Abstract

Five hot pepper varieties were grown at Haramaya University Research Farm, Dire Dawa, Ethiopia. The experiment was undertaken using completely randomized block design (RCBD) with three replications. Green peppers were stored under ambient and evaporatively cooled conditions. Significant (P ≤ 0.05) differences were observed among cultivars and storage conditions in changes in quality of pepper. Storage at ambient conditions resulted in high weight loss and rapid deterioration in chemical composition. The highest and lowest moisture contents were recorded in Melka Eshet and PBC 600, respectively. Evaporative cooler reduced weight loss and maintained higher levels of pH, ascorbic acid and marketability. The highest weight loss was recorded in Melka Dima stored at ambient condition. The lowest weight loss and highest ascorbic acid content was obtained in Mareko Fana stored in evaporative cooler. After 16 days of storage, all pepper fruits stored at ambient condition were unmarketable while those stored in evaporative cooler were kept up to 28 days. The highest pungency level was observed in ambient storage environment than in evaporative cooler. Evaporative cooling was shown to improve shelf life by four-fold compared to the ambient condition. The shelf life of pepper was improved in all varieties tested while the quality characteristics were maintained better in Mareko Fana than in the other varieties when harvested at mature-green stage and stored under evaporatively cooled storage.

Keywords: Green pepper, Variety, Chemical quality, Evaporative cooling, Ethiopia

Introduction

Pepper (Capsicum spps.) is grown in many countries of the world and its production for culinary and vegetable uses has been increased from time to time. In Ethiopia today, it is extensively produced and used. It is actually considered as a national spice. Even though no documented information is available, it was introduced to Ethiopia probably by the Portuguese in the 17 century (Hafnagel 1961). As a food, pepper has little energy value (25 Kcal 100 g−1) but it is an excellent source of vitamins A (530 IU 100 g−1) and C (128 mg 100 g−1) and a good source of vitamin B2 (0.05 mg 100 g−1), potassium (195 mg 100 g−1), phosphorus (22 mg 100 g−1), and calcium (6 mg 100 g−1) (Bosland and Votava 2000). The high nutritive and culinary value of pepper gives them a high demand in the market year round. Capsicum spps. are used fresh or dried, whole or ground into powder and alone or in combination with other flavoring agents. Pepper is used as one ingredient in production appetizers (Premavalli and Amrinder 2010). Cheul et al. (2010) reported that Capsaicin and tocopherol in red pepper seed oil enhances the thermal oxidative stability during frying indicating the importance of pepper in food industry. However, the thermal processing of pepper affects the physic-chemical qualities of the final product (Kolawole and Olaniyi 2010; Raji et al. 2010).

Fresh produce needs low temperature and high relative humidity (RH) during storage and transportation. Therefore, reducing the temperature and increasing the RH are primary means of maintaining product quality during storage and transportation. Reduced temperature decreases physiological, biochemical and microbiological activities, which are the causes for deterioration of quality attributes such as flavour, texture, colour, and nutritive value (Thompson et al. 1998; Wills et al. 1989; Seyoum and Woldetsadik 2001).

Temperature of the surrounding air and produce can be reduced by forced air cooling, hydro cooling, vacuum cooling, ice cooling and adiabatic cooling (Thompson et al. 1998). However, most of these cooling methods are unaffordable by the small-scale peasant farmers, retailers and wholesalers in Ethiopia, as they require high initial cost and power sources. In spite of that, however, it is essential to control storage temperature and RH during storage, as they are the main causes of deterioration during storage. Low temperature and high RH can be achieved using evaporative cooling (Seyoum and Woldetsadik 2001), which is a very economical and relatively efficient technique to store products than other mechanical refrigerators (Chakraverty et al. 2003).

In Ethiopia research on vegetables in general and chilli in particular has been aimed primarily at identification of new varieties for high yield and disease resistance as well as cultural practices for increasing yield. Hot pepper varieties have been developed and released by the Ethiopian Agricultural Research Institute but no information is available on the postharvest quality and shelf life of green fruits of the released varieties under different storage conditions. Hot paper is one of the most important food components in every traditional food in the country. However, keeping the freshness is one of the serious problems. Therefore, the main objective of this study was to look at the effect of storage environment on the shelf life improvement of pepper. The specific objectives of this study were to determine postharvest storage quality of different varieties of hot pepper and to compare shelf life of hot pepper varieties under evaporative cooling and ambient storage environment.

Materials and methods

Treatments and design of field experiment

Five varieties namely Mareko Fana, PBC 600, Melka Zala, Melka Dima and Melka Eshet. of hot pepper were used for this study. The first two were released in 1976 while the rest were released in 2004 by the Ethiopian Institute of Agricultural Research. The field experiment was executed at Dire Dawa of Haramaya University Farm under irrigation using Randomized Complete Block Design with three replications. Seeds of the pepper varieties were raised on nursery bed at Haramaya University main campus and transplanted to the field 55 days after emergence at a spacing of 60 cm between rows and 40 cm between plants. The plots comprised ten rows. The spacing between plots in each replication was 1 m while the spacing between adjacent replications was 2 m. All plots received recommended cultural practices uniformly including the control of insects and diseases.

Sample preparation

For the postharvest quality and shelf life studies, fruits harvesting was carried out at green mature stage when 50% of the plants attained fruits with green maturity stage. Fruits with bruises, sign of infection or those different from the group were discarded from the samples. Uniform, unblemished pepper fruits having similar size and color were then selected and hand washed with tap water to remove soil particles and to reduce microbial population on the surface. Then, the fruits were surface dried with soft cloth and subdivided and stored in evaporative cooler and at room temperature in three replications.

The storage experiment was done by combining five cultivars with two storage conditions (evaporatively cooled and ambient storage). The experiment was done in randomized complete block design with three replications. For each treatment, 3 kg pepper samples were taken randomly and kept under the two storage conditions using macro-perforated and open flexible polyethylene film on three shelves as replication. Sample from each treatment was taken to the horticulture laboratory of the Department of Plant Science at Haramaya University for chemical analysis, every 4-day, starting from the day of harvest. The data were recorded on 0, 4, 8, 12, 16, 20, 24 and 28 days after storage. Samples were stored in 80 °C freezer before analysis.

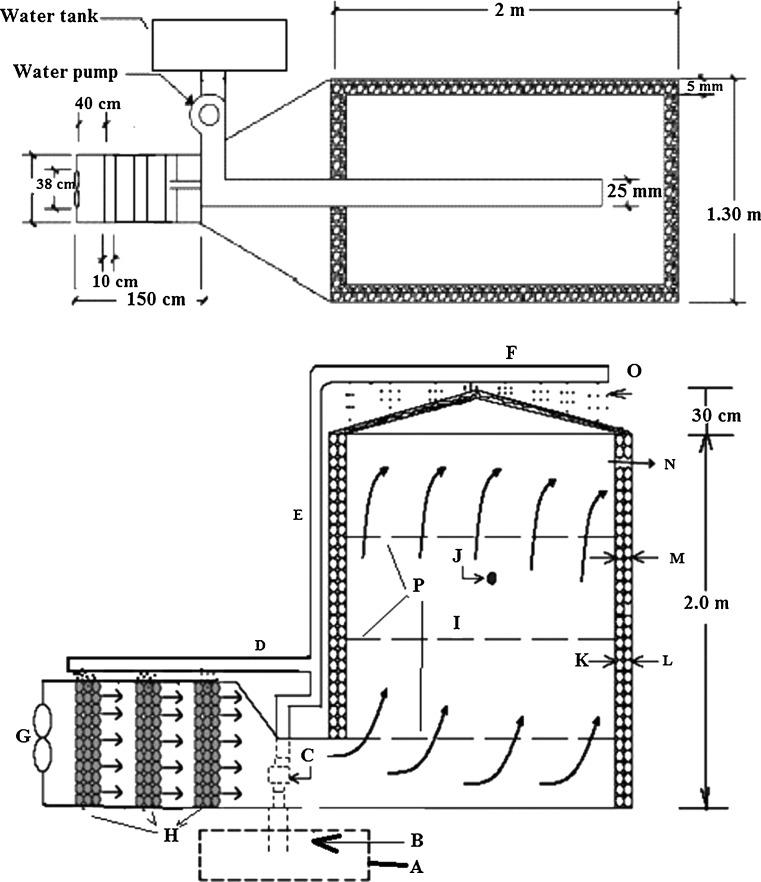

Evaporative cooler

A multi-layer, improved version of evaporative cooler developed by the Food Science and Postharvest Technology Department of Haramaya University (Getenit et al. 2008) was used as storage environment in this investigation (Fig. 1). The inner dimensions of the unit were 2 × 2 × 1.3 m, having a capacity for about 0.5 t fruit. The frame was constructed from 25 mm × 25 mm × 4 mm angel iron. The side and the top surface of the cooler are covered by sheet metal (1 mm thickness). The cooler consisted three major units; viz., an air conditioning unit, a watering system, and a storage chamber.

