Abstract

Soft denture liners act as a cushion for the denture bearing mucosa through even distribution of functional load, avoiding local stress concentrations and improving retention of dentures there by providing comfort to the patient. The objective of the present study was to compare and evaluate the tensile bond strengths of silicone-based soft lining materials (Ufi Gel P and GC Reline soft) with different surface pre treatments of heat cure PMMA denture base acrylic resin. Stainless steel dies measuring 40 mm in length; 10 mm in width and 10 mm in height (40 × 10 × 10) were machined to prepare standardized for the polymethyl methacrylate resin blocks. Stainless steel dies (spacer for resilient liner) measuring 3 mm thick; 10 mm long and 10 mm wide were prepared as spacers to ensure uniformity of the soft liner being tested. Two types of Addition silicone-based soft lining materials (room temperature polymerised soft lining materials (RTPSLM): Ufi Gel P and GC Reline soft) were selected. Ufi Gel P (VOCO, Germany), GC Reline soft (GC America) are resilient, chairside vinyl polysiloxane denture reliners of two different manufacturers. A total of 80 test samples were prepared of which 40 specimens were prepared for Group A (Ufi Gel P) and 40 specimens for Group B (GC Reline soft). In these groups, based on Pre-treatment of acrylic resin specimens each group was subdivided into four sub groups of 10 samples each. Sub-group I—without any surface treatment. Sub-group II—sand blasted Sub-group III—treated with Methyl Methacrylate monomer Sub-group IV-treated with chemical etchant Acetone. The results were statistically analysed by Kruscal Wallis test, Mann–Whitney U test, and Independent t test. The specimens treated with MMA monomer wetting showed superior and significant bond strength than those obtained by other surface treatments. The samples belonging to subgroups of GC Reline soft exhibit superior tensile bond strength than subgroups of Ufi Gel P. The modes of failure of all specimens were mostly adhesive in nature. Surface pre treatments by chemical means improved the bond strength between the silicone liners and denture base.

Keywords: Silicone soft denture liner, Denture base resin, Tensile bond strength

Introduction

Resilient liners are basically acrylic or elastomeric polymers used in the prevention of chronic soreness from dentures and in the preservation of the supporting structures. They have been an asset for the dentist in treating patients with higher residual ridge resorption, thin and non-resilient mucosal tissue, bony undercuts, bruxing tendencies, congenital or acquired oral defects requiring obturation, xerostomia and to modify transitional prosthesis after stage I and II implant surgery [1, 2].

Silicone based soft denture liners have little or no chemical adhesion to denture base resin. Debonding of soft denture liners from the denture base can be attributed to the different chemical composition of the two basic materials and microleakage between them. Therefore an adhesive primer with a solvating effect on the denture base must be used prior to application of silicone liner.

Various surface pretreatments have been done to enhance the bond strength and evaluate microleakage between the liner and denture base by roughening the bonding surface and monomer wetting. Thus, the bonding of silicone soft denture liners depends on a combination of adhesive primers, surface treatments and tensile strength of liners. Two commonly used Addition silicone-based soft lining materials (room temperature polymerised soft lining materials (RTPSLM)): Ufi Gel P and GC Reline soft were selected. The purpose of this invitro study was to evaluate the tensile bond strength of two resilient, chairside vinyl polysiloxane denture reliners of two different manufacturers (Ufi Gel P-VOCO, Germany and GC Reline Soft—GC, America) available to the processed acrylic denture base resin, with three different surface pretreatments (airborne-particle-abrasion, monomer wetting and acetone).

