Abstract

Analysts and decision makers frequently want estimates of the cost of technologies that have yet to be developed or deployed. Small modular reactors (SMRs), which could become part of a portfolio of carbon-free energy sources, are one such technology. Existing estimates of likely SMR costs rely on problematic top-down approaches or bottom-up assessments that are proprietary. When done properly, expert elicitations can complement these approaches. We developed detailed technical descriptions of two SMR designs and then conduced elicitation interviews in which we obtained probabilistic judgments from 16 experts who are involved in, or have access to, engineering-economic assessments of SMR projects. Here, we report estimates of the overnight cost and construction duration for five reactor-deployment scenarios that involve a large reactor and two light water SMRs. Consistent with the uncertainty introduced by past cost overruns and construction delays, median estimates of the cost of new large plants vary by more than a factor of 2.5. Expert judgments about likely SMR costs display an even wider range. Median estimates for a 45 megawatts-electric (MWe) SMR range from $4,000 to $16,300/kWe and from $3,200 to $7,100/kWe for a 225-MWe SMR. Sources of disagreement are highlighted, exposing the thought processes of experts involved with SMR design. There was consensus that SMRs could be built and brought online about 2 y faster than large reactors. Experts identify more affordable unit cost, factory fabrication, and shorter construction schedules as factors that may make light water SMRs economically viable.

Keywords: nuclear power economics, technology assessment

Individuals, companies and other organizations, as well as governments, must make important decisions in the face of considerable uncertainty. Although we gather what evidence we can—as individuals, we choose where to go to college, who to marry, and whether to have children—we do this all in the face of at least some irreducible uncertainty. Similarly, companies choose to invest in major new technologies, and governments adopt tax and research and development policies, without knowing for certain all the consequences their decisions will have.

Sometimes, research can yield better understanding and data, but it is rare that all uncertainty can be eliminated. This is especially true in decisions about whether to make multibillion dollar investments in the development of a new technology. In most such cases, some uncertainty will remain until the technology has actually been developed and implemented. Even then, it may take several iterations before a complex new technology can reach a downward-sloping learning curve (1), so that costs decrease with its increased adoption. At the outset, to help them reach the most informed decision possible, analysts and policy makers frequently want estimates of the cost and performance of such technologies. In doing so, they can rely on top-down assessments, informed either by comparisons with analogous technologies or informal consultation with experts, or on bottom-up engineering-economic analyses, also compiled by experts, that, although helpful, often do not capture key uncertainties. These may also be proprietary, so that results cannot be evaluated by others. A more detailed treatment of existing approaches to cost estimation can be found in SI Appendix, Section S1.

Our brains are not well-equipped to make decisions that involve considerable uncertainty. As extensive empirical research has now shown, we make such judgments using a variety of cognitive heuristics that, although they serve us adequately in many day-to-day settings, can result in overconfidence and bias that leads both lay people and experts astray when they address more complex and unusual problems (2, 3). Decision science (4–8) offers a set of strategies for improving how we make important decisions in the face of uncertainty.

In addressing such decisions, one should start with the best scientific, technical, and analytical evidence that is available. However, because such formal evidence often does not capture the full extent of what experts know, in addition to seeking informal expert advice, it is common in decision science to use formal methods to obtain systematic probabilistic judgments from experts who are intimately familiar with the current state of knowledge (9–11). For example, such methods have been used to characterize uncertainty about climate science (12, 13), the impacts of climate change (14–16), and the health impacts of environmental pollutants (17, 18). Of course, the same cognitive limitations that arise when we try to make unaided decisions also arise when experts attempt to provide probabilistic judgments (3). Too often, when seeking expert advice, little or nothing is done to limit overconfidence and reduce bias. Ubiquitous overconfidence (10) and the biases arising from cognitive heuristics, such as availability and anchoring and adjustment (2, 19–21), cannot be completely eliminated. However, well-designed expert elicitations can use a variety of strategies to help improve the quality of expert judgments (9–11).

Expert elicitation about emerging energy technologies that is deeply informed by careful technical analysis is still relatively rare (22). Here, we report the results of applying these methods to one such technology: integral light water small modular nuclear reactors (SMRs).

Why SMRs?

Morgan has argued that if aircraft were made and certified one at a time, in the way nuclear reactors have been built and certified in the U.S., “many travelers would find the level of safety unacceptable and air travel would be much more expensive…pilots and mechanics would have to be specially trained to operate each aircraft…many replacement parts would have to be custom made…[and] every time an aircraft experienced a problem engineers and managers would be unsure how to extrapolate the lessons to other aircraft…” (23). There is no way to mass produce gigawatt-scale reactors in the way that Boeing 747s and Airbus A380s are built. However, by adopting a smaller design, one that could be mass produced in a factory with high levels of quality control, and shipped to the field by road, rail, or barge, the nuclear industry might begin to look more like the aircraft industry. Because individual reactors would be smaller, the unit cost and, hence, the financial risks of buying one would be lower—no longer requiring customers to “bet the company” when they choose to build a reactor (24).