Fig. 1.

Schematic diagram of an experimental evaporative cooler: A water tank; B vertical pipe connected to water pump; C water pump (0.5 hp); D water hose to cooling pad; E vertical water pipe; F perforated horizontal water pipe; G fan; H cooling pad layers (charcoal); I storage chamber; J location of thermocouple and hygrometer; K sheet metal; L mesh wire; M wet jute sack layer; N ventilation port; O water dripping from horizontal and P shelves

The watering system is designed to continuously pump water to the top surface and wet the top surface and all sides of the cooling pad by a horizontal perforated pipe (B). Water that run down the surface of the pad by gravity is collected back into the holding tank. The water tank is placed beneath the water pump (M), and a vertical water pipe (D) withdraw water from the tank during operation, using small (0.186 KW) water tank (A). Hose is connected from a vertical pipe to sprinkle water continuously on the three cooling pads filled with charcoal (E) to increase the relative humidity while decreasing the temperature of the evaporative cooling chamber. A fan (F) derives air through the three layers of wet jute sack as an evaporative cooling pad.

The evaporative cooler consists of the psychometric unit (water and circulation systems) and the storage chamber. The main focus of this study was to develop psychometric unit that can be fitted to any fruits and vegetables storage room/chamber. The chamber is used as storage chamber during the experiments. In order to maintain the surface of the unit cool it has been covered and sprinkled with water. The psychometric unit is detachable and can be installed to any storage structure. In fact, any structure that can be made from local materials can be used as storage chamber.

Total soluble solids

Juice of pepper fruits was extracted from 10 g bulk sample of 3–4 fruits in a blender as described by Antoniali et al. (2007). The homogenized sample was filtered using funnel with filter paper in a beaker. The filtrate was taken for TSS determination. The TSS was determined by an Atago N1 hand refractometer with a range of 0 to 32 °Bx, and a resolution of 0.2 °Bx by placing 1 to 2 drops of clear juice on the prism. Between samples, the prism of the refractrometer was cleaned with tissue paper soaked in methanol, washed with distilled water and dried before use. The refractometer was standardized against distilled water (0 °Bx TSS).

Ascorbic acid

This was determined by titrating 3 g of blended pulp homogenized with 50 ml of oxalic acid at a concentration of 12%. The titration was done using 2,6-dichlorophenolindophenol method (Antoniali et al. 2007). Then ascorbic acid content (%) was calculated from the titration value, dye factor, dilution and volume of the sample and the result expressed in mg of ascorbic acid per 100 g of pulp.

Titratable acidity

Juice of pepper pod was extracted as described by Antoniali et al. (2007). An aliquot of pepper juice was extracted by weighing 10 g fruit samples and adding 90 ml of distilled water and then homogenizing it in a blender. The homogenized sample was filtered by using funnel with filter paper in a beaker. The titrable acidity (TA) of pepper measured follows the method described by (Antoniali et al. 2007) using NaOH (0.1 N) as a standardized titration solution. The titrable acidity was expressed in gram of malic acid per 100 g of sample.

pH values

Juice of pepper was extracted from 10 g fruit sample to which 90 ml distilled water was added and homogenized in a blender as described by Antoniali et al. (2007). The homogenized sample was filtered using funnel with filter paper in a beaker and the pH value of the filtrate was measured by a pH meter.

Pungency

Capsaicin was extracted from 1 g of powder to which 90 ml of 96% ethanol was added and boiled for 4 h as described in ISO 7543 (1993). Carbon black and 90 ml of 70% methanol solution were added in the extract and agitated on magnetic stirrer for 30 min. Then the extract was filtered by membrane filter paper. Blank acid solution was prepared by adding 3 ml of water and 2 ml of hydrochloric acid by diluting with methanol and blank alkali solution was prepared by adding 3 ml of water and 2 ml of hydroxide solutions diluting by methanol. The blank solution and the extract were measured by spectrophotometer absorbance at wave length of 248 nm.

Moisture content

This parameter was determined using 10 g sample from each treatment that was cut into pieces, dried in a forced air circulation oven at 70 °C to a constant weight as described by (Antoniali et al. 2007) and the results were expressed in percentage.

Physiological weight loss

Physiological weight loss (PWL) was determined following the method described by (Waskar et al. 1999). Stored fruits from each treatment were weighed at the start of the experiment and at 4 days interval for 4 weeks. The differential weight loss was calculated for each interval and converted into percentage by dividing the change with the initial weight recorded on each sampling interval.

Percentage marketable fruits

The marketable quality of the fruits was subjectively assessed according to (Mohammed et al.1999). On each sampling time, marketability of the fruits was judged by 22 trained panelists using a 1–9 rating with 1 = unusable, 3 = unsalable (poor), 5 = fair, 7 = good, 9 = excellent to evaluate the fruit quality. The size, color, firmness surface defects, sign of mould growth and shrinkage were used, as visual parameters for the rating. Fruits that received a rating of five and above were considered marketable while those rated less than five were considered unmarketable.

Statistical procedures

The data were subjected to the analysis of variance for randomized complete block design following the procedure by using SAS 6.12 version software (SAS Institute Inc., Cary, NC). Least Significant Difference (LSD) test was used to separate the means at 5%, 1% and 0.1% probability levels.

Results and discussion

Temperature and relative humidity

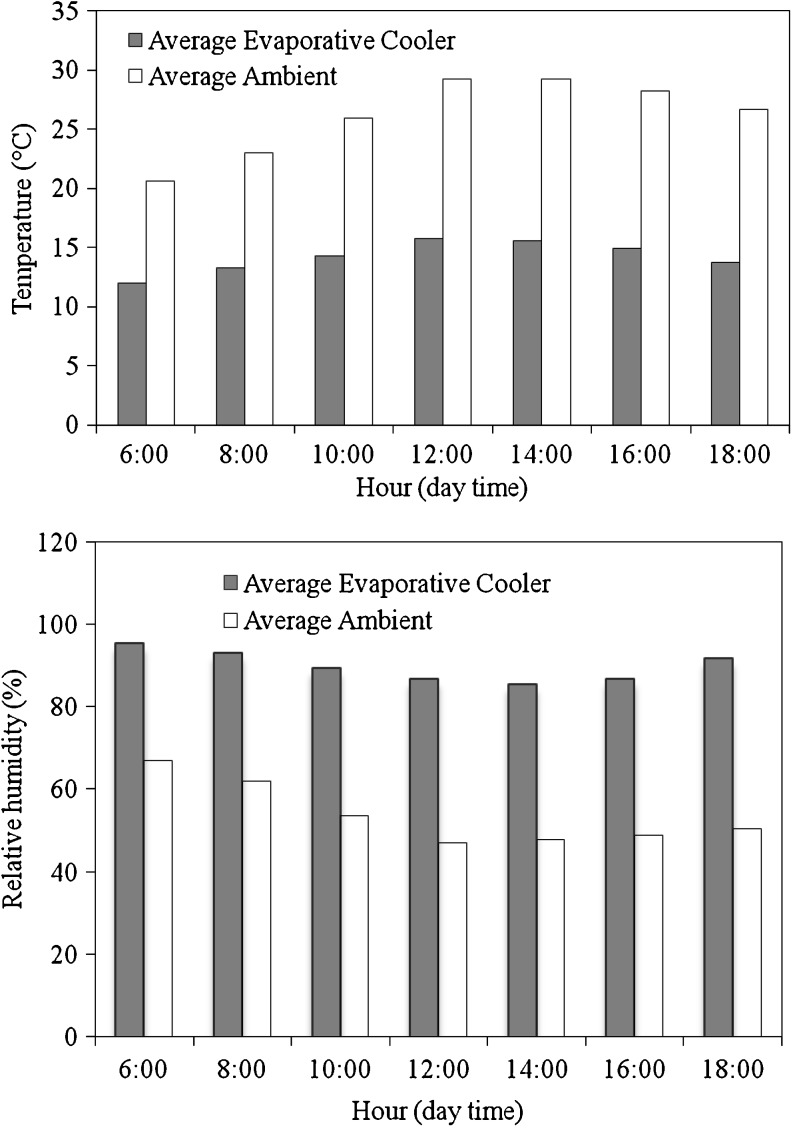

The ambient dry bulb air temperature and RH varied from 20.6 to 29.2 °C and 46.9% to 67.0% during the storage period, respectively. Inside the evaporative cooler, the dry bulb temperature and RH varied from 12.0 to 15.5 °C and 85.6% to 96.0%, respectively, during the storage period (Fig. 2). For the same geographical location, (Tefera et al. 2007) reported that the evaporatively cooled chamber maintained the temperature in the range of 14.3 to 19.2 °C and the RH varying between 70.0% and 82.4% during the storage periods. The lowest and maximum difference (wet bulb depressions) between the ambient air dry- and wet-bulb temperature were found to be 5 °C and 7 °C which was sufficient to bring a significant reduction in the temperature of air down to wet-bulb temperature after passing through the cooling pads.

