Abstract

Background:

Rhizoma dioscoreae nipponicae is a perennial herb and its roots have been widely used in Traditional Chinese Medicine (TCM).

Objective:

To develop and optimize the extraction and hydrolysis technology of diosgenin from Rhizoma dioscoreae nipponicae.

Materials and Methods:

1-methyl-3-(3-sulfopropyl)-imidazolium hydrogen sulfate ([PSMIM]HSO4), as a kind of functional ionic liquid, replaced inorganic acid, and was used in a one-step ultrasonic extraction and hydrolysis for the preparation of diosgenin (the aglycone of dioscin and an important precursor chemical in the pharmaceutical industry) from Rhizoma dioscoreae nipponicae, for the first time. The effects of various factors were evaluated. The obtained product was studied using high performance liquid chromatography (HPLC).

Results:

About 6.35 mg of diosgenin could be obtained from 2.0 g of raw material. Reusability and recycling of the ionic liquid were validated with fairly good results. The ionic liquid solution was reused four times, and the final extraction efficiency only decreased by 5%.

Conclusion:

In virtue of the obvious advantages of the green extraction and catalytic solvent, with further study, it is believed that this new one-step preparative method promises to replace the traditional methods.

Keywords: Diosgenin, extraction, hydrolysis, ionic liquid

INTRODUCTION

Diosgenin, a steroid sapogenin, is the product of hydrolysis by acids or enzymes of saponins from the plants of the Dioscorea species. As a kind of important industrial precursor chemical, it is popularly used for the commercial synthesis of cortisone, pregnenolone, progesterone, and other steroid products in the pharmaceutical industry.[1,2,3] Rhizoma dioscoreae nipponicae is a Traditional Chinese Medicine (TCM) for expelling wind, removing dampness, promoting blood circulation, diffusing the lung, and suppressing cough in cases of angina and chronic bronchitis.[4] The bioactive constituents in Dioscoreae nipponicae are mainly steroidal saponins. Among them, as a major water-insoluble saponin, dioscin is usually used, to prepare diosgenin by the hydrolysis process.

The most common extraction and preparation method of diosgenin from natural raw materials is hydrolysis with inorganic acid, such as sulfuric and hydrochloric acid, in laboratories and actual production.[5] As is well-known, these traditional techniques are increasingly failing to keep up with the pace of the new era. As a kind of novel green solvent, ionic liquids (ILs) have many unique properties, such as, negligible vapor pressure, good thermal stability, and an easily dissolvable and extracting ability.[6] These advantages are highly attractive to the present academic and industrial circles related to the natural functional resources, so many more applications are realized.[7,8,9,10,11] The traditional hydrolysis process, catalyzed by inorganic acids, always suffers from environmental pollution, energy-inefficiency, corrosion hazard, recycling difficulty of acids, as well as, carbonization of the product under high temperature, and so on. Considering these occurring disadvantages, the IL is a promising alternative or replacement for conventional inorganic acid catalysts. Furthermore, the ultrasonic-assisted process could obtain higher extraction and catalytic efficiency, and consume less solvent, which has been greatly popularized in recent years.[12]

On the basis of the above-mentioned background, ([PSMIM]HSO4) in aqueous solution was selected and used as a solvent to extract dioscin from Rhizoma dioscoreae nipponicae in this study, and at the same time it could catalyze acid hydrolysis of dioscin, to prepare diosgenin. Additionally, the effects of the key hydrolysis conditions were investigated. This new one-step ultrasonic extraction and hydrolysis method is greener and more efficient, and is expected to replace the traditional methods with further study and application.

MATERIALS AND METHODS

Materials

Rhizoma dioscoreae nipponicae was purchased from a local drug store, and then milled and dried. Standard diosgenin used for HPLC was obtained from Tauto Biological Technology Company (Shanghai, China). All chemicals involved in this study were at least of analytical reagent grade. All the ILs were synthesized according to the procedures mentioned in the literature.[13,14,15,16]

Preparation of diosgenin from Rhizoma dioscoreae nipponicae

Dried and ground raw plant material of 2.0 g was mixed with IL solution in a flask and sonicated for 30 minutes. Next the suspension was extracted and hydrolyzed under reflux at 100°C, while the ratio of material to -liquid ranged from 1:7.5 to 1:25. After the appointed reaction time, the reactor was cooled down to room temperature and the obtained mixture was filtrated using a Busher funnel. The filtrate was collected and reused for the next extraction, and the residue was washed with redistilled water until its pH was neutral. Following this the residue was dried at 60°C under vacuum and treated with 40 mL hexane, under reflux, for one hour. After extraction, the suspension was filtrated and the filtrate was distilled under vacuum. The obtained substance was dissolved with 5 mL methanol, and then filtered through a 0.45 μm microporous membrane prior to HPLC analysis.

