Abstract

A convenience ready-to-reconstitute cutlet mix containing 30% fish protein powder was developed to improve the nutritional quality of the product. Consumer survey was based on the home use test (HUT) method. The acceptance of the fish cutlet mix (FCM) was studied using a 9-point hedonic scale ranging from 1 (extremely dislike) to 9 (extremely like). Product’s characteristics and stability were studied during 6 months of storage at 27 ± 2 °C. The FCM packed in a polyethylene bag and cardboard box was stable during the storage period. There were no changes in colour, moisture gain and water activity, and TBARS values remained low. The FCM was accepted by the consumers in the study (n = 85). The average liking was high (7.5 ± 1.3) and it was influenced by frequency of fish and chicken consumption, educational level and household size. People who ate fish once a week liked the product more than other consumers. Also those with higher educational level and bigger household size. The results in this paper are important information for companies planning to develop ready-to-eat products fortified with fish proteins. The products could be means of increasing fish consumption in countries/areas where there is no tradition of consuming fresh or frozen fish.

Keywords: Ready-to-reconstitute, Fish cutlet mix, Fish protein powder, Consumer acceptance, Home use test, Storage stability

Introduction

Fish and fishery products play an important role in human nutrition as a source of proteins, fatty acids, fat-soluble vitamins and micronutrients (Altschul 1989; Belitz et al. 2009). They are also highly digestible and contain all essential amino acids (Haard 1995). However, fish and fishery products are very perishable (Gill 1995) and a preservation method such as drying can extend the shelf-life of these products by lowering the water activity to prevent microbiological, chemical and biochemical deterioration (Belitz et al. 2009). The demand for ready-to-eat (RTE) and or ready-to-cook meals is gradually growing because of their convenience (Yerlikaya et al. 2005). The sales of ready meals have been growing rapidly in Iran for the last years. They have been driven by consumer demand for convenience food, value for money and increasing product awareness. Retail and foodservice sales of ready meals are expected to grow 8% annually in volume driven by increases in household incomes as more women go out to work, the expansion of supermarket chains and wider access to modern retail outlets, a wider consumer base for the consumption of ready meals, and growing acceptance of Western eating habits (Euromonitor 2010).

Formulated RTE fish products are very popular and available in different forms (Tomoszek 2002). Fish and shrimp soup mixes and snacks are examples of dried RTE products. They are popular in Asian countries because of easy transportation, quality, stability and long shelf life (Bakar 2007). Consumers should be able to rehydrate and cook dried food mixes within a short period of time and they should be at least as nutritious and palatable as canned or frozen products (Thorner 1973).

Fish protein powder (FPP) produced from different sources of raw material (Niki and Igarashi 1982) is utilized as a binder, dispersing agent and emulsifier due to its strong interactions with other proteins and its high gelation ability (Ramirez et al. 1999; Chung et al. 2000; Carvajal et al. 2005). It can be used for producing formulated seafood and other food products (Niki et al. 1982, 1983; Park and Lin 2005). In recent years some studies have been done to investigate process conditions, quality and characteristics of FPP (Ramirez et al. 1999; Chung et al. 2000; Musa et al. 2005; Sathivel et al. 2006; Chavan et al. 2008; Shaviklo et al. 2010a, 2011a). Successful development of some convenience RTE food products from FPP has been reported by Ballester et al. (1968) for protein mix, by Gogoi et al. (1996) for rice-fish snack, by Huda et al. (2000, 2001) for fish cracker, by Sathivel et al. (2005) for fortified mayonnaise and by Shaviklo et al. (2010b, c, 2011b) for high protein corn-fish snacks and fortified ice-cream respectively.

Few studies on the development and acceptance of dried food mixes have also been reported. The products included vegetable cutlet mix based on soy proteins (ISIRI 2003), instant vegetable soup mix (Abeysinghe and Illeperuma 2006), chicken kebab mix (Modi et al. 2007), Basundi mix; an Indian dessert (Ruhil et al. 2010) and instant spice mix from seaweed (Senthil et al. 2010). However there are still opportunities to increase the value of FPP by adding them to dry mix products. Utilisation of fish in dried products including dried fish patties was also reported by Bello and Piggot (1979, 1980). All the products were stable for 4–6 months at ambient temperatures.

The idea to develop fish cutlet mix (FCM) was generated from national standard guidelines for processing and specification of vegetable cutlet mixes (ISIRI 2003) in order to improve the nutritional quality of the product and to increase fish consumption in the country. The FCM is a ready-to-reconstitute food and can be developed from various dried ingredients including FPP. It is a convenient product due to its low volume and long storage life at ambient temperatures and it has functional ingredients like FPP and soy protein. Mixing FCM with adequate water makes it possible to form/shape and fry the product within 10–15 min.

Fish consumption in Iran is low, especially in Iran’s central cities where most people live (Shilat 2008; FAO 2009a). The main obstacles in increasing fish consumption in Iran are lack of skills in preparing and cooking fish at home and peoples dislike of fish odour and flavour (Shilat 2005; FAO 2009b). But new RTE fishery products have been welcomed by Iranian consumers due to masking fish odour and flavour by using different ingredients and formulating the new products similar to existing meat and chicken products (Shaviklo 2000, 2006). The objectives of this project were to develop a nutrious convenience/ready-to-reconstitute FCM and to study the consumer acceptance, storage stability and quality changes of the product during 6 months of storage at ambient temperature.

Materials and methods

Processing of FPP

The FPP was processed at Matis (Icelandic Food and Biotech R&D) processing laboratory in Reykjavik, Iceland. Chilled fresh skinless saithe (Pollachius virens) fillets (3 days post catch) were provided from a local fish processing company, packed in 3 polystyrene boxes (net wt. of each 10 kg) and brought to the laboratory. The average length and weight of fillets were 40–45 cm and 800–1000 g, respectively. The fish fillets were kept refrigerated (<4 °C) until processing at the same day.