Fig. 2.

Day time dry-bulb average ambient and evaporative cooler temperature and RH during storage of pepper fruit for a period of 28 days (n = 3)

The average difference in dry bulb temperature between the ambient and inside the cooler was 12.0 °C, while the average difference in RH was 36.1% during the 28 days of storage. Relatively, higher RH and lower temperature were obtained in the multi-pad evaporative cooler than the previous findings in evaporative cooler from the same geographical location (Seyoum and Woldetsadik 2004; Tefera et al. 2007). The improvement in effectiveness of the evaporative cooler in lowering temperature and increasing RH than that attainable with single pad evaporative cooler appeared to be due to the introduction of additional two cooling pad in the air passage of evaporative cooling psychrometric unit. The air was allowed to pass three times through the moist pad and picked up humidity from each pad as it cooled and added more moisture to the chamber. As air flows through these wet passages, the cooling effect causes heat transfer from the dry air stream to the fluids in the wet passages.

The higher RH and lower temperature obtained from the evaporative cooler appeared to be convenient in extending the shelf life of other horticultural commodities as it was observed in pepper, in the present study. To avoid excessive loss of moisture from stored commodities, the storage environment needs to maintain high RH. This could help the commodity to balance the moisture it contains and the water vapor of the air surrounding it (Ryall and Lipton 1979). It is also interesting to note that there were little fluctuations in temperature and RH in the evaporative cooler during the holding time as compared to the wide fluctuation observed at the ambient environment. This is important from the point of view of safe and effective storage of perishable commodities. From the data presented in Fig. 2, it is evident that from 12:00 to 14:00 h, fruit stored under ambient conditions could lose excessive amount of moisture because of coupled effect of high temperature and low RH.

The evaporative cooler was effective in minimizing these extremes which is in agreement with previous reports (Seyoum and Woldetsadik 2004; Getenit et al. 2008). Throughout the 28 days of storage period, difference in temperature between evaporative cooler and ambient temperature were found to be at minimum (8.6 °C) at 6:00 h. The maximum difference (14.0 °C) was recorded at 12:00 h. Similarly, the maximum difference in RH (40.0%) was obtained at 12:00 h and the minimum difference of 28.5% was recorded at 6:00 h. This can be ascribed to the rate of evaporation of water from the wet cooling pad being higher at higher air temperature, which is supported by previous work (Rama and Narasimham 1991; Seyoum and Woldetsadik 2004).

Evaporative cooling is very efficient under hot and dry conditions of arid or semi-arid regions, where the problem of postharvest loss of fruit and vegetables is attributed to inadequate pre-cooling resulting in high fresh weight losses. However, if the ambient temperature is very high, the reduction in temperature may not be sufficient to suppress microbial development at high relative humidity (Seyoum and Woldetsadik 2004; Tefera et al. 2007).

Physiological weight loss

The interaction effects of varieties and storage environment resulted in a significant (P ≤ 0.05) variation in the percent weight loss of the pepper varieties (Table 1). During the initial storage period (day 4), PBC 600 and Mareko Fana stored at ambient condition were found to have the highest percentage of weight loss of 9.2% and 8.5%, respectively. However, Mareko Fana stored in the evaporative cooler showed the lowest percentage weight loss (1.7%) on the same date. On the 8th day, mean percent weight loss of fruits stored at ambient condition had 70.0% weight loss, than the fruits stored in the evaporative cooler. In the later stage, however, the difference in the weight loss of fruits under the two storage environments tended to narrow down. After day 16, nearly all pepper fruits stored at ambient condition were unmarketable, while those stored in the evaporatively cooled chamber remained marketable up to 28 days. After 28 days of storage in evaporatively cooled chamber, the maximum weight loss was recorded in Melka Zala (38.9%) and minimum loss in Mareko Fana (18.3%).

Table 1.

The interaction effect of storage environment and varieties on the physiological weight loss (%) of pepper fruit during storage period of 28 days

| Storage treatment/cultivars | Storage periods (days) | ||||||

|---|---|---|---|---|---|---|---|

| 4 | 8 | 12 | 16 | 20 | 24 | 28 | |

| Evaporative Cooling | |||||||

| Melka Dima | 2.7e | 9.6d | 13.3c | 17.2e | 27.9a | 29.8a | 35.5b |

| Melka Eshet | 2.8e | 8.1f | 13.3c | 17.5e | 18.9b | 20.3b | 29.1c |

| Melka Zala | 2.5f | 8.7e | 9.9d | 11.4g | 14.4d | 16.9d | 38.9a |

| Mareko Fana | 1.7g | 8.6e | 10.2d | 11.7g | 11.8e | 15.8e | 18.3e |

| PBC 600 | 2.8e | 7.3g | 7.7e | 15.6f | 16.6c | 17.6c | 22.7d |

| Ambient storage | |||||||

| Melka Dima | 7.4c | 18.7a | 22.5a | 30.4a | – | – | – |

| Melka Eshet | 6.2d | 14.1b | 22.5a | 26.2c | – | – | – |

| Melka Zala | 7.5c | 14.0b | 22.4a | 26.2c | – | – | – |

| Mareko Fana | 8.5b | 11.6c | 19.6b | 27.7b | – | – | – |

| PBC 600 | 9.2a | 13.8b | 20.2b | 21.2d | – | – | – |

| Significance | *** | *** | *** | *** | *** | *** | *** |

| SE ± | 0.12 | 0.19 | 0.22 | 0.32 | 0.22 | 0.27 | 0.21 |

| LSD (0.05) | 0.24 | 0.40 | 1.30 | 0.66 | 0.72 | 0.89 | 0.69 |

| CV (%) | 3.88 | 2.88 | 2.42 | 2.67 | 2.13 | 2.36 | 1.26 |

(n = 3)

Means within a column followed by the same letter (s) are not significantly different at P ≤ 0.05; where *** indicate significant difference at P ≤ 0.001

The higher percentage weight loss in pepper stored at ambient conditions compared to those stored in the evaporative cooler appeared to be related to the RH and temperature surrounding the produce. The evaporative cooler had more air humidity as well as cooler than the ambient storage conditions, there by capable of reducing excessive moisture loss from the produce. The types of surfaces and underlying tissues of fruit may also have a marked effect on the rate of water loss (Wills et al. 1989) which could be seen as reasons for the differences observed among the varieties.

Quality of most fruits and vegetables is affected by water loss during storage, which depends on the temperature and RH of the storage conditions (Perez et al. 2003). Hardenburg et al. (1986) mentioned that storage under low temperature is the most efficient method to maintain quality of fruits and vegetables due to its effects on reducing respiration rate, ethylene production, ripening, senescence, and rot development. High temperature increases the vapour pressure difference between the fruit and the surrounding, which is the driving potential for faster moisture transfer from the fruit to the surrounding air (Ryall and Pentzer 1982; Hardenburg et al. 1986; Salunkhe et al. 1991). In the present study too, the lower temperature and higher relative humidity maintained by the evaporatively cooled chamber as compared to the ambient condition could be the reason for the low percentage of weight loss possibly through reducing respiration and transpiration rate. Accordingly, the higher physiological weight loss shown at ambient condition can be associated with increased cell wall degradation leading to exposure of cell water for easy evaporation combined with higher membrane permeability due to faster metabolism and ripening rate at high temperature storage (Dumville and Fry 2000).

Moisture content

Moisture content of fruits of five hot pepper varieties stored under two storage conditions showed significant variation (P ≤ 0.05) during the storage periods (Table 2). At harvest, Melka Eshte and Melka Dima had significantly more moisture content than Mareko Fana and PBC 600 while Melka Zala did not show difference in moisture content from all cultivars.

Table 2.

