Abstract

Elastomeric polypeptides are very interesting biopolymers and are characterized by rubber-like elasticity, large extensibility before rupture, reversible deformation without loss of energy, and high resilience upon stretching. Their useful properties have motivated their use in a wide variety of materials and biological applications. This chapter focuses on elastin and resilin – two elastomeric biopolymers – and the recombinant polypeptides derived from them (elastin-like polypeptides and resilin-like polypeptides). This chapter also discusses the applications of these recombinant polypeptides in the fields of purification, drug delivery, and tissue engineering.

Keywords: Elastin, Elastin-like polypeptides, Elastomeric polypeptides, Resilin, Resilin-like polypeptides

1 Introduction

Elastomeric polypeptides are a class of very interesting biopolymers and are characterized by rubber-like elasticity, large extensibility before rupture, reversible deformation without loss of energy, and high resilience upon stretching. Their useful properties have motivated their use in a wide variety of materials and biological applications. Here, we focus on two elastomeric proteins and the recombinant polypeptides derived thereof.

The first elastomeric protein is elastin, this structural protein is one of the main components of the extracellular matrix, which provides structural integrity to the tissues and organs of the body. This highly crosslinked and therefore insoluble protein is the essential element of elastic fibers, which induce elasticity to tissue of lung, skin, and arteries. In these fibers, elastin forms the internal core, which is interspersed with microfibrils [1, 2]. Not only this biopolymer but also its precursor material, tropoelastin, have inspired materials scientists for many years. The most interesting characteristic of the precursor is its ability to self-assemble under physiological conditions, thereby demonstrating a lower critical solution temperature (LCST) behavior. This specific property has led to the development of a new class of synthetic polypeptides that mimic elastin in its composition and are therefore also known as elastin-like polypeptides (ELPs).

Resilin is the second elastomeric polypeptide that is discussed here. This protein, found in specialized regions of the insect cuticle, similarly demonstrates extraordinary extensibility and elasticity; its role as an elastic spring in insect organs provides clear illustration of its characteristic fatigue resistance and resilience. In fact, its mechanical properties are in near-agreement with classic rubber-elasticity theory, a remarkable feature for a hydrophilic biopolymer network. Apart from the outstanding mechanical properties, resilin provides an interesting comparison to other protein elastomers due to its hydrophilicity, but also due to the fact that resilin shares certain compositional characteristics. In particular, the high number of proline and glycine residues found in resilin as well as other protein elastomers could indicate some sort of structural importance. While silks and elastin have received the most attention from the scientific community over the past few decades, the development of recombinant resilins, facilitated by advances made in recombinant DNA technologies and protein engineering, has provided invaluable opportunities for the application of resilin as a biomaterial. Recombinant resilin could potentially see application in a variety of fields, including tissue engineering, drug delivery, biosensors, and nanobiotechnology.

This chapter will discuss the basic aspects of elastin and resilin and will address their biological role, biochemical processing, and properties. The materials inspired by elastin and resilin, such as elastin-like polypeptides and resilin-like polypeptides, and applications thereof, will also be covered.

2 Elastin and Elastin-Like Polypeptides

2.1 Elastin Biosynthesis

Elastin is a heavily crosslinked biopolymer that is formed in a process named elastogenesis. In this section, the role of elastin and the different steps of elastin production will be described, starting with transcription of the genetic code and processing of the primary transcript, followed by translation into the elastin precursor protein and its transport to the extracellular matrix. Finally, the crosslinking and fiber formation, which result in the transition from tropoelastin to elastin, are described.

Tropoelastin is the soluble precursor of elastin and consists of alternating hydrophobic and hydrophilic peptide domains. The most common amino acids in the hydrophobic domains are Gly, Val, Ala, and Pro, which are often present in repeats of tetra-, penta-, and hexapeptides, such as Gly-Gly-Val-Pro, Gly-Val-Gly-Val-Pro, Gly-Val-Pro-Gly-Val, and Gly-Val-Gly-Val-Ala-Pro, respectively [3, 4]. The hydrophilic domains are mainly composed of lysines interspersed by alanines.

Tropoelastin is encoded by a single copy gene and the alternating hydrophobic and hydrophilic domains are generally encoded by different expressed regions, or exons (Fig. 1). Those exons are alternated by introns (intragenic regions), which are not present in the final transcript. Even though a single gene is coding for tropoelastin, various types (isoforms) of tropoelastin exist due to extensive alternative splicing [5, 6]. Six exons were shown to be subject to this process in a cassette-like fashion in which an exon is either included or excluded, and this results in at least 11 human isoforms (Fig. 2, arrows) [7]. The elastin genes of human, bovine, chick, and rat have been sequenced and the amino acid sequences were determined [8]. Even though a strong similarity was found between tropoelastins from different sources, some variation does exist. Some exons are specific for a certain species, for example exon 26A is only present in human elastin. This exon is rich in charged and polar amino acids and is thought to influence the structural and biological functions of elastin [6].

Fig. 1.

Primary structure of human tropoelastin isoform 3 (EBI accession no. P15502). The highlighted regions correspond to the signal peptide and hydrophobic and hydrophilic domains. Based on [2]

Fig. 2.

cDNA structure of human tropoelastin. The alternating hydrophobic and hydrophilic domains are generally encoded by different exons, shown in white and black, respectively. The arrows indicate the six exons that are subject to alternative splicing in a cassette-like fashion. Reproduced from [8] with permission from John Wiley and Sons, copyright 1998

After mRNA splicing, the tropoelastin mRNA is translated at the surface of the rough endoplasmic reticulum (RER) in a variety of cells: smooth muscle cells, endothelial and microvascular cells, chondrocytes and fibroblasts. The approximately 70 kDa precursor protein (depending on isoform) is synthesized with an N-terminal 26-amino-acid signal peptide. This nascent polypeptide chain is transported into the lumen of the RER, where the signal peptide is removed cotranslationally [9].

Very few post-translational modifications have been found on tropoelastin. However, hydroxylation of 25% of the proline residues is observed [10]. The enzymatic modification of proline to hydroxyproline (Hyp) is performed by prolyl hydroxylase [11]. The purpose of this hydroxylation remains unclear and it is even proposed that Hyps in tropoelastin are a by-product of collagen hydroxylation as this occurs in the same cellular compartment [8].

Once the tropoelastin is synthesized, it is bound by the elastin-binding protein (EBP). This binding of EBP to tropoelastin is believed to prevent intracellular aggregation and to protect it from proteolytic degradation [12]. EBP is a 67 kDa multifunctional peripheral membrane protein and is part of the elastin receptor [13]. The two other subunits of the receptor complex are transmembrane proteins of 61 kDa and 55 kDa [14]. EBP is also equipped with a binding site for β-galactosaccharides, and binding of these sugars allosterically leads to reduced affinity for tropoelastin and results in dissociation of EBP from the 61 kDa and 55 kDa membrane proteins. While complexed with EBP, elastin is transported from the RER to the cell surface via the Golgi apparatus. Upon reaching the cell surface, it is secreted from the cell. Galactosugar moieties on microfibrils at the cell surface are then bound by EBP, which leads to release of tropoelastin (Fig. 3).

Fig. 3.

Binding and release of tropoelastin. The elastin receptor consists of a 67 kDa peripheral subunit (EBP) with two transmembrane proteins of 61 and 55 kDa. The 67 kDa protein binds tropoelastin and galactosugars through two separate sites. (a) Tropoelastin binds to the intact EBP complex. (b) Upon binding of a galactosugar, the EBP loses its affinity for both tropoelastin and the membrane-bound protein, which leads to the release of tropoelastin. Reproduced from [8] with permission from John Wiley and Sons, copyright 1998

The microfibrils act as a scaffold onto which the tropoelastin molecules are deposited. In order for tropoelastin to be incorporated into the elastic fibers it needs to be crosslinked. To facilitate the crosslinking, these elastin precursors must associate and align. This alignment is thought to proceed via the process of coacervation. This process occurs via an inverse temperature transition, which induces the aggregation of tropoelastin. At low temperatures tropoelastin is soluble in aqueous solutions; upon raising the temperature the solution becomes cloudy because the tropoelastin molecules aggregate and become ordered by the interactions between their hydrophobic domains. This phenomenon is completely reversible (by cooling) and is thermodynamically controlled. This process is also known as lower critical solution temperature (LCST) behavior and can be influenced by protein concentration, salt concentration, and pH.

After the self-assembly process, the tropoelastin molecules are enzymatically crosslinked via the lysine residues in the hydrophilic domains. In this last step of the elastogenesis, the amines of the lysine residues are enzymatically converted to aldehydes (allysine) by lysyl oxidase via oxidative deamination (Fig. 4). Lysyl oxidase is a copper-dependent amine oxidase. In the following spontaneous condensations, allysine can react with another allysine or with lysine to form di-, tri- and tetrafunctional crosslinks, to eventually yield desmosine and isodesmosine linkages [15]. The interchain crosslinking and the high number of hydrophobic residues immediately lead to insolubility of the elastin.

Fig. 4.

Structures and formation routes of crosslinks in elastin. In the first step, lysine is catalytically converted to allysine by lysyl oxidase; all subsequent condensation steps are spontaneous

2.2 General Properties of Elastin and Tropoelastin

Research into elastin, its properties, and the fiber formation was for a considerable period of time hindered due to its insolubility. However, discovery of the soluble tropoelastin precursor made new investigations possible. The tropoelastin protein can be isolated from copper-deficient animals. However, this is a very animal-unfriendly and low yielding process [2]. Therefore, it is preferred to obtain tropoelastin from overexpression in microbial hosts such as Escherichia coli (E. coli). Most studies are thus based on tropoelastin obtained via bacterial production.