Fish fillets were minced using an industrial meat mincer (Sirman-TC12E, Curtarolo, Italy). The mince was leached by washing it twice with 5 times its volume of cold water with 0.2% salt as recommended by Min et al. (1987). The mince was mixed and stirred with a stainless steel spatula for 15 min. The slurry was then passed through a cheese cloth. The wash water which contained pigments, blood and soluble nitrogenous material was discarded. Cheese cloth was used to manually remove as much water as possible from the washed mince after the second washing process. The obtained leached mince was mixed with 2.5% sucrose, 2.5% sorbitol, and 0.1% sodium tripolyphosphate (E451) as lyoprotectants in a silent cutter (Kilia bowl cutter, 201100EX, Neumunster, Germany) for 5 min. The temperature of the raw material was less than 10 °C during mixing. The mixture of leached mince and additives was placed on aluminium trays with 3 cm thickness and blast frozen for 12 h at −24 °C.

The blast frozen mixture was chopped using a large chopping knife to make frozen pieces of less than 2 cm thickness and freeze dried in a pilot lyophilizer (VirTis, Genesis Series, NY, USA) at a pressure of 250 to 50 mm Hg in the chamber and a condensing temperature of −80 °C. The plate temperature was set from −15 to 60 °C and then to +15 °C for 24 h. The semi freeze-dried fish protein was removed from the freeze-dryer machine after 24 h of operation. The fish protein was comminuted using a silent cutter (Kilia bowl cutter, 201100EX, Neumunster, Germany) for 1 min. The comminuted fish protein with less than 0.3 cm particle sizes was reloaded to the lyophilizer and dried further using the same aforementioned programme. Dried fish protein was milled using a silent cutter (Kilia bowl cutter, 201100EX, Neumunster, Germany) for 1 min and sieved using US standard test sieve with 250 μm screen mesh (Gardner Co. Inc, Pompano Beach, FL, USA). The resulting powder was vacuum packaged and stored at −24 °C until sending it to Iran where the FCM was developed.

Other ingredients

Other ingredients “i.e.” extruded soy protein granules, whole potato powder, toasted bread powder, toasted chickpea powder, soy protein isolate, garlic powder, curry powder, salt and dried parsley were obtained from a local market (Esfahan, Iran).

Developing FCM prototypes

The FCM was developed using a national standard method for processing vegetable cutlet mixes (ISIRI 2003) as a base together with technical information given by the R&D group of Zardaneh Soy Protein Products Company (Esfahan, Iran). The effects of different levels of key ingredients “i.e.” the FPP, textured soy protein, and whole potato powder on the characteristics of the new product were initially studied. Then 4 prototypes of the FCM were formulated at the Zardaneh Soy Protein Products Company (Esfahan, Iran) with the ingredients listed in Table 1. The FPP and other ingredients were weighed separately using a digital scale (PCE-BSH 6000 series laboratory balances PCE Group, Durham, UK) and mixed gently in a ribbon blender (SHADMEHR®) for 3 min. The FCM was packed using automatic weighing packing machine (SHADMEHR® Packing Industries, Tehran, Iran) in polyethylene bags (100 g). The FCM bags were put manually into cardboard boxes to protect them during handling and against ambient conditions. The products were stored at ambient temperature (27 ± 2 °C) until performing consumer survey, physical, chemical and microbiological analysis.

Table 1.

Ingredients of 4 fish cutlet mix prototypes (%)

| Ingredients | Fish cutlet mix prototypes | |||

|---|---|---|---|---|

| A | B | C | D | |

| Fish protein powder | 25 | 25 | 25 | 30 |

| Textured soy protein | 25 | 20 | 30 | 25 |

| Whole potato flake | 25 | 30 | 20 | 20 |

| Toasted bread powder | 10 | 8 | 8 | 8 |

| Toasted chickpea flour | 6 | 5 | 3.5 | 3 |

| Garlic powder | 4 | 4 | 4 | 4 |

| Curry powder | 4 | 4 | 4 | 4 |

| Salt | 1 | 3 | 3.5 | 3.5 |

| Dried parsley | 0 | 0.5 | 1 | 0.5 |

| Soy protein isolate | 0 | 0.5 | 1 | 2 |

| Total | 100 | 100 | 100 | 100 |

Evaluation and selection of FCM

Six in-house experts in food processing were used for evaluating the sensory quality of the FCM products. The specification of a vegetable cutlet mix (ISIRI 2003) was used as a basis for the sensory evaluation of the products. The prototype selection was based on the highest scores of sensory liking (odour, flavour, cohesiveness, juiciness and overall acceptability) and comments about the products. A 9-point hedonic scale ranging from 1 (extremely dislike) to 9 (extremely like) was applied to determine the attributes. The experts were first asked to evaluate each product by checking cohesiveness, sniffing and then by tasting. They rinsed their mouths with water after tasting each product. Experts were also free to write their comments about the products.

Physicochemical analysis

The FCM prototype was subjected to physicochemical analysis in triplicate after 0, 2, 4, and 6 months of storage. The proximate composition was determined according to AOAC (1990) methods. Crude protein content was determined using the Kjeldahl method (Kjeltex System-Texator, Sweden). Crude lipid content was determined by the Soxhlet method (Soxtec System-Texator, Sweden). Ash content was determined by heating samples overnight at 550 °C. Moisture content was determined by drying samples 4 h at 105 °C until constant weight was achieved.

Thiobarbituric acid reactive substances (TBARS) were determined by a slightly modified steam distillation method (Tarladgis et al. 1960), where the sample size was reduced to 5 g and antioxidants (5 ml of 0.5% propyl gallate and 0.5% ethylene diamine tetra acetic acid in water) were added to the sample during blending. Malondialdehyd-bis-(diethyl acetate) was used as a standard.