Analytical method

The yield of diosgenin was analyzed on a Shimadzu LC-20A high-performance liquid chromatography system (Tokyo, Japan) with an SPD-M20A PDA detector and a Welchrom symmetry C18 column (250 mm × 4.6 mm, 5 μm). During this process, the column temperature remained constant at 30°C, while the mobile phase applied was 100% methanol, at the flow rate of 0.8 mL / minute, with ultraviolet (UV) detection at 209 nm, and the volume for each injection being 10 μL. The concentration of diosgenin was calculated based on the standard curve obtained with the standard substances. Moreover, the extraction efficiency was expressed as the observed value of diosgenin and the maximum amount in the curve was taken to be 100%.

RESULTS

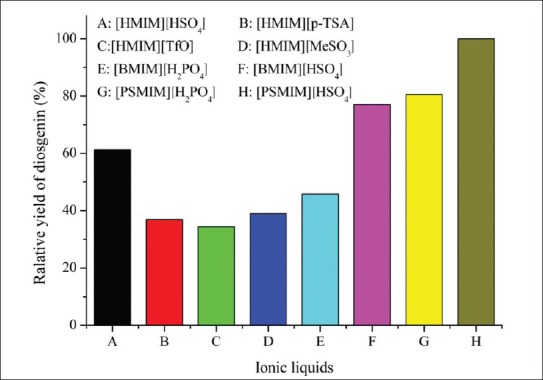

Comparison of the performance of ionic liquids

The acidity of ILs is one of the most important factors in the hydrolysis of natural glycosides. Meanwhile, excellent solubility is also needed when ILs are used as extraction solvents. Thus, eight BrÖnsted ionic liquids ([HMIM][HSO4], [HMIM][p-TSA], [HMIM][TfO], [HMIM][MeSO3], [BMIM][H2PO4], [BMIM][HSO4], [PSMIM][HSO4], and [PSMIM][H2PO4]) were first selected in our experiment. Their pH values were measured in a 20 mmol / 100g aqueous solution at 30°C, via a pH meter. They were 1.2, 5.6, 5.7, 4.9, 6.1, 1.6, 1.0, and 1.5, successively. The performance of the selected ionic liquids was compared under the same molar concentrations (2 mol / L aqueous solution) by the yields of diosgenin at 100°C, for five hours, and the results are shown in Figure 1. It was obvious that the ionic liquids [PSMIM][HSO4] could obtain the highest yield, which had higher acidity and solubility for target steroidal saponins, at the same time. Moreover, compared with other anions, [H2PO4]- and [HSO4]- could achieve a better performance. [PSMIM]+ had a sulfonic group that might cooperate with the anion, to provide a stronger catalytic effect, and the aliphatic side chain in the cations was also found with obvious contribution to better solubility for dioscin in our study. Thus, [PSMIM][HSO4] solution was chosen as the optimal solvent to perform extraction and hydrolysis of dioscin.

Figure 1.

The effect of IL types on the yield of diosgenin (2 g material mixed with 2.0 mol / L ionic liquid solution at a material to liquid ratio of 1:20 was extracted and hydrolyzed under reflux at 100°C, for five hours)

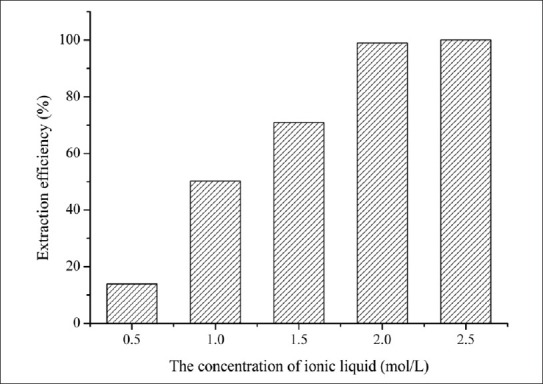

Effect of ionic liquid concentration on diosgenin yield

The concentration of ionic liquid was an important factor, which should be studied to ensure high extraction and hydrolysis efficiency of diosgenin. In this study, 40 mL of different concentrations (0.5 mol / L, 1.0 mol / L, 1.5 mol / L, 2.0 mol / L, and 2.5 mol / L) were chosen, to investigate their effect on the extraction efficiency of diosgenin. As shown in Figure 2, no significant improvement was found when it was increased to 2.0 mol / L. Thus, 2.0 mol / L of ([PSMIM]HSO4) was selected in present study.