This line of argument has led the industry to become interested in the development of SMRs that would have a power output of a few 10s to a few 100s of megawatts-electric (MWe), incorporate passive safety systems, and use modular construction techniques. Even if they cost more per unit of power delivered, the smaller size might allow customers to purchase capacity in “bite-size” increments that suit the profiles of smaller utilities or industrial firms. SMRs might also facilitate the deployment of nuclear power in locations for which large reactors are ill-suited and permit novel approaches to siting that are infeasible for large reactors. For instance, underground construction is a feature touted by four US vendors proposing light water SMR designs.*,†,‡,§

There is growing interest in incorporating these SMRs into a portfolio of energy technologies that, together, could reduce carbon dioxide emissions from electricity generation (25). Worldwide, more than 20 nuclear technology vendors are developing SMRs in a wide range of sizes and technologies (26). A partial list of these designs can be found in SI Appendix, Section S1, Table S1. Here, we concentrate on integral light water SMRs because three US-based vendors are working actively on plans to market reactors of this kind in the United States and around the world.*,†,§ Although there are few detailed economic analyses of these designs in the public literature, some top-down approaches have estimated SMR cost by scaling down from the cost per kilowatt-electric of large reactors (e.g., ref. 27). Results from such analyses are problematic because the designs of these SMRs are sufficiently different from their larger counterparts to place them on a very different cost curve. The few studies using a bottom-up approach decompose an SMR into major constituent components (many of which have yet to be fabricated) and build up a total capital-cost estimate using a combination of authors’ judgments and consultation with component vendors (e.g., ref. 28). At the early stages of design development, even these bottom-up approaches may be performed relative to a benchmark such as a large reactor design. A comparison of results from alternative approaches to cost estimation can be found in SI Appendix, Section S1.

In an effort to improve on these past estimates, and to better assess the associated uncertainty, we designed and ran an expert elicitation that (i) specified the details of two light water SMR designs, including their major subcomponents, at substantial length; (ii) made careful systematic efforts to control for and address the cognitive heuristics that can lead to bias and overconfidence; and (iii) as they responded to our questions, asked experts who are directly or indirectly engaged in light water SMR design to carefully consider all available evidence (which, in most cases, implicitly included the bottom-up engineering-economic analysis that they, or their organizations, are conducting).

Combining Technical Analysis with Expert Elicitation

We conducted 16 face-to-face interviews with experts drawn from, or closely associated with, the nuclear industry. Twelve of the experts were employed by major US reactor vendors that are actively developing commercial SMRs. Three were contractors to those firms, and one was a Department of Energy National Laboratory scientist familiar with the proposed designs. Table 1 provides a summary of expert demographics and expertise.

Table 1.

Summary of the demographics of the experts who took part in our study

| Summary information | No. |

| No. of experts | 16 |

| No. of organizations represented | 4 |

| Years spent in the nuclear industry* | |

| Cumulative | >450 |

| Average | 28 |

| SD | 14 |

| Years spent in management (including project management) | |

| Cumulative | >320 |

| Average | 22 |

| SD | 14 |

| No. of experts whose current position falls in the following areas† | |

| Auditing/financial/accounting | 2 |

| Government relations/marketing/public relations | 5 |

| Human resources/legal | 2 |

| Technical services/operations/research and development | 10 |

| Management/project management | 10 |

| Supply chain development/supply chain logistics | 4 |

This includes experience working in both military and civilian programs.

There was no limit on the number of areas of experience an expert could report; therefore, several selected multiple areas.

As detailed in SI Appendix, Section S2, we developed descriptions of two integral light water SMR designs. Because most of our experts are actively involved in commercial SMR development, we were careful to base our questions on publicly available blueprints of these reactors and not to ask for design-specific data that might compromise proprietary vendor information. Although we did not ask them to reveal company proprietary details, most were able to draw upon their detailed design knowledge when answering our questions. The specifications we developed for the first SMR [160 megawatts-thermal (MWth), 45 MWe] were based on descriptions from NuScale.† Specifications for the second SMR (800 MWth, 225 MWe) were similarly based on publicly available descriptions from Westinghouse.*

We developed five deployment scenarios. Scenario 1 involved a 1,000-MWe Generation (Gen) III+ (i.e., a current-generation) reactor. Scenario 2 involved a single 45-MWe light water SMR plant, whereas scenario 3 involved five of these SMRs cosited to form a 225-MWe complex. Twenty-four 45-MWe SMRs were cosited to form a gigawatt-scale (1,080 MWe) facility in scenario 4. Finally, scenario 5 involved a single 225-MWe unit.

The elicitation focused on assessing the “overnight capital cost” of each of the five scenarios. We were careful to define this term as the sum of engineering, procurement, and construction costs. It excluded site-work, transmission up-grades and other “owner’s costs.” In short, we asked for an estimate of the lump-sum payment (reported in 2012 dollars) that a customer would transfer to a vendor to acquire an nth-of-a-kind (NOAK) plant, excluding the cost of financing. At NOAK, it is assumed that the vendor has recouped the cost of design engineering and licensing, has exploited technological learning, and has streamlined construction management. In addition, we asked for estimates of the probability of NOAK cost reaching certain (arbitrary) targets. This gave us two ways of constructing cumulative distribution functions (CDFs) of anticipated SMR capital cost.

