Abstract

A microfluidic surface trap was developed for capturing pH-sensitive nanoparticles via a photoinitiated proton-releasing reaction of o-nitrobenzaldehyde (o-NBA) that reduces the solution pH in microchannels. The surface trap and nanoparticles were both modified with a pH-responsive polymer—poly(N-isorpopylacylamide-co-propylacrylic acid), P(NIPAAm-co-PAA). The o-NBA-coated microchannel walls demonstrated rapid proton release upon UV light irradiation, allowing the buffered solution pH in the microchannel to decrease from 7.4 to 4.5 in 60 seconds. The low solution pH switched the polymer-modified surfaces to be more hydrophobic, which enabled the capture of the pH-sensitive nanobeads onto the trap. When a photo-mask was utilized to limit the UV irradiation to a specific channel region, we were able to restrict the particle separation to only the exposed region. By controlling UV irradiation, this technique enables not only prompt pH changes within the channel, but also the capture of target molecules at specific channel locations.

INTRODUCTION

Development of lab-on-a-chip technologies for biomedical applications has been actively pursued during the past decades because miniaturized platforms can offer advantages over more conventional systems, e.g. compact size, disposable nature, minimum reagent consumption, faster reaction, and reduced specimen volume.1,2 Microfluidics technologies enable fine control and manipulation of fluids and fluid interfaces, as well as intrinsically efficient heat and mass transfer due to high surface-area-to-volume ratios.3 Therefore, microfluidics systems can potentially improve biological assays to facilitate cell biology, in vitro diagnostics, etc.4

Microfluidic systems with materials that can enable dynamic and reversible property changes (e.g., switch between hydrophilic/hydrophobic surface) have been extensively studied because these switchable phenomena are essential for various applications, including bio/chemical analysis, biosensing, and point-of-care clinical diagnostics. For example, stimuli-responsive materials respond sharply and reversibly to device-generated physical or chemical stimuli (e.g., heating) by changing their conformation and physicochemical properties5 and have been utilized for various microfluidic systems to facilitate reversible on/off flow valving.6 We have previously reported the development of stimuli-responsive microfluidic systems that incorporate temperature-sensitive surface capture system for temperature-responsive nanobead separation to facilitate chromatography and assay applications. 7–10 The surface traps captured the nanobeads uniformly above the LCST (lower critical solution temperature) and facilitated their rapid release as the temperature was reversed to below the LCST.

Although physical stimuli are advantageous because they allow local and remote control, chemical stimuli such as concentration gradients of protons, ions, and oxidizing/reducing agents are also important characteristics observed in living systems. pH shifts and gradients in microfluidic devices have, for examples, been utilized for flow control,11 isoelectric focusing,12 protein separation,13 bacteria separation,14 site-specific protein immobilization,15 cell sorting,16 and immunosensor.17 The molecules in solutions flow laminarly inside sub-millimeter channels of microfluidic devices, which leads to no turbulent mixing.18–20 In order to change solution pH in microfluidic channels, various microfluidic mixers have been developed to address the challenge.8, 21 In contrast to other stimuli that can easily penetrate through materials (e.g. heat, light, magnetic field, etc.), however, changing pH with spatial control in microfluidic devices remains difficult.22

Here we utilize a photoacid generator (PAG), o-nitrobenzaldehyde (o-NBA), to reduce the solution pH in a microfluidic channel via UV light irradiation for capturing nanoparticles using the pH-sensitive surface trap. PAGs are chemicals that release protons via a photoinitiated reaction because the pKa of PAG in an excited state is significantly lower than the ground state (Fig. S1, supporting information).23 Upon the photoexcitation of o-NBA, the aci-form is rapidly produced through the intramolecular proton transfer reaction and the proton is dissociated to induce the nitronate anion, which is converted to the o-nitrosobenzoic anion. In low-pH solutions, o-nitrosobenzoic anion may be protonated to give the neutral form of o-nitrosobenzoic acid. The photo-tautomerization for o-NBA is a photochemically allowed, thermally forbidden reaction, which determines the irreversibility. Related nitroarenes also undergo irreversible photo-tautomerization and are used as photolabile protecting group. Therefore, the back hydrogen transfer is prevented.24 Since some of the microfluidic materials such as PDMS are UV transparent,25 PAG precoated on microchannel walls can be excited by UV illumination to release protons into the flow stream, enabling solution pH reduction inside the channel. In this study, our model system demonstrates photo-induced pH-sensitive nanobead separation on surface traps in a microchannel utilizing PAG, absorbed on the channel walls, to reduce solution pH. When a photo-mask was utilized to limit the UV irradiation to a specific channel region, we were able to restrict the particle separation to only the exposed region.26, 27