Figure 2.

The effect of the concentration of ionic liquid on the extraction efficiency (2 g material mixed with ionic liquid solution at a material to liquid ratio of 1:20 was extracted and hydrolyzed under reflux at 100°C for five hours)

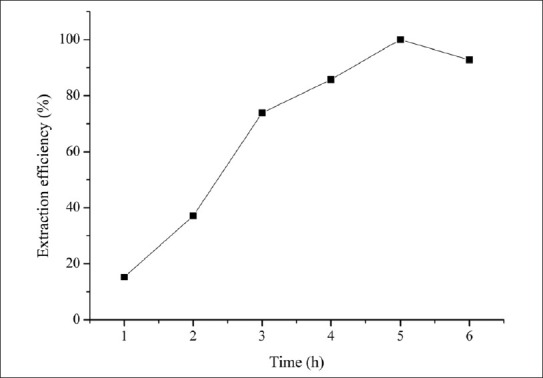

Effect of time on diosgenin yield

To investigate the effect of the reaction time on the extraction efficiency of diosgenin, comparative experiments were carried out at one, two, three, four. five, and six hours, respectively. The result is shown in Figure 3. The yield of diosgenin increased sharply within five hours, while after five hours, its yield began to decrease. This could be due to the fact that diosgenin was unstable in the acid solution for a very long time. Therefore, in the optimization process, five hours was selected as the optimal reaction time.

Figure 3.

The effect of time on extraction efficiency (2 g material mixed with ionic liquid solution at a material to liquid ratio of 1:20 was extracted and hydrolyzed under reflux at 100°C)

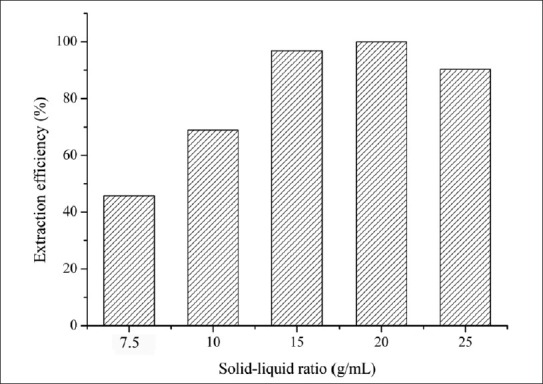

Effect of the ratio of solid to liquid on diosgenin yield

To optimize the solid–liquid ratio, comparative experiments were also carried out with 2.0 mol / L of ([PSMIM]HSO4) at a five-hour reaction time, when the solid–liquid ratio changed. Figure 4 shows the related result, and it was noticed that the yield of diosgenin reached maximum when the ratio of liquid to material was 20:1. However, there was a little reduction when the ratio improved. In view of the fact that more time and energy were required to condense the extraction solution in a later separation process, the material / liquid ratio of 1:20 was chosen, to contribute to the high yield of diosgenin.

Figure 4.

The effect of solid–liquid ratio on the extraction efficiency (2 g material mixed with 2.0 mol / L ionic liquid solution was extracted and hydrolyzed under reflux at 100°C for five hours)

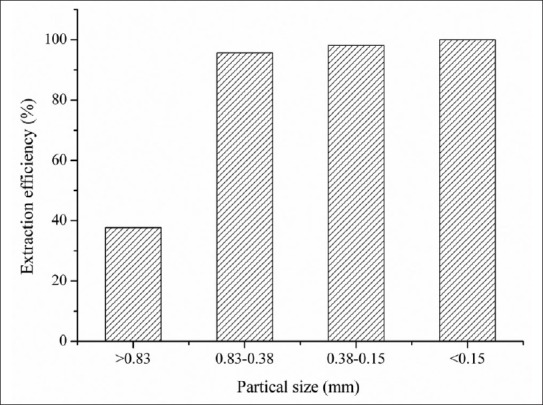

Effect of particle size on diosgenin yield

Finally, the influence of particle size on extraction efficiency was evaluated, as this parameter was often overlooked by researchers and frequently not well-defined. In general, a smaller sample particle size can produce relatively higher extraction efficiency, because a great specific surface area is more beneficial for the mass transfer between sample particles and solvent. However, more coexisting impurities will be extracted together with the target constituents, which may bring great troubles to the subsequent processing. In this study, partially ground parsley flakes have been passed through three different stacked standard-size sieves (20, 40, and 100 mesh), respectively. Four different particle size fractions have been collected (> 0.83, > 0.38 and < 0.83, < 0.38 and > 0.15, < 0.15 mm) and extracted, respectively. The results are shown in Figure 5, which indicate that when the particle size is larger than 0.83 mm, the extraction efficiency will obviously decrease. The particle size fraction (< 0.38 and > 0.15) may basically meet the requirement of the extraction.