In developing the five scenarios, we were careful to specify that the plants were being built under a “favorable” regulatory environment, overseen by a regulator such as the US Nuclear Regulatory Commission (NRC). We asked the experts to assume that no significant deviations from current US regulatory practice had occurred (for example, no major change in how waste is managed), that the regulator had deemed the SMR deployment scenarios acceptable, and that the owner had already licensed the plant. We suggested the southeastern United States as the candidate location for the plants.

To gain an understanding of the relative cost contribution of different elements in each plant, we bundled the elements of the International Atomic Energy Agency (IAEA) Code of Accounts for Nuclear Power Plants (29) into 12 categories (building and site preparation, reactor plant equipment, turbine plant equipment, etc.), so that for a subset of 12 of our 16 experts, we were able to elicit judgments about the relative contribution of each category to overall cost. Because the IAEA Code of Accounts was developed for conventional designs, we also had experts assess the relevance of each of these categories for SMRs. Details are provided in SI Appendix, Section S3.

We also asked experts to sketch the construction schedules for our hypothetical designs and sought specific insight about how, if at all, the deployment of multiple SMRs on one site might influence cost. Although not discussed in this paper, we elicited detailed views about global deployment options. Finally, we sought judgments about features that might contribute to the relative economic attractiveness and the safety and security of light water SMRs. The interview closed with an expert-led, open-ended discussion of the benefits of and challenges to deploying these new reactors.

Results

We elicited estimates of the overnight cost of each scenario in dollars per kilowatt-electric, focusing first on establishing and iteratively refining estimates of upper and lower bounds with the objective of minimizing overconfidence (10). Iteratively refining these bounds involves asking prompting questions of each expert, such as, “Can you outline a scenario that would result in a higher upper bound (or smaller lower bound) estimate of this cost?” The goal of these prompting questions is to expand the set of alternatives that the experts are contemplating, which helps them consider options they may have previously ignored. Details on strategies we used to minimize overconfidence in the elicitations can be found in SI Appendix, Section S4.

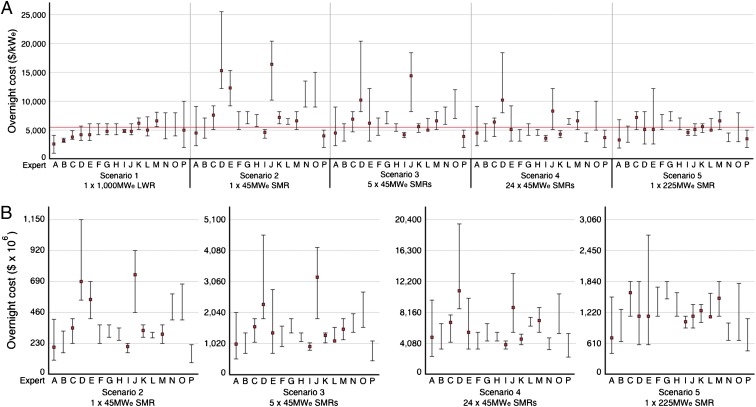

We report overnight-cost estimates in Fig. 1A. Median estimates of the overnight cost of a 1,000-MWe current-generation reactor—scenario 1—range from $2,600 to $6,600/kWe (90% confidence intervals range from $1,000 to $10,000/kWe). Given the history of cost overruns and construction delays for large reactors (31, 32), it is not surprising that median estimates of the overnight cost of a new Gen III+ plant vary by more than a factor of 2.5. Indeed, given the past history, the fact that 13 of the 16 experts provide median estimates that lie between $4,100 and $6,100/kWe might even be viewed as a sign of persistent overconfidence in the industry. Median estimates for scenario 2, a single-unit 45-MWe light water SMR, range from $4,000 to $16,300/kWe (90% confidence intervals range from $2,000 to $25,500/kWe), whereas those for a single-unit 225-MWe SMR (scenario 5) range from $3,200 to $7,100/kWe (90% confidence intervals range from $1,800 to $12,200/kWe).

Fig. 1.

Estimates of overnight cost elicited from sixteen nuclear power experts for each of five nuclear reactor deployment scenarios. (A) Each expert (A through P) provided estimates of the overnight cost per kilowatt of reactor capacity for each scenario. The details of the scenarios are noted on the horizontal axis. The solid line represents the Energy Information Administration’s 2011 estimate of the overnight cost of a dual-unit large light water reactor (LWR) plant (30). (B) For the four SMR-plant configurations, each of the estimates in A is multiplied by plant capacity to arrive at project cost. Expert M’s estimate included owner’s cost (i.e., costs that fall out of the vendor’s scope, such as site work, transmission upgrades, etc.).

