Abstract

Recent advances in MRI technology are presented, with emphasis on how this new technology impacts clinical operations (better image quality, faster exam times, and improved throughput). In addition, implications for patient safety are discussed with emphasis on the risk of patient injury due to either high local specific absorption rate (SAR) or large cumulative energy doses delivered during long exam times. Patient comfort issues are examined as well.

Keywords: MRI, Magnets, Coils, Specific absorption rate, SAR, Peripheral nerve stimulation, PNS, Patient safety

Introduction

The Magnetic Resonance Imaging (MRI) diagnostic imaging modality has enjoyed tremendous growth since its introduction to clinical practice in the early 1980s. By now it is firmly established as one of the preferred diagnostic imaging tools. After thirty years of intense research and development, the MRI technology has matured and the pace of technological changes introduced to the marketplace has slowed. However, recently the medical equipment manufacturing industry introduced new lines of MRI systems that represent a significant improvement over the existing status quo. These systems are about to cause another paradigm shift in MRI practices by altering clinical applications that were thus far difficult, time consuming, or erratic in performance. With new systems, they become so robust that they get rapidly incorporated into the MRI standards of practice. A couple of years ago such a change occurred with the introduction of a new line of MRI scanners, dubbed “wide bore”. This technology is the focus of this paper.

But progress has its price. Historically, MRI examinations were described as “safe” because the method is noninvasive and does not use ionizing radiation to produce the images. Indeed, in comparison to most other diagnostic procedures performed in hospitals and clinics, an MRI scan appears to be so benign that it could be considered harmless, and by extension, safe. Any possible hazardous side effects associated with MRI technology have been kept in check by establishing operational limits of the scanner’s hardware with such a wide safety margin that the risk of injury to a scanned patient was small enough to be easily manageable. Not anymore. In the quest for improved image quality and increased speed of imaging, the newest MRI scanners push the operational characteristics of hardware into areas where the safety margin is no longer wide enough to allow scanning of any patient without the need for careful inspection of safety issues for each patient, for each exam, and for every scanning sequence. The latter part of this paper focuses on the impact of the newest technology on maintaining the safety of imaged patients. The risks are real, and for some patients and scanning scenarios, they are greater than most people think.

Advances in technology

The magnet

With the launch of its Espree MRI system in November 2004, the Siemens Medical Solutions (SMS) unveiled a technological breakthrough, building a 1.5T tunnel magnet that was only 125 cm long and had a very large bore, 70 cm in diameter. The mainstream MRI equipment manufacturers downplayed the significance of this development by pointing out the new magnet’s shortcomings – large geometric distortions that limited the field of view (FOV) along the magnet bore to about 30–35 cm and required aggressive software-based image distortion corrections. But radiologists (and their patients) loved the new design. Its success bred a new line of magnets, dubbed “wide bore”, introduced by major MRI vendors within the 2009–2011 time frame. The flagship products in this category include GE Healthcare (GEHC) 1.5T Optima 450w introduced in the US on August 26, 2009 (Fig. 1) and 3T Discovery 750w, announced on October 6, 2011; SMS 1.5T Aera and 3T Skyra, available worldwide outside USA since 2009 and introduced in the USA on October 24, 2010; and Philips Medical Systems (PMS) Ingenia product line (both 1.5T and 3T) launched on December 2, 2010 with production beginning in July 2011.1–6

Figure 1.

An Optima 450w wide bore 1.5T MRI scanner, manufactured by GE Healthcare. Image courtesy of GE Healthcare.

