Abstract

We report that the cells in a natural honeybee comb have a circular shape at ‘birth’ but quickly transform into the familiar rounded hexagonal shape, while the comb is being built. The mechanism for this transformation is the flow of molten visco-elastic wax near the triple junction between the neighbouring circular cells. The flow may be unconstrained or constrained by the unmolten wax away from the junction. The heat for melting the wax is provided by the ‘hot’ worker bees.

Keywords: honeycomb, circular cell at birth, rounded hexagonal cell

1. Introduction

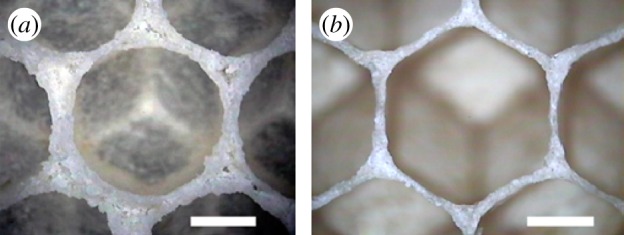

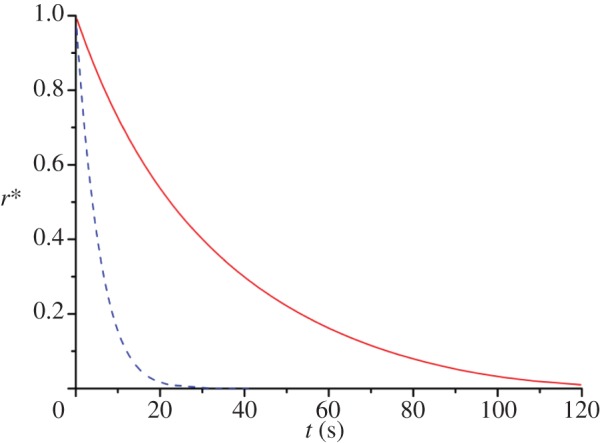

A honeybee comb is the most studied natural cellular structure. The rounded hexagonal shape of its cells has intrigued natural philosophers for several centuries, who proffered many esoteric explanations some of which would need the bees to have an uncanny ability to perform mathematical calculations or the magical quality to measure lengths and angles. A succinct historical account can be found in the paper of Pirk et al. [1], where they also give an overview of the many attempts to explain the mechanisms by which the bees construct the hexagonal cells of the comb. It is unlikely that such esoteric and even bizarre speculations would have been necessary had it been known that the fresh honeycomb cell begins its life as a circle but quickly takes on the familiar rounded hexagonal form, as shown in figure 1.

Figure 1.

Italian honeybee (Apis mellifera Ligustica) comb cell at (a) ‘birth’, and at (b) 2-days old, scale bar is 2 mm. (Online version in colour.)

Pirk et al. [1] have argued based on several experiments on molten waxes that the mechanism of this pattern transformation is rather mundane. They suggested that in analogy with these experiments that honeybees heat up wax along the entire circumference of the cell during the building process which flows thermo-plastically into an array of closed-packed cylinders formed by the worker bees themselves. The internal diameter of the cylinder (6 mm, figure 1) is roughly commensurate with the girth of the Italian bee. This mechanism would require the worker bees to heat up a large volume of wax. It is known however from environmental scanning electron microscopy of the straight portions of the 2-day-old comb cell walls that the wax flakes are still loose and not fully fused [2] suggesting that the wax may not be heated along the entire circumference of the cell. On the other hand, it is also known that the hot nurse bees put their whole thorax into the cells of the brood nest which suggests that they heat the whole cell [3–5]. We shall therefore consider this possibility too, although there is no evidence that the bees that heat the freshly built cells are the same as the hot nurse bees.

We will show that the regular pattern of rounded hexagons in the honeybee comb is a result of the progressive fusion of the circular walls induced by the flow of the visco-elastic molten wax near the triple junction. We consider two scenarios. In the first scenario, we assume that the flow is constrained by the visco-elastic unmolten wax away from the triple junction. In the second, we allow for the possibility that the entire cell wall is heated such that flow of the visco-elastic molten wax near the triple junction is unconstrained. Our calculations will therefore partially or fully confirm the experimental observations on molten waxes reported by Pirk et al. [1] and the mechanism proposed by them depending on which of these two scenarios is the most probable one. This can be verified only by actual measurement of the time of evolution from the circular to the rounded hexagonal shape of the cells.

We note en passant that the internal cell diameter decreases with the age of the comb as a result of the thickening of the walls [2]. This may explain why the age of honeycombs affects the honeybee growth and brood survivorship [6]. The hot nurse bees have been observed by infrared cameras placed inside the brood nest, but as mentioned above there is no evidence that the bees that heat the freshly built cells are the same as the hot nurse bees. A video of the hot nurse bees in action is available at http://www.hobos.de/de/lehrer-schueler-eltern/ueber-hobos/impressionen/winterbiene.html.