The main biological function of elastin is to provide elasticity to organs and tissues. However, it has been shown that elastin and peptides derived from elastin also have additional biological properties. Elastin can be degraded by several protein-degrading enzymes, such as elastases, matrix metalloproteinases, and cathepsins. The resulting elastin-derived peptides (EDP) can interact with other extracellular matrix proteins to induce a broad range of biological activities. EDPs are chemotactic for various cells, such as fibroblasts and monocytes, by binding to the EBP [16, 17]. The consensus sequence GXXPG (X being any natural amino acid) of EDPs was proposed to be crucial for the interaction with the EBP.

The coacervation of tropoelastin plays a crucial role in the assembly into elastic fibers. This coacervation is based on the LCST behavior of tropoelastin, which causes tropoelastins structure to become ordered upon raising the temperature. The loss of entropy of the biopolymer is compensated by the release of water from its chain [2, 18, 19]. This release of water results in dehydration of the hydrophobic side chains, and this is the onset of the self-assembly leading to the alignment of tropoelastin molecules.

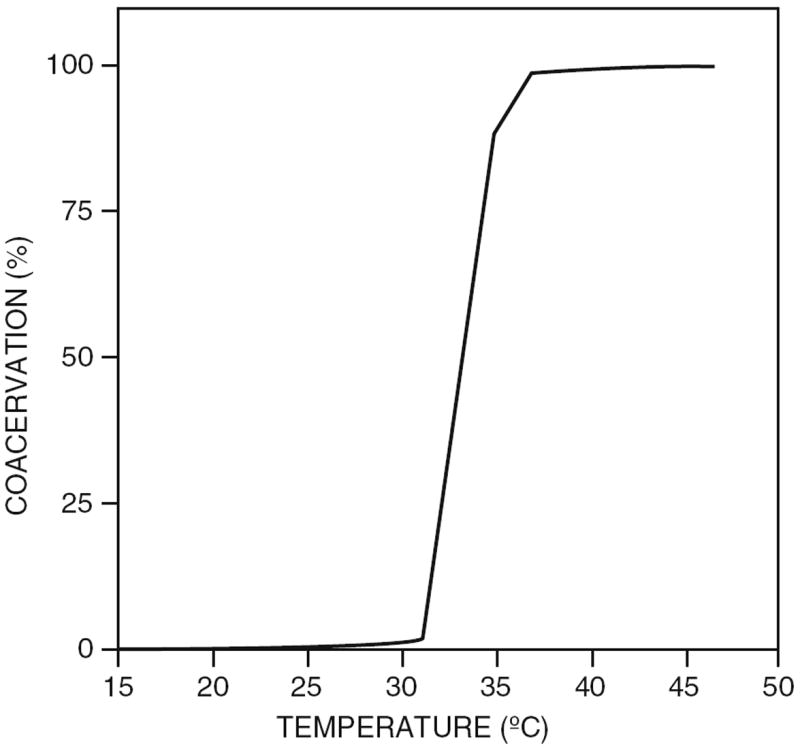

Weiss and coworkers intensively investigated the coacervation behavior of a single isoform of tropoelastin. They produced tropoelastin by overexpression in E. coli, and the coacervation was then assayed by monitoring turbidity while varying protein concentration, NaCl concentration, and pH. All these factors influence the temperature at which the coacervation is initiated. A typical tropoelastin coacervation curve is shown in Fig. 5. Increasing tropoelastin concentration resulted in a shift towards lower temperatures and a reduction of the temperature range over which coacervation took place. A lowering of coacervation temperature was also found upon increasing NaCl concentration. It is suggested that this is caused by NaCl decreasing the effective concentration of water by binding it in hydration shells, which therefore leads to an increase in protein concentration. Impurities that are able to bind the hydrophobic domains of the tropoelastin also had a major influence on the coacervation [20].

Fig. 5.

Coacervation curve of 40 mg/mL tropoelastin in 10 mM sodium phosphate pH 7.4, containing 150 mM NaCl. Maximal coacervation was obtained at 37 °C. Reproduced from [20] with permission from John Wiley and Sons, copyright 1997

This coacervation process forms the basis for the self-assembly, which takes place prior to the crosslinking. The assembly of tropoelastin is based on an ordering process, in which the polypeptides are converted from a state with little order to a more structured conformation [8]. The insoluble elastic fiber is formed via the enzymatic crosslinking of tropoelastin (described in Sect. 2.1). Various models have been proposed to explain the mechanism of elasticity of the elastin fibers. The main models are described in a review by Vrhovski and Weiss [8]. For ideal elastomers in the extended mode, all the energy resides on the backbone and can therefore be recovered upon relaxation [18]. Generally, it is believed that the mechanism of elasticity is entropy-driven, thus the stretching decreases the entropy of the system and the recoil is then induced by a spontaneous return to the maximal level of entropy [8].

2.3 Development and Properties of Recombinant Elastins

In order to obtain a better understanding of the origin of the interesting characteristics of elastin and its precursor, several groups have investigated model polymers with elastin-based sequences. Urry and coworkers performed pioneering work in this field. They were the first to synthesize the repetitive peptides, their oligomers, and the polymers that were found in the hydrophobic domains of elastin. Via this approach they determined the conformation and interactions of these domains. Of particular interest proved to be the repeat sequence of Val-Pro-Gly-Xaa-Gly (VPGXG), where the fourth residue can be any natural amino acid except proline. They observed that polymers of this pentapeptide repeat coacervate in a similar way to tropoelastin. Polypeptides containing this type of sequence were coined elastin-like polypeptides [21]. In some articles and reviews the terms elastin-mimetic polypeptides or elastin-like recombinamers are used instead of elastin-like polypeptides, however in this chapter we will refer to these polymers as elastin-like polypeptides.

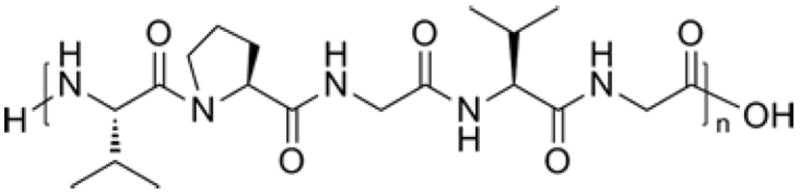

Poly(VPGVG) (Fig. 6) has been studied most thoroughly and it was shown that it exhibits an inverse phase transition. The biopolymer undergoes phase separation from solution upon increasing temperature, resulting in a β-spiral structure and simultaneous release of water molecules associated with the polymer chain (Fig. 7).

Fig. 6.

Chemical structure of poly(Val-Pro-Gly-Val-Gly)

Fig. 7.

(a) Recurring β-turn found in poly(VPGVG). (b) β-spiral structure adopted by the poly(VPGVG) upon raising the temperature above the inverse transition temperature. Reprinted from [22] with permission from Elsevier, copyright 1992

The effects of varying the fourth amino acid and the biopolymer length have been extensively investigated and models have been proposed [23-26]. ELP constructs are usually described using the notation ELP[XiYjZk-n], where the capital letters between the brackets indicate the single letter amino acid code for the Xaa-replacing residue in the pentapeptide Val-Pro-Gly-Xaa-Gly. The subscript stands for the ratio of the guest residues and the n represents the total number of pentapeptide repeats.

Figure 8a shows the turbidity measurements for different guest residues in ELP [V8X2]. Lower transition temperatures (Tt) correlate with increased hydrophobicity of the guest residue [24, 25]. This data was extrapolated to other ratios of Val:Xaa (Fig. 8b). The transition temperature could also be influenced by the molecular weight of the ELP. The Tt was shown to increase with decreasing polymer length (Fig. 8c) [23, 26].

Fig. 8.

(a) Effects of varying the amino acid at fourth position in ELP[V8X2]. (b) Extrapolation of transition temperature for other ratios of Val:Xaa. (a) and (b) Reprinted from [24] with permission from American Chemical Society, copyright 1993 (c) Molecular weight dependence of transition temperature. Reprinted from [23] with permission from Elsevier, copyright 2002

ELPs can be produced via chemical synthesis and biosynthetically. For chemical synthesis via solid phase peptide synthesis, the attainable polymer length is limited, and if long polymers with a defined length are required then the biosynthetic approach is more appropriate. An advantage of chemical synthesis is, however, that it enables the facile introduction of functional residues in the polypeptide [27]. In the biosynthetic approach, protein expression in E. coli [27], yeast [28, 29], and plants [30, 31] have been employed. This approach requires the construction of genes encoding for these repetitive polypeptides. Different methods for gene construction have been published: multimerization [32], recursive directional ligation [33], and recursive directional ligation via plasmid reconstruction [23, 34].

Several studies were performed on the optimization of expression levels of ELP proteins in E. coli. In a recent example, the expression protocol was optimized for an ELP fusion with green fluorescent protein (GFP). This fusion protein was expressed and purified in a yield of 1.6 g/L of bacterial culture, which finally yielded ~400 mg GFP/L bacterial culture. This extremely high yield was found after uninduced expression in nutrient-rich medium supplemented with phosphate, glycerol and certain amino acids, such as proline and alanine [234]. The influence of fusion order was also examined and it was found that positioning the ELP at the C-terminus of target protein resulted in significantly higher expression levels [35].

