Abstract

Use of nanoscience based technology in the food industry is fast emerging as new area for research and development. Several research groups including private companies in the industry have initiated research programmes for exploring the wide scope of nanotechnology into the value chain of food processing and manufacturing. This paper discusses the current focus of research in this area and assesses its potential impacts. Using the developed relational database framework with R&D indicators like literature and patent documents for assessment of the potential of nanotechnology in food sector, a model to organize and map nanoresearch areas to the food processing sector was developed. The study indicates that the about five basic categories of nanotechnology applications and functionalities currently in the development of food sector, include food processing, packaging, nutraceuticals delivery, food safety and functional foods.

Keywords: Nanotechnology, Food processing sector, R&D indicators

Introduction

Nanoscience and nanotechnology are essentially related to the understanding and manipulation of materials at the atomic, molecular, and macromolecular scales. The enhanced surface area per mass compared with larger-sized particles of the same chemistry renders nanosized particles more active biologically (Oberdorster et al. 2005). Applications of nanotechnology are professed to provide answers to some of the current challenges of food security concerns and can provide the needed tools to catalyse the entire agriculture and food value chain. The agri-food value chain today encompasses production to conservation, processing, packaging, transportation and even waste treatment. Tools based on nanotechnology can be expected to revolutionize both science and society, and provide multiple benefits (Lane and Kalil 2005) to the stakeholders in this value chain. Among the several special properties of nanomaterials, characteristics like greater penetrability, reactivity, surface area, and quantum properties due to their size allow for the use of less material and new or more efficient chemical and physical reactions in comparison to larger scale materials. When applied to agri-food production consumption chain, these properties allow new ways for studying individual molecules and the specific intra and intermolecular interactions; and provide insights to mechanisms of catalysis and enzyme reactions, muscular contractions, cellular transport, DNA replication and transcription, DNA unknotting and unwinding, protein folding and unfolding. During the last decade, several review articles (Moraru et al. 2003; Miller et al. 2005; Gogotsi 2006; Sanguansri and Augustin 2006; Tarver 2006; Pandey 2007; Chaudhry et al. 2008; Augustin and Sanguansri 2009; Chun 2009; Sozer and Kokini 2009; Sekhon 2010; Mukesh Kapoor 2011; Bawa and Jayathilakan 2011; Dudo et al. 2011; Rashidi and Khosravi-Darani 2011; Neethirajan and Jayas 2011; Sozer and Kokini 2012) have articulated basic aspects of nanoscience, nanomaterials and nanotechnology when applied to agri-food industries.

However, the voicing of concerns of possible deleterious impacts of nanoparticles on health and environment may be deterring factors in application to this sector. Early reports suggest that the properties of enhanced activity and penetrability properties of nanoparticles may have detrimental effects when applied to biological systems (Oberdorster et al. 2005; Maynard 2007). Therefore, the applications of nanotechnology warrant special attention in risk analysis, regulatory policy, and oversight (Davies 2007). Several discrete reports highlighting risks and social issues (ETC 2003; FOE 2008), a preliminary SWOT analysis of nanotechnology and bio safety (Bawa and Jayathilakan 2011) are now emerging in literature and voice the need to understand the potential (un)anticipated risks and prepare regulatory frameworks before the technology is actually extended into agri-food sector.

It must be mentioned here that the upsurge in world market prices of major food commodities (Trostle 2008) continues to draw the attention of policy makers to the slowing down of agricultural growth in the face of more rapid growth in demand for food. The alarming trends continue as evidenced by indications of further increases in Food Price Index by almost 6 % during July 2012 (FAO 2012), primarily driven up by an increase in grain and sugar prices. This is of even greater significance to India, where more than 54 % of the population continue to directly depend on agriculture for their livelihoods. The contribution of agriculture and allied sectors in Gross Domestic Product has significantly lowered to 16.6 % in 2010–11 as compared to 19.0 % in 2004–05, at constant 2004–05 prices. This is despite witnessing a distinct transition in agricultural scenario from traditional farming patterns yielding less than 0.5 ton/ha in the 1950s to more technology-driven systems yielding 4 ton/ha. The country faces a formidable challenge of ensuring food and nutritional security to over a billion population leading to advocacy of need for Second Green Revolution (Economic Survey 2010–11). Adding to this challenge is growing concern on recent reports indicating a decline in the cropped area by about 2 % from 185 million hectare to 182 million hectare during the last one decade (Indiastat 2011).

The globalization of agricultural trade in the 1990s has led to changes in some of the macro policies that supported agriculture. Some of these have subjected the Indian farmer to significant market risks. All of these have led to a steady decline in farm incomes and rural distress in recent years, affecting both access to food and its utilization. The problems are being compounded by degradation of the natural resource base (soil, water and climate) of agriculture. The current national policy goal of 4 % growth in agriculture to ensure food security can be achieved only by increasing productivity and incomes per unit of the scarce natural resources through effective use of improved technologies in the rural sector. One subsector with potential to drive rural economy is the food processing industry as it seeks to bring the needed synergy between industry and agriculture. A developed food processing industry is expected to lead increase in farm gate prices translating into increased rural incomes, reduce wastages, ensure value addition, promote crop diversification, generate employment opportunities as well as export earnings; thus contributing towards 4 % expected rise in GDP from agriculture. However, this requires a commitment and ensuring that there is continuous flow of new technologies into this sub-sector by taking advantage of some of the recent developments in science, including nanoscience and nanotechnology.

Emerging sciences for food sector

A remarkable array of new technologies, biotechnology, information technology, nanotechnology, etc, now exists that can be integrated into agricultural research and development to impact agricultural productivity, food and nutritional security and economic growth. Many of these emerging technologies are enabling technologies that can be extended across the agricultural value chain (from farm to plate and vice versa) (Kalpana Sastry et al. 2011a). Applications of these technologies in agri-food value chain can address many serious concerns of the agriculture sector and food industry, from farm level production to conservation, processing, packaging and even waste treatment. One example is the recent breakthrough in plant biotechnology, leading to the commercial release of Smartstax, a genetically engineered variety of corn with 8 different herbicide and pest resistance traits combined into one variety (Dow AgroSciences 2009). Similar approaches for providing solutions in animal husbandry for producing vaccines against Newcastle disease in poultry and foot and mouth disease in cattle are now emerging (Twyman et al. 2005). Developments in nanoscience and nanotechnology based applications indicate a potential to re-design the production cycle, promote natural resource conservation, restructure processing and may even redefine the food habits of the people. In the food and agricultural systems, such approaches may ensure more healthy and safe food, better packaging materials, increased bioavailability (Chen et al. 2006; Maynard et al. 2006; and Weiss et al. 2006). All of these technologies are envisaged as enabling technologies that provide for incremental, but significant, advances in productivities and efficiencies (Scott and Chen 2003; Joseph and Morrison 2006; and Kuzma and VerHage 2006), which can help further the competitive advantage for Indian agriculture. Equally significant, these technologies hold the promise of enhancement of the agro-ecosystems to further sustainable agricultural development.

