Gernah et al. (2011) reported 8.1 increase in protein content. Nagaoka (2000) and Malleshi and Desikachar (1986) support the findings that dehulling, malting and germination increase protein content of grain (Dewar et al. 1997).

Table 1.

Chemical composition of vermicelli (on dry matter basis)

| Nutrients | Ingredients | Vermicelli | SE | CD at 5% | |||||

|---|---|---|---|---|---|---|---|---|---|

| WF | GG | S | S* | WWF | MWF | MGSS | |||

| Moisture,% | 11.5 | 10.1 | 5.0 | 11.6 | 7.7 | 6.9 | 7.6 | 0.011 | NS |

| Protein,% (N x 6.5) | 10.5 | 23.0 | 20.0 | 0.2 | 9.3a | 9.4 | 13.5b | 0.010 | 0.030 |

| Ash,% | 2.5 | 2.1 | 17.0 | 0.18 | 2.9a | 4.8b | 5.8b | 0.006 | 0.018 |

| Crude fibre,% | 3.4 | 1.8 | 6.0 | 0 | 2.2 | 2.3 | 2.4 | 0.012 | 0.038 |

| CHO,% | 70.5 | 60.0 | 40.0 | 80.1 | 75.2 | 74.9 | 69.8 | 0.007 | 0.023 |

| Fat,% | 2.5 | 2.2 | 7.0 | 0.11 | 2.7a | 1.7 | 1.2b | 0.007 | 0.023 |

| Energy, kcal | 341 | 348 | 260 | 292 | 362 | 353 | 344 | 0.012 | 0.001 |

| Total Sugars,% | 5.0 | 1.8 | 1.0 | 6.2 | 5.09 | 8.9a | 4.98b | 0.269 | 0.086 |

| Reducing Sugars,% | 1.6 | 0.6 | 0.01 | 2.0 | 1.6 | 2.4a | 0.9b | 0.013 | 0.035 |

| Non reducing sugars,% | 3.4 | 1.2 | 0.09 | 4.2 | 3.44 | 6.5a | 4.00b | 0.058 | 0.021 |

| Iron, mg% | 4.0 | 3.9 | 11.4 | 1.0 | 6.0 | 5.9 | 5.0 | 0.006 | 0.013 |

| Calcium, mg% | 26.0 | 65.0 | 780 | 10 | 25 | 30 | 45 | 0.100 | 0.110 |

| Phosphorus, mg% | 335 | 345 | 210 | 10 | 217 | 217 | 272 | 0.022 | 0.031 |

| Sodium, mg% | 20.0 | 22.0 | 45.0 | 0 | 38.2a | 63.8b | 100c | 0.004 | 0.012 |

| Potassium, mg% | 290 | 1020 | 180 | 0 | 373 | 312a | 456b | 0.031 | 0.028 |

| Copper, mg% | 1.8 | 0.2 | 1.3 | 0 | 1.93a | 2.10 | 2.74b | 0.024 | 0.015 |

n = 3; Two means not having similar letter differ significantly at 5% level; WF wheat flour; GG green gram dhal; S spinach; S* sago; WWF whole wheat flour; MWF malted wheat flour; MGS malted wheat flour + green gram dhal + spinach + sago flour

Table 2.

Protein quality of plain and value added vermicelli

| Amino acids | PAAP | WWF (N2 content 1.89 g) | MWF (N2 content 2.34 g) | MGSS (N2 content 1.93 g) | |||

|---|---|---|---|---|---|---|---|

| Amino acid/gN2 | Chemical score | Amino acid/gN2 | Chemical score | Amino acid/gN2 | Chemical score | ||

| Lysine | 340 | 89.94 | 26.40 | 90.51 | 26.70 | 127.75 | 37.5 |

| Tryptophane | 60 | 37.0 | 61.70 | 35.06 | 64.80 | 45.72 | 98.26 |

| Phenylalanine + Tyrosene | 380 | 243.38 | 64.00 | 255.43 | 67.2 | 173.64 | 65.5 |