Materials and Methods

Preparation of Specimens for Tensile Bond Strength

Fabrication of Specimens

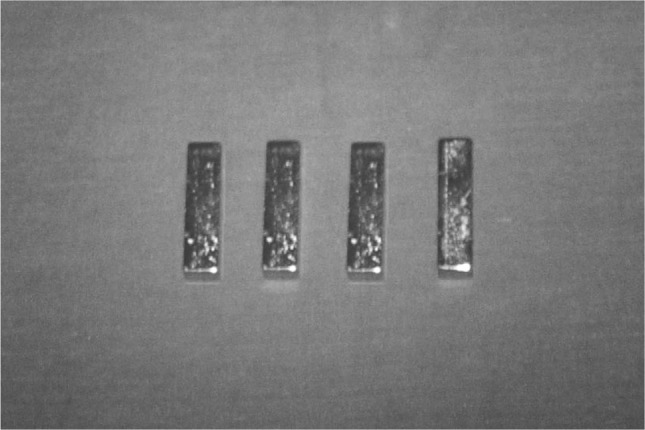

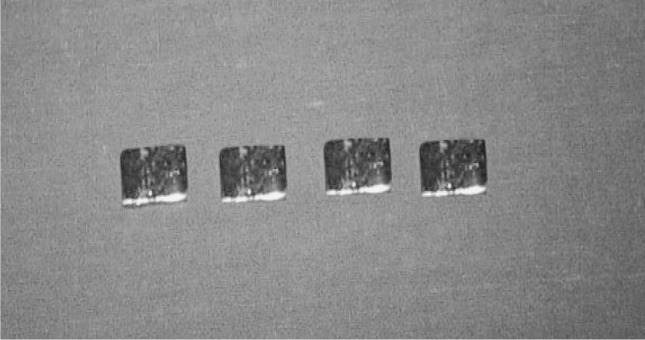

Stainless steel dies (40 × 10 × 10) were machined to prepare standardized polymethyl methacrylate resin blocks. (Fig. 1). Stainless steel dies (spacer for resilient liner) measuring (3 × 10 × 10) were prepared as spacers to ensure uniformity of the soft liner being tested (Fig. 2).

Fig. 1.

Stainless steel dies for resin blocks

Fig. 2.

Stainless steel dies for soft liners

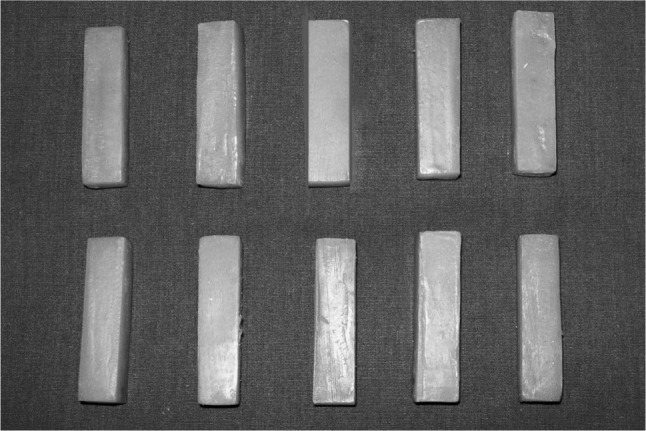

Impressions of the Stainless steel dies were made in polyether putty (Impregum Penta Putty, 3M ESPE, Germany) material to fabricate PMMA blocks. Molten wax (Hindustan Modelling Wax, India) was poured in the mold obtained from the dies. The wax blocks were allowed to cool, harden and subsequently to be invested in dental stone in a dental flask. After the dewaxing procedures, the acrylic resin (DPI, Heat cure Poly Methyl Methacrylate Resin, India) was packed in to the mold space and processed in acryliser at 75 °C for 11/2 h, followed by 100 °C for 1 h. After deflasking procedures, all the polymerized acrylic samples were finished and polished leaving the testing surface. They were then ultrasonically cleaned with distilled water and dried with compressed air to remove the surface impurities (Fig. 3).

Fig. 3.

Finished heat polymerized resin blocks

The dies for PMMA blocks and spacer were invested in laboratory polyether rubber to provide uniform space for lining material and for easy removal of the processed samples. After pretreatment the two PMMA blocks are assembled with in the polyether putty with the spacer in between.

A total of 80 test samples were prepared of which 40 specimens were prepared for Group A (Ufi Gel P) and 40 specimens for Group B (GC Reline soft). In these groups, based on pre-treatment of acrylic resin specimens each group was subdivided into four sub groups of 10 samples each.

Distribution of Specimens

Heat polymerizing PMMA resin blocks with soft liners (n = 80)

Sub-group I-specimens (control group) were without any surface treatment.

Sub-group II-specimens were sand blasted at the interfacial surface of PMMA blocks by mechanical Sand blasting (Micro-V abrasive blaster system) with 250 μm aluminium oxide particles at a pressure of 0.62 Mpa before application of the soft liner.