The interaction effect of storage environment and varieties on the moisture content (%) of pepper fruits during 28 days of storage

| Storage Treatments/Cultivars | Storage periods (days) | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 4 | 8 | 12 | 16 | 20 | 24 | 28 | |

| Evaporative Cooling | ||||||||

| Melka Dima | 91.7a | 91.5ab | 91.1a | 90.4a | 89.8a | 89.0a | 88.7a | 86.4 |

| Melka Eshet | 92.5a | 92.3a | 91.1a | 89.7a | 89.4a | 88.0a | 87.7ab | 84.0 |

| Melka Zala | 91.1abc | 89.9abc | 90.4ab | 85.6bc | 87.7ab | 88.6a | 88.0ab | 86.6 |

| Mareko Fana | 89.8bc | 88.9cde | 88.7bc | 87.2bc | 86.7abc | 85.4b | 84.8bc | 83.4 |

| PBC 600 | 89.4c | 88.1de | 87.4cd | 86.9bc | 86.6abc | 85.2b | 83.7c | 82.8 |

| Ambient storage | ||||||||

| Melka Dima | 91.7a | 88.2cd | 86.1d | 86.8bc | 85.1abc | – | – | – |

| Melka Eshet | 92.5a | 89.5bc | 89.3ab | 86.7ab | 83.8bc | – | – | – |

| Melka Zala | 91.1abc | 85.5def | 86.6cd | 85.6c | 84.1c | – | – | – |

| Mareko Fana | 89.8bc | 86.7def | 84.7de | 83.2d | 78.9d | – | – | – |

| PBC 600 | 89.4c | 84.5f | 83.6e | 84.4d | 75.0d | – | – | – |

| Significance | * | ** | ** | ** | *** | ** | ** | ns |

| SE ± | 0.50 | 0.30 | 0.25 | 0.47 | 0.52 | 0.48 | 1.05 | 1.06 |

| LSD (0.05) | 1.70 | 1.60 | 1.74 | 1.71 | 2.84 | 1.55 | 3.41 | 3.74 |

| CV (%) | 0.50 | 0.60 | 0.49 | 0.93 | 1.06 | 0.94 | 2.09 | 2.18 |

(n = 3)

Means within a column followed by the same letter (s) are not significantly different at P ≤ 0.05; ns *, **, *** indicate non significant, significant difference at P ≤ 0.05, 0.01 or 0.001, respectively. The data from day 16 onwards is meant for the evaporatively cooled storage only

During the storage period of 4 to 12 days, Melka Eshte and Melka Dima stored in the evaporatively cooled chamber retained more moisture compared to majority of the treatments. At ambient conditions, Melka Eshte fruits had relatively more moisture content compared with the other varieties, under the same storage condition, except on day 16. Significant differences among the cultivars were observed throughout the storage period except on the last day of storage. This could be due to differences in fruit tissues of the skin wax contents of cultivars. Maalekuu et al. (2006) noted that the difference in water loss rate among different genotypes could be attributed to factors such as their cuticlular wax content, difference in cell membrane degradative enzymes and their effects on membrane integrity and membrane lipid composition.

There was a general decreasing trend in the moisture content of the varieties with storage time under both storage conditions. However, the percent decrease in moisture content was pronounced in fruits stored at ambient condition. This may be due to the ripening process that undergo throughout the storage period as ripening of pepper fruit causes changes in the permeability of cell membranes, making them more sensitive to loss of water (Goodwin and Mercer 1972; Suslow 2000; Antoniali et al. 2007).

The difference in moisture contents of fruits under the two storage conditions could be attributed to the lower temperature and higher relative humidity in the evaporative cooler than in ambient conditions (Fig. 2) which could have reduced the amount and rate of moisture loss. Moreover, the lower temperature in the evaporative cooler could have reduced respiration rate and thus delayed fruit ripening and subsequently lowered permeability to moisture loss (Atta-Aly and Brecht 1995).

Marketability

The interaction effect among cultivars and storage conditions significantly (P ≤ 0.05) affected percentage of marketable pepper during the storage period (Table 3). On day 4, all pepper stored in the evaporative cooler were marketable while under the ambient storage there were 1.3% to 5.2% unmarketable fruits in the different cultivars.

Table 3.

The interaction effect of storage environments and varieties on the marketability (%) of pepper fruit during 28 days of storage

| Storage Treatment/cultivars | Storage period (days) | ||||||

|---|---|---|---|---|---|---|---|

| 4 | 8 | 12 | 16 | 20 | 24 | 28 | |

| Evaporative cooling | |||||||

| Melka Dima | 100a | 97.9c | 87.1c | 80.2c | 70.0d | 46.0d | 19.3d |

| Melka Eshet | 100a | 96.6d | 83.8d | 75.2d | 62.0e | 34.0e | 9.3e |

| Melka Zala | 100a | 98.4b | 89.1b | 82.7b | 77.3b | 56.0b | 30.7b |

| Mareko Fana | 100a | 98.9a | 91.8a | 87.3a | 82.2a | 59.8a | 37.6a |

| PBC 600 | 100a | 96.3d | 87.8c | 80.7c | 74.0c | 51.6c | 23.3c |

| Ambient storage | |||||||

| Melka Dima | 95.6e | 65.3h | 29.3h | 16.h | – | – | – |

| Melka Eshet | 94.8f | 60.7i | 20.0i | 12.7i | – | – | – |

| Melka Zala | 96.9c | 67.1f | 33.3f | 19.8f | – | – | – |

| Mareko Fana | 98.7b | 69.6e | 39.3e | 24.0e | – | – | – |

| PBC 600 | 96.5d | 65.9g | 31.3g | 18.0g | – | – | – |

| Significance | *** | *** | *** | *** | *** | *** | *** |

| SE ± | 0.086 | 0.192 | 0.607 | 0.380 | 0.378 | 0.263 | 0.555 |

| LSD (0.05) | 0.184 | 0.402 | 1.274 | 0.800 | 1.234 | 0.857 | 1.805 |

| CV (%) | 0.154 | 0.407 | 1.771 | 1.326 | 0.896 | 0.920 | 3.986 |

(n = 3)

Means within a column followed by the same letter (s) are not significantly different at P ≤ 0.05, *** indicate significant difference at P ≤ 0.001. The data from day 16 onwards is meant for the evaporatively cooled storage

Marketability of pepper stored at ambient environment was about 98.73% in Mareko Fana that had the highest percentage while Melka Eshet had the lowest percentage (94.8%) marketable fruits. On day 8, marketability of fruits under the cooler was greater than 96.0% whereas under ambient condition it dropped below 61.0% in Melka Eshet and 70.0% in Mareko Fana. On day 16, the percentage marketability of the other pepper in the cooler remained more than 80.0% except in Melka Eshet, while at ambient storage condition, the percentage of marketable pepper fruits in all of the varieties were less than 25.0%.

The extended storage life of pepper fruits stored in the evaporative cooler could be attributed from the increased RH and reduced temperature. From the above results, it appears that reduced storage temperature as a result of adiabatic cooling of the incoming air has advantageously decreased the rate of pepper fruits deterioration. Storage temperatures have strong positive correlation with the rate at which physiological, biochemical and microbiological changes occur during storage (Ryall and Lipton 1979; Ryall and Pentzer 1982; Hardenburg et al. 1986). Thus, the lower the storage temperature the lower would be the rate of deterioration of the stored produce.

In the evaporative cooler, about 82.0% of Mareko Fana fruit remained marketable until 3 weeks. While in the other varieties percentage of marketability dropped to a level of 62.0% in Melka Eshte and 77.3% in Melka Zala. Over all, Mareko Fana fruits stored in the evaporative cooler performed better than the other varieties and most of them stayed marketable, while Melka Eshte was the least. The result showed that maintaining lower temperature and higher RH in the storage combined with selecting cultivars having long shelf life could improve marketability of pepper for a relatively longer period.

A comparison based on the overall mean marketable pepper fruits after 2 weeks (day 16) clearly show that pepper fruit marketability could be increased nearly four-fold using the evaporative cooler storage system, compared with the ambient condition. This could be mainly due to the fact that low storage temperature reduces the rate of respiration and physiological activity leading to retarded senescence of fruit in storage (Pinto et al. 2004). Moreover, the increased RH in the cooler reduces shrinkage of fruits through moisture loss.

Hardenburg et al. (1986) reported the effective method of maintaining quality and controlling decay of peppers is by a rapid cooling after harvest followed by storage at low temperature with a high RH.

The visual appearance and marketability of pepper fruit stored in the evaporative cooler remained fresh and shiny with good pod color for a reasonable period of storage time. Shriveling and discoloration at ambient temperature and rotting in pepper fruits stored in the evaporative cooler storage were major causes for a decline in percent marketability, with time. This result agrees with previous reports that showed significant improvement in the shelf life of fruits and vegetables stored in evaporative cooler, in which losses associated with decay were also observed (Seyoum and Woldetsadik 2001). Although storing pepper varieties in the evaporative cooler extend their shelf life, it was hardly possible to control loss due to fruits decay. This is due to the fact that evaporative cooler, although reduced the storage temperature, was not able to maintain the temperature to optimum level for storing pepper fruits for an extended period. Therefore, it appears that a combination of disinfection, modified atmosphere packaging, and storage in evaporative cooler might improve the storage life of green pepper and other perishable produce.