EXPERIMENTAL METHOD

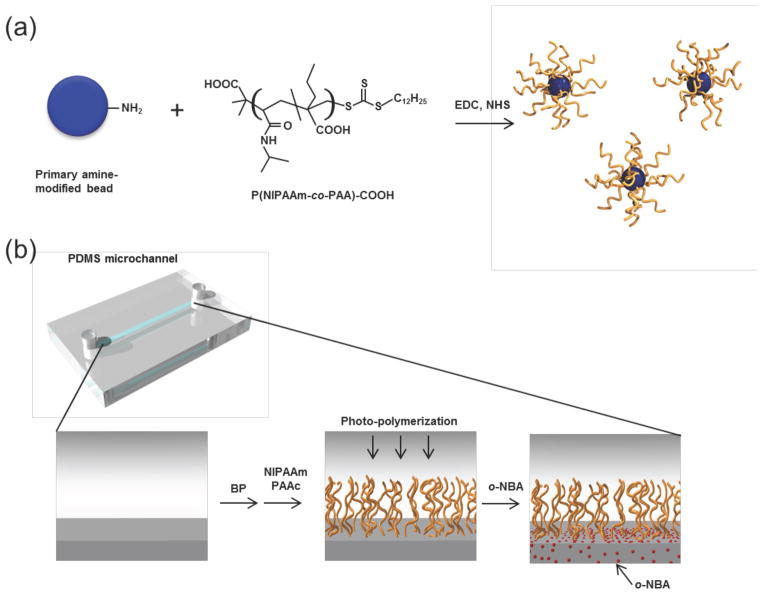

Carboxy terminated N-Isopropylacrylamide (NIPAAm) copolymer with propylacrylic acid PAA (10 mol%) was synthesized by reversible addition-fragmentation chain transfer (RAFT) polymerization according to the protocol published previously.28 The molecular weight of synthesized copolymer was 15,000 Da and the Mw/Mn was 1.17. The amino-functionalized polystyrene latex beads (100 nm diameter) (Polysciences, Polybead® Amino Microspheres, 0.1μm) were covalently modified with the carboxy terminated P(NIPAAm-co-PAA) via carbodiimide chemistry in phosphate buffer at pH 7.4 for 24 hours at room temperature. (Fig. 1(a)). The reaction was performed at a 10-fold molar excess of P(NIPAAm-co-PAA) relative to unmodified surface amine group. Beads were then separated from unreacted copolymers by centrifugation and resuspension followed by sonication. Polydimethylsiloxane (PDMS) microchannel with stimuli-responsive surface traps were prepared by adapting the protocol from our previous publications.7 PDMS microchannel with 0.1 mm deep and 0.5 mm wide was prepared by mixing the PDMS base with a curing agent and assembling using O2 plasma bonding. UV-mediated grafting was used for the surface modification of PDMS with pH-sensitive copolymer according to a previously published protocol with different monomers (Fig. 1(b)).7 For water contact angle measurements, flat PDMS membranes with grafted polymers were also prepared using the same protocol. Contact angles on the grafted surfaces at different temperatures and pH were measured using a goniometer (Rame-Hart, Inc.). o-NBA was incorporated into PDMS microchannels by presorbing the acetone solution of o-NBA (50 wt%) within the PDMS channel surface regions. The pH change inside of the PDMS microchannel was monitored using a fluorescent pH-indicator, 5-carboxyfluorescein.29 At low pH, the dye is weakly fluorescent but becomes more fluorescent with increasing pH. The solution pH versus fluorescent intensity calibration curve was constructed by taking the fluorescent images of the PDMS channels that were filled with standard solutions, different solution pH but a fixed pH-indicator concentration, using a microscopy. To observe proton release via o-NBA, the solution pH in the channel was obtained by measuring the fluorescent intensity using microscope images and comparing to the standard curve. For photo-induced bead trapping experiments, suspended pH-sensitive nanobeads were loaded and flowed into the pH-sensitive copolymer-grafted microchannel at 37°C (10 μl/min). In the presence of flow, the channel was then exposed to UV light, causing the pH change followed by aggregation and adhesion of the pH-sensitive beads to the channel wall. For the spatial control of a bead trap in the channels, UV was irradiated on a limited region in the channel through a mask with 2 mm square. No flow was used for this experiment.