Water activity (aw) was measured by using a Decagon Water Activity Meter (AquaLab Series 3, Decagon Devices, Inc. Pullman, WA, USA). About 2 g of sample was put into the instrument and aw was measured automatically after starting the program. The density was determined by placing the sample in a pre-weighed 10 ml graduated cylinder up to 10 ml mark with gentle tapping. The weight of the powder was noted to the density percentage as g powder per ml volume (Musa et al. 2005). The pH was determined in duplicate for each sample. Five g of FCM was mixed with 20 ml of deionised water and stirring for 5 min prior to measuring with an Ag/AgCl combination electrode connected to a pH meter, model PHM80 (Radiometer, Copenhagen, Denmark).

Colour was measured by placing FCM in a test tube (25 mm in diameter) which was read in a Minolta CR-400 Chroma Meter (Minolta Camera Co. LTD. Osaka, Japan) in Lab* measuring mode with CIE Illuminant C. The colour was measured 3 times turning the test tube 120˚ between measurements. Results were given as lightness (L*), redness (a*) and yellowness (b*).

Microbial analysis

The FCM prototype was subjected to microbiological analysis in triplicate after 0, 2, 4, and 6 months of storage. Total plate count, coliforms, E-coli, salmonella spp. moulds, yeasts and Bacillus cereus were measured in the products using national standard methods (ISIRI 2003) for vegetable cutlet mix.

Consumer survey

The consumer survey was based on the home use test (HUT) method. It involved the use of a questionnaire for acceptance test with consumers and for investigating their attitudes toward the FCM and convenience/RTE foods. The questionnaire consisted of 2 parts. It the first part subjects were asked to indicate their overall liking; dislike extremely (1), like extremely (9), after preparing and tasting fried FCM at home and to express their willingness; fully disagree (1), fully agree (7), to buy this product if it was available on the market. The other part of the questionnaire included questions about age, gender, education, household size, consumption frequency of fish and fish/meat/chicken products; less than once a week or less (1), once a week (2) and twice a week or more (3). Also on the importance of healthy diet to them and their families, the importance of knowing nutritional quality/list of ingredients of RTE products before purchasing, the importance of taste of food in comparison to nutritional quality; how healthy or unhealthy they considered fish, meat, chicken and their products, soy protein products and muscle food with high fat content. There were also questions on the importance of ease of preparation, taste of foods, healthiness of products, feasibility of keeping products at ambient temperature, the price of healthy food and package design. The consumers were asked to indicate their opinions of the questions and statements by checking one option from fully disagree (1), to fully agree (7) or from very unhealthy (1), to very healthy (7) or from not important at all (1), to very important (7).

Consumers selected in a shopping mall in Esfahan (Iran) were asked if they would like to take part in a consumer survey. Altogether 100 samples were prepared. The product in packaged form (100 g) along with the instruction for reconstitution and cooking, 2 questionnaires and a ready to post envelope for sending the filled questionnaires were offered to the consumers. They were informed to add 200 ml water to a FCM package and mix it for 5 min, and then fry the mixture after manual forming. Each package was enough to be evaluated by at least 2 consumers.

Statistical analysis

The experiments were carried out in triplicate and the statistical program NCSS 2000 (NCSS, UT, USA) was used for the statistical analysis. The results were given as a mean ± standard deviation (SD). The program was used to calculate multiple comparisons using Duncan’s test to determine if prototypes were different. Student’s t-test was used to determine if there was a difference between characteristics of FPP and fish cutlet mix prototype. General Linear Models (GLM) was used to observe any interaction between liking scores and other variable factors. All differences were considered statistically significant when p < 0.05.

Results and discussion

Selection of FCM prototype for consumer survey and storage stability studies

Means of hedonic ratings for sensory attributes and overall acceptability of the 4 different prototypes of FCM is shown in Table 2. Prototypes A and B had significantly lower liking scores for flavour, cohesiveness, juiciness, and overall acceptability than the other 2 prototypes. Prototype C had significantly lower liking scores in flavour, juiciness and overall acceptability than prototype D. Therefore, prototype D was selected by experts for the consumer survey and storage stability study.

Table 2.

Means scores of sensory attributes for fried fish cutlet mix given by 6 in house experts

| Attributes | Fish cutlet mix prototypes | ||||

|---|---|---|---|---|---|

| A | B | C | D | ||

| Odour | NS | 6.8 ± 0.92 | 7.1 ± 0.82 | 7.6 ± 0.67 | 7.5 ± 0.78 |

| Flavour | *** | 6.1 ± 1.25c | 7.0 ± 0.84b | 7.5 ± 0.89b | 8.6 ± 0.55a |

| Cohesiveness | *** | 2.9 ± 1.23c | 5.3 ± 1.45b | 7.4 ± 0.93a | 8.4 ± 0.67a |

| Juiciness | ** | 4.3 ± 1.24d | 5.4 ± 0.67c | 6.1 ± 0.78b | 7.6 ± 0.93a |

| Overall acceptance | * | 4.5 ± 1.43d | 5.4 ± 1.14c | 7.3 ± 0.89b | 8.3 ± 0.54a |

Scale of (1) dislike extremely, (9) like extremely. NS = Not significant.

Different small letters show significant difference within a row (* p < 0.05, ** p < 0.01, ***p < 0.001).

Physicochemical analysis

There were no differences in pH and aw between the FPP and selected FCM prototype (D) as shown in Table 3. The density and proximate composition of both products varied significantly due to different ingredients with different specifications for developing FCM. High carbohydrate content in FPP was due to the use of additives before drying leached mince to protect proteins. Protein, fat, ash and carbohydrate content of the FCM were 40.8, 2.3, 8.1 and 39.6% respectively. Moisture content and water activity of the FCM were 5.3% and 0.32 at 22 °C respectively (Table 3).

Table 3.