2.4 Applications of Elastin-Like Polypeptides

2.4.1 Temperature-Triggered Purification

After expression of poly(VPGXG) genes, the biopolymer can easily be purified from a cellular lysate via a simple centrifugation procedure, because of the inverse temperature transition behavior. This causes the ELPs to undergo a reversible phase transition from being soluble to insoluble upon raising the temperature above the Tt and then back to soluble by lowering the temperature below Tt (Fig. 9). The insoluble form can be induced via addition of salt [27]. The inverse transition can be assayed by monitoring the solution turbidity as function of temperature. The complete purification process is called inverse transition cycling (ITC), which is achieved by repeated centrifugation while alternating the temperature above and below the Tt[33].

Fig. 9.

Purification of ELPs by ITC is based on the reversible inverse phase transition. Left: Protein purification via direct ELP fusions. A soluble ELP fused to a target protein becomes reversibly insoluble upon increasing temperature above Tt. Center: Protein purification via ELP coaggregation. An excess of free ELPs enhances the aggregation of trace quantities of ELP-fusions. Right: Purification via ELP-mediated affinity capture (EMAC). ELPs are fused to capture proteins, which bind specifically and reversibly to a target protein. This target protein can then be aggregated at temperatures above the Tt. Adapted from [38] with permission from Elsevier, copyright 2010

The inverse transition temperature of the elastomeric polypeptide motivated Meyer and Chilkoti to design ELP fusion proteins. They hypothesized that the temperature-dependent inverse transition of the free biopolymer could be transferred to the fusion protein and would allow nonchromatographic separation of recombinant fusion proteins via the ITC procedure [33]. This hypothesis was furthermore supported by the results of previous studies on protein conjugates of poly(N-isopropylacrylamide), a synthetic polymer that undergoes a similar thermally driven phase transition, which showed that the transition behavior of the free polymer is retained in the conjugate [36, 37]. This founded the use of ELPs for purification of primarily recombinant proteins but also other molecules. The ELP-mediated purification procedures can be sorted into three categories: protein purification via direct ELP fusions (Fig. 9, left), protein purification via ELP coaggregation (Fig. 9, center), and purification via ELP-mediated affinity capture (EMAC) (Fig. 9, right).

Protein Purification via Direct ELP Fusion

As an example of purification via the ELP fusion approach Meyer and Chilkoti (Fig. 9, left), purified the proteins thioredoxin and tendamistat. For this purpose these target proteins and ELP were genetically fused via a short peptide sequence that included a thrombin cleavage site, which allows the removal of the ELP tag after the purification is completed. The general outline of the purification procedure is depicted in Fig. 10. They showed that ELPs could be used for purification of target proteins with technical simplicity, low cost, ease of scale-up, and capacity for multiplexing [33].

Fig. 10.

Inverse transition cycling (ITC) purification. The target proteins are genetically fused to an ELP via a short peptide linker that includes a protease cleavage site. After expression, the fusion protein is separated from the other proteins in the cellular lysate by inducing the ELP inverse temperature phase transition. The solution is then centrifuged at elevated temperature to pellet the aggregated fusion protein. The pellet is resolubilized by cooling below the Tt and the solution is centrifuged at low temperature to remove the remaining insoluble matter. This cycle of heated and cooled centrifugation is repeated several times to obtain higher purity. The target protein can then be liberated from the ELP via proteolytic cleavage and the cleaved ELP is then removed with another round of ITC. Reproduced from [39] with permission from John Wiley and Sons, copyright 2001

In a subsequent study, the effect of reducing the ELP molecular weight on the expression and purification of a fusion protein was investigated. Two ELPs, ELP [V-20] and ELP[V5A2G3-90], both with a transition temperature at ~40°C in phosphate-buffered saline (PBS) containing 1 M NaCl, were applied for the purification of thioredoxin. Similar yields were observed for both fusion proteins, resulting in a higher thioredoxin yield for the ELP[V-20] fusion, since the ELP fraction was smaller. However, a more complex phase transition behavior was observed for this ELP and therefore a selection of an appropriate combination of salt concentration and solution temperature was required [39].

The ELP expression system was compared to the conventional oligohistidine fusion, which is traditionally applied for purification by immobilized metal affinity chromatography (IMAC). Both techniques were shown to have a similar yield of the recombinant protein. The temperature-triggered approach offers a fast and inexpensive nonchromatographic separation with the possibility for larger scale purification. Although the ELP expression system may not be applicable to all types of recombinant proteins, numerous examples have already been shown [40].

In the previous examples, protease-dependent cleavage was used to remove the ELP tag and to obtain the purified target protein. However, several problems are associated with the use of a protease-dependent cleavage: additional cost of the purification process, an additional purification step to separate the protease from the target protein and possible cleavage sites in the target protein. Therefore, the methodology was optimized by introducing self-cleaving inteins for protease-independent cleavage of the target protein. Both Wood and coworkers [41] and the research groups of Chilkoti and Filipe [42] simultaneously reported on this self-cleaving ELP tag. The latter demonstrated this approach by the use of the mini-intein from Mycobacterium xenopi GyrA gene (Mxe) to purify thioredoxin [42]. Wood and coworkers published several extensive protocols describing every aspect of how to use cleavable elastin-like polypeptide tags [43, 44]. Some other proteins were also expressed as a direct ELP fusion protein and were then purified by ITC [45, 46].

Protein Purification via ELP Coaggregation

The previous ELP fusions all are examples of protein purification in which the ELP is covalently connected to the protein of choice. This approach is suitable for the purification of recombinant proteins that are expressed to high levels, but at very low concentrations of ELP the recovery becomes limited. Therefore this approach is not applicable for proteins expressed at micrograms per liter of bacterial culture, such as toxic proteins and complex multidomain proteins. An adjusted variant of ITC was designed to solve this problem. This variant makes use of coaggregation of free ELPs with ELP fusion proteins. In this coaggregation process, an excess of free ELP is added to a cell lysate to induce the phase transition at low concentrations of ELP fusion protein (Fig. 9, center). It was shown that picomolar levels of ELP fusion proteins could be purified via ELP coaggregation [47, 48]. The value of this technique was shown by the purification of low levels of ELP fused to an anti-atrazine antibody [49].

Purification via ELP-Mediated Affinity Capture

The third purification procedure is based on the combination of temperature-triggered aggregation and affinity capture and has been used to not only purify proteins [50-54] but also other molecules [55, 56], and for the removal of pollutants from a solution [57-59]. For this procedure, ELP is conjugated to a capture reagent, which can be done either genetically or chemically. This procedure eliminates the need for cleavage of ELP after purification and introduces the potential to recycle the ELP.

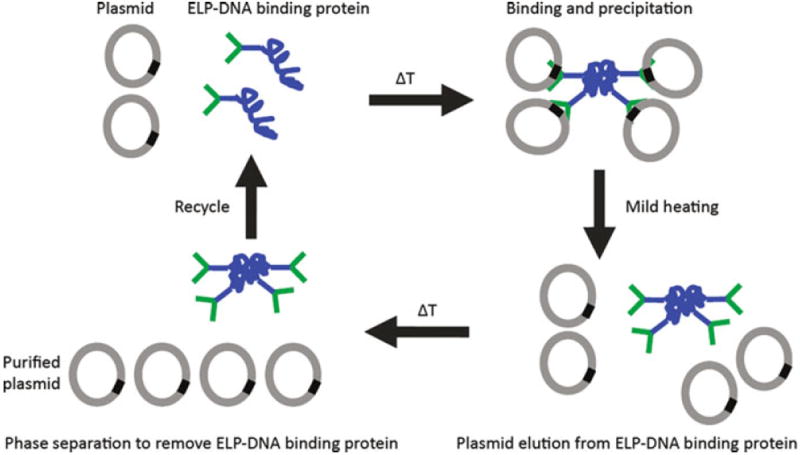

Various purification systems of this type were developed by Chen and coworkers, such as a new plasmid purification method. This system is based on the interaction between a DNA-binding protein and its cognate DNA sequence harbored on the target plasmid. Thus, an ELP is genetically fused to a DNA-binding protein. After binding of the fusion protein to the plasmid via the recognition sequence, the complex can be collected by triggering the inverse phase transition of ELP. Subsequently, the plasmid can be eluted from the DNA-binding protein by heating to ~60°C, after which the ELP-DNA binding protein is removed and recycled via centrifugation to obtain the purified plasmid in solution. A schematic overview of the plasmid purification via temperature-triggered affinity capture is depicted in Fig. 11 [55, 56].

Fig. 11.

Principle of temperature-triggered affinity purification of plasmid DNA. An ELP fused to a DNA binding protein (ELP-DNA binding protein) was used to bind a plasmid. The ELP-DNA binding protein–plasmid complex is aggregated by increasing the temperature and is then collected by centrifugation. Subsequently, the plasmid is eluted from the DNA binding protein by mild heating, after which the ELP-DNA binding protein is removed and recycled via centrifugation to obtain the purified plasmid in solution. Adapted from [56] by permission from Macmillan Publishers Ltd: Nature Protocols, copyright 2007

Proteins have been purified in a similar way, for example antibodies. For this purpose, ELPs were combined with antibody-binding domains, such as Protein G, Protein L, or Protein A [50-52, 54]. The antibodies can be bound via the ELP-antibody binding domain fusion and then those complexes can be purified via temperature-triggered precipitation. Also histidine-tagged proteins were purified by temperature-triggered purification. An ELP with repeating sequences of [(VPGVG)2(VPGKG)(VPGVG)2]21 was chemically modified by reacting the amino groups of the lysines with imidazole-2-carboxaldehyde to introduce metal-binding ligands. Subsequently, the biopolymer was charged with Ni2+ to enable binding of histidine-tagged proteins. This combined the advantages of histidine-tag purification with inverse transition cycling [53].