Figure 1.

(a) Preparation of pH-responsive P(NIPAAm-co-PAA)-grafted nanoparticles. (b) PDMS microchannel modification via photo-polymerization of P(NIPAAm-co-PAA) and the subsequent o-NBA coating.

RESULTS AND DISCUSSION

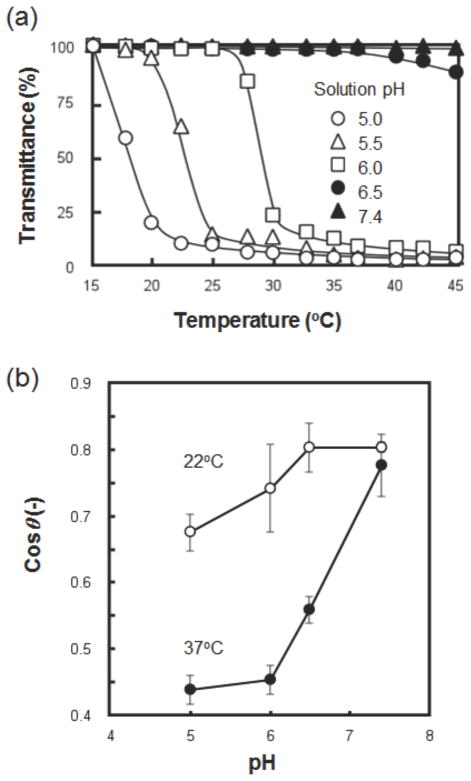

Particles with surface ligands can potentially be used for isolating target biomolecules in microfluidic environments to improve diagnostic assays.10 To capture nanobeads in the PDMS microchannel using pH shift as the stimulus, in this study, both nanobeads and channel surfaces were modified using a pH-responsive copolymer of NIPAAm and PAA, which has a higher pKa value, ca. pH 6.2, than those of conventional anionic polymers, copolymers with carboxylic acid-derived monomers, such as acrylic acid or methacrylic acid, for responding to physiologically relevant pH.28 Fig. 2(a) shows the phase transition behavior of P(NIPAAm-co-PAA) with 10 mol% PAA, synthesized by RAFT polymerization. The polymer solution % transmittance changed from ca. 100% at pH 6.5 to less than 20% when the solution pH shifted to 6.0 at the temperature above 32°C, the LCST of homo PNIPAAm. The significant LCST shift occurred when the solution pH changed from 6.5 to 6.0 because the copolymer, RAFT synthesized P(NIPAAm-co-PAA) with 10 mol% PAA, transitioned from above to below the polymer pKa, ca. 6.2. 28 When the polymer solution pH was higher than the pKa (pH ≥ 6.5), the majority of PAA groups on the polymer chains were deprotonated (ionized), which resulted in polymer chains repulsion (no aggregation). Therefore, the LCST was significantly higher, ≥ 40°C. On the other hand, lower solution pH to ≤ 6.0, resulted in protonated (deionized) PAA group, which made the polymer more hydrophobic. The polymer chains with protonated (deionized) PAA group aggregated together when pNIPAAm transitioned to be more hydrophobic via heating. Therefore, the LCST was lower, ≤ 30°C. The surface trap for capturing the pH-sensitive nanobeads was constructed by modifying PDMS microchannel walls with pH-sensitive P(NIPAAm-co-PAA) (PAA; 10 mol%) via UV-mediated graft polymerization.7, 28 Although the pH-sensitive nanobeads can aggregate and adhere to the unmodified PDMS channel surfaces in response to pH change, the surface modification with pH-sensitive polymers can rapidly transition the channel surface to hydrophilic for releasing the particles efficiently.7 The surface wettability (hydrophobic/hydrophilic) transition in response to pH was characterized by measuring the contact angles. Fig. 2(b) shows the advancing water contact angle measurements, expressed in cos θ, on P(NIPAAm-co-PAA)-grafted PDMS surfaces using solutions with various pHs. The cos θ at both 22 and 37°C decreased along with the solution pH, which confirmed that the polymer grafted PDMS surfaces became more hydrophobic because the pH reduction protonated the ionized PAA groups on the polymer graft. The contact angle difference in response to pH change is more significant at 37°C, above the LCST of PNIPAAm.