What are the common characteristics of the magnets used in these systems? They all have the patient bore diameter of 70 cm (Fig. 2), and their length is only slightly elevated when compared to the Espree magnet (Espree – 125 cm, Optima 450w and Aera – 145 cm, Ingenia 1.5T – 150 cm). Their specification volumes (SV) are larger than the Espree’s (Espree – 45 × 45 × 35 cm; Optima 450w – 47 × 47 × 42 cm, Aera – 50 × 50 × 45 cm, Ingenia 1.5T – 55 × 55 × 50 cm). The SV refers to an ellipsoidal volume inside the bore that is suitable for imaging; it is specified by manufacturers using three diameters of spherical volume (DSV) that represent the three major axes of the SV ellipsoid. The guaranteed magnetic field homogeneity is significantly better than Espree’s due to larger DSVs of the new magnets (Espree ⩽4 ppm, Optima 450w ⩽1.25 ppm, Aera ⩽4 ppm, Ingenia 1.5T ⩽5 ppm).

Figure 2.

Wide bore MRI systems have a large, 70 cm in diameter, magnet bore (measured at the walls of a finished product). This makes patient access and comfort levels much better in comparison to legacy MRI systems. The picture shows the bore of an SMS Aera 1.5T MRI system. Image courtesy of Siemens Medical Solutions.

Why does it matter? From a user’s point of view, there are several reasons. Large bore diameter significantly facilitates inpatient MRI studies. Inpatient MRI exams are often performed on very sick patients who have several devices attached or implanted (catheters, IV lines, PICC lines, vital signs monitoring sensors, drug infusion pumps, anesthesia equipment, etc.). Many patients are unconscious or uncooperative, requiring close monitoring and easy access at all times. These logistics are much easier to manage when a large bore magnet is available. For outpatient studies, two aspects of operations favor wide bore magnets. The first one is the patient’s anxiety associated with the exam. This is often attributed to claustrophobia, but statistics show that less than 5% of the population actually suffers from claustrophobia, while various sources report the incidence rate of anxiety-related reactions during MRI scan in the range of 4–30%, with 3–5% of patients unable to complete the MRI examination.7 Thus, in ambulatory settings, having a scanner with an open, unobstructed bore significantly facilitates operations, leading to exams with better image quality acquired in a shorter scan time. The other issue is large patients. In the past, the patient transport system on an MRI scanner had a weight limit of about 350 lbs. All wide bore systems discussed here have much larger weight handling capacities (Optima 450w – 500 lbs., Aera – 550 lbs., Ingenia – 550 lbs.). This feature, combined with the availability of a much larger bore size, makes it much easier to accommodate large patients, as illustrated in Fig. 3. This is a significant issue in the USA, where a growing prevalence of obesity in the general population is well known.

Figure 3.

Wide bore magnets, equipped with large load carrying patient tables, allow scanning of very large patients, as illustrated with this picture of a PMS Ingenia system. Image courtesy of Philips Medical Systems.

What is the downside of having a wide bore magnet? It does not appear that any exist, except for the slightly increased risk of adverse effects associated with large spatial variations of the magnetic field, which will be discussed in the section on safety concerns below.

The RF subsystem

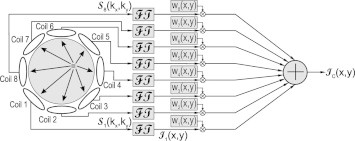

There is a revolution under way in MRI technology that has to do with the way the entire radiofrequency (RF) subsystem is designed, built, and operated. Let us consider receive RF coils first. The term “RF coil” refers to a sensor whose role is to pick up the weak NMR signals, generated by the scanned subject’s body, for further processing and image generation. The term is widely used despite obviously being a misnomer – an MRI receiver coil does not even remotely look like a coil and, strictly speaking, is an RF resonator (or an antenna). The “phased array” (PA) concept (a term apparently borrowed from radar antenna technology) is well known and in wide use in MRI scanners. In PA design, the RF receiver resonator contains multiple elements that are electrically isolated and feed into separate, autonomous data processing channels, as illustrated in Fig. 4. With proper design, a significant increase in the signal-to-noise ratio (SNR) in the resulting images can be achieved. So far, so good. But, this technology has been around for over 15 years, so why get excited about it now?

Figure 4.

The principle of operation of multi-segmented MRI receiver resonators, called “phased array coils”.