We asked our experts to estimate construction times for each of the three basic designs. There was consensus that construction would follow a traditional s curve (slow start, then more rapid progress, slower completion). On average, our experts believed that an NOAK 1,000-MWe Gen III+ plant would take 5 y from first concrete to commissioning (Table 2). There was consensus that light water SMRs could probably be built in 3 rather than 5 y, because of the increased use of modular construction, the integration of all nuclear components into a single factory-built module, and the reduced complexity of the balance of plant.

Table 2.

Fourteen experts’ estimates of construction duration in months for each of the single-unit plants

| Expert | 1,000-MWe Gen III+ LWR plant | 45-MWe SMR plant | 225-MWe SMR plant |

| A | 72 | 36 | 48 |

| B | 42 | 18 | 24 |

| D | 60 | 42 | 30 |

| E | 60 | 36 | 48 |

| F | 60 | 36 | 36 |

| G | 72 | 36 | 48 |

| H | 48 | 36 | 36 |

| I | 60 | 24 | 30 |

| J | 66 | 54 | 48 |

| K | 54 | 30 | 36 |

| L | 54 | 36 | 36 |

| N | 60 | 24 | 36 |

| O | 48 | 36 | 36 |

| P | 48 | 24 | 36 |

| Mean | 57 | 33 | 38 |

Construction duration was defined as the period from the pouring of first safety concrete to plant commissioning and delivery of the first kilowatt-hour. Experts C and M did not respond to this question.

Discussion

Almost all of the experts argued that the smaller a reactor becomes, the greater the diseconomies of scale in the cost of pressure vessel and similar components. Experts’ estimates of overnight cost for a single 45-MWe unit (scenario 2) break into two groups. Eleven experts gave median costs between $4,000 and $7,700/kWe (the average was $5,800/kWe), with 90% confidence intervals ranging from a low of $2,000/kWe to a high of $9,200/kWe. However, five experts (D, E, J, N, and O) provided estimates that lie as much as a factor of two to three higher. These experts also assessed much wider uncertainty bounds (a low of $9,000/kWe to a high of $25,500/kWe). These five experts argued that costs rise rapidly as reactors become smaller, with the result that the 45-MWe reactor is especially disadvantaged. The four of these five who worked for nuclear technology vendors claimed that finding a “sweet spot” that would allow for an economically viable but small reactor is a difficult exercise that is ongoing, even as they proceed in their detailed designs.

When we moved to consider five 45-MWe units on a single site (scenario 3), several experts were skeptical about whether such deployment strategies would be allowed because, under existing NRC regulations (33), one cannot operate more than two reactors from a single control room. Experts D, E, and I all expressed such doubts but were nevertheless willing to make cost estimates. For example, expert I said, “I don’t think this is doable…but you’re asking me to assume [that the] NRC has signed off on it. Okay, if that’s the case, this is how I’d build it.”

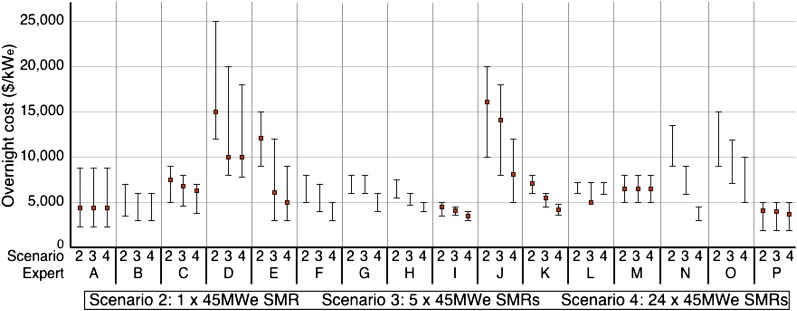

Although the rate of cost reduction varied, all but two experts believed that if locating multiple units on a single site were allowed, it would reduce unit capital costs. This is because site-specific lessons learned during the installation of the first module can be applied to later units (Fig. 2). For the case of five 45-MWe reactors on the same site, experts E, N, and O reduced their cost estimates to levels and ranges similar to those of the others. In doing this, they argued that the move to several hundred megawatts-electric would allow developers to exploit economies of scale in the supply chain and the cost-saving benefits of shared systems. Expert D reduced his median cost estimate by a third. Although he agreed with that assessment, he argued that despite the detailed information in our scenario, he believed that he needed to retain his wide confidence interval because so much remains unknown about actual deployment, from the construction-operation interface to the number and type of safety systems required to manage multimodule plants that share certain systems. Expert J did not believe that there would be significant cost advantages to cositing a modest number of SMRs. Note, however, that when the number of cosited reactors was increased to 24, even this expert believed that some cost advantage could be achieved if many SMRs could be cosited. In Fig. 1B, we multiply elicited costs by plant capacity for each scenario to arrive at estimates of “project” cost in 2012 US dollars. Expert E, J, and O anticipate large (≥2×) benefits for this case. Experts A and M argued that any savings would be canceled out by the increased regulatory constraints on managing a site with several reactors in proximity.

Fig. 2.