The last example of EMAC also makes use of metal-binding groups, although here they are used to remove heavy metal contaminants. The first report on temperature-triggered removal of cadmium made use of histidine-tagged ELPs, because they strongly bind Cd2+[57]. In a later report, ELP was fused to a metal-binding domain, which was shown to bind Cd2+ more effectively and selectively than the histidine-tagged ELPs [59]. A similar approach was followed with the construction of ELP-MerR, where an ELP was fused to the metalloregulatory protein MerR, which is responsible for regulating expression of the mercury detoxification pathway. This fusion protein was used for specific removal and recycling of mercury [58].

2.4.2 Drug Delivery

Numerous experimental therapeutics have shown potency in vitro; however, when they are tested in vivo, they often lack significant efficacy. This is often attributed to unfavorable pharmacokinetic properties and systemic toxicity, which limit the maximum tolerated dose. These limitations can be overcome by use of drug carriers. Two general types of carrier systems have been designed: drug conjugation to macromolecular carriers, such as polymers and proteins; and drug encapsulation in nanocarriers, such as liposomes, polymersomes and micelles.

Over the past decades, ELPs have also been applied in drug delivery as both macromolecular carriers and nanocarriers. The ELP-based carrier systems combine the advantages of drug carriers with the properties of ELPs. In addition to these carrier systems, ELP-based drug depots for controlled release have been designed, such as drug releasing gels and drug-eluting films.

ELPs with different transition temperatures have been employed for drug delivery. These can typically be divided into three categories:

Soluble ELPs with a Tt above the body temperature

Stimulus-responsive ELPs with a Tt in the region where phase transition can be triggered in vivo, thus slightly above body temperature

Insoluble ELPs with a Tt below body temperature

This final class of ELPs is used in nanocarriers and in drug depots. In this section, the emphasis will be on systems that have already been tested in vivo, and on some recent promising developments in the area of ELP-assisted drug delivery.

Macromolecular Carriers

In macromolecular drug delivery systems, drugs are attached to polymeric compounds, such as synthetic polymers [60], dendrimers [61], and antibodies [62], in order to enhance the delivery of the active substance to the diseased tissue and to reduce the toxicity to healthy tissue. The use of macromolecular delivery systems provides several advantages: extension of the half-life of the drug, the ability to introduce targeting moieties into the carrier, the possibility of triggered drug release, and the aforementioned reduced cytotoxicity.

In cancer treatment, passive targeting of macromolecular carriers to tumors is a commonly used approach. This passive targeting is based on the enhanced permeability and retention (EPR) effect, which leads to an accumulation of the high molecular weight carrier in the tumor tissue. The EPR effect arises from the different physiology of tumor vasculature, where the vessel walls are highly porous and lack the tight junctions that are present in healthy tissue. As a result, macromolecular carriers extravasate and accumulate preferentially in tumor tissue relative to normal tissues [63, 64].

All the aforementioned advantages and several additional features apply to ELP-based macromolecular carriers. First, ELP-based carriers are thermally responsive. Second, ELP is a biopolymer and therefore is nontoxic and biodegradable. Third, the gene-based synthesis of ELP allows the creation of genetic fusions with functional peptides and proteins, such as targeting sequences.

Recently, Chilkoti and coworkers showed the effective use of self-assembled ELP-drug conjugates in the treatment of solid tumors in mice. For this purpose, the ELP[VA8G7-160] with a transition temperature of ≫37°C was equipped with a conjugation site for hydrophobic molecules, for example therapeutics. This conjugation segment consisted of eight cysteine residues, interspersed with diglycine spacers. Doxorubicin (Dox), a hydrophobic and clinically effective drug, was modified with a terminal maleimide via an acid-labile hydrazone linker and then coupled to the thiols of the Cys residues via the maleimide–thiol reaction. This macromolecular carrier spontaneously assembled into micellar nanoparticles of ~40 nm diameter (Fig. 12). The half-life, the maximum tolerated dose, and the anti-tumor activity of these nanoparticles in mice were evaluated by administering the drug conjugates systemically. It was found that the ELP-Dox formulation allowed a higher dose than the free drug, which is probably caused by the shielding of ELP to limit the toxicity of Dox to healthy tissue. With a single injection, at the maximum tolerated dose, ELP-Dox outperformed the free drug in reducing tumor volume and this led to a substantial increase in animal survival [65].

Fig. 12.

Left: Structure of ELP[VA8G7-160] conjugated to doxorubicin via the cysteine residues. Right: Self-assembly of ELP-Dox to form nanoparticles. Reprinted from [65] by permission from Macmillan Publishers Ltd: Nature Materials, copyright 2009

The previous example of application of ELPs in drug delivery does not exploit their thermal responsiveness. In most other examples, the ELP phase transition is used to target ELP-drug conjugates towards tumors by applying local heating of tissue (local hyperthermia). Chilkoti and coworkers were the first to employ this principle. They developed a method for targeting of intravenously injected ELPs towards solid tumors by local hyperthermia. In addition, mild hyperthermia also enhanced the delivery of drugs to solid tumors, due to the increase of vascular permeability at temperatures between 40°C and 45°C [66]. Two ELPs were synthesized: ELP[V5A2G3-150] with a Tt of 41°C, which is between the body temperature and the mild hyperthermic temperature; and the control ELP[VA8G7-160] with a Tt well above 55°C, which is unresponsive at the mild hyperthermic temperature. These biopolymers were labeled with either rhodamine or with radioactive iodine for in vivo fluorescence video-microscopy and radiolabel distribution studies in nude mice with implanted human tumors. Thermal targeting of ELP [V5A2G3-150] led to an increase in tumor localization compared to the control ELP with hyperthermia and to the same polymer without hyperthermia [67, 68]. In these labeling studies, the amines in the ELPs were labeled, but in another study 14C radiolabels were incorporated into the backbone of both ELPs during protein expression. This was used to minimize the influence of the labeling while studying the biodistribution and pharmacokinetics and to prevent release of the radiolabel [69, 70]. Next, Dox was conjugated to ELP[V5A2G3-150] via an acid-labile hydrazone linker, but this lowered the Tt to below the body temperature, thus this ELP could not be employed for in vivo thermally triggered targeting [71]. In a subsequent study to minimize perturbation of the linker on the phase transition behavior and to provide an efficient and quantitative release of Dox, the chain length and the hydrophobicity of the hydrazone linker were optimized [72]. Also, the targeting of ELP towards the tumor via local hyperthermia was further optimized by thermal cycling of the tumor. This method relies on heating and cooling cycles of the tumor tissue, whereby the hyperthermia causes an increased vascular concentration of the ELP[V5A2G3-150] aggregates adhering to the vessel walls in the tumor, which upon return to normal temperature leads to an increase in transvascular transport [73]. A recent review by Chilkoti and coworkers gives a comprehensive overview on their efforts in the field of ELP-assisted drug delivery [74].

Generally, the plasma membrane of eukaryotic cells is impermeable to macro-molecular carriers. Therefore, Raucher and coworkers improved the ELP-assisted drug delivery by fusing a cell-penetrating peptide (CPP) to the ELP carrier to facilitate its cellular uptake [75, 76]. CCPs are short peptides that are capable of efficiently crossing the cellular plasma membrane and entering the cell’s cytoplasm. CPPs have been shown to deliver a variety of cargos across the cell membrane [77]. Various CPPs, such as penetratin (Pen) derived from Drosophila transcription factor Antennapaedia, the Tat peptide derived from the HIV-1 Tat protein, the hydrophobic membrane translocating sequence (MTS) from the Kaposi fibroblast growth factor, and the cationic Bac peptide derived from the bactenecin antimicrobial peptide, were fused to the N-terminus of the ELP (for sequences see Fig. 13) [78, 79]. In addition to the use of this system for delivery of Dox, therapeutic peptides were fused to the C-terminus of the CPP-ELP (Fig. 13). This design was examined for a therapeutic peptide that inhibits the oncogenic transcription factor c-Myc [78, 80] and for cell cycle inhibitory peptides [79, 81, 82]. These types of drug delivery systems were shown to be effective in different types of cancer cells, but no in vivo studies have yet been reported. However, in a recent review on CPP-ELPs for therapeutic peptide delivery it is mentioned that a Bac-ELP with a therapeutic peptide for inhibition of c-Myc is currently under investigation in mouse breast cancer models and in a rat glioma model [83].

Fig. 13.