In a word, unbundling. In traditional design, all PA elements are physically embedded within a single object that people call the MRI coil. SMS broke that tradition by introducing the concept of the Total Imaging Matrix (TIM) with the launch of Magnetom Avanto on December 1, 2003. In its original implementation TIM allowed the grouping of several coils, plugged into their own receiver channels, at the same time. This was, by itself, a technological marvel given that up to that moment, plugging more than one coil into the MRI system was a sure way to damage the hardware. But a true breakthrough came with the realization that the receiver elements do not have to be physically contained within a single piece of hardware, i.e. a “coil” could be built up by the user, combining several elements available as separate pieces, to fit the imaging task at hand. This approach was first implemented in SMS Magnetom Espree, where the spine array formed the main building block allowing different additional pieces to be plugged in and selectively activated by the operator as needed. The significance of this solution is difficult to overestimate. It looks kind of obvious today, since everybody is implementing this approach in one way or another, but the engineering prowess needed to develop the original solution was remarkable.

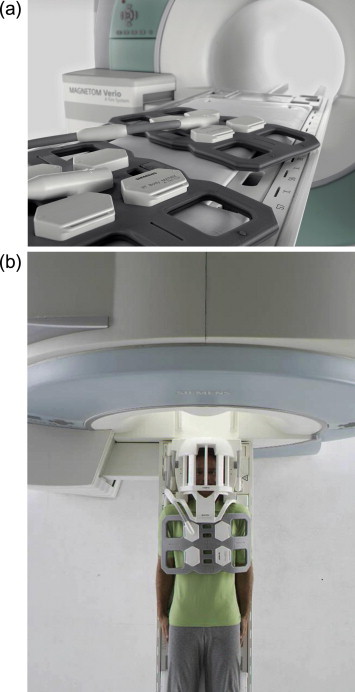

The revolution in RF receiver coil designs continues. The wide bore scanners discussed here have taken the concept of distributed coil elements to a new level. These scanners all have the spine coil built into the table permanently; other elements of the receiver PA are added by the operator on an as-needed basis, as illustrated in Fig. 5. SMS calls their design a TIM (an acronym for total imaging matrix); GEHC – GEM (geometry embracing method); and PMS – dS (dStream).

Figure 5.

An example of modular approach to receiver coil design, showing elements of a SMS TIM system. (a) The spine array is located under the cushion on the tabletop, additional elements (in this case, two flex coils) can be added as needed and plugged into receptacles visible at the far end of the table. (b) Patient setup using a spine array (under the patient), posterior and anterior head arrays, neurovascular array on top of patient neck, and torso array on the patient’s chest. All coils are plugged in and could be used at the same time. Images courtesy of Siemens Medical Solutions.

What does the user gain from this approach? The primary goal is the improvement of a signal-to-noise ratio (SNR). Higher SNR means speed (fewer image artifacts due to patient motion, faster scan time), higher SNR means better image quality (less noise), and higher SNR means new clinical applications (high resolution MRI images used for neurosurgery planning). Let us look more closely how the technology advances led to improved SNR performance of the MRI scanners.