Sub-group III-specimens were treated with Methyl Methacrylate monomer for 180 s before application of the soft liner.

Sub-group IV-specimens were treated with chemical etchant Acetone for 30 s before application of the soft liner.

Packing of the Denture Lining Material

After the pre surface treatments, primer adhesive supplied by manufacturer was applied for 1 min, and then the PMMA blocks were replaced in the polyether mold. Equal lengths of base and catalyst of soft liner was mixed for 30 s. Lining the polymerized PMMA blocks with autopolymerizing silicone soft denture liner was done after removing the Stainless steel spacer and allowed to polymerize for 10 min (Fig. 4).

Fig. 4.

Liner placed inbetween the two resin blocks

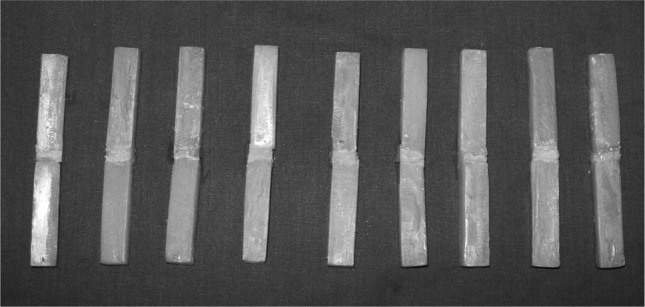

After polymerization all the specimens were recovered and excess liner flash was cut using sharp blade. Thus the final specimens were obtained with soft liner in-between two polymethyl methacrylate blocks (Fig. 5). The specimens were stored in sterile water and kept in incubator at 37 °C before testing. Two silicone soft denture liners (Ufi Gel P and GC Reline soft) were used in the study.

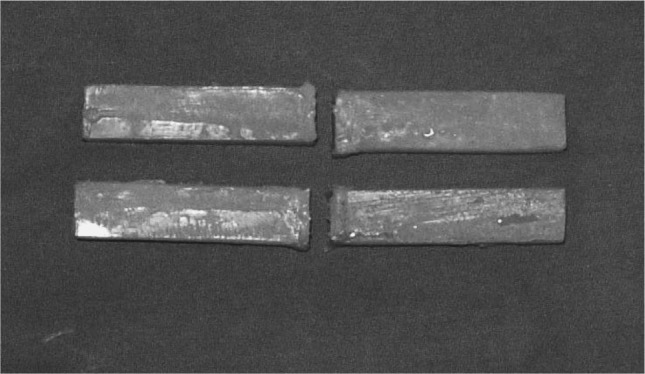

Fig. 5.

Acrylic specimens lined with liner

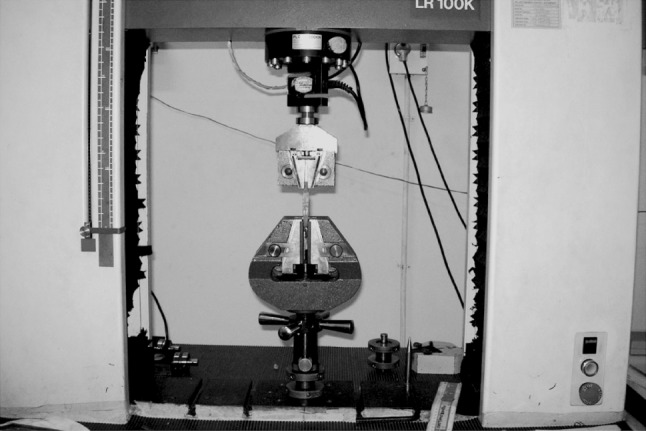

Testing of Specimens

All the specimens (Group A + Group B) were subjected to tensile bond test. Testing was Carried out in Lioyd’s Universal Testing Machine at 21 ± 1 °C.

Testing Specimens for Tensile Bond Strength

All the specimens were aligned in Universal testing machine with one end of acrylic specimen attached to upper clamp and other end of acrylic specimen to the lower clamp. The specimen was pulled with a crosshead speed of 5 mm/min. All the specimens were placed under tension until failure in the specimen occurred (Fig. 6). The liner was separated from acrylic resin specimen by pulling of clamps in opposing directions. The maximum tensile stress before failure was recorded for each specimen. The peak load applied was recorded in chart recorder. The peak load was converted to tensile bond strength by the formula,

|

Fig. 6.