Challenges of integration of emerging sciences for development

One of the major challenges for policy makers and technology developers across the world is increasing costs for R&D, shortage of trained manpower and policy framework for integrating the new technologies into applications across the agri-value chain. The objective of this paper is to address emergence of ‘nanotechnology’ and its integration and institutionalization in the Indian agricultural food production landscape. The focus is on exploring the current technological innovations in nanotechnology, and understanding of their possible role in enhancing food and nutritional availability more at the post-harvest and food processing stages. The study in this paper adopts a method using base data collected through empirical research methods (Kalpana Sastry et al. 2011a). The method is based on technology road mapping and database management concepts where it introduces the basic concepts of nanoscience through query based framework to map the potential of such technologies against the current gaps of knowledge in nanotechnology for enhancing the food quality and quantity. Using this framework, knowledge mapping of data from analysis of relevant set of literature and patents was done and possible applications of nanotechnology in this sector, either on stand-alone basis or in complementarily with the existing technologies, were identified.

Framework for assessing potential role of nanotechnology in food

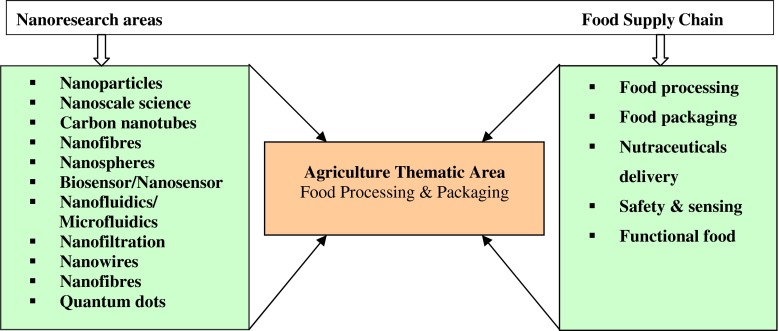

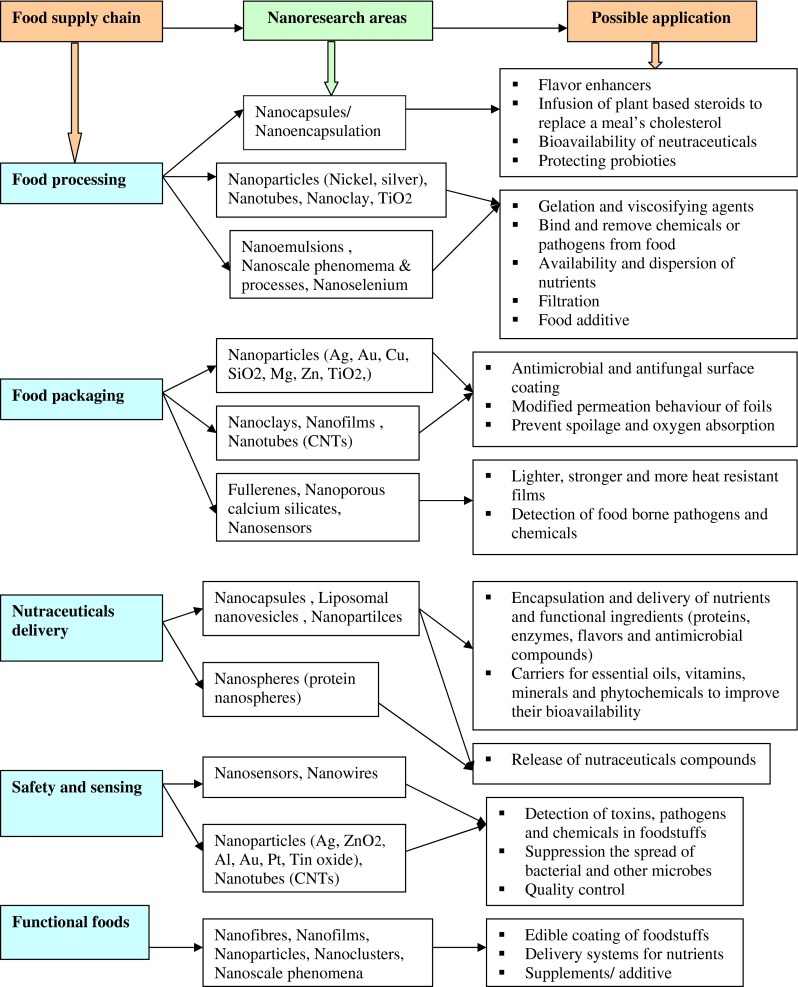

The developed framework for integrating nanotechnology research in food sector attempts to map nanoresearch areas to the food supply chain, that is, the entire production–consumption system firstly by identification of nanoresearch area and food supply chain and then relating nanoresearch with food supply chain. Using the standardized search strings and a technology-based process methodology, various nanoresearch areas and sectors of food supply chains were identified (Fig. 1). This generalized and process based framework (Fig. 1) developed through earlier work (Kalpana Sastry et al. 2010a) was used to enable identification and characterization of the outputs (publications, patents etc.), and map them to the different nanoresearch theme areas of agri-food supply chain.

Fig. 1.

Framework for integrating nanoresearch areas and food supply chain

Trends in nanoresearch with potential to impact food supply chain

Assessment through literature

A set of 160 published documents relevant to query put forth was retrieved from the database containing 1070 publication documents. The query was developed to encompass nanoresearch area, application and food sectors. The retrieved set of publications included a wide range of documents viz, reviews, original research papers, blogs, project reports, survey reports, e-discussion reports and all other authenticated types of documentation in various sources. An overview of the potential for nanotechnology in the different subsectors of the food value chain is summarized in Table 1.

Table 1.