Figure 5.

The effect of particle size on the extraction efficiency (2 g material mixed with 2.0 mol / L ionic liquid solution was extracted and hydrolyzed under reflux at 100°C, for five hours)

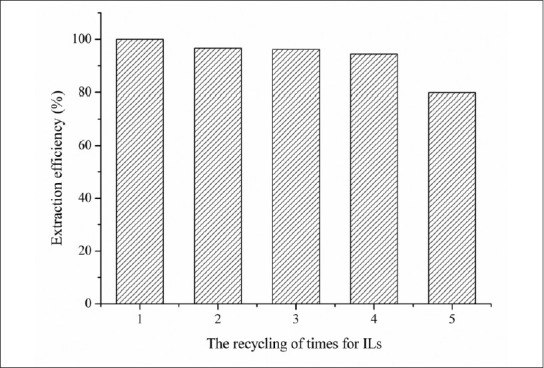

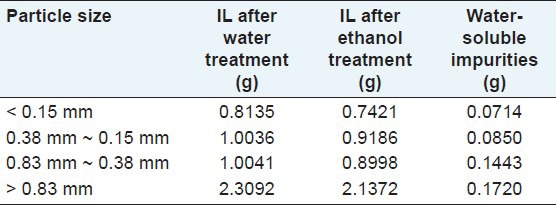

Recycling and recovering of ionic liquid

In the principle of green pharmaceutical techniques, catalyst recycling is always significant. In the study of recycling, the filtrate is reused directly four more times under optimized conditions. The results are satisfactory as shown in Figure 6. The extraction efficiency only decreases by 5%. Then in the process of recovering, the filtrate residue that comes from the hydrolysis process is washed with water, and then the cleaned mixture is distilled under vacuum to remove the water. The residual is diluted by anhydrous ethanol and filtrated to remove water-soluble impurities. As per the results shown in Table 1, it can be found that the particle size of raw materials also play an important role in the recovery of IL. When the particle size is larger than 0.83 mm, the amount of IL absorbed by the raw materials is the largest. That is, the larger particle size, the more IL absorbed. It proves that the related mechanism is micropore adsorption rather than surface adsorption, although small particles have a greater specific surface area, it will only absorb less IL. Finally, the IL is concentrated in vacuum, and subsequently added in the filtrate, which comes from the hydrolysis process. Then it can be directly used for the next extraction.

Figure 6.

The effect of recycling times on extraction efficiency

Table 1.

The effect of particle size on the recovery of Ionic Liquids

CONCLUSION

In this study, a new and efficient IL-based method has been developed for preparation of diosgenin from Rhizoma dioscoreae nipponicae. In this one-step method, ([PSMIM]HSO4) was not only an extraction solvent for dioscin, but also a promising catalyst for the hydrolysis of dioscin. Based on comprehensive and comparative studies, the hydrolysis conditions were investigated and optimized. Under optimal conditions, the IL-based method could obtain good extraction efficiency (about 6.35 mg from 2.0 g of raw material). It was more significant that these ILs were easy to be synthesized on a small and industrial scale. Compared to the traditional methods, this method was more efficient and green. Moreover, reusing and recovering of the ionic liquid were also studied, with fairly good results.

It is believed that this preparative method has great potential and broad prospects for further utilization of Rhizoma dioscoreae nipponicae and other plants of the Dioscorea species.

Footnotes

Source of Support: The study was supported by the National Science Foundation of China (No. 81102344)

Conflict of Interest: None declared.