Left: ELP carrier N-terminally fused to a cell-penetrating peptide and C-terminally fused to a therapeutic peptide. Right: Amino acid sequences for several cell-penetrating peptides (see text for details). Reprinted from [83] with permission from Elsevier, copyright 2010

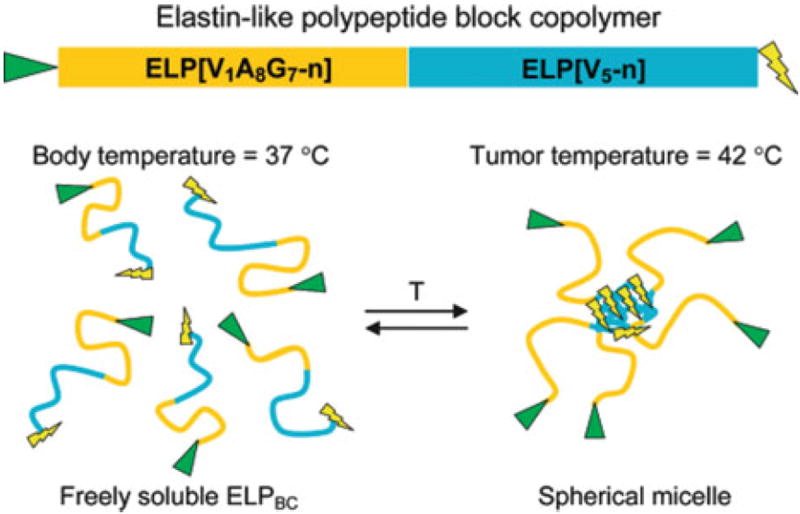

Another approach that also employs the thermal responsiveness of ELPs for drug delivery is the hyperthermia-triggered multivalency. To this end, block copolymers of two ELP regions were synthesized (ELP[VA8G7-n]-ELP[V5-n]), where one of the blocks had a transition temperature at the hyperthermic temperature of the tumor and the other block was insensitive in this temperature range. The end of the insensitive block was genetically modified with a peptidic ligand that targets a specific cellular receptor or a membrane protein that is upregulated by tumor cells. Normally, the effectiveness of this type of peptide is limited due to its systemic toxicity; however, in this approach the block copolymer was triggered by the hyperthermia in the tumor to assemble into a drug delivery vehicle displaying multiple ligands. This triggered multivalency is supposed to increase the binding affinity of the ligand-ELP in tumor tissue without increasing the accumulation in healthy tissue. A schematic overview of the design and rationale is given in Fig. 14[84, 85].

Fig. 14.

Hyperthermia-triggered multivalency. Block copolymers consisting of two ELP blocks, a hydrophilic ELP[VA8G7-n] block and a hydrophobic ELP[V5-n] block were designed. The N-terminal hydrophilic block was modified with a peptidic ligand (triangle) by gene fusion and the design also allows introduction of a drug or imaging agent at the C-terminus (lightning bolt). T temperature. Reprinted in part from [84] with permission from American Chemical Society, copyright 2008

Nanocarriers

Micellar nanocarriers have already been applied successfully for delivery of hydrophobic drugs [86]. These carriers are usually the product of self-assembled block copolymers, consisting of a hydrophilic block and a hydrophobic block. Generally, an ELP with a transition temperature below body temperature is used as hydrophobic block and the hydrophilic block can be an ELP with a transition temperature above body temperature or another peptide or protein. The EPR effect also directs these types of carriers towards tumor tissue.

In 2000, the first example of ELP diblock copolymers for reversible stimulus-responsive self-assembly of nanoparticles was reported and their potential use in controlled delivery and release was suggested [87]. Later, these type of diblock copolypeptides were also covalently crosslinked through disulfide bond formation after self-assembly into micellar nanoparticles. In addition, the encapsulation of 1-anilinonaphthalene-8-sulfonic acid, a hydrophobic fluorescent dye that fluoresces in hydrophobic environment, was used to investigate the capacity of the micelle for hydrophobic drugs [88]. Fujita et al. replaced the hydrophilic ELP block by a polyaspartic acid chain (Dm). They created a set of block copolymers with varying block lengths, ELP[V-n]-Dm where n = 40, 80, 120, or 160 and m = 22, 44, 88, or 176. They investigated the self-assembled structures and they observed the formation of particles with a homogeneous size of 50–250 nm upon triggering the transition [89].

ELP-based triblock copolypeptides have also been used to produce stimulus-responsive micelles, and Chaikof and coworkers envisioned the possible application of these micelles as controlled drug delivery vehicles. These amphiphilic triblock copolymers were constructed from two identical hydrophobic ELP endblocks and a hydrophilic ELP midblock. Below the transition temperature, loose and monodispersed micelles were formed that reversibly contracted upon heating, leading to more compact micelles with a reduced size [90].

Rodríguez-Cabello and coworkers reported a modified elastin-like polypeptide, in which the glycine at the third position of the repetitive sequence was replaced by an alanine residue. These biopolymers consisting of VPAVG repeats also showed a reversible phase transition; however, strong undercooling was needed to resolubilize this ELP [91]. This biopolymer has already been used to encapsulate the model drug dexamethasone phosphate [92]. A recent study uses this type of ELP, (VPAVG)220, to encapsulate bone morphogenetic proteins (BMPs) in ELP-based nanoparticles for drug delivery. BMPs are signaling proteins that are capable of promoting new bone formation, and the developed delivery system was shown to be effective in an in vitro cell assay [93].

Drug Depots

ELP-assisted local delivery of drugs is realized via several strategies. In the first strategy, soluble ELPs are injected and their coacervation is triggered by the body temperature. Here, the drug can be covalently attached to the ELP or it can just be mixed with the ELP. In another approach, crosslinked ELP depots containing a drug can be produced and then implanted to generate a stable release of the drug.

This first strategy was used by Setton and coworkers to trigger the in situ formation of an ELP-based drug depot for sustained release. Biodistribution studies of radiolabeled ELPs with a Tt below body temperature were performed after intra-articular injection in rats [94]. Later, drug depots of ELPs with covalently attached immunomodulator therapeutics [95] and anti-TNFα therapeutics [96] were created. Respectively, ELP[V-120] and ELP[V-60] biopolymers with a transition below body temperature were used in these studies.

The Chilkoti group applied the local injection approach for intratumoral drug delivery. ELP[V-120], with a transition at 27°C, was designed and labeled with 14C, 125I or 131I for radiotherapy. The first two labels were used to monitor tumor retention of the ELP and the last label was addressed to equip the ELP with anti-tumor activity. It was found that mice treated with 131I-labeled ELP[V-120] experienced a significantly prolonged survival over those treated with saline [97].

For the second type of drug release from depots, ELPs were crosslinked prior to implantation. In an investigation on the controlled release of the antibiotics cefazolin and vancomycin, ELP[KV16-102] was used. This ELP was crosslinked via the amines on the lysine residues using β-[tris(hydroxymethyl)phosphino]-propionic acid (THPP) to enable a high degree of antibiotic entrapment. The functionality of this approach was shown in vitro [98]. Another very recent example of this methodology is the production of drug-loaded ELP microspheres, which are crosslinked with glutaraldehyde. The ELP temperature-responsiveness was then used to open and close the pores of these microspheres [99].

In clinical trials using adenoviral vectors for gene delivery, it was shown that selective delivery of sufficient number of therapeutic gene copies remains difficult and that the lack of this selectivity caused acute toxicity and immunogenicity for the healthy tissue. Cappello and Ghandehari applied silk-elastin-like polypeptide (SELPs) [32] hydrogels to overcome the challenges of cancer gene therapy in head and neck cancer [100]. They found that intratumoral injection of adenoviruses with SELPs enhanced gene expression in tumors up to tenfold compared to viral injection without the biopolymer [101-103]. In mouse models, the SELPs efficiently controlled the duration and extent of transfection in tumors for up to 5 weeks with no detectable spread to the liver. This resulted in a fivefold greater reduction in tumor volume compared to intra-tumoral injection of adenoviruses without the biopolymer [104, 105].

2.4.3 Tissue Engineering

In the field of tissue engineering, the principles of engineering and life sciences are applied for the development of functional substitutes for damaged tissue. To this end, biomaterials have been used to replace, restore, or enhance organ function. Therefore the material needs to be able to match the characteristics of the tissue it is replacing, such as shape, physical properties, and support in cellular processes [106].

The application of ELPs in tissue engineering is attractive for several reasons: first, ELPs are based on elastin, which is a main component of the extracellular matrix. As a result they are non-immunogenic, biocompatible, and biodegradable [107]. ELPs can furthermore be produced in relatively high yields in host cells, such as bacteria, and this type of polymer synthesis provides control over the exact amino acid sequence and polymer length. ELPs can also easily be purified by exploiting their inverse temperature transition. For these reasons, ELPs were used and modified to form hydrogels, films, and fibers for various tissue engineering applications, such as cartilaginous, vascular, ocular, and liver tissue regeneration.

Setton and Chilkoti applied ELPs as a three-dimensional matrix to entrap chondrocytes. In their study, ELP[V5G3A2-90] with a transition temperature of 35°C at 50 mg/mL in PBS was used. This biopolymer can be used to generate a suspension with cells, which upon injection into a defect site will form a scaffold. They showed that in vitro the resulting ELP gel supported the viability of chondrocytes and the synthesis and accumulation of cartilage-specific extracellular matrix material. This suggested that ELPs indeed could be used for in situ formation of a scaffold for cartilaginous tissue repair [108]. Later, they also demonstrated that ELP gels could induce and support chondrocytic differentiation of human adipose-derived adult stem cells in vitro, without the addition of chondrocyte-specific growth factors [109]. Haider et al. [110] also demonstrated the potential of SELPs [32] as scaffold for the encapsulation and chondrogenesis of human mesenchymal stem cells. These SELPs irreversibly form hydrogels upon triggering the transition [110]. One significant problem is that the shear modulus of uncrosslinked ELPs is several orders lower than of articular cartilage. In order to increase the load-bearing capabilities of ELP gels, glutamine- and lysine-containing ELPs that could be enzymatically crosslinked via transglutaminase were developed [111]. Even though the shear modulus was increased and the ability to promote the synthesis and retention of cartilage tissue was retained, the crosslinking reaction proceeded over a long time, which prevented its clinical use. Therefore, a chemical crosslinking method that would proceed within a shorter time was developed. For this method, several lysine-containing ELPs were crosslinked with β-[tris (hydroxymethyl)phosphino]propionic acid (THPP) [112-114]. ELP[V6K1-224] was then used as an injectable scaffold for cartilage repair in a goat model of an osteochondral defect. It was shown that the ELP crosslinker solution was easily delivered and resulted in a stable, well-integrated gel that supported cell infiltration and matrix synthesis, but unfortunately this gel was prone to rapid degradation [115]. In a recent study, many lysine-containing ELPs were evaluated for their mechanical properties in an effort to optimize the ELP formulation for in vivo application [116].