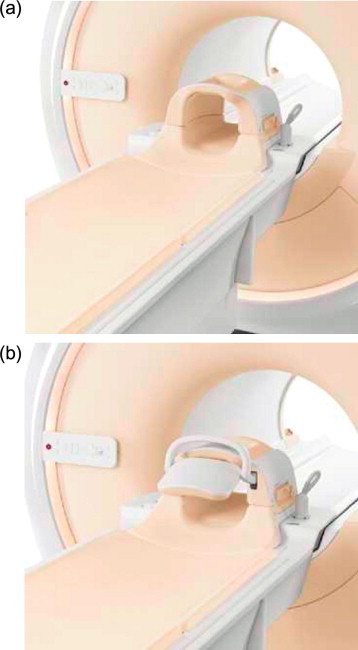

First is the issue of the number of receiver channels. Theoretically, a phased array consisting of N independent elements feeding N decoupled receiver channels, under an ideal scenario of having totally uncorrelated noise among channels and perfect sensitivity profiles, would produce images with SNR times larger than one produced with a coil composed of a single element.8 Thus, at first glance it would appear that the more the channels, the better. Taken to its logical limit, the best system would have as many channels as there are protons in the human body, so that each spin will have its independent, noise-decoupled receiver channel. This idea is absurd, for two reasons: it is impossible to build electromagnetic signal sensors that collect data from the same region in space and are fully noise-decoupled, and it is impossible to build sensors that have non-overlapping regions of signal pickup sensitivity. Thus, there is a limit to the number of receiver channels on the MRI scanner, beyond which no further improvement in SNR is observed. Where is it? Nobody appears to know at the moment. Thus, we observe a trend of adding receiver channels to the system almost daily (GEHC Optima 450w supports up to 32 channels, SMS Aera up to 64, and Ingenia, in theory, an infinite number). In the Ingenia, signals are captured and digitized within each coil itself, making the concept of “number of receiver channels” moot (there are as many as the number of the analog-to-digital converters (ADCs) the coil contains) – see Fig. 6. One has to realize that there is another process at play in this game. Adding receiver channels to the system hardware is easy and relatively inexpensive (the circuits are similar to cell phone technology). Making RF receiver coils with good performance is very difficult and not fully mastered yet, making them a “hit or miss” proposition for users (one never knows how good a particular coil really is until one starts using it routinely). Thus, efforts to improve the RF coil designs are the current focus of MRI technology development and within the next few years users can expect rapid changes in the market offerings in this area.

Figure 6.

An example of a modular design, showing elements of a PMS dStream system. A head receiver coils has a posterior element, called a Base (visible a bottom part of the head assembly) and exchangeable top elements, either a Head (a), or HeadNeck (b). In the Head configuration the system uses up to 15 receiver channels, in the HeadNeck configuration – up to 20 channels. Images courtesy of Philips Medical Systems.

Another major improvement in the receiver subsystem performance is a design that positions the digitizers as close to the pickup elements of the coils as possible. In the past, the analog connection between the coils and the bank of ADCs was quite long (up to about 100 feet) and those analog signal-carrying wires injected its own noise into the data. By moving ADCs close to the coils, that noise source was eliminated, improving the SNR significantly. In a majority of wide bore systems, the ADC circuitry is now located within the magnet enclosure itself – see Fig. 7. PMS took an extreme approach and in their Ingenias incorporated ADCs within the coils themselves, so that each coil contains integrated digitizers for all its channels and outputs digital data via a fiber optic cable. This solution appears so obvious, so why has it been implemented only now? It is extremely difficult to make electronic RF circuitry work well in strong magnetic fields, so we are witnessing another major achievement of advanced engineering.

Figure 7.

New design of the receiver pathways, as illustrated by the GEHC Discovery 750w system. The digitizing circuitry is located close to the receiver coils, shortening the analog signal path which leads to improved SNR in produced images. Image courtesy of GE Healthcare.

What is the downside of having all this wizardry available on the MRI scanner? With scanners so powerful, users have to face elevated risks to patient and operator safety, due to significant increase in operational levels of magnetic and RF fields. These issues are discussed below.

Safety and patient comfort

Fundamental risks associated with MRI technology are quite well known and thus are not going to be repeated here. A reader, interested in reviewing the basics is encouraged to consult relevant literature, for example, the ACR Guidance for Safe MRI Practices.9 The discussion that follows focuses instead on specific aspects of personnel and patient safety that have changed as a result of different performance characteristics implemented on the newest MRI hardware.

There are many regulations and industry standards that address the issues associated with the safety of MRI examinations. These documents tend to be country-specific, for obvious legal reasons. However, regulators in several countries (European Union, United States, Canada, Japan, Australia and New Zealand) adopted a common, well-known standard, developed by the International Electrotechnical Commission (IEC). The document in question is titled Particular requirements for the basic safety and essential performance of magnetic resonance equipment for medical diagnosis and is part of a large IEC 60601 standard that deals with safety aspects of design and operation of medical electrical equipment. The part of the standard that addresses MRI issues is currently in its 3rd edition10, but most equipment in use today adheres to the earlier, 2nd edition of this document.11 Because this standard is very comprehensive and is so widely applied, it will be used as a reference benchmark in the discussion that follows.