| Methionine + Cystein | 220 | 121.60 | 55.20 | 127.60 | 57.25 | 129.71 | 58.6 |

| Threonine | 250 | 95.23 | 38.00 | 100.32 | 39.05 | 138.35 | 76.6 |

| Leucine | 440 | 216.93 | 49.00 | 226.53 | 51.05 | 376.30 | 85.4 |

| Isoleucine | 250 | 116.40 | 46.56 | 122.31 | 53.05 | 166.92 | 66.8 |

| Valin | 310 | 148.15 | 47.79 | 156.75 | 49.47 | 183.90 | 65.3 |

| NDpCal% | 3.74 | 7.76 | 18.3 | ||||

WWF whole wheat flour; MWF malted wheat flour; MGS malted wheat flour + green gram dhal + spinach + sago flour

Vani and Mahinegalai (2004) developed noodles with 35% incorporation of colocassia leaves powder and found that protein, energy and iron contents were improved.

Fat content of WMF and MGSS vermicelli was low (1.7 and 1.2% respectively) which may be due to the loss of embryo and scutellum after germination. These findings are supported by Khader (2004). MWF vermicelli had significantly higher amounts of total (8.91%), reducing (2.41%) and non-reducing sugars (6.57%). The mineral content of vermicelli shows that MGS was highest in calcium, phosphorus, sodium, potassium, zinc and copper. According to Reema et al. (2004) minerals get liberated in the seed on germination and some of the bound iron is converted to more readily available form. Overall the nutritive value of MGSS was high in comparison to other vermicelli developed. This enrichment of nutrients may be due to balancing of nutrients among the cereals, pulse, vegetable and sago used. Rico et al. (2007) reported that food preparations enriched with dried vegetables have higher values for protein, fibre, iron and calcium. Similar findings have been reported by Naik (2004) and Sood (2004).

Cooking qualities

It was found that 60–65 g vermicelli with 11–12 g spice mix was sufficient for one serving of products. All the products could be prepared by boiling in water (135–200 ml) for 6–8 min. MWF vermicelli required less cooking time (6 min) and water (135 ml) in comparison with WWF and MGSS vermicelli at the same time volume of cooked vermicelli was also low (168 g). Konik et al. (1992) reported that interaction between starch and protein might influence the pasting property in wheat flour and hence good texture but decreased viscosity of the product. Batey et al. (1997) reported a non-linear correlation between amylase content and noodle quality. Nagao (1995) observed that flour with mellow gluten is suitable for noodle making. Wheat flour with added amylase and protease produced bread with higher loaf volume and had more acceptability which shows that these enzymes do not affect the elasticity of protein.

Acceptability

The mean acceptability scores of vermicelli ranged between 7.0 and 7.9 on a 9 point hedonic scale for different attributes indicating that the products were acceptable (Table 3). Mean scores of WWF, MWF and MGSS for color, texture, taste, flavour and appearance were 7.6, 7.4, 7.8 respectively at 0 month at storage witnessing that the products were liked moderately to very much by the panel. Significant (P < 0.05) difference was observed between color, texture, taste, flavor and appearance of the malted and unmalted wheat flour vermicelli but the difference was non significant when MWF and MGSS were compared. All the products were acceptable at 2 months storage.

Table 3.