Overview of potential for nanoparticles in subsectors of the food sectors

| Food sectors—Processing value chain | Application | Types of nanoparticlesa | Reference |

|---|---|---|---|

| 1. Quality control | 1. Sensors for detection of chemical contaminants | CNTs, NPs, Metal oxide nanoparticles | Chau et al. 2007, Heugens et al. 2010 |

| a. Uni-molecular sensors | • Carbon nanotubes, nanoparticles | Robinson and Morrison 2010. | |

| b. Sensor arrays | • Gold nanoparticles | Mario et al. 2010 | |

| c. Solid-state sensors | • Tin, indium, Al, zinc oxides NPs | Chau et al. 2007, Heugens et al. 2010 | |

| 2. Sensors for detection of biological contaminants | Nanowires, CNTs, QDs, NPs | Baeummer 2004; Viswanathan et al. 2006 | |

| a. Electronic biosensors | • Nanowires, carbon nanotubes, QDs , Au-NPs, Pt-NPs, Biomems | Bhattacharya et al. 2007 | |

| b. Optical biosensors | • CNTs, silica, gold nanoparticles | Heugens et al. 2010 | |

| c. Mass-change biosensors | • Au-NPs | Yonzon et al. 2004 | |

| 2. Processing technology | 1. Equipments coating for disinfection | • Nickel, silver, carbon nanoparticles | Basavaraja et al. 2008; Chen et al. 2008b |

| 2. Filtration | • Nanoclays, TiO2 | Chau et al. 2007 | |

| 3. Functional foods | 1. Delivery systems for nutrients | • Natural food ingredients in nanoform | Bouwmeester et al. 2009 |

| 2. Edible coating | • Natural food ingredients in the form of nanofibres or nanofilms | Avella et al. 2005 | |

| 4. Packaging | 1. Barrier packaging | • Nanoclays, TiO2, acrylic NPs | Robinson and Morrison 2010; McMurray et al. 2006, |

| 2. Antimicrobial packaging | • Ag, Zn incorporated in polymers | Nanowerk 2008. | |

| 3. Biodegradable packaging | • Nanoclays, metal oxides in natural polymers, CNTs | Sherman 2005, Joshi et al. 2005 | |

| 4. Regulating the internal packaging environment | • Nanoporous calicium silicate, nanocrystalline titanium particles in an ethyl cellulose polymer film | Nanowerk 2008; Johnston et al. 2008 | |

| 5. Self-healing composites | • CdSe/ ZnS NPs | Chau et al. 2007 | |

| 6. Sensor technologies in packaging | • Fullerenes, TiO2, nanoporous silica | Chen et al. 2008a; Heugens et al. 2010 | |

| 5. Nutraceuticals delivery | 1. Delivery of nutrients and functional ingredients | • Nanocapsules, liposomal nanovesicles, nanoparticles | Wen et al. 2006; ElAmin 2006. |

| 2. Release of nutraceutical compounds | • Nanospheres , Nanocapsules | Chen et al. 2006 |

aNPs: Nanoparticles, CNTs: Carbon nanotubes, QDs: Quantum dots

Assessment through patents

Any assessment of potential and emerging technologies like nanotechnology is challenging, as most research is at an early-stage. Its application to agri food systems is probably still at a conceptual level to permit realistic assessments. In such situations, analysis of patents granted in the area and related areas have often been used for making assessments about emerging technologies. This is because, patents inform not only about the inventors and the type of inventions, but they can be viewed as an important indicator of the broader trajectory of innovation in an emerging field (Jaffe and Trajitenberg 2002). While not all patents result in active commercialization, growth and accumulation of patents in a new area of technology has been considered as indicating directions for subsequent investments and related product/process innovations (Schmoch 2006). Thus patent analysis has often been used to both assess current status and trends in technology development, and classify and map the technology to relevant application areas for strategic planning (Hullmann and Meyer 2003; Daim et al. 2006; Kostoff et al. 2007). Patent documents are well structured and provide standardized information about citation, issue date, inventors, institutions and their locations, technology field classification, claims on possible applications like food processing, packaging, nutraceuticals delivery, safety and sensing etc. Their structured documentation makes them suitable for assessing technology developments in various areas.

Based on this concept, a set of 69 patents with implications for food sector was retrieved. The database of patents were collected and analyzed mainly from three resources viz., (i) freely available databases of international/national patent offices (USPTO, EPO, iPAIRS and WIPO); (ii) non-charge providers (Google patents, Free patents Online) and (iii) charge provider (Questel). This retrieved set of relevant patents through query search was further used for bibliometric and technology trend analysis.

Bibliometric analysis

Patent ownership in this sector was found to be diverse indicating the wide range of interest by prospective researchers and players. Of the 69 patent filings, 6 % were from public sector and 14 % from private sector organisations (Table 2). Patenting activity was found to be worldwide (Table 3) with EPO (26.47 %) followed by China (25 %), Korea (13.25 %), USA (7.35 %), India (4.41 %), and Mexico (1.5 %). Significantly, about 16.17 % of the patents were PCT filings reflecting that applicants for these technologies also considered applying through PCT route because of possible markets for their products. These trends indicate growing interests of all types of players in investing resources in the R&D for this activity.

Table 2.

Diversity of patent owners and countries of applicants

| Assignees | Patent % | Country | Patent % |

|---|---|---|---|

| Nanobiomatters, Spaina | 4.5 | European patent office | 26.47 |

| Arkema, Francea | 3 | China | 25 |

| Futura polyesters , Indiaa | 3 | Korea | 13.25 |

| National Research Council of Canadab | 1.5 | USA | 7.35 |

| South China University of Technology, Chinab | 1.5 | India | 4.41 |

| Jawaharlal Nehru Centre for Advanced Scientific Research, Indiab | 1.5 | Mexico | 1.5 |

| Columbia University National Science Foundation, USb | 1.5 | Taiwan | 1.5 |

| BASF, Germanya | 1.5 | Canada | 1.5 |

| Beijing Institute of Graphic Communication, Chinaa | 1.5 | Austria | 1.5 |

| Korea Advanced Institute of Science & Technology, Koreaa | 1.5 | WIPO (P.C.T) | 16.17 |

aIndustrial organization and corporate bodies, bPublic sector organizations

Table 3.