RF energy deposition

RF pulses used by the MRI scanner to manipulate proton spins within a patient’s body deposit energy in the tissue that is located within the transmit coil’s active volume. This energy is released in tissue as heat, produced by eddy currents generated by the RF energy irradiating a conductive matter, such as human tissue. If a patient’s thermoregulatory mechanisms are unable to dissipate the additional energy quickly, the irradiated tissue’s temperature will rise. If the tissue’s temperature rises above 42–43 °C for several minutes, tissue damage will occur.12 The effect is stronger (more damage in shorter time) as the temperature increase gets larger.

In practice, it is very difficult to monitor local temperature increases within a human body in real time. Thus, the industry standard relies on the concept of specific absorption rate (SAR) and specific absorbed energy (SAE) to establish safe operational limits for MRI scanners. SAR is defined as RF power deposited in a specified volume: whole body SAR averages the power over the entire patient’s body; partial body SAR averages over the volume of the patient’s body located within the effective volume of the RF transmit coil, head SAR averages over the volume of the patient’s head, and local SAR represents an average over a localized volume of tissue having a mass of 10 g.10 The SAE is defined as specific absorbed RF energy (per kilogram of tissue, averaged over the entire body) per entire MRI examination. There are many detailed limits specified in the IEC standard, but under normal clinical operating conditions, the whole body SAR can go up to 4 W/kg, with local SAR allowed to reach up to 40 W/kg (for extremities, in the first level controlled mode). SAE limit is set to 14.4 kJ/kg per MRI examination.10

What do those numbers mean? To put things in perspective, let us look at some examples, using data provided in the FAO Report on Human Energy Requirements.13 The benchmark, used to evaluate the human energy consumption is the Basal Metabolic Rate (BMR). It describes the minimum energy rate required to sustain life. Any human activity requires additional energy expenditure that the FAO categorizes using a concept of Physical Activity Ratio (PAR):

where TEE is the total energy expenditure for a given human activity. PAR of 1 describes total inactivity (including relaxed mental state), the highest value of PAR = 12.2 listed by the FAO describes the energy used by a firefighter climbing stairs in full gear.

To put SAR values in perspective, let us consider an example of a standard reference man, a male adult 30–60 years of age; his BMR is 7.013 MJ/day, or 1.16 W/kg. What kind of activity would result in generating 4 W/kg release of heat within his body? Since human energy efficiency is about 20%, then the additional energy required to release 4 W/kg as heat would be 5 W/kg above and beyond the BMR, resulting in the TEE of 6.16 W/kg, and the PAR of 5.3. That level of PAR is associated with such vigorous activities as playing tennis, mixing cement with a shovel, digging, or carrying a 27 kg load with a forehead strap. And herein lies the problem.

Under normal conditions, the heat generated by human activity is dissipated by body thermoregulatory mechanisms and environmental factors (sweating, cooling oneself by fanning or standing in a breeze, drinking cold fluids, or taking a cold shower). How quickly would a patient’s body temperature increase to dangerous levels if the thermoregulatory mechanisms were not working? The average tissue specific heat is about 3,600 J/oC kg, so dumping 4 W/kg into the tissue would result in a temperature increase of 0.0011 °C/s, or 0.07 °C/min, or 4 °C/h. If we consider the upper SAR limit for extremities, 40 W/kg, the temperature rise estimates will increase to 0.011 °C/s, 0.7 °C/min and 40 °C/h, respectively. Thus, if we were to scan a patient with severely compromised thermoregulatory capacity, say, in the left forearm, and used aggressive extremity scanning protocol with a highest allowed SAR of 40 W/kg, we could start cooking the arm in about 10 min! These examples are meant to alert the reader that advanced MRI scanners can significantly elevate the risk of patient’s tissue overheating, especially when fast, high SAR scanning sequences are used to image large patients with compromised thermoregulatory capacity.