Figure 2.

(a) Phase transition profiles of P(NIPAAm-co-PAA) (PAA 10 mol%) as a function of temperature at various pH in PBS (0.15 M). The pKa of the copolymer is ca. pH 6.2, and a large shift of LCST has been observed between pH 6.0 and 6.5 above 32°C, the LCST of homo PNIPAAm. (b) Advancing water contact angles on P(NIPAAm-co-PAA) (PAA 10 mol%)-grafted PDMS surfaces at 22 °C (open circle) and 37 °C (closed circle). The detail for PDMS surface modification is included in the experimental method. The cos θ at both temperatures decreased as the solution pH changed from 7.4 to 5.0, which confirms the surfaces became more hydrophobic in acidic solution. The contact angle difference in response to pH change is more significant at 37°C, above the LCST of PNIPAAm.

In order to capture the pH-sensitive nanobeads in the microfluidic device via the pH-responsive surface trap, o-NBA was utilized to reduce solution pH via the photoinitiated proton-releasing reaction.26,27 The proton-releasing reactions are important and useful for not only investigating dynamics of pH-dependent phenomena such as protein folding kinetics, but also on-demand changing the proton concentration quickly in solution.30 Fig. S2 (supporting information) compares the effect of o-NBA concentrations and UV irradiation time, 0–10 minutes, by measuring solution pH. When the evaluation utilized the water solutions with various o-NBA concentrations, the pH reduction was less than 2 pH-unit for the 1 mM o-NBA solution after 10 min of UV irradiation. The water solubility limits the maximum o-NBA concentration to 1 mM. Instead of dissolving o-NBA directly in DI water, we also developed o-NBA reservoirs by absorbing an acetone solution containing o-NBA into PDMS membranes. When PDMS membranes were cut, immersed in DI water (0.1 mm2 PDMS/μl H2O), and exposed to UV light for 10 minutes, the solution pH decreased significantly more and faster (open symbols) than the soluble o-NBA (Fig. S2). In particular, PDMS membranes treated with 50wt% of o-NBA decreased the solution pH from 8.0 to 3.5 (4.5 pH units) in less than 2 minutes. Compared to the o-NBA water solution, the PDMS reservoir contained larger amounts of o-NBA because o-NBA’s solubility in acetone is more than 1 M, which is 1000 times higher than in DI water.

In addition to adding the reservoirs into bulk DI water (100 ml), we also studied the pH reduction kinetics by depositing a 100 μl water drop (pH 8.0) on the 1 × 1 cm2 PDMS reservoir to mimic the solution in a microchannel. The water drop contains phenol red as a pH indicator, which changes the solution color from red to yellow when the solution pH changes from basic (pH > 8.0) to acidic (pH < 6.6). Fig. 3(a) shows the solution images during UV irradiation, 0 – 120 seconds. As soon as the UV light was applied to the water drop, the solution color immediately changed from red to yellow, which indicated the transition from pH 8.0 (basic) to less than pH 6.6 (acidic), at the interface between the drop and the PDMS surface. After 60 seconds of UV irradiation, almost the entire drop changed to yellow. This result indicates that protons were efficiently released from the o-NBA coated PDMS reservoirs.

Figure 3.

(a) Photographs of a water drop on o-NBA coated PDMS surfaces during UV irradiation. The water drops contain phenol red as a pH indicator (red above pH 8.0 and yellow below pH 6.6). After 60 seconds of UV irradiation, almost the entire drop changed to yellow (pH < 6.6). (b) PBS (pH 7.4 and 0.15 M) solution pH inside the o-NBA coated PDMS channel during UV irradiation. The pH inside the channel was detected using 5-carboxyfluorescein, a fluorescent pH indicator. The pH of PBS decreased to ca. 4.5 after 60 seconds of UV irradiation. (c) Photographs of PBS fluid inside the channels before and after UV irradiation. The fluids contain phenol red as a pH indicator (red above pH 8.0 and yellow below pH 6.6). The solution pH was reduced to less than 6.6 after 60 seconds of UV light irradiation.