Geographical scope of patent protection (Patent family jurisdiction)

| Major Traits | Jurisdictiona | Reference patent |

|---|---|---|

| Food packaging | CN-8, KR-2 , ES-1,US-4, WO-4, TW-1, AT-1, DE-1 (22) | ES2331640 A1, CN102134467 A |

| Food processing | CN-2, KR-3, WO-2 (7) | KR20110027532 A |

| Nutraceuticals | EP-1, WO-1, CN-1 (3) | CN101433528 A |

| Safety & sensing | IN-1, WO-1 (2) | IN1339/DEL/2008 A |

| Nutraceuticals & packaging | CN-2, KR-2, WO-1 (5) | KR20070076802 A |

| Processing & packaging | CN-2, WO-3, MX-1, KR-2, CA-1, EP-1 (10) | CN101570608 A |

| Packaging & safety sensors | CN-1, IN-1,GB-1, WO-1 (4) | GB0623043 D0, IN1196/MUM/2005 A |

aJurisdiction represents: CN: China, GB: United Kingdom, WO: WIPO (PCT Filing), IN: India, CA: Canada, EP: Europian patent office, KR: Republic of Korea, DE: Germany, ES: Spain, US: United State of America, TW: Taiwan-Province of China, AT: Austria, MX: Mexico

Patenting trends in each sub sector category of food supply chain (Fig. 1) in terms of patent families indicate trends of patenting across jurisdiction in packaging and processing. Applicants tend to seek wider geographical protection for technologies in these areas indicating the broad scope of such research in more markets (Table 3).

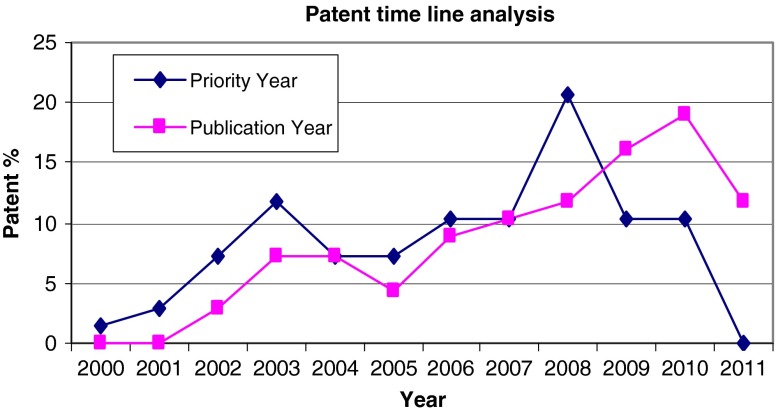

The reference date in patent documents reflects timing of invention, process and strategy of the applicant. In the present study, two indicators, namely, priority year and publication year were used to gauge trends in inventive activities over a span of years. It is known that priority date/year is the first date of filing of patent application anywhere in the world and considered closest to the invention date while publication year reflects the time the information is disclosed to the public from statutory officers. Using priority date is most often recommended as it reflects the inventive performance of technologies, while publication year reflects the rate at which statutory officers are working on these technologies and therefore the time from which it forms full prior art for other patent applications worldwide (Kalpana Sastry et al. 2011b). The quantum of patents on application of nanotechnology in food sector (Fig. 2) shows exponential growth (priority year) from year 2001–10, which declined in 2011. The same trend was observed in publication year, though not coinciding with priority year. This difference is attributed to difference in timelines at national patent offices during examinations.

Fig. 2.

Patent timeline analysis (n = 69)

Technology trend

A more detail assessment on the fields of technology was made by analysing the distribution pattern of the patents in various subfields of the categories under International Patent Classification (IPC 2012). The patents were found in about 20 IPC classes (till sub class level or the third hierarchical level of classification) covering a large domain of sectors. It is well known that a patent application can be associated with more than one IPC class and one patent may occupy more than one subclass. IPC code analysis was restricted to the fourth hierarchical level of the classification that is ‘group’ level. It was found that maximum number of patent records was in IPC code C08J which covers food packaging. The other prominent IPC codes under which the data studied were classified are listed in Table 4.

Table 4.

Distribution of patents based on IPC classification

| IPC code | Technology description | Patent % |

|---|---|---|

| C08J | Manufacture of articles or shaped materials containing macromolecular substances (manufacture of semi-permeable membranes, sheet for packaging) | 13.23 |

| C08K | Use of inorganic ingredients | 13.23 |

| C08L | Compositions of homopolymers or copolymers of unsaturated aliphatic hydrocarbons; materials for packaging & preservation | 10.29 |

| A61K | Use of chemical materials for deodorisation, disinfection or sterilisation | 4.41 |

| A22C | Processing of meat, poultry, or fish | 3 |

| A23L | Preservation of foods or foodstuffs, in general, e.g. pasteurising, sterilising, specially adapted for foods or foodstuffs, packaging | 3 |

| A23C | Dairy products: milk, butter, cheese, milk or cheese substitutes, preservation of milk & milks products | 3 |

| A23B | Preserving: canning, meat, fish, eggs, fruit, vegetables, edible seeds; chemical ripening of fruit or vegetables; the preserved, ripened, or canned | 1.5 |

| A23J | Obtaining protein compositions for foodstuffs, bulk opening of eggs and separation of yolks from white | 1.5 |

| A01N | Preservation of plants or parts: inhibiting evaporation, improvement of the appearance of leaves (preservation or chemical ripening of harvested fruit or vegetables) | 1.5 |

Total set of 69 patent records, IPC code as per WIPO IPC version 2012.01

Assessment of potential of nanotechnology through both literature and patent

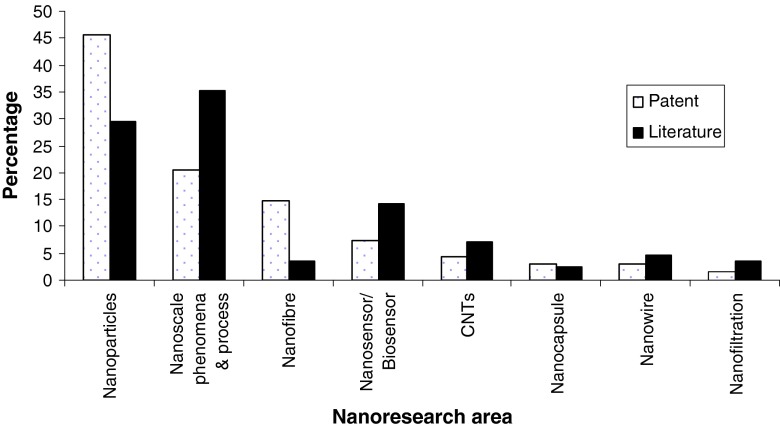

Using published literature and patent analytics, a current scenario and trends in technology development in nanotechnology in food sector was developed. A detailed analysis of the data in each of these areas can help to assess and identify relevant research tools (Hullmann and Meyer 2003; Daim et al. 2006; Kostoff et al. 2007; and Kalpana Sastry et al. 2010b), which can be integrated into the food application. Therefore, an effort was made to identify and map areas of nanoresearch and food supply chain to the determinants of food sector identified earlier, namely, food processing, packaging, nutraceutical delivery, safety & sensing and functional food (Fig. 1), and based on the knowledge mapping framework (Fig. 3), some of the areas of nanotechnology with potential applications for enhancing food sector were identified. These included food processing, packaging, quality control, nutraceutical delivery and functional foods. Nanoresearch areas were diverse ranging from formulations like gels, emulsions to particles and devices. Applications of many technologies were wide and covered a multitude of areas. Most of them were incremental and supplementing gaps in current level of knowledge for enhancing delivery, shelf life or quality of the products.

