Abstract

We have successfully fabricated x(0.65PMN-0.35PT)–(1 − x)PZT (xPMN-PT–(1 − x)PZT), where x is 0.1, 0.3, 0.5, 0.7 and 0.9, thick films with a thickness of approximately 9 µm on platinized silicon substrate by employing a composite sol–gel technique. X-ray diffraction analysis and scanning electron microscopy revealed that these films are dense and creak-free with well-crystallized perovskite phase in the whole composition range. The dielectric constant can be controllably adjusted by using different compositions. Higher PZT content of xPMN-PT–(1 − x)PZT films show better ferroelectric properties. A representative 0.9PMN-PT–0.1PZT thick film transducer is built. It has 200 MHz center frequency with a −6 dB bandwidth of 38% (76 MHz). The measured two-way insertion loss is 65 dB.

Keywords: PMN-PT, PZT, Composite films, Ultrasonic transducer

1. Introduction

A number of significant advances in high frequency ultrasonic transducers have been made in recent years. To achieve very high spatial resolution in non-destructive evaluation of materials and non-invasive imaging of superficial anatomic structures in humans as well as small animals, very high frequency (>100 MHz) ultrasonic transducers have received growing attention lately [1–3]. Moreover, very high frequency (VHF) transducers can be also applied to the manipulation of biological cells and microparticles [4–6]. However, it is challenging and time consuming to build such high frequency transducers with traditional top-down approach in which piezoelectric ceramics or crystals are lapped down and mechanically machined to the order of micrometers. Piezoelectric thick film technology may provide an alternative solution in simplifying the fabrication process of high frequency transducers.

Piezoelectric thick film techniques [7], such as screen-printing [8,9], tape-casting [10], aerosol deposition [11,12], composite sol–gel [13,14], electrophoretic deposition [15], and ink-jet printing [16] have been shown to be capable of producing piezoelectric films (<50 µm) without compromising the piezoelectric properties in comparison to those of bulk materials. Among these techniques, the composite sol–gel approach has been successfully used to fabricate several different types of piezoelectric thick films from which high frequency ultrasound transducers are built. They include lead zirconate titanate (PZT) [17], lead magnesium niobium-lead titanate (PMN-PT) [18] and potassium sodium niobate/bismuth sodium titanate (KNN/BNT) ceramics [19]. The composite sol–gel technique is a modified version of the sol–gel method, which is developed by dispersing ceramic powder into sol–gel solution and followed by optimized pyrolysis and annealing steps [7,13]. This approach has been verified to produce piezoelectric films in the range of 1–50 µm without cracks due to strongly bonded network between the sol–gel and the ceramic particles. The composite sol–gel technique is unique and desirable. It not only is capable of producing crack-free thick films, but also has a number of advantages, i.e., cost-effective, low annealing temperature, flexible and good control of film stoichiometry. Therefore, composite sol–gel approach was selected for this work.

It is known that the dielectric constant plays an important role in electrical impedance matching of transducers to the electronic components. Thus it would be desirable if the dielectric constant of a piezoelectric film can be tuned without sacrificing its piezoelectric performance. Here, we propose a simple and efficient approach to prepare x(0.65PMN-0.35PT)–(1 − x)PZT (xPMN-PT–(1 − x)PZT) composite films with controllable dielectric constant. The strategy is to mix PMN-PT (65-35) and PZT materials in different ratios to synthesize xPMN-PT–(1 − x)PZT piezoelectric films with the composite sol–gel technology. This approach should allow the dielectric constant to be tunable since the intrinsic dielectric constants of PMN-PT and PZT phases are different. It has been reported that PMN-PT/PZT composite films have a higher dielectric constant than PZT films because of the high permittivity of the PMN-PT phase[14]. However, there has been no report to date either on making tunable dielectric constant with different composition of PMN-PT/PZT ceramic films or on using xPMN-PT–(1 − x)PZT films as the active element for high frequency ultrasonic transducer fabrication.

In this letter, we demonstrate the dielectric and piezoelectric properties of xPMN-PT–(1 − x)PZT films when x = 0.1, 0.3, 0.5, 0.7 and 0.9 prepared with the composite sol–gel technique. The results show that the dielectric constant can be controllably adjusted with different compositions of PMN-PT/PZT composite films. The performance of a high frequency ultrasonic transducer fabricated from such a xPMN-PT–(1 − x)PZT film as the active element has been evaluated. The results are reported.