Testing specimen

Failure Mode Evaluation

The type of failure was assessed visually and was recorded as being adhesive or cohesive mode of failure.

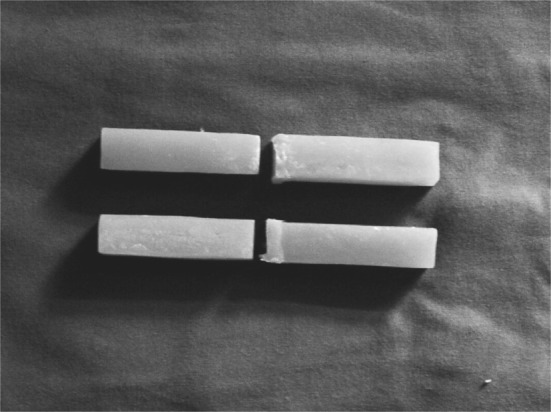

Adhesive: indicated separation occurring at liner-acrylic interface (Fig. 7). Cohesive: indicated failure within the liner material (Fig. 8).

Fig. 7.

Adhesive mode of failure

Fig. 8.

Cohesive mode of failure

Results were analyzed by using Mann–Whitney U test, Kruscal Wallis test and Independent samples ‘t’ test.

Results

All the specimens (Group A + Group B) were placed in universal testing machine (Lioyd’s) to evaluate the tensile bond strengths as

Force at debonding/cross-sectional area of the interface was recorded in N/square mm.

The Subgroup I in Group A and Group B were without any surface treatment is taken as control group. From these respective Groups, Subgroups were compared as shown in (Tables 1, 2, 3) and in overall both groups (Group A and Group B) were compared and analyzed as shown in (Table 4).

| Group A Ufigel P (n=40) | Group B GC Reline soft (n=40) | |||||||

|---|---|---|---|---|---|---|---|---|

| Subgroups | I | II | III | IV | I | II | III | IV |

| Samples (no) | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

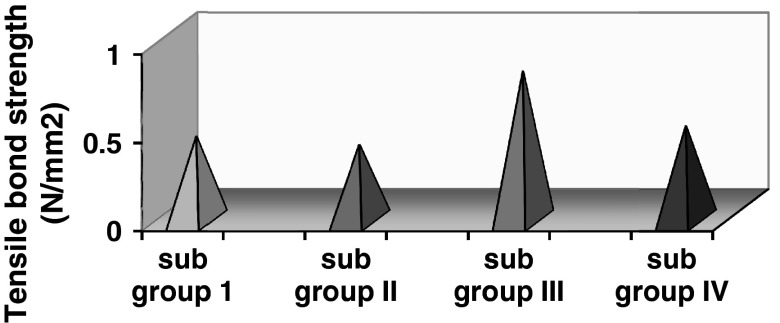

Histogram 1.

Comparison of tensile bond strength between sub groups of Group A

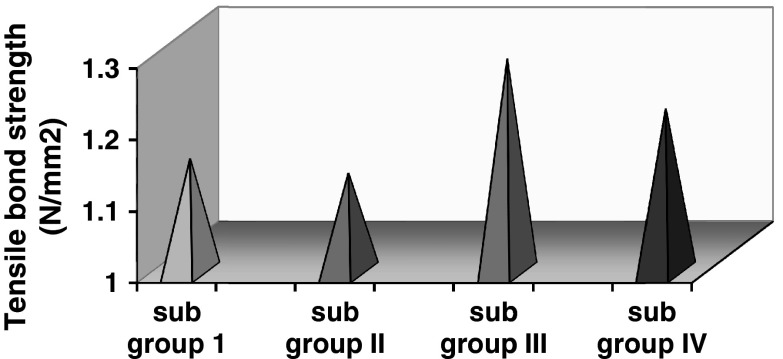

Histogram 2.