Proximate composition (%) pH, water activity (aw) and density (g/ml) of FPP and FCM products

| Product | Moisture | Protein | Fat | Ash | Salt | Carbohydrate | pH | aw | Density |

|---|---|---|---|---|---|---|---|---|---|

| FPP | 2.1 ± 0.35b | 70.3 ± 0.33a | 0.9 ± 0.01b | 3.3 ± 0.32b | 2.1 ± 0.19b | 21.4 ± 0.28b | 7.0 ± 0.08 | 0.29 ± 0.003 | 2.4 ± 0.09b |

| FCM | 5.3 ± 0.24a | 40.8 ± 0.16b | 2.3 ± 0.11a | 8.1 ± 0.18a | 3.9 ± 0.27a | 39.6 ± 0.39a | 6.5 ± 0.09 | 0.32 ± 0.002 | 5.2 ± 0.07a |

FPP: fish protein powder, FCM: fish cutlet mix; Values are means of 3 analyses. Different small letters show significant difference within a column (p < 0.05).

There were significant differences in lightness (L*), redness (a*), and yellowness (b*) of FPP and FCM due to different ingredients (Table 4). There were also significant differences between FCM powder and FCM blended with water. Adding water to FCM decreased lightness, but increased redness and yellowness because of dissolving ingredients containing colorants (curry) into the water and dispersing them to the FCM paste. This colour change is important to attract consumers before they test a product (Francis 1991) and it can be adjusted by using different spices/colorants.

Table 4.

Colour characteristics of FPP and FCM (powder and paste)

| Samples | Lightness (L*) | Redness (a*) | Yellowness (b*) |

|---|---|---|---|

| FPP | 48.3 ± 1.23a | −1.4 ± 0.18a | 2.6 ± 0.25c |

| FCM powder | 36.8 ± 1.56b | −2.2 ± 0.34b | 12.7 ± 0.56b |

| FCM paste1 | 24.4 ± 1.43c | −1.5 ± 0.25a | 14.5 ± 0.67a |

FPP: fish protein powder, FCM: fish cutlet mix;1Mixture of FCM and water (1:1).

Values are means of 3 analyses. Different small letters show significant difference within a column (p < 0.05).

There were no significant changes in the pH and TBARS values during the 6 months storage period (Table 5). Low TBARS values (2.2–2.6 μmol/kg) indicate the stability of the FCM against oxidation probably due to low water activity of the product (Belitz et al 2009). The aw value of freshly prepared FCM was 0.32 which gradually increased to 0.35 during 6 months storage probably due to increase of moisture content after packaging and during storing but the change was not significant (Table 5). Similar results were reported by Bello and Piggot (1980) for dried fish patties.

Table 5.

Physicochemical characteristics for fish cutlet mix during 6 months storage at 27 ± 2 °C

| Characteristics | M0 | M2 | M4 | M6 |

|---|---|---|---|---|

| TBARS (μmol/kg) | 2.2 ± 0.24 | 2.3 ± 0.15 | 2.3 ± 0.14 | 2.5 ± 0.17 |

| pH | 6.5 ± 0.08 | 6.4 ± 0.06 | 6.5 ± 0.06 | 6.5 ± 0.09 |

| Moisture (%) | 5.3 ± 0.35 | 5.5 ± 0.23 | 5.6 ± 0.14 | 5.7 ± 0.23 |

| Water activity (aw) | 0.32 ± 0.002 | 0.33 ± 0.001 | 0.34 ± 0.002 | 0.35 ± 0.003 |

| L* (lightness) | 24.4 ± 1.14 | 24.8 ± 0.92 | 25.2 ± 1.12 | 25.5 ± 1.15 |

| a* (redness) | −1.5 ± 0.34 | −1.5 ± 0.24 | −1.42 ± 0.15 | −1.4 ± 0.21 |

| b*(yellowness) | 14.5 ± 0.67 | 14.5 ± 0.51 | 14.5 ± 0.56 | 14.6 ± 0.43 |

Values within a row are means of 3 analyses and are equals (p > 0.05). M0 to M6 indicate storage months.

Colour measurements of FCM during 6 months storage revealed that lightness, yellowness and redness values increased slowly but not significantly (Table 5). It has been reported that the interaction of ingredients (Osuna-Garcia et al. 1997) and packaging conditions (Alvarez and Binder 1984) can influence the colour of dried products. However, colour changes during storage also depend on the degree of product exposure to light (Kim et al. 2002). In this study colour changes were not significant even after 6 months of storage at 27 ± 2 °C possibly due to low water activity, proper selection of ingredients and packaging materials.

Microbial analysis

Neither E.coli nor salmonella were detected in the FCM. No significant differences were observed in microbial quality of the product during 6 months storage. The total plate count was less than 6 × 103 cfu/g within the 6 months storage period. Coliforms, mould, yeast, and B. cereus counts remained below 10 cfu/g throughout the study indicating that the product was microbiologically safe and stable (Jay 1992). High microbial counts in dehydrated products can be due to the concentration of organism on a per g basis along with product concentration (Fanelli et al. 1965). The absence of E. coli and salmonella spp. and low counts of coliforms, mould, yeast, and B. cereous indicates sanitation quality of used water, proper handling, processing and packaging of FPP and blending of ingredients for developing FCM and confirms Good Hygiene Practices (GHP) in production areas (WHO/FAO 2001; Fewtrell et al. 2007). The results indicate that FCM is microbiologically safe when packed in polyethylene bags and stored at 27 ± 2 °C for 6 months. Similar findings have been reported for chicken kebab mix (Bello and Piggot 1980) and for dried fish patties (Modi et al. 2007).