2. Experimental

2.1. Preparation and characterization of xPMN-PT–(1 − x)PZT composite films

In this work, a sol–gel composite method was used to prepare PMN-PT/PZT composite ceramics. Fig. 1 shows the flowchart of the fabrication procedure. Specifically, the PMN-PT as well as PZT precursor sol–gel solution was synthesized using lead acetate trihydrate, zirconium n-propoxide, titanium isopropoxide, magnesium ethoxide, and niobium ethoxide as the raw materials with 2-methoxyethanol as the solvent. The xPMN-PT–(1 − x)PZT composite solution (where x is 0.1, 0.3, 0.5, 0.7 and 0.9) were prepared by ball milling a mixture of PMN-PT as well as PZT powder and precursor solution for 24 h. The mass ratio of powder to solution was 1:4. Next, the prepared composite solution was deposited on a Pt(1 1 1)/Ti/SiO2/Si(1 0 0) substrate by spin coating at 2000 rpm for 30 s. After deposition, each layer was subjected to a two-stage pyrolysis sequence to drive out the solvent and decompose organic compounds. A 1.5-min heat treatment at 200 °C was followed by another 1.5-min heat treatment at 400 °C in air. Subsequently, each layer was annealed at 700 °C for 60 s with rapid thermal annealing. The above process was repeated until the desired film thickness was achieved. Finally, the xPMN-PT–(1 − x)PZT thick films were sintered at 750 °C for 1 h at air atmosphere to increase the film crystallinity.

Fig. 1.

Fabrication procedure of the xPMN-PT–(1 − x)PZT composite films using composite sol–gel method.

The crystallized structure of PMN-PT/PZT composite films was examined by X-ray diffractometry (XRD). The thickness and morphology of the composite film were observed by a scanning electron microscope (SEM). The chromium/gold (Cr/Au) top electrodes with a dimension of 0.5 mm × 0.5 mm were sputtered through a shadow mask onto the films to evaluate electrical properties. The dielectric properties were measured with an Agilent 4292A impedance analyzer. A ferroelectric test system was used to acquire hysteresis loops.

2.2. Fabrication and evaluation of transducer

The xPMN-PT–(1 − x)PZT composite film transducer was fabricated from a combination of the silicon etching process and conventional transducer technology [19,20]. The procedures are described as follows. First, a Cr/Au thin layer (0.15 µm in total thickness) was sputtered on the top surface as the electrode. A very lossy conductive epoxy (E-solder 3022) was then applied on the films with acoustic impedance around 5.5 MRayls as backing materials with the aid of an adhesion promoter (AP-131). This backing layer was centrifuged at 3000 rpm for 15 min to increase acoustical impedance and ensure conductivity over the entire active element. After centrifugation, the acoustic impedance can be increased to 5.9 MRayls because of the improvement of density of E-solder 3022. After curing at room temperature overnight, the backing layer was lapped to around 1 mm. The sample was then diced into 0.25 mm × 0.25 mm squares. Each square carries a single thick film element. The film with the support of the backing layer was then peeled off from the silicon substrate by dipping into a 20% concentrated KOH solution at 80 °C for 5 to 10 min. After the peeling off process, the lead wire was connected to the backing layer with an additional amount of conductive epoxy. A brass housing was placed concentrically with the single element device, and an insulating epoxy was then poured into the void between the housing and the device. Next, a layer of Cr/Au was sputtered across the transducer face to form the ground plane connection. A 1.5-µm-thick parylene layer with acoustic impedance of 2.6 MRayls was vapor-deposited on the front face of the transducer, serving as an acoustic matching layer and also a protection layer. Last, the transducer was housed in modified SMA connector.

The pulse-echo response and insertion loss of the transducer were measured at room temperature in a de-ionized water bath using a pulse-echo arrangement by reflecting the transmitted signal from a polished x-cut quartz target placed at the far field region of the transducer [20]. A Panametrics model 5910R pulser/receiver was used to excite the transducer with an electrical impulse at 200 Hz repetition rate and 50 Ω damping. The reflected waveform was received and digitized by a 1 GHz LC534 LeCroy oscilloscope with 50 Ω coupling. The frequency spectrum can be generated via Fast Fourier Transform (FFT) of the received time-domain signal. The center frequency and the bandwidth at −6 dB were determined from the frequency spectrum. The insertion loss was calculated by comparing the frequency spectrum of the transmit and receive responses. Compensation was applied for the loss due to the transmission into the quartz and the attenuation in the water bath [20].