Fig. 3.

Knowledge mapping framework for integration of food supply chain with nanoresearch area

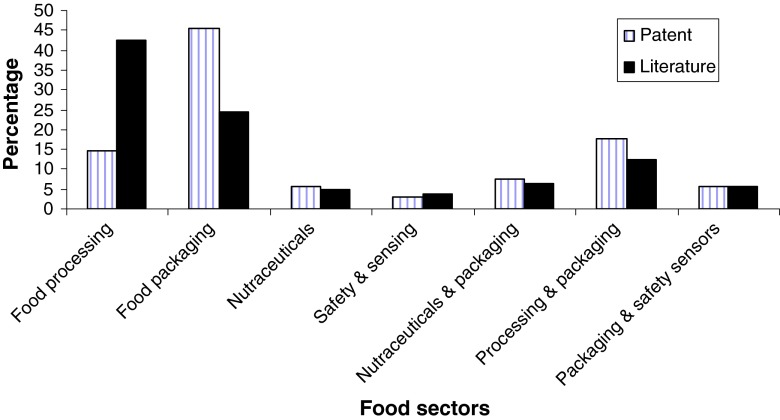

It was found that nanoparticles are the most widely researched area followed by nanoscale phenomena and processes (Fig. 4). Formulations like capsules and particles are known to enhance nutraceuticals delivery, antimicrobial packaging, delivery of nutrients and functional ingredients, detection of toxins, chemicals and pathogens in food stuffs etc. More than 50 % of records from both the databases were found to be centred on research leading to enhancing packaging technologies followed by sectors in food processing (Fig. 5). It has also been observed that patenting activities in case of food packaging are more than food processing, whereas percentage of literature in these was more in processing sector. However, research leading to technologies encompassing both processing and packaging applications was mostly applied for patents at first instance and subsequently leading to published documents. This trend indicates the commercial potential of such research and trend to build market on such technologies (Fig. 5).

Fig. 4.

Nanoresearch areas in food sector (Patents: 69, Literature: 160 publications)

Fig. 5.

Focussed subsectors in food sectors addressed by nanotechnologies (Patents: 69, Literature: 160 publications)

Nanotechnology in food sector- Indian scenario

About 6 % of published literature in set of retrieved documents was found from research organizations based in India. This indicates that current emphasis on possible application of nanotechnology for this sector has also been initiated in the country. It may be deduced that early indications of investments made by the Government of India through various grants and schemes (Nanomission 2012) have started to result in early-stage inventions. Notwithstanding the fact that Indian Patent Office has recently started online service (Indian Patent Information Retrieval System, 2012), nearly 3 patents namely [[IN2005MU01196]]; [[IN2008DE01339]] and [[WO200963508]] were found to be in various stages of patent prosecution processes in Indian Patent Office since 2005. These early indications indicate the current thrust and interests of researchers in India in this sector. It is essential that these trends should be catalysed by providing proactive steps to enhance the R&D environment are initiated through policy intervention so that investments including developing trained manpower are planned in a prudent manner. In fact, investments in India in nanotechnology are still less as compared those at the global levels. In 2008, both public and private sectors worldwide had invested about $20 billion. Market forecasts indicate $1,880 billion investments in nanotechnology-related sales across all sectors by 2015 (ChennaiFocus 2012).

Assessment of risk and safety issues

New technologies and more so, high-end types like nanotechnology promise to offer significant benefits to the food industry but can have possible risks of adverse and unintended consequences. The level of risk perceptions associated with nanotechnology was analyzed using the bibliographic database. The analysis indicated that the possible risks are of three types: environmental risks, social risks and health risks. These were indicated in almost a quarter of the publications (24 %) only. However, the search in patents database did not yield technologies for risk assessment. This indicates that despite the fast pace of nanotechnology development, evaluation tools of its possible risks has been slow. Since most of the nanotechnology applications in food industry are expected to be based on its convergence with other technologies, the lack of science-based data on hazards and exposure pathways of nanobased technologies may be challenging to regulators in dealing with potential risks. Hence, it is essential that steps be taken to decrease scientific uncertainty of the potential risks through more investments in risk analysis.

In recent years, possible adverse effects of engineered nano materials on agriculture and allied sector are also being voiced (Du et al. 2011). While it is accepted that research on environmental fate of nano particles in agri-value chain is still in its infancy, the hypothesis is that nano particles could enter the food chain via two very different routes: through particles designed specifically for agricultural applications (nutrient/pesticide delivery) or through processed food goods. Since the uptake of such particles by plants may result in entering the food chain (Cyren M Rico et al. 2011), it raises toxicity concerns about the ecosystem. Therefore, detailed life cycle analysis, particle uptake by plants, bio-distribution, entry in the food chain etc needs a thorough investigation before these tools are used as products in agri-food sector. In case of possible toxicity on humans, it is conceded that it is still early days in the study of NP-induced pulmonary toxicity.

A variety of factors have to be taken into consideration before the impact of nano particles exposure on human health is understood. It is essential to take precautionary approach and also research on in areas of nanotoxicology (Jasmine Jia’en Li et al. 2010). In addition, there is a need to involve the stakeholders in agri-value chain in the Indian context, from the early stages of technology development so that they are aware of the risks and uncertainties associated (Kalpana Sastry et al. 2010b). All these initiatives can lead to better understanding and acceptance of the products of research and catalyze the life cycle of technology development. As more technologies flow from this emerging sector, there would be more need for a coordinated risk management strategy. The evolution of a participatory, dynamic and responsive nanotechnology policy and strategy for Indian agriculture and food system would be needed if the economic impacts of this enabling technology are to reach the agrarian society.