Comparison of tensile bond strength between sub groups of Group B

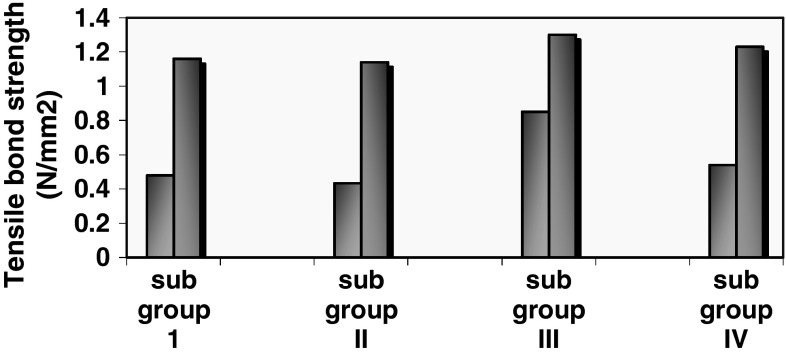

Histogram 3.

Comparison of tensile bond strength between sub groups of Group A and Group B

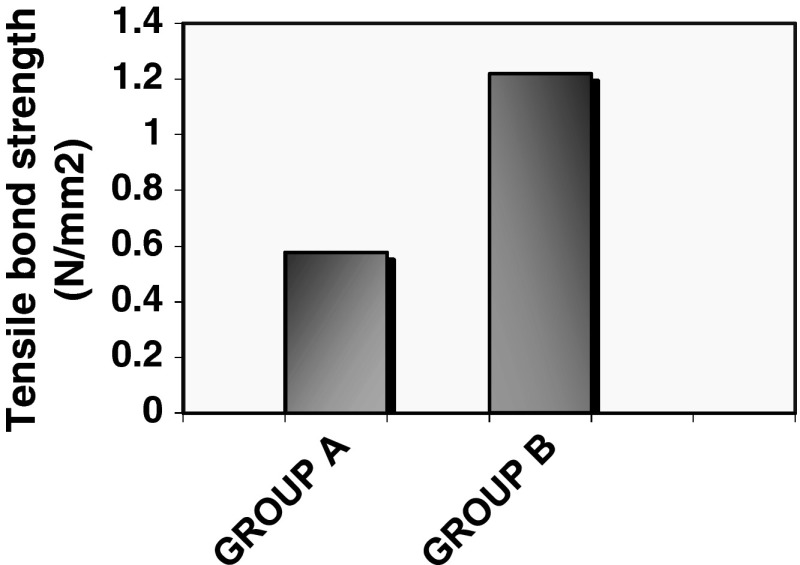

Histogram 4.

Comparison of tensile bond strength between Group A and Group B

Table 1.

Data represents the inferential statistics for comparing the mean, standard deviation and test of significance of mean values between different subgroups of Group A

| Subgroups compared | Mean | SD | Mann–Whitney U value | p value | Significance level |

|---|---|---|---|---|---|

| I versus II |

0.480 0.435 |

0.024 0.033 |

14.00 | 0.006 | NS |

| I versus III |

0.480 0.853 |

0.024 0.053 |

0.01 | 0.00 | SIG |

| I versus IV |

0.480 0.541 |

0.024 0.034 |

4.5 | 0.001 | SIG |

| II versus III |

0.435 0.853 |

0.033 0.053 |

0.01 | 0.00 | SIG |

| II versus IV |

0.435 0.541 |

0.033 0.034 |

0.02 | 0.00 | SIG |

| III versus IV |

0.853 0.541 |

0.053 0.034 |

0.01 | 0.00 | SIG |

Mann–Whitney U test was used to calculate the p value. (Histogram 1)

Table 2.

Data represents the inferential statistics for comparing the mean, standard deviation and test of significance of mean values between different subgroups of Group B

| Subgroups compared | Mean | SD | Mann–Whitney U value | p value | Significance level |

|---|---|---|---|---|---|

| I versus II |

1.16 1.14 |

0.50 0.59 |

39.5 | 0.425 | NS |

| I versus III |

1.16 1.36 |

0.50 0.58 |

1 | 0.000 | SIG |

| I versus IV |

1.16 1.23 |

0.50 0.36 |

10 | 0.02 | SIG |

| II versus III |

1.14 1.36 |

0.59 0.58 |

2 | 0.000 | SIG |

| II versus IV |

1.14 1.23 |

0.59 0.36 |

9 | 0.02 | SIG |

| III versus IV |

1.36 1.23 |

0.58 0.36 |

3 | 0.000 | SIG |

Mann–Whitney U test was used to calculate the p value. (Histogram 2)

Table 3.