Total soluble solid (TSS)

The data in Table 4, displays the TSS contents of five pepper varieties harvested at mature-green stage and subjected to two storage conditions. There was a significant (P ≤ 0.05) difference in the TSS contents of the stored fruits except on day 8 and 16 of the storage period. The TSS contents of the varieties ranged from 3.5 °Bx in Mareko Fana stored in the evaporative cooler to 6.43 °Bx in the same variety stored at ambient condition on day 8. The TSS content in this study agrees with the reports of (Antoniali et al. 2007) that recorded TSS values of 5.8 to 7.9 °Bx in yellow bell pepper assessed at different maturity stage.

Table 4.

The interaction effect of storage environment and varieties on the total soluble solid (°Brix) values of pepper fruits during 28 days of storage

| Storage treatments/cultivars | Storage period (days) | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 4 | 8 | 12 | 16 | 20 | 24 | 28 | |

| Evaporative cooling | ||||||||

| Melka Dima | 4.033d | 5.000e | 5.8 | 5.5c | 5.0 | 4.6bc | 4.4bc | 4.1ab |

| Melka Eshet | 4.700bc | 5.433cd | 5.8 | 5.4cd | 5.0 | 4.8b | 4.4b | 4.1ab |

| Melka Zala | 5.467a | 5.900a | 6.1 | 5.4cd | 5.0 | 4.7b | 4.3bc | 3.8b |

| Mareko Fana | 4.600c | 5.701b | 5.9 | 5.4cd | 4.8 | 4.3c | 4.0c | 3.5b |

| PBC 600 | 4.877b | 5.633b | 6.0 | 6.0a | 5.4 | 5.3a | 4.9a | 4.6a |

| Ambient storage | ||||||||

| Melka Dima | 4.0d | 5.6bc | 6.1 | 5.8b | 5.4 | – | – | – |

| Melka Eshet | 4.7bc | 5.6bc | 6.2 | 5.9ab | 5.3 | – | – | – |

| Melka Zala | 5.5a | 5.3d | 6.1 | 5.3d | 4.8 | – | – | – |

| Mareko Fana | 4.6c | 5.7bc | 6.4 | 6.0a | 5.5 | – | – | – |

| PBC 600 | 4.9b | 5.3d | 6.1 | 5.5c | 5.2 | – | – | – |

| Significance | *** | ** | ns | *** | ns | ** | ** | ** |

| SE ± | 0.06 | 0.08 | 0.10 | 0.09 | 0.18 | 0.11 | 0.11 | 0.19 |

| LSD (0.05) | 0.200 | 0.179 | 0.179 | 0.184 | 0.376 | 0.372 | 0.370 | 0.616 |

| CV (%) | 2.30 | 2.67 | 2.89 | 2.67 | 6.03 | 4.17 | 4.47 | 8.15 |

(n = 3)

Means within a column followed by the same letter (s) are not significantly different at P ≤ 0.05; ns, **, *** indicate non significant, significant difference at P ≤ 0.01 or 0.001, respectively. The data from day 16 onwards is meant for the evaporatively cooled storage only

At harvest, the highest TSS content was recorded from Melka Zala (5.47 °Bx) and the least in Melka Dima (4.0 °Bx). Except in variety PBC 600 that had more TSS in the evaporative cooler after the 8th day of storage period, the highest TSS contents of most varieties was reached on day 8, where, these values did not differ significantly. Mareko Fana and Melka Eshet had the highest TSS contents on 12th day of storage at ambient while all varieties except PBC 600 from evaporative cooler and Melka Eshet and Mareko Fana from ambient storage had the lowest TSS content.

There was an increase in the TSS contents of all varieties stored both at ambient and in the evaporatively cooled chamber until day 8 after which there was a decline in the TSS levels. This indicated that even at reduced temperature, starch was being converted into sugars. Generally, the rate at which the TSS levels increased was faster at ambient temperature than in the cooled chamber. Initial increase in TSS content could potentially be attributed to moisture loss by the fruits and conversion of organic acids to sugars while the decrease over the storage period from 8 to 28 days may be explained by the respiratory use of the solids by the fruit cells.

It is well known that sugars and simple acids are respiration substrates, and the longer the time of fruit respiration, the higher will be the rates of consumption of sugars and acids (Atta-Aly and Brecht 1995). The initial increase in the TSS contents, which was followed by a decrease with time, in conformity with reports of (Gorny and Kader 1998) who mentioned an increase in the amount of soluble solids as fruits ripen a decrease once senescence was reached.

Compared to fruits stored in the evaporative cooler, the higher TSS contents of pepper stored at ambient condition could be related to the higher temperature that resulted in faster conversion of starch into water-soluble sugars (Getenit et al. 2008). This condition could also increase moisture loss from the fruits thereby increasing the concentration of TSS content compared to the evaporative cooler that had higher RH (Fig. 2). According to Antoniali et al. (2007) the polysaccharides of the cell wall are broken up with a consequent increase in sugar levels during ripening. Thus, decrease in the level of TSS content in this study could be due to metabolism of majority of the soluble carbohydrates during respiration.

The equilibrium of these activities in the pepper produces an increase in the level of total soluble solids, followed by a fall after 12 days of storage (Mattoo et al. 1975; Vicentini et al. 1999), which is an agreement with the present findings. While differences in the percentage of TSS content at the time of harvest could reflect genotypic difference in carbohydrate accumulation in green-ripe fruits, variation observed in a given environment indicate potential difference in their rates of respiration and consequently their storability.

Ascorbic acid

A significant difference (P ≤ 0.001) in the ascorbic acid content of pepper fruits was observed from the interaction effect of variety and storage conditions (Table 5). The range of ascorbic acid content in this study was from 101 to 232.7 mg per 100 g−1 tissue fresh weight. Bosland and Votava (2000) reported the concentration of ascorbic acid in pepper reaching up to 340 g100 g−1, which is similar with the present observation. Others reported ascorbic acid concentrations in green pepper in the ranges of 46.6–243.0 mg 100 g−1 of dry weight (Nisperos-Carriedos et al. 1992; Howard et al. 1994; Lee et al. 1995; Gibbis and O’Garro 2004), which indicates that there is a large variation in vitamin C levels among cultivars. Bosland and Votava (2000) discussed that differences in nutritional composition are determined by the cultivar, the growing conditions and fruit maturity, and that further changes can occur during postharvest handling and storage. Howard et al. (1994) also reported differences in ascorbic acid contents between cultivars and that the contents increased with maturity in all cultivars which is in agreement with results of this study.

Table 5.

The interaction effect of storage environment and varieties on the ascorbic acid content (mg 100 g−1) of pepper juice during the 28 days of storage

| Storage treatments cultivars | Storage period (days) | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 4 | 8 | 12 | 16 | 20 | 24 | 28 | |

| Evaporative cooling | ||||||||

| Melka Dima | 109.9b | 163.6d | 163.3b | 212.8c | 150.0c | 137.0b | 116.1c | 113.8c |

| Melka Eshet | 107.6b | 129.9ef | 164.9b | 169.1f | 158.3b | 136.6b | 129.1b | 119.7c |

| Melka Zala | 101.1c | 128.6f | 131.4e | 144.1g | 131.4g | 130.0c | 115.1b | 109.0d |

| Mareko Fana | 115.5a | 195.3a | 189.0a | 232.7a | 167.8a | 150.0a | 143.3a | 131.7a |

| PBC 600 | 102.5c | 183.8b | 158.3c | 193.7d | 143.0de | 145.2a | 124.7b | 121.9b |

| Ambient storage | ||||||||

| Melka Dima | 109.9b | 131.2e | 152.3d | 184.0e | 140.0ef | – | – | – |

| Melka Eshet | 107.6b | 121.0g | 131.9e | 143.3g | 137.8f | – | – | – |

| Melka Zala | 101.1c | 115.1h | 117.4g | 131.0i | 125.3h | – | – | – |

| Mareko Fana | 115.5a | 183.7b | 161.7b | 217.0b | 145.0d | – | – | – |

| PBC 600 | 102.5c | 167.6c | 122.9f | 136.7h | 130.0g | – | – | – |

| Significance | *** | *** | ** | *** | *** | *** | *** | *** |

| SE ± | 0.93 | 1.81 | 1.57 | 1.54 | 1.03 | 1.81 | 1.57 | 1.03 |

| LSD (0.05) | 3.03 | 2.04 | 3.29 | 2.51 | 4.10 | 5.92 | 5.12 | 3.36 |

| CV (%) | 1.49 | 1.43 | 2.34 | 1.52 | 3.05 | 2.25 | 2.17 | 1.49 |

(n = 3)