Most experts believed there would be learning from cositing. Scenarios 2, 3, and 4 entailed one, five, and twenty-four 45-MWe SMRs deployed on a single site, respectively, to create nuclear installations of different capacities. Cositing reactors may decrease a plant’s overnight cost per kilowatt. These economies may be exploited by allowing for extensive use of shared systems. However, experts emphasized the importance of resolving safety questions before this occurs. Expert M’s estimate included owner’s cost.

In addition to asking for the cost of multiple cosited 45-MWe reactors, we also asked the experts to sketch experience curves that expressed the relationship between the number of modules installed at a facility and the cost of deploying an additional unit at that site for both of our SMR designs. Six experts did not have time or did not feel that they could respond in those terms. Of the 10 who did respond, the breakdown of the 20 rates provided (each of the 10 experts judged each of the two SMR designs) was as follows: 3 gave rates of 0 to 1% (i.e., essentially no learning), 9 gave rates of 10% (i.e., the costs decline by 10% with each doubling of installed capacity), 3 gave rates between 10 and 15%, and 1 gave a range from 10 to 20%. Although some experts suggested that the smaller SMR, designed for multimodule deployment, might yield higher learning rates, the results do not seem to favor one design over the other. Experts generally agreed that there has been little discussion of the intricate operating procedures that would be required to build such multireactor facilities and that deployment scenarios must be carefully studied at the design-certification stage and executed well at the construction stage.

We challenged experts to identify potential economies of scale in modular construction and the economies of volume associated with factory fabrication that might be exploited in smaller reactors (34). Without prompting from us, expert I suggested that a greater number of off-the-shelf components would compensate for diseconomies of scale in reactor size. When asked, a few others reluctantly conceded this point, admitting that the potential for such economies must be explored, especially those associated with the supply chain: everything from drafting the purchase orders to fabricating, shipping, and installing these smaller components should be easier if one could guarantee that a customer would buy 24. However, most experts were skeptical that such economies would completely offset the diseconomies of scale in reactor size.

There was disagreement about whether cositing five 45-MWe SMRs would cost less than building a stand-alone 225-MWe SMR. Seven experts believed that the complexity of the multimodule plant would lead to higher capital costs than the stand-alone plant. Five believed the reverse, citing the benefits of economies of volume that favor the plant that is designed for greater flexibility and cositing. Four (experts K, L, M, and P) judged the cost of the two deployment options to be similar.

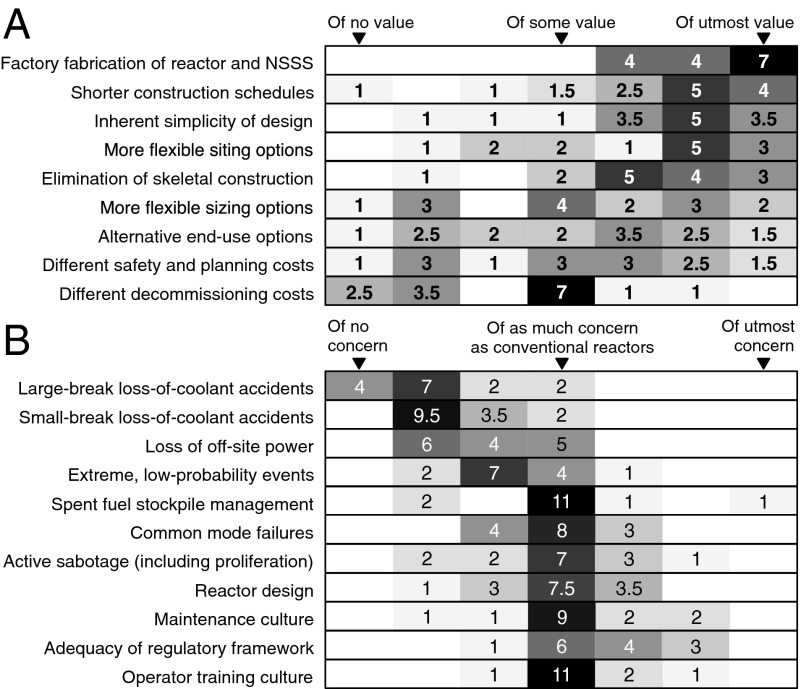

Proponents of SMRs emphasize that they may solve many problems other than project cost and construction duration. We asked experts for their judgment as to the value of a set of these benefits accrued from various sources in the literature (24, 26–28, 34, 35,*,†,‡,§). Results are reported in Fig. 3A. Factory fabrication is ranked as holding the largest potential for improvement, followed by reduced construction time, design simplicity, and flexibility in siting options.

Fig. 3.

Expert valuation of promised SMR economic and safety advantages. (A) Opinions regarding the value of SMR-specific economic and safety advantages were elicited from each expert. The darker a box is the larger the number of experts who checked it; the number of experts who checked each box is also shown. (B) Opinions regarding the safety and security challenges faced by SMRs relative to large reactors were elicited in a manner similar to A above.

There was little consensus as to whether the regulatory environment in the United States will be amenable to accommodating SMR-deployment scenarios that involve multimodule plant construction, siting SMR plants close to population centers, or exporting SMRs to countries with little or no experience operating nuclear plants.