3. Results and discussion

The XRD pattern of xPMN-PT–(1 − x)PZT composite films on a Pt/Si wafer where x is equal to 0.1, 0.3, 0.5, 0.7 and 0.9 are shown in Fig. 2. It demonstrates that pure perovskite phase of PMN-PT/PZT ceramic films were synthesized successfully in the whole composition range from the composite sol–gel method. There is no trace of pyrochlore phase presented in the XRD patterns. The wellcrystallized perovskite phase indicates a production of high-quality film with good piezoelectric properties. Fig. 3 shows the SEM micrograph of the PMN-PT/PZT composite film. It is observed that the film is dense and crack-free on the substrate. The film thickness is around 9 µm and the agglomerated size of the grains is in the range of 200–500 nm.

Fig. 2.

XRD patterns of xPMN-PT–(1 − x)PZT composite films while x is (a) 0.1, (b) 0.3, (c) 0.5, (d) 0.7 and (e) 0.9.

Fig. 3.

SEM cross-sectional micrograph of the PMN-PT/PZT composite film.

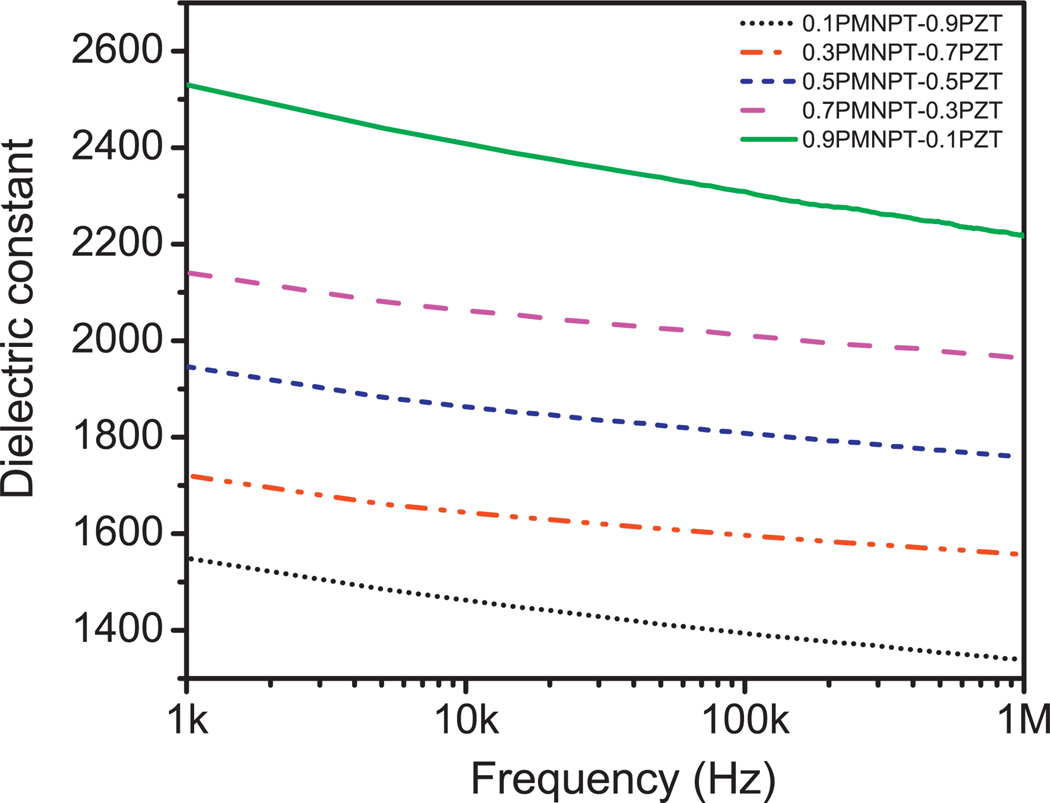

The dielectric constant and dielectric loss of the composite films were measured using an impedance analyzer. The measured dielectric losses of xPMN-PT–(1 − x)PZT films are below 0.05 between 1 kHz and 1 MHz in the whole compositions. Fig. 4 shows the frequency dependence of dielectric constants for xPMN-PT–(1 − x)PZT films of different compositions. It is worth noting that the dielectric constant is adjustable with different compositions; for instance, the dielectric constant increases with higher PMN-PT content. The change in dielectric constant can be attributed to different intrinsic permittivities of PMN-PT and PZT phases which have different polarisability in PMN-PT/PZT composite films [21]. Since PMN-PT has higher dielectric constant, the polarisability is enhanced with high content of PMN-PT which leads to an increase of dielectric constant in xPMN-PT–(1 − x)PZT films. These results suggest that tunable dielectric constant can be realized by controlling different compositions of PMN-PT/PZT ceramics via the composite sol–gel method.

Fig. 4.