Data represents the inferential statistics for comparing the mean, standard deviation and test of significance between subgroups of Group A and Group B

| Group A | Group B | p value | |||

|---|---|---|---|---|---|

| Mean | SD | Mean | SD | ||

| Sub group I | 0.480 | 0.024 | 1.162 | 0.050 | 0.000 (SIG) |

| Sub group II | 0.435 | 0.033 | 1.141 | 0.059 | 0.000 (SIG) |

| Sub group III | 0.853 | 0.053 | 1.368 | 0.058 | 0.000 (SIG) |

| Sub group IV | 0.541 | 0.034 | 1.235 | 0.036 | 0.000 (SIG) |

Independent sample t test was used to calculate the p value. (Histogram 3)

Table 4.

Data represents the inferential statistics for comparing the mean, standard deviation and test of significance of mean values between Group A and Group B

| Groups compared | Mean | SD | ‘t’ value | p value | Significance level |

|---|---|---|---|---|---|

| A | 0.5779 | 0.169 | 20.674 | < 0.000 | Significant |

| B | 1.226 | 0.102 |

Significantly mean tensile bond strength value of Group A was found to be lower than the mean value of Group B as Independent samples t test revealed a significant difference between two bond strength values. (Histogram 4)

NS not significant, SIG significant, p values, pvalue is less than 0.05 significant, pvalue is more than 0.05 not significant

The bond strength of Ufi Gel P lining material of subgroup I ranged from 0.446 to 0.513 N/mm2 with mean bond strength of 480 N/mm2. Subgroup II showed a bond strength ranging from 0.387 to 0.493 N/mm2 with a mean of 0.435 N/mm2. Subgroup III showed a bond strength ranging from 0.765 to 0.916 N/mm2 with a mean of 0.853 N/mm2 and Subgroup IV samples had a bond strength ranging from 0.493 to 0.613 N/mm2 with a mean of 0.541 N/mm2.

The bond strength of GC Reline soft denture lining material for subgroup I ranged from 1.09 to 1.24 N/mm2 with a mean of 1.26 N/mm2. The subgroup II had a bond strength ranging from 1.03 to 1.19 N/mm2 with a mean of 1.14 N/mm2.The subgroup III had a bond strength ranging from 1.30 to 1.48 N/mm2 with a mean of 1.36 N/mm2 and Subgroup IV had a bond strength ranging from 1.19 to 1.31 N/mm2 with a average mean of 1.23 N/mm2.

The statistical analysis of the four subgroups of each soft liner were compared by Kruscal Wallis test were found to be significantly different. The comparison between each subgroups were made using Mann–Whitney U test (Nonparametric) for both the soft liners. The overall comparison between the two groups for each surface treatment was made using Independent t test (parametric test) for equality of means with the help of statistical package for social science (SPSS) software.

Except for the statistical analysis between subgroups I and II p-value (>0.05) there was significant difference in other subgroups of Groups A and B with p value (<0.000). The p-values in Tables 3 and 4 infers that there is statistically significant difference in mean values between subgroups I, II, III, IV. Group B was significantly higher (mean = 1.226) than Group A (mean = 0.5779). The p value infers that there was significant difference between Groups A and B. p value (< 0.000).

Failure Analysis

The modes of failure of all specimens were mostly adhesive in nature.

Out of 40 specimens (n = 40) in Group A (Ufi Gel P), 38 specimens (n = 38) showed adhesive mode of failure and 2 specimens (n = 2) showed cohesive failure. In Group B (G C soft), 35 specimens (n = 35) showed adhesive mode of failure and 5 specimens (n = 5) showed cohesive failure.

Statistical Analysis

Tensile bond strength values of Group A subgroups and Group B subgroups are compared. It is found that the samples belonging to subgroups of Group B exhibit superior tensile bond strength than subgroups of Group A.

Discussion

The effect of roughening the bonding surface by air particle abrasion [3, 4] had higher bond strength compared with the smooth surface because of its irregularity which provides mechanical retention [5]. Pretreatment of denture base resin with monomer and acetone had shown to be effective in increasing the strength of repaired denture segments [6]. Hence, this study was intended to evaluate and compare the tensile bond strengths of two-auto polymerizing silicone soft denture liner Ufi Gel P & GC Reline Soft (silicone elastomer) after the various surface preparations.