Consumers’ acceptance

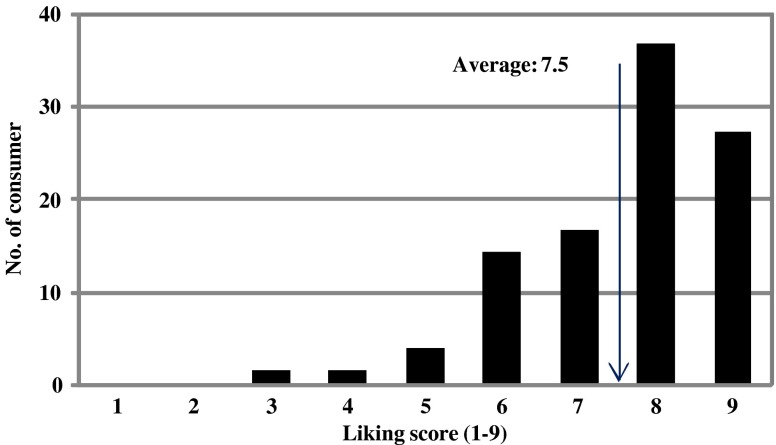

The number of survey participants who completed the questionnaires was 85, 54 females and 31 males. Total average liking was 7.5 ± 1.3 (Fig. 1). The survey revealed that the majority of the consumers (94%) favoured the FCM, but only few consumers disliked the product. Total average liking indicates the degree of dislike to liking and gives good information about the effect statues of a food prototype (Meilgaard et al. 2007). It shows how well a prototype is liked by target consumers and can be used as a decision making tool in food product development (Kristbergsson 2001). However there is no value for total average liking to indicate a success of a product. Using liking data for further product development therefore depends on type of product and company’s strategy.

Fig. 1.

Liking scores mean and histogram for fried reconstituted fish cutlet prepared from fish cutlet mix given by 85 subjects (21–50 years old) in a consumer survey in Esfahan (Iran) using home use test (HUT) method. 1 = extremely dislike, 5 = neither dislike nor like, 9 = extremely like

Liking was significantly affected by frequency of fish and chicken consumptions. Consumers who consumed fish once a week or chicken twice a week or more liked the product more than those consuming fish both more and less that once a week or consuming chicken once a week or less (Table 6). Liking was also significantly affected by household size i.e. the bigger household size the higher liking scores. The liking was influenced by educational level of participants; the higher the educational level the higher liking scores (Table 6) possibly due to their awareness about healthiness of fish/fishery products. This is in agreement with information reported for Iranian (Shilat 2007) and European consumers (Myrland et al. 2000). Consumers with low chicken and meat consumption liked the product more than those with high consumption.

Table 6.

Influence of consumers’ age, household size, gender, education and frequency fish/meat/chicken consumption on liking fish cutlet mix

| Consumer’s age (Years old) | 20–30 (n = 29) | 31–40 (n = 44) | 41–50 (n = 12) | |

|---|---|---|---|---|

| Liking scores | NS | 7.4 ± 1.47 | 7.5 ± 1.01 | 7.0 ± 1.04 |

| Households size | 1–2 (n = 37) | ≥ 3 (n = 48) | ||

| Liking scores | * | 7.2 ± 1.06b | 7.7 ± 1.25 a | |

| Gender | Men (n = 31) | Women (n = 54) | ||

| Liking scores | NS | 7.4 ± 1.28 | 7.5 ± 1.16 | |

| Education | Associate’s degree or less (n = 41) | Bachelor degree or higher (n = 44) | ||

| Liking scores | * | 7.2 ± 1.39 b | 7.7 ± 0.92 a | |

| Frequency fish consumption | Less than once a week (n = 25) | Once a week (n = 27) | Twice per week or more (n = 33) | |

| Liking scores | ** | 7.1 ± 1.42 b | 8.1 ± 0.87 a | 7.2 ± 1.08 b |

| Frequency meat consumption | Less than once a week (n = 17) | Once a week (n = 14) | Twice per week or more (n = 53) | |

| Liking scores | NS | 8.0 ± 0.74 | 7.4 ± 1.69 | 7.2 ± 1.12 |

| Frequency chicken consumption | Less than once a week (n = 7) | Once a week (n = 21) | Twice per week or more (n = 57) | |

| Liking scores | * | 8.0 ± 0.57a | 7.9 ± 1.33a | 7.2 ± 1.14b |

Different small letters show significant difference within a row (*p < 0.05, **p < 0.01). NS = Not significant

The consumers in this study said that healthy diet was very important to them and their families and that they wanted to know the nutritional quality of RTE products before purchase and would pay attention to the list of ingredients of RTE fishery products before buying them. They had positive attitudes towards the FCM. Most of them said they would buy it if the product was available on the market (Table 7).

Table 7.

Attitudes of consumers (n = 85) towards choosing FCM, importance of healthy diets, nutritional quality of RTE foods and list of ingredients

| Do you agree/disagree with the following statements? | Average scores (1–7)* | (1–3) Disagree (%) | (4) Neither agree nor disagree (%) | (5–7) Agree (%) |

|---|---|---|---|---|

| I would choose FCM if the product was available on the market: | 6.1 ± 1.01 | 9 | 10 | 81 |

| A healthy diet is very important to my family and me: | 6.3 ± 1.33 | 7 | 8 | 85 |

| I want to know the nutritional quality of RTE products before buying them: | 5.8 ± 1.42 | 12 | 5 | 83 |

| I never pay attention to the list of ingredients of RTE fish products before buying: | 2.4 ± 0.91 | 74 | 10 | 16 |

FCM: fish cutlet mix; RET: ready-to-eat; * (1) fully disagree, (7) fully agree.

Of the consumers in the study 93% and 70% agreed that fish and RTE fishery products were very healthy foods respectively while 81%, 77%, 62%, 59%, 33% and 30% agreed that chicken, food with soy protein, RTE chicken products, meat, RTE meat product and meat products with high fat content were very healthy respectively. Positive response of consumers to healthiness of fish, chicken and soy products show they were aware of the health benefits of these products (Table 8).

Table 8.