From a purely mechanics point of view, Zhang et al. [7] have shown that the structural patterns of simple periodic cellular structures at all scales (for example, a single-walled carbon nanotube (SWCNT) bundle and a millimetre-size plastic straw bundle) can transform dramatically under external stimuli. Under gradual hydrostatic straining, the circular cross-section of the nanotubes in the bundle gradually changed into a rounded hexagon when the strain reached 6%. They proved that this was a result of the minimization of the inter-tube van der Waals interaction energy. The closed-packed circular plastic straw bundle transformed into a hexagonal pattern on heating by conduction until the melting point of the plastic as a result of the minimization of the surface energy which required that the curved walls fuse together, increasing the contact area and becoming planar.

In this short paper, it is shown that, exactly as in the closed-packed plastic straw bundle heated by conduction until the melting point of the plastic, the regular pattern of rounded hexagons in the honeybee comb is a result of the progressive fusion of the circular walls induced by the flow of the visco-elastic molten wax near the triple junction.

2. Mathematical preliminaries

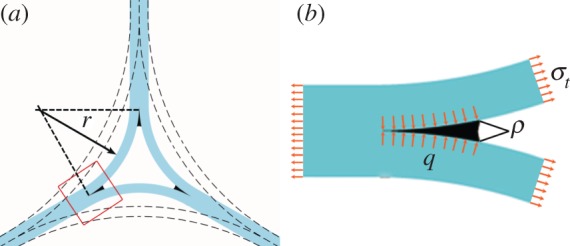

Consider the closed-packed array of circular fresh honeycomb cells at ‘birth’ (figure 1a). The individual worker bees that characteristically work side-by-side in adjacent and opposite circular tubes [8] build the circular cells. The specialist ‘hot’ workers knead and heat the wax flakes near the triple junctions until they flow visco-elastically at about 45°C. In this manner, a viscous liquid (or a semi-solid) bridge with a concave meniscus is formed at the triple junctions between the neighbouring circular cells (figure 2a). As a result of the surface tension of this bridge, a negative pressure is created in the junction, which in turn leads to a tensile state of stress in the cell walls (figure 2b). The walls are thus continuously stretched during this process. The adjoining walls progressively fuse together increasing the contact area between them and straightening. In theory, this process can continue until the entire curved walls become planar minimizing the surface energy and thus creating an array of hexagonal cells with sharp corners. But as will be proved below, that would take an infinitely long time. In practice, therefore, an array of hexagonal cells with rounded corners will be formed in a limited time.

Figure 2.

(a) Schematic diagram of a triple junction during the process of transformation. An enlarged view of the marked square is shown on (b) with the molten wax in black. (Online version in colour.)

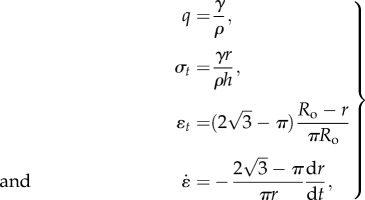

The model for the fusion of the cell walls is shown in figure 2. In this model the negative pressure q in the liquid bridge with the concave meniscus formed by the molten beeswax creates a the tensile stress σt, and a strain ɛt in the wall of the cell

|

2.1 |

where ρ is the radius of the semi-cylindrical meniscus, γ is the surface tension of the molten beeswax at 45°C, h is the thickness of the wall of the cell. Ro and r are the mean radii of the original and deformed cell at time t, respectively. An overdot denotes the rate of change with time. The expression of the tensile stress in equation (2.1)2 is different from the work of Oruganti & Ghosh [9]. This expression has been derived from the correct equilibrium condition, whereas an inappropriate equilibrium condition seems to have been used in the work of Oruganti & Ghosh [9].

Shellhammer et al. [10] have experimentally shown that the visco-elastic behaviour of beeswax is best captured by a generalized Maxwell model consisting of one spring element in parallel with two Maxwell elements. However, as the relaxation time of one of the two Maxwell elements is about 100 times longer than that of the other, the generalized Maxwell model can be replaced by one spring element in parallel with just one Maxwell element. Their measured relaxation modulus can thus be captured by the simplified equation

| 2.2 |

The visco-elastic behaviour of beeswax can be described by

| 2.3 |

where τr = η/E1, τc = τr ED/E0, ED = E0 + E1 and η is the viscosity of the wax. Substitution of (2.2) and (2.3) into (2.1) and integration gives (with r* = 1, t = 0)

| 2.4 |

where  , t is in s, and all linear dimensions are normalized by R0, such that r* = r/R0, ρ* = ρ/R0, h* = h/R0. From equation (2.4), it is clear that it would take an infinitely long time for a hexagon with sharp corners (r* = 0) to evolve. Thus, in the honeybee combs the hexagons have rounded corners (r* > 0). To estimate the time it takes for the circular cell to begin to transform into a rounded hexagon, it is necessary to use the properties of beeswax and the initial geometry of the circular cell (R0 = 3 mm).