In contrast to water, the prospect of changing buffered solution pH using PAG is more relevant for biological applications. Therefore, we also evaluate the capability of o-NBA in reducing the PBS pH using a PDMS channel that was pretreated with o-NBA (50 wt% acetone solution). The channel can hold 0.5μl of PBS and exhibits 12 mm2 inner channel surface, so the contact PDMS surface area per μl solution inside the channel is ca. 24 mm2. The study utilized 5-carboxyfluorescein, a fluorescent pH indicator, to monitor the pH reduction kinetics inside the channel by measuring the solution fluorescent intensity. Fig. 3(b) shows the PBS solution pH inside the channel versus UV irradiation time, 0–3 minutes. The solution pH immediately decreased when the UV irradiation started and reduced to ca. pH 4.5 in 60 seconds (Fig. 3(c)). The ability to adjust the PBS solution pH within the range between 7.4 and 4.5 is useful for a variety of medical and biological applications where a significant pH change is required.31 According to Fig. 3(b) and Fig. S2, the solution pH became lower when the UV irradiation time was longer and the solution pH reduction was less when the PDMS surface was treated with a lower concentration of PAG solution. Although Fig. 3(b) shows that the solution pH in the PDMS channel could be reduced to ca. pH 4.5, effective separation of pH-responsive nanobeads can occur at ca. pH 6, the nanobead’s transition pH. Therefore, the pH reduction can potentially be tuned for effective nanobead separation with minimum the impact on biological activity of trapped biomolecules by limiting the UV irradiation time and PAG solution concentration.

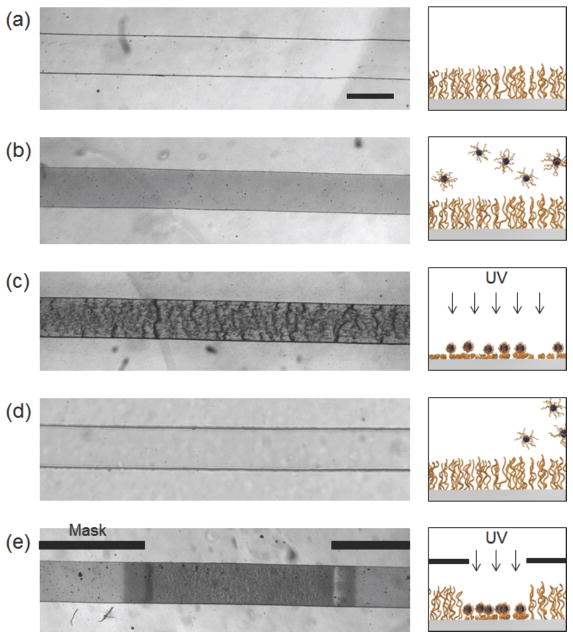

To demonstrate the photo-induced nanobead separation the pH-sensitive nanobeads were used in conjunction with the microchannel (Fig. 4(a)), grafted with pH-sensitive copolymer and pre-treated with o-NBA (50 wt% in acetone) (Fig. 1(b)). After the channel was loaded with pH-sensitive nanobeads in PBS (Fig. 4(b)), the particle capture was carried out at 37°C under continuous flow with a 10 μl/min flow rate. When the UV light was applied to the channel for 60 seconds, the pH-sensitive nanobeads aggregated and adhered to the channel wall (Fig. 4(c)) because the UV irradiation caused o-NBA in the channel wall to release protons, which reduced the solution pH. The low solution pH switched both pH-sensitive nanobeads and the pH-responsive surface trap to a more hydrophobic state, which leads to effective nanobead separation via the polymer-polymer interaction. When the UV light was turned off, the captured nanobeads were immediately released back into the flow stream within 10 seconds (Fig. 4(d)) via the PBS wash to restore the solution pH to 7.4, which reversed the nanobeads and the surface trap back to the hydrophilic state.

Figure 4.