Conclusion

Nanotechnology is considered as ‘an enabling technology that promises to contribute at many frontiers of science and technology” (NAS 2006). Incremental advancements using nanotechnology for improving and enhancing quantity and quality of food can catalyse the food processing sector, from production to conservation, processing, packaging, and even waste treatment (Frederick and Randolph 1985). Such developments can create competitive advantage and commercial success for the small scale enterprises in agri-food value chain which can benefit the entire ecosystem of smallholders. Using R&D indicators like patents and published literature, the study has explored the trends in R&D in nanoresearch as applicable to food processing value chain. Results in this study indicate that the current focus of nanotechnology research for this sector is focussed in five areas, namely, food packaging, processing, quality and safety, nutraceuticals and functional foods. All of these have major implications for the agri-food systems and impact the economic outlook for this sector. Use of nano-based materials, processes and systems in these areas indicate applications in processing techniques, packaging, transportation and storage. These applications can play an important role in reducing spoilage and extending shelf life of food products on one hand and help in retaining the nutritional value, aroma, flavour and texture of foods, and presenting them in near natural form with added conveniences.

Further, like in several other areas of agricultural research, existing technologies provide a base for the application of emerging nanotechnologies, wherein, the latter provides for necessary incremental benefits. Hence, it would be prudent to use emerging technologies like nanotechnology to complement the conventional technologies. However, for harnessing the potential such emerging technologies and making them affordable to all, a renewed emphasis needs to be on their adoption across the agri-supply chains, to assess where such innovations can contribute to better competitive advantage. Innovation platforms, which can facilitate access of these nanotechnology based tools, hasten their diffusion into research systems and promote an environment of sharing pre-competitive, upstream or platform technologies would be needed. These platforms would also need to facilitate the diffusion of the final technology products into the markets with a focus to hasten ‘local’ competencies to enhance the livelihoods in rural sectors. At the same time, a more coherent systems approach is also advocated as commissioning of any products of new and emerging technologies like nanotechnologies would need to be equipped with information docket of assessment of possible risks to health and environment, with demonstrable value and utility to all stakeholders. Taking lessons from some of the difficulties faced by products of agri-biotechnology in getting societal acceptance, it is essential a viable regulatory system for good governance of the emerging technologies be built on science-based evidence concurrently with the development of this emerging technology in the food sector at its early-stage development.

References

- Augustin MA, Sanguansri P. Nanostructural materials in the food industry. Adv Food Nutr Res. 2009;58:184–207. doi: 10.1016/S1043-4526(09)58005-9. [DOI] [PubMed] [Google Scholar]

- Avella M, De Vlieger Jan J, Errico M, Emanuela FS, Vacca P, Volpe MG. Biodegradable starch/clay nanocomposite films for food packaging applications. Food Chem. 2005;93(3):467–474. doi: 10.1016/j.foodchem.2004.10.024. [DOI] [Google Scholar]

- Baeummer A. Nanosensors identify pathogens in food. Food Technol. 2004;58:51–55. [Google Scholar]

- Basavaraja S, Balaji SD, Lagashetty A, Rajasab AH, Venkataraman A. Extracellular biosynthesis of silver nanoparticles using the fungus Fusarium semitectum. Mater Res Bull. 2008;43:1164–1170. doi: 10.1016/j.materresbull.2007.06.020. [DOI] [Google Scholar]

- Bawa AS, Jayathilakan K. Nanotechnology in processing of meat. In: Mahendrakar NS, Sachindra NM, editors. Technology of muscle foods. New Delhi: Studium Press (India) Pvt Ltd; 2011. pp. 103–133. [Google Scholar]

- Bhattacharya S, Jang JS, Yang LJ. Biomems and nanotechnology based approaches for rapid detection of biological entities. J Rapid Meth Autom Microbiol. 2007;15:1–32. doi: 10.1111/j.1745-4581.2007.00073.x. [DOI] [Google Scholar]

- Bouwmeester H, Dekkers S, Noordam MY, Hagens WI, Bulder AS, Heer C, Voorde SE, Wijnhoven SW, Marvin HJ, Sips AJ. Review of health safety aspects of nanotechnologies in food production. Regulat Toxicol Pharmacol. 2009;53(1):52–62. doi: 10.1016/j.yrtph.2008.10.008. [DOI] [PubMed] [Google Scholar]

- Chau CF, Huei Wu S, Yen G-C. The development of regulations for food Nanotechnology. Tr Food Sci Technol. 2007;18:269–280. doi: 10.1016/j.tifs.2007.01.007. [DOI] [Google Scholar]

- Chaudhry Q, Scotter M, Blackburn J, Ross B, Boxall A, Castle L, Aitken R, Watkins R. Applications and implications of nanotechnologies for the food sector. Food Addit Contam. 2008;25(3):241–258. doi: 10.1080/02652030701744538. [DOI] [PubMed] [Google Scholar]

- Chen HD, Weiss JC, Shahidi F. Nanotechnology in nutraceuticals and functional foods. Food Technol. 2006;60(3):30–36. [Google Scholar]

- Chen SH, Wu VCH, Chuang YC, Lin CS. Using oligonucleotide- functionalized Au nanoparticles to rapidly detect food-borne pathogens on a piezoelectric biosensor. J Microbiol Meth. 2008;73:7–17. doi: 10.1016/j.mimet.2008.01.004. [DOI] [PubMed] [Google Scholar]

- Chen H, Zuo X, Su S, Tang Z, Wu A, Song S, Zhang D, Fan C. An electrochemical sensor for pesticide assays based on carbon nanotube-enhanced acetycholinesterase activity. Analyst. 2008;133:1182–1186. doi: 10.1039/b805334k. [DOI] [PubMed] [Google Scholar]

- ChennaiFocus (2012) Nano Mission for Agriculture Promises Quality Food to us and Reduced Cost to Farmers. Available at: http://chennaifocus.wordpress.com/2012/02/02/nano-mission-for-agriculturepromises-quality-food-to-us-and-reduced-cost-to-farmers/ [Accessed on 02 February 2102].

- Chun AL. Will the public swallow nanofood? Nat Nanotechnol. 2009;4:790–791. doi: 10.1038/nnano.2009.359. [DOI] [PubMed] [Google Scholar]

- Rico CM, Majumdar S, Gardea MD, Videa JRP, Gardea-Torresdey JL. Interaction of nanoparticles with edible plants and their possible implications in the food chain. J Agric Food Chem. 2011;59:3485–3498. doi: 10.1021/jf104517j. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Daim TU, Rueda G, Martin H, Gerdsri P. Forecasting emerging technologies: use of bibliometrics and patent analysis. Technol Forecast Soc Change. 2006;73(8):981–1012. doi: 10.1016/j.techfore.2006.04.004. [DOI] [Google Scholar]

- Davies JC. EPA and nanotechnology: oversight for the 21st century. Washington: Project on Emerging Technologies; 2007. pp. 1–76. [Google Scholar]

- Dow AgroSciences (2009) SmartStax corn receives Japanese import approval. Press release At: http://www.dowagro.com/newsroom/corporatenews/2009/20090731a.htm [Accessed on 07August 2012].