Tirrell and coworkers designed artificial extracellular matrix (aECM) proteins for small-diameter vascular grafts. For vascular grafts, both mechanical integrity and biological interaction with host tissue are important properties. Therefore, the aECM proteins contained alternating CS5 binding domains and elastin-like poly-peptide domains (Fig. 15, aECM 3). The fibronectin CS5 domains provide cell adhesion signals whereas the ELP domains give these materials elasticity and mechanical integrity. The aECMs also contained lysine residues, either incorporated into the ELP domains or near the C- and N-termini, to allow crosslinking without interrupting the CS5 binding domains [117-119]. It was shown that these crosslinked films of aECMs had properties resembling those of the natural elastin [120]. In another study, aECMs with RGD binding domains were produced (Fig. 15, aECM 1) and compared to the CS5 domains. Here, it was found that the cellular response to aECM proteins can be modulated through choice of binding domain and that those with the RGD sequence showed rapid cell spreading and matrix adhesion [121]. Subsequently, variation in ligand density was accomplished by mixing two aECMS (Fig. 15, aECMs 1 and 2) in different ratios prior to crosslinking. Using this method, cell adhesion and spreading could be modulated [122].

Fig. 15.

Amino acid sequences of artificial extracellular matrix (aECM) proteins. Each protein contains a T7 tag, a histidine tag, a cleavage site, and elastin-like domains with lysine residues for crosslinking. The RGD cell-binding domain is found in aECM 1, whereas aECM 3 contains the CS5 cell-binding domain. aECM 2 and aECM 4 are the negative controls with scrambled binding domains for aECM 1 and aECM 3, respectively. Reprinted from [121] with permission from American Chemical Society, copyright 2004

2.4.4 Hybrid Materials

In the previous sections it was demonstrated that the stimulus-responsive behavior of ELP was transferred to ELP fusion proteins and even to non-covalently bound moieties, such as proteins, plasmids, and heavy metals, mostly for biomedical and biotechnological applications. The ability of ELPs to reversibly switch their polarity is also of great interest for the development of stimulus-responsive materials. Many approaches have therefore recently been undertaken to integrate ELPs with, for example, polymers, particles, and surfaces.

In 2003, the van Hest group produced elastin-based side-chain polymers [123]. This research was motivated by the demonstration of the occurrence of an inverse temperature transition in a single repeat of VPGVG [124]. A methacrylate-functionalized VPGVG was synthesized and used as a monomer to perform atom transfer radical polymerization (ATRP) to produce homopolymers (Fig. 16b) or ABA block copolymers (Fig. 16a), in which the A blocks are based on the methacrylate-functionalized VPGVG and the B block is a bifunctional poly(ethylene glycol) ATRP macroinitiator. It was shown that these polymers exhibited behavior similar to that of linear poly(VPGVG) [123, 125]. Later, Cameron and coworkers used another type of controlled radical polymerization (reversible addition-fragmentation chain transfer polymerization, RAFT) to produce homopolymer elastin-based side-chain polymers (Fig. 16c) [126]. They found that binary mixtures of well-defined elastin-based side-chain polymers showed a single transition temperature, which depended on the blend composition [127]. Additionally, they immobilized these elastin-based side-chain polymers on polymerized high internal phase emulsions (polyHIPE), to demonstrate the potential of this methodology to reversibly immobilize biomolecules such as enzymes [128]. Also ring-opening metathesis polymerization (ROMP) was used to prepare elastin-based oligopeptides of low molecular weight and low polydispersity [129]. More recently, random copolymers of elastin-based monomers and oligo(ethylene glycol)-based monomers were generated using ROMP [130].

Fig. 16.

Various type of elastin-based side-chain polymers (a) ABA block copolymer produced via ATRP, (b) homopolymer produced via ATRP, (c) homopolymer produced via RAFT polymerization

Inspired by the elastin-based side-chain polymers, Lemieux et al. prepared elastin-based stimulus-responsive gold nanoparticles. To this end, they capped gold particles with a layer of a single repeat of thiol-functionalized VPGVG peptides (Fig. 17a). These nanoparticles showed LCST behavior, which was modulated by varying the pH of the solution [131].

Fig. 17.

(a) Elastin-based stimulus-responsive gold nanoparticles. Reproduced from [131] by permission of The Royal Society of Chemistry (b) Functionalization of a glass surface with ELP. In the first step, the glass surface is aminosilylated with N-2-(aminoethyl)-3-aminopropyl-trimethoxysilane, then modified with glutaraldehyde. Subsequently, the stimulus-responsive bio-polymer is covalently immobilized using reductive amination. Reproduced from [132] by permission of The Royal Society of Chemistry

Besides short ELPS, longer ELPs have also been conjugated to synthetic polymers. In one approach, Cu(I)-catalyzed azide-alkyne cycloaddition click chemistry was applied. For this purpose, ELPs were functionalized with azides or alkynes via incorporation of azidohomoalanine and homopropargyl glycine, respectively, using residue-specific replacement of methionine in ELP via bacterial expression [133]. More recently, an alternative way to site-selectively introduce azides into ELPs was developed. Here, an aqueous diazotransfer reaction was performed directly onto ELP[V5L2G3-90] using imidazole-1-sulfonyl azide [134].

In another investigation, ELP[V5L2G3-90] with three lysines in the N-terminal region was immobilized on a glass surface in a microreactor to enable temperature-controlled positioning of ELP fusion proteins. For this purpose, the glass surface was first functionalized with N-2-(aminoethyl)-3-aminopropyltrimethoxysilane, followed by glutaraldehyde treatment and reductive amination to immobilize the biopolymer on the surface (Fig. 17b) [132].

Hybrid materials of poly(VPGVG)s and gold were also conveniently produced. ELP[V5A2G3-180] was adsorbed onto colloidal gold particles via electrostatic interactions [135]. Subsequently, these ELPs were covalently immobilized on the gold surface, by reacting the amines in the ELP with N-hydroxysuccinimide-activated carboxyl groups attached to gold. These stimulus-responsive particles were subsequently used to capture and release biomolecules [136].

Huang et al. were able to synthesize optically responsive hybrid materials. They used the block copolymer ELP[V-40]-ELP[V4C1-10], which was assembled onto gold nanorods via the thiol-moieties of the cysteine residues. Exposure of the ELP-functionalized gold nanorods to near-infrared light led to heating of the gold due to surface plasmon resonance (SPR). This resulted in phase transition and aggregation of the ELP-functionalized gold nanorods [137]. Also, the group of Rodriguez-Cabello reported similar hybrid materials based on ELP-functionalized gold nanoparticles [138, 139].

3 Resilin and Resilin-Like Polypeptides

3.1 Resilin Occurrence and Biosynthesis

3.1.1 Occurrence

Resilin was first discovered and brought to the attention of the scientific community by Weis-Fogh in the late 1950s [140, 141]. Through studies into arthropod locomotion, certain proteinaceous patches of the insect cuticle (i.e., exoskeleton) [142] were shown to exhibit perfect long-range elasticity and superior extensibility, supporting rapid deformation in insect organs without hysteresis. The first written descriptions of resilin in 1960 [from tendons of dragonflies (Odonata) and wing hinges of locusts (Orthoptera)] described it as a colorless, swollen isotropic rubber with remarkable elastic recovery and a unique amino acid composition [141]. Resilin did not dissolve in any solvent that did not break peptide bonds and the crosslinks were described as being “extremely stable,” though the chemistry of the crosslinks was unknown at the time. Following the initial discovery and description of resilin in locusts and dragonflies, others quickly began finding the protein throughout the Arthropoda phylum [140].

The solid cuticle of the arthropod is a complex extracellular product made of chitin (a polysaccharide) and tanned or fibrous proteins, and is often hard and colored [142]. However, in 1947, La Greca identified and described a colorless, transparent cuticle found in the wing hinges of locusts that sharply contrasted with the solid cuticle associated with insects. Later to be named “rubber-like cuticle,” these elastic hyaline structures largely went unnoticed until Weis-Fogh’s investigation of locust flight during the 1950 s [141, 143]. Detailed analysis of several elastic elements of the locust flight system revealed small cuticular patches that possessed long-range elasticity; these patches, which consisted of protein and chitin, could undergo extreme deformation before quickly returning to their original shape [144]. Through careful analysis of similar rubber-like cuticle regions prepared from different insect species, it was determined that the protein was responsible for the elastic properties of the cuticle. Further, it was determined that the protein exhibited a unique amino acid composition that differed from other insect cuticle proteins as well as other structural proteins such as collagen and elastin [141, 145]. The protein was named resilin, derived from the latin resilire, which means “to spring back” [144, 145].