The specimens were subjected to tensile bond test as suggested by Bates and Smith [7].The bond strength of liner materials can be tested using peel, tensile, shear, fatigue, creep and impact test [8]. As silicone based resilient liners have lower tear strength than the other types, the adhesive strength of such materials would best be characterized by the use of tensile bond test [9].

Dootz et al. [10] and Khan et al. [11] reported that denture liners with 10 pounds per inch (0.44 Mpa) or 4.5 kg/cm2 bond strength are acceptable for clinical use. Considering this criterion both GC Reline Soft and Ufi Gel P liners had satisfactory bond strength to PMMA denture base resin. The results of Ufi Gel P are in agreement with findings of Kulak Ozkan. Y who demonstrated Ufi Gel P had sufficient tensile bond strength (0.51 Mpa) for prosthetic applications. The results contradicted Aydin et al. who reported the tensile strength of Ufi Gel P was inadequate. The results of GC Reline Soft silicone elastomer are similar to those obtained by McCabe [12].

The lower bond strength values of air particle abraded specimens can be due to the stresses that develop at the interface of the polymethyl methacrylate resilient liner junction as the surface irregularities created by air particle abrasion may not allow a complete flow of soft denture liner and may result in void formation by air entrapment [1, 4] and on the penetration coefficient of the lining material; because the penetration coefficient is inversely proportional to viscosity, increased liner viscosity reduces penetration in to irregularities on the PMMA surface [4]. These explanations were in turn supported by the micro leakage study by Sarac et al. [13].

Surface pre treatments by chemical means like monomer wetting and organic solvent like acetone improved the bond strength of silicone liners, of which monomer wetting was proved to be more effective than acetone. The mechanism of chemical surface pretreatments is that they cause superficial crack propagation, as well as the formation of numerous pits approximately 2 μm in diameter [6]. Swelling of the outer denture base by MMA monomer wetting and acetone resulted in the infiltration of the liner adhesive primer in to these pits and cracks, resulting in lesser microleakage [13] and increased bond strength. The reason which can be suggested for higher bond strength value in MMA monomer wetting is that MMA monomer most probably reaches deep in to the polymer chains and facilitates the penetration of adhesive primer than acetone. Presence of significant bond strength values are a sign of absence or less micro leakage, the high bond strength values resulting from chemical surface pre treatments in the present study are similar to the results of micro leakage study by Sarac et al. [13].

Comparing the Mean bond strength values of Ufi Gel P (0.5779) and GC Reline Soft (1.226) silicone soft denture liners indicates that GC Reline Soft has higher tensile bond strength to PMMA than Ufi Gel P. However, changes in the chemical structure and material composition may explain any differences between the bond strengths of similar lining materials. Bond strength alone cannot be used as a single criterion for the selection of a particular liner. Therefore selection of a material is not only influenced by the properties available but also on the situation being treated [14].

All the samples of Ufi Gel P (38 specimens) and GC Reline Soft (35 specimens) showed adhesive mode of failure. This indicates that the bond strength within the liner molecules was greater than the bond strength between the liner and PMMA resin. The test conditions may not simulate the clinical situation, because the test specimens had double adhesive surfaces and clinical cases have a single adhesive surface.

Relined dentures are exposed to repetitive mechanical stress during mastication. Factors like saliva and its composition, diet of the patient, temperature changes, oral hygiene, and presence of systemic diseases have to be considered as it may alter the longevity of the liners which may lead to changes in the value of bond strength. Factors such as processing methods, water sorption, thermal stresses, hardness, tear strength, colour stability are all properties of soft denture liners needed to be investigated in order to predict which materials will provide best clinical service. Therefore further investigations are necessary to evaluate the bonding under more closely simulated clinical conditions.

Conclusion

Within the parameters of the materials used and the study design, the following inferences were drawn:

The specimens treated with MMA monomer wetting showed superior and significant bond strength than those obtained by other surface treatments. Followed by wetting with acetone and least for Air abraded specimens with Al2O3 particles.

Among the two silicone liners GC Reline Soft showed an overall superior performance over Ufi Gel P.