Frequency dependence of dielectric constants of xPMN-PT–(1 − x)PZT composite films where x is 0.1, 0.3, 0.5, 0.7 and 0.9.

The ferroelectric hysteresis loops of xPMN-PT–(1 − x)PZT thick films of different compositions are shown in Fig. 5, and the insert is the remnant polarization (Pr) as a function of compositions. The ferroelectric hysteresis loops exhibit a good symmetry for all compositions. Higher Pr are observed at higher PZT contents of these xPMN-PT–(1 − x)PZT ceramic systems. Due to the weak polarization of PMN-PT phase in PMN-PT/PZT composite films [14], we propose that it slows down the ferroelectric transition and kinetics; as a result, the ferroelectric switching is hindered. Hence, the decrease in polarization can be attributed to the increasing portion of PMNPT, which restricts or hinders the ferroelectric contribution from the PZT content.

Fig. 5.

Polarization-electric field hysteresis loops of xPMN-PT–(1 − x)PZT composite films where x is 0.1, 0.3, 0.5, 0.7 and 0.9. Insert: the remnant polarization (Pr) as a function of compositions.

In order to minimize the transducer size, the piezoelectric film with high dielectric constant is preferred. Here, a single element transducer was fabricated from a 0.9PMN-PT–0.1PZT thick film as described. The fabricated transducer was poled at 100°C for 10 min at 120 V in air to elicit the piezoelectric response. Fig. 6 shows the measured pulse-echo waveform and normalized frequency spectrum of the transducer. The central frequency is 199 MHz and the −6 dB bandwidth is around 38.2%. The measured insertion loss of this transducer is 65 dB. The results show the capability of this tunable dielectric constant xPMN-PT–(1 − x)PZT composite film for high frequency (>100 MHz) biomedical applications, such as ultrasonic biomicroscopy or acoustic tweezer. The insertion loss will be further improved in the future for better performance by introducing a matching layer of more optimized acoustic impedance [22].

Fig. 6.

Measured pulse-echo waveform (solid line) and normalized spectrum (dashed line) for 0.9PMN-PT–0.1PZT composite film transducer.

4. Conclusions

In summary, we have fabricated xPMN-PT–(1 − x)PZT (where x is 0.1, 0.3, 0.5, 0.7 and 0.9) thick films with a thickness around 9 µm on platinum-buffered Si substrate via the composite sol–gel method. The results show that these films are crack-free and dense with well-crystallized perovskite phase in the whole composition range. We can controllably adjust the dielectric constant of PMN-PT/PZT films by varying the composition. Additionally, we verified that higher PZT content yields better ferroelectric properties in these xPMN-PT–(1 − x)PZT composite films. A high frequency single element transducer utilizing 0.9PMN-PT–0.1PZT thick film was built. The measured center frequency is 200 MHz with a −6 dB bandwidth of 38% (76 MHz) and the insertion loss is 65 dB. This type of xPMNPT–(1 − x)PZT film transducers may satisfy current needs of VHF biomedical applications.

Acknowledgements

This work has been supported by NIH P41-EB218 and NSF 1026215.

References

- 1.Shung KK, Zippuro M. Ultrasonic transducers and arrays. IEEE Engineering in Medicine and Biology Magazine. 1996;15:20–30. [Google Scholar]

- 2.Lukacs M, Sayer M, Foster S. Single element high frequency (<50 MHz) PZT sol gel composite ultrasound transducers. IEEE Transactions on Ultrasonics Ferroelectrics and Frequency Control. 2000;47:148–159. doi: 10.1109/58.818757. [DOI] [PubMed] [Google Scholar]

- 3.Coleman DJ, Silverman RH, Chabi A, Rondeau MJ, Shung KK, Cannata J, Lincoff H. High-resolution ultrasonic imaging of the posterior segment. Ophthalmology. 2004;111:1344–1351. doi: 10.1016/j.ophtha.2003.10.029. [DOI] [PubMed] [Google Scholar]

- 4.Takeuchi M, Abe H, Yamanouchi K. Ultrasonic micromanipulation of small particles in liquid using VHF-range leaky wave transducers. IEEE Ultrasonics Symposium Proceedings. 1994;1:607–610. [Google Scholar]

- 5.Lee J, Teh SY, Lee A, Kim HH, Lee C, Shung KK. Single beam acoustic trapping. Applied Physics Letters. 2009;95:073701. doi: 10.1063/1.3206910. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Lee J, Ha K, Shung KK. A theoretical study of the feasibility of acoustical tweezers: Ray acoustics approach. Journal of the Acoustical Society of America. 2005;117:3273–3280. doi: 10.1121/1.1886387. [DOI] [PubMed] [Google Scholar]