REFERENCES

- 1.Ferandes P, Cruz A, Angelova B, Pinheiro HM, Cabral JM. Microbialconversion of steroid compounds: Recent developments. Enzyme Microb Technol. 2003;32:688–705. [Google Scholar]

- 2.Sauders R, Cheetham PS, Hardman R. Microbial transformation of crude fenugreek steroids. Enzyme Microb Technol. 1986;8:549–55. [Google Scholar]

- 3.Huang W, Zhao HZ, Ni JR, Zuo H, Qiu LL, Li H. Concurrent removal and accumulation of heavy metals by the three aquatic macrophytes. Bioresour Technol. 2008;99:7091–7. doi: 10.1016/j.biortech.2008.01.002. [DOI] [PubMed] [Google Scholar]

- 4.Yao L, Dong WR, Lu F, Liu SM. 2 Hz Electro-acupuncture at Yinlingquan (SP9) and Ququan (LR8) acupoints induces changes in blood flow in the liver and spleen. Am J Chin Med. 2012;40:75–84. doi: 10.1142/S0192415X12500061. [DOI] [PubMed] [Google Scholar]

- 5.Cheng P, Zhao HZ, Zhao B. Pilot treatment of wastewater from dioscorea zingiberensis C.H. Wright production by anaerobic digestion combined with a biological aerated filter. Bioresour Technol. 2009;100:2918–25. doi: 10.1016/j.biortech.2009.01.054. [DOI] [PubMed] [Google Scholar]

- 6.Welton T. Room-temperature ionic liquids: Solvents for synthesis and catalysis. Chem Rev. 1999;99:2071–84. doi: 10.1021/cr980032t. [DOI] [PubMed] [Google Scholar]

- 7.Ma WY, Lu YB, Hu JH, Chen ZZ, Zhang YJ, Pan J. Application of ionic liquids based microwave-assisted extraction of three alkaloids N-nornuciferine, O-nornuciferine, and nuciferine frome lotus leaf. Talanta. 2010;80:1292–7. doi: 10.1016/j.talanta.2009.09.027. [DOI] [PubMed] [Google Scholar]

- 8.Cao XJ, Ye XM, Lu YB, Yu Y, Mo WM. Ionic liquid-based ultrasonic-assisted extraction of piperine from white pepper. Anal Chim Acta. 2009;640:47–51. doi: 10.1016/j.aca.2009.03.029. [DOI] [PubMed] [Google Scholar]

- 9.Zhang LJ, Geng YL, Duan WJ, Wang DJ, Fu MR, Wang X. Ionic liquid-based ultrasound-assisted extraction of fangchinoline and tetrandrine from Stephaniae tetrandrae. J Sep Sci. 2009;32:3550–4. doi: 10.1002/jssc.200900413. [DOI] [PubMed] [Google Scholar]

- 10.Du FY, Xiao XH, Luo XJ, Li GK. Application of ionic liquids in the microwave-assisted extraction of polyphenolic compounds from medicinal plants. Talanta. 2009;78:1177–84. doi: 10.1016/j.talanta.2009.01.040. [DOI] [PubMed] [Google Scholar]

- 11.Wu KK, Zhang QL, Liu Q, Tang F, Long YM, Yao SZ. Ionic liquid surfactant-mediated ultrasonic-assisted extraction coupled to HPLC: Application to analysis of tanshinones in Salvia miltiorrhiza bunge. J Sep Sci. 2009;32:4220–6. doi: 10.1002/jssc.200900398. [DOI] [PubMed] [Google Scholar]

- 12.Chen JH, Liu XP, Xu XQ, Lee FS, Wang XR. High-performance liquid chromatographic analysis of bioactive triterpenes in Perilla frutescens. J Pharm Biomed Anal. 2007;32:1175–9. doi: 10.1016/s0731-7085(03)00160-2. [DOI] [PubMed] [Google Scholar]

- 13.Li L, Yu ST, Xie CX, Liu FS, Li HJ. Synthesis of glycerol triacetate using functionalized ionic liquid as catalyst. J Chem Technol Biotechnol. 2009;84:1649–52. [Google Scholar]

- 14.Wang YY, Li W, Dai LY. Efficient cyclodehydration of diethylene glycol in Bronsted acidic ionic liquids. Chem Zvesti. 2008;62:313–7. [Google Scholar]

- 15.Chu Y, Deng H, Cheng JP. An acidity scale of 1,3-dialkylimidazolium salts in dimethyl sulfoxide solution. J Org Chem. 2007;72:7790–3. doi: 10.1021/jo070973i. [DOI] [PubMed] [Google Scholar]

- 16.Fang D, Cheng H, Gong K, Shi QR, Zhou XL, Liu ZL. A green and novel procedure for the preparation of ionic liquid. J Fluor Chem. 2008;129:108–11. [Google Scholar]