To determine which cost and risk factors are alleviated by SMRs, we asked experts to assess relevant issues on a seven-point scale (Fig. 3B). The risks of loss-of-coolant accidents and loss of offsite power were judged to be lower for SMRs relative to conventional plants. This is to be expected because the elimination of large-diameter plumbing makes the risk of a large-break loss-of-coolant accident much lower, and passive safety systems are designed to reduce dependence on offsite power and operator intervention. Most experts raised the question of spent fuel management, but, in terms of proliferation risk, our experts believed that light water SMRs do not change the technology’s current security paradigm.

Reporting all of the arguments experts advanced in a 2–3 h interview is not feasible. Here, we have tried to convey a sense of the dialog that we had with experts and highlighted the sources of uncertainty discussed most by our experts.

Uncertainty about capital cost is a key factor in the debate over whether, how soon, and to what extent SMRs will play a significant role in future energy systems. Although our results provide an improved understanding of this factor, there are obviously other factors that affect the viability of SMRs as an energy source. These include questions about the nature of the future regulatory environment and about safety, spent fuel management, operating cost, the speed with which the transition will occur from first-of-a-kind plants to NOAK plants, and the amount of learning that will occur over the course of this transition. The answers will depend on, and be interrelated with, the size of domestic and international markets that develop. At this stage of the technology’s development, many of these questions are unanswerable, nor are the technical experts we interviewed in a position to offer informed judgments about most such matters.

Results from our expert elicitations provide quantitative support for four important insights about SMRs. First, although the vision of dramatic cost reduction through factory mass production remains appealing, and may yet be realized with the development of future advanced designs, the lower bounds on our experts’ cost estimates suggest strongly that this vision will not be achieved by the light water SMRs that will be available on the market over the next few decades.

Second, even if we adopt our experts’ upper bound estimates of overnight cost for single-unit SMRs, it seems likely that a single SMR unit will cost considerably less in absolute terms than the several billion dollars required for large Gen III+ nuclear plants. In locations where public attitudes will allow SMRs to be built, the biggest factor in the decision to construct a plant may shift from the customer’s ability to finance the project to a careful consideration of opportunity cost. As the reduction of CO2 emissions becomes more important, an SMR’s smaller size may also open markets outside of the electricity industry. We know of one major US chemical company that, when company officials thought, a few years ago, that the US Congress was about to pass significant controls of carbon dioxide emissions, gave serious consideration to building an SMR. The promise of SMRs may also grow as the limitations of integrating variable and intermittent renewable power into systems become more widely appreciated. In the future, both lower up-front cost and new markets could yield a more attractive economic paradigm for SMR vendors.

Third, even when considerable detail is provided about the technical design and regulatory environment that plausibly may apply for first-generation SMRs, experts who are intimately involved in their design have highly diverse views about what they will cost when sited under a range of scenarios. To some extent, this uncertainty might have been anticipated qualitatively from published point estimates. However, as SI Appendix, Section S1, Fig. S1 indicates, most prior point estimates are on the low side of the cost ranges that several of our experts assessed. The two that report uncertainty report much tighter ranges. Our results make the disagreement, and even the uncertainty in the estimates by individual experts, much more explicit. The results identify some of the key uncertainties that vendor engineers believe must be resolved before more robust cost assessments can be made. This should prove useful for research decision makers and other relevant stakeholders.

Finally, results from this paper can be used directly as inputs in stochastic simulation models that are designed to explore the likely evolution of the energy system over the next several decades and to assess the cost and timing of meeting a variety of low-carbon-energy targets.

Materials and Methods

Protocol Development.

We iteratively expanded and refined the interview protocol based on an initial set of questions on cost, construction duration, reactor cositing, and SMR-deployment potential. Questions eventually encompassed a nuclear project’s code of accounts (the list of items required to construct a nuclear facility), as well as general questions on SMR economics, safety and security challenges associated with these reactors, and even possible staffing issues. Experts were also provided with the opportunity to raise any concerns they had, both with our protocol (e.g., “You missed this important question”) and with small reactors in general (e.g., “SMRs will only work if…”).

Several rounds of pilot interviews with nonexperts highlighted problems in the phrasing of some questions. These were rephrased to better delineate the scope of the investigation, and a “background” section was expanded to provide as much reference information as the pilot testers deemed necessary to absorb the tasks at hand. Consultations with social science researchers raised methodological questions regarding the structure of response forms and visual aids. After further revisions, additional pilot testing was carried out; this time, with an expert from the pool of experts that we had been building during the course of the protocol’s development. Because experts have demanding schedules, we constrained the protocol, so that it took around 2 h, although some interviews took more than 3 h. Necessarily, a balance had to be struck between items that went on the protocol forms and those that were verbally relayed to each expert. Interviews were recorded, and, upon transcription, audio files were deleted.

Expert Selection.

Experts were selected based on their ongoing engagement in current SMR-development efforts. All interviews were conducted face-to-face in experts’ offices, where they could gain access to literature and other materials if needed. Before arranging individual interviews, we secured approval from senior management and agreed that personal and corporate identities would be kept confidential.