Attitudes of consumers (n = 85) towards healthiness/unhealthiness of fish, meat and chicken and related RTE products and soy protein products

| How healthy or unhealthy are the following food products? | Average scores (1–7)* | (1–3) Unhealthy (%) | (4) Neither healthy nor unhealthy (%) | (5–7) Healthy (%) |

|---|---|---|---|---|

| Fish: | 6.6 ± 1.03 | 0 | 7 | 93 |

| RTE fish products: | 5.4 ± 1.32 | 12 | 18 | 70 |

| Meat: | 5.0 ± 1.56 | 18 | 23 | 59 |

| RTE meat products: | 3.9 ± 1.50 | 36 | 31 | 33 |

| Chicken: | 5.5 ± 1.24 | 10 | 9 | 81 |

| RTE chicken products: | 4.7 ± 1.33 | 23 | 15 | 62 |

| Muscle foods with high fat content: | 3.0 ± 1.15 | 61 | 9 | 30 |

| Foods with soy protein: | 5.4 ± 1.67 | 16 | 7 | 77 |

RTE: ready-to-eat; *(1) very unhealthy, (7) very healthy.

Almost every consumer (98%) in the study agreed that healthiness and taste were the most important attributes of food products followed by price (92%), package design (85%), and ease of preparation (81%) and keeping it at ambient temperatures (77%) as shown in Table 9. These opinions are in support of developing new healthy and convenience fishery products that possibly could affect and change dietary habits of consumers. However it is taste, healthiness and price of RTE products that are the most important issues and food producers should consider them when developing new products. The results also support previous findings that incorporating fish protein to popular formulated foods such as; burgers, nuggets, sausages, snacks etc. could be welcomed by people (Shaviklo 2005a, b, 2007; Rafipour et al. 2008) and it seems developing convenience and RTE fishery products might be the best option to increase fish consumption in Iran or possibly in other countries with low consumption of fish.

Table 9.

Attitudes of consumers (n = 85) towards importance of easy preparation of the product, tastes, healthiness, storage conditions of the product, price and food packaging design

| How important are the following? | Average scores (1–7)* | (1–3) Not important (%) | (4) Neither important nor unimportant (%) | (5–7) Important (%) |

|---|---|---|---|---|

| That the product is easy to prepare: | 5.7 ± 1.31 | 8 | 11 | 81 |

| That the product tastes good: | 6.5 ± 1.40 | 0 | 2 | 98 |

| That the product is healthy: | 6.7 ± 1.23 | 0 | 2 | 98 |

| That it is possible to keep the product in ambient temperature: | 5.5 ± 1.56 | 12 | 11 | 77 |

| The price of a healthy RTE product: | 6.0 ± 1.25 | 2 | 6 | 92 |

| Packaging design: | 5.8 ± 1.42 | 3 | 12 | 85 |

RTE: ready-to-eat; * (1) not important at all, (7) very important.

Conclusion

The dry cutlet mix packed in a polyethylene bag and a cardboard box was quite stable at ambient temperature during 6 months of storage. This was confirmed by the physical, chemical and microbial analysis in the study. The ready-to-reconstitute FCM with 30% FPP was accepted by the consumers in this study. It was more successful with consumers eating fish once a week than other consumers, also with consumers with high chicken consumption, bigger household size and higher educational level. This was in agreement with consumers attitudes towards healthy foods and that fish and fish products are healthier that other muscle or protein based food products but it must be kept in mind that taste and price are also among the most important attributes when choosing or buying food products. Package design, ease of preparation and storage at ambient temperatures were also important. The number of consumers (n = 85) limits how much can be concluded from this study and the results must be regarded as indications of their attitudes.

The results are important and positive for companies planning to develop RTE product fortified with fish proteins. The fish protein powder would be produced by upgrading by-products or underutilized/low value species and the products could be means of increasing fish consumption in countries or areas where there is no tradition of consuming fresh or frozen fish.

Acknowledgments

The support of the United Nations University-Fisheries Training Programme, Matis (Icelandic Food and Biotech R&D), Rannis (Icelandic Centre for Research) and Zardaneh (Soy Protein Company, Esfahan, Iran) to this study is gratefully acknowledged. The authors would like to thank Adalheidur Olafsdottir at Matis for her advice on the consumer survey and Hoshang Bahrami and R&D group at Zardaneh Co. for their cooperation in the product development.

References

- Abeysinghe CP, Illeperuma CK. Formulation of an MSG (Monosodium Glutamate) free Instant vegetable soup mix. J Natn Sci Foundation Sri Lanka. 2006;34(2):91–95. [Google Scholar]

- Altschul AM. Low-calorie foods. Food Technol. 1989;43(4):113–125. [Google Scholar]

- Alvarez RJ, Binder JM. Protection of spice quality using clear plastic packaging. Dairy Food Sanitation J. 1984;4:464–465. [Google Scholar]

- Official Methods of Analysis. 15. Washington DC: Association of Official Analytical Chemists; 1990. [Google Scholar]

- Bakar J (2007) Processing formulated fish and fish products. In: Handbook of Food Product Manufacturing, Hui YH (ed) Wiley & Sons, Inc, p 915–930

- Ballester D, Barja I, Yanez E, Donoso G. Protein-rich mixtures for human consumption based on fish flour, sunflower press cake meal, dried skim milk and wheat flour. Brit J Nutr. 1968;22:255–259. doi: 10.1079/BJN19680031. [DOI] [PubMed] [Google Scholar]

- Belitz HD, Grosch W, Schieberle P. Food Chemistry. 4. Berlin, Germany: Springer-Verlag Press; 2009. pp. 211–218. [Google Scholar]

- Bello RA, Piggot GM. A new approach to utilize minced fish flesh in dried products. J Food Sci. 1979;2:355–362. doi: 10.1111/j.1365-2621.1979.tb03788.x. [DOI] [Google Scholar]

- Bello RA, Piggot GM. Dried fish patties: storage stability and economic considerations. J Food Process Pres. 1980;4:247–260. doi: 10.1111/j.1745-4549.1980.tb00610.x. [DOI] [Google Scholar]

- Carvajal PA, Lanier TC, Macdonald GA. Stabilization of proteins in surimi. In: Park JW, editor. Surimi and Surimi Seafood. 2. London: Francis and Taylor Group; 2005. pp. 163–225. [Google Scholar]

- Chavan BR, Basu S, Kovale SR. Development of edible texturised dried fish granules from low-value fish croaker (Otolithus argenteus) and its storage characteristics. CMU J Nat Sci. 2008;1:173–182. [Google Scholar]