The proximity of a danger zone can be illustrated by another example. The US Food and Drug Administration’s (FDA) MAUDE database contains reports of adverse events, associated with the use and operation of medical devices.14 A search for adverse events associated with MRI, reported to the FDA within the eighteen month period (1/1/2011 to 6/30/2012) reveals 253 incidents associated with MRI scanners (product code LNH) and 8 incidents associated with the use of specialty MRI coils (product code MOS). About half of the listed incidents report thermal injury to the patient. Most of these injuries involve localized damage, such as burns up to the third degree and up to about 7 cm in size, but there are reports of sentinel events that resulted in serious injury to the patient.

dB/dt, or time-varying magnetic fields

There are safety issues associated with time-varying magnetic fields produced by an MRI scanner, such as Peripheral Nerve Stimulation (PNS), and spatially-varying magnetic fields, such as interactions with ferromagnetic objects (strong pulling on ferrous objects brought close to the magnet). However, here we want to focus on risks associated with scanning patients with implanted hardware. Most implants used today carry the “MRI conditional” designation, which means patients carrying them can undergo MRI examination if certain restrictions are met. Most manufacturers of implanted devices specify, as one of the conditions, that the rate of change of magnetic field over the region of the body containing the device does not exceed a set value. For example, Medronic specifies that the gradient dB/dt field must be limited to 20 T/s or less over the location of an implanted Deep Brain Stimulator, such as Activa RC Model 37612. What does that mean and how is this information used to evaluate the risk associated with a specific examination?

Thus far, the evaluation of an MRI system for compliance with such restrictions focused on gradient subsystem (MFG) performance. Thus, one would start with maximum slew rate (SR – the measure of how fast the gradients could be ramped up to their required strength, a vital characteristics of a scanner). From the product datasheets one can find out the SR ratings of the wide bore scanners: Optima 450w – 150 T/s m, Discovery 750 – 200 T/s m, Aera – 125 T/s m, Skyra – 200 T/s m, Ingenia 1.5T with Omega gradients – 200 T/s m, Ingenia 3T with Omega gradients – 200 T/s m. To arrive at the maximum dB/dt rate, we have to multiply the SR by the patient bore radius, in this case 0.35 m (the same for all systems) to calculate the greatest rate of change of the magnetic field, which in case of MFG is at the point farthest away from the magnet isocenter. Thus, we get dB/dt ranging from 43.75 T/s (for Aera) to 70 T/s (for systems with SR of 200). Thus, it appears that if we limit the SR to 57 by selecting appropriate scanning sequences, we should be in a safe territory.

Not necessarily. In the analysis presented above, the effects of spatially-varying fields produced by the magnet have not been included. An MRI magnet produces a very uniform static magnetic field only within its specification volume that is centered on the magnet’s isocenter. Outside this volume, the strength of the field starts decaying rapidly (everyone wants a magnet with a very small fringe field footprint), producing static magnetic field gradients that are, for the wide bore magnet designs, strongest in the region of the magnet’s bore entrance. Since static field gradients do not induce electrical currents in space, most people assume they play a role in ferromagnetic interactions, but can be disregarded in dB/dt analysis. This is not quite the case. For example, the Ingenia 3T magnet has a maximum static spatial gradient of 17 T/m, located near the edges of the magnet bore entrance. If we pull the patient out of the bore moving the table at 2 m/s (e.g. in an emergency situation) we will generate a time-varying dB/dt of 34 T/s, thus creating a serious risk of a sentinel event occurrence. With recent news on the development of MRI-compatible pacemakers, situations where the patient with a pacemaker will qualify for and undergo an MRI examination are bound to emerge; proper procedures to guard against situations as those described above must therefore be developed and adhered to.