Changes in quality of vermicelli during storage at 30–35 °C RH 65%

| Particulars | Storage months | Vermicilli | ||

|---|---|---|---|---|

| WWF | MWF | MGSS | ||

| Color | 0 | 7.9 ± 0.08 | 7.6 ± 0.08 | 7.9 ± 0.20 |

| 1 | 7.6 ± 0.30 | 7.5 ± 0.45 | 7.7 ± 0.52 | |

| 2 | 7.6 ± 0.19 | 7.4 ± 0.23 | 7.7 ± 0.47 | |

| Texture | 0 | 7.6 ± 0.18 | 7.1b ± 0.23 | 7.7a ± 0.10 |

| 1 | 7.5 ± 0.34 | 7.0 ± 0.30 | 7.3 ± 0.23 | |

| 2 | 7.7 ± 0.33 | 7.2 ± 0.30 | 7.6 ± 0.49 | |

| Taste | 0 | 7.6a ± 0.13 | 7.5b ± 0.05 | 7.8a ± 0.04 |

| 1 | 7.3b ± 0.35 | 7.0a ± 0.30 | 7.6 ± 0.54 | |

| 2 | 7.6 ± 0.26 | 7.2 ± 0.25 | 7.7 ± 0.55 | |

| Flavor | 0 | 7.5a ± 0.06 | 7.5b ± 0.10 | 7.2a ± 0.09 |

| 1 | 7.3 ± 0.40 | 7.6 ± 0.35 | 7.6 ± 0.24 | |

| 2 | 7.6 ± 0.35 | 7.7 ± 0.52 | 7.5 ± 0.33 | |

| Appearance | 0 | 7.6a ± 0.08 | 7.3b ± 0.15 | 7.4a ± 0.30 |

| 1 | 7.3 ± 0.12 | 7.2 ± 0.33 | 7.8 ± 0.42 | |

| 2 | 7.5 ± 0.34 | 7.3 ± 0.15 | 7.6 ± 0.37 | |

| Mean | 0 | 7.6 ± 0.01 | 7.4a ± 0.11 | 8.1b ± 0.27 |

| 1 | 7.4 ± 0.20 | 7.2a ± 0.26 | 7.8b ± 0.52 | |

| 2 | 7.6 ± 0.19 | 7.3 ± 0.21 | 7.6 ± 0.42 | |

| Moisture, g% | 0 | 7.7 ± 0.04 | 6.9 ± 0.30 | 7.8 ± 0.57 |

| 1 | 7.9 ± 0.12 | 7.0 ± 0.33 | 7.9 ± 0.46 | |

| 2 | 8.0 ± 0.21 | 7.1 ± 0.61 | 8.0 ± 0.12 | |

| Total viable count, log cfu/g | 0 | 3.32 | 3.54 | 3.66 |

| 1 | 3.20 | 3.46 | 3.30 | |

| 2 | 3.19 | 3.41 | 3.22 | |

| Yeast & mold, log cfu/g | 0 | 3.63 | 3.57 | 3.61 |

| 1 | 3.49 | 3.49 | 3.43 | |

| 2 | 3.30 | 3.39 | 3.34 | |

n = 3; Two means not having similar letter differ significantly at 5% level; WWF whole wheat flour; MWF malted wheat flour; MGS malted wheat flour + green gram dhal + spinach + sago flour,values are mean ± SD of three observations

Shelf life

The moisture content (Table 3) of vermicelli ranged from 6.9% to 8%. It increased with increase in storage period but statistically non-significant and within the prescribed limit of storage. Malleshi et al. (1989) observed that malted ragi products could be safely stored for 100 days at the moisture level of 11%. Microbial examination of vermicelli showed that the load of total viable counts and yeast and mold reduced from 3.32 to 3.19 log cfu/g, 3.54 to 3.41 log cfu/g and 3.66 to 3.22 log cfu/g in WWF, MWF and MGSS respectively after storage of 2 months may be due to low moisture content and water activity of the sample. According to Shanti et al. (2000) small quantity of free water in dried food product do not support the growth of microorganism and the cell dies. Vermicelli was found safe for consumption throughout the storage period. Lower counts may also be due to the hygienic practices maintained during the preparation, handling and storage.

Conclusion

Vermicelli could successfully be prepared using whole/malted wheat flour. Vermicelli was acceptable and had good nutritional value. Further, addition of green gram dhal, spinach and sago improved nutrient content. MGSS vermicelli was found best among all the variation developed. All the three types of vermicelli were nutritious and could be safely stored for 2 months at room temperature (20–25 °C).

Acknowledgement

Authors are grateful to Dean, College of Home Science and Head, Department of Foods and Nutrition, College of Home Science, MPUAT, Udaipur for providing all the facilities to conduct the research.