Resilin is often found in the insect cuticle as part of a relatively simple composite material containing only the protein and chitin [141, 144]. Chitin is found in nearly all types of arthropod cuticle in the form of stiff filaments that run parallel to the surface of the cuticle, but that gradually change direction to form a helicoidal pattern. The resilin-containing cuticle in locust wing-hinge ligament contains the helicoidal chitin structures and makes the ligament difficult to stretch, but capable of bending and twisting deformations [144]. It was determined that the elasticity of the rubber-like cuticle was derived from the resilin protein as the treatment of the cuticle with proteases, strong acids, or bases left only the chitinous component, which was delicate and inextensible [141].

Following the discovery of resilin in the locust and dragonfly [141, 146], resilin was more widely found in other arthropods. Resilin was discovered in the salivary pump of assassin bugs and in the feeding pump of Rhodnius prolixus where, in both cases, it acted as an elastic antagonist to muscle action [140, 147]. Other instances of resilin serving the function of an elastic spring in feeding/pumping mechanisms include the tsetse fly [148], reduviid bugs [149], and honey bees [150]. These elastic resilin springs act as an energy-saving mechanism for the insects by providing a passive means of emptying the pump cavities [148, 149]. In the honey bee, resilin was found to provide resistance to the power stroke of the venom-dispensing pump and also served to facilitate the stinging action by providing cushioning for the stinger apparatus [150].

Resilin has also been found to serve an important role in the sound production of arthropods, notably in the Cicadae family, but also in Pyralidae family (moths) and in scorpions [151-157]. Relatively thick patches of resilin (100–150 μm) are found in the tymbals, which are the sound production organs of the cicada. As seen in the feeding/pumping mechanisms, these elastic patches provide spring-like elasticity that returns the tymbal to its rest position following release of tension in the tymbal muscle. The resilin contained in these structures must operate under very rapid stress-release cycles, in the 1–10 kHz range for some cicadas, but despite these demanding mechanical requirements, it has been found that energy losses can be less than 20% [140, 151, 154, 156, 157].

The elasticity, rapid response, and low energy dissipation serve a particularly important role in the mechanically active tissues responsible for the locomotion of insects. In addition to the description of resilin in the flight systems of the locust and the dragonfly [146], the protein was found to contribute to insect flight in damselflies [158], beetles [159], and other species of the Dermapteran order [160]. Resilin was found in the components of the wing in these insects where it served to provide spring-like recovery of different wing elements following deformation, as well as to dampen the aerodynamic forces felt by the wing [158-160]. Apart from flight, resilin has been found in the ambulatory systems of cockroaches [161, 162] and house flies [163]; resilin provides elasticity to the joints and thereby facilitates rapid movement in both species [161, 162]. Resilin in insect tarsus has been indicated in additional taxa [164], including ants and bees [165]. Perhaps the most notable application of resilin-based rubber-like elasticity in the locomotion of insects is seen in the jumping mechanism of fleas [166-171] and other jumping arthropods [172-176]. Initial investigations of these jumping mechanisms suggested a spring-like model, with resilin serving as the major elastic element responsible for storing the energy required for a jump [169, 171, 174, 176]; however, competing evidence has suggested that the chitinous components are actually responsible for most of the energy storage [168, 173].

The rubber-like elasticity of resilin is only one of its outstanding mechanical properties; it also demonstrates a remarkable capacity for stretching. The extensibility of resilin can be seen in the ability of some insects to swell their abdomens to many times the original size. For example, resilin has been found in the cuticle of the physogastric queen termite, which has been shown to increase the size of its abdomen up to 50 times following fertilization [177]. Honey ants, which swell their abdomens when gorging on food, have also been shown to contain resilin [178]. The one unifying characteristic with respect to the occurrence of resilin in arthropods is that it can almost always be found when rubber-like elasticity is a prerequisite for function. However, resilin also appears in unexpected places such as the lens cuticle of the firefly, Photinus pyralis Linnaeus [179], and even outside of the insect community as in the case of the maxilliped flagella of crabs and crayfish [180].

3.1.2 Biosynthesis

Interest in the composition of resilin, specifically in its primary structure, grew in the early 1990s when Lombardi and Kaplan published the amino acid sequences of tryptic digests of cockroach resilin [181]. These sequences were found to resemble the tryptic digest sequences of locust resilin investigated by Ardell and Andersen, who subsequently used both sets of sequences to search for genes that may code for resilin in Drosophila melanogaster. This effort led to the discovery of two genes that produce peptides homologous to the tryptic digest sequences from both the cockroach and locust [144, 182]. One of the genes, CG15920, was suggested to encode the precursor protein for resilin. The gene product had an amino acid composition and an isoelectric point that closely resembled resilin [182]. It contained a 17-residue signal peptide sequence at the N-terminus, indicating that it may be secreted into the extracellular space [182, 183], and it contained a sequence that resembled the R&R-2 variant of the Rebers–Riddiford consensus sequence that has been identified in the binding of proteins to chitin in the insect cuticle [182, 184]. Many cuticle proteins from evolutionary disparate species of insect were found to contain some variant of this sequence, G-X7-[DEN]-G-X6-[FY]-X-A-[DGN]-X2,3-G-[FY]-X-[AP] (X is any amino acid and the numerical subscript is the number of residues) [185], leading to the belief that the highly conserved sequence served an important biological function such as the binding to chitin in the cuticle [186]. Subsequent expression and characterization of this domain has provided convincing evidence for its role in binding to chitin [185, 187].

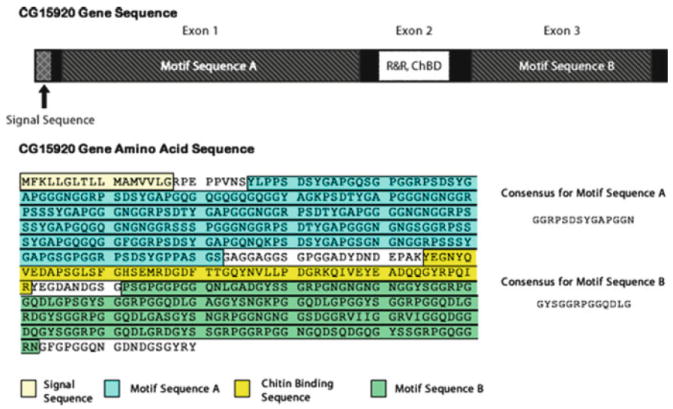

However, the most important indication that the CG15920 gene encoded a resilin precursor was the discovery of highly conserved repeat sequences. These resilin “motif” sequences are repeated in domains on either side of the chitin binding domain (see Fig. 18). The first motif sequence, GGRPSDSYGAPGGGN, is located in the N-terminal region (exon 1) with respect to the chitin binding domain (exon 2), while the second motif sequence, GYSGGRPGGQDLG, dominates the C-terminal region (exon 3) of the CG15920 gene product [182]. As discussed in Sect. 3.3, these sequences have provided the basis for the development of recombinant resilin-like polypeptides that attempt to recreate the long-range elasticity of natural resilin. Furthermore, the modules of the CG15920 gene appear to mirror the protein-chitin-protein morphology of the insect cuticle. Additionally, it has been shown that there are two splices of the CG15920 gene: one that contains the chitin binding domain and one where it is absent [182, 187, 188]. It is possible that the synthesis of the two variants depends on whether chitin is being synthesized in the rubber-like cuticle. For instance, the synthesis of chitin-binding resilin may be unregulated during the formation of chitin lamellae while the alternative variant is synthesized primarily to form the embedding proteinaceous matrix. Recent research into putative resilin genes has revealed a high level of conservation for the resilin genes amongst Drosophila species, but these putative resilin genes can vary once outside a particular genus of insect [188].

Fig. 18.

CG15920 gene sequence and primary structure. The consensus repeat sequences are also represented. The highlighted regions correspond to the signal sequence, R&R chitin-binding domain, and the elastomeric domains containing repeat motifs A and B. Reproduced from [182, 188] with permission from Elsevier, copyright Elsevier 2001, 2010

The amino acid composition of resilin was elucidated shortly after its first description and was shown to be unique among other structural proteins found in Nature; a summary of the amino acid sequence is given in Table 1.

Table 1.

Amino acid composition of resilin from wing-hinge and prealar arm of locust

| Amino acid | Resilin

|

Comparison

|

|||

|---|---|---|---|---|---|

| Residues/105 g protein

|

Residues/105 g protein

|

||||

| Average wing-hinge | Prealararm | Collagen (oxhide) | Elastin (oxligamentum nuchae) | Silk fibroin (Bombyxmori) | |

| Asp | 113 | 122 | 52 | 4.5 | 16 |

| Thr | 35 | 34 | 19 | 8 | 12 |

| Ser | 91 | 91 | 41 | 8 | 160 |

| Glu | 53 | 54 | 76 | 14 | 14 |

| Pro | 87 | 89 | 125 | 156 | 5 |

| Gly | 448 | 414 | 354 | 398 | 590 |

| Ala | 129 | 120 | 116 | 212 | 389 |

| Val | 30 | 36 | 21 | 148 | 30 |

| Met | Nil | Nil | 6.5 | (<1) | Nil |

| iLeu | 20 | 19 | 14 | 31 | 9 |

| Leu | 26 | 27 | 28 | 66 | 7 |

| Tyr | 29 | 35 | 5 | 9 | 69 |

| Phe | 30 | 27 | 14 | 30 | 8 |

| Amide N | (102) | – | (46) | (3) | – |

| Lys | 6 | – | 27 | 3 | 4 |

| His | 8.5 | – | 4.5 | 0.5 | 2 |

| Arg | 40 | – | 47 | 5 | 6 |

| Total | 1,145 | 1,128 | 1,063a | 1,093 | 1,321 |

Results of amino acid analysis performed on resilin from the locust Schistorcerca gregaria, compared with values for collagen, elastin, and silk fibroin. Reproduced from [145] with permission from Elsevier, copyright Elsevier 1961

Includes 106 hydroxyproline and 7 hydroxylysine

Resilin has a greater percentage of acidic residues than collagen, elastin, and silk fibroin and contains fewer non-polar residues (i.e., Gly, Ala, Val, Ile, Leu, Pro, Met, and Phe) than silk fibroin and elastin. The significant content of acidic residues might account for resilin’s hydrophilicity as well as its low isoelectric point, as indicated through swelling experiments [141, 145]. Resilin contains little to no methionine, cysteine, hydroxyproline, and tryptophan. Except for silk fibroin, resilin contains more tyrosine residues than the other structural proteins compared in the Table 1. The levels of tyrosine in the insect cuticle can vary from 4% to 13% (by weight) and in resilin, tyrosine accounts for approximately 5% of the total weight [145, 189, 190].