- Dudo A, Choi DH, Scheufele DA. Food biotechnology in the news: coverage patterns and thematic emphasis during the last decade. Appetite. 2011;56:78–89. doi: 10.1016/j.appet.2010.11.143. [DOI] [PubMed] [Google Scholar]

- Du W, Sun Y, Ji R, Zhu J, Wu J, Guo H. TiO2 and ZnO nanoparticles negatively affect wheat growth and soil enzyme activities in agricultural soil. J Environ Monit. 2011;13:822–828. doi: 10.1039/c0em00611d. [DOI] [PubMed] [Google Scholar]

- Economic Survey (2010–11). Chapter 8 Agriculture and Food Management, At: http://indiabudget.nic.in [Accessed on August 10, 2012].

- ElAmin A (2006). Nanotech database compiles consumer items on the market. Available from http://www.foodproductiondailyusa.com/news/ng.asp?id=66516 [Accessed on 11 July 2012].

- ETC (2003) Down on the Farm: The Impact of Nanoscale Technologies on Food and Agriculture. Available at http://www.etcgroup.org/en/materials/publications.html?pub_id=80 [Accessed on June 13, 2012]

- FAO (2012) Food Price Index, Available at www.fao.org/worldfoodsituation/wfs-home/foodpricesindex/en/ [Accessed on September 26, 2012]

- FOE (2008) Friends of the Earth. Out of the laboratory and onto our plates: Nanotechnology in Food and Agriculture. Available at http://www.foe.org/pdf/nano_food.pdf [Accessed on 13 June 2012]

- Frederick B, Randolph B. Emerging agricultural technologies, public policy and implications for Third World Agriculture: The case of biotechnology. Am J Agric Econ. 1985;67(5):1170–1175. doi: 10.2307/1241394. [DOI] [Google Scholar]

- Gogotsi Y (2006) Nanomaterials handbook. CRC Press, Taylor and Francis group, Boca Raton, FL

- Heugens Evelyn HW, Susan WP Wijnhoven, Eric AJ Bleeke (2010) Technology sector Evaluation: Agrifood. Report for the ObservatoryNANO, July 2010. Pages 1-23. At: www.observatorynano.eu [Accessed 21 July 2012]

- Hullmann A, Meyer M. Publications and patents in nanotechnology: an overview of previous studies and the state of the art. Scientometrics. 2003;58(3):507–527. doi: 10.1023/B:SCIE.0000006877.45467.a7. [DOI] [Google Scholar]

- IndiaStat (2011) Agricultural area/Land use. http://www.indiastat.com/agriculture/2/agriculturalarealanduse/152/stats.aspx [Accessed on 14 August 2012]

- IPC 2012. International Patent Classification. http://www.wipo.int/export/sites/www/classifications/ipc/en/guide/guide_ipc_20.pdf Internet Version of the Classification Available at <http://www.wipo.int/classifications/ipc/ipc8/?lang=en> [Accessed on 02 January 2012]

- Indian Patent Information Retrieval System (2012) Available at http://ipindia.nic.in/ipirs1/patentsearch.htm. [Accessed on 16 August 2012]

- [IN2005MU01196]; Oxygen scavenging composition. Available at http://ipindia.nic.in/ipirs1/patentsearch.htm. [Accessed on August 16, 2012]

- [IN2008DE01339] A sensor for detecting air leakage in packed items and storage plants. http://ipindia.nic.in/ipirs1/patentsearch.htm. [Accessed on August 16, 2012]

- Jaffe AB, Trajitenberg M. Patents, citations and innovations: a window on the knowledge economy. Cambridge: MIT; 2002. [Google Scholar]

- Li JJ’e, Muralikrishnan S, Ng C-T, Yung L-YL, Bay B-H. Nanoparticle-induced pulmonary toxicity. Exp Biol Med. 2010;235:1025–1033. doi: 10.1258/ebm.2010.010021. [DOI] [PubMed] [Google Scholar]

- Johnston JH, Grindrod JE, Dodds M, Schimitschek K. Composite nano-structured calcium silicate phase change materials for thermal buffering in food packaging. Curr Appl Phys. 2008;8:508–511. doi: 10.1016/j.cap.2007.10.059. [DOI] [Google Scholar]

- Joseph T, Morrison M (2006) Nanotechnology in agriculture and food. Institute of Nanotechnology, European Nanotechnology Gateway. Available at http://www.nanoforum.org [Accessed on 26 July 2012].

- Joshi KA, Tang J, Haddon R, Wang J, Chen W, Mulchandani A. A disposable biosensor for organophosphorus nerve agents based on carbon nanotubes modified thick film strip electrode. Electroanalysis. 2005;17:54–58. doi: 10.1002/elan.200403118. [DOI] [Google Scholar]

- Kalpana Sastry R, Rashmi HB, Rao NH, Ilyas SM. Integrating nanotechnology into agri-food systems research in India: a conceptual framework. Technol Forecast Soc Change. 2010;77:639–648. doi: 10.1016/j.techfore.2009.11.008. [DOI] [Google Scholar]

- Kalpana Sastry R, Rashmi HB, Rao NH. Nanotechnology patents as R&D indicators for disease management strategies in agriculture. J Intell Prop Rights. 2010;1(5):197–205. [Google Scholar]

- Kalpana Sastry R, Rashmi HB, Rao NH. Nanotechnology for enhancing food security in India. Food Policy. 2011;36:391–400. doi: 10.1016/j.foodpol.2010.10.012. [DOI] [Google Scholar]

- Kalpana Sastry R, Rashmi HB, Jyothi B. Research and development perspectives of transgenic cotton: evidence from patent landscape studies. J Intell Prop Rights. 2011;16:139–153. [Google Scholar]

- Kostoff RN, Koytcheff RG, Lau CGY. Global nanotechnology research literature overview. Curr Sci. 2007;92(11):1492–1498. [Google Scholar]

- Kuzma J, VerHage P. Nanotechnology in agriculture and food production. Washington: Woodrow Wilson International Center for Scholars; 2006. pp. 1–42. [Google Scholar]

- Lane N, Kalil T. The national nanotechnology initiative: present at the creation. Issues Sci Technol. 2005;21(4):49–54. [Google Scholar]