Means within a column followed by the same letter (s) are not significantly different at P ≤ 0.05 where *** indicate significant difference at P ≤ 0.001. The data from day 16 onwards is meant for the evaporatively cooled storage only

The ascorbic acid content of all hot pepper cultivars harvested at mature-green stage and stored both in the evaporative cooler and ambient condition showed increment until day 12 and then steadily declined afterwards. At harvest, the highest (115.5 mg 100 g−1) and lowest (101.1 mg 100 g−1) ascorbic acid values were observed in Mareko Fana and Melka Zala, respectively. Mareko Fana stored in the evaporative cooler had the highest ascorbic acid content throughout the storage period. The lowest ascorbic acid values were found in Melka Zala, stored at ambient condition. Over all, pepper stored in evaporatively cooled showed higher ascorbic acid content than those stored at ambient environment. This could be due to the low temperature in the former storage (lower by 10.0 °C) than the ambient condition that might have retarded aging through reduced respiration rate. On the other hand, high temperature which is known to increase enzymatic catalysis that leads to biochemical breakdown of compounds in fruit and vegetables (Yeshida et al. 1984) and could be responsible for the reduced ascorbic acid content of pepper stored at ambient conditions.

In this study, the increment in the ascorbic acid content on day 12 compared to the content at harvest ranged from about 30.0% in Melka Zala stored in ambient condition to over 100% in Mareko Fana stored in evaporative cooler. Similarly, at the end of the storage period, fruits stored in the evaporative cooler showed reduction in ascorbic acid content from 24.3% in Melka Zala to 46.3% in Melka Dima compared to their peak concentrations on day 12. Castro et al. (2002) also reported similar decreasing trends in ascorbic acid content in low temperature storage where the ascorbic acid loss ranged from 11.0% to 70.0%. Ascorbic acid is most sensitive to destruction when the commodity is subjected to adverse handling and storage conditions; losses are enhanced by higher temperatures, low relative humidity and physical damage (Nunes and Emond 1999).

Titritable acidity

Table 6 shows the result of TA contents of pepper varieties stored under two storage conditions. The interaction effect between varieties and storage conditions was found to be highly significant (P ≤ 0.001) throughout the storage period which ranged between 0.13% and 0.64%. TA showed increment up to first week of storage and decreased afterwards.

Table 6.

The interaction effect of storage environment and varieties on the titrtable acidity (%) of pepper juice during 28 days of storage of period

| Storage treatments cultivars | Storage period (days) | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 4 | 8 | 12 | 16 | 20 | 24 | 28 | |

| Evaporative cooling | ||||||||

| Melka Dima | 0.221c | 0.263f | 0.373f | 0.355f | 0.328d | 0.268c | 0.134d | 0.201e |

| Melka Eshet | 0.201d | 0.268f | 0.335f | 0.335g | 0.326d | 0.290c | 0.201d | 0.216d |

| Melka Zala | 0.402b | 0.536b | 0.514de | 0.439d | 0.406c | 0.402b | 0.335b | 0.411b |

| Mareko Fana | 0.397b | 0.533b | 0.522cd | 0.514c | 0.498ab | 0.476a | 0.467a | 0.469a |

| PBC 600 | 0.480a | 0.636a | 0.603b | 0.596a | 0.529a | 0.439a | 0.311c | 0.335c |

| Ambient storage | ||||||||

| Melka Dima | 0.221c | 0.302e | 0.271g | 0.266h | 0.141f | – | – | – |

| Melka Eshet | 0.201d | 0.214g | 0.277g | 0.268h | 0.189e | – | – | – |

| Melka Zala | 0.402b | 0.219g | 0.465e | 0.402e | 0.402d | – | – | – |

| Mareko Fana | 0.397b | 0.518c | 0.549c | 0.585a | 0.462b | – | – | – |

| PBC 600 | 0.480a | 0.469d | 0.621a | 0.536b | 0.527ab | – | – | – |

| Significance | *** | *** | *** | *** | *** | *** | *** | *** |

| SE ± | 0.004 | 0.010 | 0.015 | 0.007 | 0.005 | 0.011 | 0.011 | 0.039 |

| LSD (0.05) | 0.012 | 0.012 | 0.038 | 0.012 | 0.038 | 0.036 | 0.013 | 0.033 |

| CV (%) | 1.94 | 4.54 | 5.55 | 2.61 | 2.13 | 5.15 | 5.37 | 2.37 |

(n = 3)

Means within a column followed by the same letter (s) are not significantly different at P ≤ 0.05; *** indicate significant difference at P ≤ 0.001. The data from day 16 onwards is meant for the evaporatively cooled storage only

Change in TA and pH are founded on changes in citric, malic and ascorbic acid. Concentrations of these acids are known to diminish during ripening (Medlicott et al. 1986). Storage at ambient condition resulted in faster decline in TA of peppers as compared with the evaporative cooler storage. This could be associated with the higher rate of respiration with increasing temperature that might have utilized titritable acids as a substrate for this catabolic process. It is known that evaporatively cooled storage reduce particularly respiratory activity, delaying the ripening process and increasing shelf life of fruits and vegetable (Thompson et al. 1998; Getenit et al. 2008).

Higher (0.5%) and lower (0.2%) values of TA were recorded in PBC 600 and Melka Eshet at harvest, respectively. PBC 600 continued to have the highest TA up to 16 days of storage while at the later storage period Mareko Fana was found to have more. The minimum values were recorded in Melka Dima under ambient storage environment. Similarly, other varieties had lower TA values under ambient than evaporatively cooled storage. This could be because of high temperature that could raise respiration rate which could also raise use of organic acids in the respiration process (Wills et al. 1989; Antoniali et al. 2007) with the variations among cultivars in a given storage could be due to their genetic make up.

While fruits ripen, metabolic reactions increase, increasing the concentration of organic acids involved in the krebs cycle. Apart from this, these acids make up the energetic reserves and the metabolic reactions that involve the synthesis of pigments, enzymes and other materials and degradation of pectin and celluloses, which are essential for the ripening process (Lurie and Klein 1990; Antoniali et al. 2007) which could be the cause for gradual reduction of the TA. According to Mohammed et al. (1999) higher fruit acidity is an advantage, which causes a lower incidence of spoilage. The present result is in conformity with previous reports that showed soon after harvest, overall acidity increased and then decreased in storage (Castro et al. 2002). Getenit et al. (2008) also presented an acidity decrease and a pH increase along with maturity evolution.

pH values

Significant difference (P ≤ 0.05) in pH content of pepper fruit was observed between varieties considered in this study throughout the storage period except on day 4 and 16 (Table 7). The pH values in this study seemed to confirm the literature information available on the pH values of pepper (Cochran 1964; Gonzalez-Aguilar et al. 1999).

Table 7.

The interaction effect of storage environments and varieties on the pH values of pepper fruit during 28 days of storage

| Storage treatments cultivars | Storage period (days) | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 4 | 8 | 12 | 16 | 20 | 24 | 28 | |

| Evaporative cooling | ||||||||

| Melka Dima | 6.0a | 6.1 | 6.2bc | 6.3bc | 6.5 | 6.5a | 6.6ab | 6.7a |

| Melka Eshet | 6.1a | 6.1 | 6.2b | 5.5e | 5.8 | 6.4ab | 6.7a | 6.5b |

| Melka Zala | 6.0a | 6.2 | 6.3b | 6.1d | 6.1 | 6.3abc | 6.3c | 6.4d |

| Mareko Fana | 5.2b | 5.9 | 6.0de | 6.1d | 6.0 | 6.1c | 6.4c | 6.5bc |

| PBC 600 | 5.2b | 5.9 | 6.0d | 5.4e | 5.8 | 6.2bc | 6.4bc | 6.5cd |

| Ambient storage | ||||||||

| Melka Dima | 6.0a | 6.3 | 6.6a | 6.6a | 6.8 | – | – | – |

| Melka Eshet | 6.1a | 6.3 | 6.3b | 6.4b | 6.5 | – | – | – |

| Melka Zala | 6.0a | 6.0 | 6.1cd | 6.1cd | 6.3 | – | – | – |

| Mareko Fana | 5.2b | 5.7 | 5.9e | 6.0d | 6.6 | – | – | – |

| PBC 60 | 5.2b | 6.2 | 6.3b | 6.3b | 6.5 | – | – | – |

| Significance | *** | ns | ** | *** | ns | * | ** | *** |

| SE ± | 0.01 | 0.11 | 0.08 | 0.09 | 0.10 | 0.07 | 0.05 | 0.02 |

| LSD (0.05) | 0.21 | 0.25 | 0.18 | 0.19 | 0.29 | 0.22 | 0.17 | 0.07 |

| CV (%) | 1.94 | 3.02 | 2.33 | 2.49 | 2.69 | 1.89 | 1.37 | 0.61 |

(n = 3)