References

- Official methods of analysis. 16. Washington: Association of Official Analytical Chemists; 1995. [Google Scholar]

- Compendium of methods for the microbiological analysis of food. 4. Washington: American Public Health Association; 2001. [Google Scholar]

- Batey IL, Gras PW, Curtin BW. Contribution of chemical structure of wheat starch to Japanese noodle quality. J Sci Food Agric. 1997;74:503–508. doi: 10.1002/(SICI)1097-0010(199708)74:4<503::AID-JSFA826>3.0.CO;2-B. [DOI] [Google Scholar]

- Dewar J, Orovan E, Taylor JN. Effect of alkaline steeping on water uptake and malt quality of sorghum. J Inst Brew. 1997;103:283–285. doi: 10.1002/j.2050-0416.1997.tb00957.x. [DOI] [Google Scholar]

- FAO/WHO/UNU (2007) Protein and amino acid requirements in human nutrition. Who Technical series no.935. Report of a joint FAO/ WHO/ UNU expert consultation, United Nation University, Geneva

- Gernah GI, Ariahu GC, Ingbian EK. Effect of malting and lactic fermentation on some chemical and functional properties of maize. Am J Food Technol. 2011;6:404–412. doi: 10.3923/ajft.2011.404.412. [DOI] [Google Scholar]

- Gill BS, Singh N, Sodhi NS. Studies on physico chemical, textural, and functional properties of wheat flour from different Indian cultivars. J Food Sci Technol. 2006;43:56–64. [Google Scholar]

- Gopaldas T, Deshpande S, John C. Studies on a wheat-based amylase rich food. Delhi: Daya Publishing House; 1988. [Google Scholar]

- Khader V. Textbook of food science and technology. New Delhi: Indian Council of Agricultural Research; 2004. [Google Scholar]

- Konik M, Miskelly DM, Gras PW. Contribution of starch and non starch parameter to the eating quality of Japanese white noodles. J Sci Food Agric. 1992;58:403–406. doi: 10.1002/jsfa.2740580315. [DOI] [Google Scholar]

- Lindsey WL, Norwal MA (1969) Anew DPTA-Tea soil test for zinc and iron. Agron 61:84

- Malleshi NG, Desikachar HSR. Nutritive value of malted millet flour. Plant Food Hum Nutr. 1986;36:191–196. doi: 10.1007/BF01092036. [DOI] [Google Scholar]

- Malleshi NG, Balasubramanyam N, Indiramma AR. Packaging and storage studies on malted ragi and green gram based weaning foods. J Food Sci Technol. 1989;26:68–71. [Google Scholar]

- Manay NS, Sadaksharaswamy M. Foods, facts and princilples. New Delhi: New Age International Pvt Ltd; 2000. [Google Scholar]

- Nagao S. Wheat products in East Asia. Cereal Food World. 1995;40:482–487. [Google Scholar]

- Nagaoka A. Use of endogeneous enzymes in development of functional foods from wheat. Nutr Abstr Rev. 2000;74(series A):1086. [Google Scholar]

- Naik R (2004) Value addition of underutilized foods. XXXVI Annual report, Nutrition Society of India, Hydrabad

- Nelson M, Somoygi S (1957) Methods in enzymology, vol III. Academic Press, New York, p 85

- Reema CK, Hira C, Sadana B. Nutrition evaluation of supplementary food prepared from germinated cereals and legumes. J Food Sci Technol. 2004;41(6):627–629. [Google Scholar]

- Rico D, Martin-Diana AB, Barat JM, Barry RC (2007) Extending and measuring the quality of fresh–cut fruits and vegetables: a review. Trends Food Sci Technol 18:373–386

- Shanti D, Manimegalai U, Chitra P. Studies on the storage behavior of instant vada mix. Indian Food Pack. 2000;54(5):72–76. [Google Scholar]

- Snedecor GW, Cocharan WG. Statistical methods. Calcutta: Oxford and IBH Publishing Company; 1967. [Google Scholar]

- Sood S (2004) Functional properties of cereal. XXXVI Annual report, Nutrition Society of India, Hyderabad

- Swaminathan M. Food science, chemistry and experimental foods. Bangalore: Bangalore Printing and Publishing Co. Ltd.; 1987. [Google Scholar]

- Vani V, Mahinegalai G. Processing of high protein pulse based noodles. Indian Food Pack. 2004;58(2):63–67. [Google Scholar]