- Mario G, Tamara F, Eric G. Potential applications of nanotechnology in the agro-food sector. Sci Technol Aliment Campinas. 2010;30(3):573–581. [Google Scholar]

- Maynard AD. Nanotechnology: the next big thing, or much ado about nothing? Ann Occup Hyg. 2007;51:1–12. doi: 10.1093/annhyg/mel071. [DOI] [PubMed] [Google Scholar]

- Maynard AD, Aitken RJ, Butz T, Colvin V, Donaldson K, Oberdörster G, Philbert M, Tinkle SS, Tran L, Walker NJ, Warheit DB. Safe handling of nanotechnology. Nature. 2006;444(7117):267–269. doi: 10.1038/444267a. [DOI] [PubMed] [Google Scholar]

- McMurray TA, Dunlop PSM, Byrne JA. The photocatalytic degradation of atrazine on nanoparticulate TiO2 films. J Photochem Photobiol A. 2006;182:43–51. doi: 10.1016/j.jphotochem.2006.01.010. [DOI] [Google Scholar]

- Miller JC, Serrato RM, Miguel JRC, Kundhal GA (2005) The handbook of naonotechnology. In: Graffagnini M (ed) Wiley, Hoboken

- Moraru C, Panchapakesan C, Huang Q, Takhistov P. Nanotechnology: a new frontier in food science. Food Technol. 2003;57(12):24–29. [Google Scholar]

- Mukesh Kapoor Nanotechnology in food sector: current developments and future prospects. Ind Food Ind. 2011;30(4):44–55. [Google Scholar]

- Nanomission (2012) Introduction-Nanomission. At: http://www.ckmnt.com/about-nano-mission.html [Accessed on July 7, 2012]

- NAS (2006) A matter of size: Triennial review of the national nanotechnology initiative. National Academy of Sciences, Washington DC, National Academies Press

- Nanowerk (2008) Food nanotechnology—how the industry is blowing it. Available at: http://www.nanowerk.com/spotlight/spotid=5305.php [Accessed on 16 April 2012]

- Neethirajan S, Jayas DS. Nanotechnology for the food and bioporcessing industries. Food Bioprocess Technol. 2011;4:39–47. doi: 10.1007/s11947-010-0328-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Oberdorster G, Oberdorster E, Oberdorster J. Nanotoxicology: an emerging discipline evolving from studies of ultrafine particles. Environ Health Perspect. 2005;113:823–839. doi: 10.1289/ehp.7339. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pandey RC. Food nanotechnology: an overview of the developing research area. Ind Food Ind. 2007;26(2):36–40. [Google Scholar]

- Rashidi L, Khosravi-Darani K. The applications of nanotechnology in food industry. Crit Rev Food Sci Tachnol. 2011;51:723–730. doi: 10.1080/10408391003785417. [DOI] [PubMed] [Google Scholar]

- Robinson DKR, Morrison MJ (2010) Nanotechnologies for food packaging: Reporting the science and technology research trends: Report for the ObservatoryNANO. August 2010. Pages 1-20. At: www.observatorynano.eu [Accessed on 05 August 2010]

- Sanguansri P, Augustin MA. Nanoscale meterials development: a food industry perspective. Tr Food Sci Technol. 2006;17:547–556. doi: 10.1016/j.tifs.2006.04.010. [DOI] [Google Scholar]

- Scott N, Chen H (2003) Nanoscale science and engineering for agriculture and food systems. A National Planning Workshop. November 18–19, 2002. Available at http://www.nseafs.cornell.edu/web.roadmap.pdf [Accessed on 03 January 2012]

- Sekhon BS. Food nanotechnology-An overview. Nanotechnol Sci Appl. 2010;3:1–15. [PMC free article] [PubMed] [Google Scholar]

- Sherman LM (2005) Chasing nanocomposites. Available from http://www.ptonline.com/articles/200411fa2.html [Accessed on 05 January 2012]

- Schmoch U. Double- boom cycles and the comeback of science-push and market –pull. Res Policy. 2006;36:1000–1015. doi: 10.1016/j.respol.2006.11.008. [DOI] [Google Scholar]

- Sozer N, Kokini JL (2009) Nanotechnology and its applications in the food sector. Trends Biotechnol 27:82–89 [DOI] [PubMed]

- Sozer N, Kokini JL. The applications of nanotechnology. In: Pico Y, editor. Chemical analysis of food- Techniques and applications. Elsevier: Academic; 2012. pp. 145–176. [Google Scholar]

- Tarver T. Food nanotechnology. Food Technol. 2006;11(6):22–26. [Google Scholar]

- Trostle R (2008) Global agricultural supply and demand: Factors contributing to the recent increase in food commodity prices/ WRS-0801. Economic Research Service/USDA, pp 1-30. At: http://www.ers.usda.gov/Publications/WRS0801/WRS0801.pdf [Accessed on 05 July 2012]

- Twyman RM, Schillberg S, Fischer R. The transgenic plant in the pharmaceutical market. Expert Opin Emerg Drugs. 2005;10:185–218. doi: 10.1517/14728214.10.1.185. [DOI] [PubMed] [Google Scholar]

- Viswanathan S, Wu LC, Huang MR, Ho JAA. Electrochemical immunosensor for cholera toxin using liposomes and poly (3,4-ethylenedioxythiophene)-coated carbon nanotubes. Anal Chem. 2006;78:1115–1121. doi: 10.1021/ac051435d. [DOI] [PubMed] [Google Scholar]

- Weiss J, Takhistov P, Mcclements J. Functional materials in food nanotechnology. J Food Sci. 2006;71(9):R107–R116. doi: 10.1111/j.1750-3841.2006.00195.x. [DOI] [Google Scholar]

- Wen HW, DeCory TR, Borejsza-Wysocki W, Durst RA. Development of neutravidin tagged-liposomal nanovesicles as universal detection reagents in bioassay. Talanta. 2006;68:1264–1272. doi: 10.1016/j.talanta.2005.07.032. [DOI] [PubMed] [Google Scholar]

- [WO200963508] Nanoparticle composition and process thereof. http://ipindia.nic.in/ipirs1/patentsearch.htm. [Accessed on 16 August 2012]

- Yonzon CR, Jeoung E, Zou S, Schatz GC, Mrksich M, Van Duyne RP. A comparative analysis of localized and propagating surface plasmon resonance sensors: the binding of Concanavalin A to a monosaccharide functionalized self- assembled monolayer. J Am Chem Soc. 2004;126:12669–12676. doi: 10.1021/ja047118q. [DOI] [PubMed] [Google Scholar]