, t is in s, and all linear dimensions are normalized by R0, such that r* = r/R0, ρ* = ρ/R0, h* = h/R0. From equation (2.4), it is clear that it would take an infinitely long time for a hexagon with sharp corners (r* = 0) to evolve. Thus, in the honeybee combs the hexagons have rounded corners (r* > 0). To estimate the time it takes for the circular cell to begin to transform into a rounded hexagon, it is necessary to use the properties of beeswax and the initial geometry of the circular cell (R0 = 3 mm).

The thickness of the fresh cell wall (h) of the Italian honeybee comb has been measured and reported by Zhang et al. [2] and the mean value is 90 μm. Its surface tension γ is known to be low, reducing from about 37 × 10–3 N m−1 at 20°C to about 33 × 10–3 N m−1 at 45°C [11]. Although the elastic modulus of the cell wall of a 2-day-old Italian honeybee comb (figure 1b) has been measured by Zhang et al. [2] at 25°C, the wall of the comb cell at ‘birth’ is rather a loose collection of wax flakes (figure 1a) compared with the denser 2-day-old wall (figure 1b). Thus, the modulus of the wall at ‘birth’ will be significantly less than that at the age of two days. We use the values measured by Shellhammer et al. [10] for beeswax at 25°C: ED = 34.44 kPa, τr = 14.31 s, η = τr E1 = 108.4 kPa s. This estimate of viscosity is well within the range 104–1010 Pa s reported by Darvell & Wong [12] in the temperature range 30–40°C.

It is also known [8] that the fresh wax wall of an African honeybee comb loses its elastic modulus by a factor of 3.5 when the temperature rises from 25°C to 45°C. It can be assumed that a similar temperature dependence of the fresh wax wall prevails in the Italian honeybee comb, which means that ED = 9.84 kPa, τr = 4.09 s, and thus η = 8.85 kPa s at 45°C.

2.1. Scenario 1

The molten wax in the bridge is surrounded by the unheated wax walls. The constitutive behaviour of this composite liquid–solid cell wall material can be estimated as that of a mixture of the visco-elastic molten phase with that of the visco-elastic unmolten wax phase. Assuming that the viscous molten phase volume fraction is about 10%, the viscosity of composite cell wall material will be 10η. Likewise, the modulus of elasticity of the composite cell wall material will be equal to 0.1ED at 45°C + 0.9ED at 25°C. Thus, for the composite cell wall near the liquid bridge we have by the rule of mixtures, ED = 31.98 kPa, η = 88.5 kPa s.

The only remaining parameter is the radius of the concave meniscus of the molten wax ρ. It is hard, if not impossible to measure it in situ, but it can be estimated as follows. Consider the instant (t > 0) when the three molten wax bridges in the triple junction (figure 2a) are touching one another, so that the concave menisci form a circle of radius ρ. From geometrical considerations, it follows that at this instant

| 2.5 |

It is obvious that ρ* ≤ 0.155. Equation (2.4) can therefore be written as

|

2.6 |

For example, for the radius to reduce to 1 mm (r* = 1/3 and ρ* = 0.052), the time taken can be calculated from equation (2.6), and it works out to be just 36.3 s.

2.2. Scenario 2

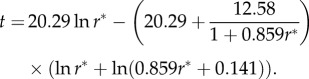

The molten wax in the bridge is able to flow unconstrained as the entire cell is heated. This means that there is no need to introduce a liquid–solid composite and that the entire cell material has the following properties at 45°C: ED = 9.84 kPa, τr = 4.09 s, and thus η = 8.85 kPa s. In this scenario, equation (2.4) for the evolution of r* is now only approximate, because it does not include the small additional tensile stress in the wall induced by the uniform expansion of the cell by heating. Substitution of the material properties, and (2.5) into (2.4) will lead to an equation similar to (2.6) which we do not reproduce here. It is clear, however, that this scenario is more dynamic. For example, for the radius to reduce to 1 mm (r* = 1/3 and ρ* = 0.052), the time taken works out to be just 6.1 s compared with 36.3 s in scenario 1 above. The evolution of the dimensionless radius of the rounded hexagon r* with t in both scenarios is shown in figure 4.

Figure 4.