Both GC Reline Soft and Ufi Gel P had satisfactory bond strength to PMMA denture base resin, which are clinically acceptable.

Failures of soft liner specimens were predominantly adhesive.

Changes in the oral environment, may lead to significant differences in the bond strength between the two materials. A further study, especially a clinical trial can however conclusively prove the real utility of different resilient liners and surface treatments.

References

- 1.Amin WM, Fletcher AM, Ritche GM. The nature of the interface between polymethyl methacrylate denture base materials and soft lining materials. J Dent. 1981;9:336–346. doi: 10.1016/0300-5712(81)90007-5. [DOI] [PubMed] [Google Scholar]

- 2.Sertgoz A, Kulak Y, Gedik H, Taskonak B. The effect of thermo cycling on peel strength of six denture lining materials. J Oral Rehabil. 2002;29(6):583–587. doi: 10.1046/j.1365-2842.2002.00888.x. [DOI] [PubMed] [Google Scholar]

- 3.El-Hadary A, Drummond JL. Comparative study of water sorption and tensile bond strength of two soft lining materials. J Prosthet Dent. 2000;83:356–361. doi: 10.1016/S0022-3913(00)70140-5. [DOI] [PubMed] [Google Scholar]

- 4.Jacobson NL, Mitchell DL, Johnson DL, Holt RA. Lased and sandblasted denture base surface preparation affecting resilient liner bonding. J Prosthet Dent. 1997;78:153–158. doi: 10.1016/S0022-3913(97)70119-7. [DOI] [PubMed] [Google Scholar]

- 5.Eick JD, Craig RG, Peyton FA. Properties of resilient denture liners in simulated mouth conditions. J Prosthet Dent. 1962;12:1043–1052. doi: 10.1016/0022-3913(62)90159-2. [DOI] [Google Scholar]

- 6.Sarac YS, Sarac D, Kulunk T, Kulunk S. Effect of chemical surface treatments of different denture base resins on the shear bond strength of denture repair. J Prosthet Dent. 2005;94:259–266. doi: 10.1016/j.prosdent.2005.05.024. [DOI] [PubMed] [Google Scholar]

- 7.Arena CA, Evans DB, Hilton TJ. A comparison of bond strengths among chairside hard reline materials. J Prosthet Dent. 1993;70:126–131. doi: 10.1016/0022-3913(93)90006-A. [DOI] [PubMed] [Google Scholar]

- 8.Sinobad D, Murphy WM, Huggett R, Brooks S. Bond strength and rupture properties of some soft denture liners. J Oral Rehabil. 1992;19(2):151–160. doi: 10.1111/j.1365-2842.1992.tb01093.x. [DOI] [PubMed] [Google Scholar]

- 9.Kutay O. Comparison of tensile and peel bond strength of resilient liners. J Prosthet Dent. 1994;71:525–531. doi: 10.1016/0022-3913(94)90194-5. [DOI] [PubMed] [Google Scholar]

- 10.Dootz ER, Koran A, Craig RG. Comparison of soft denture lining material as a function of accelerated agent. J Prosthet Dent. 1993;69:114–119. doi: 10.1016/0022-3913(93)90250-R. [DOI] [PubMed] [Google Scholar]

- 11.Khan Z, Martin J, Collard S. Adhesion characteristics of light cure denture base material bonded to resilient lining material. J Prosthet Dent. 1989;62:196–200. doi: 10.1016/0022-3913(89)90313-2. [DOI] [PubMed] [Google Scholar]

- 12.McCabe JF. A polyvinylsiloxane denture lining material. J Dent. 1998;26:521–526. doi: 10.1016/S0300-5712(98)00022-0. [DOI] [PubMed] [Google Scholar]

- 13.Sarac YS, Basoglu T, Ceylan GK, Sarac D, Yapici O. Effect of denture base surface pretreatment on microleakage of a silicon based resilient liner. J Prosthet Dent. 2004;92:283–287. doi: 10.1016/j.prosdent.2004.06.004. [DOI] [PubMed] [Google Scholar]

- 14.Kawano F, Dootz ER, Koran A, Craig RG. Comparison of bond strengths of six denture liners to denture base resin. J Prosthet Dent. 1992;68:368–372. doi: 10.1016/0022-3913(92)90347-D. [DOI] [PubMed] [Google Scholar]