Photographs of the P(NIPAAm-co-PAA)-grafted nanobeads inside PDMS channels. The channels were modified with P(NIPAAm-co-PAA) followed by coating with o-NBA (a). The suspension of beads in PBS (pH 7.4) was injected into the channel and incubated at 37°C under 10μl/min flow rate and show no bead separation (b), and then exposed to UV lamp for one minute under the same flow rate to capture the pH-sensitive beads (c). The UV lamp was turned off and the PBS was kept flowing for 5 minutes at 37°C under the same flow rate to release the captured beads back to the flow stream (d). Captured particles at a specific channel region using a photo-mask (e). The suspension of beads in PBS (pH 7.4) was injected into the channel and incubated at 37°C, and then exposed to UV lamp through a mask with 2 mm square transparent region for one minute. No flow was used for the spatial control experiment.

While Fig. 3(b) shows the solution pH reduced to ca. 4.5 after 60 seconds of UV light irradiation, the nanobead separation required significantly less time. Because the nanobead separation started from the PDMS channel walls and the nanobeads are ca. 100 nm diameter, we can consider consider that the separation occurred no further than 10 μm (100x nanobead and 23% channel volume) on the PDMS surface. Assuming the diffusion coefficient for hydronium is H3O+ is 1.33×10−5 cm2/s,32 the estimated diffusion time for 10 μm distance is 0.0376 seconds, which is significantly shorter than the residence time of the nanbeads in the channel, ca. 3 seconds. Additionally, the nanobead separation occurred around pH 6 when the polymers on the particles and the PDMS surfaces transitioned to be more hydrophobic. The transition to pH 6 occurred ca. 5x faster than the reduction to pH 4.5. Therefore, the nanobead separation rapidly occurred in the channel under the flow condition.

We also investigated the possibility to achieve nanobead separation with spatial control, at a specific channel location. The study utilized a photo-mask, which limited the UV light irradiation to a specific channel region. As seen in Fig. 4(e), the particles aggregated only in the photo-illuminated region, duplicating the pattern on the mask. Because the light source was not collimated and proton diffusion is very fast, particle aggregation was also observed underneath the mask boundaries. These results indicate that the o-NBA surface coatings can change solution pH inside the channel promptly by UV irradiation without any on-device mixing technologies.8,21 This technique can be utilized for target molecule separation at specific locations in the microchannel by using photomask to control UV irradiation spatially. Although the phototautomerization of o-NBA has been known to be irreversible, the pH change in the PDMS channel can potentially be repeated for multiple cycles because each short UV light irradiation can only excite small fraction of the o-NBA deposited on the PDMS surfaces.26 Therefore, the remaining o-NBA can be used for additional UV light irradiation.

CONCLUSION

We have developed pH-responsive surface traps in PDMS microfluidic channels for capturing pH-sensitive nanobeads via UV light irradiation. o-NBA, a PAG, was coated onto PDMS microfluidic channel walls for reducing the buffer pH inside the channel from 7.4 to 4.5 via 60-second UV light irradiation. The photoinitiated pH reduction via o-NBA coating was utilized to capture pH-sensitive P(NIPAAm-co-PAA)-grafted nanobeads onto the channel walls where P(NIPAAm-co-PAA) was also grafted. We were able to control the nanobead separation to a specific channel region by limiting the UV light irradiation via a photo-mask. This technique can potentially be utilized for effective target molecule separation in the microfluidic channels.

Supplementary Material

Acknowledgments

The authors would like to thank Dr. Gabriel Lopez, who kindly suggested to utilize photoacid generator for the experiments. The authors would like to express their gratitude to the NIH for funding (EB000252).

Footnotes

The authors declare no competing financial interest.

Details of experimental methods. Schematic description of proton-releasing photodissociation reaction of PAG. Photo-induced pH jump experiments.