Evolution of the radius of the deformed cell r* with time t using the generalized Maxwell model for visco-elastic beeswax the (red solid line corresponds to heating near the triple junctions only, while the dashed line corresponds to heating the entire cell circumference). (Online version in colour.)

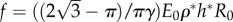

In other words, the circular honeycomb cell begins to take on the rounded hexagonal form as soon as the ‘hot’ worker bees heat the wax either near the triple junction only or over the whole circumference. This is confirmed by our observations during the very early stages of the comb construction. The photograph shown in figure 1a was taken when the worker bees were interrupted in their building activity. The beekeeper ‘smoked’ the swarm of bees from the hive before they had finished building the comb (figure 3). It was therefore possible to observe all the cells in the comb. Only some of the cells at the bottom of comb which were still incomplete and shorter than the standard 10 mm length were found to be of circular shape (figure 1a). Even these circular cells had already taken the familiar hexagonal form just 0.5 mm away from the bottom. This suggests that the circular cells transform into the rounded hexagonal form during the process of building. When the combs are fully finished, we found that all of the cells were built to the standard length (about 10 mm) and there were no circular cells left (figure 1b).

Figure 3.

Combs during construction on two different wooden frames. (Online version in colour.)

In conclusion, it should be stressed that we have looked at the transformation of a circular cell in the honeybee comb to a rounded hexagon in a two-dimensional context purely from a mechanics point of view. We cannot but marvel at the crucial role played by the bees in this process; they knead, heat and thin the wax exactly where it is needed. It should also be mentioned that the constraint provided by the third dimension is likely to increase the time we have calculated. Finally, to identify the most probable of the two scenarios proposed above it will be necessary to measure the radius of the cell as it is evolving from the circular to the rounded hexagonal shape and to compare the measurements with the predictions of figure 4. This is not an easy task but we plan to undertake it soon.

Funding statement

K.Z. and J.W. acknowledge the support of the National Natural Science Foundation of China through grants 11202025, 10932001 and 11172002.

References

- 1.Pirk CWW, Hepburn HR, Radloff SE, Tautz J. 2004. Honeybee combs: construction through a liquid equilibrium process? Naturwissenschaften 91, 350–353. ( 10.1007/s00114-004-0539-3) [DOI] [PubMed] [Google Scholar]

- 2.Zhang K, Duan HL, Karihaloo BL, Wang J. 2010. Hierarchical, multilayered cell walls reinforced by recycled silk cocoons enhance the structural integrity of honeybee combs. Proc. Natl Acad. Sci. USA 107, 9502–9506. ( 10.1073/pnas.0912066107) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Kleinhenz M, Bujok B, Fuchs S, Tautz J. 2003. Hot bees in empty cells—brood nest heating from within. J. Exp. Biol. 206, 4217–4231. ( 10.1242/jeb.00680) [DOI] [PubMed] [Google Scholar]

- 4.Bujok B, Kleinhenz M, Fuchs S, Tautz J. 2002. Hot spots in the beehive. Naturwissenschaften 89, 299–301. ( 10.1007/s00114-002-0338-7) [DOI] [PubMed] [Google Scholar]

- 5.Tautz J. 2008. The buzz about bees. Heidelberg, Germany: Springer. [Google Scholar]

- 6.Berry JA, Delaplane KS. 2001. Effects of comb age on honey bee colony growth and brood survivorship. J. Apicult. Res. 40, 3–8. [Google Scholar]

- 7.Zhang K, Zhao XW, Duan HL, Karihaloo BL, Wang J. 2011. Pattern transformations in periodic cellular solids under external stimuli. J. Appl. Phys. 109, 084907 ( 10.1063/1.3567110) [DOI] [Google Scholar]

- 8.Hepburn HR. 1986. Honeybees and wax, an experimental natural history. Heidelberg, Germany: Springer. [Google Scholar]

- 9.Oruganti RK, Ghosh AK. 2007. Fabrication of nickel honeycombs. Acta Material. 55, 6074–6083. ( 10.1016/j.actamat.2007.07.031) [DOI] [Google Scholar]

- 10.Shellhammer TH, Rumsey TR, Krochta JM. 1997. Viscoelastic properties of edible lipids. J. Food Eng. 33, 305–320. ( 10.1016/S0260-8774(97)00030-7) [DOI] [Google Scholar]

- 11.Bartell FE, Zuidema HH. 1936. Wetting characteristics of solids of low surface tension such as talc, waxes and resins. J. Am. Chem. Soc. 58, 1449–1454. ( 10.1021/ja01299a041) [DOI] [Google Scholar]

- 12.Darvell BW, Wong NB. 1989. Viscosity of dental waxes by use of Stokes’ law. Dental Mater. 5, 176–180. ( 10.1016/0109-5641(89)90009-2) [DOI] [PubMed] [Google Scholar]