Means within a column followed by the same letter (s) are not significantly different at P ≤ 0.05; ns, *, ** and ***, indicate significant difference at P ≤ 0.05, 0.01 or 0.001 respectively. The data from day 16 onwards is meant for the evaporatively cooled storage only

The increase in the pH values of pepper at higher temperature with increase in storage time was in agreement with the pervious findings by Gonzalez-Aguilar et al. (1999). The authors reported pH values in the range of 5.99 to 6.50, with an increasing trend during storage time. At harvest, fruits of Melka Dima, Melka Eshte and Melka Zala had significantly more pH than the remaining two varieties. The pH of Melka Dima fruits remained highest while those of Mareko Fana remained lowest during most part of the storage period. In general, the pH content of fruits in all varieties showed an increasing trend over the storage period. But Cochran (1964) verified a drop in the pH of the bell pepper during its transformation from unripe green to red stage, while Vicentini et al. (1999) showed that such difference was not significant.

Antoniali et al. (2007) also reported that there was no significant difference in pH values of pepper during ripening. Medlicott and Thompson (1985) also reported the tendency of increasing pH values and reduced acidity with prolonged storage time since the fruit with proceeding of the ripening process is going to diminish its predominant malic acid. According to Mizrach et al. (1997), carbohydrate and acid metabolism are closely connected during postharvest ripening period which would thus raise pH of the produce.

Pungency

The data in Table 8 displays the pungency (capsaicin content) of five hot pepper varieties harvested at mature-green stage and subjected to two storage conditions. The capsaicin content of hot pepper varieties was significantly different (P ≤ 0.05) at harvest and after 12 days of storage.

Table 8.

Pungency (% capsaicin) of five hot pepper varieties stored in evaporative cooler and ambient condition

| Variety | % Capsaicin | |

|---|---|---|

| At harvest | After 12 days | |

| Melka Dima | 1.59b | 1.81e |

| Melka Eshet | 1.58b | 1.94d |

| Melka Zala | 1.96a | 2.13c |

| Mareko Fana | 1.69b | 2.26b |

| PBC 600 | 2.05a | 2.54a |

| Significance | ** | *** |

| SE ± | 0.06 | 0.04 |

| LSD (0.05) | 0.20 | 0.12 |

| CV (%) | 6.11 | 4.80 |

| Storage environment | ||

| Ambient | – | 2.27 |

| Evaporative cooler | – | 2.01 |

| Significance | – | *** |

| SE ± | – | 0.08 |

| LSD (0.05) | – | 0.27 |

(n = 3)

Means within a column followed by the same letter (s) are not significantly different at P < 0.05 where ** and *** indicate significant difference at P ≤ 0.01 or 0.001, respectively

At harvest high pungency content was recorded in PBC 600 (2.1%) and Melka Zala (2.0%) compared to the remaining varieties that recorded pungency levels of about 1.6% to 1.7%. On day 12 also, PBC 600 had the highest pungency values (2.5%) compared to all other varieties. Fruits of all pepper varieties recorded significantly more pungency value on 12th day compared to at harvest.

Over all, capsaicin content varied from 1.6% to 2.5%, which appeared to be lower than results of Gibbis and O’Garro (2004), who reported capsaicin content range of 0.3% to 4.1% in green fruits of 28 hot pepper accessions. This difference may be attributed to the type of cultivar, environment under which the crop grown and/or the procedure followed in the assessment of pungency of the fruit. The pungency level appeared to related with fruit size as PBC 600 that had the smallest fruits size (Table 2) had more pungency compared to those with larger mean fruit weight. This result agrees with that of Gomez Fuentes et al. (1988) who reported capsaicin content to be inversely related to fruit diameter, length and thickness.

High capsaicin content (2.3%) was also observed in peppers subjected to ambient storage conditions than in those stored in the evaporative cooler. Mean pungency of fruits stored at ambient condition was 13.0% more than that in fruits stored in the evaporative cooler. This increasing concentration of capcasinoids under warmer temperature than at lower temperature might be due to faster ripening as well as loss in moisture content of the fruits (Sathiyamurthy et al. 2002). During ripening, capsaicin concentration reaches a maximum then it turns over and degrades to secondary products (Bernal and Barceló 1996). It is assumed that peroxidases catalyze capsasinoid oxidation and plays a central role in its metabolism in pepper (Yu et al. 2005). Peroxidase activity is lower in fruits which have low moisture content (Bernal and Barceló 1996). Lower peroxidase and capsaicin oxidase activity means that the oxidation, or breakdown, of capsaicin will be slower when fruits have low moisture. Thus, both higher rates of synthesis and lower rates of degradation could also contribute to the greater concentration of capsaicin in fruits with low moisture content (Gibbis and O’Garro 2004; Yu et al. 2005), which is in agreement with the result of this study.

Conclusion

Melka Dima gave earliest as well as the highest fresh green fruits which were nearly four fold of Mareko Fana, commonly cultivated variety. The shelf life of green pepper stored in the evaporative cooler was effectively improved compared with storage under ambient condition. Quality attributes were found to be best in Mareko Fana variety which was stored in the evaporative cooler. In this variety more than 80.0% of the stored fruits remained marketable after storage period of 20 days. Melka Dima, after similar storage period had 70.0% marketable fruits with relatively lower chemical quality attributes. The change in the quality parameters under both storage conditions was largely dependent on variety. The result also showed that maintaining lower temperature and higher RH during storage combined with selecting cultivars having long shelf life could maintain fruit quality and reduce loss.

References

- Antoniali SA, Paulo ML, Ana Maria M, Rogério TF, Juliana S. Physico-chemical characterization of ‘zarco hs’ yellow bell pepper for different ripeness stages. Sci Agric. 2007;64:19–22. doi: 10.1590/S0103-90162007000100003. [DOI] [Google Scholar]

- Atta-Aly MA, Brecht JK (1995) Effect of postharvest high temperature on tomato fruit ripening and quality. pp. 250–256. In: Ait-Oubahou A, El-Otmani (eds) Proceeding of the International Symposium “Postharvest Physiology, Pathology and Technologies for Horticultural Commodities: Recent Advances”. Institute Agronomic et Veterinaire Hassan II. Agadir, Moroc

- Bernal MA, Barceló AR. 5,5′-dicapsaicin, 4′-O-5-dicapsaicin ether, and dehydrogenation polymers with high molecular weights are the main products of the oxidation of capsaicin by peroxidase from hot pepper. J Agric Food Chem. 1996;43:352–355. doi: 10.1021/jf00050a017. [DOI] [Google Scholar]

- Bosland PW, Votava EJ. Pepper: vegetable and spice capsicums. New York: CABI; 2000. [Google Scholar]

- Castro JM, Avila VCM, Rocha FM, Ochoa MA, Gallegos IA (2002) Effect of controlled atmospheres on quality of green pepper poblano (ancho). Proceedings of the 16th International Pepper Conference. November 10–12, Tampico, Tamaulipas, Mexico

- Chakraverty A, Mujumdar SA, Raghavan SG, Ramaswamy SH. Handbook of postharvest technology. Cereals, fruits, vegetables tea and spices. New York: Marcel Deker Inc; 2003. [Google Scholar]

- Cheul YY, Prabhat KM, Kyu-Ho H, Michihiro F, Kangduk C, Cheon JK, Chi-Ho L. Capsaicin and tocopherol in red pepper seed oil enhances the thermal oxidative stability during frying. J Food Sci Technol. 2010;47(2):162–165. doi: 10.1007/s13197-010-0032-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cochran HL. Changes in pH of the pimiento during maturation. Proc Am Soc Hortic Sci. 1964;84:409–411. [Google Scholar]

- Dumville JC, Fry SC. Uronic acid-containing oligosaccharins: their biosynthesis, degradation and signaling roles in non-diseased plant tissues. Plant Physiol Biochem. 2000;38:125–140. doi: 10.1016/S0981-9428(00)00163-7. [DOI] [Google Scholar]

- Getenit H, Seyoum T, Woldetsdik K. The effect of cultivar, maturity stage and storage environment on quality of tomatoes. J Food Eng. 2008;87:467–498. doi: 10.1016/j.jfoodeng.2007.12.031. [DOI] [Google Scholar]