- 7.Zhou QF, Lau ST, Wu DW, Shung K. Piezoelectric films for high frequency ultrasonic transducers in biomedical applications. Progress in Materials Science. 2011;56:139–174. doi: 10.1016/j.pmatsci.2010.09.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Thiele ES, Damjanovic D, Setter N. Processing and properties of screenprinted lead zirconate titanate piezoelectric thick films on electroded silicon. Journal of the American Ceramic Society. 2001;84:2863–2868. [Google Scholar]

- 9.Kuscer D, Skalar M, Holc J, Kosec M. Processing and properties of 0.65Pb(Mg1/3Nb2/3)O3–0.35PbTiO3 thick films. Journal of the European Ceramic Society. 2009;29:105–113. [Google Scholar]

- 10.Levassort F, Bove T, Ringgaard E, Tran-Huu-Hue LP, Holc J, Lethiecq M. Complete range of tape-cast piezoelectric thick films for high frequency ultrasonic transducers. IEEE Ultrasonics Symposium Proceedings. 2003;1–2:2003–2006. [Google Scholar]

- 11.Lebedev M, Akedo J. Effect of thickness on the piezoelectric properties of lead zirconate titanate films fabricated by aerosol deposition method. Japanese Journal of Applied Physics, Part 1 – Regular Papers Short Notes & Review Papers. 2002;41:6669–6673. [Google Scholar]

- 12.Lau ST, Li X, Zhou QF, Shung KK, Ryu J, Park DS. Aerosol-deposited KNN-LSO lead-free piezoelectric thick film for high frequency transducer applications. Sensors and Actuators A: Physical. 2010;163:226–230. [Google Scholar]

- 13.Barrow DA, Petroff TE, Sayer M. Thick ceramic coatings using a sol gel based ceramic–ceramic 0–3 composite. Surface and Coatings Technology. 1995;76–77:113–118. [Google Scholar]

- 14.Dorey RA, Whatmore RW. Electrical properties of high density PZT and PMNPT/ PZT thick films produced using ComFi technology. Journal of the European Ceramic Society. 2004;24:1091–1094. [Google Scholar]

- 15.Chen J, Fan H, Chen X, Fang P, Yang C, Qiu S. Fabrication of pyrochlorefree PMN–PT thick films by electrophoretic deposition. Journal of Alloys and Compounds. 2009;471:L51–L53. [Google Scholar]

- 16.Wang TM, Derby B. Ink-jet printing and sintering of PZT. Journal of the American Ceramic Society. 2005;88:2053–2058. [Google Scholar]

- 17.Zhu BP, Wu DW, Zhou QF, Shi J, Shung KK. Lead zirconate titanate thick film with enhanced electrical properties for high frequency transducer applications. Applied Physics Letters. 2008;93:012905. doi: 10.1063/1.3095504. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Zhu BP, Han JX, Shi J, Shung KK, Wei Q, Huang YH, Kosec M, Zhou QF. Lift-off PMN-PT thick film for high-frequency ultrasonic biomicroscopy. Journal of the American Ceramic Society. 2010;93:2929–2931. doi: 10.1111/j.1551-2916.2010.03873.x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Sien Ting L, Hong Fen J, Xiang L, Wei R, Qifa Z, Shung KK. KNN/BNT composite lead-free films for high-frequency ultrasonic transducer applications. IEEE Transactions on Ultrasonics, Ferroelectrics and Frequency Control. 2011;58:249–254. doi: 10.1109/TUFFC.2011.1793. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Cannata JM, Ritter TA, Wo-Hsing C, Silverman RH, Shung KK. Design of efficient, broadband single-element (20–80 MHz) ultrasonic transducers for medical imaging applications. IEEE Transactions on Ultrasonics, Ferroelectrics and Frequency Control. 2003;50:1548–1557. doi: 10.1109/tuffc.2003.1251138. [DOI] [PubMed] [Google Scholar]

- 21.Bellaiche L, Vanderbilt D. Intrinsic piezoelectric response in perovskite alloys: PMN-PT versus PZT. Physical Review Letters. 1999;83:1347–1350. [Google Scholar]

- 22.Zhou Q, Cha JH, Huang Y, Zhang R, Cao W, Shung KK. Alumina/epoxy nanocomposite matching layers for high-frequency ultrasound transducer application. IEEE Transactions on Ultrasonics Ferroelectrics and Frequency Control. 2009;56:213–219. doi: 10.1109/TUFFC.2009.1021. [DOI] [PMC free article] [PubMed] [Google Scholar]