Conclusions

MRI technology continues to evolve, introducing new system designs that produce better image quality, yield larger throughput, and introduce new scanning methods that continue to change diagnostic imaging standards of practice. When run correctly, MRI scanners are perfectly safe. However, the newest models are capable of running with characteristics that are much closer to the safe operational boundaries than the legacy systems have been. Thus, extra care and vigilance are required of the operator, especially when using heavy-duty scanning protocols (such as DTI, fMRI, DCE, or single shot acquisitions, for example). Patients with implanted devices, compromised thermoregulatory capabilities, or with impaired capability to sense or communicate heat sensations should be scanned with utmost care. This particularly applies to the inpatient population, where cases of patients that are unconscious, are sedated, are locally anesthetized, are thermally insulated, have a fever, are on drug regimes that might affect their thermoregulatory capabilities, have an impaired capability to perspire, or are at risk of cardiac arrest are far more frequent than in the outpatient population.

Footnotes

Peer review under responsibility of King Saud University.

References

- 1.Optima MR450w with GEM. Technical Data. GE Healthcare, Document MWS DOC1037440, July 2012.

- 2.Discovery MR750w with GEM. Technical Data. GE Healthcare, Document MWS DOC0935035, March 2011.

- 3.Magnetom Aera. A Tim + Dot System. Siemens Medical Solutions, Document, Order No A91MR-9011-11-4A00, November 2011.

- 4.Magnetom Skyra. A Tim + Dot System. Siemens Medical Solutions, Document, Order No A91MR-9013-11-4A00, November 2011.

- 5.Changing Expectations. Philips Magnetic Resonance Ingenia 1.5T with Omega HP gradients. Philips Medical Systems, Document ID 4522 962 68921, January 2011.

- 6.Changing Expectations. Philips Magnetic Resonance Ingenia 3.0T with Omega HP gradients. Philips Medical Systems, Document ID 4522 962 66071, November 2010.

- 7.Katznelson R., Djaiani G.N., Minkovich L., Fedorko L., Carroll J., Borger M.A. Prevalence of claustrophobia and MRI after coronary artery bypass graft surgery. Neuropsychiatric Dis Treat. 2008;4:487–493. doi: 10.2147/ndt.s2699. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Roemer P.B., Edelstein W.A., Hayes C.E., Souza S.P., Mueller O.M. The NMR Phased Array. MRM. 1990;16:192–255. doi: 10.1002/mrm.1910160203. [DOI] [PubMed] [Google Scholar]

- 9.Kanal E., Barkovich A.J., Bell C., Borgstede J.P., Bradley W.G., Froelich J.W. ACR guidance document for safe MR practices: 2007. AJR. 2007;188:1447–1474. doi: 10.2214/AJR.06.1616. [DOI] [PubMed] [Google Scholar]

- 10.IEC 60601–2-33:2010, Medical Electrical Equipment – Part 2–33: Particular requirements for the basic safety and essential performance of magnetic resonance equipment for medical diagnosis. International Standard, Edition 3.0.

- 11.IEC 60601–2-33:2002, Medical Electrical Equipment – Part 2–33: Particular requirements for the basic safety and essential performance of magnetic resonance equipment for medical diagnosis. International Standard, Edition 2.0.

- 12.Dewhirst M.W., Viglian B.L., Lora-Michiels M., Hanson M., Hoopes P.J. Basic principles of thermal dosimetry and thermal thresholds for tissue damage from hyperthermia. Int J Hyperthermia. 2003;19:267–294. doi: 10.1080/0265673031000119006. [DOI] [PubMed] [Google Scholar]

- 13.Food and Agriculture Organization (FAO) of the United Nations. Human Energy Requirements. Report of a Joint FAO/WHO/UNU Expert Consultation. FAO Food and Nutrition Technical Report Series 2001:1.

- 14.US Food and Drug Administration, Center for Devices and Radiological Health. Manufacturer and User Facility Device Experience (MAUDE) Database. http://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfMAUDE/Search.cfm. Accessed July 17, 2012.