References

- 1.Harrison DJ, Fluri K, Seiler K, Fan ZH, Effenhauser CS, Manz A. Micromachining a miniaturized capillary electrophoresis-based chemical analysis system on a chip. Science. 1993;261:895–897. doi: 10.1126/science.261.5123.895. [DOI] [PubMed] [Google Scholar]

- 2.Quake SR, Scherer A. From micro- to nanofabrication with soft materials. Science. 2000;290:1536–1540. doi: 10.1126/science.290.5496.1536. [DOI] [PubMed] [Google Scholar]

- 3.deMello AJ. Control and detection of chemical reactions in microfluidic systems. Nature. 2006;442:394–402. doi: 10.1038/nature05062. [DOI] [PubMed] [Google Scholar]

- 4.El-Ali J, Sorger PK, Jensen KF. Cells on chips. Nature. 2006;442:403–411. doi: 10.1038/nature05063. [DOI] [PubMed] [Google Scholar]

- 5.Ding Z, Fong RB, Long CJ, Hoffman AS, Stayton PS. Size-dependent control of the binding of biotinylated proteins to streptavidin using a polymer shield. Nature. 2001;411:59–62. doi: 10.1038/35075028. [DOI] [PubMed] [Google Scholar]

- 6.Beebe DJ, Moore JS, Yu Q, Liu RH, Kraft ML, Jo BH, Devadoss C. Microfluidic tectonics: A comprehensive construction platform for microfluidic systems. Proc Natl Acad Sci USA. 2000;97:13488–13493. doi: 10.1073/pnas.250273097. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Ebara M, Hoffman JM, Hoffman AS, Stayton PS. Switchable surface traps for injectable bead-based chromatography in PDMS microfluidic channels. Lab Chip. 2006;6:843–848. doi: 10.1039/b515128g. [DOI] [PubMed] [Google Scholar]

- 8.Hoffman JM, Ebara M, Lai JJ, Hoffman AS, Folch A, Stayton PS. A helical flow, circular microreactor for separating and enriching “smart” polymer-antibody capture reagents. Lab Chip. 2010;10:3130–3138. doi: 10.1039/c004978f. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Golden AL, Battrell CF, Pennell S, Hoffman AS, Lai JJ, Stayton PS. Simple fluidic system for purifying and concentrating diagnostic biomarkers using stimuli-responsive antibody conjugates and membranes. Bioconjug Chem. 2010;21:1820–1826. doi: 10.1021/bc100169y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Lai JJ, Nelson KE, Nash MA, Hoffman AS, Yager P, Stayton PS. Dynamic bioprocessing and microfluidic transport control with smart magnetic nanoparticles in laminar-flow devices. Lab Chip. 2009;9:1997–2002. doi: 10.1039/b817754f. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Eddington DT, Beebe DJ. Flow control with hydrogels. Adv Drug Del Rev. 2004;56:199–210. doi: 10.1016/j.addr.2003.08.013. [DOI] [PubMed] [Google Scholar]

- 12.Cui H, Horiuchi K, Dutta P, Ivory CF. Multistage isoelectric focusing in a polymeric microfluidic chip. Anal Chem. 2005;77:7878–7886. doi: 10.1021/ac050781s. [DOI] [PubMed] [Google Scholar]

- 13.Egatz-Gomez A, Thormann W. Micropreparative isoelectric focusing protein separation in a suspended drop. Electrophoresis. 2011;32:1433–1437. doi: 10.1002/elps.201000684. [DOI] [PubMed] [Google Scholar]

- 14.Cabrera CR, Yager P. Continuous concentration of bacteria in a microfluidic flow cell using electrokinetic techniques. Electrophoresis. 2001;22:355–362. doi: 10.1002/1522-2683(200101)22:2<355::AID-ELPS355>3.0.CO;2-C. [DOI] [PubMed] [Google Scholar]

- 15.Shi M, Peng Y, Yu S, Liu B, Kong J. Site-specific protein immobilization in a microfluidic chip channel via an IEF-gelation process. Electrophoresis. 2007;28:1587–1594. doi: 10.1002/elps.200600569. [DOI] [PubMed] [Google Scholar]

- 16.Kirchhof K, Andar A, Yin HB, Gadegaard N, Riehle MO, Groth T. Polyelectrolyte multilayers generated in a microfluidic device with pH gradients direct adhesion and movement of cells. Lab Chip. 2011;11:3326–3335. doi: 10.1039/c1lc20408d. [DOI] [PubMed] [Google Scholar]

- 17.Tseng YT, Yang CS, Tseng FG. A perfusion-based micro opto-fluidic system (PMOFS) for continuously in-situ immune sensing. Lab Chip. 2009;9:2673–2682. doi: 10.1039/b823449c. [DOI] [PubMed] [Google Scholar]