- Chung YC, Ho ML, Chyan FL, Jiang ST. Utilization of freeze-dried mackerel (Scomber australasicus) muscle proteins as a binder in restructured meat. Fisheries Sci. 2000;66:130–135. doi: 10.1046/j.1444-2906.2000.00019.x. [DOI] [Google Scholar]

- Euromonitor (2010) Ready Meals in Iran. Euromonitor International. November 2010, p 50

- Fanelli MJ, Peterson AC, Gunderson MF. Microbiology of dehydrated soups. I. A survey. Food Technol. 1965;19(5):83–86. [Google Scholar]

- FAO (2009a) Fishery and Aquaculture Country Profiles Iran. Food and Agriculture Organization of the United Nations. Available at: http://www.fao.org/fishery/countrysector/FI-CP_IR/en. [Accessed 20 March 2010].

- FAO (2009b) National Aquaculture Sector Overview Iran. Food and Agriculture Organization of the United Nations. Available at: http://www.fao.org/fishery/countrysector/naso_iran/en. [Accessed 20 March 2010].

- Fewtrell L, Prüss-Üstün A, Bos R, Gore F, Bartram J (2007) Water, sanitation and hygiene; quantifying the health impacts at national and local level in countries with incomplete water supply and sanitation coverage. Geneva, World Health Organization. Environmental Burden of Disease Series No. 15. Available at: http://www.who.int/quantifying_ehimpacts/publications/en/, p 12–50. [Accessed 20 March 2010].

- Francis FJ (1991) Colour measurements and interpretation. In: Instrumental Methods of Quality Assurance in Foods, Fung D, Matthews RF(eds), Marcel Dekker, New York, p 189–209

- Gill T (1995) Biochemical and chemical methods for assessment of fish quality. In: Quality and Quality Changes in Fresh Fish, Huss HH (ed), FAO Fisheries Technical Paper nr. 348. Rome, Italy, p 139–150

- Gogoi BK, Oswalt AJ, Choudhury GS. Reverse screw elements and feed composition effects during twin-screw extrusion of rice flour and fish muscle blends. J Food Sci. 1996;3:590–595. doi: 10.1111/j.1365-2621.1996.tb13165.x. [DOI] [Google Scholar]

- Haard NF. Composition and nutritive value of fish proteins and other nitrogen compounds. In: Ruiter A, editor. Fish and Fishery Products: Composition, Nutritive Properties and Stability. Guilford, UK: Biddles Ltd; 1995. pp. 77–115. [Google Scholar]

- Huda N, Abdullah A, Babji AS (2000) Physicochemical and sensory characteristics of crackers formulated with surimi powder. In: International Seminar on the Role of Chemistry in Industry and Environment, pp 1–5 Padand, West Sumatra, Indonesia, 30–31 Aug

- Huda N, Abdullah A, Babji AS (2001) Substitution of tapioca flour with surimi powder in traditional crackers. In: 16th Scientific Conference Nutrition Society of Malaysia, Kuala Lumpur, Malaysia, 24–25 March

- ISIRI (2003) Vegetable protein and its product, cutlet powder; specifications and test methods. Institute of Standards and Industrial Research of Iran, ISIRI nr. 6935

- Jay JM. Modern Food Microbiology. 4. New York, USA: Chapman & Hall; 1992. pp. 356–370. [Google Scholar]

- Kim S, Park JB, Hwang IK. Quality attributes of various varieties of Korean red pepper powder (Capsicum annum L.) and colour stability during sunlight exposure. J Food Sci. 2002;67:2957–2961. doi: 10.1111/j.1365-2621.2002.tb08845.x. [DOI] [Google Scholar]

- Kristbergsson K (2001) From ideas to products concepts and prototype. In: Food Innovation Management; from Idea to Success, Treillon R (ed), Food Net, ENSIA, Massy, p 72–82

- Meilgaard M, Civille GV, Carr BT. Sensory Evaluation Techniques. 4. New York: CRC Press; 2007. pp. 56–87. [Google Scholar]

- Min TS, Cheng NM, Fujiwara T, Kuang HK, Hasegawa H. Handbook on the Processing of Frozen Surimi and Fish Jelly Products in Southeast Asia. Singapore: Marine Fisheries Research Development, MFRD; 1987. pp. 10–18. [Google Scholar]

- Modi VK, Sachindra NM, Nagegowda P, Mahendrakar NS, Rao DN. Quality changes during the storage of dehydrated chicken kebab mix. Int J Food Sci Tech. 2007;42:827–835. doi: 10.1111/j.1365-2621.2007.01291.x. [DOI] [Google Scholar]

- Musa KH, Aminah A, Wan-Aida WM. Functional properties of surimi related to drying methods. Malays Appl Biol. 2005;2:83–87. [Google Scholar]

- Myrland O, Trondsen T, Johnston RS, Lund E. Determinants of seafood consumption in Norway: lifestyle, revealed preferences, and barriers to consumption. Food Qual Prefer. 2000;11:169–188. doi: 10.1016/S0950-3293(99)00034-8. [DOI] [Google Scholar]

- Niki H, Igarashi S. Some factors in the production of active fish protein powder. Bull Japan Soc Sci Fish. 1982;8:1133–1137. doi: 10.2331/suisan.48.1133. [DOI] [Google Scholar]

- Niki H, Deya E, Kato T, Igarashi S. The process of producing active fish protein powder. Bull Japan Soc Sci Fish. 1982;7:999–1004. doi: 10.2331/suisan.48.999. [DOI] [Google Scholar]

- Niki H, Kato T, Deya E, Igarashi S. Water holding capacity, emulsifying capacity and storage ability of active fish protein powder. Bull Japan Soc Sci Fish. 1983;1:91–96. doi: 10.2331/suisan.49.91. [DOI] [Google Scholar]