After briefly explaining our objectives and the format of the interview, we discussed the issue of cognitive heuristics (2, 10, 19–21, 36, 37) and explained the strategies that we would use to minimize the overconfidence they can produce (10). We then reviewed the technical background of the designs, we had developed.

The form in which questions were asked aimed to minimize overconfidence; for example, instead of being asked immediately for a median (or “best”) estimate during an elicitation of overnight cost, experts were asked to provide a lower-bound estimate and then justify it against candidate lower values, followed by an upper-bound estimate and then similarly justify that, and to provide a median only if they felt comfortable doing so. We asked the same question multiple ways to ensure consistency of the results. For example, once a CDF was elicited from each expert for a deployment scenario, we prompted the expert for an estimate of the probability of that scenario costing less than, or greater than, certain (randomly selected) target costs. This allowed us to construct two CDFs per scenario per expert. If an expert’s responses generated two inconsistent CDFs, the expert was made aware of this fact and given the opportunity to explain the inconsistency or to change his or her estimate.

The full expert elicitation protocol is available in SI Appendix, Section S2.

Supplementary Material

Acknowledgments

A.A. was supported by the Steinbrenner Institute at Carnegie Mellon and by the Crown Prince’s International Scholarship Program, Bahrain. I.L.A. and M.G.M. were supported by the Center for Climate and Energy Decision Making (SES-0949710) through a cooperative agreement between the National Science Foundation and Carnegie Mellon University and by a grant from the John D. and Catherine T. MacArthur Foundation (12-101167-000-INP).

Footnotes

The authors declare no conflict of interest.

This article is a PNAS Direct Submission.

*Anness M, Technology development, design and safety features of Westinghouse SMR and its deployment scheme. Workshop on Technology Assessment of Small and Medium-Sized Reactors (SMRs) for Near Term Deployment, December 5–9, 2011, International Atomic Energy Agency, Vienna, Austria.

†Reyes JN, Technology development, design and safety features of NuScale and its deployment scheme. Workshop on Technology Assessment of Small and Medium-Sized Reactors (SMRs) for Near Term Deployment, December 5–9, 2011, International Atomic Energy Agency, Vienna, Austria.

‡Anton S, HI-SMUR 140. Presentation to the Nuclear Regulatory Commission, July 21, 2011, Washington, DC.

§Kim TJ (2010) Generation mPower. Presentation to the American Nuclear Society, November 2, 2010, Washington, DC.

This article contains supporting information online at www.pnas.org/lookup/suppl/doi:10.1073/pnas.1300195110/-/DCSupplemental.

References

- 1.Yeh S, Rubin ES. A review of uncertainties in technology experience curves. Energy Econ. 2012;34(3):762–771. [Google Scholar]

- 2.Hastie R, Dawes R. Rational Choice in an Uncertain World: the Psychology of Judgment and Decision Making. Los Angeles, CA: Sage; 2010. [Google Scholar]

- 3.Henrion M, Fischhoff B. Assessing uncertainty in physical constants. Am J Phys. 1986;54:791–798. [Google Scholar]

- 4.Raiffa H, Schlaifer R. Applied Statistical Decision Theory. Cambridge, MA: Harvard University; 1961. [Google Scholar]

- 5.Howard RA, Matheson JE, editors. The Principles and Applications of Decision Analysis. Menlo Park, CA: Strategic Decisions Group; 1984. [Google Scholar]

- 6.Keeney RL. Decision analysis: An overview. Oper Res. 1982;30(5):803–838. doi: 10.1287/opre.30.5.803. [DOI] [PubMed] [Google Scholar]

- 7.Watson SR, Buede DM. Decision Synthesis: The Principles and Practice of Decision Analysis. New York: Cambridge Univ Press; 1987. [Google Scholar]

- 8.von Winterfeldt D, Edwards W. Decision Analysis and Behavioral Research. New York: Cambridge Univ Press; 1986. [Google Scholar]

- 9.Spetzler CS, Staël von Holstein C-AS. Probability encoding in decision analysis. Manage Sci. 1975;22:340–352. [Google Scholar]

- 10.Morgan MG, Henrion M. Uncertainty: A Guide to Dealing with Uncertainty in Quantitative Risk and Policy Analysis. Cambridge, New York: Cambridge Univ Press; 1990. [Google Scholar]

- 11.Hetes B, et al. EPA Expert Elicitation Task Force White Paper. Washington DC: Environmental Protection Agency; 2011. Available at www.epa.gov/stpc/pdfs/ee-white-paper-final.pdf. Accessed May 7, 2013. [Google Scholar]

- 12.Morgan MG, Keith DW. Subjective judgments by climate experts. Environ Sci Technol. 1995;29(10):468A–476A. doi: 10.1021/es00010a753. [DOI] [PubMed] [Google Scholar]

- 13.Morgan MG, Adams P, Keith D. Elicitation of expert judgments of aerosol forcing. Clim Change. 2006;75(1):195–214. [Google Scholar]