- Gibbis HAA, O’Garro LW. Capsacin content of West Indies hot pepper cultivars using colorimetric and chromatographic techniques. HortScience. 2004;39:132–135. [Google Scholar]

- Goodwin TW, Mercer EI. Introduction to plant biochemistry. New York: Pergamon Press Oxford; 1972. p. 359. [Google Scholar]

- Gomez Fuentes R, Canessa Mora W, Fuentes RG, Mora W. Preliminary survey of chili cultivars (Capsicum spp.) Capsicum Newsletter. 1988;7:47–48. [Google Scholar]

- Gonzalez-Aguilar GA, Cruz A, Baez R. Storage quality of bell peppers pretreated with hot water and polyethylene packaging. J Food Qual. 1999;22:287–299. doi: 10.1111/j.1745-4557.1999.tb00558.x. [DOI] [Google Scholar]

- Gorny JR, Kader AA (1998) Fresh-cut products: maintaining quality and safety, UC Davis, Workshop Sep 15–16

- Hafnagel HP. Agriculture in Ethiopia. Rome: Food and Agricultural Organization of United of the United Nation; 1961. [Google Scholar]

- Hardenburg RE, Watada AE, Wang CY. The commercial storage of fruits, vegetables, florist, and nursery stocks. Washington: Agriculture Handbook; 1986. [Google Scholar]

- Howard LR, Griffin LE, Lee Y. Steam treatment of minimally processed carrot sticks to control surface discoloration. J. Food Sci. 1994;59(2):356–358. doi: 10.1111/j.1365-2621.1994.tb06965.x. [DOI] [Google Scholar]

- Kolawole OF, Olaniyi OO. Effect of osmotic pretreatment on air drying characteristics and colour of pepper (Capsicum spp) cultivars. J Food Sci Technol. 2010;47(5):488–495. doi: 10.1007/s13197-010-0083-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lee Y, Howard LR, Villalon B. Flavonoids and antioxidant activity of fresh Pepper (Capsicum annum) cultivars. J Food Sci. 1995;60:473–476. doi: 10.1111/j.1365-2621.1995.tb09806.x. [DOI] [Google Scholar]

- Lurie S, Klein J. Heat treatment on ripening apples: differential effect on physiology and biochemistry. Plant Physiol. 1990;78:181–186. doi: 10.1111/j.1399-3054.1990.tb02078.x. [DOI] [Google Scholar]

- Maalekuu K, Elkind Y, Frenkel AL, Lurie S, Fallik E. The relationship between water loss, lipid content, membrane integrity and LOX activity in ripe pepper fruit after storage. Postharvest Biol Technol. 2006;42:248–255. doi: 10.1016/j.postharvbio.2006.06.012. [DOI] [Google Scholar]

- Mattoo KA, Murata T, Pantastico EB, Chachin K, Ogata K, Phan CT. Chemical changes during ripening and senescence. In: Pantastico ErB., editor. Postharvest physiology, handling and utilization of tropical and subtropical fruits and vegetables. Westport: The AVI Publish; 1975. pp. 103–127. [Google Scholar]

- Medlicott AP, Thompson AK. Analysis of sugars and organic acids in ripening fruits by high performance liquid chromatography. J Sci Food Agric. 1985;36:561–566. doi: 10.1002/jsfa.2740360707. [DOI] [Google Scholar]

- Medlicott AP, Reynolds JB, Thompson EK. Effects of temperature on the ripening of mango fruit (Mangifera indica L. var. Tommy Atkins) J Sci Food Agric. 1986;37:469–474. doi: 10.1002/jsfa.2740370506. [DOI] [Google Scholar]

- Mizrach A, Filtsanov U, Fuchs V. An ultrasonic nondestructive method for measuring maturity of fruit. Trans ASAE. 1997;40:1107–1111. [Google Scholar]

- Mohammed M, Wilson LA, Gomes PL. Postharvest sensory and physiochemical attributes of processing and non-processing tomato cultivar. J Food Qual. 1999;22:167–182. doi: 10.1111/j.1745-4557.1999.tb00549.x. [DOI] [Google Scholar]

- Nisperos-Carriedos MO, Buslig BS, Shaw PE. Simultaneous detection of dehydroascorbic, aascorbic and some organic cids in fruits and vegetables by HPLC. J Agric Food Chem. 1992;40:1127–1130. doi: 10.1021/jf00019a007. [DOI] [Google Scholar]

- Nunes MC, Emond JF. Chlorinated water treatments affects postharvest quality of green bell peppers. J Food Qual. 1999;22:353–361. doi: 10.1111/j.1745-4557.1999.tb00563.x. [DOI] [Google Scholar]

- Perez K, Mercado J, Soto-Valdez H. Effect of storage temperature on the shelf life of Hass avocado (Persea americana) Food Sci Tecnol Int. 2003;10:73–77. doi: 10.1177/1082013204043763. [DOI] [Google Scholar]

- Pinto AC, Alues RE, Pereira EC. Efficiency of different heat treatment procedures in controlling disease of mango fruits. Proceedings of the seventh international mango symposium. Acta Hort. 2004;645:551–553. [Google Scholar]

- Premavalli KS, Amrinder SB. Development of ready-to-eat appetisers based on pepper and their quality evaluation. J Food Sci Technol. 2010;47(6):638–643. doi: 10.1007/s13197-010-0105-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Raji A, Falade KO, Abimbolu F. Effect of sucrose and binary solution on osmotic dehydration of pepper varieties (Capsicum spp.) J Food Sci Technol. 2010;47(3):305–309. doi: 10.1007/s13197-010-0048-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rama M, Narasimham P. Evaporation cooling of potatoes in small naturally ventilated chambers. J Food Sci Technol. 1991;28:145–148. [Google Scholar]

- Ryall AL, Lipton WJ. Vegetables and melon. Handling, transportation and storage of fruits. 2. Westport: The AVI Publishing; 1979. [Google Scholar]

- Ryall AL, Pentzer WT. Handling, transpiration and storage of fruits and vegetables, fruits and tree nuts. 2. Westport: AVI Publishing; 1982. [Google Scholar]

- Salunkhe DK, Bolin HR, Reddy NR (1991) Storage, processing, and nutritional quality of fruits and vegetables. 2nd edn. Fresh Fruits Veg 1:365

- Sathiyamurthy VA, Eeraragavathatham DV, Chezhiyan N. Studies on the capsaicin content in chilli hybrids. Capsicum Eggplant Newsl. 2002;21:44–47. [Google Scholar]

- Seyoum T, Woldetsadik K. Natural ventilation evaporative cooling of Mango. J Agric Biotech Environ. 2001;2:1–2. [Google Scholar]

- Seyoum T, Woldetsadik K. Forced ventilation evaporative cooling: a case study on banana, papaya, orange, mandarin, and lemon. Trop Agric. 2004;81:1–6. [Google Scholar]

- Suslow T. Bell peppers hit with late season losses to decay. Perishable Handling. 2000;101:1–8. [Google Scholar]

- Tefera A, Seyoum TW, Woldetsdik K. Effect of disinfection, packaging, and storage environment on the shelf life of mango. Biosyst Eng. 2007;96:1537–1550. doi: 10.1016/j.biosystemseng.2006.10.006. [DOI] [Google Scholar]

- Thompson JF, Mitchell FG, Runsey TR, Kasmire RF, Crisosto CH (1998) Commercial cooling of fruits, vegetables and flowers, UC Davis, USA, DANR publication No 21567:61–68

- Vicentini NM, Castro TMR, Cereda MP. Influência de películas de fécula de mandioca na qualidade pós-colheita de frutos de pimentão (Capsicum annum L.) Ciênc Tecnol Aliment. 1999;19:127–130. doi: 10.1590/S0101-20611999000100023. [DOI] [Google Scholar]

- Waskar DP, Khedlar RM, Garande VK. Effects of postharvest treatment on the shelf life and quality of pomegranate in evaporative cooling chamber and ambient conditions. J Food Sci Technol. 1999;2:114–117. [Google Scholar]

- Wills RBH, McGlasson WB, Graham D, Tlee H, Hall EG. Postharvest:—an introduction to the physiology and handling of fruit and vegetables. 3. New York: Van Nostrand Reinhold; 1989. [Google Scholar]

- Yeshida O, Nakagaua H, Ogura N, Sato T. Effect of heat treatment on the development of polygalacturonase activity in tomato fruit during ripening. Plant Cell Physiol. 1984;25:500–509. [Google Scholar]

- Yu S, Yu-Yun C, Ni-Lun T. Capsaicin biosynthesis in water-stressed hot pepper fruits. Bot Bull Acad Sin. 2005;46:35–42. [Google Scholar]