- Osuna-Garcia JA, Wall MM, Waddell CA. Natural antioxidants for preventing colour loss in stored paprika. J Food Sci. 1997;62:1017–1021. doi: 10.1111/j.1365-2621.1997.tb15027.x. [DOI] [Google Scholar]

- Park JW, Lin JTM (2005) Surimi: Manufacturing and evaluation. In: Surimi and Surimi Seafood, 2nd edn, Park JW (ed), Taylor and Francis Group. London, p 33–106

- Rafipour F, Jalili H, Arshad R, Hoseini H, Shaviklo GR, Hosein-Abadi M (2008) Development and evaluation of fish balls made from silver carp (Hypophthal molitrix) mince with and without starch. Iranian Fisheries Research Organization. Project Report nr. 03-8401-84002, Tehran, Iran

- Ramirez JA, Diaz-Sobac R, Morales OG, Vazquez M. Evaluation of freeze-dried surimi from tilapia and fat sleeper as emulsifiers. CyTA J Food. 1999;4:210–214. [Google Scholar]

- Ruhil P, Singh RRB, Jain DK, Patel AA, Patil GR. A comparative study of kinetic and connectionist modelling for shelf-life prediction of Basundi mix. J Food Sci Technol. 2010;48(2):204–210. doi: 10.1007/s13197-010-0158-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sathivel S, Bechtel PJ, Babbitt JK, Prinyawiwatkul W, Patterson M. Functional, nutritional and rheological properties of protein powders from arrow tooth flounder and their application in mayonnaise. J Food Sci. 2005;2:57–63. [Google Scholar]

- Sathivel S, Bechtel PJ, Prinyawiwatkul W. Physicochemical and rheological properties of salmon protein powders. Int J Food Eng. 2006;2:3–9. [Google Scholar]

- Senthil A, Mamatha BS, Vishwanath P, Bhat KK, Ravishankar GA (2010) Studies on development and storage stability of instant spice adjunct mix from seaweed (Eucheuma). J Food Sci Technol. doi:10.1007/s13197-010-0165-3 [DOI] [PMC free article] [PubMed]

- Shaviklo GR. Manual on surimi and surimi-based products; using local fish species. Tehran, Iran: Naghsh-e Mehr publication; 2000. pp. 24–56. [Google Scholar]

- Shaviklo GR. Production of shrimp burger in Iran. INFOFISH Int Mag. 2005;2:31–34. [Google Scholar]

- Shaviklo GR. Surimi products gain popularity in Iran. INFOFISH Int Mag. 2005;5:35–40. [Google Scholar]

- Shaviklo GR. Quality improvement of farmed fish in Iranian markets. Aquaculture Asia. 2006;3:30–32. [Google Scholar]

- Shaviklo GR. Fish sausage from silver carp surimi. INFOFISH Int Mag. 2007;1:34–38. [Google Scholar]

- Shaviklo GR, Thorkelsson G, Kristinsson HG, Arason S, Sveinsdottir K. The influence of additives and drying methods on quality attributes of fish protein powder made from saithe (Pollachius virens) J Sci Food Agric. 2010;90:2133–2143. doi: 10.1002/jsfa.4062. [DOI] [PubMed] [Google Scholar]

- Shaviklo GR, Olafsdottir A, Sveinsdottir K, Thorkelsson G, Rafipour F (2010b) Quality characteristics and consumer acceptance of a high fish protein puffed corn-fish snack. J Food Sci Technol. doi:10.1007/s13197-010-0191-1 [DOI] [PMC free article] [PubMed]

- Shaviklo GR, Thorkelsson G, Sigurgisladottir S, Rafipour F (2010c) Quality changes during storage of extruded puffed corn snacks incorporated with freeze dried saithe (Pollachius virens) protein and stabilized minces from rainbow trout (Oncorhynchus mykiss) and silver carp (Hypophthalmichthys molitrix). J Sci Food Agric doi:10.1002/jsfa.4261

- Shaviklo GR, Thorkelsson G, Arason S, Sveinsdottir K (2011a) Characteristics of freeze-dried fish protein isolated from saithe (Pollachius virens). J Food Sci Technol. doi:10.1007/s13197-011-0285-4 [DOI] [PMC free article] [PubMed]

- Shaviklo GR, Thorkelsson G, Sveinsdottir K, Rafipour F (2011b) Chemical properties and sensory quality of ice cream fortified with fish protein. J Sci Food Agric. doi:10.1002/jsfa.4299 [DOI] [PubMed]

- Shilat . Fish consumer’s sociology. Tehran, Iran: Research and Planning Division of Iran Fisheries Organization; 2005. [Google Scholar]

- Shilat . An investigation on fish consumption behaviour of consumers in Tehran. Tehran, Iran: Research and Planning Division of Iran Fisheries Organization; 2007. [Google Scholar]

- Shilat . Iran Fisheries Statistics. Tehran. Iran: Research and Planning Division of Iran Fisheries Organization; 2008. [Google Scholar]

- Tarladgis BG, Watts BM, Younathan MT. A distillation method for the quantitative determination of malonaldehyde in rancid foods. JAOCS. 1960;37:44–48. doi: 10.1007/BF02630824. [DOI] [Google Scholar]

- Thorner ME. Convenience and Fast Food Handbook. Connecticut, USA: AVI Publishing Co. Westport; 1973. pp. 229–245. [Google Scholar]

- Tomoszek D. What is a ready meal? In: Menlove A, editor. Ready Meal Technology. Surrey, England: Leatherhead Publishing; 2002. pp. 1–12. [Google Scholar]

- Recommended international code of practice general principles of food hygiene. Food and Agriculture Organization of the United Nations and World Health Organization. Rome: Joint FAO/WHO Food Standards Programme, FAO; 2001. [Google Scholar]

- Yerlikaya P, Gokoglu N, Uran H. Quality changes of fish patties produced from anchovy during refrigerated storage. Eur Food Res Technol. 2005;220:287–291. doi: 10.1007/s00217-004-1035-x. [DOI] [Google Scholar]