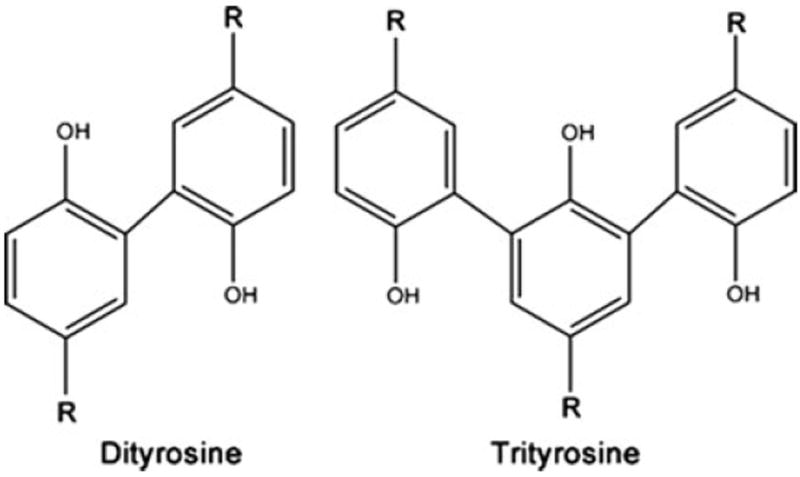

Andersen demonstrated that two novel fluorescent compounds served as the chemical crosslinks in resilin [189-192]. These aromatic α-amino acids contained a phenolic group and were shown to be a diaminodicarboxylic acid and a triamino-tricarboxylic acid: dityrosine and trityrosine (see Fig. 19) [192]. Physical measurements determined the average molecular weight between junction points to be ~5,000 Da in the case of dragonfly resilin [193], which corresponds closely to the value of ~3,000 Da derived from the amino acid analysis, assuming that the fluorescent amino acids constitute the crosslinks in resilin. Other various forms of crosslinking, such as disulphide bridges, ester groups, amide bonds, etc., had been ruled out, leading to the conclusion that these novel fluorescent compounds were indeed the only crosslinks for the network protein [189-192, 194, 195]. The formation of di- and trityrosine or homolog crosslinks was later discovered in other elastic tissues, including those originating from higher organisms. Dityrosine has been isolated from elastin [196], collagen [197], fibroin, keratin [198], and other structural proteins and tissues [199-201]. The crosslinking of the tyrosine residues can result from the phenolic coupling of two phenoxy radicals of the residues [202]; this is initiated by a radical species (i.e., •OH) and was shown to be mediated, ex vivo, by the reaction of a peroxidase and hydrogen peroxide [203].

Fig. 19.

Dityrosine and trityrosine crosslinks found in resilin. The R groups connect to the backbone of the polypeptide chain

Additionally, the crosslinking and immobilization of resilin in the insect cuticle appears to occur very quickly, perhaps as soon as it is deposited. Temperature also plays a role; it has been found that the rate and the extent to which resilin is crosslinked increases with increasing temperatures [204-206]. The exact mechanism by which resilin is actually crosslinked is still largely unknown and although peroxidase has been demonstrated to form di- and trityrosines there is no substantiated proof of this mechanism for the formation of the resilin network [144, 207]. The discovery of the resilin gene and interest in the development of recombinant resilins (discussed in Sect. 3.3) may reinvigorate the study of the crosslinking of resilin [144].

3.2 General Properties of Resilin

Crosslinked resilin is a highly stable, swollen isotropic rubber that is resistant to both high temperatures and protein coagulants. Resilin in neutral water is unaffected by heating up to 125°C and does not begin to degrade until 140–150°C. Additionally, a myriad of fixatives, and tanning and coagulating agents are virtually unsuccessful in bringing about permanent change in resilin from the rubbery state to the solid state, even with prolonged treatment [141]. Only under the most extreme conditions, outside physiological ranges, is the protein irreparably altered; for example, the protein degrades under high or low pH conditions or when incubated with proteases. In fact, resilin is quite easily digested by proteolytic enzymes including papain, various trypsins, chymotrypsin, pepsin, elastase from porcine sources, and the mixture of enzymes found in the saliva of Reduviid bugs [141]. Resilin is transparent and absent of any color; however, the refractive index of resilin cuticle exceeds 1.4 and the water content at neutral pH is 50–60%, which indicates a very concentrated material. Resilin swells in alkaline buffers and shrinks in acidic buffer, but the material remains rubbery under all conditions unless it is dried out or dehydrated in pure alcohol [141]. Dried resilin behaves like a glassy polymer, but when reintroduced to water it regains its rubbery nature and demonstrates all the properties of an amorphous polymer network above its glass transition. Nonpolar solvents have proven completely incapable of penetrating the resilin cuticle; very few polar solvents will plasticize the protein matrix, which is insoluble in all solvents. Resilin will shrink from dehydration in alcohols and also become glassy (as when dried), but the protein will swell and become rubbery in ethylene glycol, formic acid and formamide. Resilin is also capable of isotropic, reversible swelling; resilin can be swollen in alkaline buffer, shrunk in acidic buffer and then swollen once again when returned to an alkaline buffer [141]. In addition to the absolute insolubility of resilin in nonpolar solvents, the protein also proved to be resistant to chaotropic solutes such as urea, guanidine hydrochloride, and alkaline cupric ethylenediamine, the latter of which demonstrated the ability to disrupt hydrogen bonding in silk fibroin without destroying peptide bonds. Additionally, resilin was unaffected by agents that disrupt the disulphide bridges of cystine. The insolubility of resilin under all of these conditions and its remarkable resistance to heat supports the suggestion that the protein exists as a covalently crosslinked network with very chemically stable crosslinks [141, 145].

Resilin and elastin, unlike other structural proteins, fulfill both definitions of an “elastic” material. Colloquially speaking, resilin and elastin are stretchy or flexible. They also fulfill the strict definition of an elastic material, i.e., the ability to deform in proportion to the magnitude of an applied stress without a loss of energy, and the recovery of the material to its original state when that stress is removed. Resilin and elastin are alone in the category of structural proteins (e.g., collagen, silk, etc.) in that they have the correct blend of physical properties that allow the proteins to fulfill both definitions of elasticity. Both proteins have high extensibility and combine that property with remarkable resilience [208].

Resilin from dragonfly tendon is capable of stretching 3–4 times its resting length before breaking and will completely recover even after weeks of an applied tensile stress. The tensile strength was measured to be at least 30 kg cm−2 (2.94 MPa) and the elastic modulus has been reported to be approximately 6 kg cm.−2 (0.588 MPa) [141, 144, 193], but the initial elastic modulus has been reported to be as high as 20 kg cm.−2 (1.96 MPa) [146, 208]. The toughness and the resilience of dragonfly tendon has been reported to be 4 MJ m−3 and 92%, respectively [208]. Possibly due to the addition of stiffer elements (i.e., the chitin lamellae), the prealar arm of the wing-hinge of the locust was found to have a slightly higher elastic modulus at 9 kg cm−2 (0.882 MPa). The mechanical properties of resilin are dependent on pH and on the swelling of the material; resilin swelled in alkaline buffers becomes increasingly stiff. Dynamic testing of the prealar arm revealed that the loss factor, defined as the ratio of energy irreversibly lost as heat to the total change in stored elastic energy, was exceedingly low at about 3.5% per half cycle when strained at biologically relevant frequencies (15–20 cycles/s). Even at high frequencies, such as 200 cycles/s, the loss factor remained less than 10% and, as mentioned previously, the loss factor is low even in the extreme case of cicada sound production [140, 146, 151, 156, 157].

Resilin and elastin have relatively high extensibility and resilience, but as compared to the collagen and the silks, the proteins sacrifice stiffness (elastic modulus) and strength (see Table 2). Collagen and dragline silk are much stiffer materials, but lack the extensibility that is characteristic of the rubber-like proteins. On the other hand, the mussel byssus fibers and the viscid silk have the extensibility of resilin and elastin, but lack the resilience [208].

Table 2.

Material properties of structural proteins and synthetics

| Material | Modulus, Einit (GPa) | Strength, σmax (GPa) | Extensibility, εmax | Toughness (MJ m−3) | Resilience (%) |

|---|---|---|---|---|---|

| Elastin (bovine ligament)a | 0.0011 | 0.002 | 1.5 | 1.6 | 90 |