- 18.Atencia J, Beebe DJ. Controlled microfluidic interfaces. Nature. 2005;437:648–655. doi: 10.1038/nature04163. [DOI] [PubMed] [Google Scholar]

- 19.Hatch A, Kamholz AE, Hawkins KR, Munson MS, Schilling EA, Weigl BH, Yager P. A rapid diffusion immunoassay in a T-sensor. Nat Biotechnol. 2001;19:461–465. doi: 10.1038/88135. [DOI] [PubMed] [Google Scholar]

- 20.Weigl BH, Yager P. Microfluidics - Microfluidic diffusion-based separation and detection. Science. 1999;283:346–347. [Google Scholar]

- 21.Lee HL, Boccazzi P, Ram RJ, Sinskey AJ. Microbioreactor arrays with integrated mixers and fluid injectors for high-throughput experimentation with pH and dissolved oxygen control. Lab Chip. 2006;6:1229–1235. doi: 10.1039/b608014f. [DOI] [PubMed] [Google Scholar]

- 22.Lin CF, Lee GB, Wang CH, Lee HH, Liao WY, Chou TC. Microfluidic pH-sensing chips integrated with pneumatic fluid-control devices. Biosens Bioelectron. 2006;21:1468–1475. doi: 10.1016/j.bios.2005.06.005. [DOI] [PubMed] [Google Scholar]

- 23.Choi J, Hirota N, Terazima M. A pH-jump reaction studied by the transient grating method: Photodissociation of o-nitrobenzaldehyde. J Phys Chem A. 2001;105:12–18. [Google Scholar]

- 24.Migani A, Leyva V, Feixas F, Schmierer T, Gilch P, Corral I, Gonzalez L, Blancafort L. Ultrafast irreversible phototautomerization of o-nitrobenzaldehyde. Chem Commun. 2011;47:6383–6385. doi: 10.1039/c1cc11085c. [DOI] [PubMed] [Google Scholar]

- 25.Beebe DJ, Moore JS, Bauer JM, Yu Q, Liu RH, Devadoss C, Jo BH. Functional hydrogel structures for autonomous flow control inside microfluidic channels. Nature. 2000;404:588–590. doi: 10.1038/35007047. [DOI] [PubMed] [Google Scholar]

- 26.Techawanitchai P, Ebara M, Idota N, Asoh TA, Kikuchi A, Aoyagi T. Photo-switchable control of pH-responsive actuators via pH jump reaction. Soft Matter. 2012;8:2844–2851. [Google Scholar]

- 27.Techawanitchai P, Idota N, Uto K, Ebara M, Aoyagi T. A smart hydrogel-based time bomb triggers drug release mediated by pH-jump reaction. Sci Technol Adv Mater. 2012;13:064202. doi: 10.1088/1468-6996/13/6/064202. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Yin X, Hoffman AS, Stayton PS. Poly(N-isopropylacrylamide-co-propylacrylic acid) copolymers that respond sharply to temperature and pH. Biomacromolecules. 2006;7:1381–1385. doi: 10.1021/bm0507812. [DOI] [PubMed] [Google Scholar]

- 29.Breeuwer P, Drocourt JL, Rombouts FM, Abee T. A novel method for continuous determination of the intracellular pH in bacteria with the internally conjugated fluorescent probe 5 (and 6-)-carboxyfluorescein succinimidyl ester. Appl Environ Microbiol. 1996;62:178–183. doi: 10.1128/aem.62.1.178-183.1996. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Abbruzzetti S, Crema E, Masino L, Vecli A, Viappiani C, Small JR, Libertini LJ, Small EW. Fast events in protein folding: structural volume changes accompanying the early events in the N-->I transition of apomyoglobin induced by ultrafast pH jump. Biophys J. 2000;78:405–415. doi: 10.1016/S0006-3495(00)76603-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Garbern JC, Minami E, Stayton PS, Murry CE. Delivery of basic fibroblast growth factor with a pH-responsive, injectable hydrogel to improve angiogenesis in infarcted myocardium. Biomaterials. 2011;32:2407–2416. doi: 10.1016/j.biomaterials.2010.11.075. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Wraight CA. Chance and design—Proton transfer in water, channels and bioenergetics proteins. Biochim Biophys Acta. 2006;1757:886–912. doi: 10.1016/j.bbabio.2006.06.017. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.