- 14.Zickfeld K, et al. Expert judgments on the response on the Atlantic meridional overturning circulation to climate change. Clim Change. 2007;82(3):235–265. [Google Scholar]

- 15.Zickfeld K, Morgan MG, Frame DJ, Keith DW. Expert judgments about transient climate response to alternative future trajectories of radiative forcing. Proc Natl Acad Sci USA. 2010;107(28):12451–12456. doi: 10.1073/pnas.0908906107. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Morgan MG, Pitelka LP, Shevliakova E. Elicitation of expert judgments of climate change impacts on forest ecosystems. Clim Change. 2001;49(3):279–307. [Google Scholar]

- 17.Morgan MG, Morris SC, Meier AK, Shenk DL. A probabilistic methodology for estimating air pollution health effects from coal-fired power plants. Energy Syst Policy. 1978;2(3):287–310. [Google Scholar]

- 18.Roman HA, et al. Expert judgment assessment of the mortality impact of changes in ambient fine particulate matter in the U.S. Environ Sci Technol. 2008;42(7):2268–2274. doi: 10.1021/es0713882. [DOI] [PubMed] [Google Scholar]

- 19.Tversky A, Kahneman D. Judgment under uncertainty: Heuristics and biases. Science. 1974;185(4157):1124–1131. doi: 10.1126/science.185.4157.1124. [DOI] [PubMed] [Google Scholar]

- 20.Kahneman D, Slovic P, Tversky A, editors. Judgment Under Uncertainty: Heuristics and Biases. New York: Cambridge Univ Press; 1982. [DOI] [PubMed] [Google Scholar]

- 21.Kahneman D. Thinking Fast and Slow. New York: Farrar, Straus and Giroux; 2011. [Google Scholar]

- 22.Curtright A, Morgan MG, Keith D. Expert assessment of future technology. Environ Sci Technol. 2008;42(24):9031–9038. doi: 10.1021/es8014088. [DOI] [PubMed] [Google Scholar]

- 23.Morgan MG. What would it take to revitalize nuclear power in the United States? Environment. 1996;35(2):7–9, 30–32. [Google Scholar]

- 24.Rosner R, Goldberg S. Small Modular Reactors – Key to Future Nuclear Power Generation in the U.S. Chicago: Energy Policy Institute at Chicago, The University of Chicago; 2011. [Google Scholar]

- 25.Chu S. Charge to the Secretary of Energy Advisory Board Small Modular Reactors (SMRs) Subcommittee. 2012. Memorandum from the Secretary of Energy (Department of Energy, Washington, DC) [Google Scholar]

- 26.International Atomic Energy Agency . Status of Small and Medium Sized Reactor Designs. Vienna: International Atomic Energy Agency; 2011. [Google Scholar]

- 27.Kuznetsov V, Barkatullah N. 2009. Approaches to assess competitiveness of small and medium sized reactors. International Conference on Opportunities and Challenges for Water Cooled Reactors in the 21st Century, Vienna, Austria, 27–30 October 2009, Book of Extended Synopses (International Atomic Energy Agency, Vienna). Available at http://www-pub.iaea.org/MTCD/publications/PDF/P1500_CD_Web/htm/pdf/General/Book%20of%20Extended%20Synopses.pdf.

- 28.Zhang Z, Sun Y. Economic potential of modular reactor nuclear power plants based on the Chinese HTR-PM project. Nucl Eng Des. 2007;237(23):2265–2274. [Google Scholar]

- 29.International Atomic Energy Agency 2000. Economic Evaluation of Bids for Nuclear Power Plants, 1999 Edition, IAEA Technical Report Series No. 396 (International Atomic Energy Agency, Vienna)

- 30.Energy Information Administration . Updated Capital Cost Estimates for Electricity Generation Plants. Washington, DC: Office of Energy Analysis, Department of Energy; 2010. [Google Scholar]

- 31.Cooper M. The Economics of Nuclear Reactors: Renaissance or Relapse? South Royalton, VT: Institute for Energy and the Environment, Vermont Law School; 2009. [Google Scholar]

- 32.Bupp IC, Derian J. Light Water: How the Nuclear Dream Dissolved. New York: Basic Books; 1978. pp. 48–76. [Google Scholar]

- 33. Nuclear Regulatory Commission (2012) Conditions of licenses, US Code of Federal Regulations, Title 10, Section 50.54.m.2.i (Nuclear Regulatory Commission, Washington, DC)

- 34.Carelli MD, et al. Economic features of integral, modular, small-to-medium size reactors. Prog Nucl Energy. 2010;52(4):403–414. [Google Scholar]

- 35.Ingersoll DT. Deliberately small reactors and the second nuclear era. Prog Nucl Energy. 2009;51(4):589–603. [Google Scholar]

- 36.Cooke R. Experts in Uncertainty: Opinion and Subjective Probability in Science. New York: Oxford Univ Press; 1991. [Google Scholar]

- 37.Lichtenstein S, Fischhoff B. In: Judgment Under Uncertainty: Heuristics and Biases. Kahneman D, Slovic P, editors. New York: Cambridge Univ Press; 1982. pp. 306–334. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.